Numerical Simulation of Airflow Distribution in a Pregnant Sow Piggery with Centralized Ventilation

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

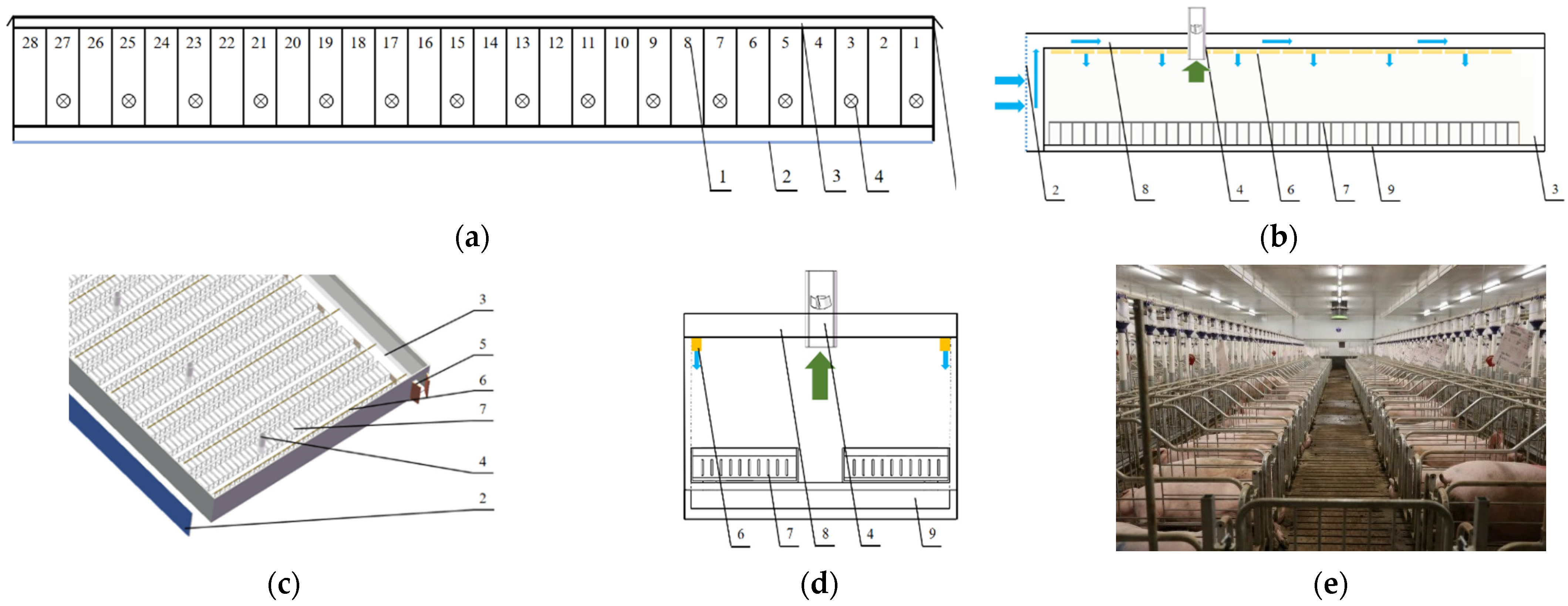

2.1. Test Piggery

2.2. Model Parameter Measurement

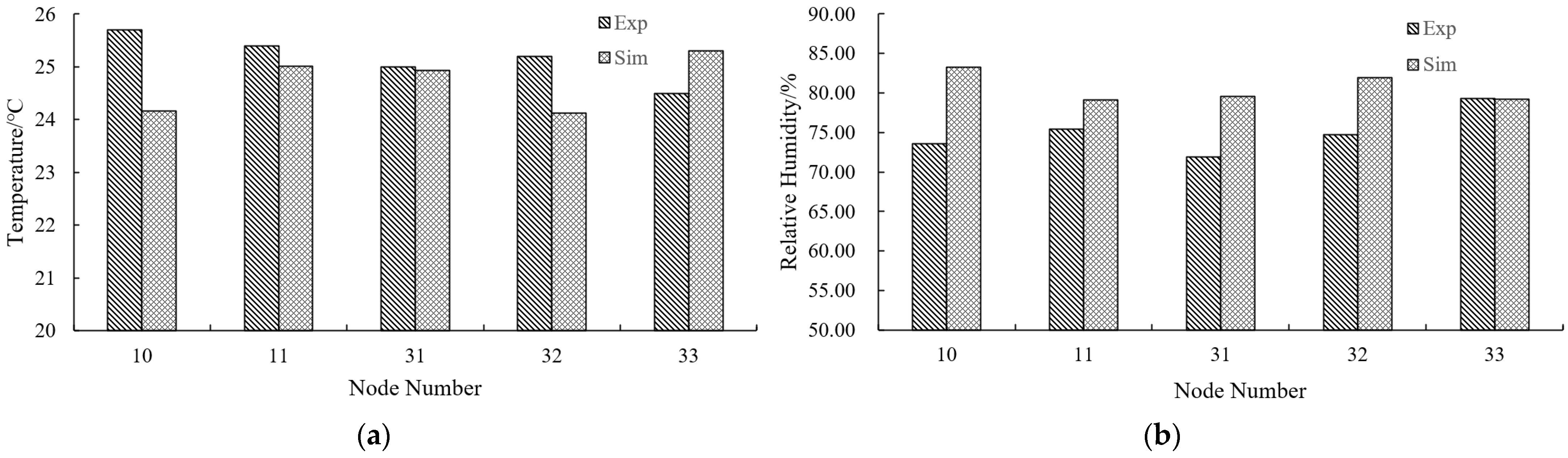

3. CFD Numerical Model

3.1. Basic Governing Equation

3.1.1. Mass Conservation Equation

3.1.2. Momentum Conservation Equation

3.1.3. Energy Conservation Equation

3.1.4. Component Transport Equation

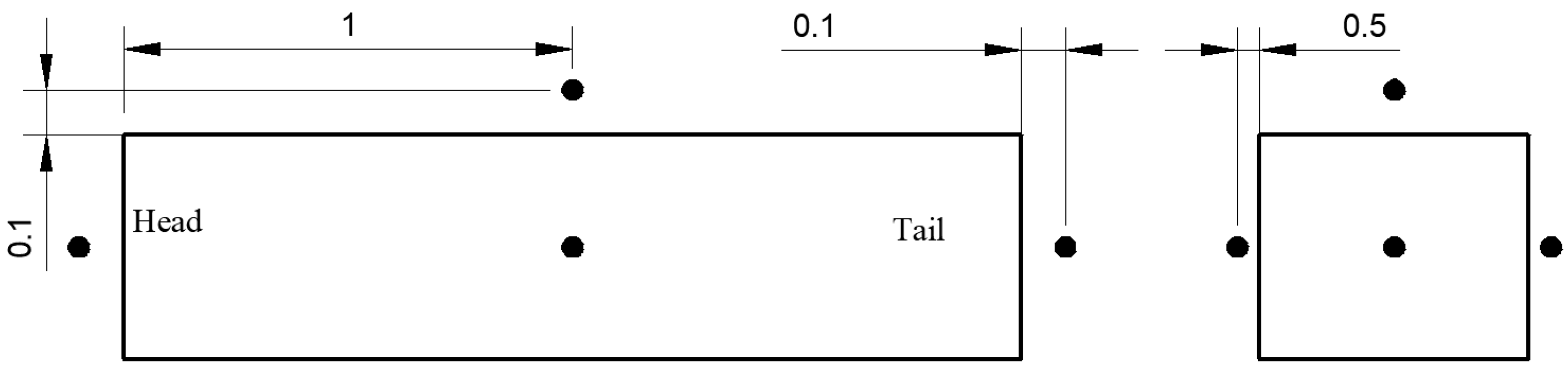

3.2. Numerical Model Preprocessing

3.3. Setting and Solving Boundary Conditions

- (1)

- The gas in the piggery is a Newtonian fluid;

- (2)

- The gas in the piggery is incompressible in the flow process and conforms to the Boussinesq assumption;

- (3)

- Water vapor does not condense on the solid walls;

- (4)

- There is good airtightness in the piggery.

4. Results

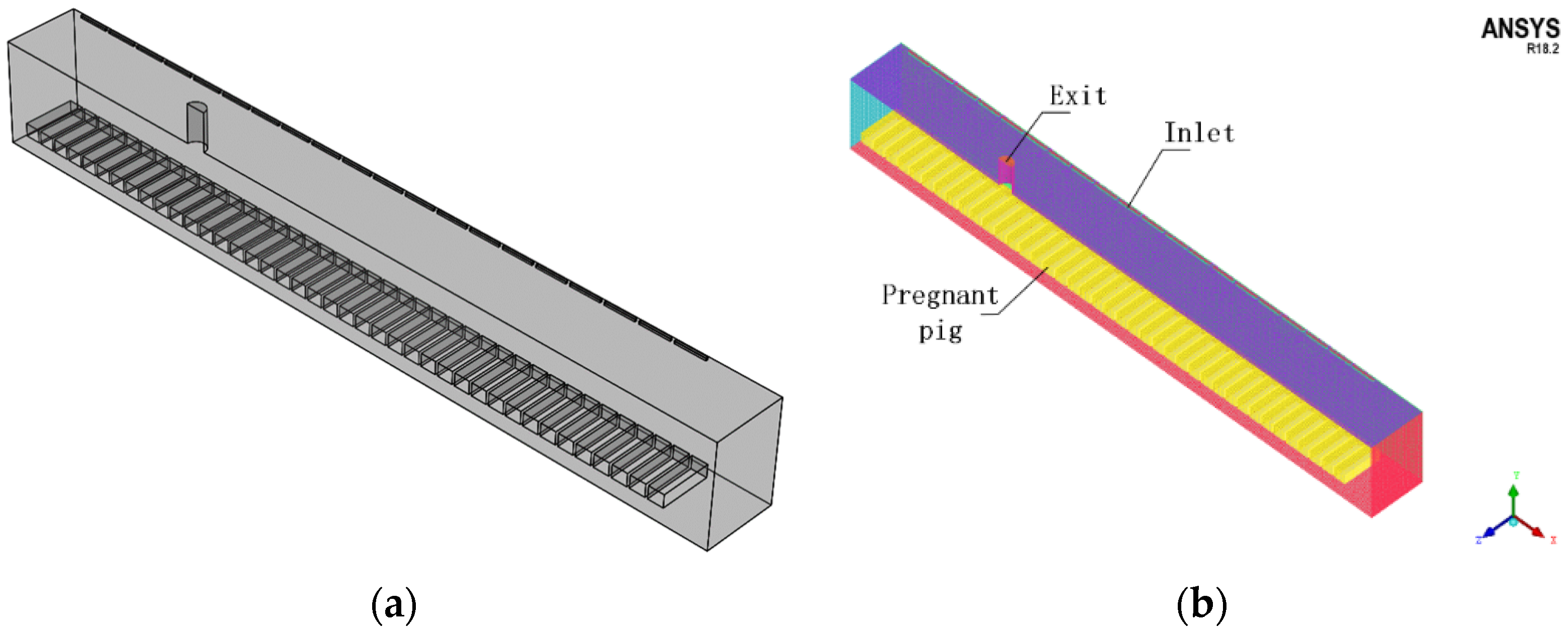

4.1. Test Validation

4.2. Piggery Environmental Assessment

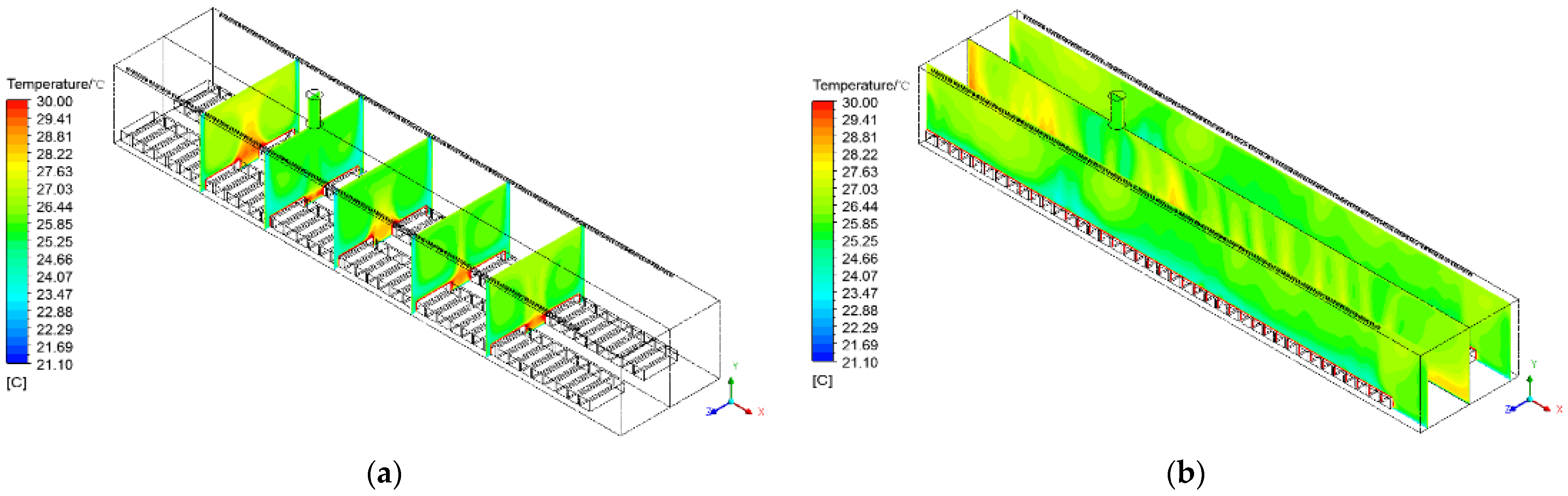

4.2.1. Temperature Distribution

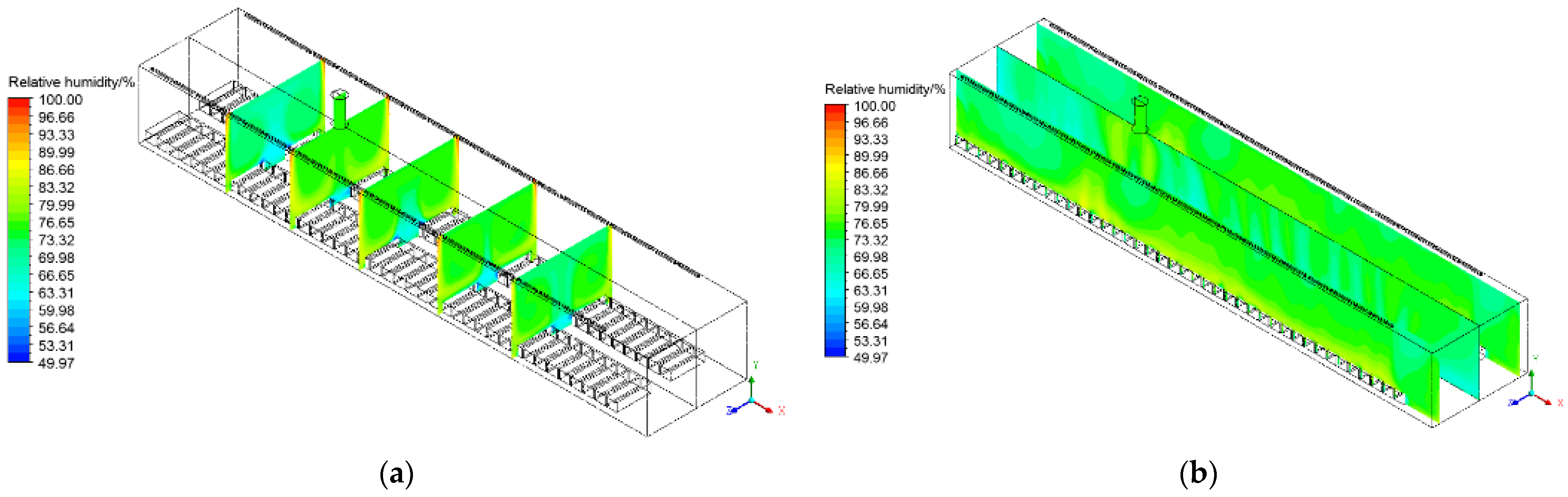

4.2.2. Humidity Distribution

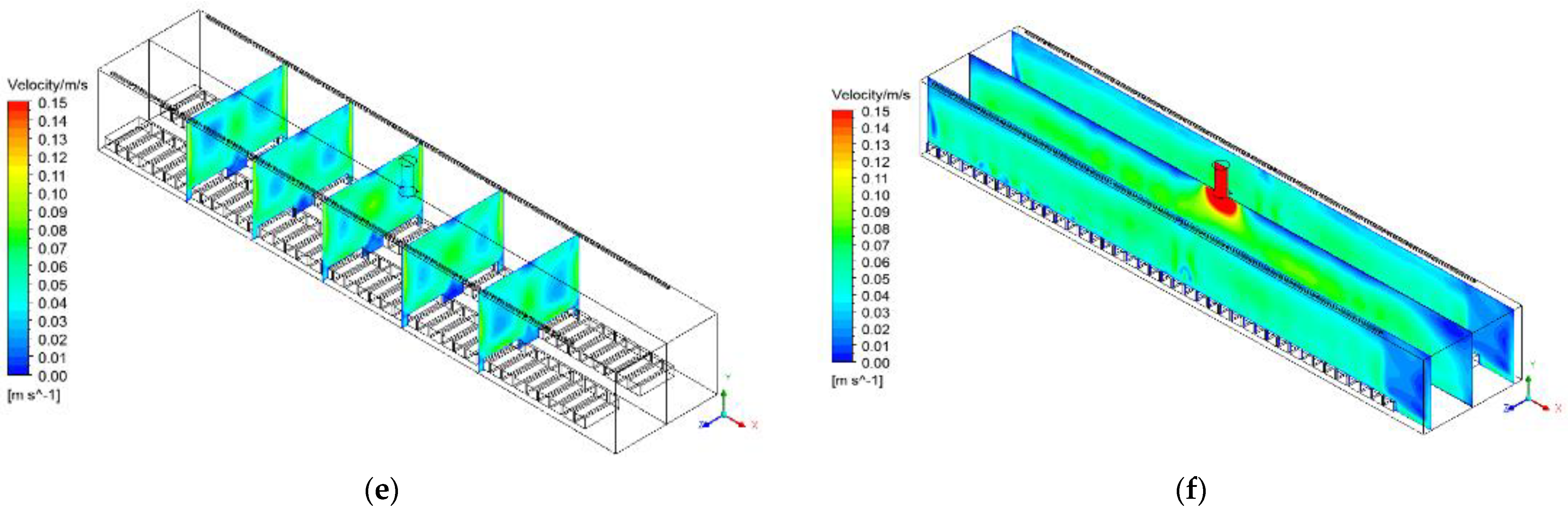

4.2.3. Velocity Distribution

4.3. The Effect of Exit Position

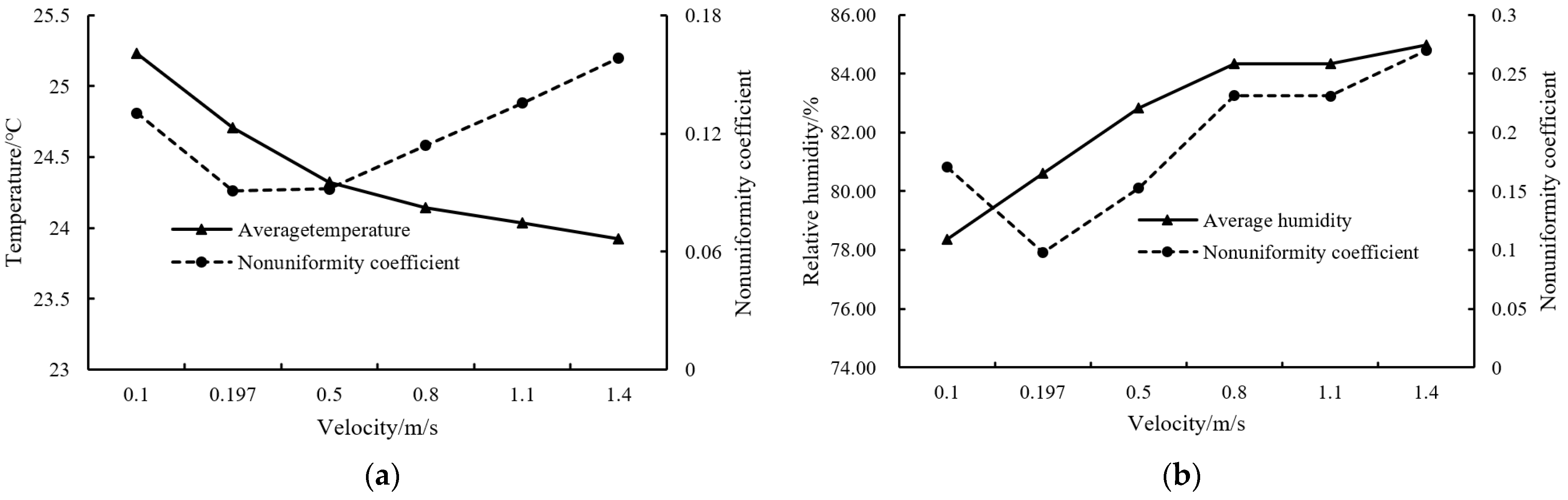

4.4. The Effect of Velocity

4.5. Evaluation of Body Surface Comfort of Pigs

5. Discussion

6. Conclusions

- (1)

- The CFD model was used to simulate the temperature and humidity distribution in the piggery. The maximum difference between the simulated and the experimental temperature values was less than 1.54 °C, and the relative error ranged from 0.28% to 5.99%, with an average relative error of 3.06%. The maximum difference between the simulated and the tested relative humidity values was less than 10% RH, and the relative error ranged from 0.06% to 13.14%, with an average relative error of 7.68%. Therefore, good agreement between the simulation and test results was demonstrated.

- (2)

- The temperature and humidity fields and the uniformity coefficient of the two air outlet locations were compared. When the temperature field is given priority, positioning the air outlet in the middle of the unit will help to increase the uniformity of the temperature field but will reduce the uniformity of the humidity field.

- (3)

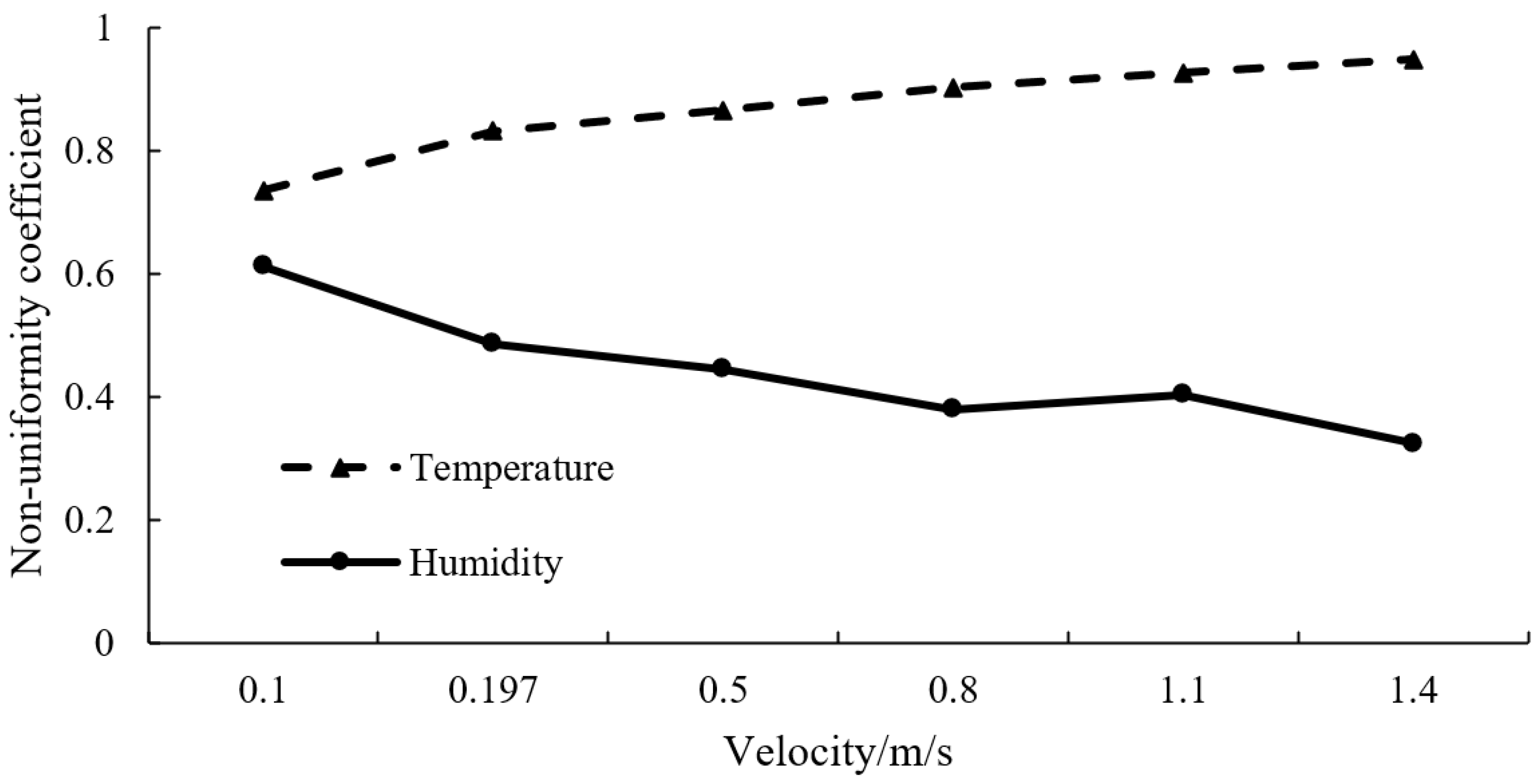

- With an increase in the air speed in the inlet, the temperature showed a downward trend while the relative humidity showed an upward trend; however, the uniformity of the two both increased first and then decreased. Considering the temperature and the humidity, along with the corresponding non-uniformity coefficient, the ventilation speed of 0.5 m/s was selected as the optimal inlet speed for the pregnant sow piggery.

- (4)

- With an increase in the velocity at the air inlet, the uniformity of the temperature distribution on the body surface of pregnant pigs decreases, while the uniformity of the relative humidity distribution increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, H.; Ge, Y. Impact of African Swine Fever on Pig Production and Market. Chin. J. Anim. Sci. 2020, 56, 168–172. [Google Scholar]

- Ministry of Agriculture and Rural Affairs of China. The Ministry of Agriculture and Rural Affairs of China Holds a Regular Press Conference on the Pig Production Situation in October. Available online: http://www.gov.cn/xinwen/2019-11/22/content_5454733.htm (accessed on 22 November 2019).

- Zhu, Z.; Li, M.; Zhang, X. Analysis on effects of African swine fever on China’s pig market and industry development. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 205–210, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Nie, Y.; Qiao, J. Impact of African Swine Fever on the Development of Pig Industry in China. J. Agric. Sci. Technol. 2019, 21, 11–17. [Google Scholar]

- The State Council of China. Opinions on the Key Work of “Agriculture, Rural Areas and Farmers” to Ensure the Realization of Comprehensive Well-Off Society as Scheduled. Available online: http://www.moa.gov.cn/nybgb/2020/202002/202004/t20200414_6341529.htm (accessed on 5 February 2020).

- Huang, C.; Li, Y.; Xu, Z. Effect of Piggery Air and Airbone Harmful Substances on Health of Pig Community and Its Controlling Technology. Acta Ecol. Anim. Domastici 2012, 33, 80–84. [Google Scholar]

- Xie, Q.; Ni, J.-Q.; Bao, J.; Liu, H. Simulation and verification of microclimate environment in closed swine piggery based on energy and mass balance. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 148–156, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Takai, H.; Nimmermark, S.; Banhazi, T.; Norton, T.; Jacobson, L.D.; Calvet, S.; Hassouna, M.; Bjerg, B.; Zhang, G.-Q.; Pedersen, S.; et al. Airborne pollutant emissions from naturally ventilated buildings: Proposed research directions. Biosyst. Eng. 2013, 116, 214–220. [Google Scholar] [CrossRef][Green Version]

- Bjerg, B.; Rong, L.; Zhang, G. Computational prediction of the effective temperature in the lying area of pig pens. Comput. Electron. Agric. 2018, 149, 71–79. [Google Scholar] [CrossRef]

- Spoolder, H.A.M.; Aarnink, A.A.J.; Vermeer, H.M.; van Riel, J.; Edwards, S.A. Effect of increasing temperature on space requirements of group housed finishing pigs. Appl. Anim. Behav. Sci. 2012, 138, 229–239. [Google Scholar] [CrossRef]

- Zeng, Z.; Zeng, F.; Han, X.; Elkhouchlaa, H.; Yu, Q.; Lü, E. Real-Time Monitoring of Environmental Parameters in a Commercial Gestating Sow House Using a ZigBee-Based Wireless Sensor Network. Appl. Sci. 2021, 11, 972. [Google Scholar] [CrossRef]

- Wang, K.; Li, K.; Li, W.; Lin, J.; Lou, Z.; Zhu, X. CFD simulation of indoor hygrothermal environment and particle matter of weaned pig building. Trans. Chin. Soc. Agric. Mach. 2017, 48, 270–278, (In Chinese with English Abstract). [Google Scholar]

- Huynh, T.T.T.; Aarnink, A.J.A.; Gerrits, W.J.J.; Heetkamp, M.J.H.; Canh, T.T.; Spoolder, H.A.M.; Kemp, B.; Verstegen, M.W.A. Thermal behaviour of growing pigs in response to high temperature and humidity. Appl. Anim. Behav. Sci. 2005, 91, 1–16. [Google Scholar] [CrossRef]

- Carroll, J.A.; Burdick, N.C.; Chase, C.C., Jr.; Coleman, S.W.; Spiers, D.E. Influence of environmental temperature on the physiological, endocrine, and immune responses in livestock exposed to a provocative immune challenge. Domest. Anim. Endocrinol. 2012, 43, 146–153. [Google Scholar] [CrossRef]

- Myer, R.; Bucklin, R. Influence of Hot-Humid Environment on Growth Performance and Reproduction of Swine; Institute of Food and Agricultural Sciences, University of Florida: Gainesville, FL, USA, 2018. [Google Scholar]

- Vitt, R.; Weber, L.; Zollitsch, W.; Hörtenhuber, S.; Baumgartner, J.; Niebuhr, K.; Piringer, M.; Anders, I.; Andre, K.; Hennig-Pauka, I.; et al. Modelled performance of energy saving air treatment devices to mitigate heat stress for confined livestock buildings in Central Europe. Biosyst. Eng. 2017, 164, 85–97. [Google Scholar] [CrossRef]

- Valiño, V.; Perdigones, A.; Iglesias, A.; Garcia, J.L. Effect of temperature increase on cooling systems in livestock farms. Clim. Res. 2010, 44, 107–114. [Google Scholar] [CrossRef][Green Version]

- Xuan, Y.M.; Xiao, F.; Niu, X.F.; Huang, X.; Wang, S.W. Research and application of evaporative cooling in China: A review (I)—Research. Renew. Sustain. Energy Rev. 2012, 16, 3535–3546. [Google Scholar] [CrossRef]

- Justino, E.; Nääs, I.; Carvalho, T.; Neves, D.; D’Alessandro Salgado, D. The impact of evaporative cooling on the thermoregulation and sensible heat loss of sows during farrowing. Eng. Agric. 2014, 34, 1050–1061. [Google Scholar] [CrossRef]

- Rigo, E.J.; Nascimento, M.; Silva, N. Performance and thermoregulation of lactating sows housed in different locations inside a shed with an evaporative cooling system in a tropical environment. Arq. Bras. Med. Vet. Zootec. 2019, 71, 1750–1758. [Google Scholar] [CrossRef]

- Qi, F.; Shi, Z.; Huang, J.; Li, H. Determination of maximum ventilation and evaluation on the performance of the cooling system for commercial piggerys in different climate zones. Trans. Chin. Soc. Agric. Eng. 2021, 37, 202–209, (In Chinese with English Abstract). [Google Scholar]

- Wiegert, J.G.; Knauer, M.T.; Shah, S.B. Effect of pad cooling on summer barn environment and finishing pig temperature. J. Anim. Sci. 2017, 95 (Suppl. 2), 35. [Google Scholar] [CrossRef]

- Dağtekin, M.; Karaca, C.; Yildiz, Y.; Başçetinçelik, A.; Paydak, Ö. The effects of air velocity on the performance of pad evaporative cooling systems. Afr. J. Agric. Res. 2011, 6, 1813–1822. [Google Scholar]

- Cheng, Q.; Feng, H.; Meng, H.; Zhou, H. CFD study of the effect of inlet position and flap on the airflow and temperature in a laying hen house in summer. Biosyst. Eng. 2021, 203, 109–123. [Google Scholar] [CrossRef]

- Yi, Q.; Janke, D.; Thormann, L.; Zhang, G.; Amon, B.; Hempel, S.; Nosek, S.; Hartung, E.; Amon, T. Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution. Appl. Sci. 2020, 10, 4931. [Google Scholar] [CrossRef]

- Xie, Q.; Ni, J.-Q.; Bao, J.; Su, Z. Correlations, variations, and modelling of indoor environment in a mechanically-ventilated pig building. J. Clean. Prod. 2021, 282, 124441. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Yi, Q.; Zhang, G.; Amon, T.; Janke, D.; Li, X.; Chen, B.; He, Y.; Wang, K. Numerical evaluation on ventilation rates of a novel multi-floor pig building using computational fluid dynamics. Comput. Electron. Agric. 2021, 182, 106050. [Google Scholar] [CrossRef]

- Seo, I.; Lee, I.; Moon, O.; Hong, S.; Hwang, H.; Bitog, J.; Kwon, K.; Ye, Z.; Lee, J. Modelling of internal environmental conditions in a full-scale commercial pig house containing animals. Biosyst. Eng. 2012, 111, 91–106. [Google Scholar] [CrossRef]

- Qin, C.; Wang, X.; Zhang, G.; Yi, Q.; He, Y.; Wang, K. Effects of the slatted floor layout on flow pattern in a manure pit and ammonia emission from pit-A CFD study. Comput. Electron. Agric. 2020, 177, 105677. [Google Scholar] [CrossRef]

- Gautam, K.R.; Rong, L.; Iqbal, A.; Zhang, G. Full-scale CFD simulation of commercial pig building and comparison with porous media approximation of animal occupied zone. Comput. Electron. Agric. 2021, 186, 106206. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Choi, C.Y. Evaluation of a precision air-supply system in naturally ventilated freestall dairy barns. Biosyst. Eng. 2018, 175, 1–15. [Google Scholar] [CrossRef]

- Rong, L.; Aarnink, A.J.A. Development of ammonia mass transfer coefficient models for the atmosphere above two types of the slatted floors in a pig house using computational fluid dynamics. Biosyst. Eng. 2019, 183, 13–25. [Google Scholar] [CrossRef]

- Yeo, U.-H.; Lee, I.-B.; Kim, R.-W.; Lee, S.-Y.; Kim, J.-G. Computational fluid dynamics evaluation of pig house ventilation systems for improving the internal rearing environment. Biosyst. Eng. 2019, 186, 259–278. [Google Scholar] [CrossRef]

- Cheng, Q.; Mu, Y.; Li, B. CFD simulation of influence of air supply location on airflow and temperature in stacked-cage hen piggery with tunnel ventilation. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 192–199, (In Chinese with English Abstract). [Google Scholar]

- Li, H.; Rong, L.; Zhang, G. Reliability of turbulence models and mesh types for CFD simulations of a mechanically ventilated pig house containing animals. Biosyst. Eng. 2017, 161, 37–52. [Google Scholar] [CrossRef]

- Blanes-Vidal, V.; Guijarro, E.; Balasch, S.; Torres, A. Application of computational fluid dynamics to the prediction of airflow in a mechanically ventilated commercial poultry building. Biosyst. Eng. 2008, 100, 105–116. [Google Scholar] [CrossRef]

- Bustamante, E.; García-Diego, F.J.; Calvet, S.; Estellés, F.; Beltrán, P.; Hospitaler, A.; Torres, A.G. Exploring Ventilation Efficiency in Poultry Buildings: The Validation of Computational Fluid Dynamics (CFD) in a Cross-Mechanically Ventilated Broiler Farm. Energies 2013, 6, 2605–2623. [Google Scholar] [CrossRef]

- Kwon, K.-S.; Lee, I.-B.; Zhang, G.Q.; Ha, T. Computational fluid dynamics analysis of the thermal distribution of animal occupied zones using the jet-drop-distance concept in a mechanically ventilated broiler house. Biosyst. Eng. 2015, 136, 51–68. [Google Scholar] [CrossRef]

- Xin, Y.; Rong, L.; Wang, C.; Li, B.; Liu, D. CFD study on the impacts of geometric models of lying pigs on resistance coefficients for porous media modelling of the animal occupied zone. Biosyst. Eng. 2022, 222, 93–105. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zong, C.; Zhang, G. Assessing response surface methodology for modelling air distribution in an experimental pig room to improve air inlet design based on computational fluid dynamics. Comput. Electron. Agric. 2017, 141, 292–301. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zong, C.; Zhang, G. A numerical study on forced convective heat transfer of a chicken (model) in horizontal airflow. Biosyst. Eng. 2016, 150, 151–159. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zhang, G. Study on convective heat transfer from pig models by CFD in a virtual wind tunnel. Comput. Electron. Agric. 2016, 123, 203–210. [Google Scholar] [CrossRef]

- Mondaca, M.R.; Choi, C.Y. An Evaluation of Simplifying Assumptions in Dairy Cow Computational Fluid Dynamics Models. Trans. ASABE 2016, 59, 1575–1584. [Google Scholar] [CrossRef]

- Zeng, Z.; Dong, B.; Lv, E.; Xia, J.; Wu, P.; Shen, H. Design and experiment of wireless multi-point and multi-source remote monitoring system for pig house environment. Trans. Chin. Soc. Agric. Mach. 2020, 51, 332–340, (In Chinese with English Abstract). [Google Scholar]

- Lü, E.; Lu, H.; Wang, G.; Zeng, Z.; Xia, J.; Guo, J.; Wang, Y.; Dong, B.; Wu, P. One Multi-Point Wireless Intelligent Monitoring System and Method for Livestock and Poultry Breeding Environmental Parameters. China Invention Patent CN201910281334.3, 9 April 2019. [Google Scholar]

- Lü, E.; Lu, H.; Wang, G.; Zeng, Z.; Xia, J.; Guo, J.; Wang, Y.; Dong, B.; Wu, P. One Environment Multi-Source Information Sensing and Early Warning System and Method. China Invention Patent CN201910281348.5, 9 April 2019. [Google Scholar]

- Xie, R.; Tang, H.; Tao, W.; Liu, G.; Liu, K.; Wu, J. Optimization of cold-plate location in refrigerated vehicles based on simulation and test of no-load temperature field. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 290–298, (In Chinese with English Abstract). [Google Scholar]

- Guo, J.; Wei, X.; Du, X.; Ren, J.; Lü, E. Numerical simulation of liquid nitrogen injection in a container with controlled atmosphere. Biosyst. Eng. 2019, 187, 53–68. [Google Scholar] [CrossRef]

- Lin, J.; Liu, J.; Meng, Q.; Lei, M.; Tong, Y.; Gao, Y. Numerical CFD simulation and verification of summer indoor temperature and airflow field in boar building. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 207–212, (In Chinese with English Abstract). [Google Scholar]

- Cheng, X.; Mao, H.; Ni, J. Numerical prediction and CFD modeling of relative humidity and temperature for greenhouse-crops system. Trans. Chin. Soc. Agric. Mach. (Trans. CSAM) 2011, 42, 173–179, (In Chinese with English Abstract). [Google Scholar]

- Liu, Y.; Zeng, Z.; Guo, J.; Lü, E.; Meng, Q. Numerical simulation and experimental verification of effect of CO2 enrichment on flow field of greenhouse. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2015, 31, 194–199, (In Chinese with English Abstract). [Google Scholar]

- Zeng, Z.; Wei, X.; Lv, E.; Liu, Y.; Yi, Z.; Guo, J. Numerical simulation and experimental verification of temperature and humidity in centralized ventilated delivery pigsty. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 210–217, (In Chinese with English Abstract). [Google Scholar]

- Guo, J.; Liu, Y.; Lü, E. Numerical Simulation of Temperature Decrease in Greenhouses with Summer Water-Sprinkling Roof. Energies 2019, 12, 2435. [Google Scholar] [CrossRef]

| Name | Type/Company | Range/Precision |

|---|---|---|

| Thermal anemometer | testo 425 Teto Group, German | 0–20 m/s 0.03 m/s + 5% |

| Thermohydrograph | CENTER 310 Taiwan Qunte Co., Ltd, China | −20–60 °C 0–100% |

| Thermal imager | FLIR T400 Phil Corporation, America | −20–120 °C Sensitivity < 0.045 °C |

| Boundary Condition | Boundary Type | Option | Numerical Value |

|---|---|---|---|

| Building envelope | Non-slip boundary | Temperature | Ceiling: 26.8 °C |

| Floor: 22.3 °C | |||

| Wall: 26.8 °C | |||

| Pregnant pig | Non-slip boundary | Temperature | 37.5 °C |

| Air intake | Velocity inlet | Velocity | 0.197 m/s |

| Temperature | 21.1 °C | ||

| Relative humidity | 99% | ||

| Mass reaction | 0.0156 | ||

| Fan export | Pressure outlet | Temperature Humidity Mass fraction | 23.7 °C 70% 0.0109 |

| Outlet Position | Average Temperature [°C] | Temperature Non-Uniformity Coefficient | Average Humidity | Humidity Non-Uniformity Coefficient |

|---|---|---|---|---|

| Original location | 24.71 | 0.091 | 80.62% | 0.098 |

| Middle | 24.89 | 0.086 | 79.76% | 0.127 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Li, B.; Lu, H.; Lü, E.; Guo, J.; Jiang, Y.; Zeng, Z. Numerical Simulation of Airflow Distribution in a Pregnant Sow Piggery with Centralized Ventilation. Appl. Sci. 2022, 12, 11556. https://doi.org/10.3390/app122211556

Wei X, Li B, Lu H, Lü E, Guo J, Jiang Y, Zeng Z. Numerical Simulation of Airflow Distribution in a Pregnant Sow Piggery with Centralized Ventilation. Applied Sciences. 2022; 12(22):11556. https://doi.org/10.3390/app122211556

Chicago/Turabian StyleWei, Xinyu, Bin Li, Huazhong Lu, Enli Lü, Jiaming Guo, Yihong Jiang, and Zhixiong Zeng. 2022. "Numerical Simulation of Airflow Distribution in a Pregnant Sow Piggery with Centralized Ventilation" Applied Sciences 12, no. 22: 11556. https://doi.org/10.3390/app122211556

APA StyleWei, X., Li, B., Lu, H., Lü, E., Guo, J., Jiang, Y., & Zeng, Z. (2022). Numerical Simulation of Airflow Distribution in a Pregnant Sow Piggery with Centralized Ventilation. Applied Sciences, 12(22), 11556. https://doi.org/10.3390/app122211556