Abstract

The current study deals with the design of ultra-high molecular weight polyethylene (UHMWPE) composites by integrating various micro and nanoparticles as reinforcements for enhanced performance of acetabular cups in hip prostheses. For the design, a data-driven design approach was implemented, exploiting natural computing techniques such as Artificial Neural Network (ANN) and Genetic Algorithm (GA). Experimental data related to UHMWPE reinforced with carbon nanotube, graphene, carbon fiber, and hydroxyapatite were gathered from the published works of previous researchers. To study the relationship between the volume fraction and the morphology of the particles with the tribological and mechanical properties of the composites, ANN modeling and sensitivity analyses were used. Optimization of the properties was done with the developed ANN models as objective functions in order to find the optimal combinations of reinforcements, which helps to achieve enhanced tribo-mechanical properties of the composites. This natural computing approach of designing the UHMWPE composites paved a way for experimentation.

1. Introduction

Ultra-high molecular weight polyethylene (UHMWPE) is deemed as the right material for the connecting parts of total joint replacements (TJR), such as hip and knee joints, in different forms, such as straight and cross linked. UHMWPE is chosen due to the high fatigue and wear resistance, high toughness against fracture, and biocompatibility when compared to other kinds of polymers [1,2,3]. In order to know the outcomes and lifespan of a TJR material, the following parameters are considered: oxidation consistency, and the mechanical and wear properties of the composite materials [4,5]. The hip joint is among the most powerful synovial joints in the human body. A point of concern with regard to substitution of hip joints is the osteolytic condition of the acetabular attachments in the course of time; osteolysis stimulates antagonistic reactions in the soft tissues, which are caused by the particles delivered due to the counteracting metallic parts, necessitating correction by medical procedure [6,7]. In the later years, such corrections by medical procedure have expanded: at present, 5% of revision surgeries after two years of the initial procedure are done only for the sterile extrication of the inserts [8].

Different researchers have proposed various techniques, such as cross linking of polymers, inclusion of fillers and particulate, and so forth [9,10,11], to overcome the issue of osteolysis. While the metallic contacts interface with the acetabular bearing, the inclusion of fillers and particulates into UHMWPE drastically decreases the friction and wear rate, which ultimately increases the enactment of the polymer. The addition of these reinforcements into the UHMWPE is improved by compression molding technique rather than injection molding, where the flow of UHMWPE is not supported due its viscosity [12,13]. The usage of several particles as reinforcements for the polymer-centered composite materials brings together the application of reinforcements of numerous dimensions to attain physical characteristics that are superior to using a single filler. The idea of using multiple fillers is needed for an intelligent outcome, which helps to achieve an improvement in the tribological and mechanical properties of the resulting composite. Sensible enhancements on the wear properties were seen on such UHMWPE composites with various reinforcements in tandem [14,15,16]. A few particles that have been utilized by researchers for strengthening the composites after considering enhancement of the properties of UHMWPE are as follows: a single or multiwalled carbon nanotube (SW or MWCNT) [17,18], graphene/graphene oxide (GO) [16,19], carbon fiber (CF) [11,20], zirconia [21], nano-Al2O3 [22,23], nano/micro hydroxyapatite (HAP) [24,25], and nano-SiO2 [26]. A noticeable impact is the boosting of the characteristics of these composites by these fillers or particulates, accompanied by the modification of its effects.

Considering the abovementioned factors, it was proposed that numerous micro/nano particles may have the chance of improving various properties simultaneously. Shi et al. have investigated that there is a tremendous rise in the mechanical properties of the UHMWPE nano HAP composites by in situ filling, especially Young’s modulus and the yield strength. He also observed a 38.2% reduction in the average coefficient of friction (CoF) values with 1% nano HAP fillers with UHMWPE [27]. Abdelbary et al. [28] and Shan Shan et al. [29] have elaborately reviewed the use of carbon fibers with the UHMWPE composites that provide enriched properties, both in mechanical and tribological behavior, owing to the interaction between the carbon fiber and UHMWPE. Xiaohong Chen et al. observed that with the increase in GO content from 0.1 to 1%, UHMWPE–GO composites showed a drop in COF value and wear ratio [30]. On adding CNT to UHMWPE, the wear resistance of the composite increases, uplifting the load-bearing capability, and the same has been investigated by Zoo et al. [31]. Due to the lighter weight of CNT—almost 7 times less than that of steel—where its specific strength is also much higher than that of steel, it paves a way for the capable use of reinforcement for polymer composites. The film formation of CNT onto the surface during the interaction of the metallic counterface also reduces the friction parameters. Combination of CNT and graphene-based UHMWPE composites has led to a substantial reduction in wear properties because of the nano-carbon-based particles present in it. These particles have a self-lubricating behavior and the same has been observed by other researchers [16,32].

This research work highlights the inventive works that implement AI techniques in regular trial techniques (experimentation) to design UHMWPE composites with multiple reinforcements. The regular trial techniques are monotonous, and do not get commendable outcomes, such as discovering reinforcement materials of expected structure and size of the particles by designing such composites with complex micro/nano particles coupled as reinforcements. In addition to this, unwinding the determined associations between the different kinds of particles and volume fraction will help to develop productive UHMWPE composites that present a supreme performance. It is additionally very challenging to formulate actual models that are dependent on the complicated associations between its structure, composition, and properties. Therefore, a data-informative-based modelling technique, in particular, ANN, is used, which is a natural computing technique utilized in the designing of materials [33,34,35,36,37]. In order to have a better understanding of the impact of nanoparticles when utilized as reinforcements for UHMWPE composites, ANN is utilized to model the same.

The process of modelling includes a collection of data from the published literature involving discrete augmentations of MWCNT, graphene, carbon fiber (CF), and HAP, and in mixture. Another natural computing technique, Genetic Algorithm (GA), has been utilized [38], involving the created ANN models as objective functions in order to optimize the parameters and for the process of designing composites that have greater enhancement in the required properties. GA is successfully applied both in a single and multi-objective fashion for the development of composites with esteem performance [39,40,41]. The utilization of ANN models as fitness functions in optimization using GA are greatly in use for the design of materials for numerous applications [42,43]. Comparative methodology of utilizing different artificial intelligence techniques is used for the design of composites for prosthetic and dental applications [40,44]. UHMWPE composites with two nanoparticles were designed and developed with the improved mechanical and tribological properties by the current authors in the previous study [16]. Addition of multiple type of fillers can overcome the shortcomings of any single type of filler, and even provide a synergistic effect. In the current work, the four multiscale particles, namely, MWCNT, graphene, carbon fiber, and hydroxyapatite, are added to the framework, to highlight the improved tribo-mechanical behavior. Thus, the objective of this study is to employ a natural computing-based design of novel hybrid UHMWPE composites with complex reinforcements, such as combined micro and nano particles, which display unrivaled mechanical and wear properties, for utilization in the acetabular cup of an artificial hip joint.

2. Materials and Methods

2.1. Database

The database, comprising 787 datasets, was obtained through articles published on composites of UHMWPE reinforced with CF, graphene, MWCNT, and HAP [1,14,20,31,32,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68]. Altogether, 18 variables were considered as inputs, which incorporate the weight proportion and molecule dimensions of the micro/nano particles, with five variables considered as outputs; i.e., three mechanical properties, namely, ultimate tensile strength (UTS), hardness (H), and Young’s modulus (E), as well as two tribological properties, namely, the specific wear rate (SWR) and coefficient of friction (CoF). Five independent ANN models were created to understand the relation between the inputs and outputs. The created models were then utilized for the minimization of the tribological properties and maximization of the mechanical properties. Table 1 portrays the input and output variables. However, in ANN modelling, the connection utilized for the standardization of each variable dropping between −1 and 1 is shown in Equation (1), to limit the error.

where XN corresponds to the normalized value, and Xmax and Xmin correspond to the maximum and minimum values of the input variable X.

Table 1.

Higher and lower values of every input and output parameter, with its normal deviation and average.

2.2. Computational Techniques

To design the hybrid UHMWPE composites, two natural computing techniques were utilized in this work: 1) ANN was used to develop data-driven models; and 2) GA was used to optimize the tribo-mechanical properties in a single and multi-objective manner, utilizing the created ANN model as the fitness function to GA. GA and ANN are briefly explained in the following portions.

2.2.1. Development of Models Using ANN

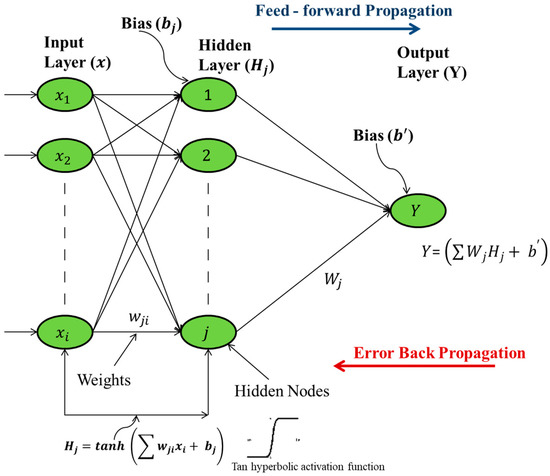

The feedforward backpropagated algorithm, using the scaled conjugate gradient method [69], is the type of ANN used in this work. Eighteen input variables incorporating the weight proportion and size of the micro/nano particles were considered as the input nodes in the input layer and five output variables—two tribological properties and three mechanical properties—were considered the output nodes in the output layer. The output layer is connected to the input layers by means of a hidden or a concealed layer that has to be iterated by the user. The configuration of ANN is signified by the 18-N-1 scheme, where 18 denotes the total input variables, N denotes the number of hidden layers, and 1 denotes each of the output variables. The linking of each layer is done by functions. A non-linear transfer function—the tan hyperbolic (tanh) function—links the input and hidden nodes (Hj), which is expressed in the Equation (2), comprising the weighted sum of the normalized inputs () and the connection weights () that connect the input to the hidden layers.

The output node (Y) was then determined by the weighted sum of the outputs, and the connection weights of the hidden-to-output layer by the linear function is expressed in Equation (3).

Here, the bias values and correspond to the input-to-hidden and hidden-to-output layers, respectively. During the process of learning, the deviation from the targeted output to the real output is fed back to regulate the weights and bias values of the corresponding layers [36]. The above computation is explained in Figure 1. The developed models are used as objective functions for the optimization work. The entire ANN modelling was done by utilizing the Neural Network toolbox in MATLAB®.

Figure 1.

Configuration of ANN.

2.2.2. Sensitivity Analysis

The building up of any new material involves a fundamental understanding of the absolute impact of the different input parameters on the final combined tribological and mechanical properties of the composites. However, it is very repetitive to decide the result of the input parameters on the output because of the intertwined, concealed connections of the ANN models. The sensitivity analysis that assists with discovering all pertinent influences from a bunch of potential elements can be overwhelming in this case. It is practical to decide the relationship among the output and input parameters via different approaches. This study uses an associated method, namely, the connection weight method [70], where the product of the raw input-hidden (wji) and hidden-output (Wj) connection weights are summed across all hidden neurons. These values are assigned as sensitivity for each of the input variables. The same method has been utilized here and in previous works [37,71] for the design of new materials. To discover the pertinent significance of the variables, it utilizes the layer weights of the input-to-hidden and hidden-to-output from the created ANN model.

2.2.3. Genetic Algorithm and Multi-Objective Optimization

The objective functions generated from the ANN models were used for optimization using the Genetic Algorithm (GA). One form of the stochastic search algorithms that have evolved from nature is the GA. GA helps to arrive at feasible solutions in a population. It is a subset of AI, much alike other search algorithms that help to find a region of feasible solutions to eventually attain one that resolves the given problem. The feasible solutions are denoted as ‘genes’—a series of characters from a certain script. Fresh solutions can be created by ‘mutating’ participants of the present population, and also by ‘breeding’ two solutions. The enhanced solutions are nominated to mate and mutate, removing the inferior ones. GA is a probabilistic method of searching, in which the states investigated are not defined exclusively by the properties of the issues [72]. This GA-based optimization includes a function called objective function, in a distinct or a multi-objective manner, by incorporating or neglecting the constraints.

In case of multi-objective problems, the genetic search is performed following the concept of Pareto optimality [38,71]. Due to the presence of more than one conflicting objective function, the idea of optimal solution changes from the unique solution to a set of solutions, which lead to compromises between the objectives. This set of solutions is called a Pareto front. In a Pareto front, no solution exists that is not as good as some member of the Pareto set in terms of all the objectives, and definitely better in terms of one objective. As genetic algorithms can process a number of solutions in parallel, it can easily find the solutions in the Pareto front. In GA, the selection of the solutions is done using a process called the non-domination principle. The important aspects of multiple-objective optimization using GA are as follows: (1) selection based on a non-domination principle; and (2) niching in objective and/or decision variable space. This method of search optimization is utilized here to build UHMWPE hybrid composites with multiple micro/nano particles to attain feasible values of the tribo-mechanical properties. The optimization was performed using the GA multi-objective optimization toolbox in MATLAB® with different parameters, as shown in Table 2.

Table 2.

Parameters of the GA.

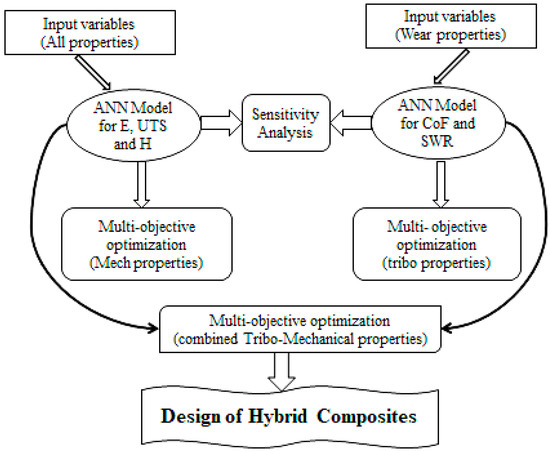

2.2.4. Scheme of the Computational Arrangement

Five various ANN models were created utilizing the dataset as shown in Table 1, comprising the self-determining input variables for the mechanical and wear properties. The impacts of the input parameters seized by the created ANN models were studied by sensitivity analysis. Both the tribological and mechanical properties were optimized separately in a multi-objective manner as there were conflicts among the properties during modelling. To attain the hybrid UHMWPE composites, both the tribo-mechanical properties were then optimized in tandem in a multi-objective manner by keeping the tribo test parameters constant in order to equalize the input variables of both properties. Through all these above-stated optimization studies, the optimal solutions were generated and final compositions for the hybrid UHMWPE composites reinforced with multiple micro/nano particles were decided for manufacturing the designed hybrid composites for further experimentation. The actual computational arrangement narrated in this section is illustrated in Figure 2.

Figure 2.

Process flowchart of the computational arrangement.

3. Design of Hybrid Composites

3.1. Modelling Using ANN

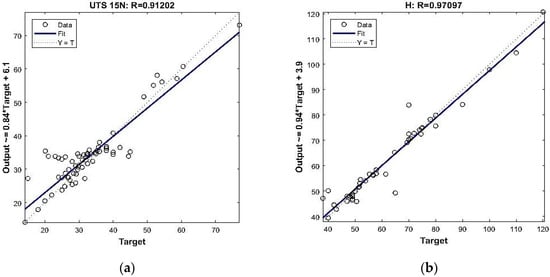

Five separate ANN models were created after considering all the input and output variables. After several iterations on varying the hidden neurons in the range between 3 and 15, the feasible models, which had a minimal error with 15, 12, 9, 11, and 12 hidden neurons, were chosen for each of the output variables as three mechanical properties (UTS, H, and E) and two wear properties (SWR and CoF). The predictability of these distinctly trained ANN models are shown with the help of scatter diagrams, as illustrated in Figure 3. The best predictability of the ANN models are evidently seen through the higher correlation coefficients for the corresponding mechanical characteristics of UTS, H, and E, being 0.91202, 0.97097, and 0.90693, respectively. Similarly, the corresponding tribological properties of SWR and CoF were 0.91876 and 0.98709.

Figure 3.

Predictability of the ANN models for (a) UTS, (b) H, (c) E, (d) SWR, and (e) CoF.

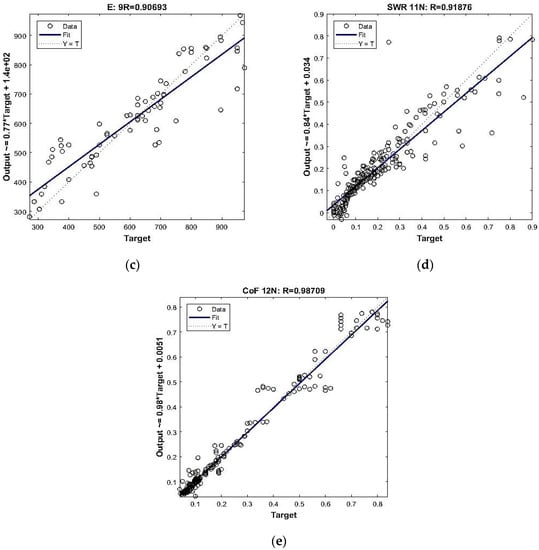

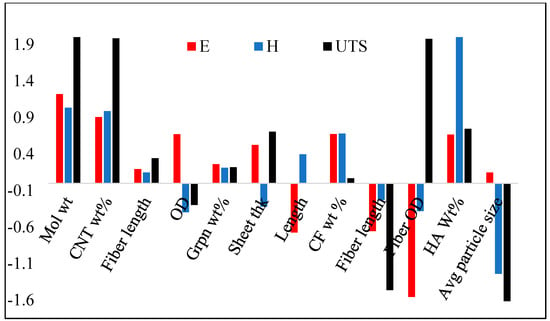

3.2. Sensitivity Analysis

Figure 4 and Figure 5 illustrate the sensitivity analysis plots of the created ANN models. The mechanical and tribological properties bring forth the relationship between all the input variables, comprising the quantity of the four particles in percentage, along with its geometry and its corresponding output parameters, namely, UTS, H, E, SWR, and CoF. The sensitivity plot of the mechanical properties depicted in Figure 3 shows that with the variation in UHMWPE’s molecular weight, there is an encouraging increase in Young’s modulus, with the following exceptions: graphene’s sheet length, the length of CF, and the OD of CF. This leads to a depressing effect. Likewise, there is an encouraging increase in the ultimate tensile strength, with the following exceptions: MWCNT’s fiber length, the length of CF, and the average particle size of HAP. This shows a depressing effect; it also is clearly seen that there is an encouraging outcome on the hardness of most of the variables, with the exception being the MWCNT’s fiber OD, graphene’s sheet thickness, the length of CF, the OD of CF, and the average particle size of HAP, which shows a depressing outcome. It is obvious from Figure 3 that by changing the UHMWPE’s molecular weight, all three mechanical properties tended to show an improvement that can be employed as objective or fitness functions for further optimization studies.

Figure 4.

Sensitivity analysis for UTS, H, and E.

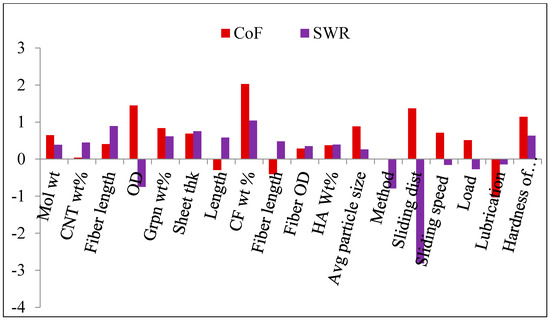

Figure 5.

Sensitivity analysis for CoF and SWR.

The sensitivity plot of the tribological properties, as depicted in Figure 4, highlights the fact that with the variation in UHMWPE’s molecular weight, there is an encouraging outcome on the coefficient of friction for most of the variables, with the exception being graphene’s sheet length, the length of CF, and the method of lubrication, which results in a negative outcome. It also is clearly seen that there is an encouraging outcome on all the variables of the specific wear rate, comprising the composition and geometry of the particles, with the exception being MWCNT’s fiber OD, wherein most of the variables of the testing parameters of the wear test show a negative outcome, with the exception being the hardness of the contact material. Related results were found by Kanagaraj et al. [46] on the wear test parameters, such as the sliding distance, which raises the wear rate and reduces CoF in the increase of MWCNT, with an increase in the tensile strength and Young’s modulus of the composite. Likewise, the addition of graphene helps to improve the hardness, tensile strength, and wear rate, but decreases the CoF, as also observed by Bahrami et al. [54,55]. Similarly, HAP has a constructive consequence on the wear and biological behavior but decreases the strength. This was also found by Guohan Shi et al. and Macuvele et al. [27,73]. Furthermore, there is a constructive influence on the strength and destructive influence on the CoF due to the addition of CF. The same has been observed by other researchers [74,75].

Therefore, it is obvious from the sensitivity analysis that the inclusion of multiple particles introduces a conflict of interest among the distinct tribological properties and the combined tribo-mechanical behavior of the hybrid UHMWPE composites, calling for a multi-objective-based optimization study.

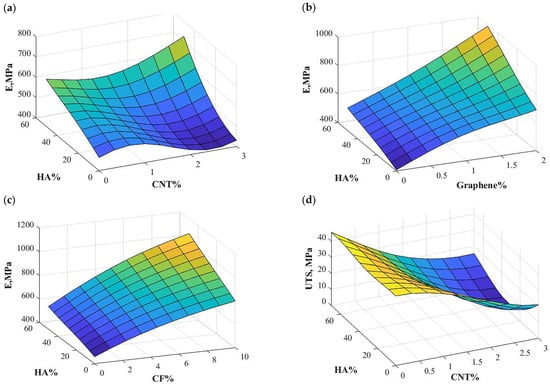

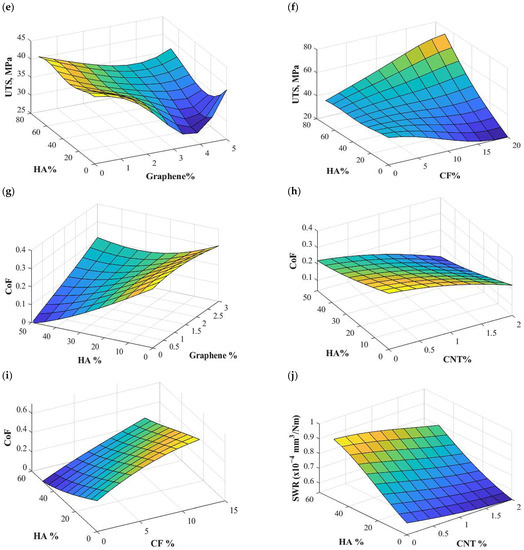

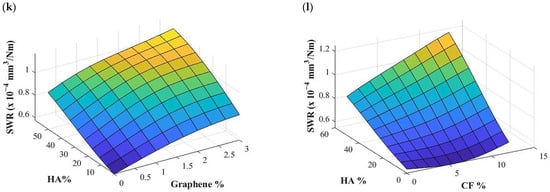

3.3. Surface Plots

Figure 6 depicts the surface plots of the mechanical properties, namely, E and UTS, along with the tribological properties CoF and SWR, by considering the average value of the corresponding input parameters. The plots were generated by plotting each of the above-said output parameters with the combination of weight percentage of HAP with each of the weight percentages of the other three particles (CNT, graphene, and CF). The below surface plots provide similar observations as the sensitivity analysis, showing the correlation between the input and output variables. Figure 6a–c signify the variation in E due to the effect of the four different reinforcement particles. From these figures, it is evident that to have an increase in Young’s modulus, the amount of HAP required is quite high—about 40 to 50% more in weight—compared to the other particles, such as CNT and graphene, which require a maximum of 2% each. E increases gradually with the addition of CF.

Figure 6.

Surface plots showing the variation in (a) E with CNT–HA wt%, (b) E with graphene–HA wt%, (c) E with CF–HA%, (d) UTS with CNT–HA wt%, (e) UTS with graphene–HA wt%, (f) UTS with CF–HA%, (g) CoF with graphene–HA wt%, (h) CoF with CNT–HA wt%, (i) CoF with CF–HA%, (j) SWR with CNT–HA wt%, (k) SWR with graphene–HA wt%, and (l) SWR with CF–HA%.

Likewise, Figure 6d–f signify the variation in UTS due to the influence of the four different particles. Even in these figures, the role of HAP on the strength of the UHMWPE composites is not predominant when compared to the other particles. The strength increases with the increase in CNT, up to 2%, and beyond that it decreases. The effect of graphene on the strength is also up to a weight of 3%, and the increase in strength is not very significant up to 10% of CF; then, it decreases. Figure 6g–I represent the variation in CoF due to the influence of the four different particles. Here, the role of HAP influences the reduction in CoF significantly along with the combination of three other particles. Figure 6j–l signify the variation in SWR due to the influence of the four different particles. From these figures, it is clearly seen that all the four particles play a crucial part in the decline of the wear rate of the composites, with a lesser amount of particles, as HAP varies from 10 to 15%, SWR decreases gradually as CNT increases from 0.5 to 2%, graphene requires 0.5 to 3%, and SWR decreases gradually up to 8% of CF, increasing slightly thereafter. Hence, the sensitivity analysis and surface plots showed a suitable correlation between the input variables and corresponding outputs, paving a way forward for the design of UHMWPE hybrid composites through optimization studies in a multi-objective fashion, since there is a clash among the tribological and mechanical properties individually and in tandem.

3.4. Multi-Objective Optimization of Tribo-Mechanical Properties

Optimization is done with GA in a multi-objective fashion without having any constraints on the composition of the particles. The same GA parameters, as shown in Table 2, utilized in an earlier study by the authors [16] were used for the optimization. The created models of ANN for each of the tribological and mechanical properties were utilized as fitness functions. The different combinations of tribo-mechanical properties viz E_CoF_SWR and H_CoF_SWR were chosen so as to attain the optimal solutions on the composition of all the four particles to design the composites.

Table 3 shows the range of different input parameters for both the tribological and mechanical properties, with variation in the UHMWPE’s molecular weight without considering any constraints on the parameters. From Table 3, it is evident that for the different combinations of tribo-mechanical properties, there is not much significance regarding the CNT requirements of the composites; i.e., a maximum of 2% and 0.1%, respectively, on the above-said combination, by varying the molecular weight of UHMWPE. Likewise, when it comes to graphene, it is required in a much smaller amount in the combination of tribological properties with E than with H. We can thus infer that graphene plays a major role in increasing the hardness than the elastic modulus. Similarly, the effect of CF on the combined tribo-mechanical properties has no or less significance on the composition, except for the molecular weight of 4 million gm/mol. As with the case of HAP, it is required in lesser amounts at lower molecular weights—till 4 million gm/mol—after which it increases significantly for the combination of E_CoF_SWR. There is a requirement for a larger amount of HAP with no substantial change in the combination of H_CoF_SWR on varying the molecular weight. Hence, similar trends in the effect on the composition of the reinforcement materials are observed from the multi-objective optimization in comparison with the sensitivity analysis and surface plots.

Table 3.

Series of input variables of tribo-mechanical properties on varying molecular weight without constraints.

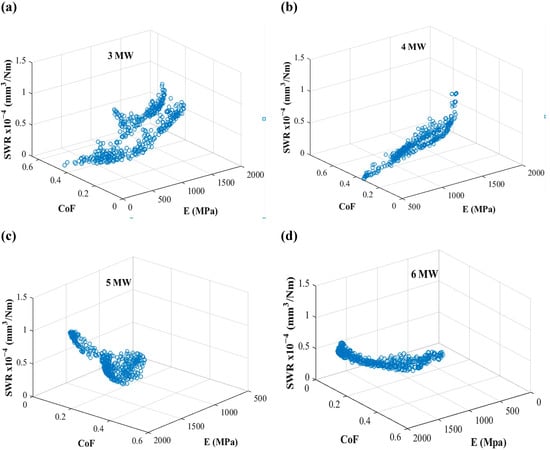

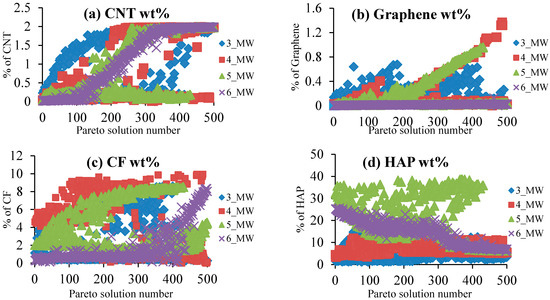

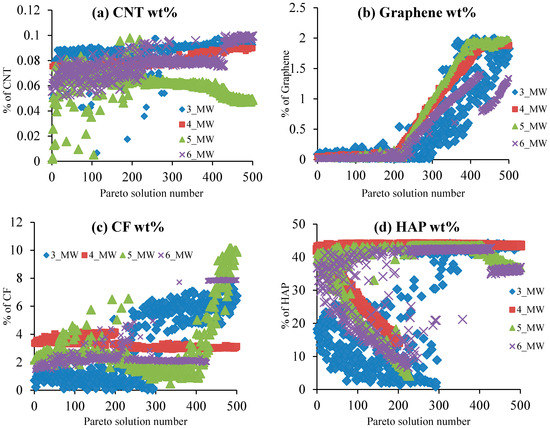

Figure 7 illustrates the 3-dimensional plots of the different Pareto fronts of the combined tribo-mechanical properties CoF, SWR, and E, varying the different molecular weight of the matrix material without having any constraints on the amount of the reinforcement particles to be added. From Figure 7, it is evident that in order to have superior amount of E, the specific wear rate is also improved, which reduces the CoF for all the different values of UHMWPE’s molecular weight. In the actual scenario, the articulating surface must have a lower wear rate and the enhancement of all the required properties is feasible from all these Pareto fronts at their tail region, where the optimal solutions are achievable. The corresponding optimal solutions of the different reinforcement particles without constraints for the grouping of E, COF, and SWR are shown in Figure 8 for the different molecular weights of the matrix material sorted in increasing order of SWR. It is obvious from Figure 8a that the amount of CNT required for enhancement in the value of CoF, SWR, and E is higher at the lower molecular weights and less at the higher molecular weights among the optimal solutions. A similar trend is also observed in the case of CF, which is clearly seen in Figure 8c. The amount of graphene required is predominantly low, as seen in Figure 8b, for all the molecular weights of the matrix, and the role of graphene in the increase in E is insignificant; the same has been described clearly in the Section 3.2 and Section 3.3.

Figure 7.

3D Pareto front of E, CoF, and SWR without constraints on varying the molecular weight of UHMWPE (a) 3, (b) 4, (c) 5, and (d) 6.

Figure 8.

Deviation of the particles in the Pareto solutions for E, CoF, and SWR.

However, it is just the opposite in the case of HAP, where the lower the UHMWPE’s molecular weight, the lesser is the HAP requirement, which is evident from Figure 8d. The consumption of HAP is also huge when compared to the other particles.

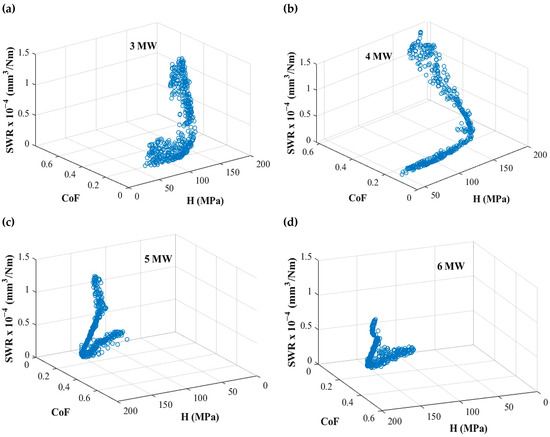

Figure 9 designates the 3-dimensional plots of the different Pareto fronts for the combined tribo-mechanical properties H, CoF, and SWR on varying the molecular weight of UHMWPE without having any constraints on the amount of the reinforcement particles to be added. Related styles on the Pareto fronts are observed as in the combination of H, CoF, and SWR, as it is agreed that considerable enhancement on the tribo-mechanical properties can be seen where the optimal solutions lie at the tail region of the Pareto fronts.

Figure 9.

3D Pareto front of H, CoF, and SWR without constraints on varying the molecular weight of UHMWPE (a) 3, (b) 4, (c) 5, and (d) 6.

The corresponding ideal solutions of the different reinforcement particles without constraints for the grouping of H, CoF, and SWR are shown in Figure 10 for the different molecular weights of the matrix material sorted by an increasing trend in SWR. It is obvious from the Figure 10a that the amount of CNT required for the enhancement of H, CoF, and SWR in tandem is quite low, as the influence of CNT on the increase in the value of H is insignificant. The same has been described elaborately in Section 3.2 and Section 3.3 through the simulation studies, to understand the influence of reinforcement particles on the output properties. As for the graphene requirement for the enhancement of these properties, it follows a similar trend in all the molecular weights, and the difference in the amount of required graphene is considerably significant, which is evident from Figure 10b.

Figure 10.

Deviation in the reinforcements in the Pareto solutions for H, CoF, and SWR.

It is obvious from the Figure 10c that the amount of CF required is considerably reduced when compared to the previous combination of the properties. The amount of CF required is also significantly less in all the molecular weights of the matrix, except in 3 million gm/mol. Similarly, there is a similar trend in the variation in HAP from Figure 10d on varying the molecular weight of UHMWPE. Even in this combination of properties, the required amount of HAP is quite high when compared to most optimal solutions.

4. Conclusions

The following are the conclusions arrived at from this work:

- -

- The correlations of the different input variables with the tribo-mechanical behavior were revealed efficiently by the created ANN models.

- -

- The ANN models can be used as objective functions for the GA-driven multi-objective optimization of the properties, towards their simultaneous improvement.

- -

- A set of non-dominated optimal solutions on the variations in the different micro/nano particles on the different combinations of the mechanical and tribological properties can be generated from the optimization studies.

- -

- The solutions can be explicitly observed to propose plans to design the hybrid UHMPWE composites.

- -

- Further, the multi-objective optimization can be carried out on considering the constraints on the total amount of the reinforcement particles to reduce the amount of required particles.

- -

- This kind of computational design of materials paves the way for experimental trials to understand the tribo-mechanical behavior of hybrid UHMWPE composites.

Author Contributions

Data curation, V.A.; Formal analysis, V.A.; Resources, J.P.D.; Supervision, S.D.; Writing—original draft, S.D.; Writing—review & editing, J.P.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the ongoing research activities by the authors’ group.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| UHMWPE | Ultra-high molecular weight polyethylene |

| ANN | Artificial Neural Network |

| GA | Genetic Algorithm |

| TJR | Total joint replacement |

| SW or MWCNT | Single or multiwalled carbon nanotube |

| GO | Graphene oxide |

| CF | Carbon fiber |

| HAP | Hydroxyapatite |

| CoF | Coefficient of friction |

| SWR | Specific wear rate |

| UTS | Ultimate tensile strength |

| E | Young’s modulus |

| H | Hardness |

| OD | Outer diameter |

| wt% | Weight percentage |

References

- Macuvele, D.L.; Nones, J.; Matsinhe, J.V.; Lima, M.M.; Soares, C.; Fiori, M.A.; Riella, H.G. Advances in ultra high molecular weight polyethylene/hydroxyapatite composites for biomedical applications: A brief review. Mater. Sci. Eng. C 2017, 76, 1248–1262. [Google Scholar] [CrossRef]

- Affatato, S.; Ruggiero, A.; Merola, M. Advanced biomaterials in hip joint arthroplasty. A review on polymer and ceramics composites as alternative bearings. Compos. Part B Eng. 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Ghalme, S.G.; Mankar, A.; Bhalerao, Y. Biomaterials in Hip Joint Replacement. Int. J. Mater. Sci. Eng. 2016, 4, 113–125. [Google Scholar] [CrossRef]

- Gohil, S.V.; Suhail, S.; Rose, J.; Vella, T.; Nair, L.S. Polymers and Composites for Orthopedic Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Cunha, M.; Bevis, M.J.; Sousa, R.A.; Reis, R.L. Processing and properties of bone-analogue biodegradable and bioinert polymeric composites. Compos. Sci. Technol. 2003, 63, 389–402. [Google Scholar]

- Partridge, S.; Tipper, J.L.; Al-Hajjar, M.; Isaac, G.H.; Fisher, J.; Williams, S. Evaluation of a new methodology to simulate damage and wear of polyethylene hip replacements subjected to edge loading in hip simulator testing. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 106, 1456–1462. [Google Scholar] [CrossRef]

- Kelly, J.M. Ultra-high molecular weight polyethylene. J. Macromol. Sci. Polym. Rev. 2002, 42, 355–371. [Google Scholar] [CrossRef]

- Luthra, J.S.; AL-Habsi, S.; AL-Ghanami, S.; Ghosh, S.; AL-Muzahemi, K. Understanding Painful Hip in Young Adults: A Review Article. Hip Pelvis 2019, 31, 129. [Google Scholar] [CrossRef]

- Muratoglu, O.K.; Bragdon, C.R.; O’Connor, D.; Perinchief, R.S.; Estok, I.I.D.M.; Jasty, M.; Harris, W.H. Larger diameter femoral heads used in conjunction with a highly cross-linked ultra-high molecular weight polyethylene: A new concept. J. Arthroplasty 2001, 16 (Suppl. S1), 24–30. [Google Scholar] [CrossRef]

- Senatov, F.S.; Gorshenkov, M.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D.; Sudarchikov, V.A. Fractographic analysis of composites based on ultra high molecular weight polyethylene. Compos. Part B Eng. 2014, 56, 869–875. [Google Scholar] [CrossRef]

- Scholz, M.S.; Blanchfield, J.P.; Bloom, L.D.; Coburn, B.H.; Elkington, M.; Fuller, J.D.; Gilbert, M.E.; Muflahi, S.A.; Pernice, M.F.; Rae, S.I.; et al. The use of composite materials in modern orthopaedic medicine and prosthetic devices: A review. Compos. Sci. Technol. 2011, 71, 1791–1803. [Google Scholar] [CrossRef]

- Wood, W.J.; Maguire, R.G.; Zhong, W.H. Improved wear and mechanical properties of UHMWPE-carbon nanofiber composites through an optimized paraffin-assisted melt-mixing process. Compos. Part B Eng. 2011, 42, 584–591. [Google Scholar] [CrossRef]

- Gupta, A.; Tripathi, G.; Lahiri, D.; Balani, K. Compression Molded Ultra High Molecular Weight Polyethylene-Hydroxyapatite-Aluminum Oxide-Carbon Nanotube Hybrid Composites forHard Tissue Replacement. J. Mater. Sci. Technol. 2013, 29, 514–522. [Google Scholar] [CrossRef]

- Salari, M.; Mohseni Taromsari, S.; Bagheri, R.; Faghihi Sani, M.A. Improved wear, mechanical, and biological behavior of UHMWPE-HAp-zirconia hybrid nanocomposites with a prospective application in total hip joint replacement. J. Mater. Sci. 2019, 54, 4259–4276. [Google Scholar] [CrossRef]

- Chang, B.P.; Akil, H.M.; Affendy, M.G.; Khan, A.; Nasir, R.B.M. Comparative study of wear performance of particulate and fiber-reinforced nano-ZnO/ultra-high molecular weight polyethylene hybrid composites using response surface methodology. Mater. Des. 2014, 63, 805–819. [Google Scholar] [CrossRef]

- Vinoth, A.; Datta, S. Design of the ultrahigh molecular weight polyethylene composites with multiple nanoparticles: An artificial intelligence approach. J. Compos. Mater. 2019, 54, 002199831985992. [Google Scholar] [CrossRef]

- Sreekanth, P.S.R.; Kanagaraj, S. Influence of multi walled carbon nanotubes reinforcement and gamma irradiation on the wear behaviour of UHMWPE. Wear 2015, 334–335, 82–90. [Google Scholar] [CrossRef]

- Fonseca, A.; Kanagaraj, S.; Oliveira, M.S.A.; Simões, J.A.O. Enhanced UHMWPE Reinforced with MWCNT through Mechanical Ball-Milling. Defect Diffus. Forum 2011, 312–315, 1238–1243. [Google Scholar] [CrossRef]

- Zhang, Y.; Nayak, T.R.; Hong, H.; Cai, W. Graphene: A versatile nanoplatform for biomedical applications. Nanoscale 2012, 4, 3833–3842. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Maksimkin, A.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D.; Kuskov, K.V.; Bugakov, V.I. Investigation of structure, mechanical and tribological properties of short carbon fiber reinforced UHMWPE-matrix composites. Compos. Part B Eng. 2015, 76, 79–88. [Google Scholar] [CrossRef]

- Duraccio, D.; Strongone, V.; Malucelli, G.; Auriemma, F.; de Rosa, C.; Mussano, F.D.; Genova, T.; Faga, M.G. The role of alumina-zirconia loading on the mechanical and biological properties of UHMWPE for biomedical applications. Compos. Part B Eng. 2019, 164, 800–808. [Google Scholar] [CrossRef]

- Xiong, D.S.; Lin, J.M.; Fan, D.L. Wear properties of nano-Al2O3/UHMWPE composites irradiated by gamma ray against a CoCrMo alloy. Biomed. Mater. 2006, 1, 175–179. [Google Scholar] [CrossRef]

- Pal, S.; Roy, S.; Bag, S. Hydroxyapatite coating over alumina—Ultra high molecular weight polyethylene composite biomaterials. Trends Biomater. Artif. Organs 2005, 18, 106–109. [Google Scholar]

- Jaggi, H.S.; Kumar, S.; Das, D.; Satapathy, B.K.; Ray, A.R. Morphological correlations to mechanical performance of hydroxyapatite-filled HDPE/UHMWPE composites. J. Appl. Polym. Sci. 2014, 132, 1–10. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Sonjaitham, N.; Tchaikina, M.V.; Sergeev, V.P.; Ivanova, L.R.; Shilko, S.V. Wear-resistant ultrahigh-molecular-weight polyethylene-based nano- and microcomposites for implants. J. Nanotechnol. 2012, 2012, 729756. [Google Scholar] [CrossRef][Green Version]

- Shi, G.; Cao, Z.; Yan, X.; Wang, Q. In-situ fabrication of a UHMWPE nanocomposite reinforced by SiO2 nanospheres and its tribological performance. Mater. Chem. Phys. 2019, 236, 121778. [Google Scholar] [CrossRef]

- Shi, G.; Yan, X.; Wang, Q.; Cao, Z.; Min, L.; Ji, L. Hydroxyapatite/ultra-high molecular weight polyethylene nanocomposites fabricated by in situ hydrothermal synthesis for wear-resistance and friction reduction. J. Appl. Polym. Sci. 2020, 137, 49276. [Google Scholar] [CrossRef]

- Abdelbary, A.Y.S.M. Tribological behavior of fiber-reinforced polymer composites. In Tribology of Polymer Composites: Characterization, Properties, and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 63–94. [Google Scholar]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, S.; Zhang, L.; Zhu, P.; Zhang, G. Design and Characterization of the Surface Porous UHMWPE Composite Reinforced by Graphene Oxide. Polymers 2021, 13, 482. [Google Scholar] [CrossRef]

- Zoo, Y.S.; An, J.W.; Lim, D.P.; Lim, D.S. Effect of carbon nanotube addition on tribological behavior of UHMWPE. Tribol. Lett. 2004, 16, 305–310. [Google Scholar] [CrossRef]

- Golchin, A.; Wikner, A.; Emami, N. An investigation into tribological behaviour of multi-walled carbon nanotube/graphene oxide reinforced UHMWPE in water lubricated contacts. Tribol. Int. 2016, 95, 156–161. [Google Scholar] [CrossRef]

- Datta, S. Materials Design Using Computational Intelligence Techniques; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Thomas, K.A.; Dey, S.; Sultana, N.; Sarkar, K.; Datta, S. Design of Ti composite with bioactive surface for dental implant. Mater. Manuf. Process. 2020, 35, 643–651. [Google Scholar] [CrossRef]

- Chakraborty, S.; Chattopadhyay, P.P.; Ghosh, S.K.; Datta, S. Incorporation of prior knowledge in neural network model for continuous cooling of steel using genetic algorithm. Appl. Soft Comput. J. 2017, 58, 297–306. [Google Scholar] [CrossRef]

- Vinoth, A.; Datta, S. Optimization of Mechanical Characteristics of UHMWPE Composites Using Computational Intelligence. In Structural Integrity Assessment. Lecture Notes in Mechanical Engineering; Prakash, R., Suresh Kumar, R., Nagesha, A., Sasikala, G., Bhaduri, A., Eds.; Springer: Singapore, 2020; pp. 211–220. [Google Scholar] [CrossRef]

- Vinoth, A.; Nirmal, K.N.; Khedar, R.; Datta, S. Optimizing the Tribological Properties of UHMWPE Nanocomposites—An Artificial Intelligence based approach. In Trends in Mechanical and Biomedical Design; Lecture Notes in Mechanical Engineering; Akinlabi, E., Ramkumar, P., Selvaraj, M., Eds.; Springer: Singapore, 2021; pp. 831–843. [Google Scholar] [CrossRef]

- Kramer, O. Genetic Algorithm Essentials; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Ganguly, S.; Patra, A.; Chattopadhyay, P.P.; Datta, S. New training strategies for neural networks with application to quaternary Al-Mg-Sc-Cr alloy design problems. Appl. Soft Comput. J. 2016, 46, 260–266. [Google Scholar] [CrossRef]

- Sultana, N.; Sikdar Dey, S.; Chattopadhyay, P.P.; Datta, S. Informatics based design of prosthetic Ti alloys. Mater. Technol. 2014, 29, B69–B75. [Google Scholar] [CrossRef]

- Sinha, A.; Sikdar Dey, S.; Chattopadhyay, P.P.; Datta, S. Optimization of mechanical property and shape recovery behavior of Ti-(∼49at.%) Ni alloy using artificial neural network and genetic algorithm. Mater. Des. 2013, 46, 227–234. [Google Scholar] [CrossRef]

- Dutta, T.; Dey, S.; Datta, S.; Das, D. Designing dual-phase steels with improved performance using ANN and GA in tandem. Comput. Mater. Sci. 2019, 157, 6–16. [Google Scholar] [CrossRef]

- Bhaumik, S.; Maggirwar, R.; Datta, S.; Pathak, S.D. Analyses of anti-wear and extreme pressure properties of castor oil with zinc oxide nano friction modifiers. Appl. Surf. Sci. 2018, 449, 277–286. [Google Scholar] [CrossRef]

- Roy, S.; Dey, S.; Khutia, N.; Roy Chowdhury, A.; Datta, S. Design of patient specific dental implant using FE analysis and computational intelligence techniques. Appl. Soft Comput. 2018, 65, 272–279. [Google Scholar] [CrossRef]

- Ali ABin Abdul Samad, M.; Merah, N. UHMWPE Hybrid Nanocomposites for Improved Tribological Performance Under Dry and Water-Lubricated Sliding Conditions. Tribol. Lett. 2017, 65, 1–10. [Google Scholar] [CrossRef]

- Kanagaraj, S.; Mathew, M.T.; Fonseca, A.; Oliveira, M.S.A.; Simoes, J.A.O.; Rocha, L.A. Tribological characterisation of carbon nanotubes/ultrahigh molecular weight polyethylene composites: The effect of sliding distance. Int. J. Surf. Sci. Eng. 2010, 4, 305. [Google Scholar] [CrossRef]

- Manoj Kumar, R.; Sharma, S.K.; Manoj Kumar, B.V.; Lahiri, D. Effects of carbon nanotube aspect ratio on strengthening and tribological behavior of ultra high molecular weight polyethylene composite. Compos. Part A Appl. Sci. Manuf. 2015, 76, 62–72. [Google Scholar] [CrossRef]

- An, Y.; Tai, Z.; Qi, Y.; Yan, X.; Liu, B.; Xue, Q.; Pei, J. Friction and wear properties of graphene oxide/ultrahigh-molecular-weight polyethylene composites under the lubrication of deionized water and normal saline solution. J. Appl. Polym. Sci. 2014, 131, 1–11. [Google Scholar] [CrossRef]

- Ren, P.G.; Di, Y.Y.; Zhang, Q.; Li, L.; Pang, H.; Li, Z.M. Composites of ultrahigh-molecular-weight polyethylene with graphene sheets and/or MWCNTs with segregated network structure: Preparation and properties. Macromol. Mater. Eng. 2012, 297, 437–443. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Tercero, J.E.; Agarwal, A. Synthesis and characterization of multiwalled carbon nanotube reinforced ultra high molecular weight polyethylene composite by electrostatic spraying technique. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2493–2499. [Google Scholar] [CrossRef]

- Suñer, S.; Gowland, N.; Craven, R.; Joffe, R.; Emami, N.; Tipper, J.L. Ultrahigh molecular weight polyethylene/graphene oxide nanocomposites: Wear characterization and biological response to wear particles. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 106, 183–190. [Google Scholar] [CrossRef]

- Chih, A.; Ansón-Casaos, A.; Puértolas, J.A. Frictional and mechanical behaviour of graphene/UHMWPE composite coatings. Tribol. Int. 2017, 116, 295–302. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Kharitonov, A.P.; Mostovaya, K.S.; Kaloshkin, S.D.; Gorshenkov, M.V.; Senatov, F.S.; Chukov, D.I.; Tcherdyntsev, V.V. Bulk oriented nanocomposites of ultrahigh molecular weight polyethylene reinforced with fluorinated multiwalled carbon nanotubes with nanofibrillar structure. Compos. Part B Eng. 2016, 94, 292–298. [Google Scholar] [CrossRef]

- Bahrami, H.; Ahmad Ramazani, S.A.; Shafiee, M.; Kheradmand, A. Preparation and investigation of tribological properties of ultra-high molecular weight polyethylene (UHMWPE)/graphene oxide. Polym. Adv. Technol. 2016, 27, 1172–1178. [Google Scholar] [CrossRef]

- Bahrami, H.; Ramazani, A.S.A.; Kheradmand, A.; Shafiee, M.; Baniasadi, H. Investigation of Thermomechanical Properties of UHMWPE/Graphene Oxide Nanocomposites Prepared by in situ Ziegler-Natta Polymerization. Adv. Polym. Technol. 2015, 34, 1–7. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, R.; Liang, L.; Wang, Y. Study on the preparation and characterization of ultra-high molecular weight polyethylene-carbon nanotubes composite fiber. Compos. Sci. Technol. 2005, 65, 793–797. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Kaloshkin, S.D.; Kaloshkina, M.S.; Gorshenkov, M.V.; Tcherdyntsev, V.V.; Ergin, K.S.; Shchetinin, I.V. Ultra-high molecular weight polyethylene reinforced with multi-walled carbon nanotubes: Fabrication method and properties. J. Alloys Compd. 2012, 536 (Suppl. S1), S538–S540. [Google Scholar] [CrossRef]

- Naresh Kumar, N.; Yap, S.L.; Bt Samsudin, F.N.; Khan, M.Z.; Pattela Srinivasa, R.S. Effect of argon plasma treatment on tribological properties of UHMWPE/MWCNT nanocomposites. Polymers 2016, 8, 295. [Google Scholar] [CrossRef] [PubMed]

- Tai, Z.; Chen, Y.; An, Y.; Yan, X.; Xue, Q. Tribological behavior of UHMWPE reinforced with graphene oxide nanosheets. Tribol. Lett. 2012, 46, 55–63. [Google Scholar] [CrossRef]

- Tenison, N.; Baena, J.C.; Yu, J.; Peng, Z.X. Development of Mixing Methods of UHMWPE/Carbon Nanotubes (CNT) Composites for Use in Artificial Joint. Key Eng. Mater. 2017, 739, 81–86. [Google Scholar] [CrossRef]

- Baena, J.C.; Peng, Z. Dispersion state of multi-walled carbon nanotubes in the UHMWPE matrix: Effects on the tribological and mechanical response. Polym. Test. 2018, 71, 125–136. [Google Scholar] [CrossRef]

- Sreekanth, P.S.R.; Reddy, N.R.; Lahkar, M.; Kanagaraj, S. Biocompatibility studies on MWCNTs reinforced ultra high molecular weight polyethylene nanocomposites. Trends Biomater. Artif. Organs 2013, 27, 1–9. [Google Scholar]

- Wang, Y.; Yin, Z.; Li, H.; Gao, G.; Zhang, X. Friction and wear characteristics of ultrahigh molecular weight polyethylene (UHMWPE) composites containing glass fibers and carbon fibers under dry and water-lubricated conditions. Wear 2017, 380–381, 42–51. [Google Scholar] [CrossRef]

- Lee, J.H.; Kathi, J.; Rhee, K.Y.; Lee, J.H. Wear properties of 3-aminopropyltriethoxysilane-functionalized carbon nanotubes reinforced ultra high molecular weight polyethylene nanocomposites. Polym. Eng. Sci. 2010, 50, 1433–1439. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Kaloshkin, S.D.; Tcherdyntsev, V.V.; Senatov, F.S.; Danilov, V.D. Structure and properties of ultra-high molecular weight polyethylene filled with disperse hydroxyapatite. Inorg. Mater. Appl. Res. 2012, 3, 288–295. [Google Scholar] [CrossRef]

- Liu, J.L.; Zhu, Y.Y.; Wang, Q.L.; Ge, S.R. Biotribological behavior of ultra high molecular weight polyethylene composites containing bovine bone hydroxyapatite. J. China Univ. Min. Technol. 2008, 18, 606–612. [Google Scholar] [CrossRef]

- Efe, G.; Altınsoy, İ.; Türk, S.; Bindal, C. An Investigation on UHMWPE-HAp Composites Manufactured by Solution-Gelation Method. Sak. Univ. J. Sci. 2020, 24, 1–9. [Google Scholar] [CrossRef][Green Version]

- Ran, X.; He, J.; Bao, X.-J.; Di, Z. Microstructure and mechanical properties of HA/UHMWPE composites. Trans. Mater. Heat Treat. 2011, 2. [Google Scholar]

- Kurt, H.I.; Oduncuoglu, M. Application of a Neural Network Model for Prediction of Wear Properties of Ultrahigh Molecular Weight Polyethylene Composites. Int. J. Polym. Sci. 2015, 2015, 315710. [Google Scholar] [CrossRef] [PubMed]

- Olden, J.D.; Joy, M.K.; Death, R.G. An accurate comparison of methods for quantifying variable importance in artificial neural networks using simulated data. Ecol. Modell. 2004, 178, 389–397. [Google Scholar] [CrossRef]

- Datta, S.; Chattopadhyay, P.P. Soft computing techniques in advancement of structural metals. Int. Mater. Rev. 2013, 58, 475–504. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Pearson-Education: New Delhi, India, 2002; p. 432. [Google Scholar] [CrossRef]

- Macuvele, D.L.; Colla, G.; Cesca, K.; Ribeiro, L.F.; da Costa, C.E.; Nones, J.; Breitenbach, E.R.; Porto, L.M.; Soares, C.; Fiori, M.A.; et al. UHMWPE/HA biocomposite compatibilized by organophilic montmorillonite: An evaluation of the mechanical-tribological properties and its hemocompatibility and performance in simulated blood fluid. Mater. Sci. Eng. C 2019, 100, 411–423. [Google Scholar] [CrossRef]

- Vadivel, H.S.; Golchin, A.; Emami, N. Tribological behaviour of carbon filled hybrid UHMWPE composites in water. Tribol. Int. 2018, 124, 169–177. [Google Scholar] [CrossRef]

- Lin, L.; Schlarb, A.K. The roles of rigid particles on the friction and wear behavior of short carbon fiber reinforced PBT hybrid materials in the absence of solid lubricants. Tribol. Int. 2018, 119, 404–410. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).