Research on Evolution Characteristics of Shale Crack Based on Simultaneous Monitoring of Multi-Parameters

Abstract

:1. Introduction

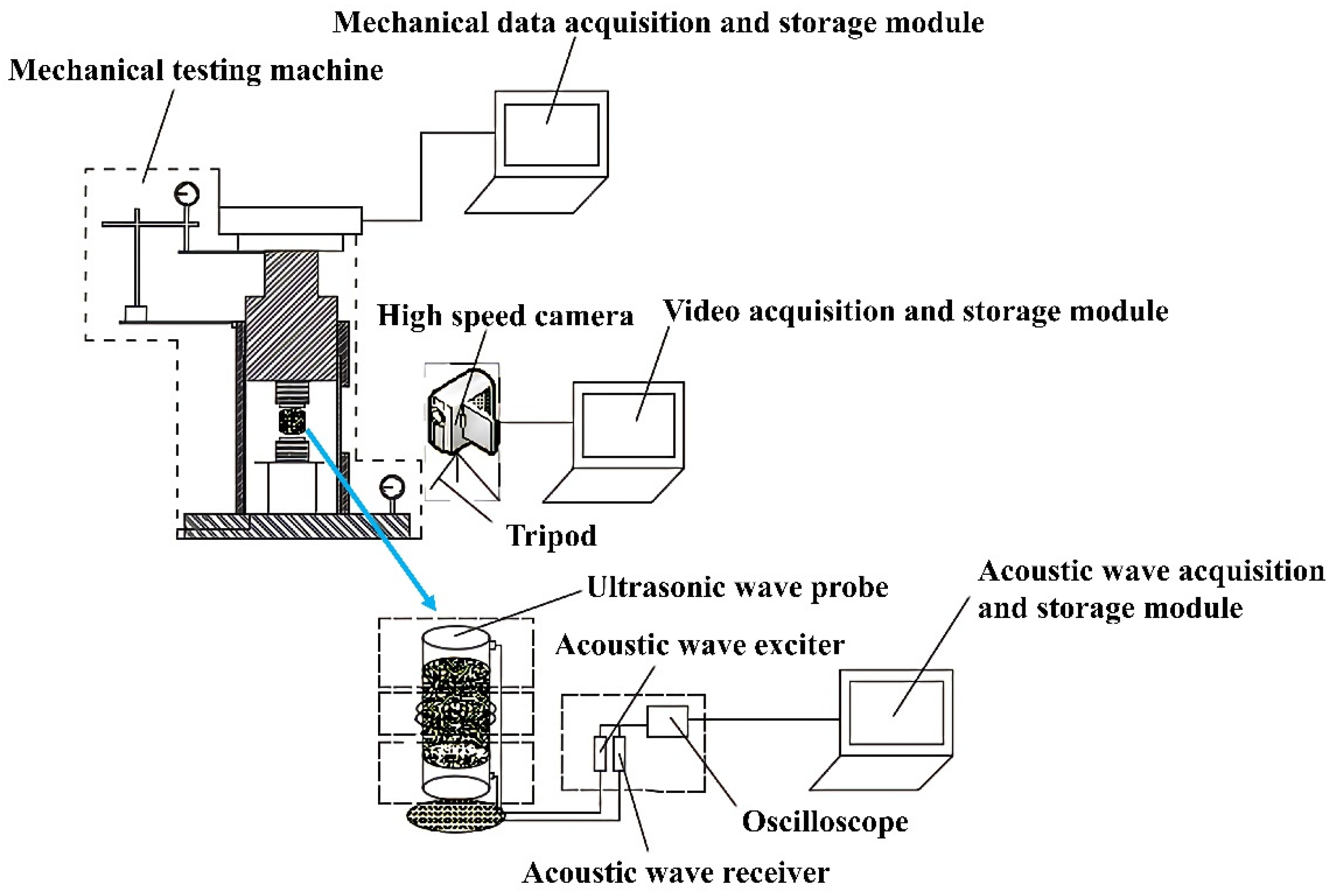

2. Experimental Set-Up

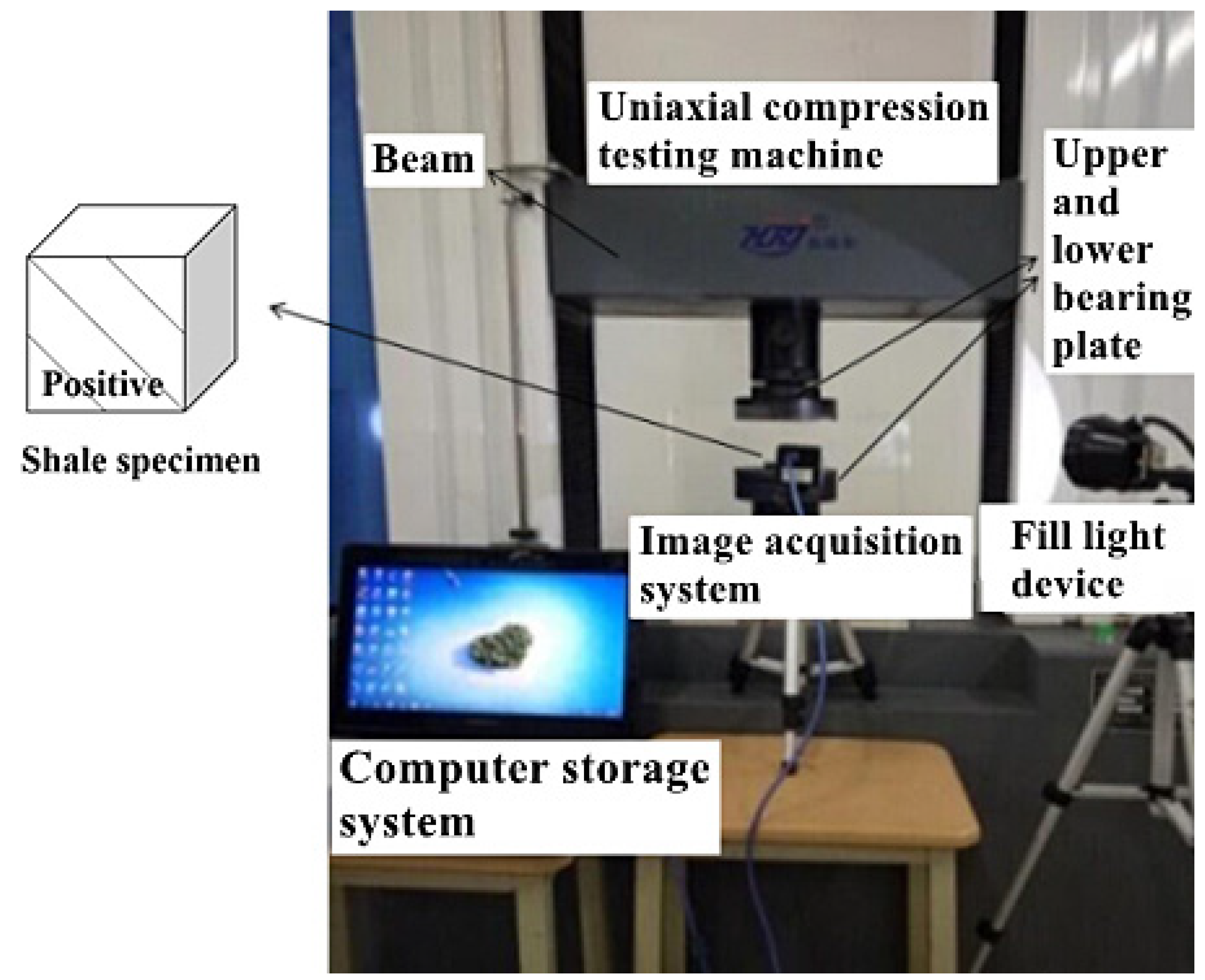

2.1. Loading Experimental Apparatus

2.2. Monitoring System of Mesoscopic Fracture

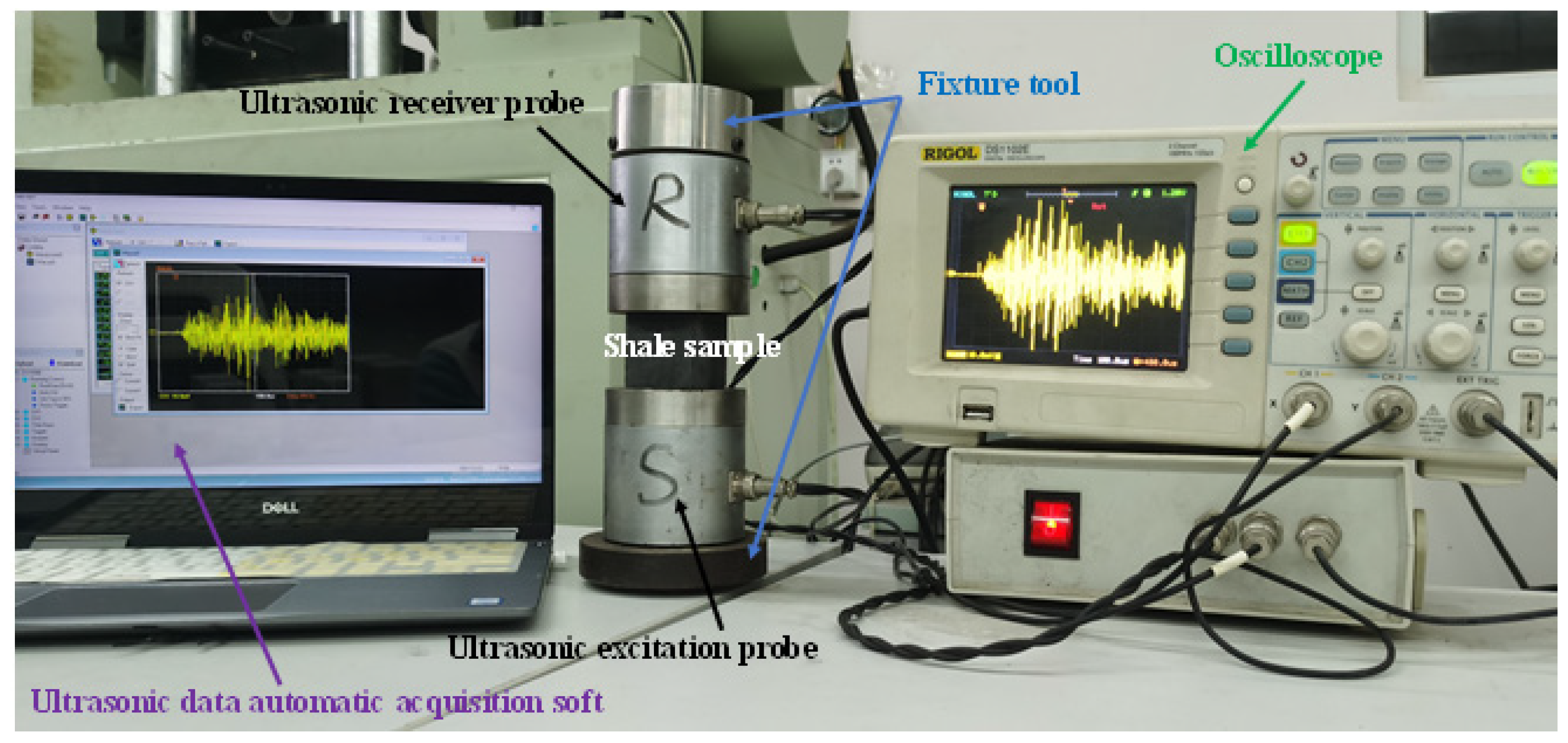

2.3. Ultrasonic Data Acquisition System

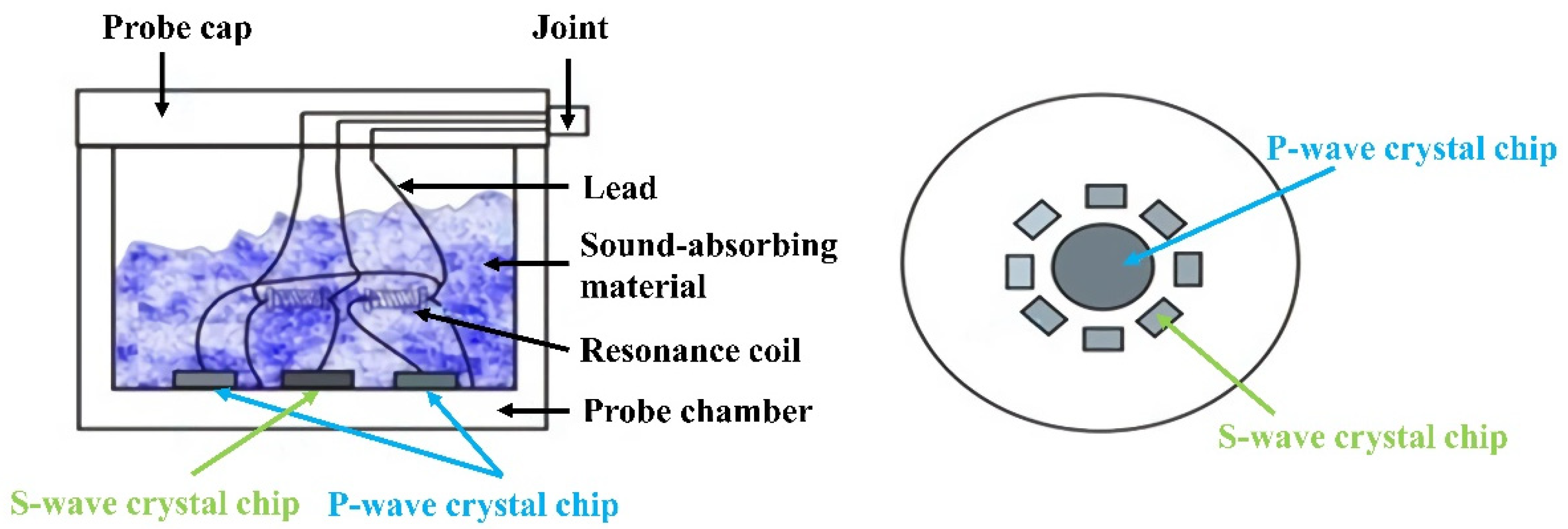

2.3.1. Ultrasonic Wave Probe

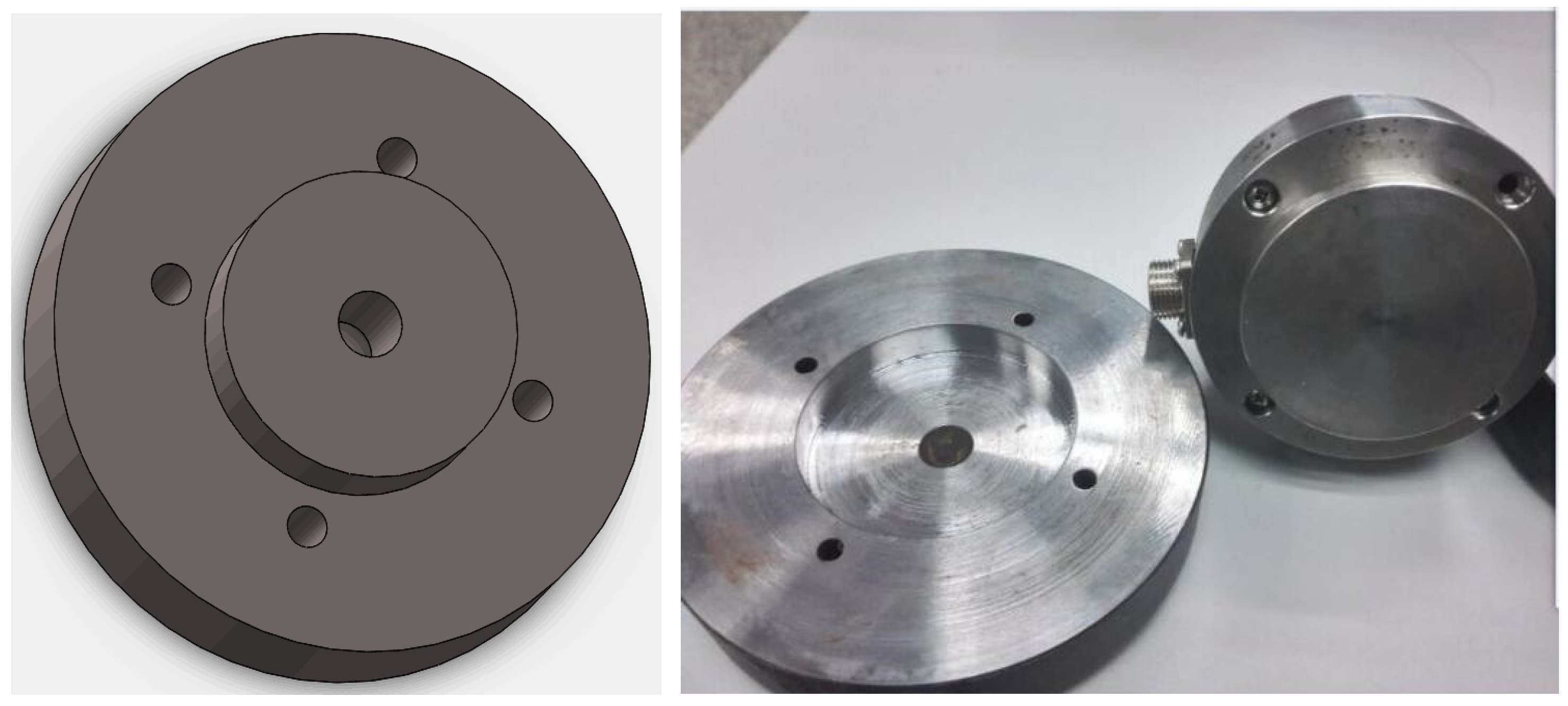

2.3.2. Fixture Tool

2.3.3. Automatic Acquisition Software

3. Experimental Method and Principle

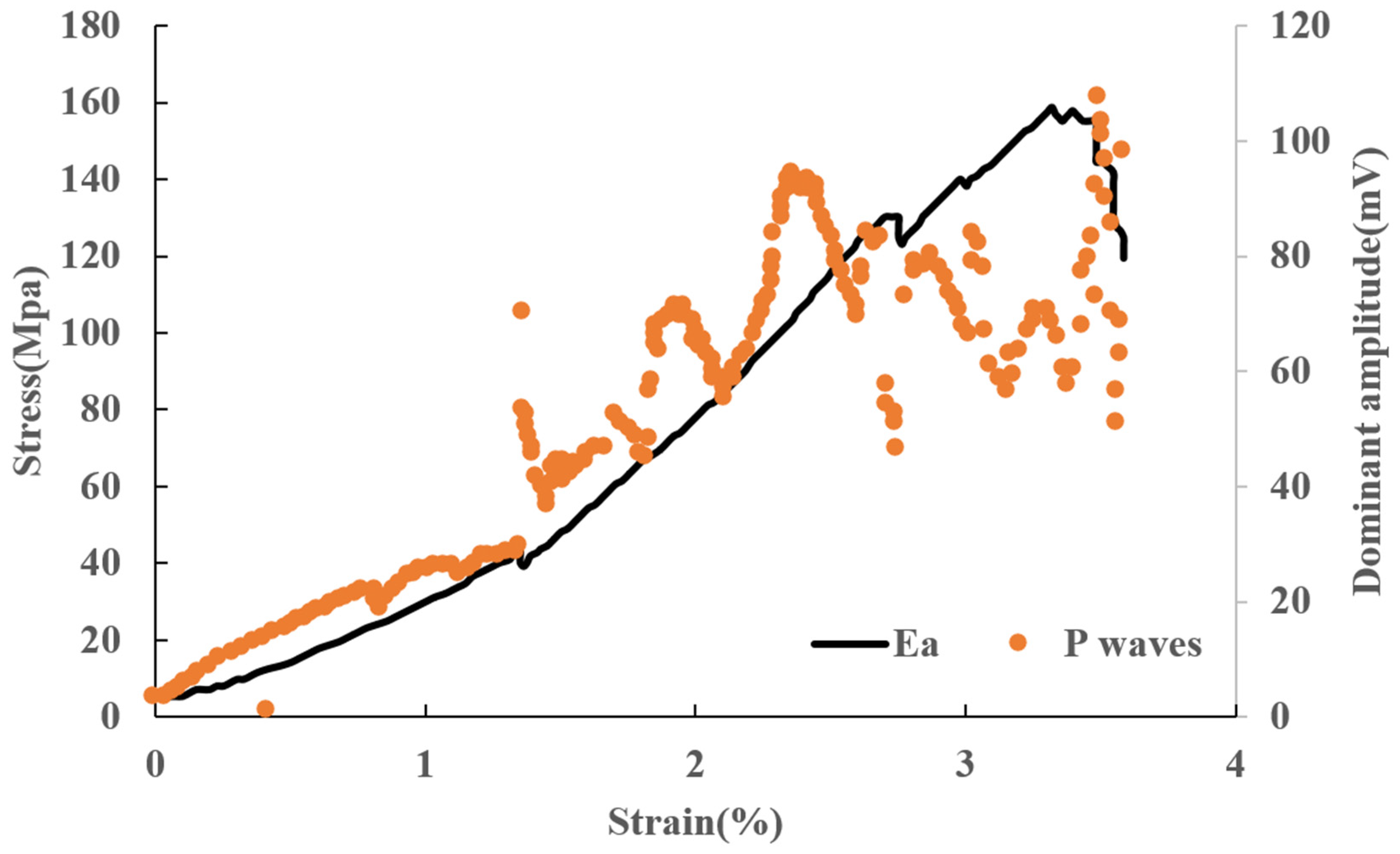

3.1. Processing of Acoustic Wave Signals

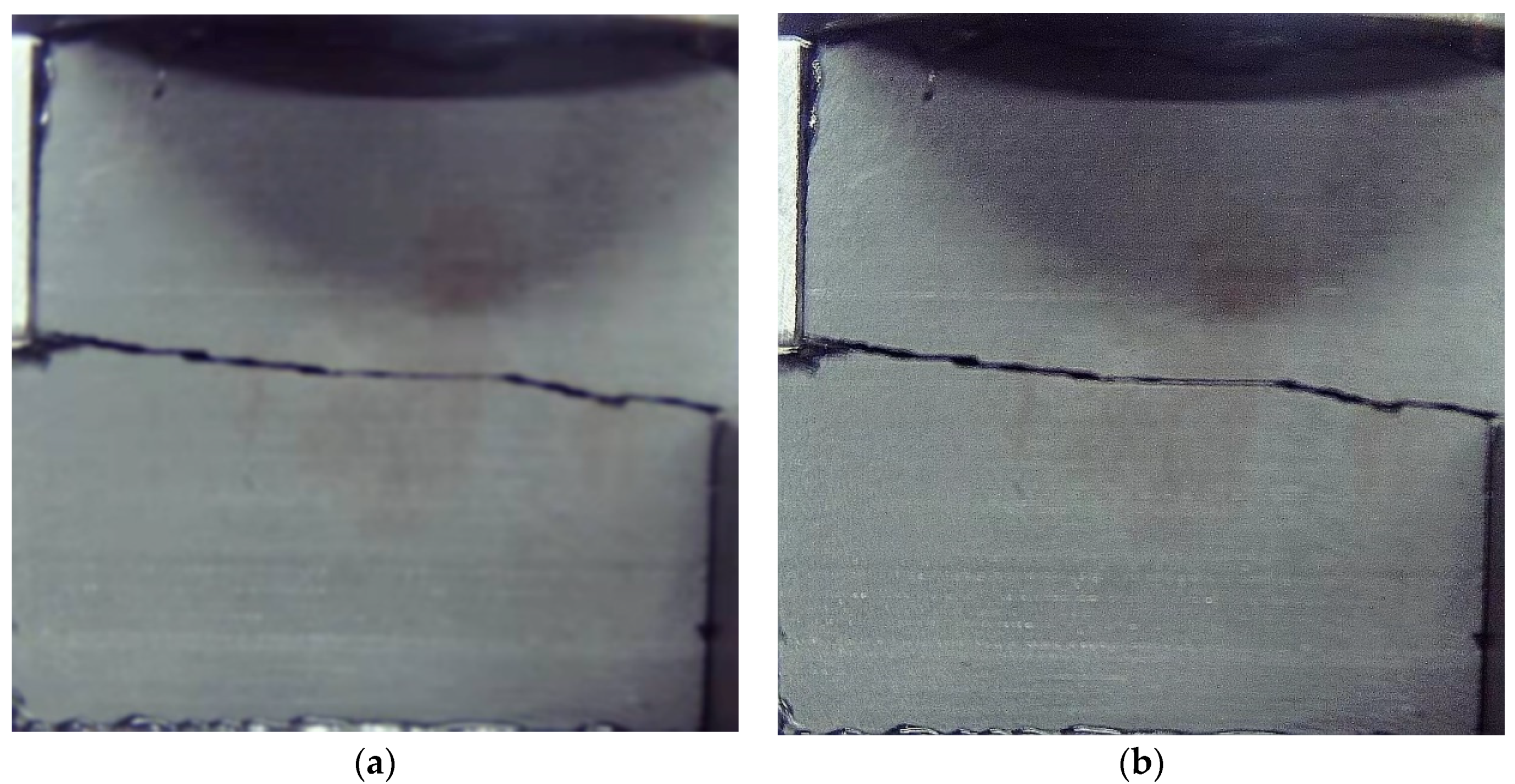

3.2. Processing of Video Signals

3.2.1. Image Pre-Processing

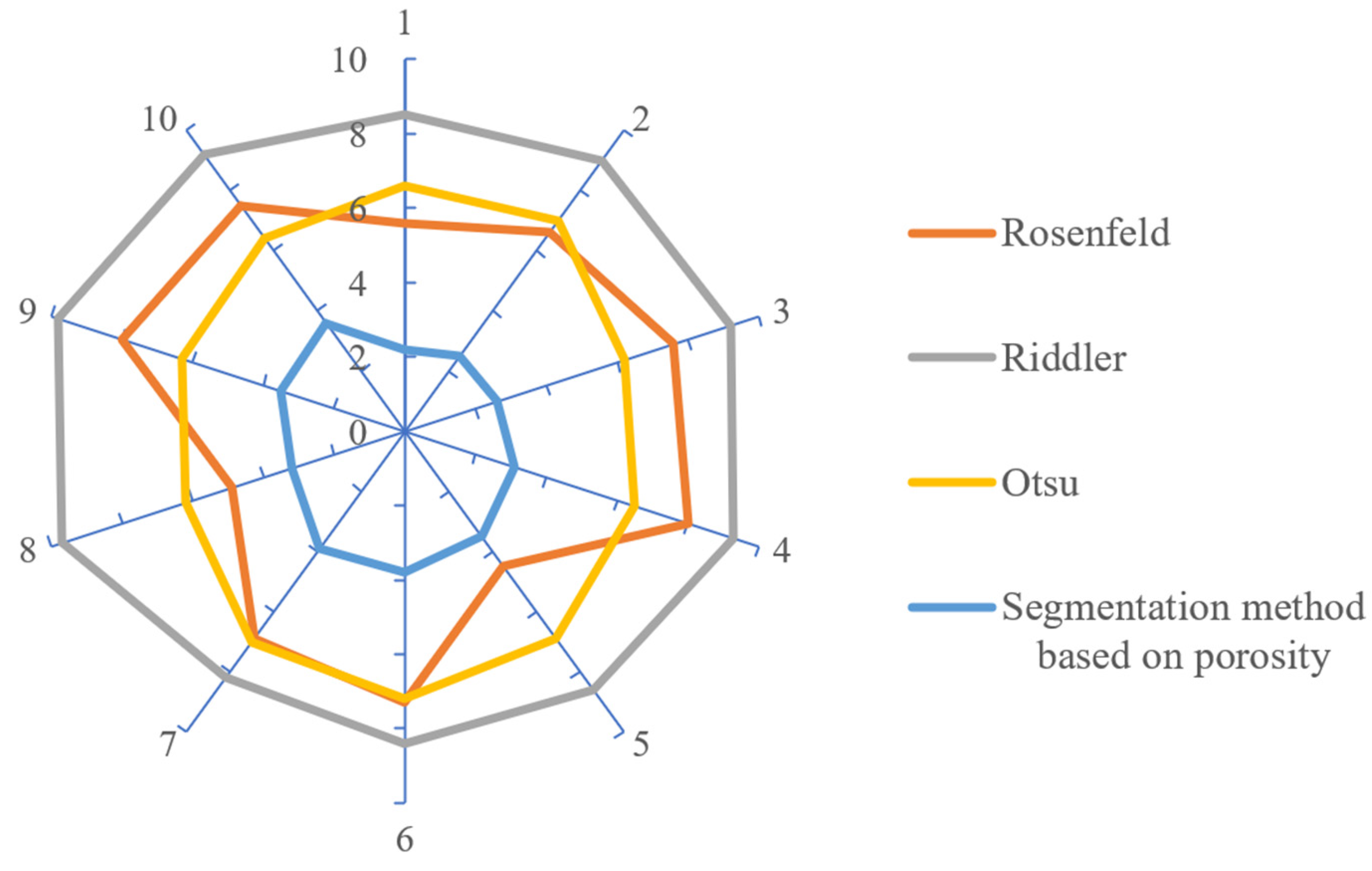

3.2.2. Image Segmentation

4. Test Results and Analysis

5. Conclusions and Recommendations

- (1)

- A device testing micro-crack evolution characteristics of shale has been designed to realize simultaneous monitoring of ultrasonic, mechanical and video information in crack evolution processes of shale under load so as to analyze acoustic and mechanical characteristic responses at key points of crack propagation.

- (2)

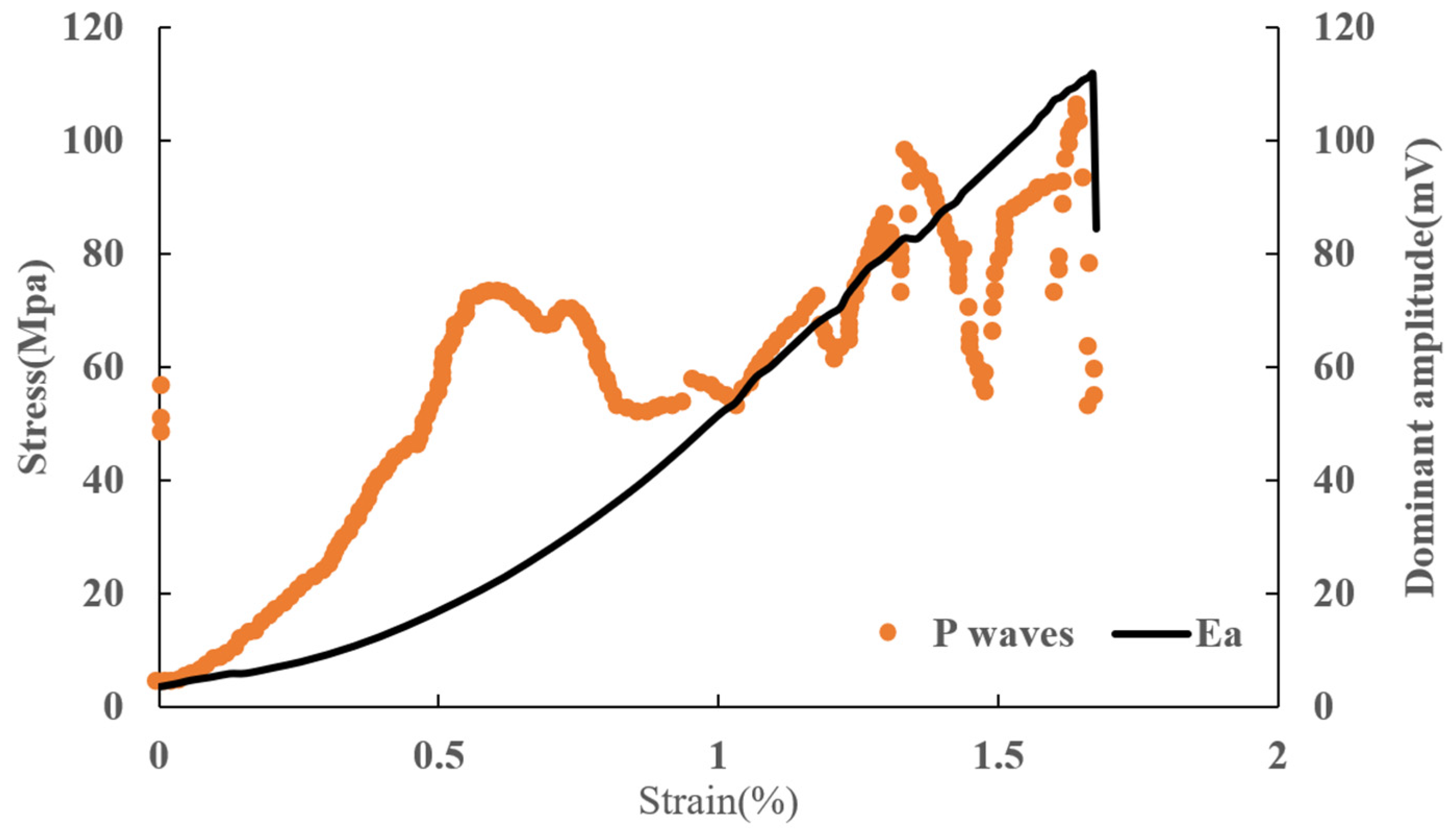

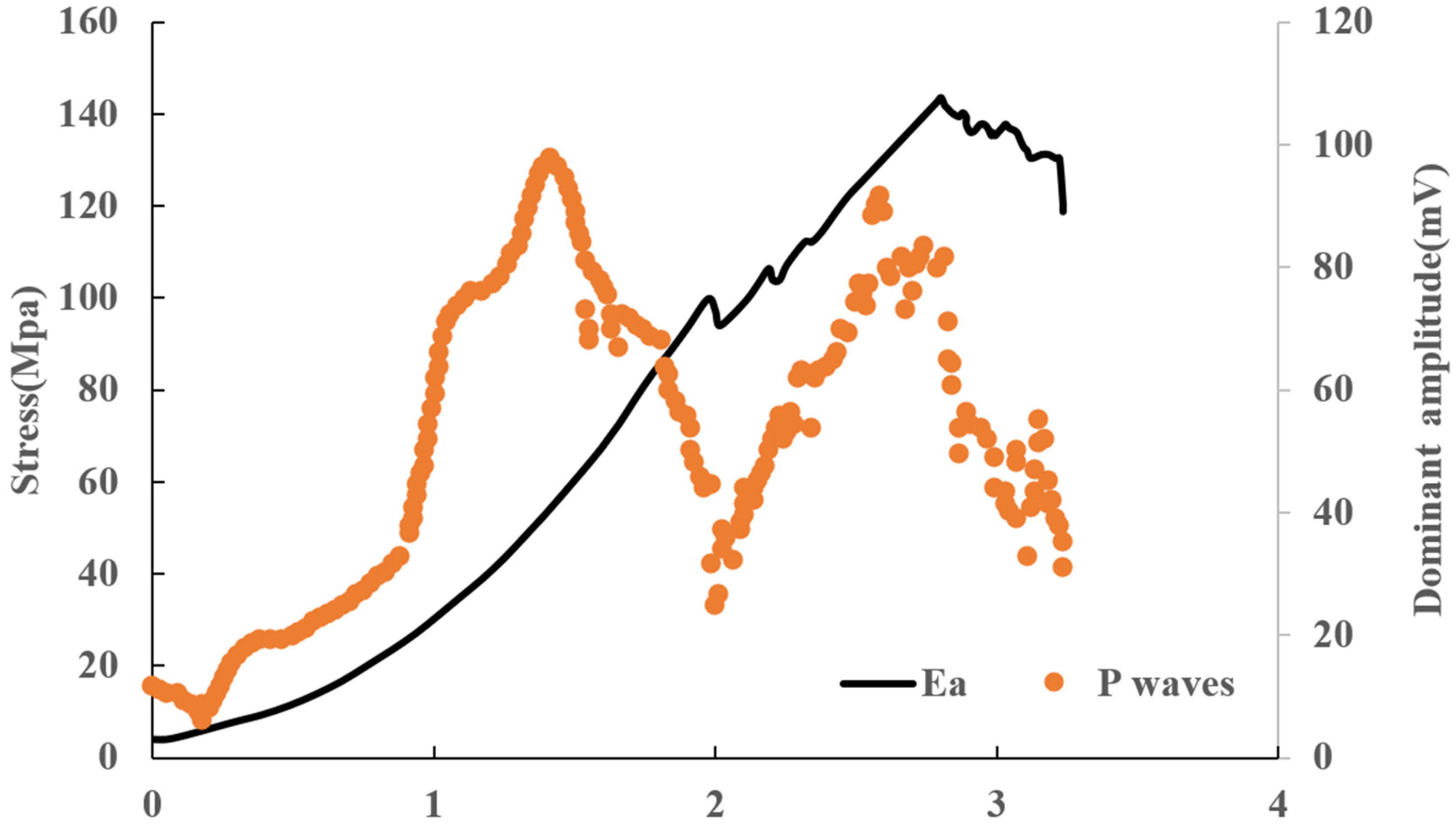

- With increases in load, shale undergoes four stages of destruction, crack initiation, propagation, penetration and overall failure. The dominant amplitude curve of acoustic wave matches well with the stress–strain curve in fluctuating points, which indicates that during the process of shale shear failure, acoustic characteristics and mechanical characteristics are in good agreement, proving the validity of predicting rock mechanical parameters with acoustic data.

- (3)

- Combined with the video monitoring, it was found that at several points when shale crack occurred, the mechanical curve did not change, while acoustic characteristics had big changes. This indicates that during the load process of shale, the dominant amplitude of acoustic waves is more sensitive to rock cracking than mechanical parameters.

- (4)

- Due to the lighting, the video only monitored one surface of the shale sample. For further studies, test equipment needs to be modified. Adding CT scanning technology is recommended, which will help improve the completeness of the description of crack state changes during loading process of the rock sample.

- (5)

- This research can provide theoretical foundations for the evaluation of deformation mechanism and stability of host rocks in underground engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, J.; Cheng, L.C.; Tan, H.Y.; Wang, L.; Wu, H. Effects of Original Cracks on Macro-Meso Evolution Law of Coal Shear Failure. Chin. J. Rock Mech. Eng. 2013, 32, 33–40. [Google Scholar]

- Ge, X.R. Deformation Control Law of Rock Fatigue Failure, Real-Time X-Ray CT Scan Of Geotechnical Testing, And New Method Of Stability Analysis of Slopes And Dam Foundations. Chin. J. Rock Mech. Eng. 2008, 30, 1–20. [Google Scholar]

- Liu, D.M.; Cai, M.F.; Zhou, Y.B.; Chen, Z.Y. Dynamic Monitoring on Developing Process of Rock Cracks. Chin. J. Rock Mech. Eng. 2006, 25, 467–472. [Google Scholar]

- Zhao, C.; Tian, J.S.; Matsuda, H.; Zhao, C.F.; Bao, C. Crack Propagation and Damage of Rock Under Uniaxial Compression Based on Global Strain Field Analysis. Chin. J. Rock Mech. Eng. 2015, 34, 763–769. [Google Scholar]

- Zhang, M.Y.; Yuan, J.X.; Li, T.J.; Shang, J.L.; Kong, C.J. Mechanism of Deformation and Failure for Rock in Uniaxial Compression Test. Chin. J. Rock Mech. Eng. 1998, 17, 1–8. [Google Scholar]

- Zhu, Z.D.; Qu, W.P.; Jiang, Z.J. Quantitative Test Study on Mesostructure of Rock. Chin. J. Rock Mech. Eng. 2007, 26, 1313–1324. [Google Scholar]

- Sun, X.Z.; Shen, B.; Li, Y.Y.; Zhang, B.L.; Jiang, N. Laboratory Study of Three-Dimensional Crack Propagation in Rock-Like Material Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Wan, W.; Zhao, Y.L. Experimental study on crack propagation and the coalescence of rock-like materials with two preexisting fissures under biaxial compression. Bull. Eng. Geol. Environ. 2020, 79, 3121–3144. [Google Scholar] [CrossRef]

- Wang, D.J.; Tang, H.M.; Elsworth, D.; Wang, C. Fracture evolution in artificial bedded rocks containing a structural flaw under uniaxial compression. Eng. Geol. 2019, 250, 130–141. [Google Scholar] [CrossRef]

- Wang, Y.; Que, Y.M.; Wang, C.; Li, C.H. Three-dimensional observations of meso-structural changes in bimsoil using X-ray computed tomography (CT) under triaxial compression. Constr. Build. Mater. 2018, 190, 773–786. [Google Scholar] [CrossRef]

- He, Q.Y.; Li, Y.C.; Li, D.Q.; Zhang, C.G. Microcrack fracturing of coal specimens under quasi-static combined compression-shear loading. J. Rock Mech. Geotech. Eng. 2020, 12, 1014–1026. [Google Scholar] [CrossRef]

- Zhao, M.J.; Wu, D.L. Ultrasonic Velocity and Attenuation of Rock under Uniaxial Loading. Chin. J. Rock Mech. Eng. 1999, 18, 51–55. [Google Scholar]

- Pan, L.H.; Cheng, L.J.; Zhang, Y.; Lu, Z.H.; He, P.; Huang, S. Determination of shale brittleness index based on rock stress-strain curve and ultrasonic p-wave velocity (In Chinese). Patent CN104865124B, 27 October 2017. [Google Scholar]

- Zhai, X.J.; Fu, R.H. Study on the relationship between rock dilatancy and ultrasonic shear wave rate. J. Southwest Univ. Sci. Technol. 2007, 22, 39–42. [Google Scholar]

- Liu, X.J.; Liu, H.; Xu, X.L.; Han, L.; Liang, L.X. Experimental Reasearch on Acoustic Wave Propagation Characteristic of Low Porosity and Permeability Sandstone Under Loading Conditions. Chin. J. Rock Mech. Eng. 2009, 28, 560–567. [Google Scholar]

- Zhu, H.L.; Chen, Q.; Xu, X.H.; Liu, H.; Wen, X.Y.; Chen, J.L. Acoustic properties of dolomite under compression and its application to fracture research. Theor. Appl. Mech. 2019, 51, 949–960. [Google Scholar]

- Xie, H.P.; Liu, J.F.; Ju, Y.; Li, J.; Xie, L.Z. Fractal property of spatial distribution of acoustic emissions during the failure process of bedded rock salt. Int. J. Rock Mech. Min. Sci. 2011, 48, 1344–1351. [Google Scholar] [CrossRef]

- Simpson, N.D.J.; Stroisz, A.; Bauer, A. Failure mechanics of anisotropic shale during Brazilian tests. In Proceedings of the 48th U.S. Rock Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 18 August 2014; p. 13. [Google Scholar]

- Ishida, T.; Kanagawa, T.; Kanaori, Y. Source distribution of acoustic emissions during an in-situ direct shear test: Implications for an analog model of seismogenic faulting in an inhomogeneous rock mass. Eng. Geol. 2010, 110, 66–76. [Google Scholar] [CrossRef] [Green Version]

- Xiao, F.; Liu, G.; Zhang, Z.; Shen, Z.; Zhang, F.; Wang, Y. Acoustic emission characteristics and stress release rate of coal samples in different dynamic destruction time. Int. J. Min. Sci. Technol. 2016, 26, 981–988. [Google Scholar] [CrossRef]

- Moradian, Z.A.; Ballivy, G.; Rivard, P.; Gravel, C.; Rousseau, B. Evaluating damage during shear tests of rock joints using acoustic emissions. Int. J. Rock Mech. Min. Sci. 2010, 47, 590–598. [Google Scholar] [CrossRef]

- Bunger, A.P.; Kear, J.; Dyskin, A.V. Sustained acoustic emissions following tensile crack propagation in a crystal-line rock. Int. J. Fract. 2015, 193, 87–98. [Google Scholar] [CrossRef]

- He, Q.Y.; Zhu, L.; Li, Y.C.; Li, D.Q.; Zhang, B.Y. Simulating Hydraulic Fracture Re-orientation in Heterogeneous Rocks with an Improved Discrete Element Method. Rock Mech. Rock Eng. 2021, 54, 2859–2879. [Google Scholar] [CrossRef]

- Li, D.Q.; Li, Y.C.; Zhu, W.C. Analytical Modelling of Load-Displacement Performance of Cable Bolts Incorporating Cracking Propagation. Rock Mech. Rock Eng. 2020, 53, 3471–3483. [Google Scholar] [CrossRef]

- US Energy Information Agency and Advanced Research Institute. E.I. Technically Recoverable Shale Oil and Shale Gas Resources: An Assessment of 137 Shale Formations in 41 Countries Outside the United States; US Energy Information Agency and Advanced Research Institute: Washington, DC, USA, 2013.

- Foster Natural Gas Report Group. Energy Information Administration’s Annual Energy Outlook 2015 Shows the U.S. Will Continue to Reduce Reliance on Foreign Fuels Imports. Foster Nat. Gas Rep. 2015, 1–154. [Google Scholar]

- Dong, D.Z.; Zou, C.N.; Li, J.Z.; Wang, S.J.; Li, X.J.; Wang, Y.M.; Huang, J.L. Shale gas resource potential and prospect of exploration and development. Geol. Bull. China 2011, 31, 324–336. [Google Scholar]

- Xiao, G.; Bai, Y.H.; Cai, C.Y. Key Technologies Progress of Shale Oil and Gas Development; Wuhan University Press: Wuhan, China, 2015. [Google Scholar]

- Zoback, M.D.; Barton, C.A.; Brudy, M.; Castillo, D.A.; Finkbeiner, T.; Grollimund, B.R. Determination of stress orientation and magnitude in deep wells. Int. J. Rock Mech. Min. Sci. 2003, 40, 1049–1076. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, M. Real time prediction of borehole instability based on actual drilling data. Acta Pet. Sin. 2011, 32, 324–328. [Google Scholar]

- Lee, H.; Ong, S.H.; Azeemuddin, M.; Goodman, H. A wellbore stability model for formations with anisotropic rock strengths. J. Pet. Sci. Eng. 2012, 96, 109–119. [Google Scholar] [CrossRef]

| Num | Density (g/cm−3) | Modulus of Elasticity (104 Mpa) | Poisson’s Ratio | Compressive Strength (MPa) |

|---|---|---|---|---|

| Z0-6 | 2.15 | 1.30 | 0.18 | 156.83 |

| Z45-6 | 2.13 | 1.78 | 0.13 | 111.85 |

| Z90-3 | 2.18 | 1.19 | 0.24 | 144.49 |

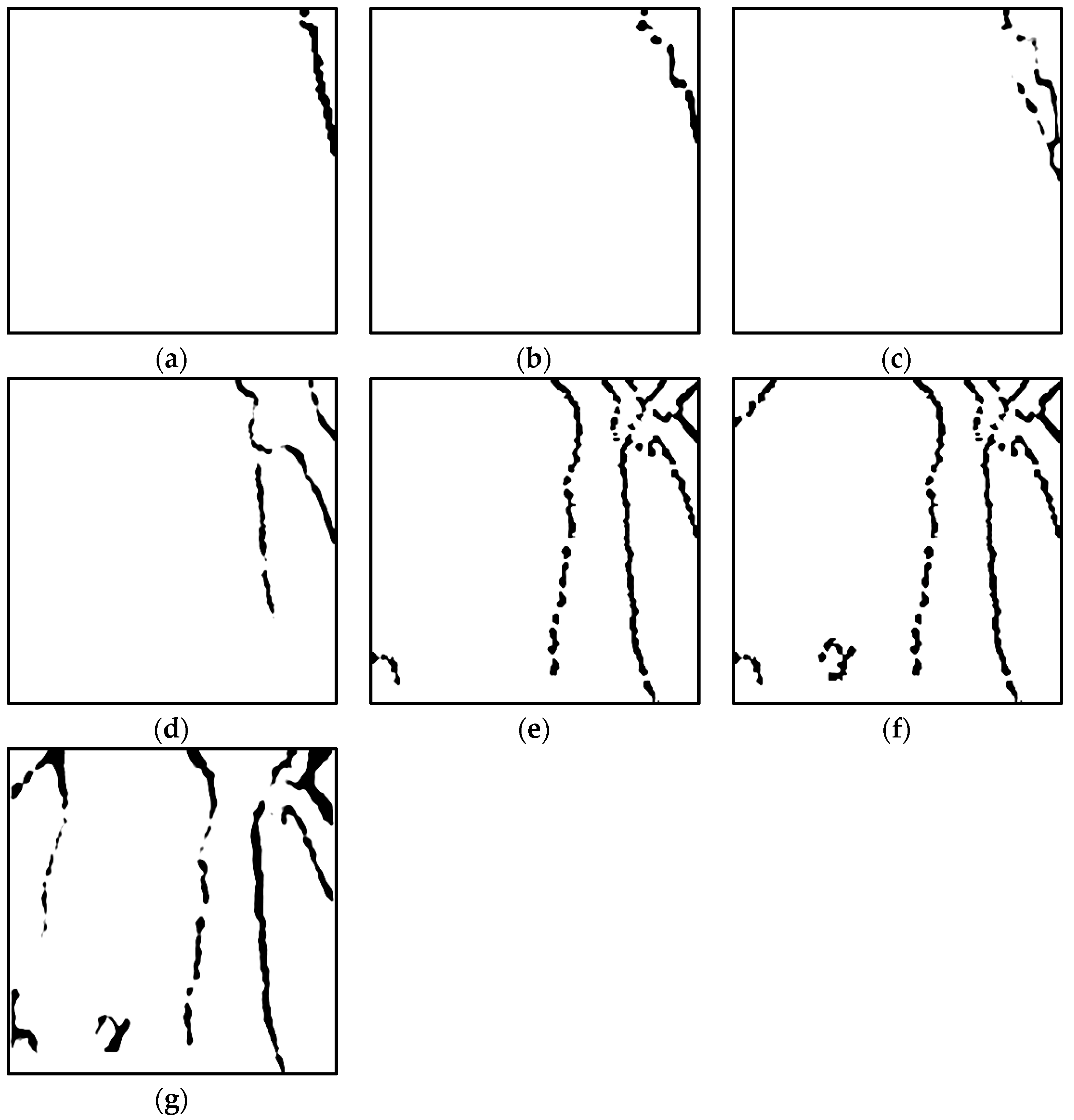

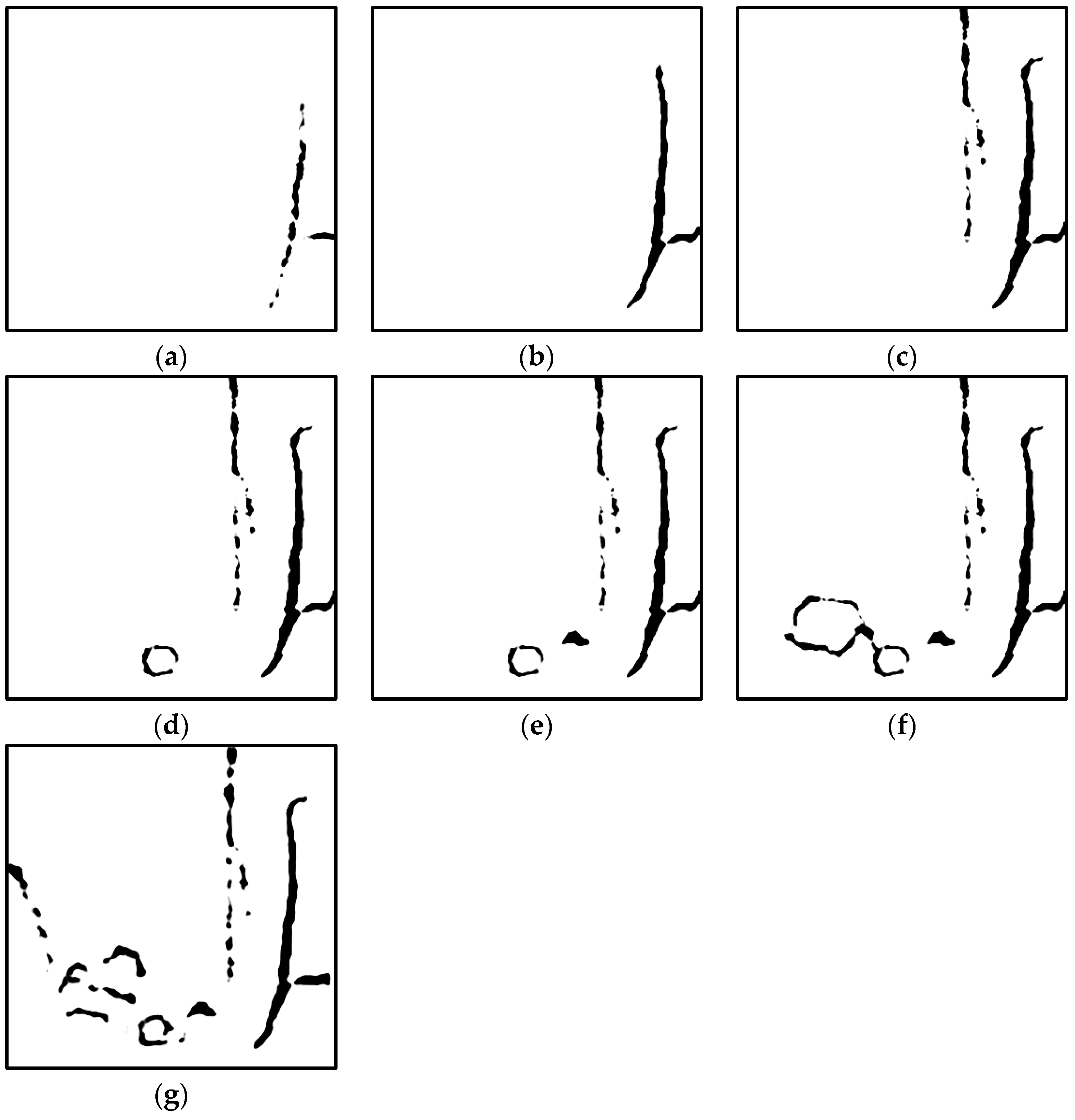

| Crack No. | Time (S) | Strain Corresponding to the Crack Image (%) | Stress Corresponding to the Crack Image (MPa) |

|---|---|---|---|

| a | 634.64 | 2.04 | 80.11 |

| b | 652.32 | 2.10 | 83.46 |

| c | 705.64 | 2.27 | 97.24 |

| d | 861.60 | 2.79 | 125.65 |

| e | 1072.56 | 3.49 | 143.71 |

| f | 1075.64 | 3.50 | 143.37 |

| g | 1091.64 | 3.56 | 127.89 |

| Crack No. | Time (S) | Strain Corresponding to the Crack Image (%) | Stress Corresponding to the Crack Image (MPa) |

|---|---|---|---|

| a | 1007.32 | 1.64 | 111.79 |

| b | 1007.64 | 1.64 | 110.74 |

| c | 1011.00 | 1.65 | 111.23 |

| d | 1021.64 | 1.66 | 111.79 |

| e | 1022.00 | 1.66 | 111.25 |

| f | 1022.32 | 1.67 | 106.20 |

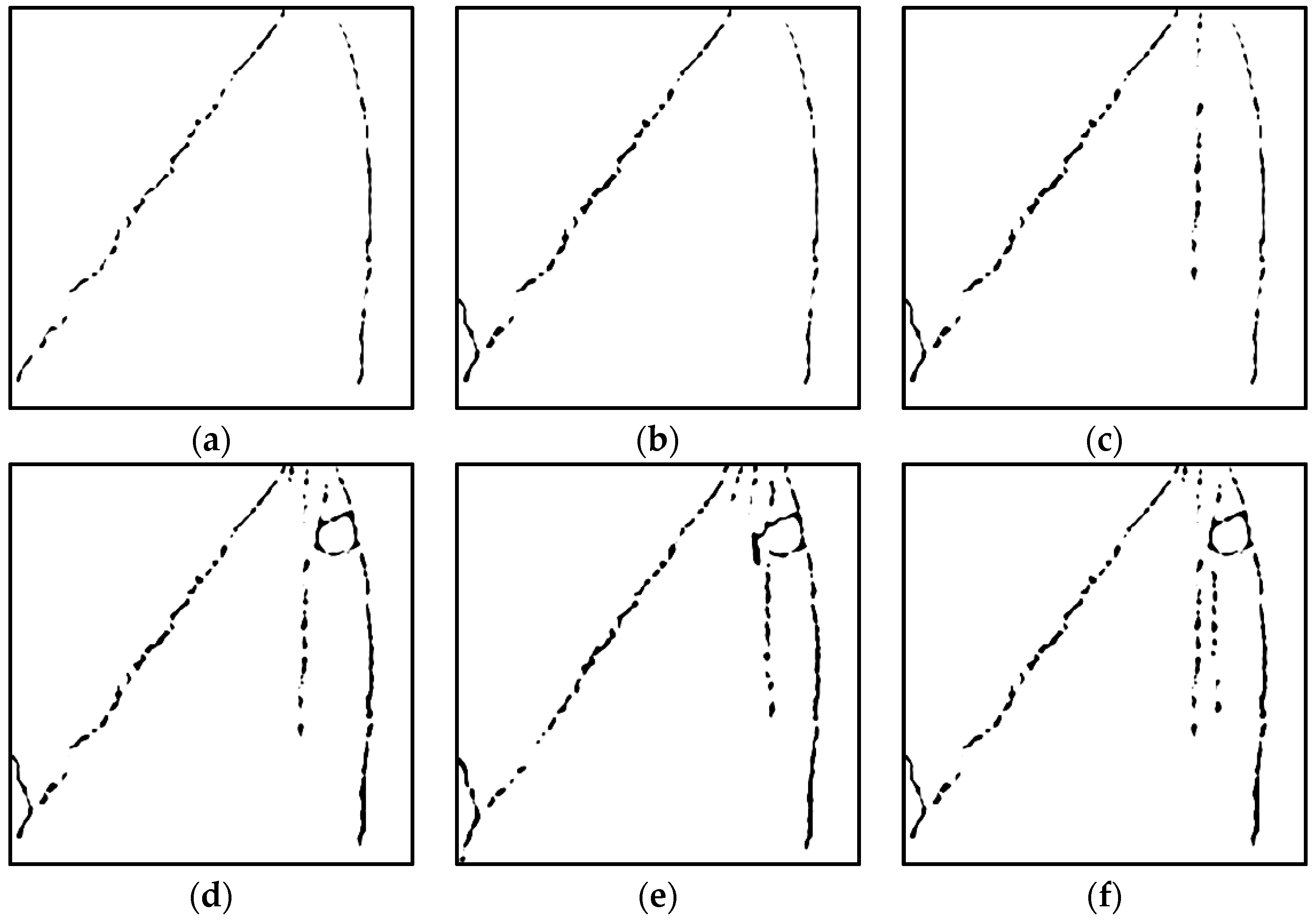

| Crack No. | Time (S) | Strain Corresponding to the Static Crack Image (%) | Stress Corresponding to the Static Crack Image (MPa) |

|---|---|---|---|

| a | 628.32 | 2.02 | 95.01 |

| b | 682.24 | 2.19 | 105.92 |

| c | 796.96 | 2.27 | 97.24 |

| d | 812.60 | 2.65 | 134.73 |

| e | 820.60 | 2.79 | 143.71 |

| f | 864.96 | 2.80 | 144.38 |

| g | 865.32 | 2.81 | 144.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Xu, F.; Su, P.; Zhu, H.; Zhang, Y.; Liu, Y.; Jia, D.; Guo, X.; Chen, J.; Liu, D. Research on Evolution Characteristics of Shale Crack Based on Simultaneous Monitoring of Multi-Parameters. Appl. Sci. 2022, 12, 860. https://doi.org/10.3390/app12020860

Chen Q, Xu F, Su P, Zhu H, Zhang Y, Liu Y, Jia D, Guo X, Chen J, Liu D. Research on Evolution Characteristics of Shale Crack Based on Simultaneous Monitoring of Multi-Parameters. Applied Sciences. 2022; 12(2):860. https://doi.org/10.3390/app12020860

Chicago/Turabian StyleChen, Qiao, Fenglin Xu, Pengcheng Su, Honglin Zhu, Yifang Zhang, Yang Liu, Dongming Jia, Xiaozai Guo, Jilong Chen, and Dunlong Liu. 2022. "Research on Evolution Characteristics of Shale Crack Based on Simultaneous Monitoring of Multi-Parameters" Applied Sciences 12, no. 2: 860. https://doi.org/10.3390/app12020860

APA StyleChen, Q., Xu, F., Su, P., Zhu, H., Zhang, Y., Liu, Y., Jia, D., Guo, X., Chen, J., & Liu, D. (2022). Research on Evolution Characteristics of Shale Crack Based on Simultaneous Monitoring of Multi-Parameters. Applied Sciences, 12(2), 860. https://doi.org/10.3390/app12020860