Abstract

This article presents the results of research on the influence of moisture on changes in the physical properties, i.e., the length, width, thickness, and weight, of dressed and untreated cereal seeds in order to improve the simulation process based on the discrete element method (DEM). The research was conducted on the seeds of three winter cereals, i.e., triticale, rye, and barley. The seeds with an initial moisture content of about 7% were moistened to five levels, ranging from 9.5% to 17.5%, at an increment of 2%. The statistical analysis showed that moisture significantly influenced the physical properties of the seeds, i.e., their length, width, thickness, and weight. As the moisture content of the seeds increased, there were greater differences in their weight. The average increase in the thousand kernel weight resulting from the increase in their moisture content ranged from 4 to 6 mg. The change in the seed moisture content from 9.5% to 17.5% significantly increased the volume of rye seeds from 3.10% to 14.99%, the volume of triticale seeds from 1.00% to 13.40%, and the volume of barley seeds from 1.00% to 15.33%. These data can be used as a parameter to improve the DEM simulation process.

1. Introduction

According to the data of the Central Statistical Office [1], the average share of certified seeds in the total amount of cereal seeds used for sowing in Poland in 2020 amounted to only 17.7%. It was even lower, i.e., 15.4%, when cereal mixtures were taken into account. These shares were also similar in 2018, when they amounted to 17.1% and 14.7%, respectively [2]. These data show that uncertified seeds stored directly on farms are sown in more than 80% of farmland in Poland. Globally, this is not an isolated case. According to Masyitah et al. [3], unclassified seeds from previous harvests are used in more than 60% of the area of rice plantations in Indonesia.

Unclassified seeds from previous harvests are stored in flat (usually brick granaries) or vertical warehouses (metal silos) [4], where they come into contact with the atmospheric air of different humidity, which depends on variable weather conditions. Research conducted in Spain [5] revealed a close dependence between air humidity and changes in the moisture content of seeds stored in hórreos (traditional grain storage buildings), which ensure natural ventilation. The researchers observed that when the relative air humidity exceeded 90%, the average humidity inside the warehouse buildings decreased by 5.2%. If the relative air humidity was lower than 65%, the humidity inside the warehouse was 3.2% higher. The research showed that the geographical location, altitude, and exposure to wind influenced changes in relative humidity inside the grain warehouse [5].

It is important to store healthy, dry, clean, and pest-free cereal grains. The moisture content is an important parameter affecting the quality of stored seeds. It is taken into account in grain quality standards [6]. Too high moisture content causes biochemical and microbiological changes in seeds, which limit the time of their safe storage. In consequence, seeds warm up, become infested by fungal pathogens, mold, and other microorganisms. On the other hand, too low humidity may increase the susceptibility of seeds to mechanical damage, which will result in a loss [7,8]. Inappropriate storage conditions reduce the quality of seeds. As a result, they can neither be sown nor used as food or feed [6]. Contemporary storage of cereal grains involves a sequence of treatments protecting them from unfavorable processes lowering their quality. The drying and cooling of seeds enable their long-term storage [9].

Numerous studies have shown that the physical properties of cereal grains and the seeds of other crops depend mainly on their water content [10] and change significantly with it [11,12]. As results from scientific publications, the water content in seeds affects not only their dimensions, but also the values of the external friction coefficient, angle of repose, and cohesion [13]. For this reason, it is necessary to know the physical properties of agricultural products to predict the quality of the raw material before, during, and after processing. It helps to design technological processes and determine the use by dates [14,15,16]. The knowledge of changes in the physical properties of biomaterials caused by moisture is necessary to design technological lines for the sorting, cleaning, separation, transport, storage, processing, and packaging of seeds. This knowledge is also necessary for engineers constructing sowing, planting, and cereal harvesting machinery [17,18,19,20,21,22], because, as results from scientific publications, when the dimensions of seeds change, so do their position and the degree to which they fill the space (working volume) in the dispensing units of seed drills., which affects the seed sowing efficiency and uniformity [23].

Simulation methods such as the finite element method (FEM) and discrete element method (DEM) are increasingly often used to design machinery for sorting, cleaning, separation, transport, storage, processing, and packaging. The FEM is used both in strength tests [24] and to test contacts between the elements of machinery [25]. The DEM is used to simulate transport [26], milling [27], crushing, screening, and many other processes involving granular material. Numerous studies have shown that the DEM is an effective tool simulating the behavior of granular materials. The accuracy of the simulation largely depends on the contact models, the physical parameters of particles and the input parameters [28]. There are no available scientific publications with the results of research on the influence of the moisture content in cereal grains on their dimensions, i.e., their length, width, thickness, and the shape factor. These physical parameters of seeds can be used as input data in the DEM simulation of specific technological processes (dosing, transport, milling, etc.). The water content in seeds stored on farms ranges very widely, from less than 10% to about 17–18%. Due to such high variability in the seed moisture content, the authors of this study decided to investigate this issue.

The knowledge of the physical properties of the seeds of cereals and other crops can also be used to determine the efficiency of machines, assess the quality of end products, and to classify cultivars and distinguish between them [29]. The geometric traits determining the dimensions and shape of seeds are an important group of physical properties of cereal raw materials [30,31]. It is important to know them when constructing machines and devices (e.g., for the pneumatic transport, sorting, hulling, and grinding of seeds) and selecting the parameters of their operation [32,33].

The aim of the study was to determine the influence of the moisture content on the physical properties of grains of three winter cereals, i.e., triticale, rye, and barley, in order to improve the simulation of seed dosage and transport in the sowing unit of a pneumatic seed drill and to select the simulation parameters based on the discrete element method (DEM).

The aim of the study was to determine the range of variability in the basic physical parameters of the seeds of three winter cereals, i.e., triticale, rye, and barley, depending on the seed moisture content so as to select the simulation parameters in the discrete element method (DEM) and to improve the simulation of seed dosage and transport in the sowing unit of a pneumatic seed drill.

2. Materials and Methods

The research was conducted on the seeds of three winter cereals, i.e., triticale (Gringo cultivar—Danko Company, Choryń, Poland), rye (Agata cultivar—Danko Company, Poland), and barley (LG Veronika cultivar—Top Farms Nasiona, Runowo, Poland) (Figure 1).

Figure 1.

The seeds of three winter cereals used in the study: (a)—untreated seeds and (b)—dressed seeds.

Both dressed and untreated seeds were used in the research. The seeds were wet-dressed with Syngenta [34] Vibrance Gold fungicide in September 2019 in order to protect them from the pathogens and pests on their surface or inside. Before the experiment the initial seed moisture content measured with a RADWAG MAX 50/WH moisture analyzer was about 7%. The measurement accuracy was up to 0.01%. Next, the moisture content in the samples was increased to levels of about 9.5%, 11.5%, 13.5%, 15.5%, and 17.5% by adding an appropriate amount of water Mw, as can be seen in Equation (1) [35,36,37]:

where Mw is the amount of water necessary to increase the moisture content in g, Mp is the weight of the moistened sample in g, W1 is the initial moisture content of the sample in %, and W2 is the assumed moisture content of the sample in %.

The moisture content was increased by adding an appropriate amount of water to samples weighing 20 g. Next, the samples were refrigerated for 24 h at a temperature of 3–4 °C. Then, 100 seeds of each cereal species were randomly selected from each moistened sample and their physical parameters were measured. The other seeds were used for measurements of the moisture content.

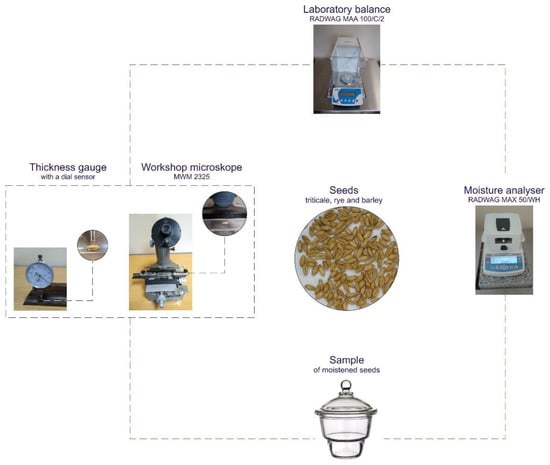

The physical properties of seeds were measured in accordance with the methodology described by Kaliniewicz et al. [38]. The physical characteristics, such as the length and width of the seeds, were measured with an MWM 2325 workshop microscope with an accuracy of 0.02 mm. The thickness of the seeds was measured with an accuracy of 0.01 mm by means of a thickness gauge with a dial sensor. The weight of the seeds was measured with an accuracy of 0.1 mg by means of a RADWAG WAA 100/C/2 laboratory balance. Figure 2 shows a diagram with the devices used for the measurements of the physical parameters of the seeds.

Figure 2.

A diagram with the devices used for the measurements of the physical parameters of the seeds used in the experiment, depending on their moisture content.

The following parameters were calculated based on geometric measurements of the seeds:

The geometric equivalent diameter Dg (Equation (2)), aspect ratio R (Equation (3)), and sphericity index Φ (Equation (4)) are as follows [30]:

where T is the seed thickness (mm), W is the seed width (mm), L is the seed length (mm), and mD is the unit weight (Equation (5)) [39]:

where m is the seed weight (mg).

The following equation was used to calculate the volume of seeds Vg, whose shape resembles a rotational ellipsoid (Equation (6)) [40]:

The results of measurements and calculations were statistically processed with the Statistica program (version 13) at a significance level of 0.05, using the module of descriptive statistics and analysis of variance. The differences between the physical characteristics and the level of moisture were determined by means of one-way analysis of variance (ANOVA). Statistically significant differences were determined with Duncan’s test [41,42].

3. Results and Discussion

Table 1, Table 2 and Table 3 show the results of measurements of the physical characteristics of the seeds of three types of winter cereals—triticale, barley, and rye, depending on their moisture content. The analysis of their dimensions showed that as their moisture content increased, so did their dimensions (length, width, and thickness) and weight. In extreme cases, the differences in the length between the winter triticale seeds with the highest and the lowest moisture content were as large as about 0.11 mm, or even 0.25 mm for dressed seeds. The width of the seeds decreased slightly as their moisture content increased, whereas their thickness increased slightly by 0.04–0.13 mm. The weight of the seeds also increased along with the increase in their moisture content. In extreme cases the thousand kernel weight increased from about 4 mg to 6 mg. As far as the seeds of the other two types of cereals are concerned, i.e., both untreated and dressed barley and rye seeds, their width and thickness increased along with the increase in their moisture content. The weight of the seeds also increased along with their moisture content. As results from the data provided in reference publications, the physical properties of seeds change along with the increase in their moisture content. The moisture content, external friction, and material density are the parameters with the greatest influence on the course of technological processes [43,44,45,46,47]. The differences in the nature of changes in the dimensions of winter triticale, barley, and rye seeds may have been caused by differences between individual seeds in their ability to absorb water as well as differences in their chemical composition, morphological structure, and the endosperm structure. The water absorption capacity of cereal seeds is important not only during their storage, but also during their conditioning before milling. Flourish seeds absorb water faster than vitreous seeds, are softer, and do not require long maturing [48,49].

Table 1.

The statistical parameters of the physical characteristics of winter triticale seeds.

Table 2.

The statistical parameters of the physical characteristics of winter barley seeds.

Table 3.

The statistical parameters of the physical characteristics of winter rye seeds.

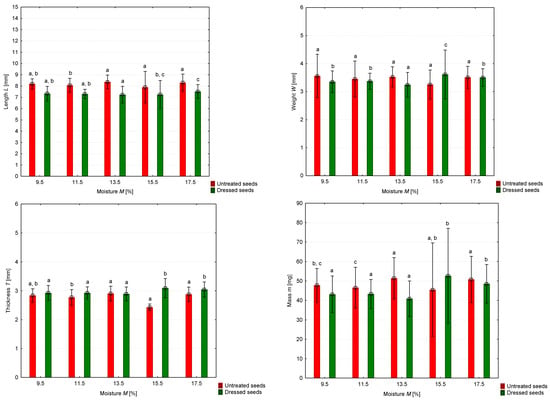

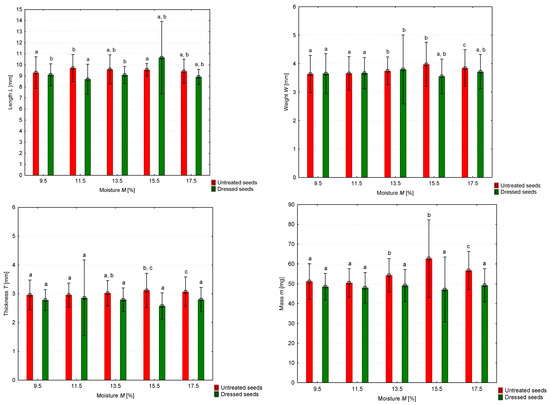

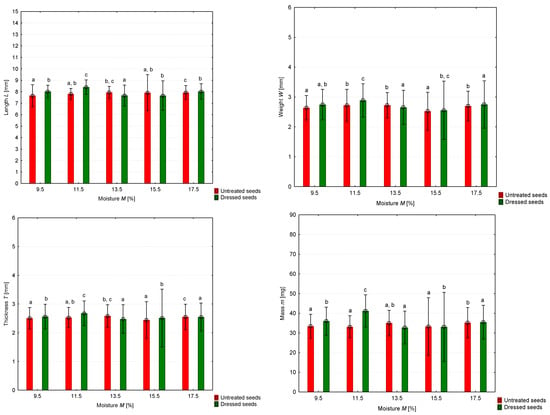

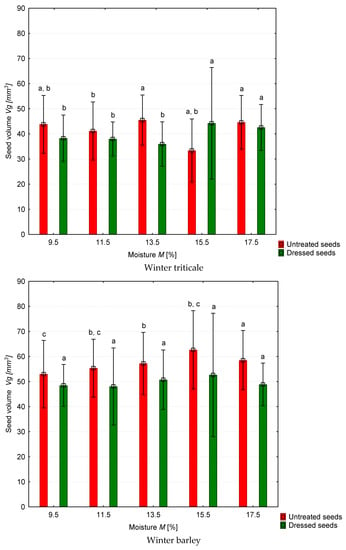

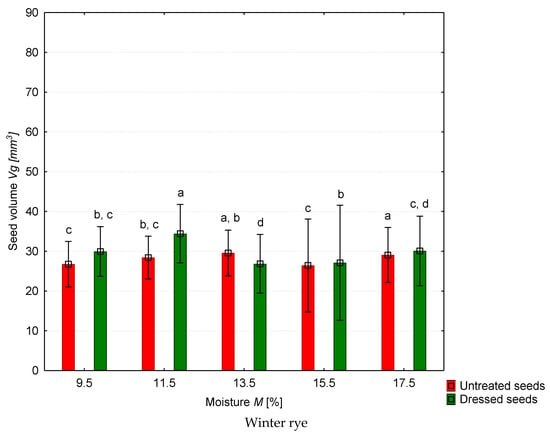

Additionally, the differences between the values of the physical traits and the weight of the triticale, barley, and rye seeds depending on their moisture content and their significance were illustrated in graphs in order to increase the legibility of the results (Figure 3, Figure 4 and Figure 5).

Figure 3.

The physical parameters (the mean value and standard deviation) of winter triticale seeds. Note: a, b, c—different letters indicate significant differences at p < 0.05 in the group of dressed and untreated seeds (Duncan’s test).

Figure 4.

The physical parameters (the mean value and standard deviation) of winter barley seeds. Note: a, b, c—different letters indicate significant differences at p < 0.05 in the group of dressed and untreated seeds (Duncan’s test).

Figure 5.

The physical parameters (the mean value and standard deviation) of winter rye seeds. Note: a, b, c—different letters indicate significant differences at p < 0.05 in the group of dressed and untreated seeds (Duncan’s test).

Table 4 shows the mean values of the geometric equivalent diameter Dg, the aspect ratio R, and the sphericity ratio Φ, as well as the unit weight mD calculated on the basis of measurements of the physical traits of the seeds of the species under analysis. The winter barley seeds with a moisture content of 17.5% were characterized by the highest mean value of the equivalent geometric diameter Dg and unit weight, whereas the lowest values of these parameters were noted in the dressed winter rye seeds with moisture content values of 13.5% and 11.5%. The barley seeds with a moisture content of 11.5% were characterized by the highest mean aspect ratio R. The highest mean value of the sphericity index Φ was noted in the dressed winter triticale seeds with a moisture content of 15.5%. The mean values of the seed indexes were similar to the data presented by other authors for these species of cereals [47,50,51,52]. The values of these coefficients, calculated based on the dimensions of the seeds, are significant for various separation processes. They also characterize the shape of the seeds to a certain extent, and their numerical value can be used as a criterion for the selection of seeds. As can be read in scientific publications [53,54], the values of the physical characteristics of seeds may vary even within one cultivar due to the significant influence of agrobiological conditions. The conditions of cultivation, climate, fertilization, and other treatments applied to crops affect the individual physical characteristics of seeds, mostly their average length, and to a lesser extent, their thickness and width [55]. They are also important for the selection of appropriate characteristics when separating seeds during cleaning and sorting, and they help to determine the load of machines and devices used in cereal processing. Apart from that, each separation process is different even if the same species is used as the base material, because there may be differences in the granulometric characteristics, moisture content, botanical composition, purity, and alignment of seeds.

Table 4.

The mean values of the indexes of the cereal seeds.

Due to the ambiguous nature of changes in the physical characteristics of the triticale, barley, and rye seeds as well as the coefficients describing their shape depending on their moisture content, it was necessary to calculate the seed volume Vg. The results showed that although there were some differences in changes in the volume of the dressed and untreated seeds within the same species, the nature of these changes was generally similar—the volume of the seeds tended to increase along with their moisture content (rye—from 3.10% up to 14.99%, triticale—from 1.00% to 13.40%, and barley—from 1.00% to 15.33%). The statistical analysis of changes in the volume of seeds showed that the change in the moisture content of the rye, triticale, and barley seeds within 9.5–17.5% caused a significant increase in their volume (Figure 6). This means that the seed volume can be used as a parameter to improve the DEM simulation process. This fact was confirmed in a study on the volumetric scaling of rice seeds with the discrete element method (DEM) [56] and in a study where the volume-to-surface ratio was used to describe and control particles [57].

Figure 6.

The volume of the dressed and untreated winter triticale, barley, and rye seeds. Note: a, b, c, d—different letters indicate significant differences at p < 0.05 in the group of dressed and untreated seeds (Duncan’s test).

4. Conclusions

The analysis of variance showed that the moisture content of the dressed and untreated winter triticale, barley, and rye seeds significantly affected their physical characteristics, i.e., length, width, thickness, and weight. The greatest differences in the weight of the seeds were observed when their moisture content varied within 9.5–17.5%. The average increase in the thousand kernel weight ranged from 4 mg to 6 mg. There was also a significant dependence between the seed moisture content Wz and the values of the coefficients describing the shape of the seeds, i.e., the equivalent geometric diameter Dg, aspect ratio R, sphericity index Φ, and unit weight mD. The values of the coefficients describing the shape of the seeds tended to change along with the increasing seed moisture content. The nature of these changes depended on the seed species and whether they were dressed or not. The changes in the seed moisture content within 9.5–17.5% significantly increased the volume of the rye (from 3.10% to 14.99%), triticale (from 1.00% to 13.40%), and barley seeds (from 1.00% to 15.33%). This information can be used as a parameter for improvement of the simulation process based on the discrete element method (DEM).

Author Contributions

Conceptualization, Ł.G.; methodology, Ł.G. and E.K.; software, Ł.G.; validation, Ł.G., E.K. and P.M.; formal analysis, Ł.G. and P.M.; investigation, Ł.G.; resources, P.M.; data curation, Ł.G. and P.M.; writing—original draft preparation, Ł.G., E.K. and P.M.; writing—review and editing, Ł.G., P.M. and K.K.; visualization, Ł.G. and E.K.; supervision, Ł.G.; project administration, P.M. and K.K.; fund acquisition, Ł.G. All authors have read and agreed to the published version of the manuscript.

Funding

The research was supported by the National Centre for Research and Development under the LIDER VIII programme, project No. LIDER/24/0137/L-8/16/NCBIR/2017.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- GUS, Central Statistics Poland. 2020. Available online: https://stat.gov.pl/files/gfx/portalinformacyjny/pl/defaultaktualnosci/5515/6/14/1/rocznik_statystyczny_rolnictwa_2020 (accessed on 25 August 2021).

- GUS, Central Statistics Poland. 2018. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rolnictwa-2018,6,12.html (accessed on 25 August 2021).

- Masyitah, M.; Augussabti, A.; Kasimin, S. Tingkat Adopsi Petani Terhadap Benih Unggul Padi Sawah Di Kabupaten Aceh Besar Provinsi Aceh. J. AGRIFO 2019, 4, 1–6. [Google Scholar] [CrossRef]

- Stejskal, V.; Hubert, J.; Kučerová, Z.; Munzbergová, Z.; Lukáš, J.; Žd’árková, E. The influence of the type of storage on pest infestation of stored grain in the Czech Republic. Plant Soil Environ. 2003, 49, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Perez-Garcia, O.A.; Carreira, X.C.; Carral, E.; Fernandez, M.E.; Mariño, R.A. Evaluation of traditional grain store buildings (hórreos) in Galicia (NW Spain): Analysis of outdoor/indoor temperature and humidity relationships. Span. J. Agric. Res. 2010, 8, 925–935. [Google Scholar] [CrossRef]

- Tomkiewicz, D. Construction and operation of corn seed humidity sensor using near-infrared radiation. Agric. Eng. 2009, 6, 309–314. (In Polish) [Google Scholar]

- Horoszkiewicz-Janka, J.; Korbas, M.; Mrówczyński, M. Metodyka integrowanej ochrony pszenicy ozimej i jarej dla producentów. In Methodology of Integrated Protection of Winter Wheat and Spring for Producers; Wydawnictwo IOR: Poznań, Poland, 2013. (In Polish) [Google Scholar]

- Borkowska, B.; Banach, D. Ocena wybranych cech fizykochemicznych pszenicy i żyta z północnego i południowego regionu Polski [Assessment of selected physicochemical properties of wheat and rye from the northern and southern region of Poland]. Rocz. Nauk. Stowarzyszenia Ekon. Rol. I Agrobiz 2018, 20, 18–21. (In Polish) [Google Scholar] [CrossRef]

- Rudziński, R. Zasady przechowywania i magazynowania towarów pochodzenia rolniczego. [Rules for storage and warehousing of goods of agricultural origin] Zeszyty Naukowe Uniwersytetu Przyrodniczo-Humanistycznego w Siedlcach. Adm. I Zarządzanie T. 2011, 15, 113–126. (In Polish) [Google Scholar]

- Horabik, J. Charakterystyka właściwości fizycznych roślinnych materiałów sypkich istotnych w procesach składowania. Acta Agrophys. 2001, 54, 5–121. [Google Scholar]

- Kaliniewicz, Z.; Anders, A.; Markowski, P.; Tylek, P.; Owoc, D. Analysis of the physical properties of spindle seeds for seed sorting operations. Sci. Rep. 2021, 11, 13625. [Google Scholar]

- Andrejko, D. Wpływ wilgotności i wymiarów cząstek na gęstość sypkich surowców roślinnych. Inż. Rol. 2015, 11, 9–17. [Google Scholar]

- Rusinek, R.; Horabik, J. Selected mechanical parameters of rapeseeds. Agric. Eng. 2006, 6, 213–221. (In Polish). Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-article-BAR0-0053-0024 (accessed on 30 May 2021).

- Sahin, S.; Sumnu, S.G. Physical Properties of Foods; Springer Science Business Media, LLC. New York: New York, NY, USA, 2006. [Google Scholar]

- Altuntas, E.; Demirtola, H. Effect of moisture content on physical properties of some grain legume seeds. N. Z. J. Crop Hort. 2007, 35, 423–433. [Google Scholar] [CrossRef]

- Izli, N. Effect of moisture on the physical properties of three varieties of kenaf seeds. J. Food Sci. Technol. 2015, 52, 3254–3263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karimi, M.; Kheiralipour, K.; Tabatabaeefar, A.; Khoubakht, G.M.; Naderi, M.; Heidarbeigi, K. Effect of moisture content on physical properties of wheat. Pak. J. Nutr. 2009, 8, 90–95. [Google Scholar] [CrossRef] [Green Version]

- Kalkan, F.; Kara, M. Handling, frictional and technological properties of wheat as affected by moisture content and cultivar. Powder Technol. 2011, 213, 116–122. [Google Scholar] [CrossRef]

- Shelake, P.S.; Yadav, S.; Jadhav, M.L.; Dabhi, M.N. Effect of moisture content on physical and mechanical properties of turmeric (Curcumalonga) rhizome. Curr. J. Appl. Sci. Technol. 2018, 30, 1–7. [Google Scholar] [CrossRef]

- Jadhav, K.L.; Mohnot, P.; Shelake, P.S. Investigation of engineering properties of vegetable seeds required for the design of pneumaticseeder. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 1163–1171. [Google Scholar] [CrossRef]

- Salawu, A.T.; Isiaka, M.; Attanda, M.L. Design related physical properties of snake tomato seeds. Acad. Res. Int. 2014, 5, 1–10. [Google Scholar]

- Rajaiah, P.; Mani, I.; Kumar, A.; Lande, S.D.; Singh, A.K. Role of physical and engineering properties of rice (Oryzasativa) cultivars for designing of precision planter. Indian J. Agric. Sci. 2015, 85, 1602–1608. [Google Scholar]

- Rawa, T.; Lipiński, A.; Łazarczyk, A. Eksperymentalne określenie kierunku ustawienia nasion pszenicy w gnieździe kołeczkowego zespołu wysiewającego. Probl. Inż. Rol. 2000, 4, 29–36. (In Polish) [Google Scholar]

- Chodurski, M.; Dębski, H.; Samborski, S.; Teter, A. Numerical strength analysis of the load-bearing frame of a palletizing robot’s universal head. Eksploat.–Maint. Reliab. 2015, 17, 374–378. [Google Scholar] [CrossRef]

- Jachimowicz, J.; Wawrzyniak, A. Zastosowanie MES w zagadnieniach kontaktu elementów maszyn. In Application of FEM in the Issues of Contact of Machine Elements; Prace Instytutu Podstaw Budowy Maszyn/Politechnika Warszawska: Warszawa, Poland, 1999; pp. 69–108. (In Polish) [Google Scholar]

- Gierz, Ł.; Warguła, Ł.; Kukla, M.; Koszela, K.; Zwiachel, T.S. Computer Aided Modeling of Wood Chips Transport by Means of a Belt Conveyor with Use of Discrete Element Method. Appl. Sci. 2020, 10, 9091. [Google Scholar] [CrossRef]

- Bautista, R.C.; Siebenmorgen, T.J. Evaluation of laboratory mills for milling small samples of rice. Appl. Eng. Agric. 2002, 18, 577–583. [Google Scholar] [CrossRef]

- Petingco, M.C.; Casada, M.E.; Maghirang, R.G.; Fasina, O.O.; Chen, Z.; Ambrose, R.P.K. Influence of Particle Shape and Contact Parameters on DEM-Simulated Bulk Density of Wheat. Trans. ASABE 2020, 63, 1657–1672. [Google Scholar] [CrossRef]

- Fathollahzadehl, H.; Mobli, H.; Jafari, A.; Rafiee, S.; Mohammadi, A. Some physical properties of tabarzeh apricot kernel. Pak. J. Nutr. 2008, 7, 645–651. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical properties of plant and animal materials. In Characteristics and Mechanical Properties; Gordon and Breach Science Publishers: New York, NY, USA, 1986. [Google Scholar]

- Tylek, P. Measuring selected properties of seeds by computer image processing. Zesz. Probl. Postepow Nauk. Rol. 2009, 423, 335–341. (In Polish) [Google Scholar]

- Grochowicz, J. Maszyny do czyszczenia i sortowania nasion [Machines for cleaning and sorting seeds]. In Wydawnictwo AR Lublin; Wydawnictwo Akademii Rolniczej: Bydgoszcz, Poland, 1994; ISBN 83-901612-9-X. (In Polish) [Google Scholar]

- Kusińska, E. Wpływ przechowywania na właściwości fizyczne ziarna owsa. Acta Agrophys. 2001, 58, 105–114. [Google Scholar]

- Vibrance-Gold–Zaprawy Nasienne. Available online: https://www.syngenta.pl/srodki-ochrony-roslin/zaprawy-nasienne/vibrance-gold-access (accessed on 16 June 2021).

- Zewdu, A.D.; Solomon, W.K. Moisture-dependent physical properties of tef seed. Biosyst. Eng. 2007, 96, 57–63. [Google Scholar] [CrossRef]

- Dursun, E.; Dursun, I. Some physical properties of caper seed. Biosyst. Eng. 2005, 92, 237–245. [Google Scholar] [CrossRef]

- Balasubramanian, D. Physical properties of raw cashew nut. J. Agric. Eng. Res. 2001, 78, 291–297. [Google Scholar] [CrossRef]

- Kaliniewicz, Z.; Markowski, P.; Anders, A.; Jadwisieńczak, B.; Rawa, T.; Szczechowicz, D. Basic physical properties of Norway spruce (Piceaabies (L.) Karst.) seeds. Tech. Sci. 2016, 19, 103–115. [Google Scholar]

- Kaliniewicz, Z.; Tylek, P.; Markowski, P.; Anders, A.; Rawa, T.; Jóźwiak, K.; Fura, S. Correlations between the germination capacity and selected physical properties of Scots pine (Pinus sylvestris, L.) seeds. Baltic Forestry 2013, 19, 201–211. [Google Scholar]

- Gastón, A.L.; Abalone, R.M.; Giner, S.A. Wheat drying kinetics. Diffusivities for sphere and ellipsoid by finite elements. J. Food Eng. 2002, 52, 313–322. [Google Scholar] [CrossRef]

- Rabiej, M. Statystyka z Programem Statistica. In Statisctics in Statistica Software; Helion: Gliwice, Poland, 2012; ISBN 9788324641109. [Google Scholar]

- Stanisz, A. Accessible Course in Statistics Based on the STATISTICA PL Software on Examples from Medicine. In Tome 1. Basic Statistics; StatSoftPolska: Kraków, Poland, 2007. (In Polish) [Google Scholar]

- Kram, B.B. Badania współczynnika tarcia zewnętrznego ziarna zbóż w funkcji wilgotności [Research on the coefficient of external friction of corn grain in humidity function]. Inż. Rol. 2006, 10, 175–182. Available online: http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BAR0-0051-0095 (accessed on 17 December 2021).

- Kaliniewicz, Z.; Żuk, Z.; Krzysiak, Z. Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels. Sustainability 2018, 10, 1003. [Google Scholar] [CrossRef] [Green Version]

- Hebda, T.; Micek, P. Zależności Pomiędzy Właściwościami Geometrycznymi Ziarna Zbóż [Dependences between Geometrical Features of Cereal Grain]. Inż. Rol. 2005, 6, 233–241. (In Polish). Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-33138867-224a-40d6-9ab0-09fd574e8be3 (accessed on 17 December 2021).

- Horabik, J.; Molenda, M. Właściwości Fizyczne Sypkich Surowców Spożywczych. In Physical Properties of Granular Food Materials; Acta Agrophysica: Lublin, Poland, 2002; pp. 1–96. (In Polish) [Google Scholar]

- Boac, J.M.; Casada, M.E.; Maghirang, R.G.; Harner, J.P., III. Material and interaction properties of selected grains and oilseeds for modeling discrete particles. Trans. ASABE 2010, 53, 1201–1216. [Google Scholar] [CrossRef] [Green Version]

- Fang, C.; Campbell, G.M. On predicting roller milling performance V: Effect of moisture content on the particle size distribution from first break milling of wheat. J. Cereal Sci. 2003, 37, 31–41. [Google Scholar] [CrossRef] [Green Version]

- Dziki, D.; Różyło, R.; Laskowski, J.; Grundas, S. Evaluation of wheat grain physical properties carried out using an analyser of single seeds. Agric. Eng. 2011, 126, 39–46. (In Polish) [Google Scholar]

- Kaliniewicz, Z. Analysis of frictional properties of cereal seeds. Afr. J. Agric. Res. 2013, 45, 5611–5621. [Google Scholar]

- Markowski, M.; Żuk-Gołaszewska, K.; Kwiatkowski, D. Influence of variety on selected physical and mechanical properties of wheat. Ind. Crops Prod. 2013, 47, 113–117. [Google Scholar] [CrossRef]

- Sologubik, C.A.; Campañone, L.A.; Pagano, A.M.; Gely, M.C. Effect of moisture content on some physical properties of barley. Ind. Crops Prod. 2013, 43, 762–767. [Google Scholar] [CrossRef]

- Hebda, T.; Micek, P. Cechy geometryczne ziarna wybranych odmian zbóż [Geometric features of grain for selected corn varieties]. Inż. Rol. 2007, 11, 187–193. [Google Scholar]

- Kaliniewicz, Z.; Biedulska, J.; Jadwisieńczak, B. Assessment of Cereal Seed Shape with the Use of Sphericity Factors; Technical Sciences/University of Warmia and Mazury in Olsztyn: Olsztyn, Poland, 2015. [Google Scholar]

- Kolankowska, E.; Choszcz, D.J.; Markowski, P. An Analysis of Selected Physical Properties of Ancient Wheat Species. Sustainability 2017, 9, 1970. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Tekeste, M.Z.; Li, Y.; Gaul, A.; Zhu, D.; Liao, J. Scaled-up rice grain modelling for DEM calibration and the validation of hopper flow. Biosyst. Eng. 2020, 194, 196–212. [Google Scholar] [CrossRef]

- Medina, D.A.; Jerves, A.X. A geometry-based algorithm for cloning real grains 2.0. Granul. Matter 2019, 21, 2. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).