Abstract

Smart farming with precise greenhouse monitoring in various scenarios is vital for improved agricultural growth management. The Internet of Things (IoT) leads to a modern age in computer networking that is gaining traction. This paper used a regression-based supervised machine learning approach to demonstrate a precise control of sensing parameters, CO2, soil moisture, temperature, humidity, and light intensity, in a smart greenhouse agricultural system. The proposed scheme comprised four main components: cloud, fog, edge, and sensor. It was found that the greenhouse could be remotely operated for the control of CO2, soil moisture, temperature, humidity, and light, resulting in improved management. Overall implementation was remotely monitored via the IoT using Message Query Telemetry Transport (MQTT), and sensor data were analysed for their standard and anomalous behaviours. Then, for practical computation over the cloud layer, an analytics and decision-making system was developed in the fog layer and constructed using supervised machine learning algorithms for precise management using regression modelling methods. The proposed framework improved its presentation and allowed us to properly accomplish the goal of the entire framework.

1. Introduction

Plant development has proven to be a novel test, because plant fields and strength are becoming more crucial for commercial and food crops. The scarcity of agricultural knowledge and information on new developments is one of the significant problems faced by modern agriculture [1]. In the past, instead of applying a general marvel to all plants, our ancestors avoided employing technological development for particular plant growth. Now that plants may be raised in unusually typical natural settings and specialized plants can be cultivated under certain circumstances, there are higher yield and less compost [2,3]. As a result of lower-cost technology that allows farmers to optimise production, precision agriculture (PA) for plant growth in greenhouses is gaining popularity. The greenhouse is a transparent house-like structure that regulates temperature, moisture, light infiltration, and other factors for optimal plant growth. PA is a method for detecting, monitoring, and responding to environmental changes. It is a method for detecting greenhouse climate, after which the data are recognized and uploaded to the cloud, and the agriculturist takes action based on the data. It may be seen in the most recent technological innovation, the IoT, which is expertise that employs web-based methods to connect everything or any device to the Internet. The exact agricultural framework is improving as a result of recent advancements in Wireless Sensor Networks (WSNs), which are more advanced than the Internet of Things. Precision agriculture is the most advanced cultivating technology with a vast framework that has lately emerged. In the case of a sudden shift in the greenhouse, it entails identifying, estimating, and transmitting nursery data to farmers [4,5].

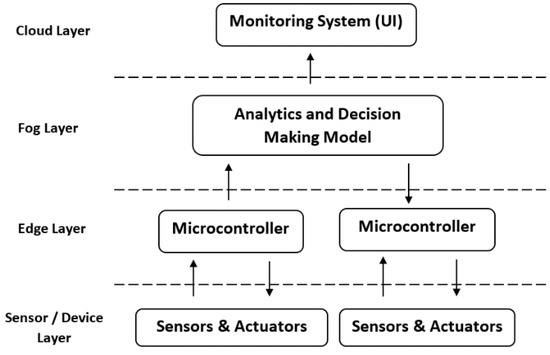

A greenhouse is a simple structure that maintains a microclimate favourable to solid plant growth, such as water stream management, temperature control, and other factors. As a result, it offers shielding from, e.g., too much light, extreme temperatures, infections, and creepy crawlies. The four essential benefits of an intelligent greenhouse system, as indicated in Figure 1, are maintaining perfect microclimate conditions, optimizing irrigation and fertilization methods, controlling infection and avoiding disease outbreaks, and reducing theft and enhancing security. By maintaining the proper environmental conditions, farmers could cultivate any plant in all seasons. Greenhouse farming is significant, which illustrates why it has become so popular. Because greenhouses hold moisture, they use far less water than traditional horticulture. This reduces the time spent editing and expands the sorts of harvests available. Temperature and humidity are carefully controlled to meet the demands of the plants. Nurseries can also be used to develop slow-growing crops. Pests may be readily dealt with. Harvests may be made under various environmental conditions, making them incredibly versatile. The varying climatic conditions in the greenhouse affect plant growth, resulting in a lower yield at the end of cultivation. As a result, greenhouse gases, temperature, soil moisture, and light must all be managed and monitored. This problem could be solved by implementing IoT innovations in precision agriculture using machine learning, which involves the precise application of certain greenhouse factors for optimal plant development, such as temperature management, water flow control, and light radiation, among others. In precision agriculture, agricultural inputs are utilised in precise amounts to obtain increased average yields, compared with traditional cultivation techniques, resulting in an increase in agricultural productivity, which prevents soil degradation; reduces the use of the chemical applications, fertilisers, pesticides, and herbicides in crop production; and promotes the efficient use of water resources. It is also helpful in the dissemination of modern farm practices to improve quality and quantity and reduce the cost of production. In machine learning, regression-based analyses help to understand how the value of the dependent variable changes according to an independent variable when other independent variables are held fixed, resulting in the precise control of agricultural output [6,7]. The main contributions of the paper are as follows:

Figure 1.

Intelligent smart farming framework for greenhouse management.

- Design of a four-layer framework for an IoT-based intelligent farming system that can support the deployment of a low-cost farming system with smart solutions;

- Evaluation of the proposed precision analytics and decision-making model based on supervised regression machine learning performance through different experimentations.

The rest of the paper is organized as follows: In Section 2, related work regarding intelligent models using various data analytics algorithms is discussed. The details of the proposed smart farming framework are presented in Section 3. Section 4 describes an experimental evaluation along with the results. Section 5 finally presents conclusions regarding the proposed scheme.

2. Literature Review

An intelligent agricultural system was developed with the help of several researchers. Initially, most of the authors used a variety of sensors and actuators to meet their objectives to obtain the most efficient management possible. Intelligent and precise control systems based on the Internet of Things for smart agriculture are divided according to two implementation phases, with the first one being IoT-based monitoring systems and the second one being artificial intelligence systems based on the IoT. Some authors performed their research on either one or both systems, which are summarized below.

2.1. IoT-Based Monitoring Systems

For complete distribution nurseries employing tolerable saline water, a flexible system was developed that could adjust to soilless culture conditions. Internet of Things (IoT) technology was used to create a highly flexible perceptual framework for regulating and monitoring nursery temperature. A reduced, personal, and resource-efficient IoT system for SA based on Commercial Off-The-Shelf (COTS) gadgets accepting short- and long-range communication media was also described. The improvement in vegetable nursery management through the selection, interpretation, and analysis of sensor data is recognized as an important boundary of developing plants [8,9,10]. A suggested arrangement minimized network idleness to some extent compared with current Internet of Things horticultural and growing solutions [11,12,13,14]. An Autonomous Farming System [15,16] based on fog processing vision and LoRa innovation was developed. The investigation revolved around the structure and design of a web-enabled measuring cultivating framework that addressed the need of people to fiercely tend to their developing crops [17,18,19,20]. RiceTalk recognizes the rice effect using non-picture IoT devices. AgriTalk is a low-cost IoT system for precise soil development cultivation [21,22]; they conducted trials on turmeric development, demonstrating that AgriTalk significantly improved the quality of turmeric. A connection link quality oriented route (LQOR) protocol was suggested for adaptable IoT networks. Karim et al. designed [23,24,25] and tested a Cloud IoT-based, late scourge choice emotionally supportive network; they built a choice emotionally supportive network to reduce potato blight. A planned structure [26,27,28] served as a screen for a greenhouse, a hen house, and a fish tank; it made use of Raspberry Pi to track and regulate the weather. IoT sensors and actuators are important for screening and responding to the climate [29,30,31,32]. The development of a portable LoRaWAN passage device that could increase the profitability and precision of nurseries was described [33]. The authors of [34,35] developed a power-sensitive, able-to-adapt, IoT-based design for domestic farmers and rational objectives that allowed them to evaluate the environmental effect on plant advancements by observing dirt moisture [36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51].

2.2. Artificial Intelligence Systems Based on the IoT

The authors added to continuing IoT breakthroughs in horticulture and enhancements in equipment and programming frameworks. An autonomous Fuzzy Logic Controller (FLC) with Internet of Things capabilities was built for the analysis and the etymological dynamic analysis of fertigation (manure + water) in a nursery. A new plan for agricultural farmland prudence was devised. A Raspberry Pi device was used to identify any suspicious activity or movement in a ranch area; PiCam was then triggered to take a photo of the scene. A detecting organization collected field data for certain harvests; then, they used AI to develop a notice message that presented both the data and the information. Another study proposed a framework whose goal was to continually develop an image-processing-based mechanical weed control system (WCS) for weed control in onion fields. A data collection architecture based on Internet of Things technology and crisp picture recognition was proposed. An innovative cultivating system based on the MQTT protocol could collect data in the passive mode for sustained examination, creating and distributing a superb invention for the horticulture industry that improved natural and rural maintainability, crop discernibility, and overall yield. Using a typical IoT system, a technique for enhancing farm production by effectively planning water sources and preparations depending on harvest flow needs, natural circumstances, and climatic data was developed. The use of IoT devices to create a brilliant solar-powered agricultural observation system was demonstrated. S. Sarangi et al. created a helpful edge IoT system that incorporated a flexible and adaptive sensor hub and helped users to handle difficulties locally. P. Sureephong et al. examined the integrative arranging of an Internet of Things-based Wetting Front Detector (IoT-WFD), emphasizing how to improve the IoT-WFD plan for a sparkling-water system framework.

3. Methodology

3.1. Proposed Framework

The proposed intelligent farming system model for greenhouses is depicted in Figure 1. The four essential architectural layers are the cloud, fog, edge, and sensor/device. The sensor layer includes the various sensors and actuators related to the field environment. The edge layer mainly consists of a controller unit with which multiple sensors and actuators are interfaced for data acquisition and for sending data to the fog layer for further processing. The main objective of the fog layer is to develop the analytics and decision-making model based on data acquired from the edge layer and to provide the control signals to the edge layer for controlling the actuators. Finally, a data representation of sensors and actuators is displayed in the cloud layer in the form of a user interface (UI) dashboard. The suggested system is notable for its ability to assist farmers by providing greenhouse management using an IoT-based precision farming framework. The purpose is to supply agriculturists with remotely controlled greenhouse agricultural elements, such as soil moisture, CO2, light, and temperature, from afar, and depending on the soil moisture values; furthermore, a command for the greenhouse doors or windows to roll up/down may be given using this system. Agriculturists are unable to physically visit the fields as a result of this.

3.1.1. Sensor Layer

In this experiment, Gerbera and Broccoli were the crops that were considered in the greenhouse, which is primarily a climate-sensitive environment. The sensors used to monitor the factors in the greenhouse environment included a gas sensor, a dht11 sensor for temperature and humidity, a light sensor, a gas sensor, and a moisture sensor. In addition, actuators were chosen and deployed to control equipment such as fans and pumps according to relaying parameters. Advantages of using a greenhouse management system for crops include controlled RH, temperature, and light; protection from rain, storms, and scorching sun; and pest and disease control.

3.1.2. Edge Layer

Sensors, referred to as nodes or edges, were put in the field at various locations and connected to a low-power microcontroller designed for the IoT. We used Node MCU ESP 32 in our experiment, which could gather and analyse data from sensors before transferring them to the edge layer’s base station. Sensors had to be calibrated and checked against an expected value to collect data in analogue or digital form according to the requirements. Data were collected for various climate variables, both healthy and unhealthy, to better comprehend all possible environmental situations and to assure crop survival through accurate crop management.

3.1.3. Fog Layer

This layer’s primary responsibility was to deal with decision making, to control the activity of the edge layer, and to communicate related data to the cloud layer for use by farmers. A machine learning algorithm created the decision-making system via many processing phases, starting from the data generated by edge-layer sensors:

- Data gathering by IoT devices, particularly sensors, which could collect data in real time or in small batches (temperature, humidity, camera vision, light intensity, etc.);

- Data collection and aggregation in a target database;

- Filtration of stored data: Algorithms could be used to clean and correct the data in this step;

- Data classification depended on its intended purpose;

- Computing: During this phase, calculations were performed on the classified data (e.g., the amount of water to pump);

- Making decisions based on predictions and visualizing data in the form of reports or dashboards.

3.1.4. Cloud Layer

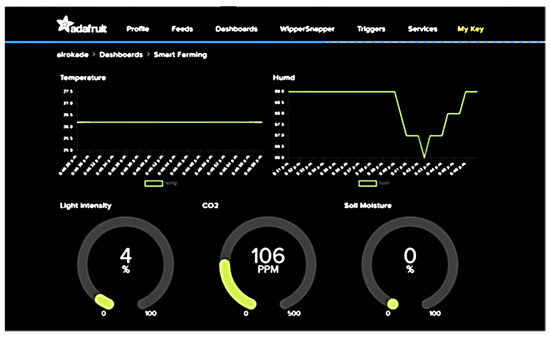

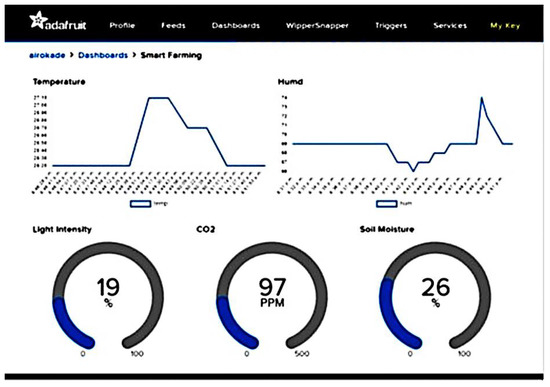

Data from each node in the edge layer, which were subsequently processed and controlled at the base station, were visualized in the cloud layer using an Adafruit IO Cloud platform. Farmers could track crop cultivation progress using a graphical interface (UI)-based application.

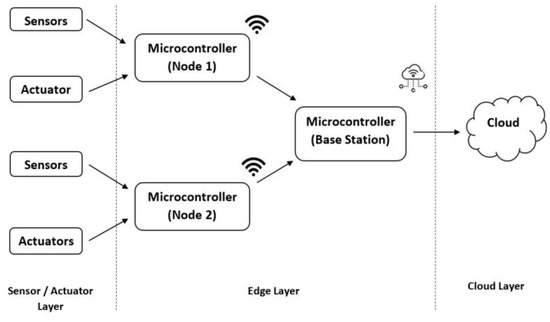

3.2. Experimental Model

A prototype experimental model was created using an embedded system device that included several sensors and a microprocessor to test the proposed innovative greenhouse system, as shown in Figure 2.

Figure 2.

Proposed framework for acquisition of data in greenhouse environment.

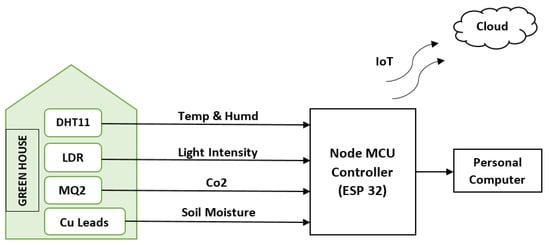

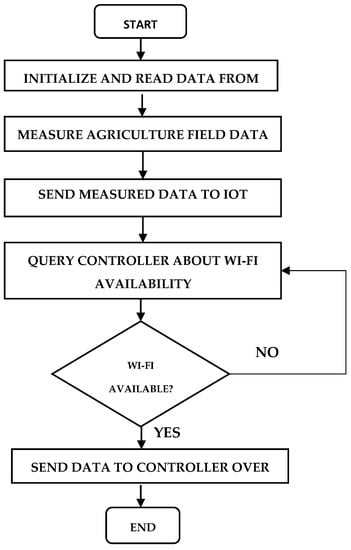

The proposed model tracked greenhouse characteristics for two crops, Gerbera and Broccoli, in different climates. A microcontroller, Node MCU ESP 32, was connected to all the needed sensors for obtaining the greenhouse parameters, as depicted in Figure 3. A personal computer was used to collect data serially with timestamp values of 1 h for the data logging of various parameters. Temperature and humidity, which were taken using the dht11 sensor, light intensity, which was taken using the LDR Sensor, CO2, which was taken using the MQ2 sensor, and soil moisture, which was taken using Cu leads, were all continually monitored for ten days on the Adafruit IO Cloud platform utilizing the MQTT protocol under day and night conditions within specific time intervals. The operational workflow of the proposed system and how the procedure operated are defined in Figure 4.

Figure 3.

Proposed experimental model.

Figure 4.

Workflow of experimental model.

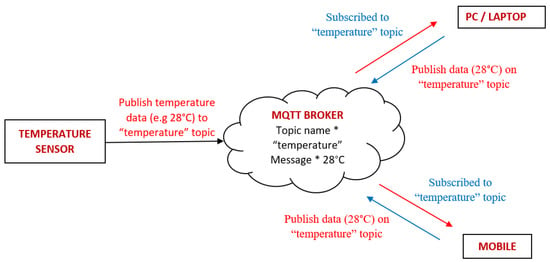

Adafruit IO is a platform for visualizing, responding to, and interacting with sensor data. With the support of MQTT, the data are also kept private and safe. MQTT (Message Queue Telemetry Transport) is a TCP/IP-based lightweight publish–subscribe protocol. MQTT employs a message broker to route messages between senders who send them and receivers who are interested in receiving them. Notifications can be published and subscribed to using the same client. Each letter is associated with a specific subject. The message routing information is the topic and is essentially a string with slash-separated hierarchical levels. Clients subscribe to these topics, and the broker sends them all messages with topics that match their subscriptions. Wildcards can also be used to easily subscribe to several topics. For example, Figure 5 shows how temperature sensor data from a greenhouse system are sent.

Figure 5.

Workflow of MQTT for sensor data [14].

3.3. Analytics and Decision-Making Model

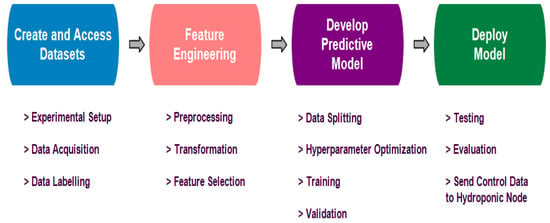

The proposed methodology developed in the fog layer for the data analytics system using machine learning algorithms, typically regression modelling, is shown in Figure 6 and is discussed in detail below.

Figure 6.

Implementation flow of data analytics system.

3.3.1. Dataset Creation and Access

In the machine learning approach, to train a model based on a dataset developed from an experimental setup, the data are fragmented into training and test data, with their equivalent output data labels. Here, in our case, there was a total number of 1024 of sensor data samples for each sensing parameter, and the training-to-test ratio was split into fragment data in a 70:30 ratio; i.e., 70% of data were used to train the model, while 30% were used to test the model that was built on them.

3.3.2. Feature Engineering

The acquired dataset sample values were available in *.csv format; these raw data were retrieved using the “Matlab” programming language. This process assists in grabbing data and implementing regression techniques using machine learning. Feature extraction is a mechanism of searching novel features by choosing or/and merging existing features to generate a reduced feature subset while precisely and entirely relating datasets deprived of loss of information. Finally, feature selection is a procedure for choosing the dimensions of the features of the dataset that makes use of machine learning techniques such as clustering, classification, etc. It can be attained utilizing various methods, such as univariate analysis, correlation analysis, etc. Univariate feature selection was used in our case, which works by selecting the best features based on univariate statistical tests.

3.3.3. Predictive Model Development

After the feature extraction process, training and test features were obtained from the training and test datasets, respectively. Then, to train the model, two supervised regression machine learning algorithms were used: multi-layer perceptron neural network (MLP) and support vector machine (SVM). So, effective parameters needed to be tuned or set for the best regression result of the test dataset while training using hyperparameter tuning. The selection of two regression-based algorithms was based on the advantages; SVM works comparably well when there is an understandable margin of dissociation between classes, and it is also more productive in high-dimensional spaces, while MLP has the ability to solve complex nonlinear problems and also handles large amounts of input data well with quick predictions after training.

Support vector machine (SVM) is a supervised classification and regression method. SVM’s main idea is shifting nonlinear data to a new space in which the data may be linearly separated by employing a hyper-plane that accurately separates the data by following two crucial conditions; because distinct classes of vectors have various aspects, the distances between the hyperplane and the vectors must be used. In Equation (1), assumption function h has the following definition:

Class +1 is assigned to points above or on the hyperplane, whereas class −1 is assigned to points below the hyperplane.

An artificial neural network (ANN) with one or more hidden layers is known as a multi-layer perceptron neural network. A perceptron is a neural network consisting of just one neural model. It simulates high nonlinear functions, which are the foundation of deep learning neural networks. Equation (2) shows the degree of inaccuracy in an output node j in the nth data point (training example), which can be represented by:

where “d” is the goal value and “y” is the perceptron’s output value. The node weights can then be modified depending on adjustments that reduce the overall output error, as shown in Equation (3):

The difficulty in selecting a set of ideal hyperparameters for a model learning algorithm is known as hyperparameter tuning or optimization. A hyperparameter is the value of a parameter that is used to influence the learning process. The grid search technique was utilized, which is the most basic form of hyperparameter tuning. We generated a model for each conceivable combination of all the hyperparameter values supplied, evaluated each model, and chose the architecture that delivered the best results using this method. Below is a description of the technique for hyperparameter-guided adjusting of the model:

Step 1: Define a machine learning model;

Step 2: For the selected approach, define the range of possible values for all hyperparameters;

Step 3: Define a sampling mechanism for hyperparameter values;

Step 4: Create a criterion for judging the model;

Step 5: Develop a cross-validation technique for determining the system’s efficiency.

4. Model Deployment

In the deployment phase, data were tested based on a trained model and evaluated using system performance parameters. The predicted output label generated was used to control the data of the hydroponic model in the device layer from the fog layer (Algorithm 1).

| Algorithm 1. Proposed Algorithms |

| INPUT |

“Features Set”

|

| OUTPUT |

| Predicted output with label values (regression). |

| Step1: Collect input data. |

| Step2: Prepare the feature data and label data from raw dataset values from Datasets. |

| Step3: Apply feature engineering to each feature data. |

| Step4: Find the missing and unknown values, and replace the mean values. |

| Step5: Calculate the normalized value of all features sets. |

| Step6: Scale all feature data into a specific range. |

| Step7: Select the machine learning model for regression, SVM, and MLP. |

| Step8: Choose the range of possible values for hyperparameters of ML algorithms. |

| Step9: Optimize the values of the hyperparameters using the Grid Search CV Optimization algorithm. |

| Step10: Evaluate and find the best score and estimator for the selected classifier. |

| Step11: Validate the model using K-Fold Validation Learning Method. |

| Step12: Set best-selected hyperparameters tuned for the ML training process. |

| Step13: Initialize the feature data and label data for the training dataset. |

| Step14: Train the model for respective ML algorithms. |

| Step15: Validate the model performance using the K-fold cross-validation method. |

| Step16: If validation is successful, then save/deploy the trained model, and if not, repeat steps 2 or step 10. |

| Step17: Initialize the feature data for the testing dataset. |

| Step18: Load the trained model of ML algorithms. |

| Step19: Predict the results for its label values (regression). |

| Step20: Evaluate RMSE (Regression) to check system performance. |

5. Experimental Result and Discussion

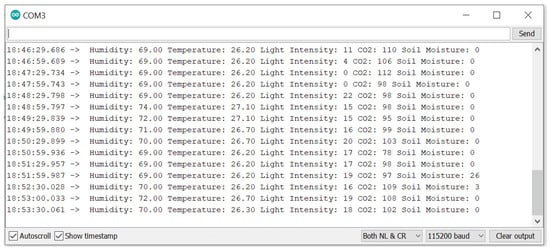

The proposed experimental plan was implemented on a prototype that was tested, as shown in Figure 7, considering two crops under various conditions. The three primary phases of experimentation were the creation of basic model-embedded systems for plant growth and feeding, the construction of a sensor net for intelligent greenhouse monitoring, and the automation of actuators. The proposed approach employed an embedded system to analyse greenhouse execution parameters such as CO2, soil moisture, temperature, and plant light, yielding accurate results. All the readings were observed under several conditions and monitored on a personal computer using serial communication, as shown in Figure 8. In addition, all these sensor data were monitored via the Internet on the Adafruit IO Cloud dashboard by publishing data from the nodes to the broker of Adafruit. Then, the user could subscribe to these data to access them in real-time, as defined in Figure 9 and Figure 10.

Figure 7.

Experimental testbench.

Figure 8.

Sensor output on serial monitor with timestamp values.

Figure 9.

Sensor output on Adafruit IO Cloud IoT dashboard for Case 1.

Figure 10.

Sensor output on Adafruit IO Cloud IoT dashboard for Case 2.

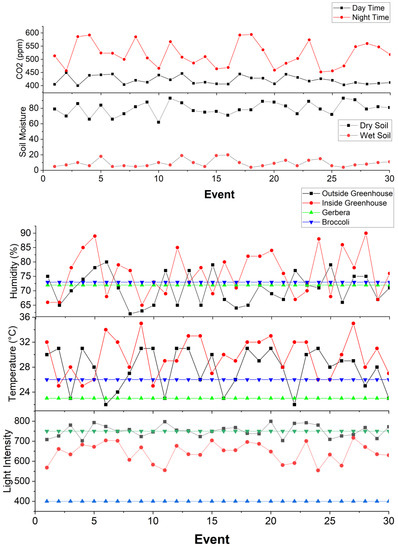

The greenhouse doors/windows could also be rolled up/down depending on the soil moisture conditions. The plant photosynthesis process requires higher CO2 concentration and water level in the evenings than during the day; with these two sources of energy, the photosynthesis method keeps the plant cool and encourages rapid growth. Because the greenhouse absorbs CO2 from day to night, it maintains a maximum CO2 level at night; this was confirmed after completing a CO2 concentration level experiment in a greenhouse, as illustrated in Figure 11. As a result, as seen in Figure 11, the CO2 level decreased during the day.

Figure 11.

Sensor parameter representation relative to outside and inside the greenhouse for two crops, Gerbera and Broccoli.

Because too much water can induce a fungal infection in the plant and too little water can cause the plant to grow dry or even die, the amount of water in the soil is critical. As a result, the amount of water required by the plant is crucial. Plants need more water with CO2 during the night for photosynthesis. When the soil moisture sensor gave a negative value, the plants were entirely covered in water, as shown in Figure 11. The greenhouse windows/doors closed automatically using a DC motor. The positive value indicated that the soil was dry and had to be re-wetted, as shown in Figure 11. Temperature is one of the most critical parameters in a greenhouse; it should be kept as high as feasible. Blooming, fruiting, photosynthesis, seed germination, and other processes are all aided by warmth. Consequently, compared with the temperature and relative humidity range outside the greenhouse, the humidity and temperature range within the greenhouse were preserved to the greatest extent feasible. The numerous colours of sunshine enhance the photosynthetic system, which is among the systems used by plants and is essential for plant development, flowering, and shape.

Consequently, in contrast with the average light penetration outside the greenhouse, a sustainable quantity of light penetration within the greenhouse was maintained. Furthermore, based on the sensor utilized for research and the technology used to design the system, our suggested model was far superior to those proposed in previous work performed by various authors, as described in Table 1.

Table 1.

Comparative analysis table.

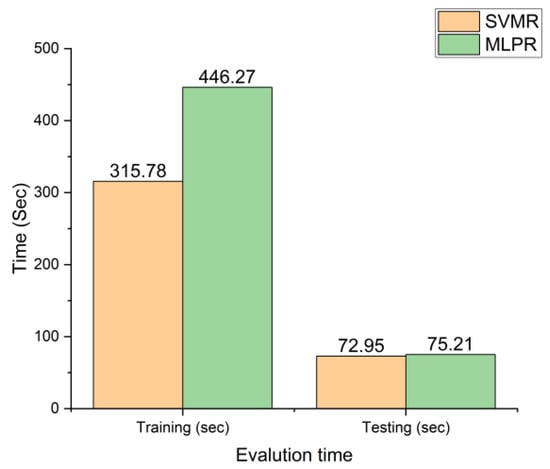

The classification of the analytics and decision-making model was conducted on a laptop with a 2.30 GHz Intel (R) Core (TM) CPU, 8 GB RAM, and Windows 10 (64 bit) operating system, with no other processes running in the background. MATLAB IDE was used to program the intelligent model, statistics, and machine learning toolbox from MATLAB. The RMSE performance metrics were evaluated to check the system’s efficacy. The hyperparameters required to tune the regression modelling for both classifiers are shown in Table 2, along with the final range selected for both classifiers in the last column. The evaluation time with the hyperparameter-tuning phase is shown in Table 3, with a graphical representation in Figure 12.

Table 2.

Hyperparameter tuning for regression modelling.

Table 3.

Evaluation time for training (including hyperparameter optimization) and testing.

Figure 12.

Representation of evaluation time.

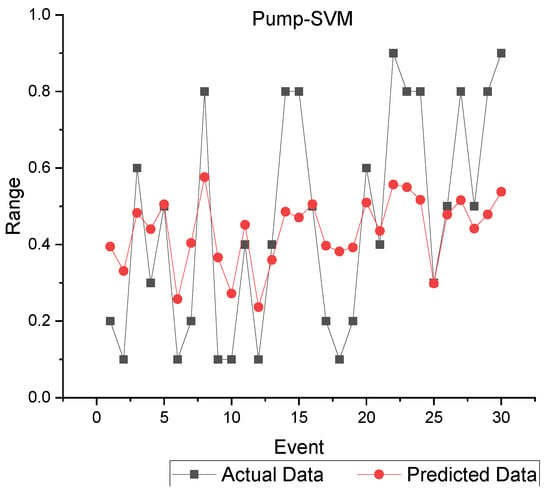

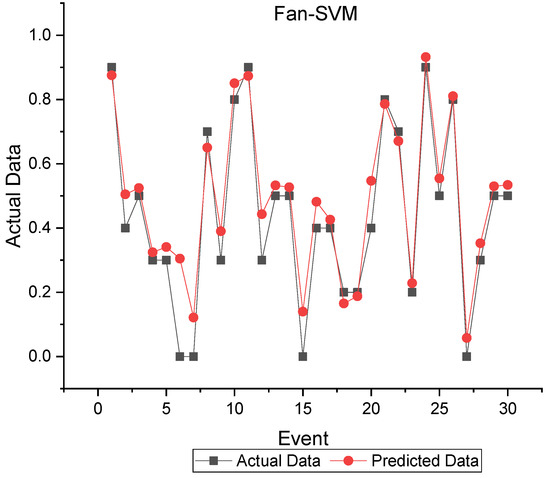

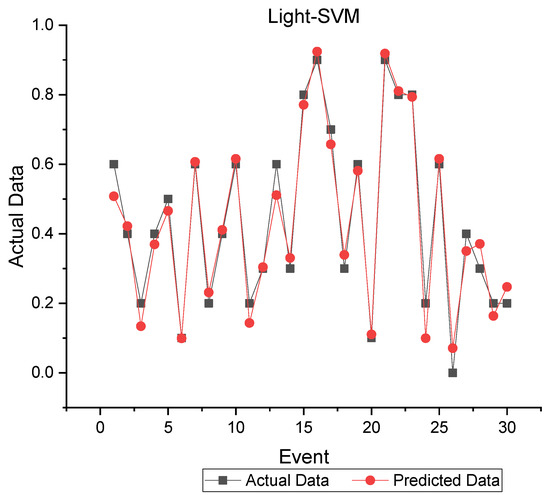

Figure 13, Figure 14 and Figure 15 show the graphs for the actual data and prediction data for pump, fan, and light using support vector machine (SVM) algorithm, respectively.

Figure 13.

Representation of actual and prediction data for pump SVM.

Figure 14.

Representation of actual and prediction data for fan SVM.

Figure 15.

Representation of actual and prediction data for light SVM.

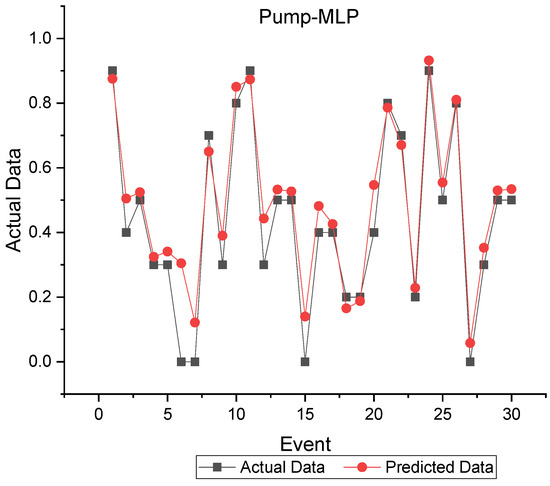

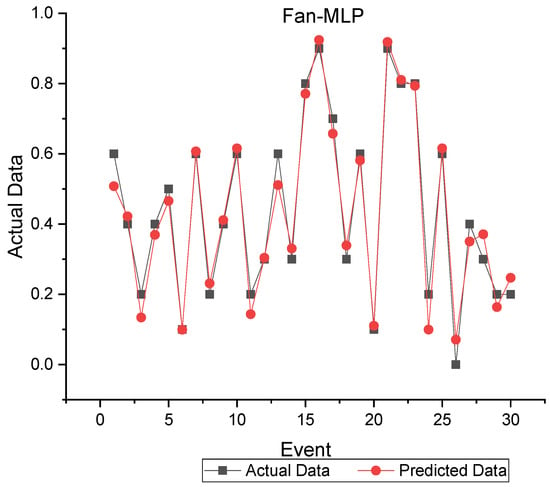

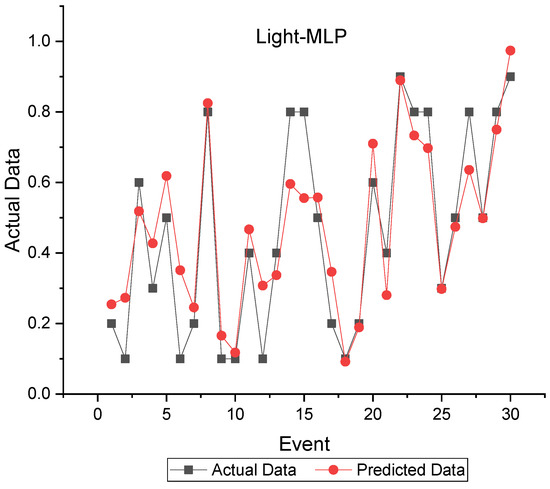

Figure 16, Figure 17 and Figure 18 show the graphs for the actual data and prediction data for pump, fan, and light using the multilayer perceptron (MLP) algorithm, respectively.

Figure 16.

Representation of actual and prediction data for pump MLP.

Figure 17.

Representation of actual and prediction data for fan MLP.

Figure 18.

Representation of actual and prediction data for light MLP.

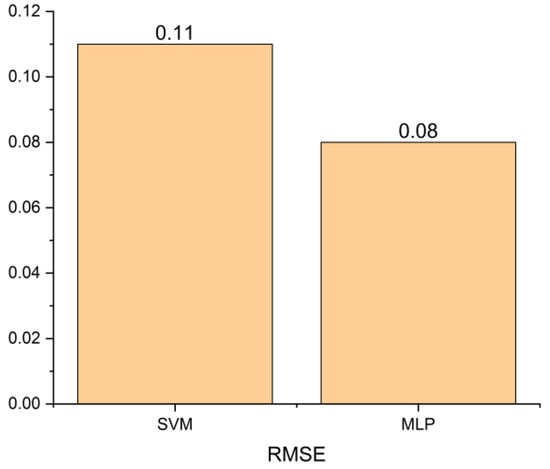

The regression performance of the RMSE parameters for both classifiers is depicted in Table 4. It can be observed from Figure 19 that the MLP regressor had a minimum RMSE value as compared with the SVM classifier for the pump, fan, and light control processes.

Table 4.

RMSE for regression.

Figure 19.

Representation of RMSE value.

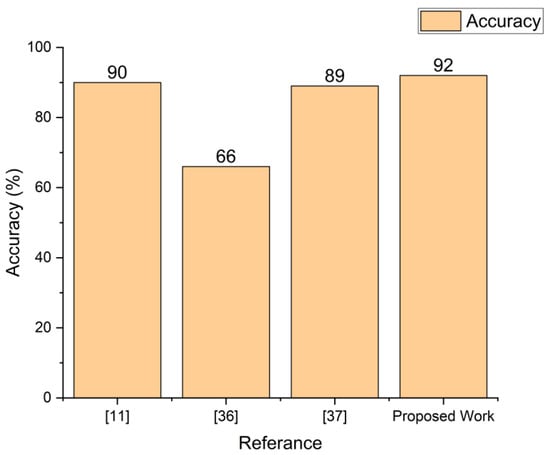

The comparative analysis of various existing models is shown in Table 5. It indicated that the proposed model’s accuracy was better than existing techniques used to build intelligent farming systems (Figure 20).

Table 5.

Comparative analysis of various existing studies.

Figure 20.

Representation of accuracy value in %.

6. Conclusions

This study proposes an automated intelligent greenhouse system that can integrate and deploy Internet of Things concepts and capabilities with an existing design. With real-time sensor data, a framework allows the user to control and monitor real-time data between the device and the fog layer, and vice versa. Furthermore, data are stored in the cloud and are accessible from anywhere. The Internet of Things concept is applied to the system to make growing food easier by streamlining the growing and monitoring processes using a secure cloud. Furthermore, using the Internet of Things addresses one of the most pressing concerns in automation today, maintenance, by offering a platform for monitoring the entire system from the cloud, lowering maintenance costs. As a result, the proposed system uses the IoT to help farmers while simultaneously enhancing the yield by maintaining accurate greenhouse factors such as soil moisture, CO2, temperature, and light. The findings for greenhouse elements such as soil moisture, CO2, temperature, and light for broccoli and gerbera plants are investigated using a graphical depiction based on real-world data collected using the suggested model. On Adafruit IO, equipment is used to keep track of greenhouse elements from afar, including soil moisture, CO2, temperature, and light. Farmers may collect these data using an Adafruit IO Cloud account and an internet connection. Finally, using regression-based supervised machine learning algorithms, the performance of the innovative greenhouse system is evaluated for intelligent, precise management. However, further work that may be conducted to improve the system includes integrating data analytics or machine learning to develop algorithms to anticipate outcomes; adding more sensor parameters, such as pH, EC, and other soil micronutrient measurement sensors to obtain more accurate data; and assisting the artificial intelligence system in predicting the outcome.

Author Contributions

Conceptualization, A.R. and M.S.; methodology, A.R.; software, P.K.M.; validation, P.K.M., R.S. and T.A.; formal analysis, R.S.; investigation, T.A.; resources, A.R.; data curation, M.S.; writing—original draft preparation, A.R.; writing—review and editing, P.K.M.; supervision, M.S.; project administration, R.S. and T.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ferrag, M.A.; Shu, L.; Yang, X.; Derhab, A.; Maglaras, L. Security and Privacy for Green IoT-Based Agriculture: Review, Blockchain Solutions, and Challenges. IEEE Access 2020, 8, 32031–32053. [Google Scholar] [CrossRef]

- Gong, W.; Zhang, X.; Wang, Y.; Tang, W.; Chen, Y.; Li, D. Review of Intelligent Control Methods for Greenhouse Cluster Systems. In Proceedings of the 2019 International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Atlanta, GA, USA, 14–17 July 2019; pp. 235–239. [Google Scholar] [CrossRef]

- Gupta, M.; Abdelsalam, M.; Khorsandroo, S.; Mittal, S. Security and Privacy in Smart Farming: Challenges and Opportunities. IEEE Access 2020, 8, 34564–34584. [Google Scholar] [CrossRef]

- Navarro, E.; Costa, N.; Pereira, A. A Systematic Review of IoT Solutions for Smart Farming. Sensors 2020, 20, 4231. [Google Scholar] [CrossRef]

- O’Donncha, F.; Grant, J. Precision Aquaculture. IEEE Internet Things Mag. 2019, 2, 26–30. [Google Scholar] [CrossRef]

- Patil, S.M.; Sakkaravarthi, R. Internet of things based smart agriculture system using predictive analytics. Asian J. Pharm. Clin. Res. 2017, 10, 148–152. [Google Scholar] [CrossRef]

- Aleotti, J.; Amoretti, M.; Nicoli, A.; Caselli, S. A Smart Precision-Agriculture Platform for Linear Irrigation Systems. In Proceedings of the 2018 26th International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split, Croatia, 13–15 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Brunelli, D.; Albanese, A.; D’Acunto, D.; Nardello, M. Energy Neutral Machine Learning Based IoT Device for Pest Detection in Precision Agriculture. IEEE Internet Things Mag. 2019, 2, 10–13. [Google Scholar] [CrossRef]

- Khriji, S.; El Houssaini, D.; Kammoun, I.; Besbes, K.; Kanoun, O. Energy-Efficient Routing Algorithm Based on Localization and Clustering Techniques for Agricultural Applications. IEEE Aerosp. Electron. Syst. Mag. 2019, 34, 56–66. [Google Scholar] [CrossRef]

- Monteleone, S.; de Moraes, E.A.; Maia, R.F. Analysis of the variables that affect the intention to adopt Precision Agriculture for smart water management in Agriculture 4.0 context. In Proceedings of the 2019 Global IoT Summit (GIoTS), Aarhus, Denmark, 17–21 June 2019; pp. 1–6. [Google Scholar]

- Pandey, A.K.; Chauhan, M. IOT Based Smart Polyhouse System using Data Analysis. In Proceedings of the 2019 International Conference on Issues and Challenges in Intelligent Computing Techniques (ICICT), Ghaziabad, India, 27–28 September 2019; Vloume 1, pp. 1–5. [Google Scholar] [CrossRef]

- Rajeswari, S.; Suthendran, K.; Rajakumar, K. A smart agricultural model by integrating IoT, mobile and cloud-based big data analytics. In Proceedings of the International Conference on Intelligent Computing and Control (I2C2), Coimbatore, India, 23–24 June 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Shafi, U.; Mumtaz, R.; Iqbal, N.; Zaidi, S.M.H.; Hussain, I.; Mahmood, Z. A Multi-Modal Approach for Crop Health Mapping Using Low Altitude Remote Sensing, Internet of Things (IoT) and Machine Learning. IEEE Access 2020, 8, 112708–112724. [Google Scholar] [CrossRef]

- Stamatescu, G.; Dragana, C.; Stamatescu, I.; Ichim, L.; Popescu, D. IoT-Enabled Distributed Data Processing for Precision Agriculture. In Proceedings of the 2019 27th Mediterranean Conference on Control and Automation (MED), Akko, Israel, 1–4 July 2019; pp. 286–291. [Google Scholar] [CrossRef]

- Stewart, J.; Stewart, R.; Kennedy, S. Internet of Things—Propagation modelling for precision agriculture applications. In Proceedings of the Wireless Telecommunications Symposium, Chicago, IL, USA, 26–28 April 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Sun, H.; Zhu, Q.; Ren, J.; Barclay, D.; Thomson, W. Combining Image Analysis and Smart Data Mining for Precision Agriculture in Livestock Farming. In Proceedings of the Combining Image Analysis and Smart Data Mining for Precision Agriculture in Livestock Farming, Exeter, UK, 21–23 June 2017; pp. 1065–1069. [Google Scholar] [CrossRef]

- Temprilho, A.; Nobrega, L.; Pedreiras, P.; Goncalves, P.; Silva, S. M2M Communication Stack for Intelligent Farming. In Proceedings of the 2018 Global Internet of Things Summit (GIoTS), Bilbao, Spain, 4–7 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Yashaswini, L.S.; Vani, H.U.; Sinchana, H.N.; Kumar, N. Smart automated irrigation system with disease prediction. In Proceedings of the 2017 IEEE International Conference on Power, Control, Signals and Instrumentation Engineering (ICPCSI), Chennai, India, 21–22 September 2017; pp. 422–427. [Google Scholar] [CrossRef]

- Zamora-Izquierdo, M.A.; Santa, J.; Martínez, J.A.; Martínez, V.; Skarmeta, A.F. Smart farming IoT platform based on edge and cloud computing. Biosyst. Eng. 2018, 177, 4–17. [Google Scholar] [CrossRef]

- Subahi, A.F.; Bouazza, K.E. An Intelligent IoT-Based System Design for Controlling and Monitoring Greenhouse Temperature. IEEE Access 2020, 8, 125488–125500. [Google Scholar] [CrossRef]

- Kour, V.P.; Arora, S. Recent Developments of the Internet of Things in Agriculture: A Survey. IEEE Access 2020, 8, 129924–129957. [Google Scholar] [CrossRef]

- Carrasquilla-Batista, A.; Chacon-Rodriguez, A. Standalone Fuzzy Logic Controller Applied to Greenhouse Horticulture Using Internet of Things. In Proceedings of the 2019 7th International Engineering, Sciences and Technology Conference (IESTEC), Panama, Panama, 9–11 October 2019; pp. 574–579. [Google Scholar] [CrossRef]

- Angadi, S.; Katagall, R. Agrivigilance: A Security System For Intrusion Detection In Agriculture Using Raspberry Pi And Opencv. Int. J. Sci. Technol. Res. 2019, 8, 1260–1267. [Google Scholar]

- Codeluppi, G.; Cilfone, A.; Davoli, L.; Ferrari, G. VegIoT Garden: A modular IoT Management Platform for Urban Vegetable Gardens. In Proceedings of the 2019 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Portici, Italy, 24–26 October 2019; pp. 121–126. [Google Scholar] [CrossRef]

- Ahmed, N.; De, D.; Hussain, I. Internet of Things (IoT) for Smart Precision Agriculture and Farming in Rural Areas. IEEE Internet Things J. 2018, 5, 4890–4899. [Google Scholar] [CrossRef]

- Araby, A.A.; Elhameed, M.M.A.; Magdy, N.M.; Said, L.A.; Abdelaal, N.; Allah, Y.T.A.; Darweesh, M.S.; Fahim, M.A.; Mostafa, H. Smart IoT Monitoring System for Agriculture with Predictive Analysis. In Proceedings of the 2019 8th International Conference on Modern Circuits and Systems Technologies, Thessaloniki, Greece, 13–15 May 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Arakeri, M.P.; Kumar, B.P.V.; Barsaiya, S.; Sairam, H.V. Computer vision based robotic weed control system for precision agriculture. In Proceedings of the 2017 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Udupi, India, 13–16 September 2017; pp. 1201–1205. [Google Scholar] [CrossRef]

- Baghrous, M.; Ezzouhairi, A.; Benamar, N. Towards Autonomous Farms Based on Fog Computing. In Proceedings of the 2019 2nd IEEE Middle East and North Africa COMMunications Conference (MENACOMM), Manama, Bahrain, 19–21 November 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Belista, F.C.L.; Go, M.P.C.; Lucenara, L.L.; Policarpio, C.J.G.; Tan, X.J.M.; Baldovino, R.G. A Smart Aeroponic Tailored for IoT Vertical Agriculture using Network Connected Modular Environmental Chambers. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Chen, W.-L.; Lin, Y.-B.; Ng, F.-L.; Liu, C.-Y.; Lin, Y.-W. RiceTalk: Rice Blast Detection Using Internet of Things and Artificial Intelligence Technologies. IEEE Internet Things J. 2019, 7, 1001–1010. [Google Scholar] [CrossRef]

- Chen, W.-L.; Lin, Y.-B.; Lin, Y.-W.; Chen, R.; Liao, J.-K.; Ng, F.-L.; Chan, Y.-Y.; Liu, Y.-C.; Wang, C.-C.; Chiu, C.-H.; et al. AgriTalk: IoT for Precision Soil Farming of Turmeric Cultivation. IEEE Internet Things J. 2019, 6, 5209–5223. [Google Scholar] [CrossRef]

- Farhan, L.; Kharel, R.; Kaiwartya, O.; Quiroz-Castellanos, M.; Raza, U.; Teay, S.H. LQOR: Link Quality-Oriented Route Selection on Internet of Things Networks for Green Computing. In Proceedings of the 2018 11th International Symposium on Communication Systems, Networks & Digital Signal Processing (CSNDSP), Budapest, Hungary, 18–20 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Foughali, K.; Fathallah, K.; Frihida, A. A Cloud-IOT Based Decision Support System for Potato Pest Prevention. Procedia Comput. Sci. 2019, 160, 616–623. [Google Scholar] [CrossRef]

- Gnanaraj, A.A.; Jayanthi, J.G. An Application Framework for IoTs Enabled Smart Agriculture Waste Recycle Management System. In Proceedings of the 2017 World Congress on Computing and Communication Technologies (WCCCT), Budapest, Hungary, 18–20 July 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Gutierrez, S.; Martinez, I.; Varona, J.; Cardona, M.; Espinosa, R. Smart Mobile LoRa Agriculture System based on Internet of Things. In Proceedings of the 2019 IEEE 39th Central America and Panama Convention (CONCAPAN XXXIX), Guatemala City, Guatemala, 20–22 November 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Hirsch, C.; Bartocci, E.; Grosu, R. Capacitive Soil Moisture Sensor Node for IoT in Agriculture and Home. In Proceedings of the 2019 IEEE 23rd International Symposium on Consumer Technologies (ISCT), Ancona, Italy, 19–21 June 2019; pp. 97–102. [Google Scholar] [CrossRef]

- Horng, G.-J.; Liu, M.-X.; Chen, C.-C. The Smart Image Recognition Mechanism for Crop Harvesting System in Intelligent Agriculture. IEEE Sensors J. 2019, 20, 2766–2781. [Google Scholar] [CrossRef]

- Pooja, S.; Uday, D.V.; Nagesh, U.B.; Talekar, S.G. Application of MQTT protocol for real time weather monitoring and precision farming. In Proceedings of the 2017 International Conference on Electrical, Electronics, Communication, Computer, and Optimization Techniques (ICEECCOT), Mysuru, India, 15–16 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Prabha, R.; Sinitambirivoutin, E.; Passelaigue, F.; Ramesh, M.V. Design and Development of an IoT Based Smart Irrigation and Fertilization System for Chilli Farming. In Proceedings of the 2018 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 22–24 March 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Sadowski, S.; Spachos, P. Solar-Powered Smart Agricultural Monitoring System Using Internet of Things Devices. In Proceedings of the 2018 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 22–24 March 2018; pp. 18–23. [Google Scholar] [CrossRef]

- Sarangi, S.; Naik, V.; Choudhury, S.B.; Jain, P.; Kosgi, V.; Sharma, R.; Bhatt, P.; Srinivasu, P. An Affordable IoT Edge Platform for Digital Farming in Developing Regions. In Proceedings of the 2019 11th International Conference on Communication Systems & Networks (COMSNETS), Bengaluru, India, 7–11 January 2019; pp. 556–558. [Google Scholar] [CrossRef]

- Sureephong, P.; Wiangnak, P.; Wicha, S. The comparison of soil sensors for integrated creation of IOT-based Wetting front detector (WFD) with an efficient irrigation system to support precision farming. In Proceedings of the 2017 International Conference on Digital Arts, Media and Technology (ICDAMT), Chiang Mai, Thailand, 1–4 March 2017; pp. 132–135. [Google Scholar] [CrossRef]

- Khalaf, O.I.; Ogudo, K.A.; Singh, M. A fuzzy-based optimization technique for the energy and spectrum efficiencies trade-off in cognitive radio-enabled 5G network. Symmetry 2021, 13, 47. [Google Scholar] [CrossRef]

- Walia, G.S.; Singh, P.; Singh, M.; Abouhawwash, M.; Park, H.J.; Kang, B.G.; Mahajan, S.; Pandit, A.K. Three-Dimensional Optimum Node Localiza-tion in Dynamic Wireless Sensor Networks. CMC-Comput. Mater. Contin. 2022, 70, 305–321. [Google Scholar] [CrossRef]

- Singh, M.; Kumar, M.; Malhotra, J. Energy efficient cognitive body area network (CBAN) using lookup table and energy harvesting. J. Intell. Fuzzy Syst. 2018, 35, 1253–1265. [Google Scholar] [CrossRef]

- Hassan, M.; Singh, M.; Hamid, K. Survey on NOMA and Spectrum Sharing Techniques in 5G. In Proceedings of the 2021 IEEE International Conference on Smart Information Systems and Technologies (SIST), Nur-Sultan, Kazakhstan, 28–30 April 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Rokade, A.; Singh, M. Analysis of Precise Green House Management System using Machine Learning based Internet of Things (IoT) for Smart Farming. In Proceedings of the In Proceedings of the 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 7–9 October 2021; pp. 21–28. [Google Scholar] [CrossRef]

- Kadu, A.; Singh, M. Comparative Analysis of e-Health Care Telemedicine System Based on Internet of Medical Things and Artificial Intelligence. In Proceedings of the 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 7–9 October 2021; pp. 1768–1775. [Google Scholar] [CrossRef]

- Hassan, M.; Singh, M.; Hamid, K. Impact Of Power And Bandwidth On The Capacity Rate And Number Of Users In Sc-Noma. Harbin Gongye Daxue Xuebao/J. Harbin Inst. Technol. 2021, 53, 118–124. [Google Scholar]

- Hassan, M.; Singh, M.; Hamid, K. Overview of Cognitive Radio Networks. In Journal of Physics: Conference Series; IOP Publishing: Dhanbad, India, 2021; Volume 1831. [Google Scholar]

- Roy, S.K.; Singh, M.; Sharma, K.K.; Bhargava, C.; Singh, B.P. Mathematical Modelling of Simple Passive RC Filters Using Floating Admittance Technique. In Proceedings of the 2020 IEEE International Conference for Innovation in Technology (INOCON), Bangluru, India, 6–8 November 2020; pp. 1–6. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).