1. Introduction

Pile foundations, as load-bearing elements supporting superstructures, often display strong load-bearing capacity under various challenging engineering and geological circumstances. Pile fracture, expansion, shrinkage, segregation, and other problems are frequently brought on by subpar construction technology, a complex geological environment, a limited level of construction personnel, and other factors. This makes pile foundation engineering a project that is difficult to control. These issues are directly connected to people’s lives and property safety. Foundation pile quality checking is a crucial step in reducing engineering hazards. After years of development, the low strain reflection wave method has become an efficient tool for engineering the examination of pile integrity due to its straightforward equipment, lightweight, low cost, and accurate and dependable test findings [

1].

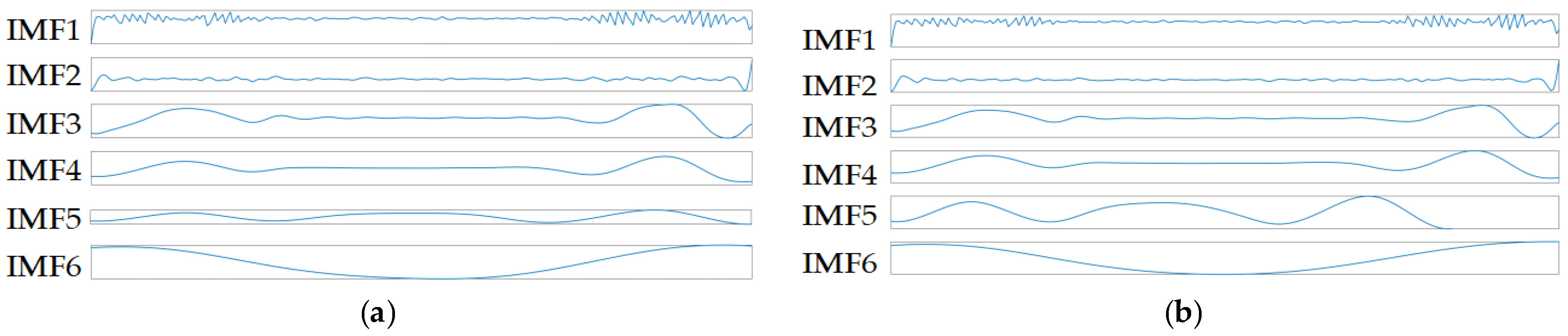

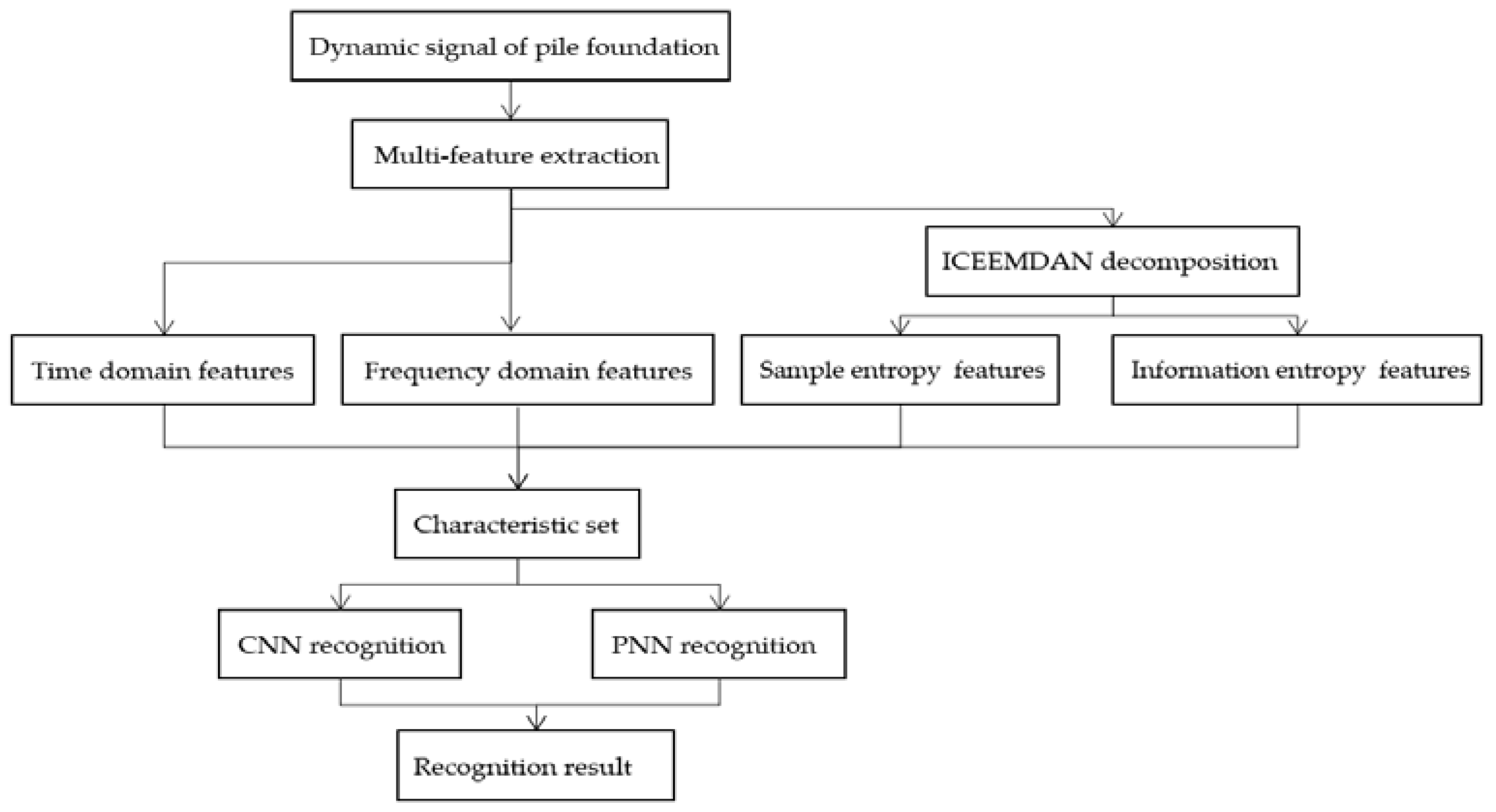

The low-strain reflection approach involves detecting and analyzing stress waves using sensors. The reflection and transmission of the stress waves occur when the impedance of the cross section changes during propagation. The integrity of the foundation pile is judged by analyzing and processing the stress reflected wave signal. Signal processing and signal feature extraction are essential to determine the accuracy of subsequent pile foundation detection classification and recognition. Wavelet analysis is very effective for the local feature analysis of the signal [

2], but the nature of the signal in other time and frequency domains is not fully considered. Moreover, the wavelet transform is very dependent on the wavelet basis function and the decomposition level, and there is a great deal of artificiality in selecting the basis function. Many scholars have selected the wavelet basis function with a stroke [

3,

4,

5]. The same signal uses different wavelet basis functions to decompose. It will have different effects, which directly affect the discriminant effect of the dynamic signal and result in a reduction in the method’s practicality. Several Intrinsic Mode Functions (IMF) are directly separated from the signal using the Empirical Mode Decomposition (EMD) technique [

6]. The fact that each IMF is orthogonal to the others is essential. Nevertheless, the only drawback is that modal aliasing occurs quickly in decomposition. Ensemble Empirical Mode Decomposition (EEMD) is an excellent solution to the phenomenon of mode mixing. In 2009, Zhaohua Wu et al. [

7] from Florida State University added white noise to EMD. However, it is necessary to set the white noise amplitude and the number of iterations artificially, which results in significant reconstruction errors and poor decomposition completeness. To overcome the reconstruction inaccuracy, Torres et al. [

8] developed an entire ensemble empirical mode decomposition with adaptive noise (CEEMDAN). White noise then embraces the signal using the original EEMD approach, effectively reducing the model complexity. However, CEEMDAN still produces a small number of faulty components and residual noise in the decomposition process. Therefore, Colominas et al. [

9] proposed an Improved CEEMDAN (ICEEMDAN) in 2014. Based on CEEMDAN, the signal is continually divided by adding Gaussian white noise, and the resulting signal is averaged. In contrast to the CEEMDAN signal decomposition technique, this method dramatically inhibits the phenomenon of faulty components in signal decomposition and effectively improves the efficiency of signal decomposition.

All of the above signal processing methods could successfully capture the signal’s features, and some professors have researched the extraction of eigenvalues. Cai, Q.Y. [

10] used multi-resolution analysis to capture the feature vector representing the power spectrum’s power composition fed into a neural network to identify the pile defect. To obtain the energy mean and power spectrum in the frequency range as feature vectors to input into the neural network, Bai, Q.L. [

11] employed wavelet transform. Jiang, X.L. [

12] selected Daubechies4 wavelet 5-layer multi-resolution analysis to extract the characteristic frequency spectrum amplitude. In 2015, Kang, W.X. and Li, J.D. [

13] of the Harbin Institute of Technology proposed for the first time that quantized information entropy could be used to detect stress wave signals, and the quantized information entropy was proved to be very comprehensive after experiments. Li, J.D. [

14] built a feature vector using quantized information entropy, energy, and variance utilizing the wavelet package calculation. The results revealed that the feature is helpful for stress wave signal singularity detection. From the above studies, it can be concluded that in the processing of foundation pile dynamic measurement signals, the feature values extracted are all from the same dimension, mostly variance, power spectrum means, and information entropy, which does not differentiate enough between defects. However, the defect information in the foundation pile detection signal under layered soil conditions is very complex and rich. It is often insufficient to characterize the complex signal with only one-dimensional features, so a more in-depth study is needed in extracted features.

Machine learning is frequently utilized in defect recognition as science and technology advance. Support vector machines are well suited to the learning method for small sample situations, cleverly solving the dimensionality problem and avoiding dimensional disasters. Kang, W.X. [

15], Li, Z.B. [

16], and Xue, Z.J. [

17] used support vector machines to identify the type and degree of foundation pile defects based on the minor sample nature of the test data, which improved the accuracy of the classification of foundation pile defects. Deep learning is also advancing quickly, and neural networks, with their strong self-learning and nonlinear mapping capabilities, are particularly suitable for recognizing complex signals. Good results have been achieved in recognizing foundation pile defects [

18,

19].

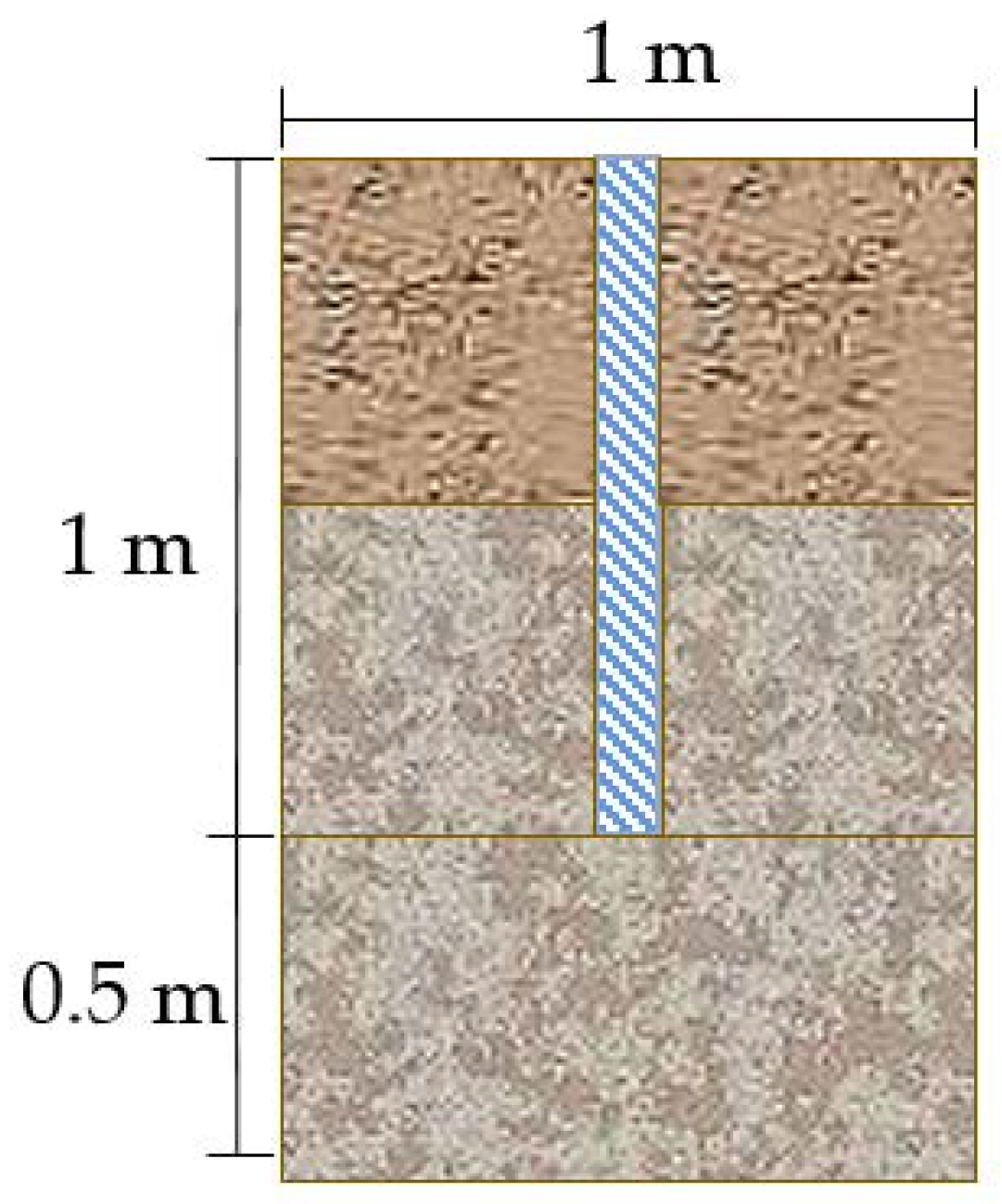

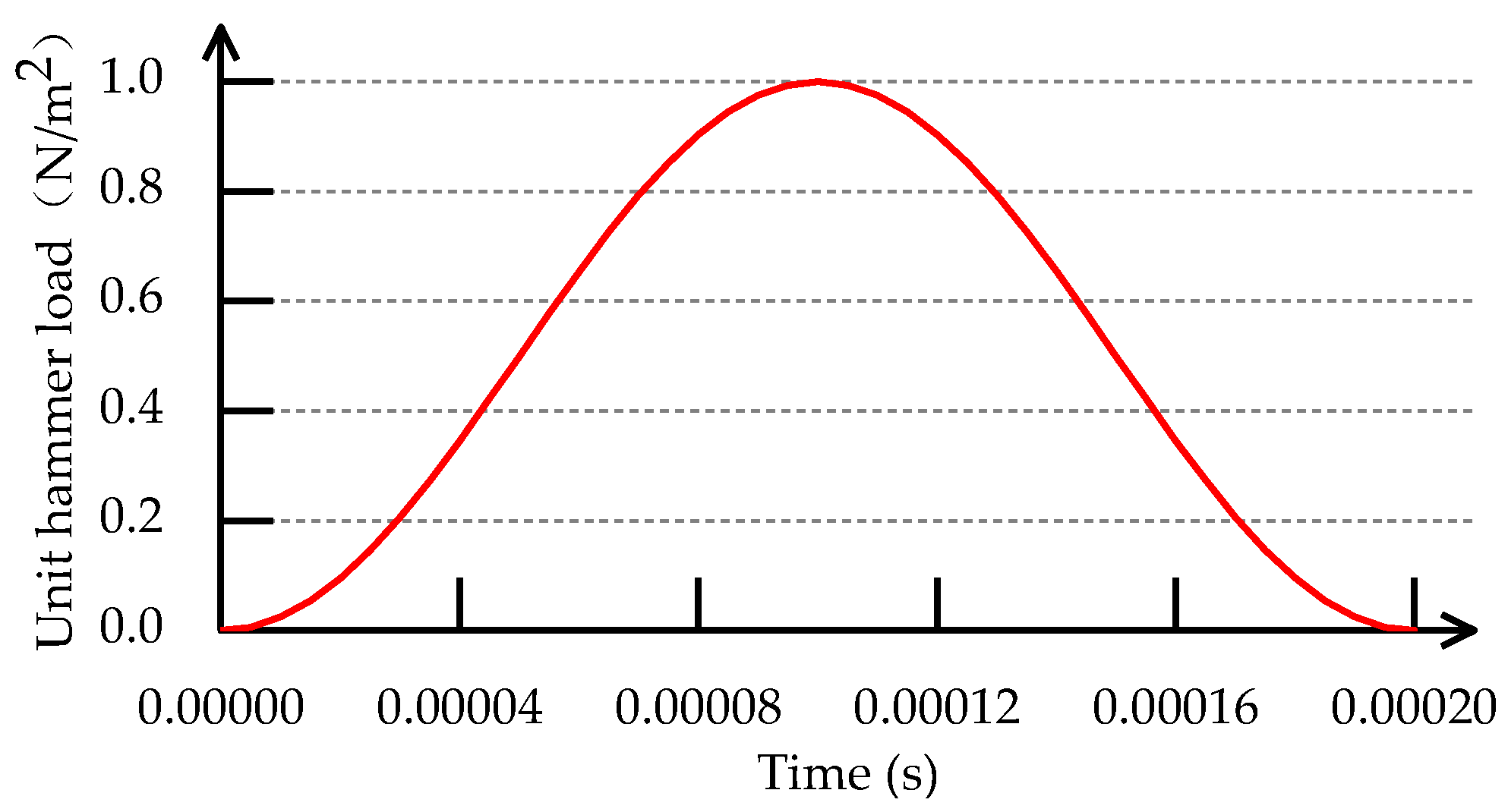

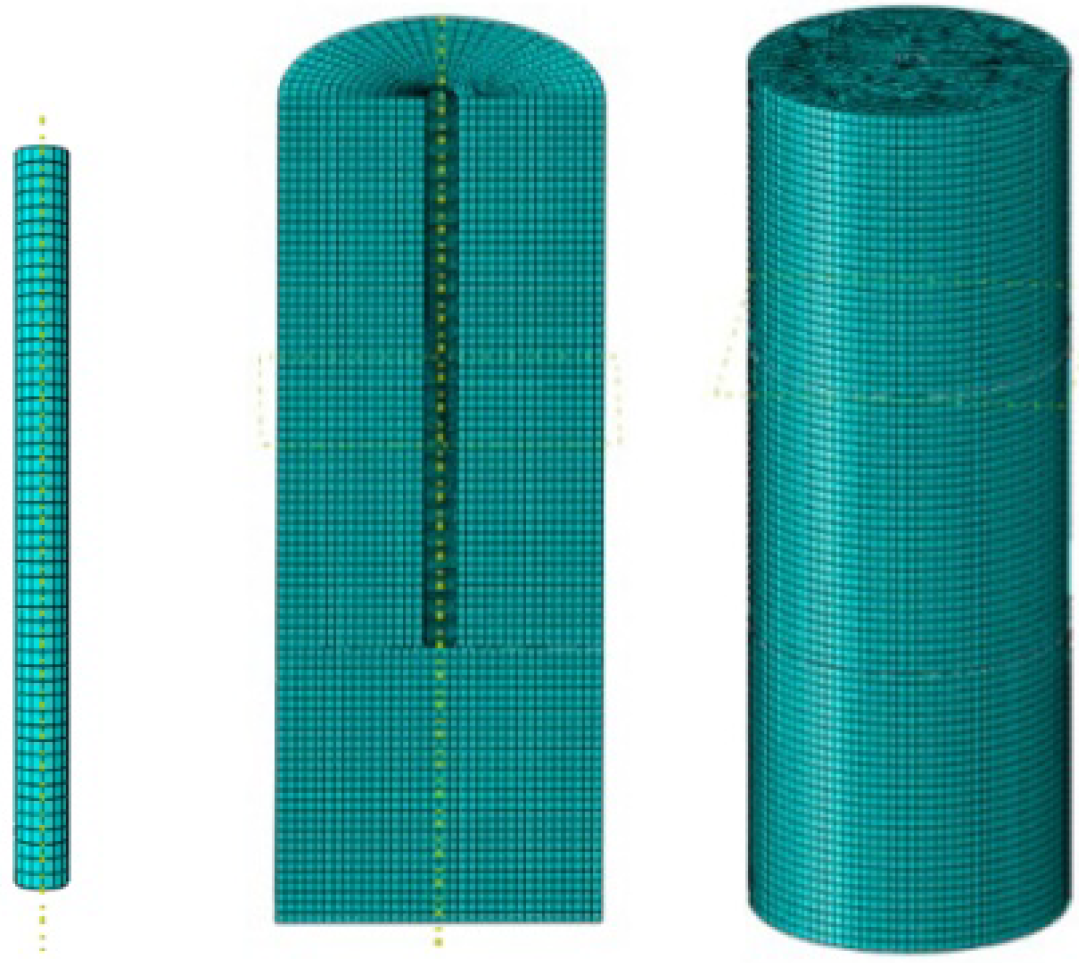

It is challenging to show during foundation pile integrity testing when the engineering properties of the soil on the pile side change significantly whether the characteristic signals on the curve are brought on by pile defects or geological changes simply based on the reflected wave curve in the field [

20]. To avoid the interference of soil formation on the foundation pile integrity and improve the inspectors’ efficiency, this paper analyses the changing pattern and characteristics of the dynamic measurement curve of the pile body with common defects by establishing a three-dimensional finite element model and verifies the numerical simulation using experiments. The article combines multi-feature extraction and a convolutional neural network to achieve an accuracy of 97.8% in recognizing foundation pile defects, which realizes the automated detection of foundation pile defects.

The quality problem of foundation pile engineering will involve various aspects. Consequently, the state places a high value on the quality inspection department; yet, due to testing expenses and project progress limitations, the quality inspection department usually uses random inspections to control the quality of the project. Random inspection results tend to miss some defective foundation piles, and the inspection results lack impartiality. It is essential to research and explore methods for testing foundation piles at a lower cost and a higher level of inspection. Therefore, this research has good theoretical and practical application value and is highly important in terms of both societal and economic rewards.

3. Results and Discussion

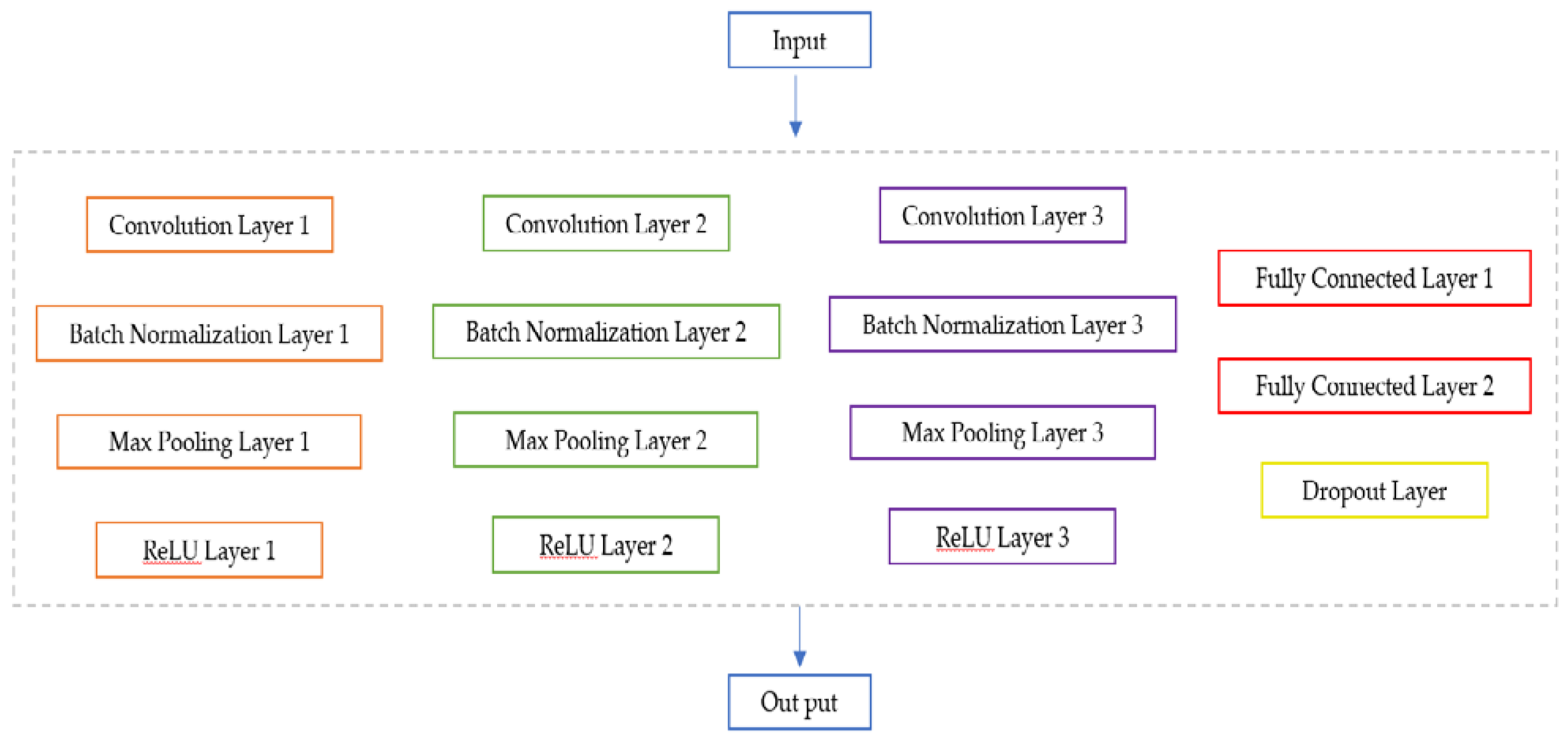

3.1. CNN Pile Defect Recognition

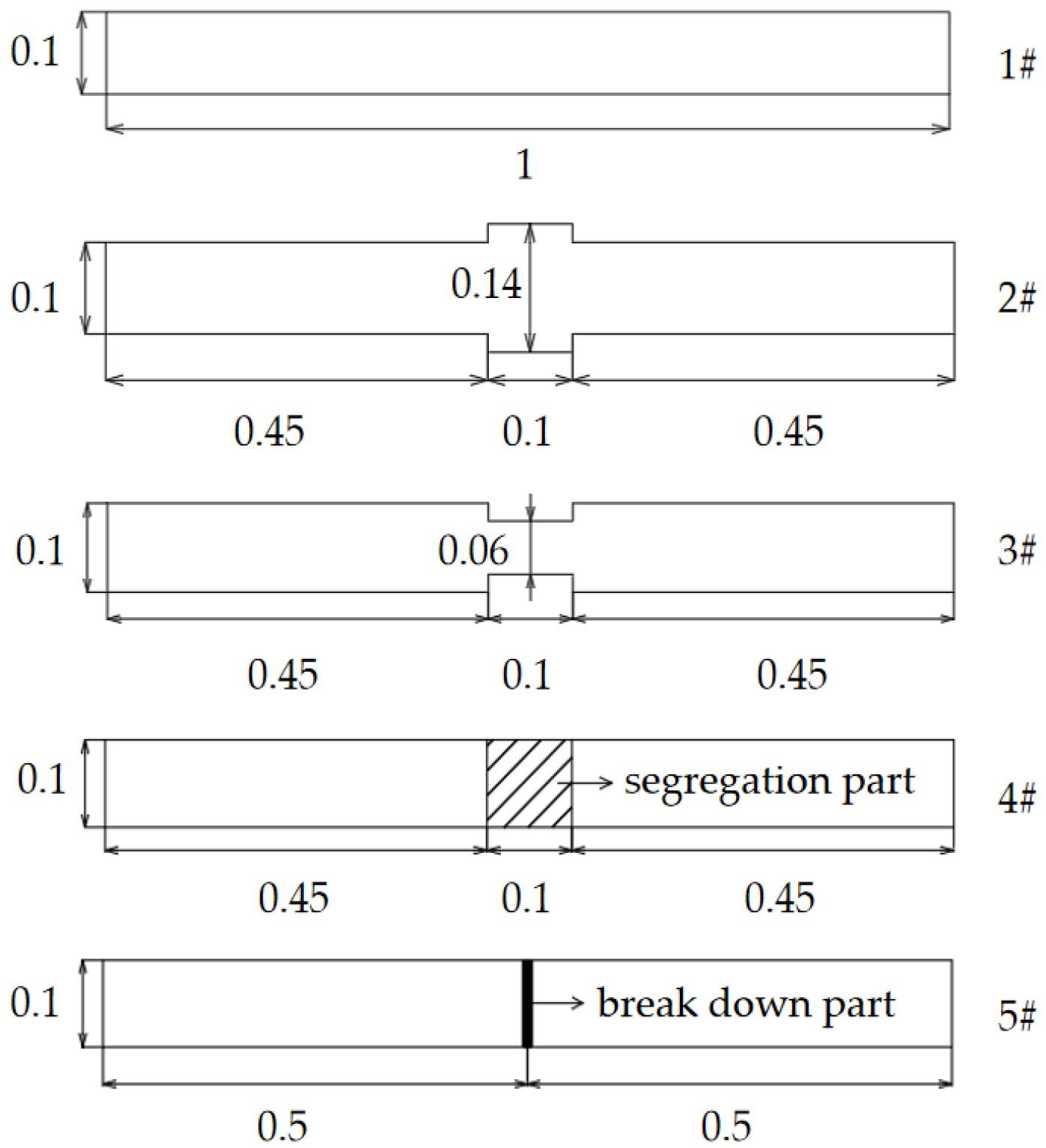

The ABAQUS finite element simulation result is the source of sample data for the identification model. With a training set of 9 × 100 samples, a validation set of 9 × 40 samples, and a test set of 9 × 20 samples, the foundation pile dynamic measurements were taken as the data set by varying the defect size, defect location, and soil thickness under the formation soil conditions of stiffer soils above and below the pile perimeter, respectively.

We define 1, 2, 3, 4, and 5 to mean intact pile, expanded diameter pile, reduced diameter pile, separated pile, and broken pile, respectively. g denotes layered soil, h denotes layered soil boundary in the upper part of the defect, and i layered soil boundary in the lower part of the defect. The labels for the classification categories are shown in

Table 9. After that, the CNN models were used to identify the categories. In

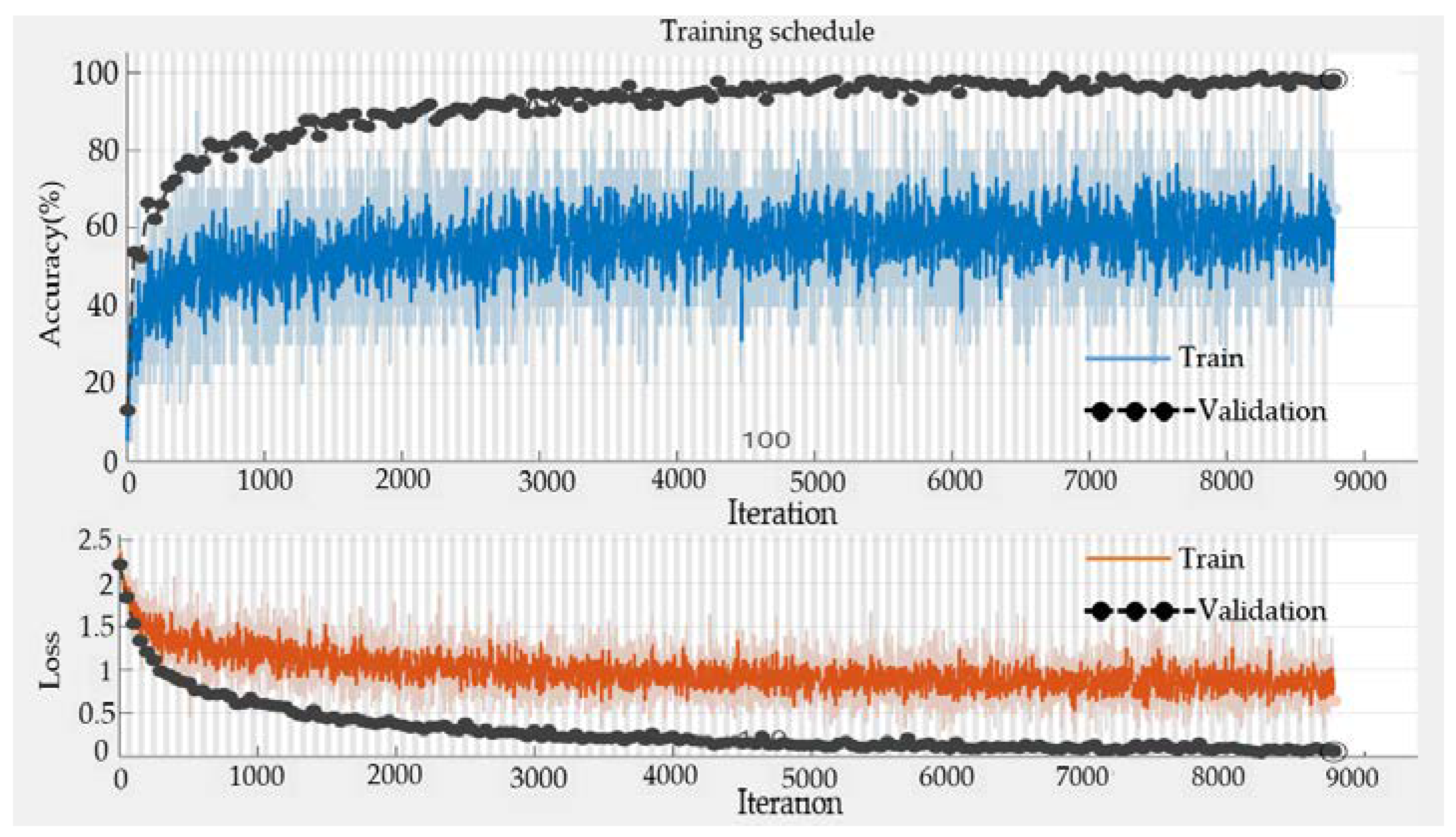

Figure 14, the training schedule is displayed.

The training results of the CNN revealed that the accuracies of the training base were 98.67%, and the validation set was 98.33%.

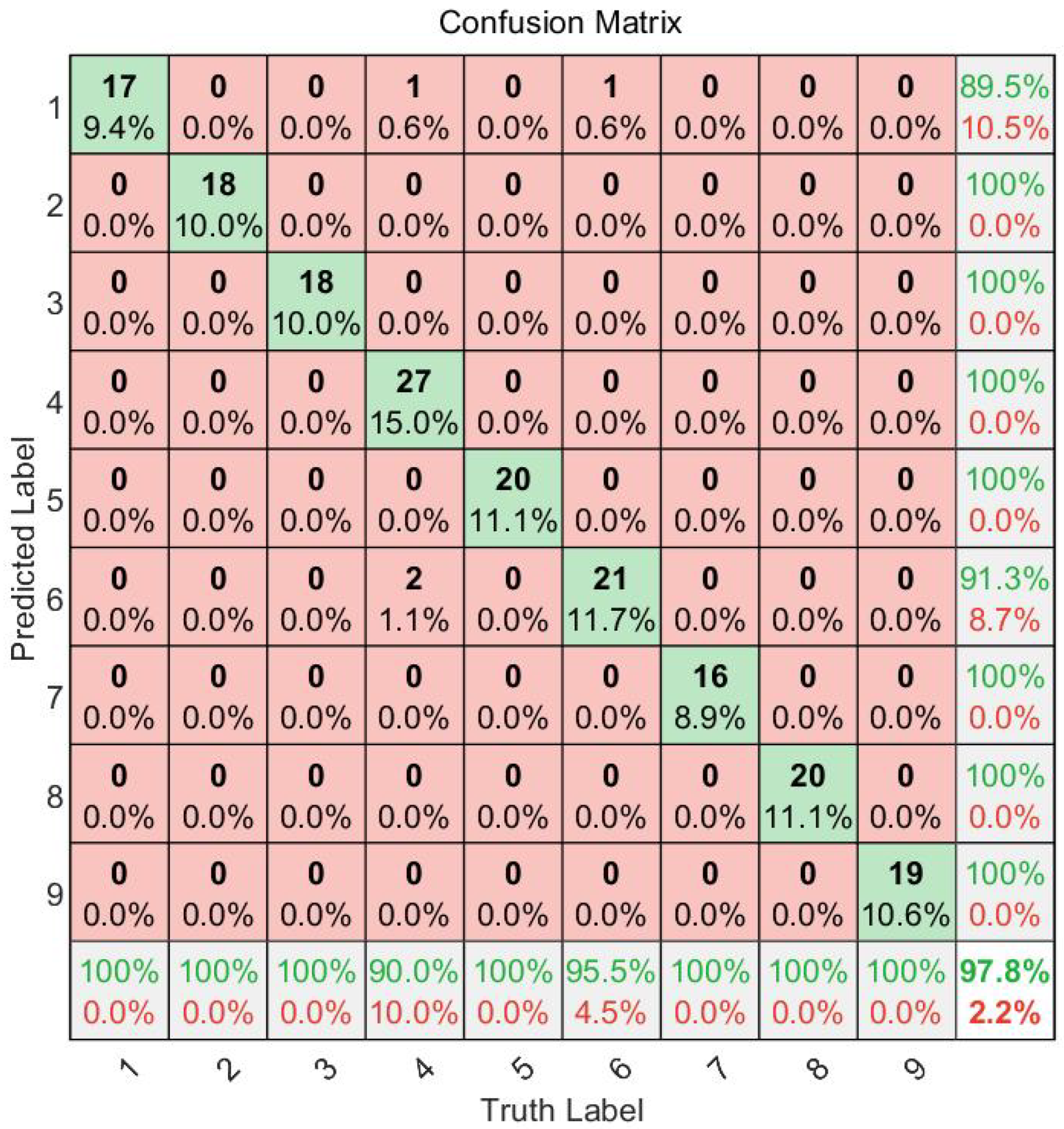

The CNN prediction findings in this research are presented using a mixed matrix. The pink box in the confusion matrix depicts the proportion of predictions that deviate from the actual values. The green diagonal line indicates that the expected results match the test labels.

Figure 15 demonstrates that such a CNN recognition model has an accuracy rate of 97.8%, with lower identification rates of 90% and 95.5% for classes 4 and 6, respectively. The remaining categories all received 100% recognition. To avoid the impact of soil formation on the dynamic testing curve of layered soil, the model can accurately identify the type of faults and the location of layered soil.

3.2. CNN Recognition Results for Different Domain Features

This paper uses this classifier for comparative analysis from the perspective of feature composition, respectively, with the division of the sample dataset remaining unchanged, to further illustrate the accuracy of multi-domain features combined with CNN for recognizing foundation pile defects.

Table 10 displays the accuracy results for CNN model recognition in the time, frequency, and time–frequency domains, respectively.

The analysis of

Table 10 reveals that the test accuracy achieved by the suggested method is 97.78%, which is significantly higher than any single-domain characteristics. This suggests that multi-domain features offer more excellent feature information in CNN recognition than single-domain features.

3.3. Probabilistic Neural Network (PNN) Pile defect Identification

A feed-forward neural network constructed from radial basis function networks, the Probabilistic Neural Network classifier (PNN classifier), was used in an experiment comparison to demonstrate the superiority of the CNN model further. It is a supervised network classifier that uses Bayes classification rules and is based on the idea of probabilistic statistics. This study used the Parzen window function density estimation approach to estimate the conditional probability when performing classification pattern recognition. The Parzen method yields the probability density function estimation equation shown below.

In the formula, Xai is the ith training vector of the defect pattern, m is the training sample quantity of the defective pattern, and the δ smoothing parameter.

The construction process of the PNN recognition model is as follows.

Step 1: We created a training set consisting of 9 × 120 data samples and a test set consisting of 9 × 140 data samples obtained from numerical simulations.

Step 2: Defective category is the intended result, and existing defective feature data is used as the input to the training samples. After training, a PNN model for defect classification and recognition is obtained from the network.

Step 3: Testing of the network’s performance was performed. Regression simulations were run on the training samples after the connection weights between the neurons in each layer were replaced in the network. The network was successfully trained and could be used to predict the class of unknown samples when the expected output of the training samples matched the simulated output of the PNN network.

Step 4: Classification prediction of unknown defective sample data using the constructed PNN model.

The category names used in this experiment adhere to the plan described in

Section 3.1.

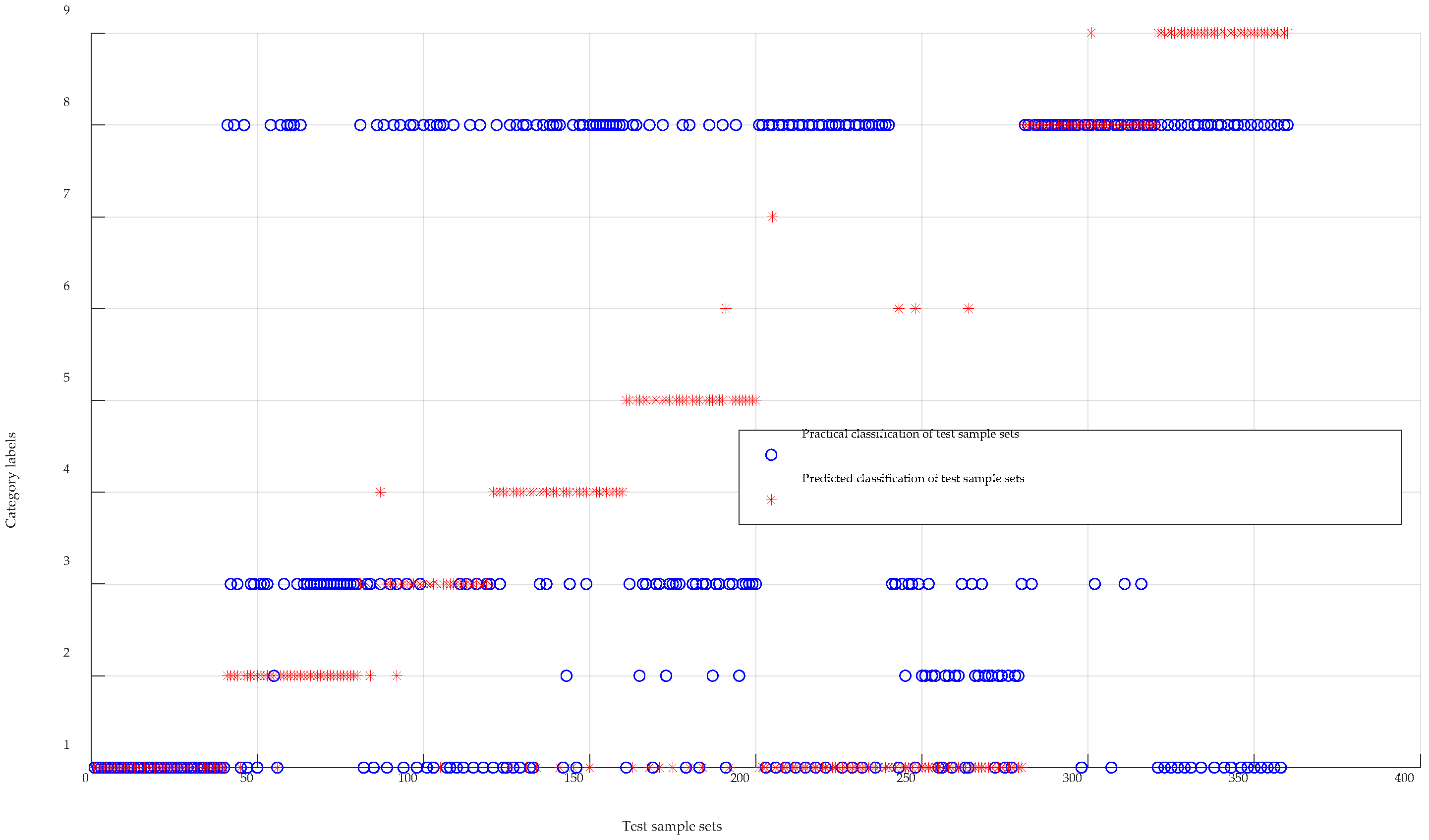

Figure 16 displays the PNN classification findings, while

Table 11 displays the precise classification accuracies. In

Figure 16, the symbols ○ and * stand for the actual and expected labels, respectively. When they overlap, the predicted labels match the actual ones. This model’s recognition accuracy was only 28.6%.

4. Conclusions and Future Work

To boost the effectiveness of pile recognition work, this research studies the reflected wave signal characteristics of foundation piles in layered soils using the traditional low-strain reflected wave method. In order to automatically classify and identify pile flaws, the signal is processed to extract feature indicators from three dimensions: time domain, frequency domain, and time–frequency domain. This is done in conjunction with a neural network. The following are the primary conclusions.

- (1)

When the ICEEMDAN technique is utilized to decompose reflected wave signals from foundation piles under paved soil conditions, it lays the foundation for the accuracy of CNN identification. The correlation coefficient criterion filters the valuable components, removing the redundant components.

- (2)

The convolutional neural network was used to classify and identify each group, and the feature sets extracted from the three dimensions were fed into the network with an accuracy of more than 90%, proving the excellent reliability of the CNN model for the detection of the foundation pile problem.

- (3)

When single-domain features for foundation pile recognition were fed into the CNN model, the results were 88.89% for time domain features, 77.22% for frequency domain features, and 86.11% for time–frequency domain features. The accuracy of the multi-feature extraction method in conjunction with CNN is 97.8%. This method has high accuracy and effectively distinguishes the kind of foundation pile when the soil surrounding the pile is stratified, increasing the inspectors’ effectiveness.

Due to the irregular geometries of foundation pile flaws in real projects and the complexity of the geological environment, practical engineering necessitates more advanced detecting tools and data processing approaches. The accuracy of foundation pile identification utilizing the low-strain reflection wave method in layered soils may be significantly improved, and foundation pile flaws in layered soils can be automatically diagnosed in this study. These findings are significant for technical applications and have some theoretical importance. Although this paper’s pile defect identification model achieves good identification results based on supervised learning, the data sample cannot contain all the pile defect data in the project, and the pile defects are unknown. As a result, it is necessary to explore how to achieve high accuracy in the small sample and apply unsupervised learning algorithms in pile defects to improve the theoretical significance and practical value.