Experimental Study on the Mechanical Behaviors of Loess Reinforced with Randomly Distributed Basalt Fiber

Abstract

:1. Introduction

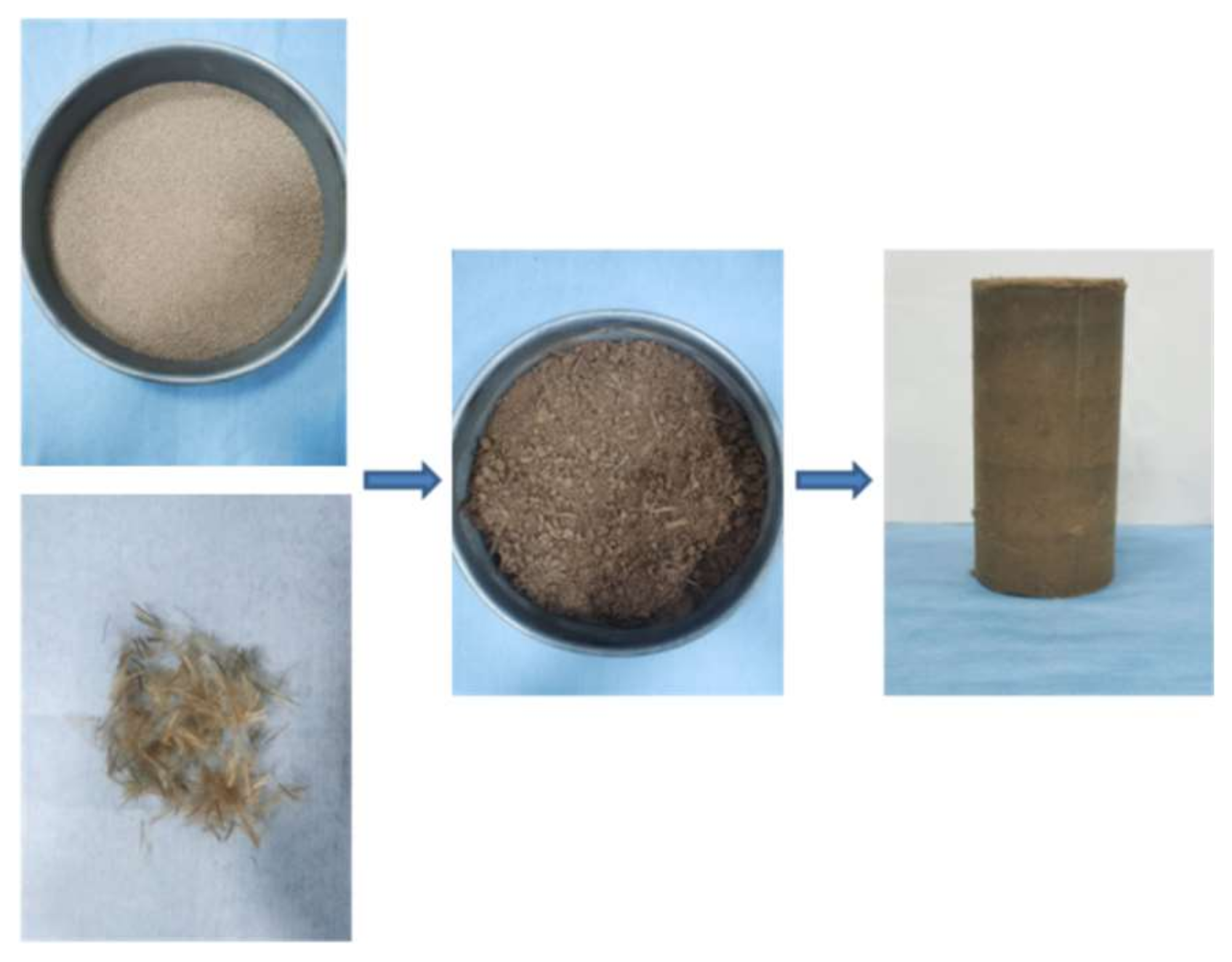

2. Materials and Methods

2.1. Test Materials

2.2. Sample Preparation

2.3. Test Method

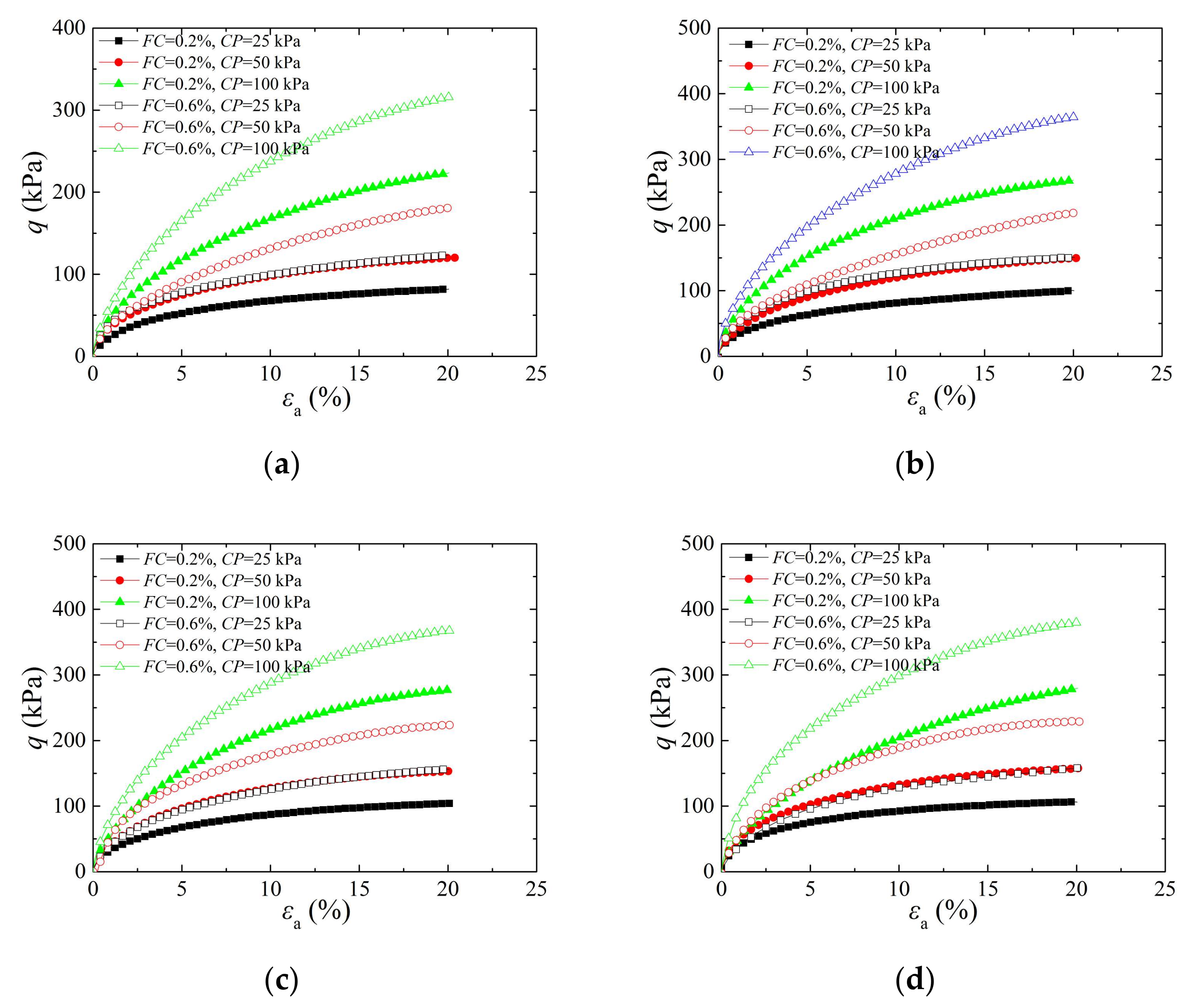

3. Stress–Strain Relationship of Basalt-Fiber-Reinforced Loess

3.1. Effect of Fiber Content on Strength

3.2. Effect of Fiber Length on Strength

3.3. Effect of Cell Pressure on Strength

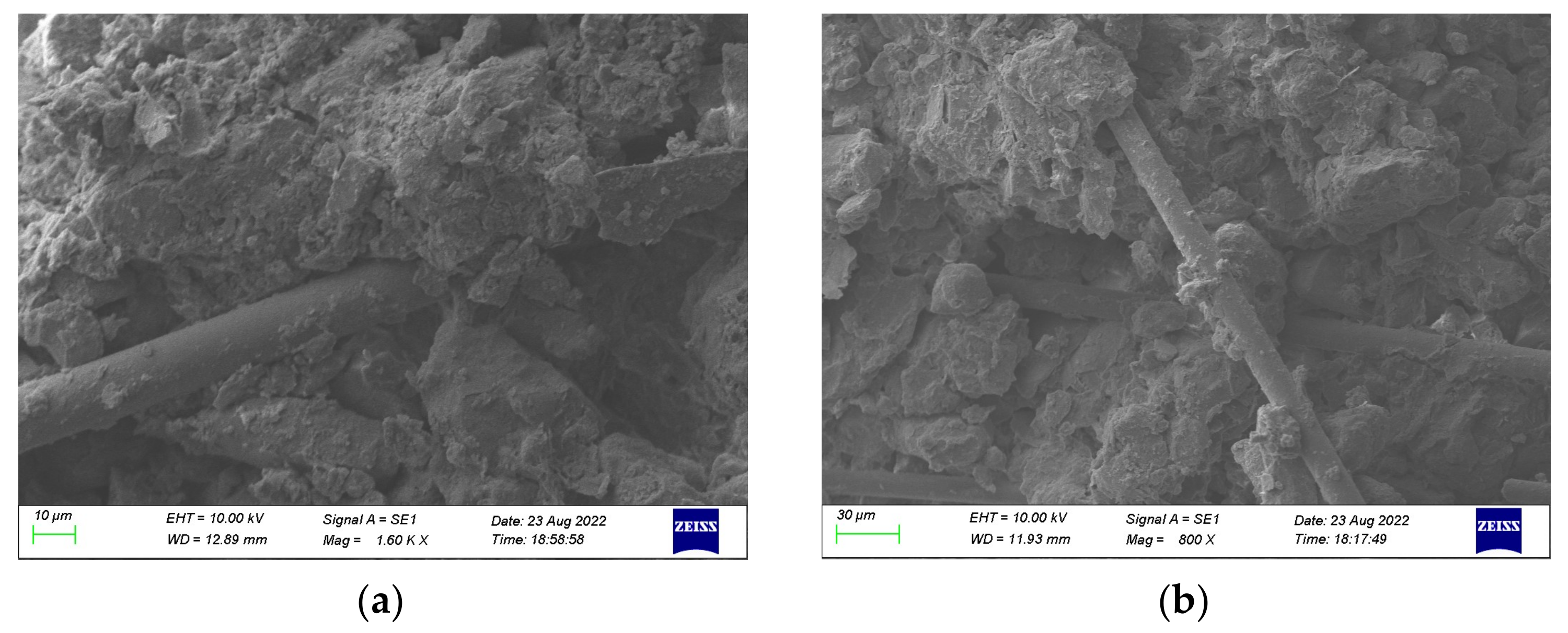

3.4. Microstructure of Basalt-Fiber-Reinforced Loess

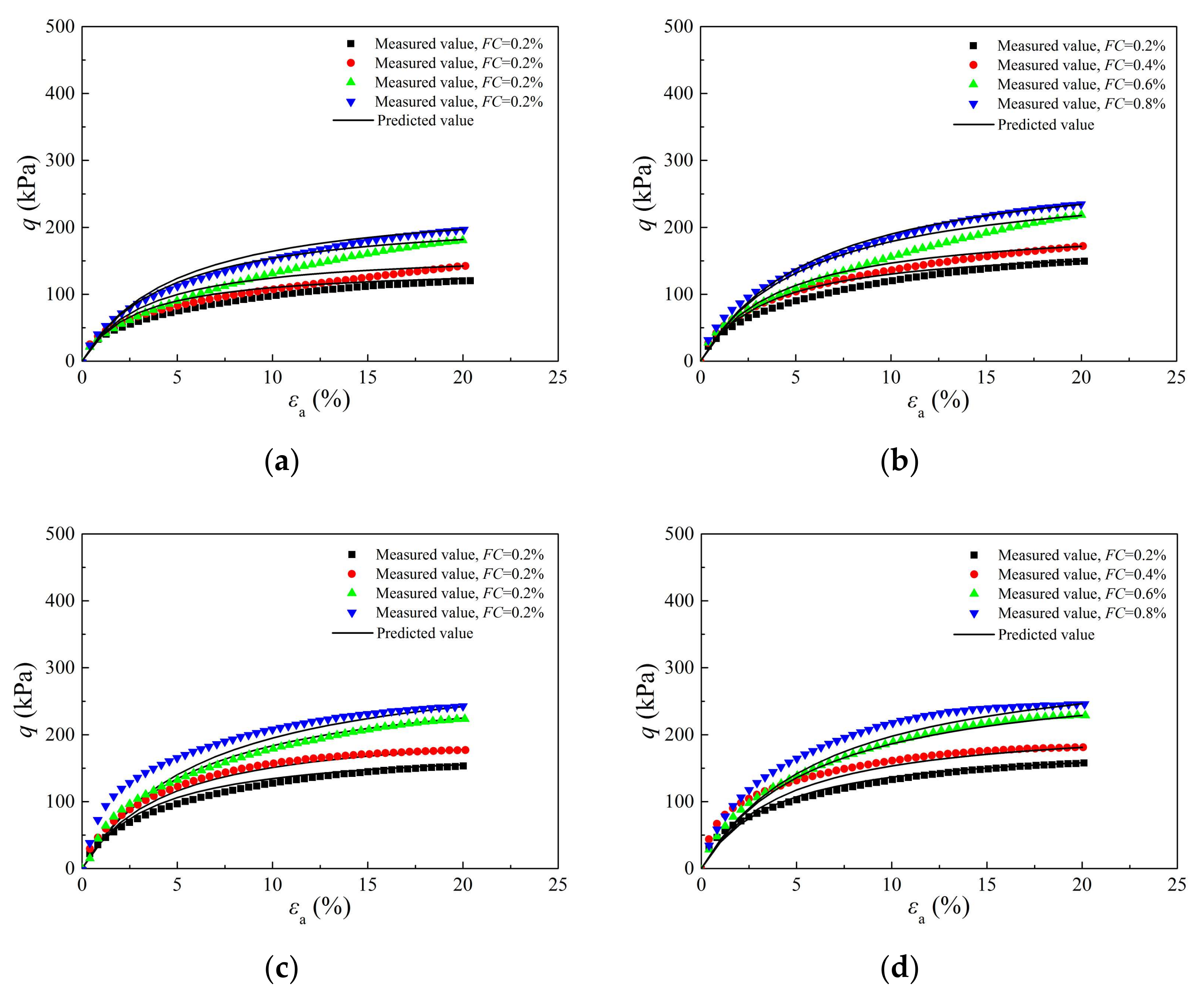

4. Constitutive Model of Basalt-Fiber-Reinforced Loess

4.1. Model Establishment

4.2. Parameter Fitting

- (1)

- Under the fixed cell pressure, the parameter a1 has a small internal change with different FL and FC, thereby, the average value of a1 is taken as an estimate value of a1*.

- (2)

- Under the fixed cell pressure and FL, the parameter a2 increased with the increase in FC. Therefore, taking the parameter a2 at FC = 0.2% as the basic value, a2*(FC = 0.4%) = 1.7 a2*(FC = 0.2%), a2*(FC = 0.6%) = 1.9 a2*(FC = 0.2%), a2*(FC = 0.8%) = 2.3 a2*(FC = 0.2%).

- (3)

- Under the fixed cell pressure and FC, the parameter a2 increased with the increase in FL. Therefore, taking the parameter a2 at FL = 4 mm as the basic value, a2*(FL = 8 mm) = 1.6 a2*(FL = 4 mm), a2*(FL = 12 mm) = 2.3 a2*(FL = 4 mm), a2*(FL = 16 mm) = 3.0 a2*(FL = 4 mm).

| σ3 (kPa) | FL (mm) | FC (%) | a | b | R2 | a1 | a2 | a1* | a2* |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 4 | 0.2 | 0.02826 | 0.00710 | 0.99552 | 0.02826 | 0.00284 | 0.02000 | 0.00284 |

| 4 | 0.4 | 0.02711 | 0.00612 | 0.99023 | 0.02711 | 0.00490 | 0.00483 | ||

| 4 | 0.6 | 0.03092 | 0.00420 | 0.98458 | 0.03092 | 0.00504 | 0.00540 | ||

| 4 | 0.8 | 0.02268 | 0.00408 | 0.99536 | 0.02268 | 0.00653 | 0.00653 | ||

| 8 | 0.2 | 0.02560 | 0.00556 | 0.99589 | 0.0256 | 0.00445 | 0.00454 | ||

| 8 | 0.4 | 0.02143 | 0.00496 | 0.99490 | 0.02143 | 0.00794 | 0.00772 | ||

| 8 | 0.6 | 0.02501 | 0.00357 | 0.98213 | 0.02501 | 0.00857 | 0.00863 | ||

| 8 | 0.8 | 0.01806 | 0.00344 | 0.99444 | 0.01806 | 0.01101 | 0.01045 | ||

| 12 | 0.2 | 0.02279 | 0.00544 | 0.99802 | 0.02279 | 0.00653 | 0.00653 | ||

| 12 | 0.4 | 0.01540 | 0.00485 | 0.99923 | 0.0154 | 0.01164 | 0.01110 | ||

| 12 | 0.6 | 0.01887 | 0.00358 | 0.99739 | 0.01887 | 0.01289 | 0.01241 | ||

| 12 | 0.8 | 0.01129 | 0.00359 | 0.99877 | 0.01129 | 0.01723 | 0.01502 | ||

| 16 | 0.2 | 0.01893 | 0.00550 | 0.99693 | 0.01893 | 0.00880 | 0.00852 | ||

| 16 | 0.4 | 0.01177 | 0.00495 | 0.99875 | 0.01177 | 0.01584 | 0.01448 | ||

| 16 | 0.6 | 0.01718 | 0.00350 | 0.99753 | 0.01718 | 0.01680 | 0.01619 | ||

| 16 | 0.8 | 0.01236 | 0.00340 | 0.99909 | 0.01236 | 0.02176 | 0.01960 |

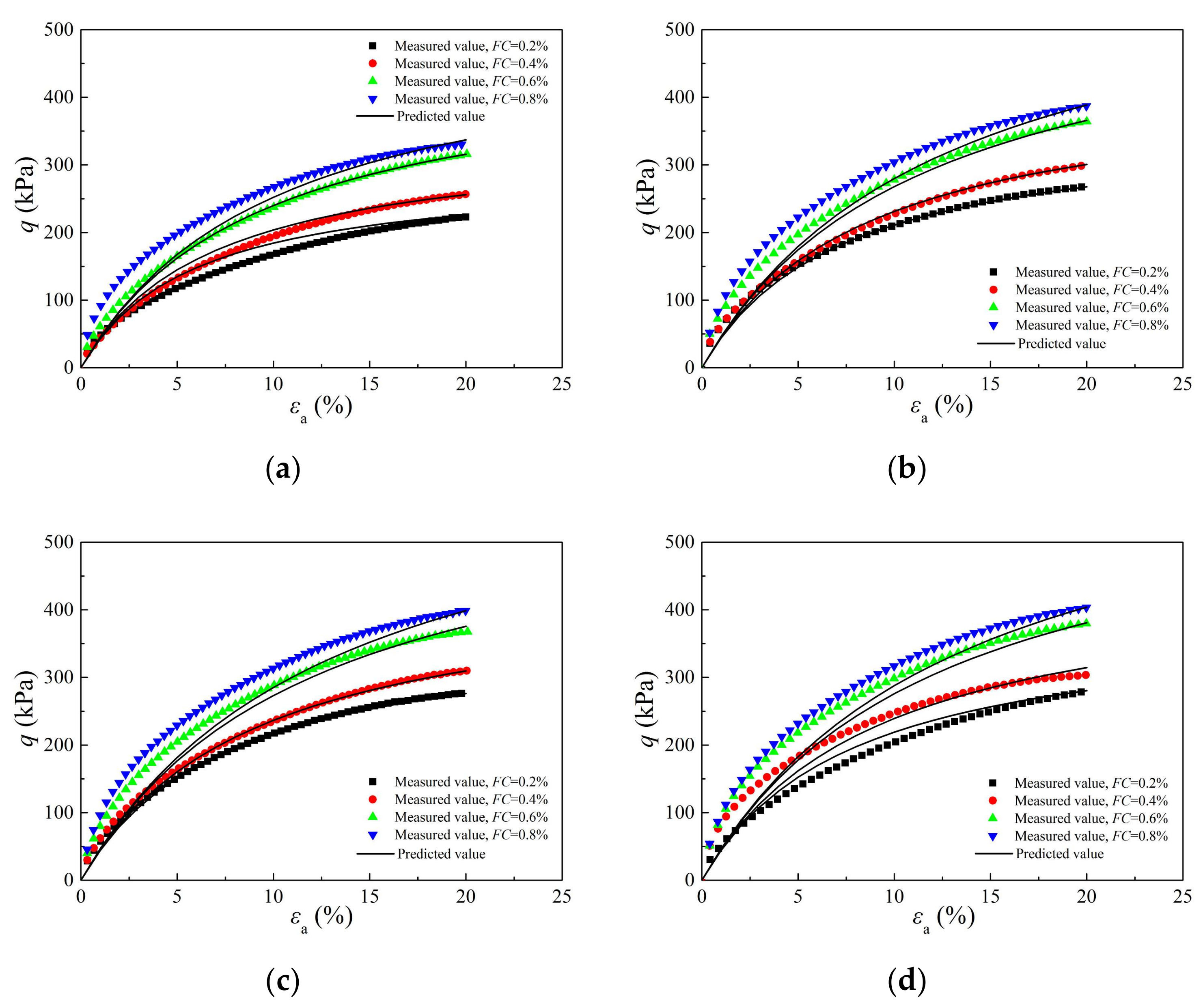

4.3. Model Validation

5. Conclusions

- (1)

- The stress–strain curve of the unreinforced soil exhibited strain-softening, while that of reinforced soil showed strain-hardening. The peak strength of the fiber-reinforced soil was significantly higher than that of the unreinforced soil and increased with the increase in fiber content.

- (2)

- The peak strength of fiber-reinforced soil gradually increased with the increase in fiber length, and the peak strength of 12 and 16 mm fiber lengths increased slightly than the 8 mm fiber length.

- (3)

- The peak strength of the fiber-reinforced soil increased with the increase in cell pressure. When the fiber length was 16 mm and the fiber content was 0.6%, the peak strength reached 158.01, 229.67, and 380.31 kPa under 25, 50, and 100 kPa cell pressure, respectively.

- (4)

- Soil particles had anchoring effect on fibers, and fibers had a bridging effect on soil particles. The anchoring effect and bridging effect improved the cohesion and friction of the reinforced soil.

- (5)

- The experimental results agreed well with the predicted results, indicating that the established model and the parameter estimation method are suitable for describing the constitutive relationship of basalt-fiber-reinforced loess.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Zhang, J.L.; Liu, J. Experimental study on the shear behaviors of polypropylene fiber-reinforced sand. KSCE J. Civ. Eng. 2019, 23, 4992–5001. [Google Scholar] [CrossRef]

- Zhang, J.L.; Yang, Z.Y.; Yang, Q.; Yang, G.; Li, G.; Liu, J. Liquefaction behavior of fiber-reinforced sand based on cyclic triaxial tests. Geosynth. Int. 2021, 28, 316–326. [Google Scholar] [CrossRef]

- Zhang, J.L.; Yang, Z.Y.; Yang, Q.; Li, G.; Liu, J. Pore water pressure model for sands reinforced with randomly distributed fibers based on cyclic triaxial tests. Soil Dyn. Earthquake Eng. 2021, 148, 106812. [Google Scholar] [CrossRef]

- Dong, C.F.; Zhang, W.Y.; Sun, X.L.; Xie, B.L. Experimental study on the shear strength of lignin fiber-improved loess. Saf. Environ. Eng. 2022, 29, 102–110. [Google Scholar]

- Xiong, Y.; Deng, H.F.; Peng, M.; Qi, Y.; Li, T. Shear properties of loess reinforced with four synthetic fibers. J. Yangtze River Sci. Res. Inst. 2022, 39, 122–126. [Google Scholar]

- Lu, H.; Yan, C.G.; Jia, Z.L.; Lan, H.X.; Shi, Y.L.; Yang, X.H.; Zhang, Z.Q. Shear strength and disintegration properties of polypropylene fiber-reinforced loess. J. Traffic Transp. Eng. 2021, 21, 82–92. [Google Scholar]

- An, N.; Yan, C.G.; Wang, Y.C.; Lan, H.X.; Bao, H.; Xu, J.B.; Shi, Y.L.; Sun, W.F. Experimental study on anti-erosion performance of polypropylene fiber-reinforced loess. Rock Soil Mech. 2021, 42, 501–510. [Google Scholar]

- Hu, W.L.; He, P.L.; Liu, H. Experimental study on optimization of shear strength parameters of basalt fiber loess. Chin. J. Geol. Hazard Control. 2019, 30, 92–97. [Google Scholar]

- Xu, J.; Wu, Z.P.; Chen, H.; Shao, L.T.; Zhou, X.G.; Wang, S.H. Study on strength behavior of basalt fiber-reinforced loess by digital image technology (DIT) and scanning electron microscope (SEM). Arabian J. Sci. Eng. 2021, 46, 11319–11338. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.P.; Chen, H.; Shao, L.T.; Zhou, X.G.; Wang, S.H. Triaxial shear behavior of basalt fiber-reinforced loess based on digital image technology. KSCE J. Civ. Eng. 2021, 25, 3714–3726. [Google Scholar] [CrossRef]

- Wu, Z.P.; Xu, J.; Chen, H.; Shao, L.T.; Zhou, X.G.; Wang, S.H. Shear strength and mesoscopic characteristics of basalt fiber-reinforced loess after dry-wet cycles. J. Mater. Civ. Eng. 2022, 34, 04022083. [Google Scholar] [CrossRef]

- Yan, C.G.; An, N.; Wang, Y.C.; Sun, W.F. Effect of dry-wet cycles and freeze-thaw cycles on the antierosion ability of fiber-reinforced loess. Adv. Mater. Sci. Eng. 2021, 2021, 8834598. [Google Scholar] [CrossRef]

- Mariri, M.; Moayed, R.Z.; Kordnaeij, A. Stress-strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J. Mater. Civ. Eng. 2019, 31, 04019291. [Google Scholar] [CrossRef]

- Xue, Z.F.; Cheng, W.C.; Wang, L.; Song, G.Y. Improvement of the shearing behaviour of loess using recycled straw fiber reinforcement. KSCE J. Civ. Eng. 2021, 25, 3319–3335. [Google Scholar] [CrossRef]

- Yang, B.H.; Weng, X.Z.; Liu, J.Z.; Kou, Y.N.; Jiang, L.; Li, H.L.; Yan, X.C. Strength characteristics of modified polypropylene fiber and cement-reinforced loess. J. Cent. South Univ. 2017, 24, 560–568. [Google Scholar] [CrossRef]

- Lian, B.Q.; Peng, J.B.; Zhan, H.B.; Cui, X.S. Effect of randomly distributed fibre on triaxial shear behavior of loess. Bull. Eng. Geol. Environ. 2020, 79, 1555–1563. [Google Scholar] [CrossRef]

- Zhang, J.; Weng, X.Z.; Liu, J.Z. Strength and water stability of a fiber-reinforced cemented loess. J. Eng. Fibers Fabr. 2018, 13, 72–83. [Google Scholar] [CrossRef]

- Gao, Z.N.; Zhong, X.M.; Wang, Q.; Su, Y.Q.; Wang, J. The influence of freeze-thaw cycles on unconfined compressive strength of lignin fiber-reinforced loess. J. Renewable Mater. 2022, 10, 1063–1080. [Google Scholar] [CrossRef]

- Sarli, J.M.; Hadadi, F.; Bagheri, R.A. Stabilizing geotechnical properties of loess soil by mixing recycled polyester fiber and nano-SiO2. Geotech. Geol. Eng. 2020, 38, 1151–1163. [Google Scholar] [CrossRef]

- Wang, X.G.; Liu, K.; Lian, B.Q. Experimental study on ring shear properties of fiber-reinforced loess. Bull. Eng. Geol. Environ. 2021, 80, 5021–5029. [Google Scholar] [CrossRef]

- Duncan, J.M.; Chang, C.Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found. Div. 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.A.; Li, G.; Zhang, J.L. Investigation of the mechanical behavior of polypropylene fiber-reinforced red clay. Appl. Sci. 2021, 11, 10521. [Google Scholar] [CrossRef]

| Gs | ρ (g/cm3) | w (%) | e | wL(%) | wP (%) | IP | ρdmax (g/cm3) | wopt (%) |

|---|---|---|---|---|---|---|---|---|

| 2.70 | 1.68 | 14.2 | 0.835 | 25.8 | 16.7 | 9.1 | 1.72 | 15.0 |

| Diameter (μm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Density (g/cm3) | Elongation at Fracture (%) |

|---|---|---|---|---|

| 10 | 3500–4500 | 100 | 2.65 | 2.2 |

| σ3 (kPa) | FL (mm) | FC (%) |

|---|---|---|

| 25 | 0 | 0 |

| 4 | 0.2, 0.4, 0.6, 0.8 | |

| 8 | 0.2, 0.4, 0.6, 0.8 | |

| 12 | 0.2, 0.4, 0.6, 0.8 | |

| 16 | 0.2, 0.4, 0.6, 0.8 | |

| 50 | 0 | 0 |

| 4 | 0.2, 0.4, 0.6, 0.8 | |

| 8 | 0.2, 0.4, 0.6, 0.8 | |

| 12 | 0.2, 0.4, 0.6, 0.8 | |

| 16 | 0.2, 0.4, 0.6, 0.8 | |

| 100 | 0 | 0 |

| 4 | 0.2, 0.4, 0.6, 0.8 | |

| 8 | 0.2, 0.4, 0.6, 0.8 | |

| 12 | 0.2, 0.4, 0.6, 0.8 | |

| 16 | 0.2, 0.4, 0.6, 0.8 |

| σ3 (kPa) | FL (mm) | FC (%) | a | b | R2 | a1 | a2 | a1* | a2* |

|---|---|---|---|---|---|---|---|---|---|

| 25 | 4 | 0.2 | 0.03927 | 0.01053 | 0.99754 | 0.03927 | 0.00211 | 0.02000 | 0.00223 |

| 4 | 0.4 | 0.03898 | 0.00917 | 0.99457 | 0.03898 | 0.00367 | 0.00379 | ||

| 4 | 0.6 | 0.02589 | 0.00709 | 0.99470 | 0.02589 | 0.00425 | 0.00424 | ||

| 4 | 0.8 | 0.02514 | 0.00644 | 0.99615 | 0.02514 | 0.00515 | 0.00513 | ||

| 8 | 0.2 | 0.03189 | 0.00875 | 0.99547 | 0.03189 | 0.00350 | 0.00357 | ||

| 8 | 0.4 | 0.01930 | 0.00759 | 0.99930 | 0.01930 | 0.00607 | 0.00607 | ||

| 8 | 0.6 | 0.02004 | 0.00573 | 0.99777 | 0.02004 | 0.00688 | 0.00679 | ||

| 8 | 0.8 | 0.02026 | 0.00529 | 0.99650 | 0.02026 | 0.00846 | 0.00821 | ||

| 12 | 0.2 | 0.02901 | 0.00833 | 0.99709 | 0.02901 | 0.00500 | 0.00513 | ||

| 12 | 0.4 | 0.02629 | 0.00700 | 0.99603 | 0.02629 | 0.00840 | 0.00873 | ||

| 12 | 0.6 | 0.02444 | 0.00530 | 0.99589 | 0.02444 | 0.00954 | 0.00975 | ||

| 12 | 0.8 | 0.02093 | 0.00521 | 0.99380 | 0.02093 | 0.01250 | 0.01181 | ||

| 16 | 0.2 | 0.02215 | 0.00840 | 0.99843 | 0.02215 | 0.00672 | 0.00670 | ||

| 16 | 0.4 | 0.01967 | 0.00730 | 0.99686 | 0.01967 | 0.01168 | 0.01138 | ||

| 16 | 0.6 | 0.02427 | 0.00528 | 0.99791 | 0.02427 | 0.01267 | 0.01272 | ||

| 16 | 0.8 | 0.00832 | 0.00551 | 0.99922 | 0.00832 | 0.01763 | 0.01540 | ||

| 100 | 4 | 0.2 | 0.02279 | 0.00346 | 0.99023 | 0.02279 | 0.00277 | 0.02000 | 0.00274 |

| 4 | 0.4 | 0.02243 | 0.00281 | 0.99555 | 0.02243 | 0.00450 | 0.00465 | ||

| 4 | 0.6 | 0.01695 | 0.00239 | 0.99284 | 0.01695 | 0.00574 | 0.00520 | ||

| 4 | 0.8 | 0.01138 | 0.00250 | 0.99491 | 0.01138 | 0.00800 | 0.00629 | ||

| 8 | 0.2 | 0.01664 | 0.00296 | 0.99531 | 0.01664 | 0.00474 | 0.00438 | ||

| 8 | 0.4 | 0.01711 | 0.00255 | 0.99029 | 0.01711 | 0.00816 | 0.00744 | ||

| 8 | 0.6 | 0.01312 | 0.00215 | 0.99057 | 0.01312 | 0.01032 | 0.00832 | ||

| 8 | 0.8 | 0.01094 | 0.00209 | 0.99444 | 0.01094 | 0.01338 | 0.01007 | ||

| 12 | 0.2 | 0.01754 | 0.00277 | 0.99419 | 0.01754 | 0.00665 | 0.00629 | ||

| 12 | 0.4 | 0.01677 | 0.00244 | 0.99238 | 0.01677 | 0.01171 | 0.01070 | ||

| 12 | 0.6 | 0.01277 | 0.00211 | 0.99493 | 0.01277 | 0.01519 | 0.01196 | ||

| 12 | 0.8 | 0.01062 | 0.00203 | 0.99444 | 0.01062 | 0.01949 | 0.01447 | ||

| 16 | 0.2 | 0.02115 | 0.00262 | 0.98878 | 0.02115 | 0.00838 | 0.00821 | ||

| 16 | 0.4 | 0.01227 | 0.00272 | 0.99498 | 0.01227 | 0.01741 | 0.01395 | ||

| 16 | 0.6 | 0.01115 | 0.00213 | 0.99444 | 0.01115 | 0.02045 | 0.01560 | ||

| 16 | 0.8 | 0.01050 | 0.00200 | 0.99444 | 0.01050 | 0.02560 | 0.01888 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kou, H.; Ma, Q.; Han, S. Experimental Study on the Mechanical Behaviors of Loess Reinforced with Randomly Distributed Basalt Fiber. Appl. Sci. 2022, 12, 9744. https://doi.org/10.3390/app12199744

Kou H, Ma Q, Han S. Experimental Study on the Mechanical Behaviors of Loess Reinforced with Randomly Distributed Basalt Fiber. Applied Sciences. 2022; 12(19):9744. https://doi.org/10.3390/app12199744

Chicago/Turabian StyleKou, Honggang, Qiang Ma, and Shunli Han. 2022. "Experimental Study on the Mechanical Behaviors of Loess Reinforced with Randomly Distributed Basalt Fiber" Applied Sciences 12, no. 19: 9744. https://doi.org/10.3390/app12199744

APA StyleKou, H., Ma, Q., & Han, S. (2022). Experimental Study on the Mechanical Behaviors of Loess Reinforced with Randomly Distributed Basalt Fiber. Applied Sciences, 12(19), 9744. https://doi.org/10.3390/app12199744