Abstract

The design and performance optimization of fully electric trucks constitute an integral goal of the transport sector to meet climate emergency measures and local air quality requirements. Most studies in the literature have determined the optimum pack size based on economic factors, without accounting for the details of pack behavior when varying the size. In this paper, the effect of battery pack sizing and cargo capacity of a class 8, 41-ton truck on its overall energy performance and technical parameters of its powertrain is investigated. For this purpose, the proposed electric truck is designed and mathematically modelled using AVL CRUISE M software. The second-order equivalent circuit model is developed to predict the battery packs’ parameters. The proposed battery pack model is extracted from experimental analysis on SONY VTC6 lithium-ion batteries performed in the lab. The weight changes due to adding the battery packs to the truck are also estimated and have been taken into account. The mathematical model of the powertrain is simulated in the long-haul driving cycle considering different cargo capacities and battery pack sizes. The results of this study revealed that the battery pack voltage reached its minimum value when the maximum cargo capacity was applied for the 399 kWh battery pack. In addition, increasing the occupied cargo capacity from 10% to 100% resulted in an increase in the regenerative brake energy of up to 9.87 kWh, while changing the battery size imposed minimal impacts on regenerative brake energy recovery as well as energy consumption.

1. Introduction

As climate change becomes an increasingly pressing issue, the automotive industry is shifting towards electrification of vehicles to reduce carbon emissions. EV sales rose by 68% globally between 2017–2018 [1]. However, the heavy-duty vehicle industry has not seen the same volume of electric vehicle sales [2,3,4]. In 2020, global sales of electric heavy-duty trucks accounted for less than 1% of the total sales [5,6]. The trucking industry contributed 23% of transport GHG emissions in the US [7]. The low level of electrification of this space presents a large opportunity for a reduction in carbon emissions.

A primary reason for the dependence of the truck manufacturing industry on fossil fuels is the high energy demands compared to passenger cars [8]. Heavy-duty EVs require larger energy storage due to their greater range, weight, and aerodynamic load demands compared to passenger EVs [9,10,11]. Most heavy-duty trucks must travel long distances between each stop. This requires large batteries to be installed [12] or electric roads, which require large investments for infrastructure [13]. Since battery energy density is lower than fuel tanks used in Internal Combustion Engine (ICE) trucks, the energy storage system in heavy-duty vehicles becomes expensive and heavy due to electrification [9,14]. Accordingly, the extra mass of the battery packs reduces the cargo capacity since the total weight of the truck needs to remain constant during electrification [9,15].

Various studies have analyzed the electrification of heavy-duty vehicles addressing aforementioned challenges. Mauler et al. [9] conducted an economic analysis between diesel, fuel cell, and battery electric long-haul trucks in the United States. Current battery electric trucks were seen to be nearly competitive to diesel trucks for trips below 500 km. For weight constrained cargo exceeding 500 km, fuel cells were nearly competitive to diesel. The more volume constrained the cargo, the greater the advantage to the battery electric truck, since the added mass of the battery pack does not limit cargo capacity. Energy and fuel price had a large effect on all of the comparisons, and such comparisons do not consider charging nor hydrogen refueling availability. Tanco et al. [16] also found that energy and fuel price influence electric truck feasibility in Latin America, with upfront costs being the largest barrier. Besides the cost of electricity, the cost of a battery pack influences the economic feasibility of EV heavy-duty vehicles. Vijayagopal and Rousseau [14] determined that the cost of battery pack depends on desired range and influences electric truck upfront costs. Nykvist and Olson [17] proposed using smaller battery packs for heavy-duty trucks and improving the fast charging network in order to reduce both the cost of battery electric trucks and their weight, improving their weight carrying capacity. Optimizing heavy-duty truck battery pack size would maximize the economic viability of such vehicles [18]. Baek et al. [18] were able to find an ideal battery pack size by factoring in charging costs, battery costs, depreciation costs, and revenue. Large battery packs maximize range and payload size, but unnecessarily increase the weight and require a larger initial investment. On the contrary, a small battery pack limits the range and carrying capacity and relies more on the charging network. The previously mentioned studies rely on economic factors to determine the pack size, but details of pack behavior are not accounted for when varying the size. The subject of this research is to perform the optimal pack sizing considering the distance, power, weight, size of truck, and the volume of transported goods in order to maximize efficiency and energy usage of a heavy-duty truck. Combining cell parametrization through lab testing for a pack model to test various pack sizes of electric truck provides detailed insight into pack behavior variation. Cell testing was conducted using pulse discharges to obtain transient and steady-state behavior at various SOC increments. This data was then parametrized using MATLAB Simulink R2022a with a nonlinear least-squares optimization and a Trust-Region-Reflective algorithm. Error was minimized using sum squared error. This parametrization yielded ECM parameters which were used for the pack model. An AVL pack model was used with the cell parameters for the sizing optimization. The pack model was used to evaluate various pack configurations and capacities to optimize power, weight, range, and cell health for the 41-ton truck.

This article brings a new viewpoint to the existing literature in the battery electric truck modelling and optimal pack sizing of batteries based on experimental data. Results of the study inform an ideal pack configuration based on the truck weight, and how varying truck parameters influences pack behavior.

This paper is organized as follows; Section 2.1 (battery electric powertrain modelling) discusses the methodology used to mathematically model the proposed powertrain, Section 2.2 (parametric analysis) contains the variables assigned in the model to determine the impacts of cargo capacity and battery pack sizing on the model output parameters, and Section 2.3 (battery cell characterization) describes the methodology used to parametrize second-order ECM used for modelling of batteries using lab data. Section 3.1 and Section 3.2, located in the results section, discuss battery parametrization and parametric study results, respectively.

2. Methodology

2.1. Battery Electric Powertrain Modelling

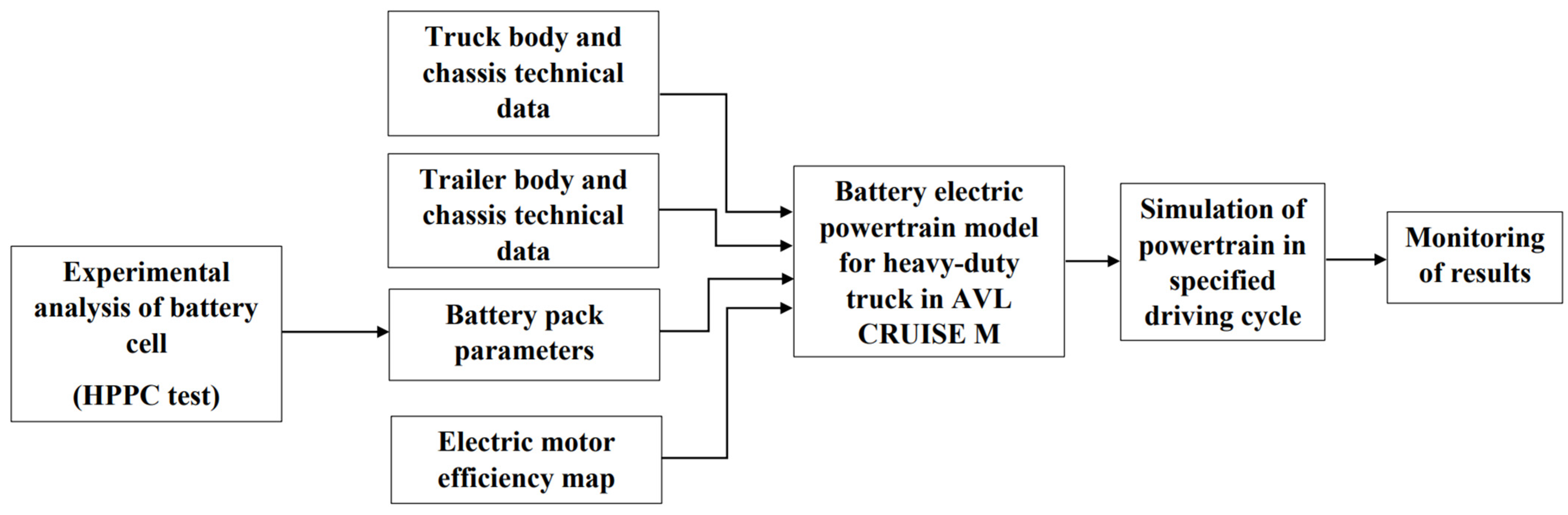

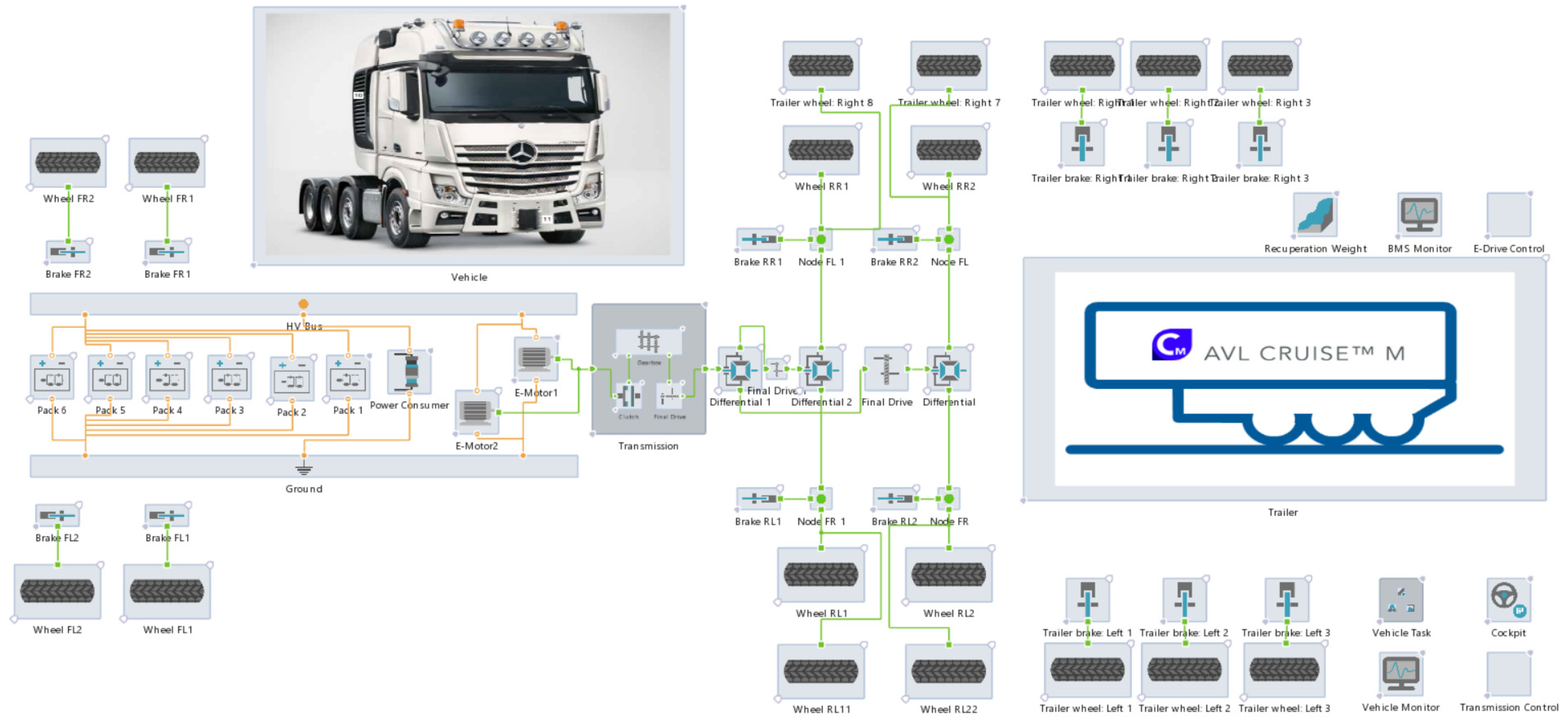

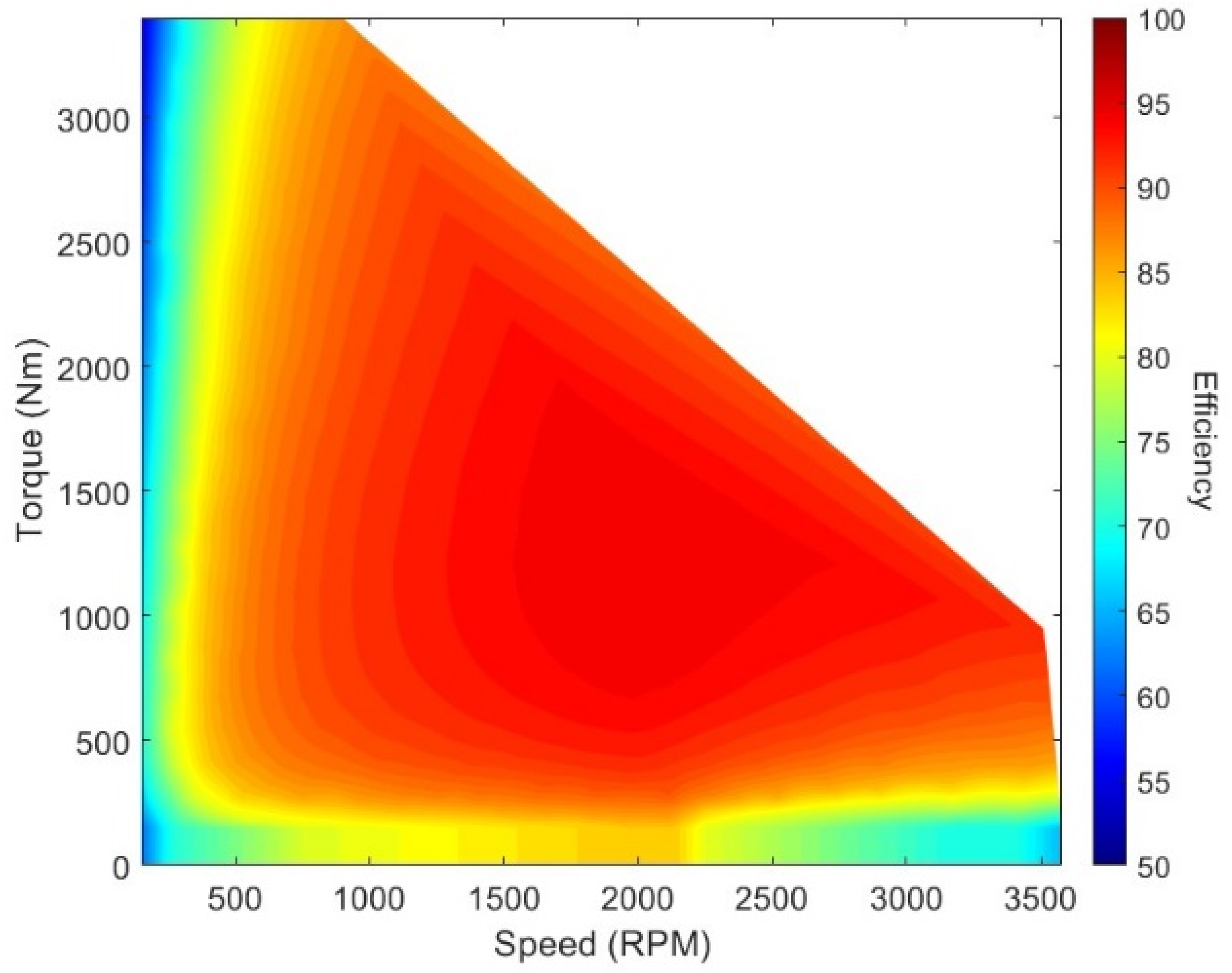

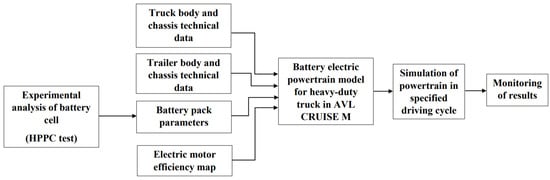

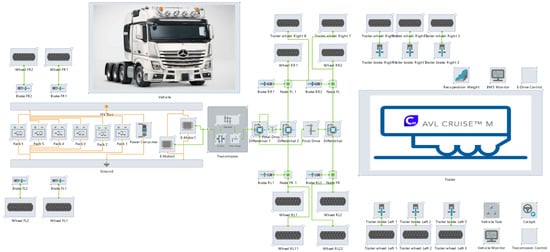

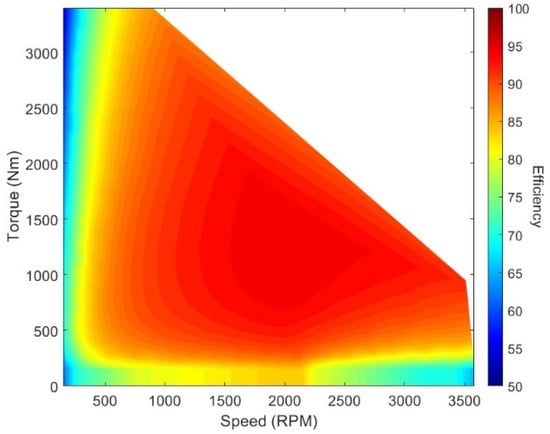

The battery electric powertrain of a heavy-duty class 8 truck is modelled using AVL CRUISE M R2022.1 software [19]. The modelling process is indicated in Figure 1. The Mercedes Benz Actros 41-ton truck, featuring 8 wheels and 4-wheel drive (8 × 4) is considered as the case study with its technical parameters presented in Table 1. The battery electric powertrain components in AVL CRUISE M R2022.1 software are presented in Figure 2 with the electric motor efficiency presented in Figure 3. The electrical network of the proposed powertrain includes two electric motors and six packs of batteries. The battery packs are sized and modelled based on specifications of Sony VTC6 lithium-ion battery. The battery pack specifications are provided in Table 2.

Figure 1.

Flow diagram of modelling process.

Table 1.

Truck and trailer bodies technical parameters.

Figure 2.

Block diagram for AVL vehicle model.

Figure 3.

The electric motor efficiency map.

Table 2.

Battery pack parameters.

The originally diesel Mercedes Actros truck is considered the case study in this paper. Therefore, the weight change associated with the electrification of this truck is obtained based on the weight of components exchanged. These values are presented in Table 3. The transmission and drivetrain weight were assumed to be equal for the diesel and electric powertrains. The mass loss from removing the fuel and fuel tank was estimated by using 50% of the full capacity tank weight for the Actros as a conservative estimate for the average amount of fuel in the truck during long-haul driving. The electric vehicle weight addition includes weight from the two motors, battery pack, inverter, and DC/DC converter. Dual motors were used to obtain high efficiency compared to a single larger motor [20], and permanent magnet motors were selected for their high specific torque [21]. In order to determine the effect of pack size on weight, the required structural mass for a given energy capacity was determined based on previous studies. The cell energy density was used to calculate pack energy density, based on a 60% percentage weight of cells to total pack weight. This value was chosen based on typical gravimetric energy densities achieved with current battery packing methods [22,23,24,25]. The resulting pack gravimetric energy density is 140 kg/kWh. The pack weight was then calculated for each pack size by dividing the power capacity by 140 Wh/kg.

Table 3.

Weight of Diesel and Electric powertrain components.

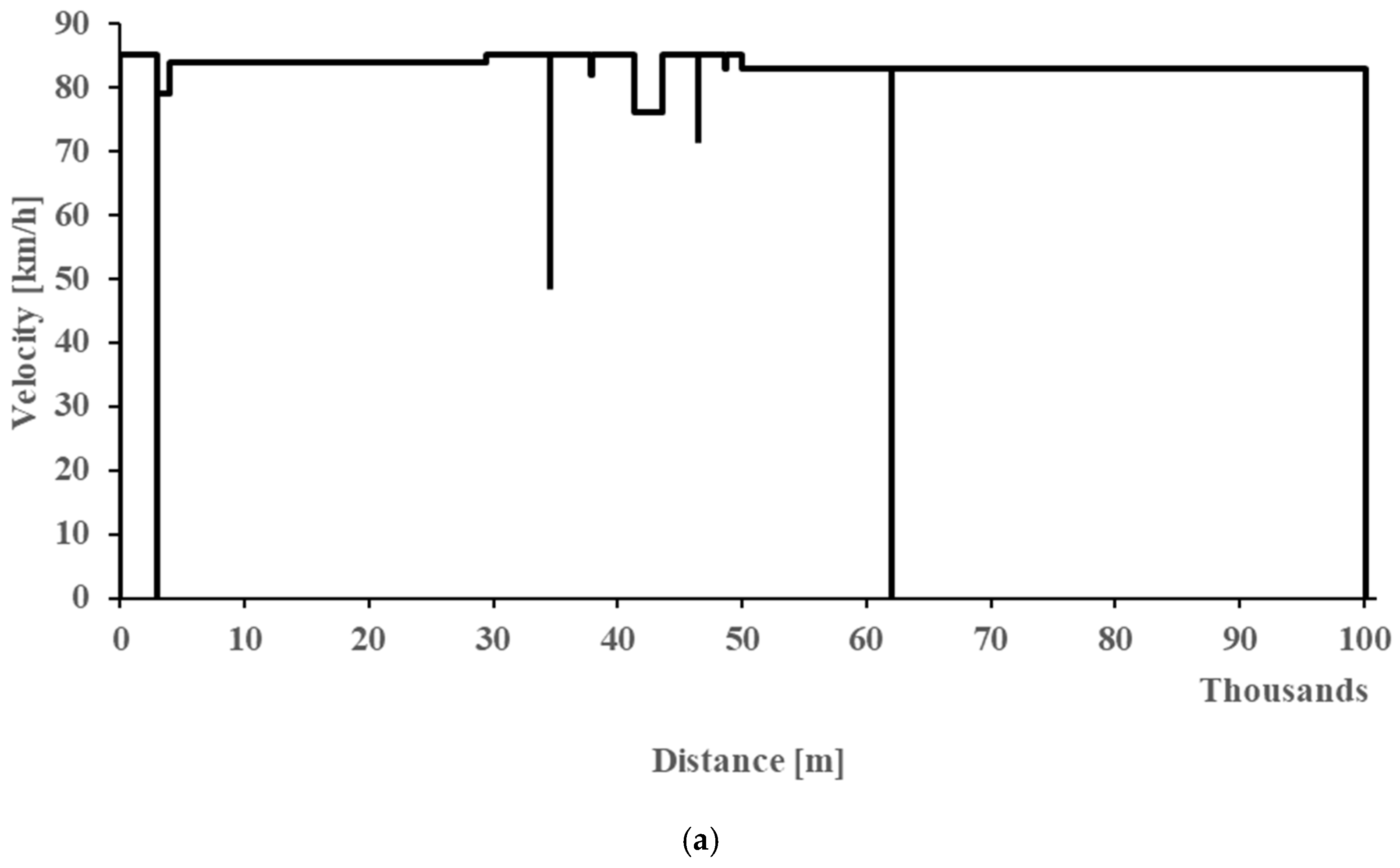

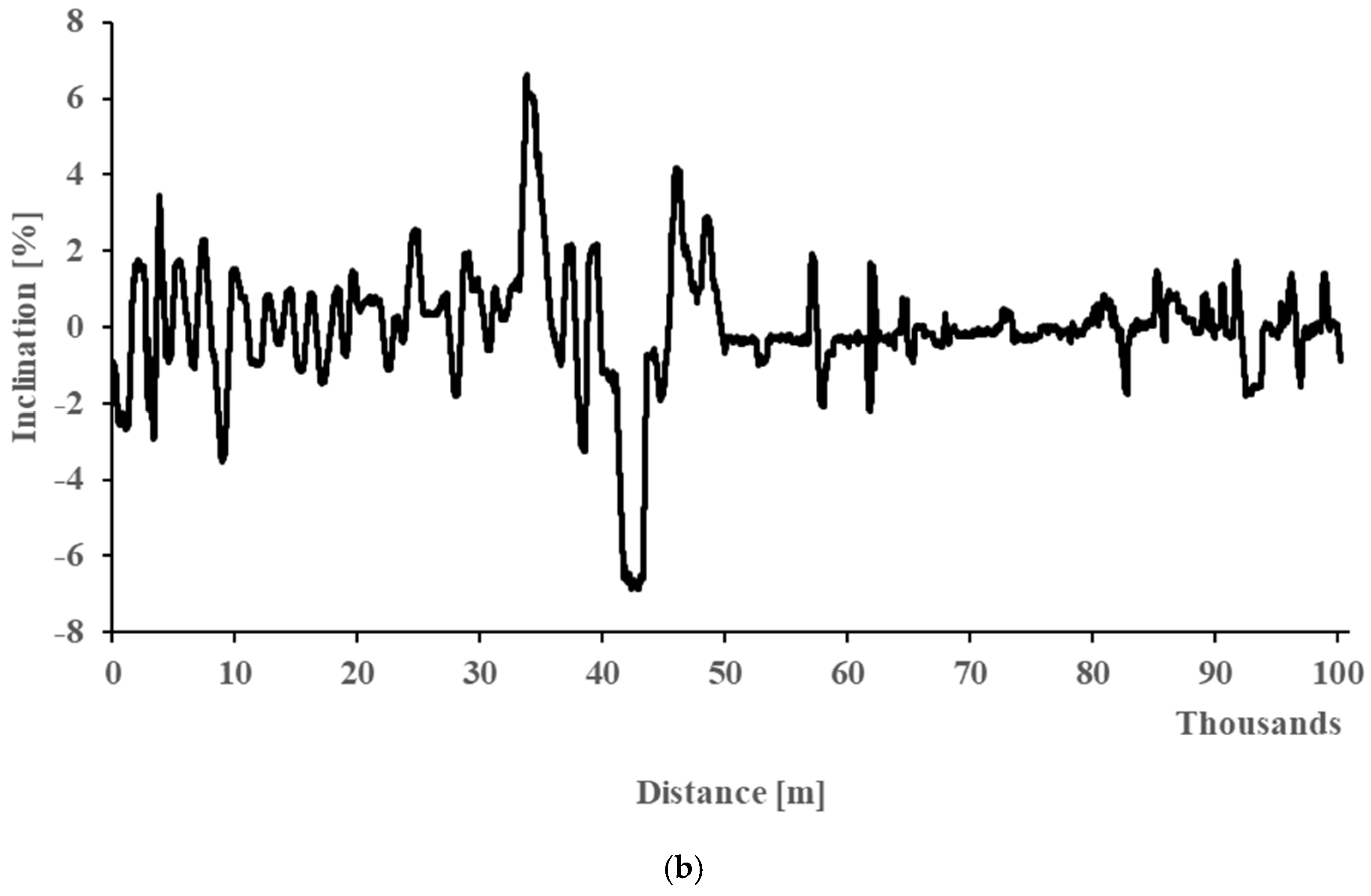

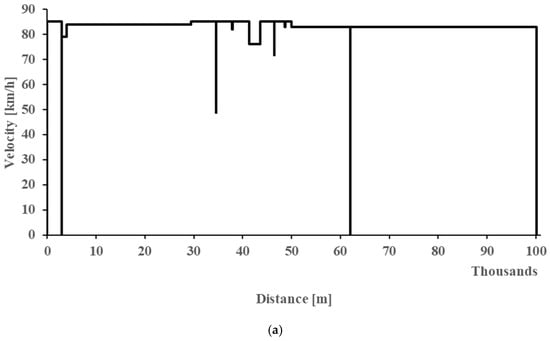

A long-haul driving cycle (Figure 4) was used in order to evaluate the transient performance of the 41-ton truck at various pack capacities. The driving cycle represents a typical trip of a heavy-duty truck, which undergoes brief accelerations and decelerations, but generally cruises at highway speeds of approximately 85 kph. Inclination also varies during this cycle to accurate modelling of real-life driving conditions [26,27].

Figure 4.

The (a) velocity profiles and (b) road inclination variations in the Long-haul driving cycle [26,27].

2.2. Parametric Analysis

A parametric study is performed to size the battery packs and investigate their impacts on technical parameters of the powertrain. The battery pack size is determined by changing the number of cell rows in each pack and considering the variations in cargo capacity. Cells in parallel were varied from 35 to 45, increasing the total pack energy from 399 to 513 kWh. This was the primary variable of the study since pack size variation is a crucial design choice for a heavy-duty vehicle. The occupied cargo capacity is also varied between 10% and 100%. Different case scenarios considered in this paper are shown in Table 4.

Table 4.

Case scenarios for parametric study performed.

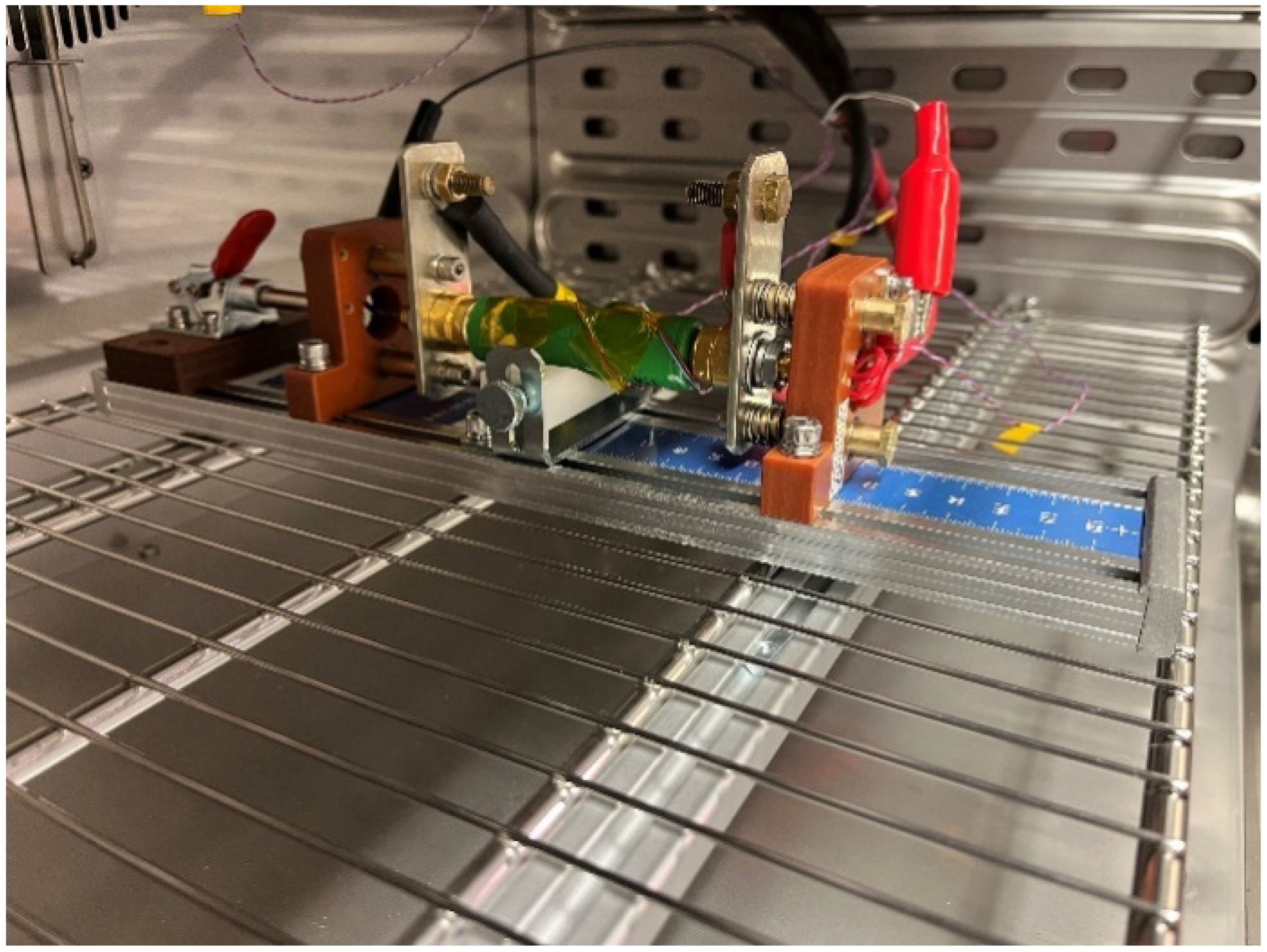

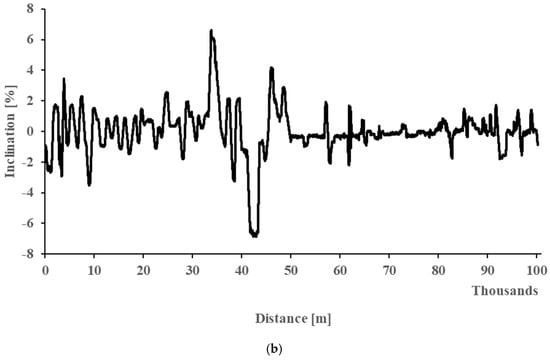

2.3. Battery Cell Characterization

The second-order equivalent circuit model is used for the mathematical modelling of each battery pack shown in Figure 2. For this purpose, the SONY VTC6 cylindrical battery cells were tested in a High Voltage Energy Storage (HVES) lab at Oxford Brookes University. The HPPC tests were performed for characterization of the battery cells in the lab at a temperature of 25 °C. In HPPC tests, the battery cell underwent a discharge test at 1.5 C, which provided a picture of voltage at various SOC, as well as the transient response to current pulses. The cell has a maximum voltage of 4.2 V, and a capacity of 3000 mAh. As an approximation, 1.5 C was chosen as a typical discharge rate seen for commercial automobiles [17,18,28,29]. The cell was placed in a testing chamber to hold the temperature constant (Figure 5). A clamping apparatus which utilizes spring force was used to provide firm contact between the cell terminals and the power supply. Voltage across the cell was measured by clipping leads to metal at each plate, while current was recorded using an Arbin battery tester (ARBIN LBT21084). Thermocouples were used to obtain the temperature of the cell, and the experiment was conducted at 25 °C to gain an understanding of behavior at average ambient temperature.

Figure 5.

Sony VTC6 cell experimental setup.

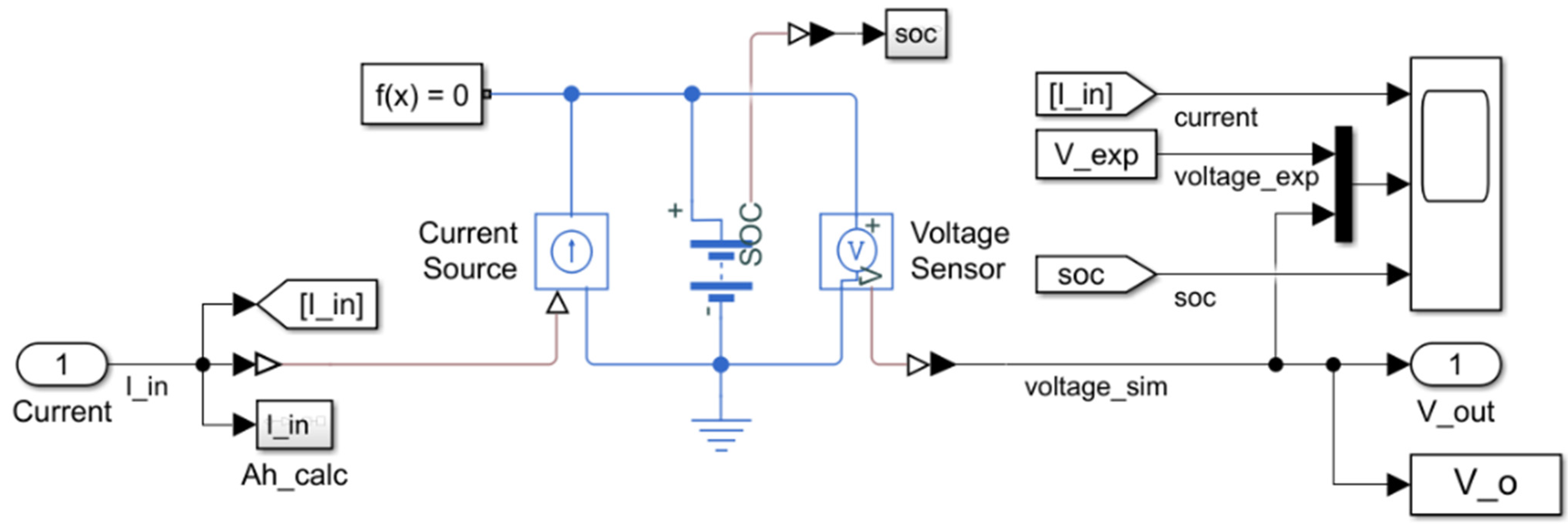

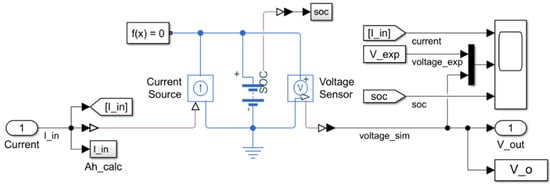

After data was obtained from the HPPC tests, a second-order ECM was developed in MATLAB Simulink to characterize the cell behavior for use in pack modelling with AVL CRUISE M. The model uses a battery block, which is controlled by defining parameters such as internal resistance, dynamic time constants and resistances, capacity, and cell voltage. Current is controlled through the “Current Source” block, which received the same input current as the experimental tests. The “Voltage Sensor” block outputs cell voltage, while the “SOC” block outputs the state of charge (Figure 6). The model received parameter values from a separate MATLAB workspace, and it sends outputs and input current to the parameter estimate module as well as the workspace.

Figure 6.

MATLAB model used for cell parameter estimation.

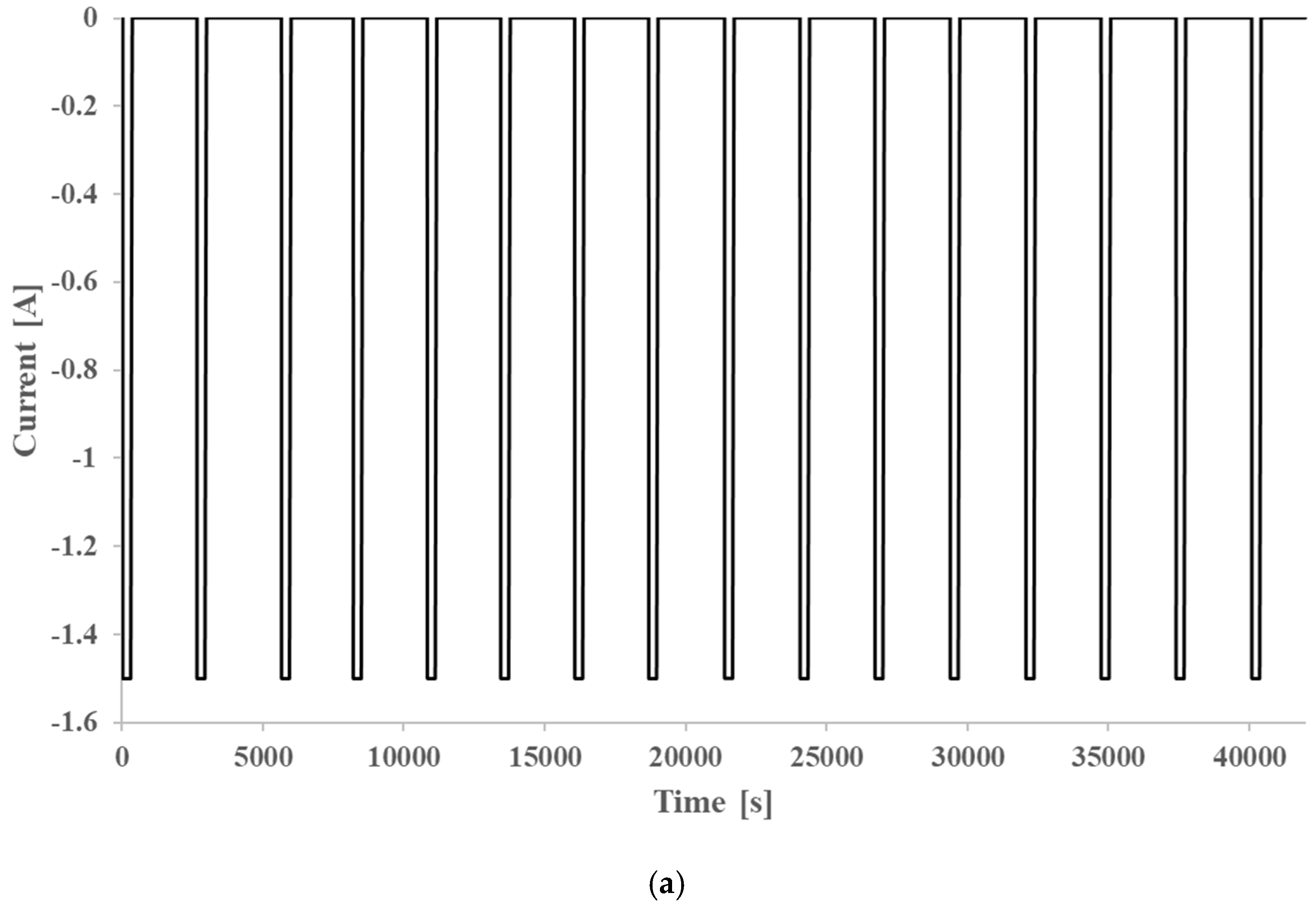

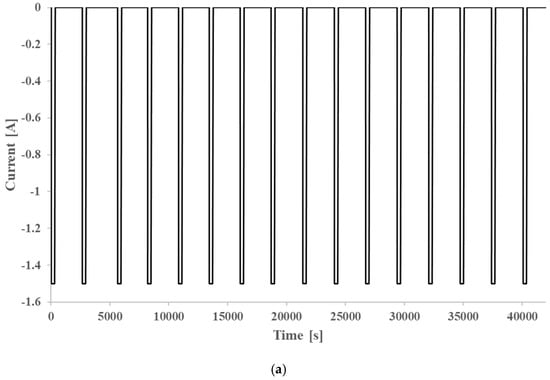

Each parameter can be expressed as an array of values, each value being defined at a specific SOC. In this particular case, 16 discharge pulses were conducted experimentally to take the cell from 4.2 V to 3.4 V, so all parameter arrays had 16 items.

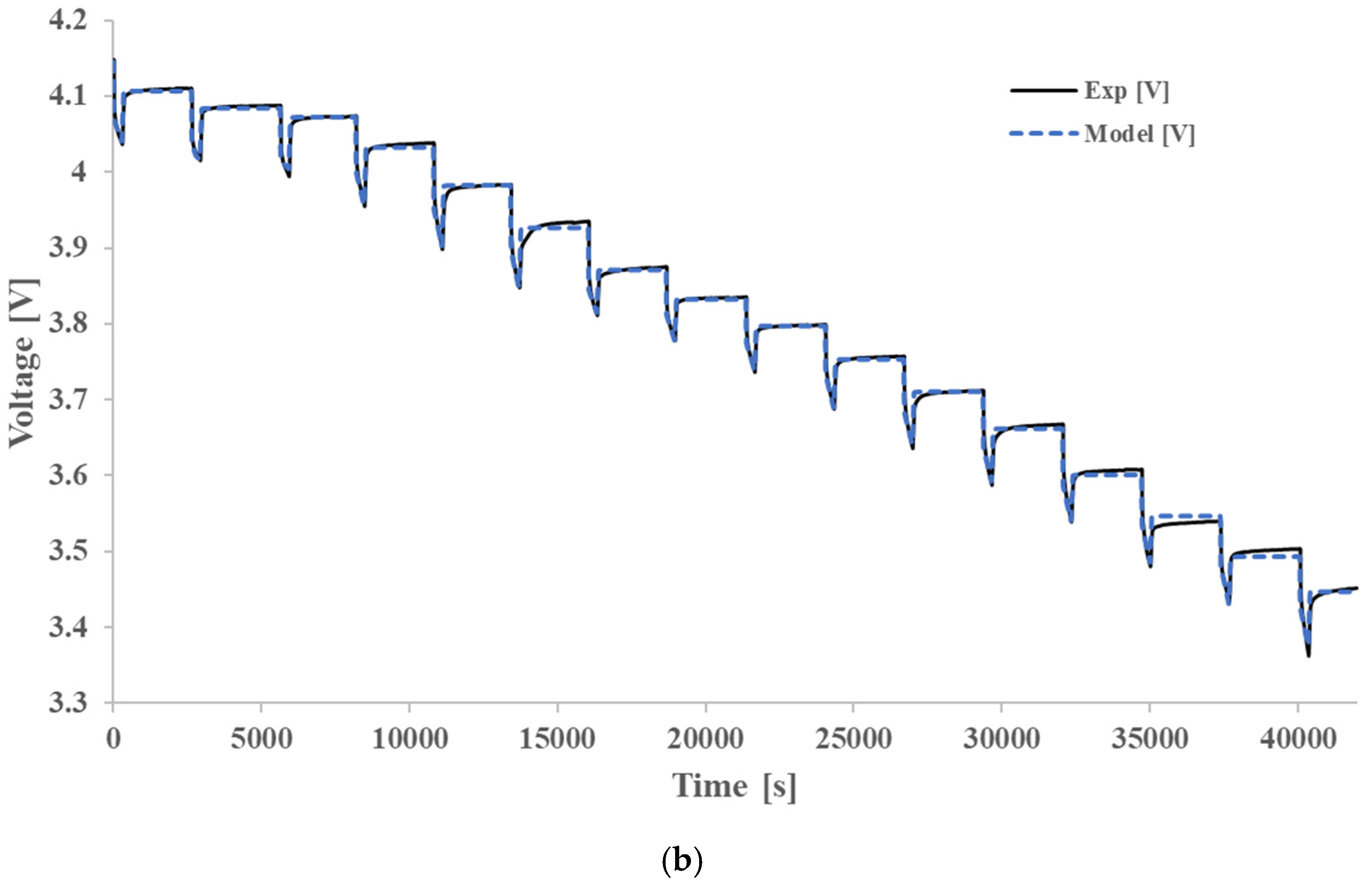

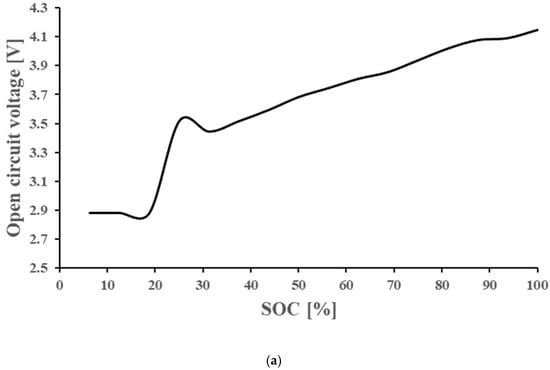

Simulink’s built-in parameter estimator was used to determine parameter values which matched experimental results. The varied parameters were voltage, first and second dynamic resistances, first and second-time constants, and static resistance. The Levenberg–Marquardt algorithm was used to iteratively find parameters that resulted in minimizing the least-squares difference from the experimental results. The parametrization resulted in closely matching voltage vs SOC graphs, with an R² value of 99% (Figure 7).

Figure 7.

Parametrization results for the second-order ECM compared to experimental results, (a) applied current profile in HPPC test versus time and (b) cell voltage response in different times calculated by model and obtained in HPPC tests.

3. Result and Discussion

3.1. Experimental Tests Results

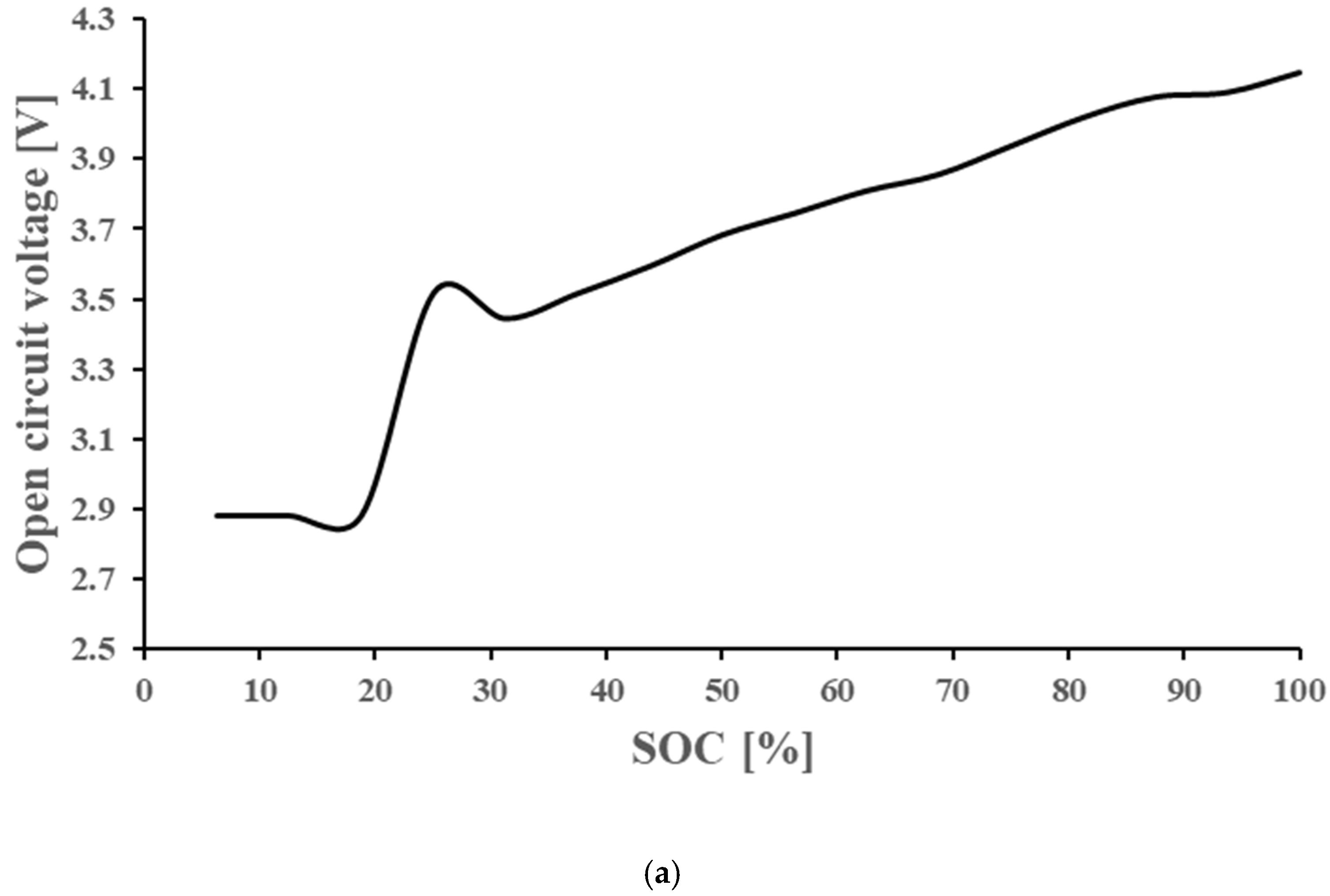

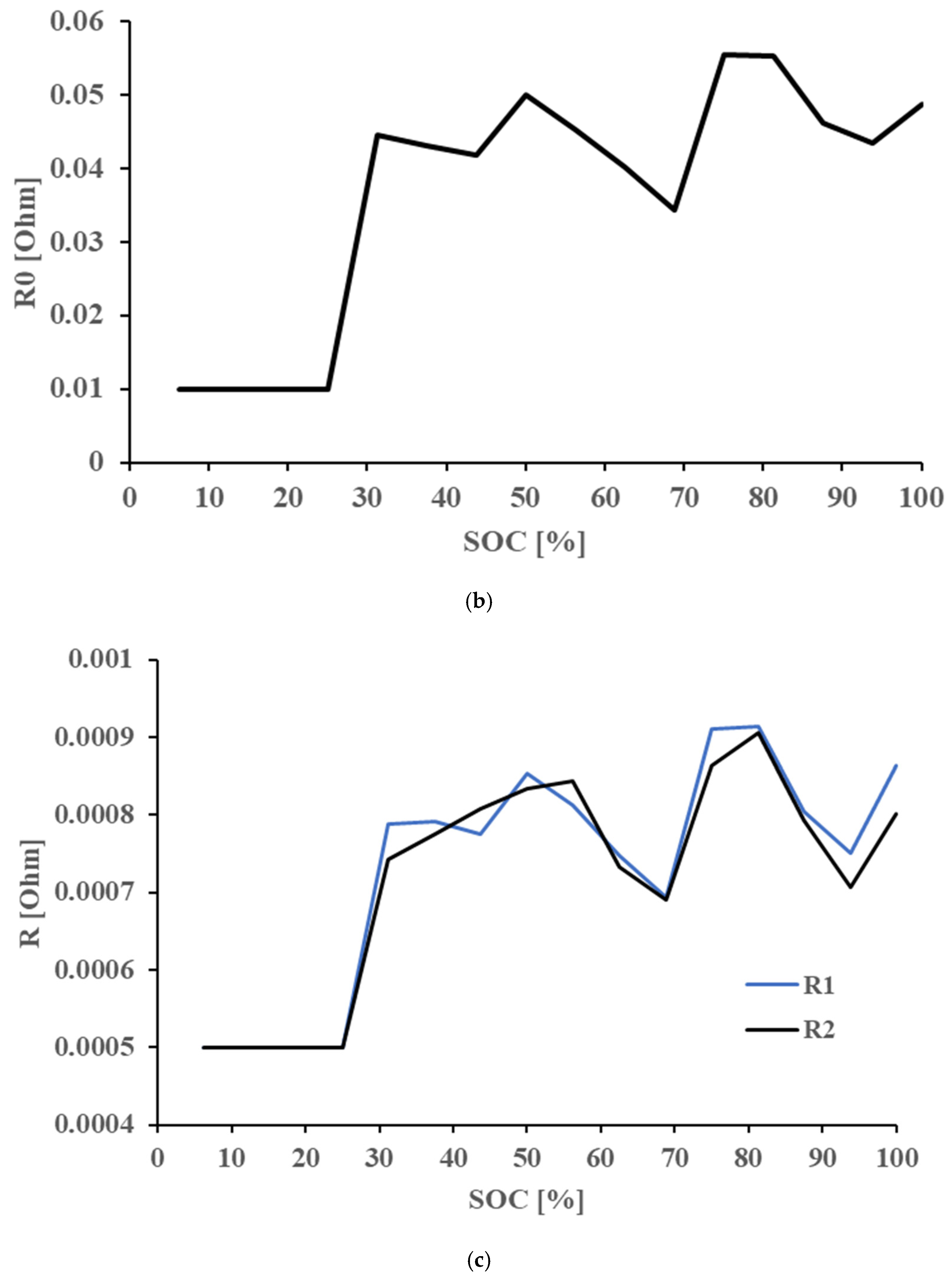

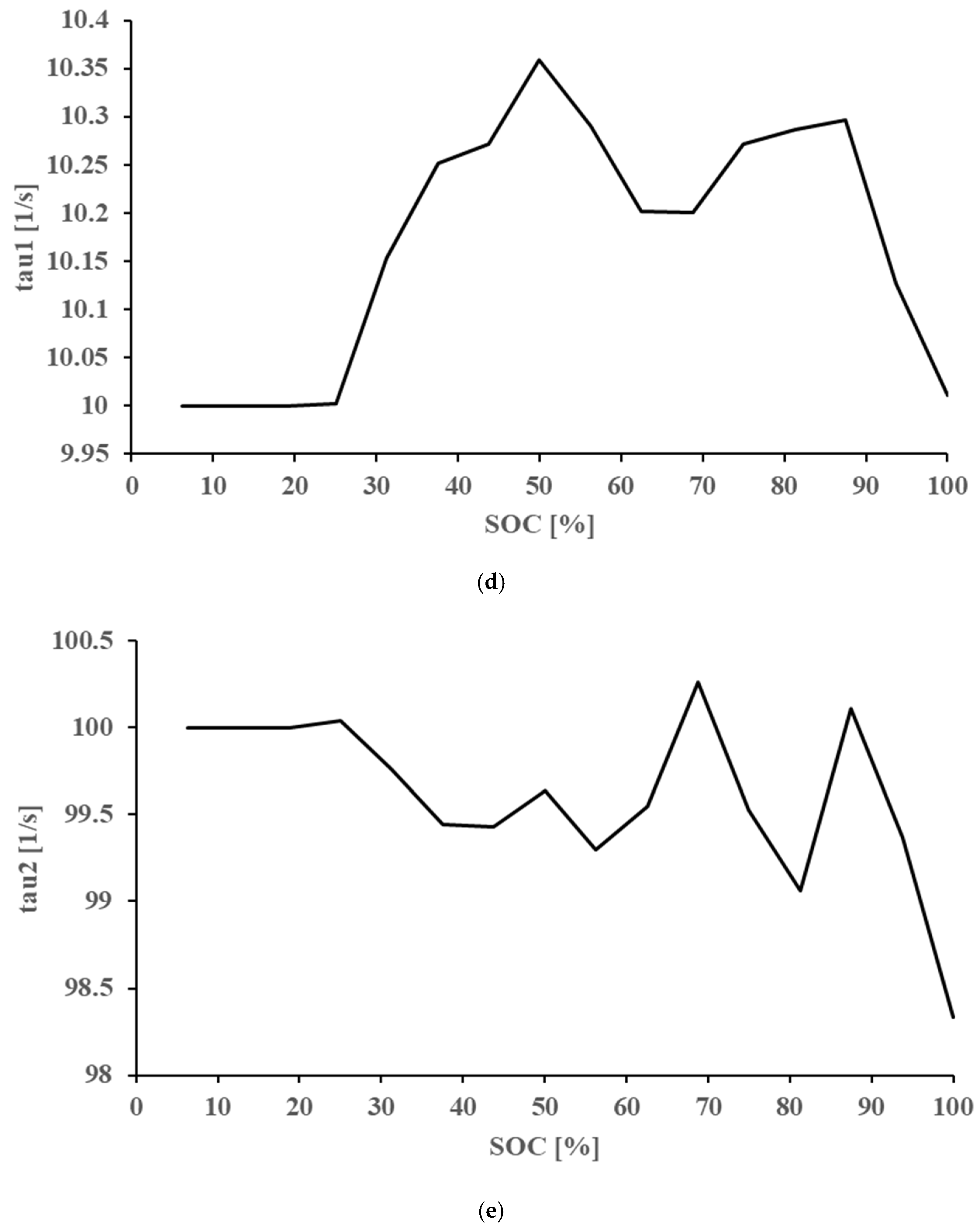

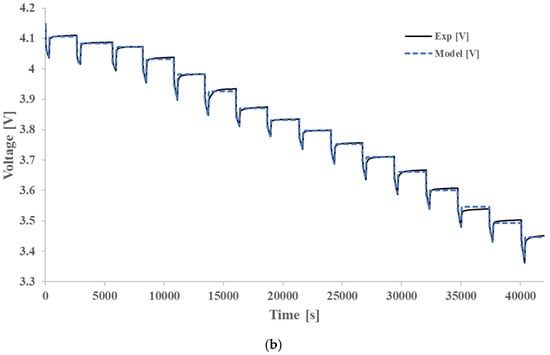

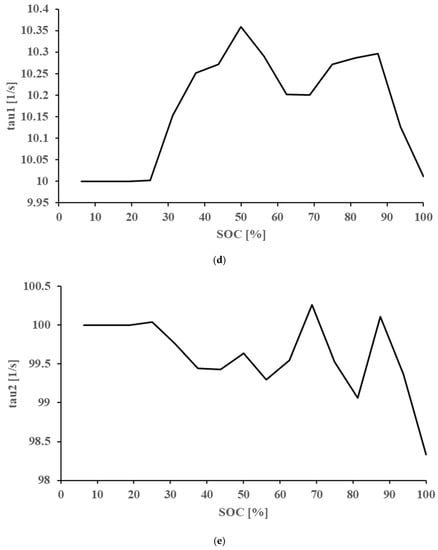

The estimated parameters based on HPPC lab data for second-order ECM are shown in Figure 8a–e. These parameters are used as the input of the battery pack model shown in Figure 2 for simulation of lithium-ion battery behavior under the transient conditions of the driving cycle.

Figure 8.

The estimated parameters for second order ECM using HPPC data: (a) open circuit voltage, (b) static ohmic resistance, (c) dynamic constants resistances, (d) first time constant and (e) second time constant in various state of charges.

3.2. Parametric Analysis

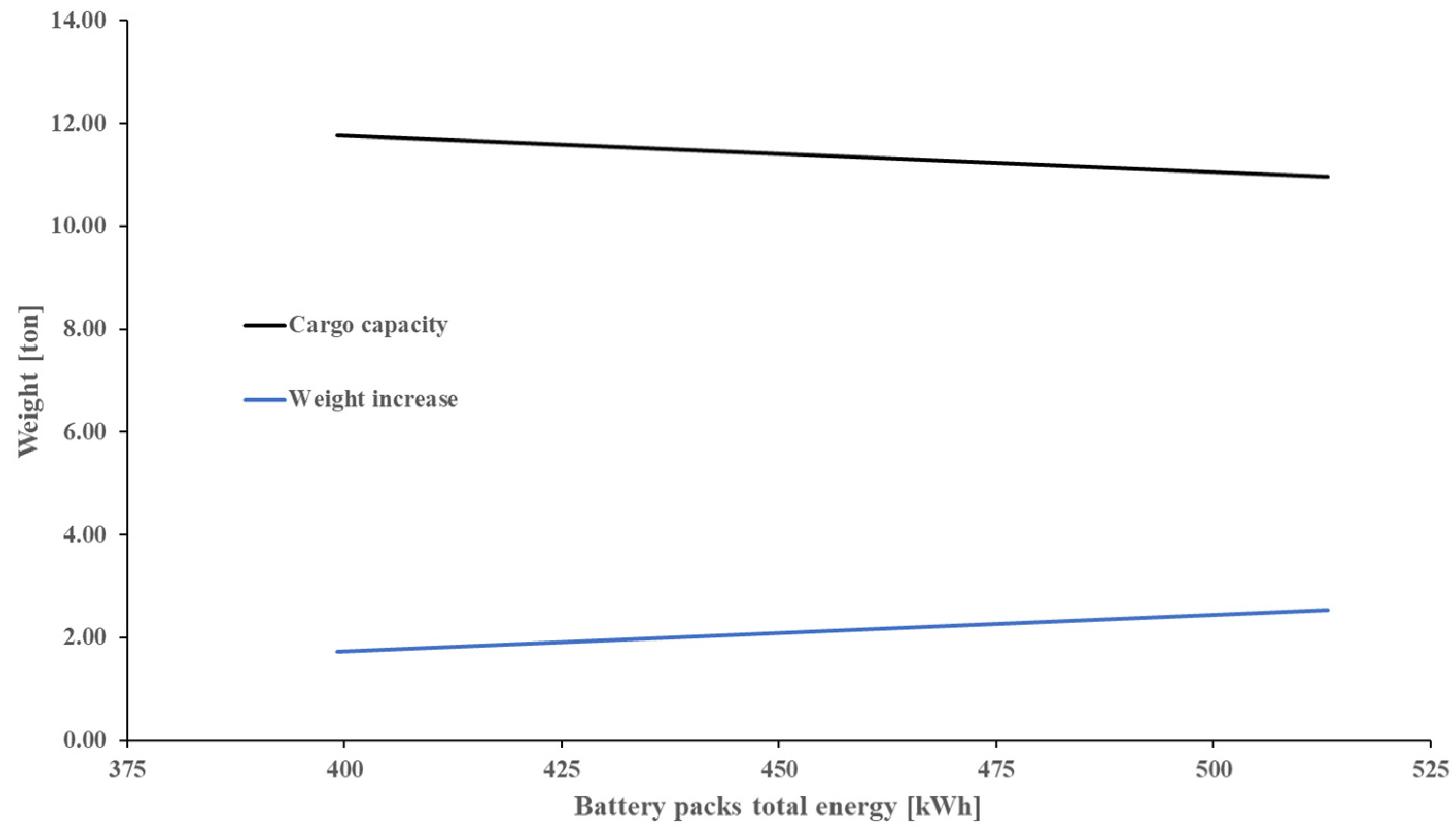

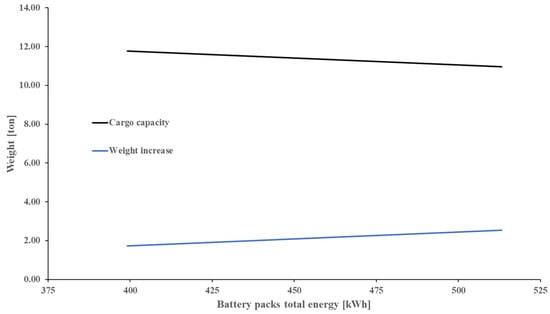

The effects of battery pack size variations on the cargo capacity of the proposed battery electric truck are shown in Figure 9. Electrification of the truck resulted in a decrease in its cargo capacity from 13.5 tons to 11.77 tons, 11.36 tons, and 10.96 tons by increasing the battery pack size to 399 kWh (35 rows), 456 kWh (40 rows), and 513 kWh (45 rows), respectively.

Figure 9.

Effect of battery pack size on cargo capacity.

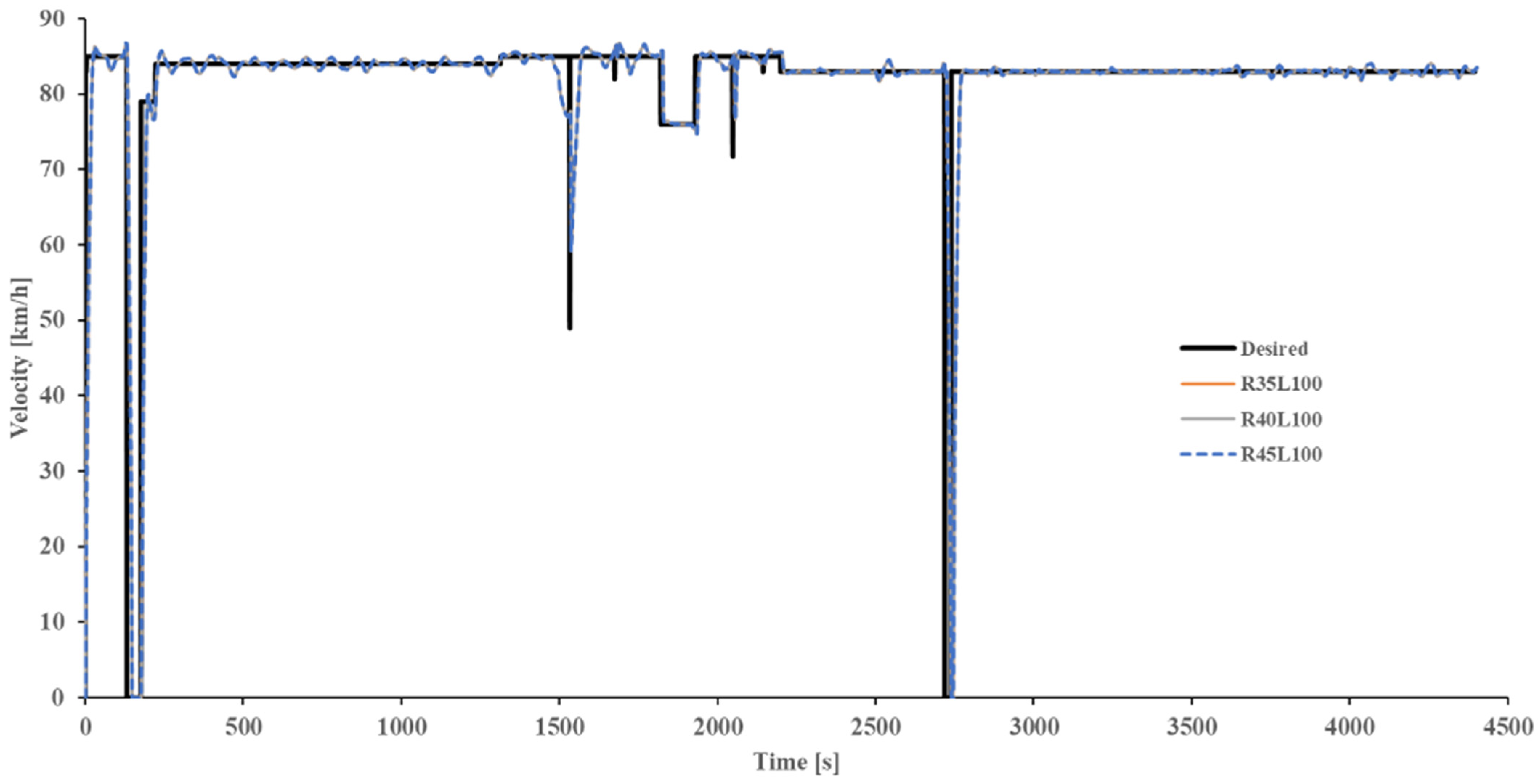

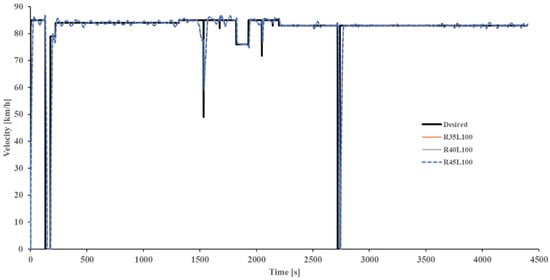

The difference between the desired and actual velocity of the proposed battery electric truck for different battery pack sizes at 100% cargo load is shown in Figure 10. The fluctuations in actual velocity in cruising velocities (desired profile) are due to the existence of road inclination, resulting in activation and deactivation of the brake pedal. The desired velocity is caught in most of the points, and minor deviation is observed in sudden acceleration point following from electric motor moment of inertia. Furthermore, Figure 10 also indicates that desired torque at various speeds is delivered by dual motors installed in the battery electric powertrain.

Figure 10.

Truck desired and actual velocity for different case studies in various times in proposed driving cycle.

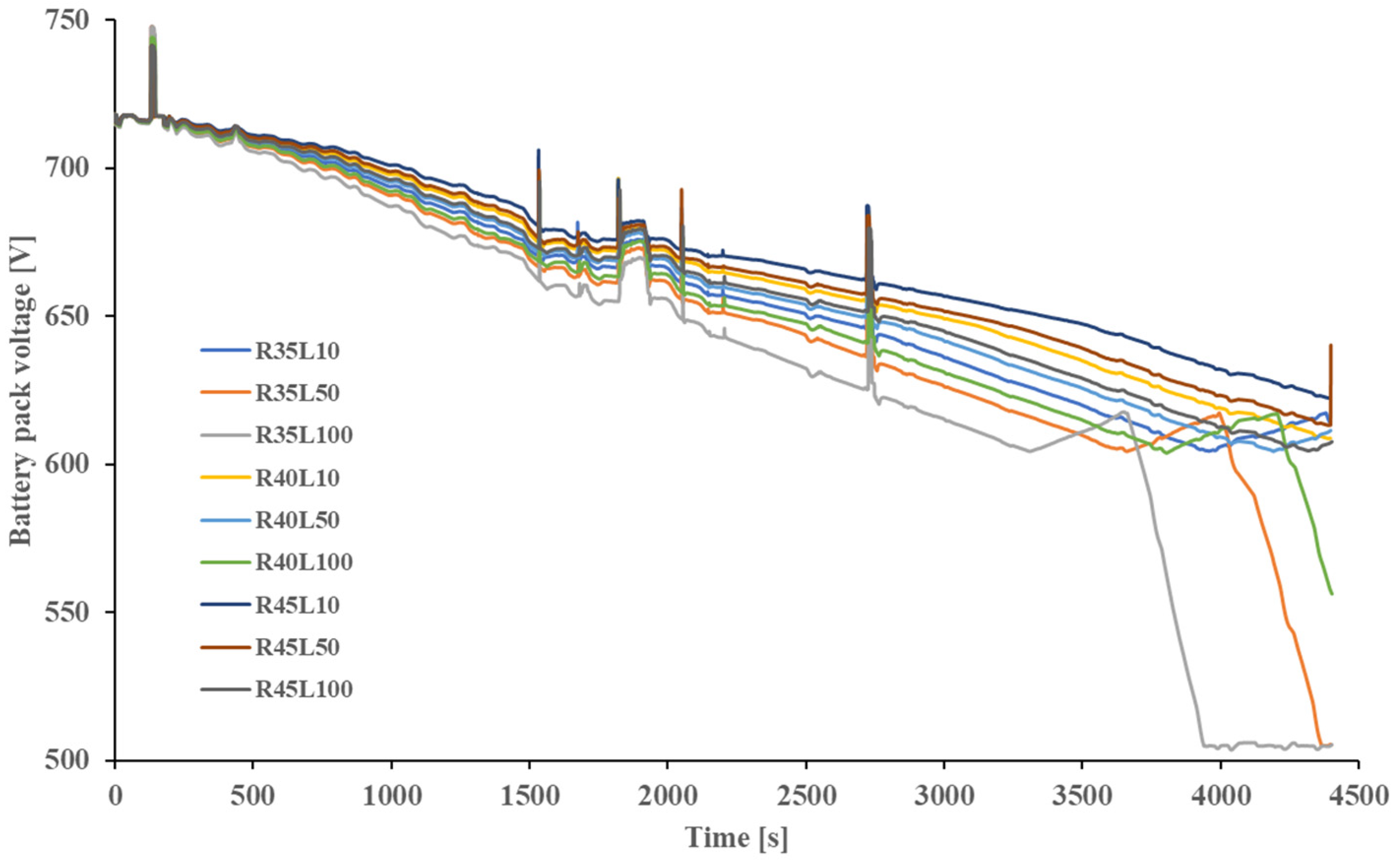

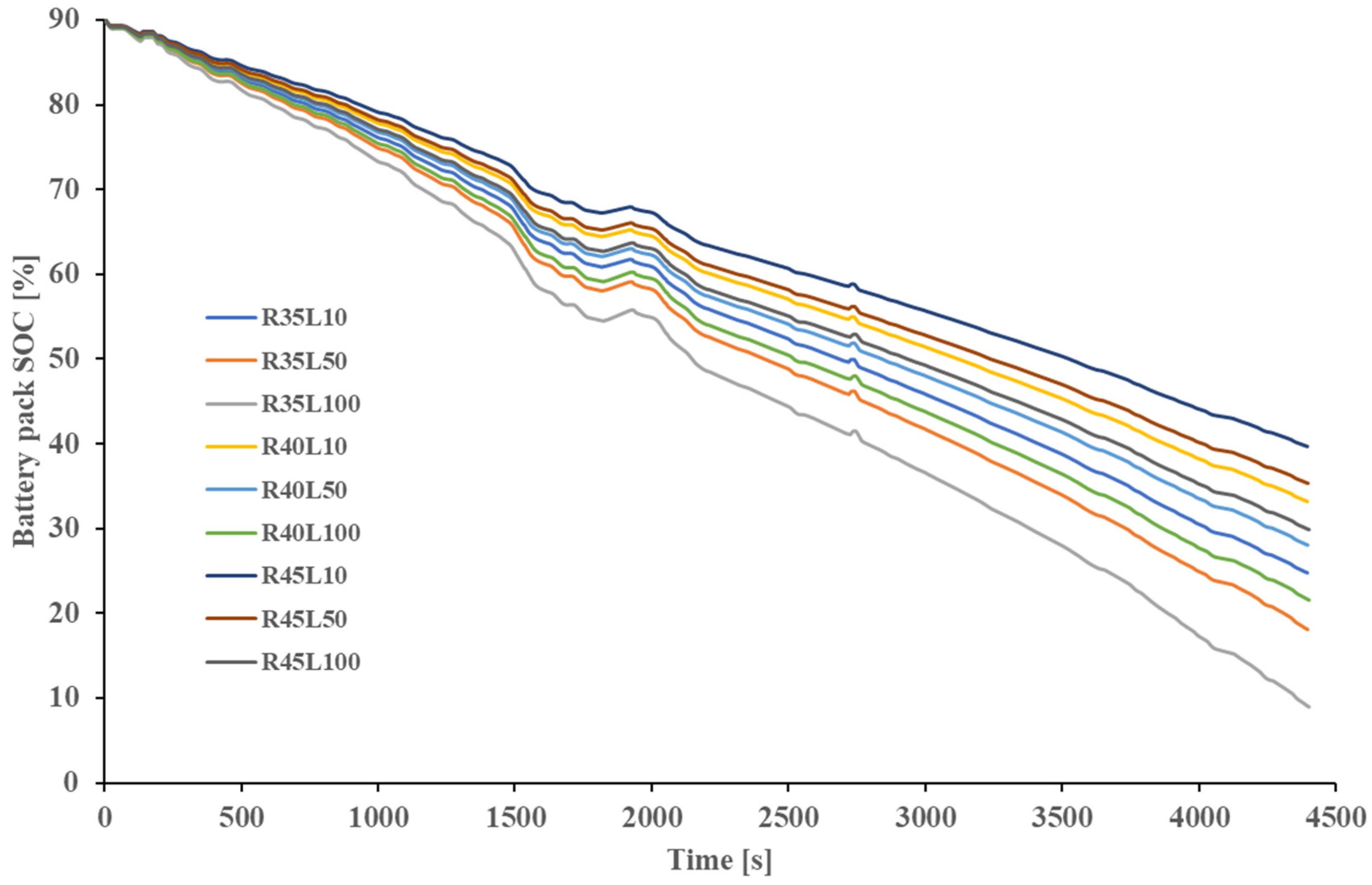

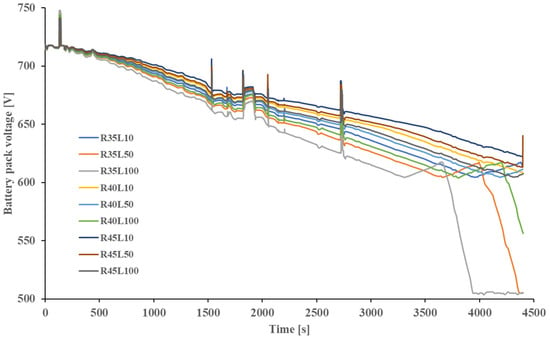

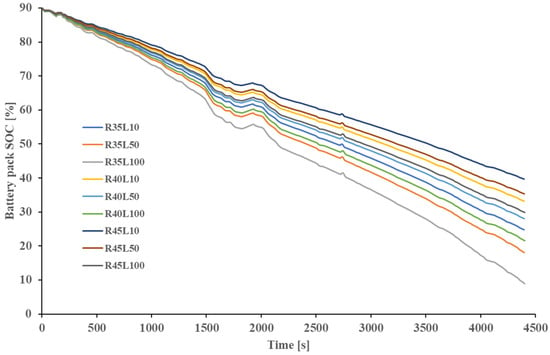

The battery pack voltage change during travel for different case scenarios is shown in Figure 11. By increasing the battery size, the overall voltage of the pack increased, while increment of occupied cargo capacity resulted in decrease of battery pack voltage due to faster discharging of the pack leading to sharp fade of voltage. There are four sharp increases in voltage during travel due to sharp changes in velocity as can be seen in Figure 11. When the velocity decreases sharply, a drastic increase in voltage is also observed. These sudden voltage jumps can be controlled by employing a programmed battery management system. In the last period of travel, steep increase of voltage is seen for R35L50, R35L100 and R40L100 due to reaching below 30% in SOC (Figure 12). As indicated in Figure 8a, there is a fluctuation in open circuit voltage for SOCs between 20% and 30%. The same trend is reflected in battery pack voltage, as is demonstrated in Figure 11. The most voltage fade belongs to R35L100 case scenario with lowest size of the battery and highest cargo capacity. This led to a sharper decrease in the battery pack voltage due to high power demand, resulting in a lower SOC being reached at the end of travel compared to other scenarios.

Figure 11.

The battery pack voltage variations during travel for different scenarios.

Figure 12.

The battery pack SOC variations during travel for different scenarios.

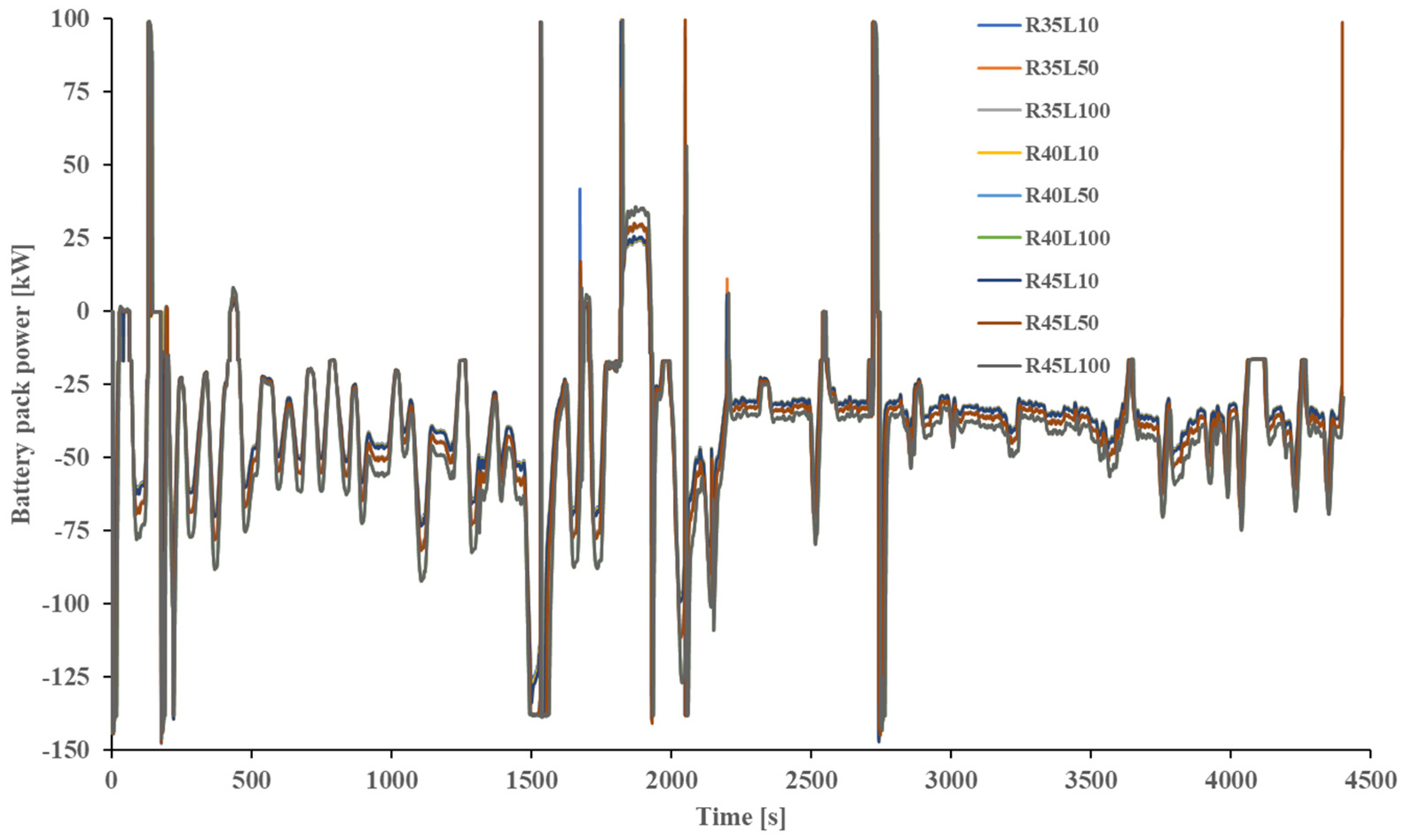

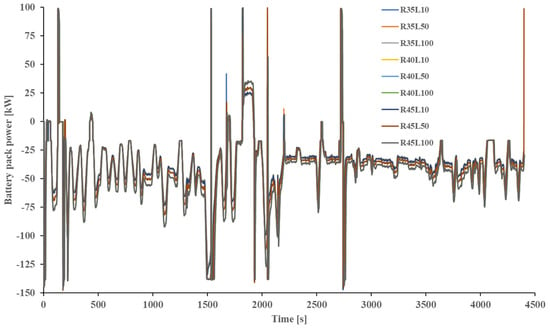

The battery power change is shown in Figure 13 in various time steps of the driving cycle for different scenarios. The discharging power increased during truck cruising speeds due to the increase in the cargo load. The highest charging peaks are achieved in the R45L100 scenario due to the existence of a larger battery and a large load (cargo) resulting in higher values of regenerative brake energy. However, the charging sudden peaks should be capped as well as discharging sharp peaks to prevent the battery from being damaged due to high temperature.

Figure 13.

The battery pack power variations during travel for different scenarios.

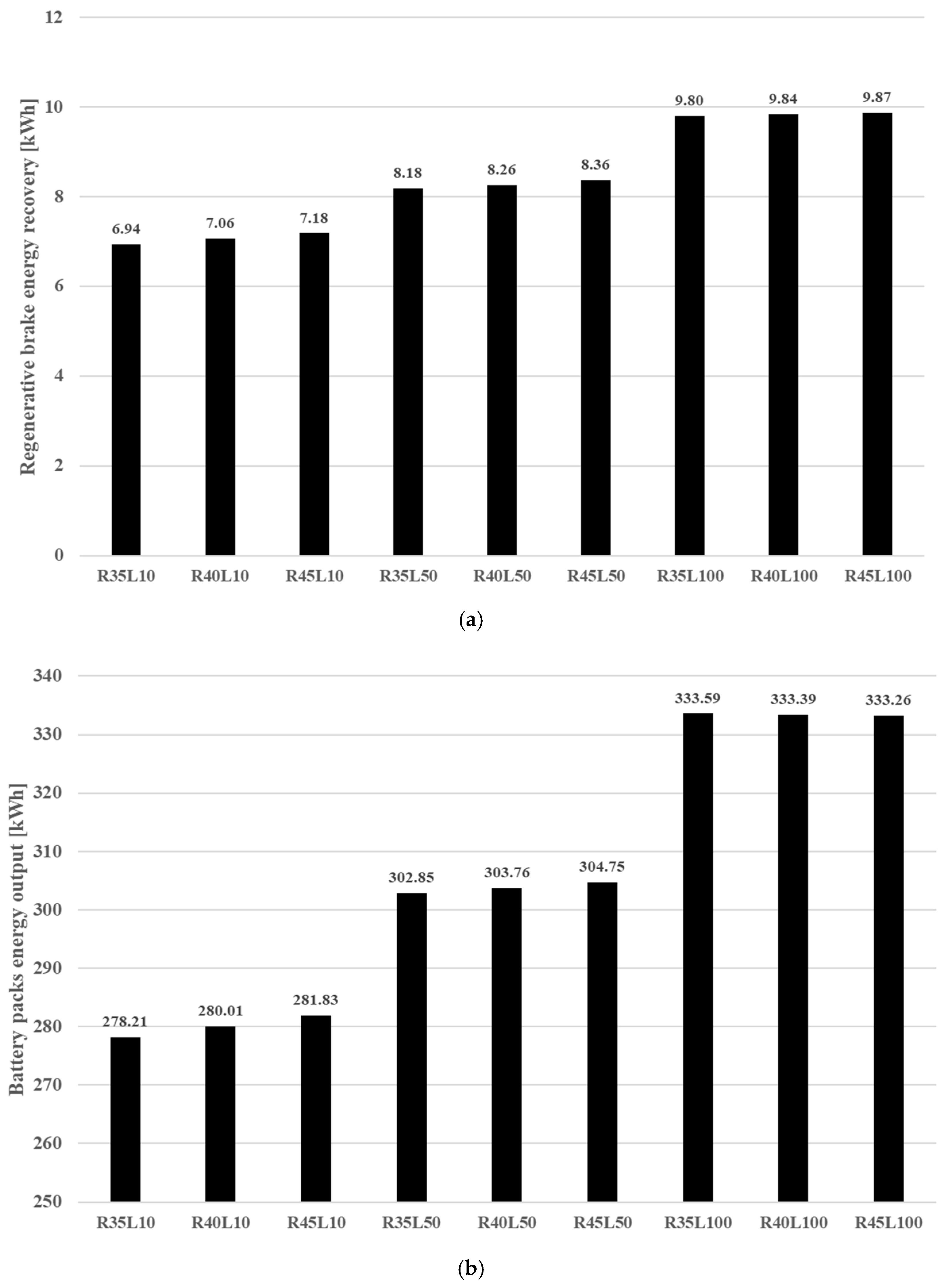

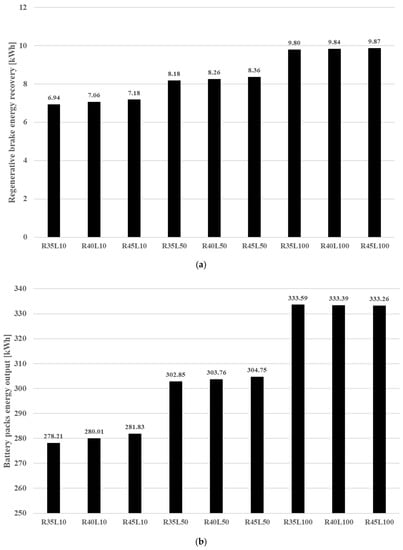

The cumulated energy recovered by regenerative brakes and consumed energy during travel for different scenarios is shown in Figure 14a,b. Regenerative brake energy increased from 6.94 kWh to approximately 9.87 kWh due to the increment in the truck cargo capacity between 10% and 100%. In addition, an increase in the battery cell rows in the packs from 35 to 40 and 45 resulted in energy recovery increases of 1.73% and 3.46% for 10% load, 0.98% and 2.2% for 50% load and 0.41% and 0.74% for 100% load, respectively. In addition, there were negligible changes in the energy consumption due to the increase in battery size since power demand remains constant.

Figure 14.

(a)The regenerative brake energy recovery and (b) battery pack energy output during travel for different scenarios.

4. Conclusions

In this paper, a parametric analysis is performed to assess the effect of battery pack sizing and cargo capacity of a truck on its energy performance. As the case study, the electrification of a class 8, 41 tons’ truck is performed by modelling and simulation of its battery electric powertrain in AVL CRUISE M software. The experimental lab battery testing data is used to parametrize the battery pack model in this study. Issues such as weight changes due to the addition of battery packs to the truck are also addressed. A parametric study is employed consisting of various case scenarios to evaluate the impacts of the battery pack size and cargo capacity on truck performance and energy consumption. The main conclusions drawn from this study can be listed as:

- -

- Electrification of the Mercedes–Benz Actros 41-ton truck resulted in decreasing of its cargo capacity from 13.5 tons to 12.27 tons, 11.86 tons, and 11.46 tons by increasing battery pack size from 399 kWh to 456 kWh and 513 kWh, respectively.

- -

- Employment of dual electric motors in the powertrain resulted in gaining desired torque at various speeds during travel in long haul driving cycle.

- -

- Increasing the battery size boosted the overall voltage of the pack, while an increment in occupied cargo capacity resulted in a decreased battery pack voltage due to faster discharging of the pack, leading to a sharp decrease in voltage.

- -

- The greatest decrease in voltage was achieved in battery packs when the cargo capacity was equal to 100% and the lowest size of battery pack was used. This leads to a sharper decrease in the battery pack voltage due to high power demand, resulting in a lower SOC at the end of travel compared to other scenarios.

- -

- The highest charging peaks were achieved for the scenario with the biggest battery pack size and full cargo capacity due to recovering higher values of regenerative brake energy.

- -

- Regenerative brake energy increased from 6.94 kWh to approximately 9.87 kWh by incrementing the truck occupied cargo capacity up to 100%.

- -

- Increase of total battery packs size from 399 kWh to 456 kWh and 513 kWh resulted in energy recovery increases of 1.73% and 3.46% for 10% load, 0.98% and 2.2% for 50% load and 0.41% and 0.74% for 100% load, respectively.

As a limitation of this research, it can be mentioned that the employed second-order ECM used to model the battery packs is not capable of predicting their capacity fade after driving in various number of cycles, which should be addressed and solved in future steps of this research. The developed methodology coupled with the experimental data presented in this paper would assist the future research and development activities aiming to truly optimize the performance of heavy-duty trucks to tackle the global net-energy targets as well as the local air quality requirements.

Author Contributions

Conceptualization, methodology, software, validation, A.T.L. and F.S.; formal analysis, S.R., A.A. and F.S.; resources, S.R. and A.A.; writing—original draft preparation, A.T.L., F.S. and S.R.; writing—review and editing, F.S., A.T.L. and S.R.; visualization, A.T.L. and F.S.; supervision, S.R., A.A. and F.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The related data are presented within the manuscript.

Acknowledgments

Special thanks to AVL List GmbH for providing the simulation tools through their University Partnership Program with Oxford Brookes University.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| EV | Electric Vehicle |

| ECM | Equivalent Circuit Model |

| SOC | State of Charge |

| HPPC | Hybrid Pulse Power Characterization |

| ICE | Internal Combustion Engine |

References

- Ding, S.; Li, R. Forecasting the sales and stock of electric vehicles using a novel self-adaptive optimized grey model. Eng. Appl. Artif. Intell. 2021, 100, 104148. [Google Scholar] [CrossRef]

- Borlaug, B.; Muratori, M.; Gilleran, M.; Woody, D.; Muston, W.; Canada, T.; Ingram, A.; Gresham, H.; McQueen, C. Heavy-duty truck electrification and the impacts of depot charging on electricity distribution systems. Nat. Energy 2021, 6, 673–682. [Google Scholar] [CrossRef]

- Machado, P.G.; Teixeira, A.C.; Collaço, F.M.; Mouette, D. Review of life cycle greenhouse gases, air pollutant emissions and costs of road medium and heavy-duty trucks. Wiley Interdiscip. Rev. Energy Environ. 2021, 10, e395. [Google Scholar] [CrossRef]

- Fenton, D.; Kailas, A. Redefining Goods Movement: Building an Ecosystem for the Introduction of Heavy-Duty Battery-Electric Vehicles. World Electr. Veh. J. 2021, 12, 147. [Google Scholar] [CrossRef]

- IEA. Trucks and Buses; IEA: Paris, France, 2022. Available online: https://www.iea.org/reports/trucks-and-buses (accessed on 1 August 2022).

- Borlaug, B.; Moniot, M.; Birky, A.; Alexander, M.; Muratori, M. Charging Needs for Electric Semi-Trailer Trucks. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Giuliano, G.; Dessouky, M.; Dexter, S.; Fang, J.; Hu, S.; Miller, M. Heavy-duty trucks: The challenge of getting to zero. Transp. Res. Part D Transp. Environ. 2021, 93, 102742. [Google Scholar] [CrossRef]

- Kyle, P.; Kim, S.H. Long-term implications of alternative light-duty vehicle technologies for global greenhouse gas emissions and primary energy demands. Energy Policy 2011, 39, 3012–3024. [Google Scholar] [CrossRef]

- Mauler, L.; Dahrendorf, L.; Duffner, F.; Winter, M.; Leker, J. Cost-effective technology choice in a decarbonized and diversified long-haul truck transportation sector: A US case study. J. Energy Storage 2022, 46, 103891. [Google Scholar] [CrossRef]

- Xie, S.; Lang, K.; Qi, S. Aerodynamic-aware coordinated control of following speed and power distribution for hybrid electric trucks. Energy 2020, 209, 118496. [Google Scholar] [CrossRef]

- Mareev, I.; Becker, J.; Sauer, D.U. Battery dimensioning and life cycle costs analysis for a heavy-duty truck considering the requirements of long-haul transportation. Energies 2018, 11, 55. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Coban, H.H.; Rehman, A.; Mohamed, A. Analyzing the Societal Cost of Electric Roads Compared to Batteries and Oil for All Forms of Road Transport. Energies 2022, 15, 1925. [Google Scholar] [CrossRef]

- Vijayagopal, R.; Rousseau, A. Electric truck economic feasibility analysis. World Electr. Veh. J. 2021, 12, 75. [Google Scholar] [CrossRef]

- Mareev, I.; Sauer, D.U. Energy Consumption and Life Cycle Costs of Overhead Catenary Heavy-Duty Trucks for Long-Haul Transportation. Energies 2018, 11, 3446. [Google Scholar] [CrossRef]

- Tanco, M.; Cat, L.; Garat, S. A break-even analysis for battery electric trucks in Latin America. J. Clean. Prod. 2019, 228, 1354–1367. [Google Scholar] [CrossRef]

- Nykvist, B.; Olsson, O. The feasibility of heavy battery electric trucks. Joule 2021, 5, 901–913. [Google Scholar] [CrossRef]

- Baek, D.; Chen, Y.; Chang, N.; Macii, E.; Poncino, M. Optimal Battery Sizing for Electric Truck Delivery. Energies 2020, 13, 709. [Google Scholar] [CrossRef]

- Available online: https://www.avl.com/cruise-m (accessed on 1 August 2022).

- Mantriota, G.; Reina, G. Dual-Motor Planetary Transmission to Improve Efficiency in Electric Vehicles. Machines 2021, 9, 58. [Google Scholar] [CrossRef]

- Agamloh, E.; von Jouanne, A.; Yokochi, A. An Overview of Electric Machine Trends in Modern Electric Vehicles. Machines 2020, 8, 20. [Google Scholar] [CrossRef]

- Dixit, M.; Parejiya, A.; Essehli, R.; Muralidharan, N.; Haq, S.U.; Amin, R.; Belharouak, I. SolidPAC is an interactive battery-on-demand energy density estimator for solid-state batteries. Cell Rep. Phys. Sci. 2022, 3, 100756. [Google Scholar] [CrossRef]

- Sankaran, G.; Venkatesan, S. Standardization of electric vehicle battery pack geometry form factors for passenger car segments in India. J. Power Sources 2021, 502, 230008. [Google Scholar] [CrossRef]

- Yang, C. Running battery electric vehicles with extended range: Coupling cost and energy analysis. Appl. Energy 2022, 306, 118116. [Google Scholar] [CrossRef]

- Li, J.; Du, Z.; Ruther, R.E.; An, S.J.; David, L.A.; Hays, K.; Wood, M.; Phillip, N.D.; Sheng, Y.; Mao, C. Toward low-cost, high-energy density, and high-power density lithium-ion batteries. JOM 2017, 69, 1484–1496. [Google Scholar] [CrossRef]

- Pell, J.; Schörghuber, C.; Schubert, T.; Ozli, S. Energy and Lifetime Management for Fuel Cell Powered Trucks. ATZheavy Duty Worldw. 2020, 13, 42–47. [Google Scholar] [CrossRef]

- Basma, H.; Beys, Y.; Rodríguez, F. Battery Electric Tractor-Trailers in the European Union: A Vehicle Technology Analysis. Retrieved from the International Council on Clean Transportation. 2021. Available online: https://theicct.org/publications/eu-tractor-trailers-analysis-aug21 (accessed on 1 August 2022).

- Hales, A.; Brouillet, E.; Wang, Z.; Edwards, B.; Samieian, M.A.; Kay, J.; Mores, S.; Auger, D.; Patel, Y.; Offer, G. Isothermal Temperature Control for Battery Testing and Battery Model Parameterization. SAE Int. J. Electrified Veh. 2021, 10, 105–122. [Google Scholar] [CrossRef]

- Ramesh Babu, A.; Andric, J.; Minovski, B.; Sebben, S. System-Level Modeling and Thermal Simulations of Large Battery Packs for Electric Trucks. Energies 2021, 14, 4796. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).