Temperature Effect on Electrical Resistivity Measurement Using an Embedded Sensor to Estimate Concrete Water Content

Abstract

1. Introduction

2. Methods and Materials

2.1. Electrical Resistivity Measurements

2.2. Temperature Correction Models

2.3. Experimental Program

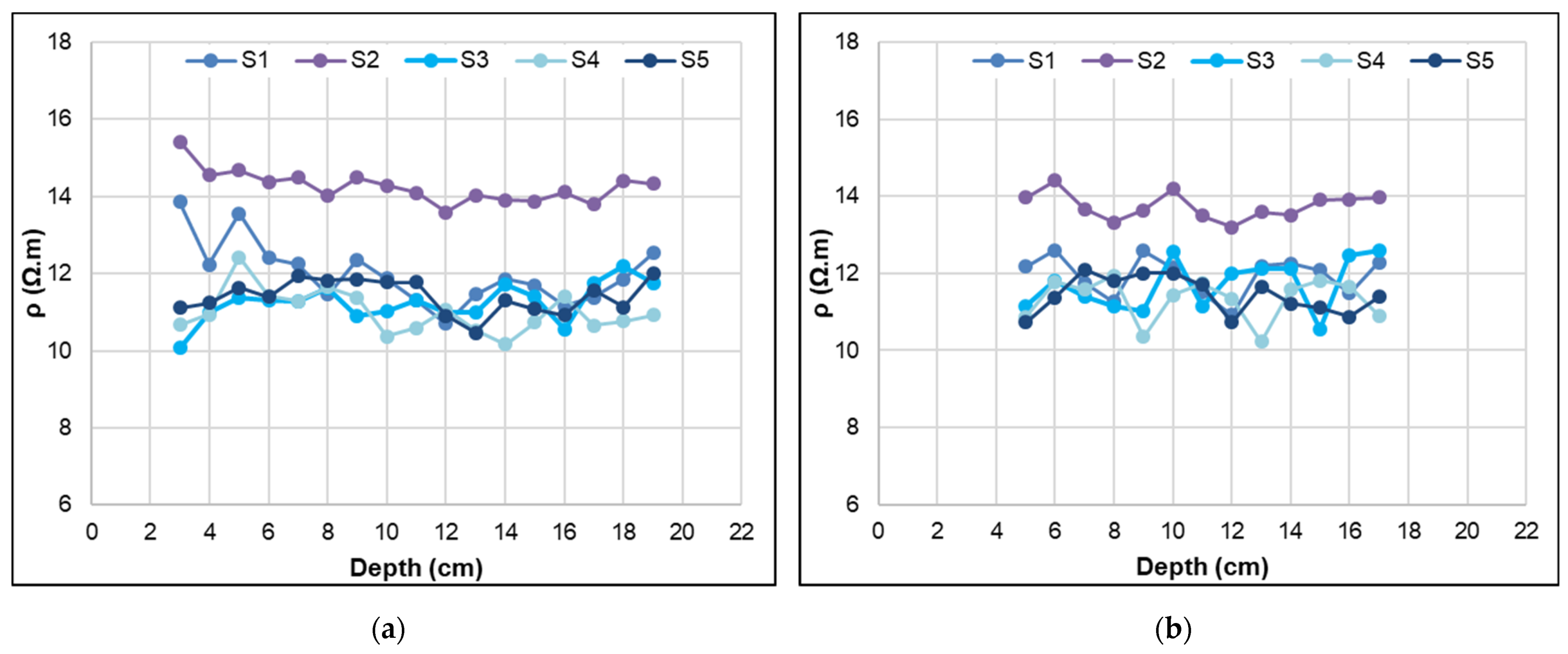

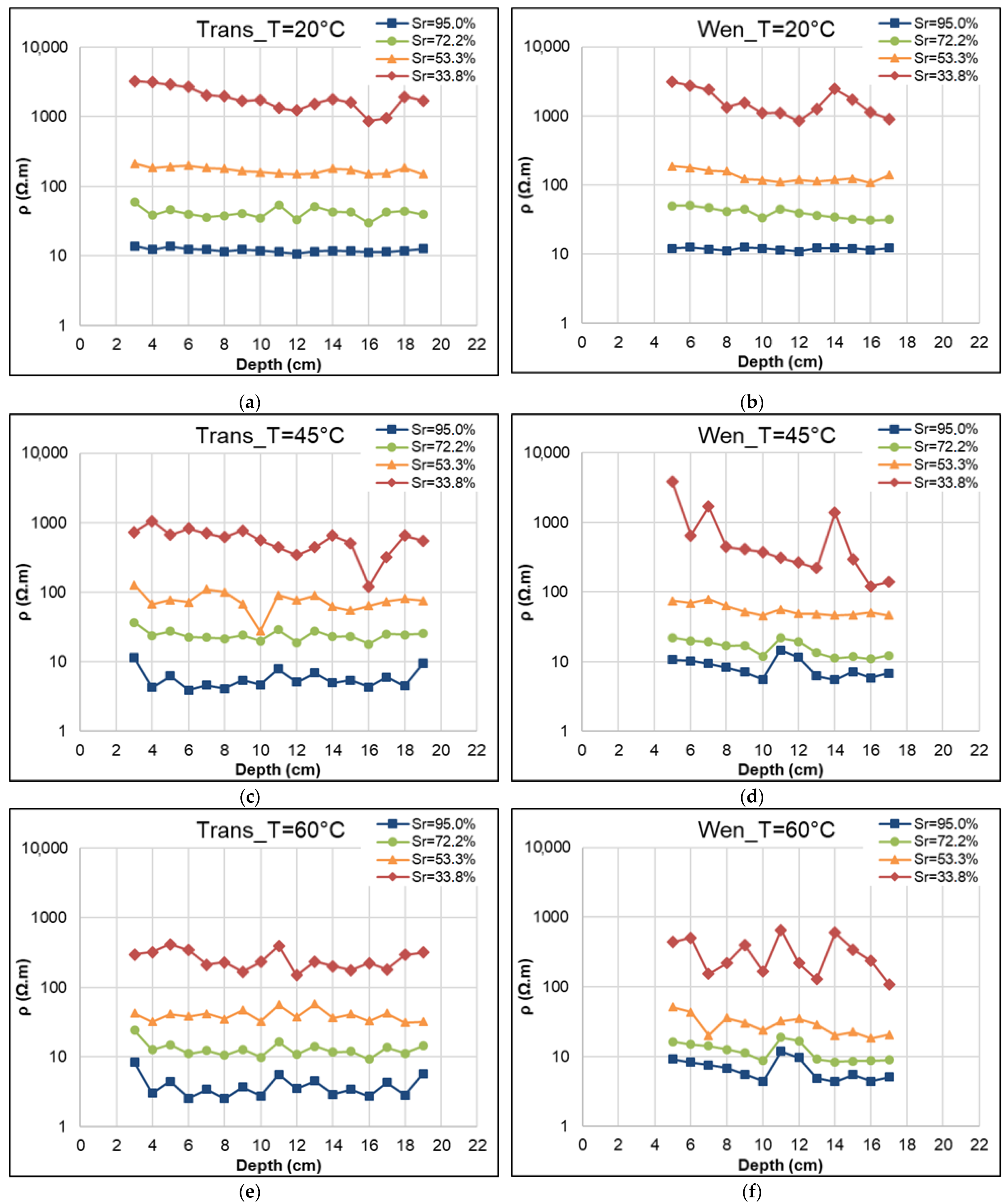

3. Results

4. Discussion of the Temperature Influence on Resistivity

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baroghel-Bouny, V. Concrete Design for a Given Structure Service Life—Durability Management with Regard to Reinforcement Corrosion and Alkali-Silica Reaction—State of the Art and Guide for the Implementation of a Predictive Performance Approach Based upon Durability Indicators, (French version 2004); AFGC: Paris, France, 2007; 252p. [Google Scholar]

- Lawrence, C.D. Mortar Expansions Due to Delayed Ettringite Formation: Effects of Curing Period and Temperature. Cem. Concr. Res. 1995, 25, 903–914. [Google Scholar] [CrossRef]

- Malbois, M.; Nedjar, B.; Lavaud, S.; Rospars, C.; Divet, L.; Torrenti, J.-M. On DEF expansion modelling in concrete structures under variable hydric conditions. Constr. Build. Mater. 2019, 207, 396–402. [Google Scholar] [CrossRef]

- McCarter, W.J.; Chrisp, T.M.; Butler, A.; Basheer, P.A.M. Near–surface sensors for condition monitoring of cover-zone concrete. Constr. Build. Mater. 2001, 15, 115–124. [Google Scholar] [CrossRef]

- Sbartaï, Z.M.; Laurens, S.; Rhazi, J.; Balayssac, J.P.; Arliguie, G. Using radar direct wave for concrete condition assessment: Correlation with electrical resistivity. J. Appl. Geophys. 2007, 62, 361–374. [Google Scholar] [CrossRef]

- Minagawa, H.; Miyamoto, S.; Hisada, M. Relationship of Apparent Electrical Resistivity Measured by Four-Probe Method with Water Content Distribution in Concrete. J. Adv. Concr. Technol. 2017, 15, 278–289. [Google Scholar] [CrossRef]

- Du Plooy, R.; Villain, G.; Palma-Lopes, S.; Ihamouten, A.; Dérobert, X.; Thauvin, B. Electromagnetic non-destructive evaluation techniques for the monitoring of water and chloride ingress into concrete: A comparative study. Mater. Struct. 2015, 48, 369–386. [Google Scholar] [CrossRef]

- Balayssac, J.-P.; Garnier, V. (Eds.) Non-Destructive Testing and Evaluation of Civil Engineering Structures; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Smyl, D. Electrical tomography for characterizing transport properties in cement-based materials: A review. Constr. Build. Mater. 2020, 244, 118299. [Google Scholar] [CrossRef]

- Larsen, C.K.; Sellevold, E.J.; Askeland, F.; Østvik, J.M.; Vennesland, O. Electrical resistivity of concrete part II: Influence of moisture content and temperature. In Proceedings of the 2nd International Symposium on Advances in Concrete through Science and Engineering, Quebec city, QC, Canada, 11–13 September 2006. [Google Scholar]

- Fares, M.; Villain, G.; Bonnet, S.; Palma-Lopes, S.; Thauvin, B.; Thiéry, M. Determining chloride content profiles in concrete using a resistivity probe. Cem. Concr. Compos. 2018, 94, 315–326. [Google Scholar] [CrossRef]

- Archie, G.E. The electrical resistivity log as an aid in determining some reservoir characteristics. Trans. Am. Inst. Min. Metall. Eng. 1942, 146, 54–62. [Google Scholar] [CrossRef]

- Lim, Y.-C.; Kim, T.; Hwang, C.-S. Modeling for apparent resistivity estimation along direction of electrode array above rebar in electrical resistivity measurement. J. Build. Eng. 2020, 31, 101417. [Google Scholar] [CrossRef]

- Polder, R.B. Test methods for on site measurement of resistivity of concrete—A RILEM TC-154 technical recommendation. Constr. Build. Mater. 2001, 15, 125–131. [Google Scholar] [CrossRef]

- Alhajj, M.A.; Palma-Lopes, S.; Villain, G. Accounting for steel rebar effect on resistivity profiles in view of reinforced concrete structure survey. Constr. Build. Mater. 2019, 223, 898–909. [Google Scholar] [CrossRef]

- Gowers, K.; Millard, S. Measurement of concrete resistivity for assessment of corrosion. ACI Mater. J. 1999, 96, 536–541. [Google Scholar]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R. Corrosion of Steel in Concrete; Wiley: Weinheim, Germany, 2013. [Google Scholar]

- Rasch, E.; Willy Hinrichsen, F. Über eine Beziehung zwischen elektrischer Leitfähigkeit und Temperatur. Z. Für Elektrochem. Und Angew. Phys. Chem. 1908, 14, 41–46. [Google Scholar]

- Keller, G.V.; Frischknecht, F.C. Electrical Methods in Geophysical Prospecting; Pergamon: Oxford, UK, 1966. [Google Scholar]

- Castellote, M.; Alonso, M.C.; Andrade, C. Standardization, to a reference of 25 °C, of electrical resistivity for mortars and concretes in saturated or isolated conditions. ACI Mater. J. 2002, 99, 119–127. [Google Scholar]

- Polder, R.; Andrade, C.; Elsener, B.; Vennesland, Ø.; Gulikers, J.; Weidert, R.; Raupach, M. Test methods for on site measurement of resistivity of concrete. Mater. Struct. 2000, 33, 603–611. [Google Scholar] [CrossRef]

- Lataste, J.-F. Évaluation Non Destructive de L’état D’endommagement des Ouvrages en Béton Armé Par Mesures de Résistivité Electrique. Ph.D. Thesis, Université de Bordeaux 1, Bordeaux, France, 2002. [Google Scholar]

- Chataigner, S.; Saussol, J.-L.; Dérobert, X.; Villain, G.; Aubagnac, C. Temperature influence on electromagnetic measurements of concrete moisture. Eur. J. Environ. Civ. Eng. 2015, 19, 482–495. [Google Scholar] [CrossRef][Green Version]

- Elkey, W.; Sellevold, E.J. Electrical Resistivity of Concrete; Norwegian Public Roads Administration Publication: Oslo, Norway, 1995; 33p. [Google Scholar]

- Hayley, K.; Bentley, L.R.; Gharibi, M.; Nightingale, M. Low temperature dependence of electrical resistivity: Implications for near surface geophysical monitoring. Geophys. Res. Lett. 2007, 34, L18402. [Google Scholar] [CrossRef]

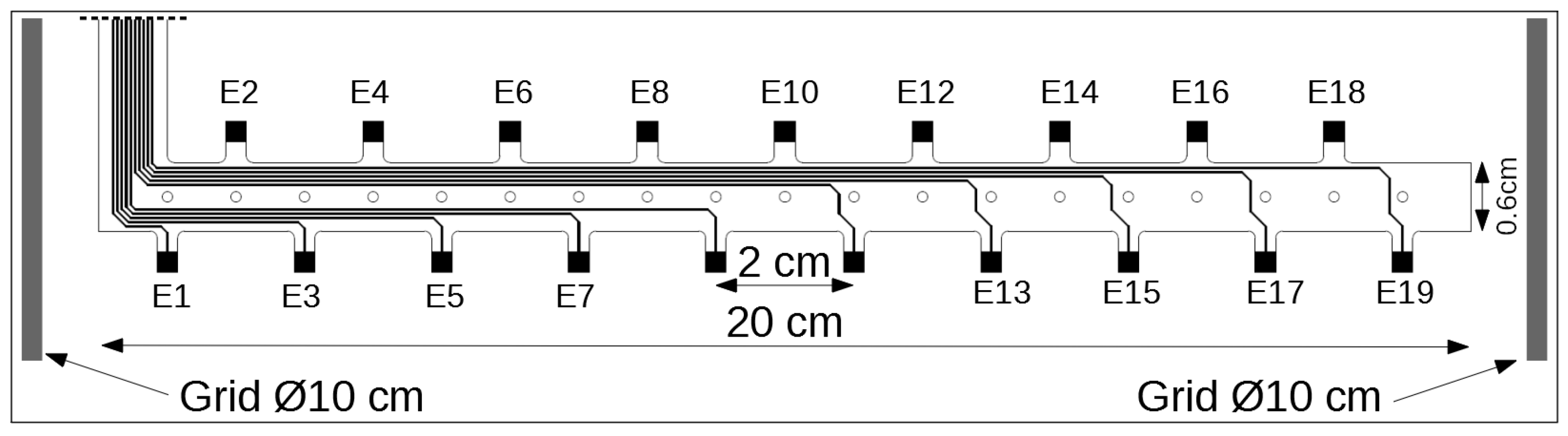

- Badr, J.; Fargier, Y.; Palma-Lopes, S.; Deby, F.; Balayssac, J.-P.; Delepine-Lesoille, S.; Cottineau, L.-M.; Villain, G. Design and validation of a multi-electrode embedded sensor to monitor resistivity profiles over depth in concrete. Constr. Build. Mater. 2019, 223, 310–321. [Google Scholar] [CrossRef]

- Lecieux, Y.; Schoefs, F.; Bonnet, S.; Lecieux, T.; Palma-Lopes, S. Quantification and uncertainty analysis of a structural monitoring device: Detection of chloride in concrete using DC electrical resistivity measurement. Nondestruct. Test. Eval. 2015, 30, 216–232. [Google Scholar] [CrossRef]

- Villain, G.; Sbartaï, Z.M.; Lataste, J.-F.; Garnier, V.; Dérobert, X.; Abraham, O.; Bonnet, S.; Balayssac, J.-P.; Nguyen, N.T.; Fares, M. Characterization of water gradients in concrete by complementary NDT methods. In Proceedings of the International Symposium Non-Destructive Testing in Civil Engineering (NDT-CE 2015), Berlin, Germany, 15–17 September 2015; 12p. [Google Scholar]

- Bässler, R.; Mietz, J.; Raupach, M.; Klinghoffer, O. Corrosion Monitoring sensors for durability assessment of reinforced concrete structures. In Proceedings of the International Society for Optical Engineering (SPIE 2000), Newport Beach, CA, USA, 20–26 January 2000. [Google Scholar]

- McCarter, W.J.; Starrs, G.; Chrisp, T.M. Electrical conductivity, diffusion, and permeability of Portland cement-based mortars. Cem. Concr. Res. 2000, 30, 1395–1400. [Google Scholar] [CrossRef]

- Chrisp, T.M.; Starrs, G.; McCarter, W.J.; Rouchotas, E.; Blewett, J. Temperature-conductivity relationships for concrete: An activation energy approach. J. Mater. Sci. Lett. 2001, 20, 1085–1087. [Google Scholar] [CrossRef]

- Osterminski, K.; Schießl, P.; Volkwein, A.; Mayer, T.F. Modelling reinforcement corrosion–Usability of a factorial approach for modelling resistivity of concrete. Mater. Corros. 2006, 57, 926–931. [Google Scholar] [CrossRef]

- McCarter, W.J.; Taha, H.M.; Suryanto, B.; Starrs, G. Two-point concrete resistivity measurements: Interfacial phenomena at the electrode–concrete contact zone. Meas. Sci. Technol. 2015, 26, 085007. [Google Scholar] [CrossRef]

- Bockris, J.O.; Reddy, A.K.N. Volume 1: Modern Electrochemistry: Ionics, 2nd ed.; Springer: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Liu, Y.; Presuel-Moreno, F.J. Normalization of Temperature Effect on Concrete Resistivity by Method Using Arrhenius Law (with Appendix). Mater. J. 2014, 111, 433–442. [Google Scholar] [CrossRef]

- Pour-Ghaz, M.; Isgor, O.B.; Ghods, P. The effect of temperature on the corrosion of steel in concrete. Part 1: Simulated polarization resistance tests and model development. Corros. Sci. 2009, 51, 415–425. [Google Scholar] [CrossRef]

- Parrott, L.J. Moisture conditioning and transport properties of concrete test specimens. Mater. Struct. 1994, 27, 460. [Google Scholar] [CrossRef]

- Villain, G.; Garnier, V.; Sbartaï, Z.M.; Derobert, X.; Balayssac, J.-P. Development of a calibration methodology to improve the on-site non-destructive evaluation of concrete durability indicators. Mater. Struct. 2018, 51, 40. [Google Scholar] [CrossRef]

- Hunkeler, F. The resistivity of pore water solution—a decisive parameter of rebar corrosion and repair methods. Constr. Build. Mater. 1996, 10, 381–389. [Google Scholar] [CrossRef]

- Villagrán Zaccardi, Y.A.; Fullea García, J.; Huélamo, P.; Di Maio, A.A. Influence of temperature and humidity on Portland cement mortar resistivity monitored with inner sensors. Mater. Corros. 2009, 60, 294–299. [Google Scholar] [CrossRef]

- Du Plooy, R.; Lopes, S.P.; Villain, G.; Dérobert, X. Development of a multi-ring resistivity cell and multi-electrode resistivity probe for investigation of cover concrete condition. NDT E Int. 2013, 54, 27–36. [Google Scholar] [CrossRef]

| Constituents | Origin | Quantity (kg/m3) |

|---|---|---|

| Aggregates 4/12 | Boulonnais | 984 |

| Sand 0/4 | Boulonnais | 890 |

| Cement CEM I 52.5 N | Val d’Azergue | 350 |

| Effective water (Weff) | 206 | |

| Weff/C | 0.59 | |

| Compressive strength at 28 days | 42.6 + 1.3 MPa | |

| Porosity accessible to water at 28 days | 15.3 + 0.3% |

| ρ (Ω.m) | 95.0 ± 2.0% | 72.2 ± 1.0% | 53.3 ± 0.3% | 33.8 ± 0.5% | ||

|---|---|---|---|---|---|---|

| Transmission | 20 °C | 11.9 ± 1.3 | 40.1 ± 4.6 | 175 ± 22.1 | 1906 ± 142 | |

| 45 °C | 8.0 ± 0.6 | 26.5 ± 1.0 | 71.5 ± 7.2 | 883 ± 279 | ||

| 60 °C | 5.3 ± 0.4 | 15.8 ± 2.4 | 42.4 ± 4.3 | 379 ± 101 | ||

| Wenner | 20 °C | 12.1 ± 1.1 | 42.5 ± 6.1 | 140 ± 15.5 | 1710 ± 383 | |

| 45 °C | 8.1 ± 1.9 | 17.7 ± 3.8 | 61.6 ± 9.2 | 641 ± 145 | ||

| 60 °C | 5.7 ± 1.7 | 10.3 ± 2.6 | 31.8 ± 7.1 | 303 ± 54 | ||

| A (Ω.m) | R2 | ||

|---|---|---|---|

| 95.0 ± 2.0 | 9.82 × 10−3 | 20.14 | 0.937 |

| 72.2 ± 1.0 | 9.25 × 10−3 | 20.40 | 0.890 |

| 53.3 ± 0.3 | 2.53 × 10−3 | 27.06 | 0.940 |

| 33.8 ± 0.5 | 1.74 × 10−3 | 33.54 | 0.942 |

| Configuration | 95.0 ± 2.0% | 72.2 ± 1.0% | 53.3 ± 0.3% | 33.8 ± 0.5% | ||

|---|---|---|---|---|---|---|

| Transmission | 20–45 °C | 1.32 | 1.36 | 2.37 | 2.15 | |

| 45–60 °C | 2.29 | 2.69 | 2.72 | 3.80 | ||

| Wenner | 20–45 °C | 1.35 | 2.33 | 2.25 | 2.50 | |

| 45–60 °C | 1.93 | 2.79 | 3.22 | 3.51 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badr, J.; Mahfoud, E.; Villain, G.; Balayssac, J.-P.; Palma Lopes, S.; Fargier, Y.; Yven, B. Temperature Effect on Electrical Resistivity Measurement Using an Embedded Sensor to Estimate Concrete Water Content. Appl. Sci. 2022, 12, 9420. https://doi.org/10.3390/app12199420

Badr J, Mahfoud E, Villain G, Balayssac J-P, Palma Lopes S, Fargier Y, Yven B. Temperature Effect on Electrical Resistivity Measurement Using an Embedded Sensor to Estimate Concrete Water Content. Applied Sciences. 2022; 12(19):9420. https://doi.org/10.3390/app12199420

Chicago/Turabian StyleBadr, Joanna, Elie Mahfoud, Géraldine Villain, Jean-Paul Balayssac, Sérgio Palma Lopes, Yannick Fargier, and Béatrice Yven. 2022. "Temperature Effect on Electrical Resistivity Measurement Using an Embedded Sensor to Estimate Concrete Water Content" Applied Sciences 12, no. 19: 9420. https://doi.org/10.3390/app12199420

APA StyleBadr, J., Mahfoud, E., Villain, G., Balayssac, J.-P., Palma Lopes, S., Fargier, Y., & Yven, B. (2022). Temperature Effect on Electrical Resistivity Measurement Using an Embedded Sensor to Estimate Concrete Water Content. Applied Sciences, 12(19), 9420. https://doi.org/10.3390/app12199420