Characterisation of Bario Rice Flour Varieties: Nutritional Compositions and Physicochemical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Rice Flour Production

2.2.2. Nutritional Compositions

2.2.3. Physicochemical Properties

2.2.4. Thermal Properties

2.2.5. Statistical Analysis

3. Results and Discussion

3.1. Nutritional Compositions

3.1.1. Moisture Content

3.1.2. Ash Content

3.1.3. Crude Fibre Content

3.1.4. Crude Protein Content

3.1.5. Crude Fat Content

3.1.6. Carbohydrate Content

3.1.7. Amylose Content

3.2. Physicochemical Properties

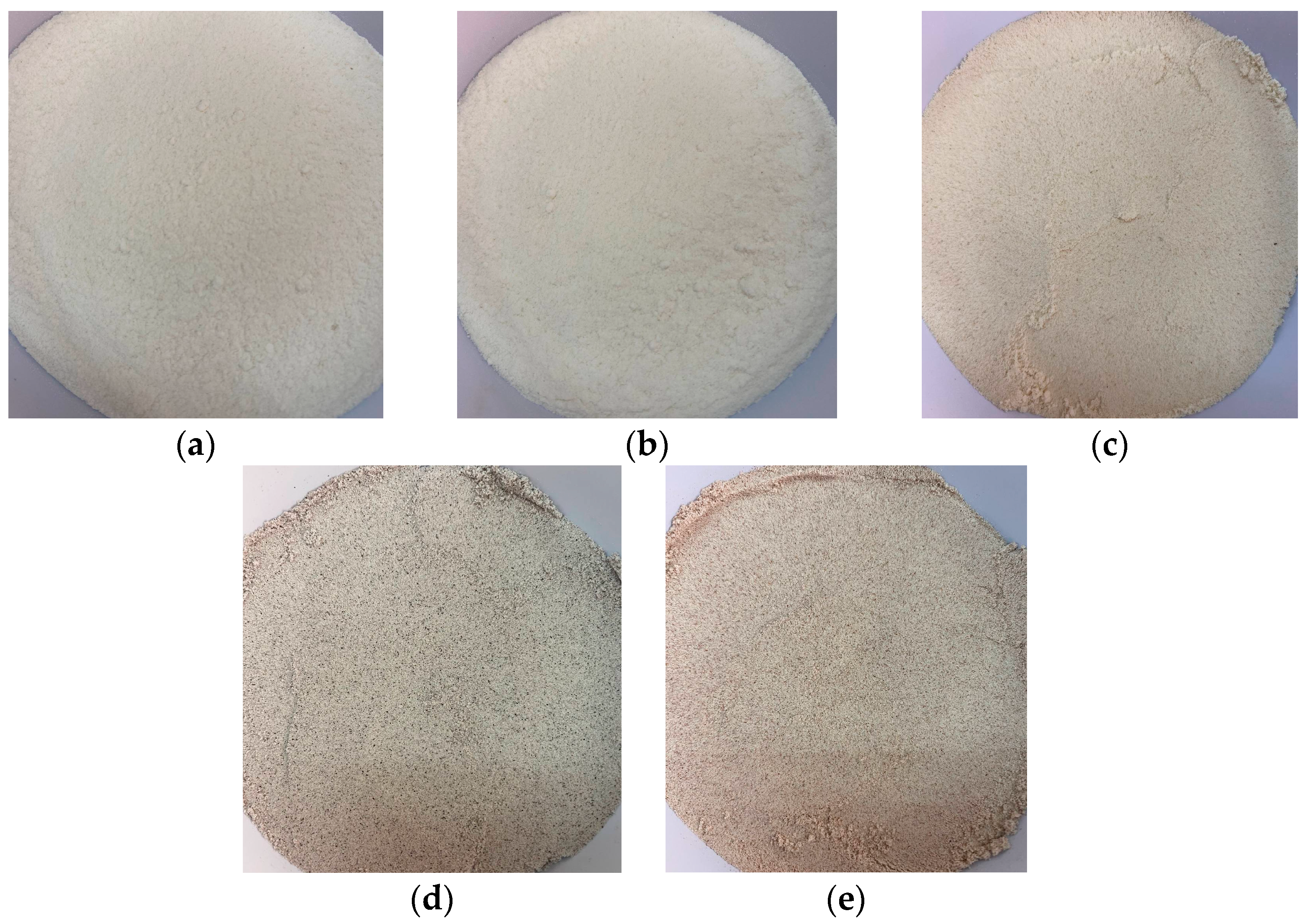

3.2.1. Colour Analysis

3.2.2. Water Absorption Capacity

3.2.3. Swelling Capacity

3.2.4. Water Solubility Index

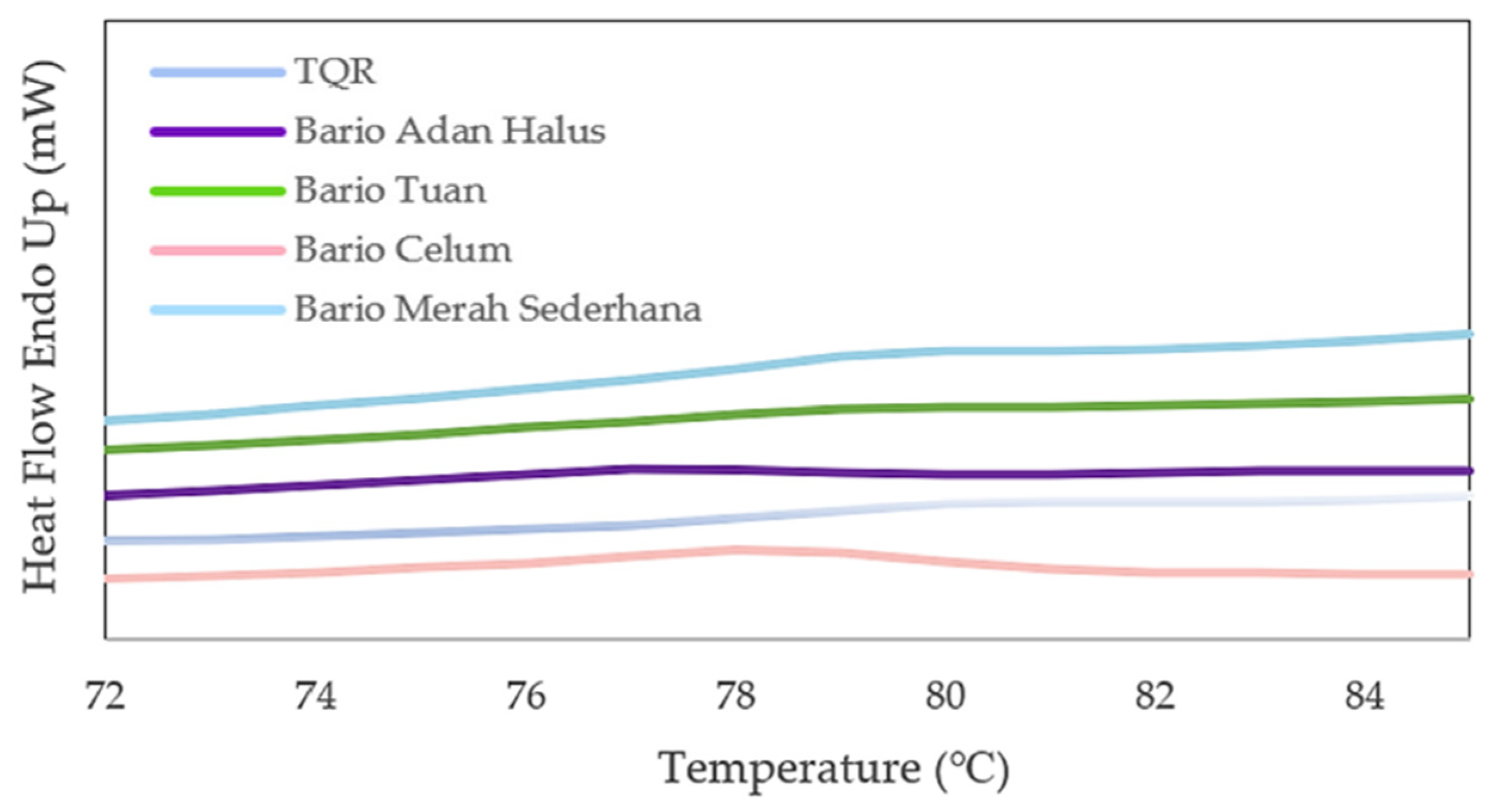

3.2.5. Gelatinitisation

3.2.6. Retrogradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ooms, N.; Delcour, J.A. How to impact gluten protein network formation during wheat flour dough making. Curr. Opin. Food Sci. 2019, 25, 88–97. [Google Scholar] [CrossRef]

- Lin, H.I.; Yu, Y.Y.; Wen, F.I.; Liu, P.T. Status of Food Security in East and Southeast Asia and Challenges of Climate Change. Climate 2022, 10, 40. [Google Scholar] [CrossRef]

- Grain and Feed Annual (Annual Report MY2022-0001). Available online: https://apps.fas.usda.gov/newgainapi/api/Report/DownloadReportByFileName?fileName=Grain%20and%20Feed%20Annual_Kuala%20Lumpur_Malaysia_MY2022-0001.pdf (accessed on 11 July 2022).

- Ren, Y.; Linter, B.R.; Linforth, R.; Foster, T.J. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020, 11, 5333–5345. [Google Scholar] [CrossRef] [PubMed]

- Asri, N.; Rostami-Nejad, M.; Anderson, R.P.; Rostami, K. The gluten gene: Unlocking the understanding of gluten sensitivity and intolerance. Appl. Clin. Genet. 2021, 14, 37. [Google Scholar] [CrossRef]

- Catassi, C.; Verdu, E.F.; Bai, J.C.; Lionetti, E. Coeliac disease. Lancet 2021, 399, 2413–2426. [Google Scholar] [CrossRef]

- Bascuñán, K.A.; Araya, M.; Roncoroni, L.; Doneda, L.; Elli, L. Dietary gluten as a conditioning factor of the gut microbiota in celiac disease. Adv. Nutr. 2020, 11, 160–174. [Google Scholar] [CrossRef] [PubMed]

- Tharise, N.; Julianti, E.; Nurminah, M. Evaluation of physico-chemical and functional properties of composite flour from cassava, rice, potato, soybean and xanthan gum as alternative of wheat flour. Int. Food Res. J. 2014, 21, 1642–1643. [Google Scholar]

- Feizollahi, E.; Mirmoghtadaie, L.; Mohammadifar, M.A.; Jazaeri, S.; Hadaegh, H.; Nazari, B.; Lalegani, S. Sensory, digestion, and texture quality of commercial gluten-free bread: Impact of broken rice flour type. J. Texture Stud. 2018, 49, 395–403. [Google Scholar] [CrossRef]

- Aleman, R.S.; Paz, G.; Morris, A.; Prinyawiwatkul, W.; Moncada, M.; King, J.M. High protein brown rice flour, tapioca starch & potato starch in the development of gluten-free cupcakes. Food Sci. Technol. 2021, 152, 112326. [Google Scholar] [CrossRef]

- Wu, T.; Wang, L.; Li, Y.; Qian, H.; Liu, L.; Tong, L.; Zhou, S. Effect of milling methods on the properties of rice flour and gluten-free rice bread. Food Sci. Technol. 2019, 108, 137–144. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, D.C.; Lee, S.E.; Kim, O.W.; Kim, H.; Lim, S.T.; Kim, S.S. Effects of rice flour size fractions on gluten free rice bread. Food Sci. Biotechnol. 2014, 23, 1875–1883. [Google Scholar] [CrossRef]

- Luo, S.; Yan, X.; Fu, Y.; Pang, M.; Chen, R.; Liu, Y.; Chen, J.; Liu, C. The quality of gluten-free bread made of brown rice flour prepared by low temperature impact mill. Food Chem. 2021, 348, 129032. [Google Scholar] [CrossRef] [PubMed]

- Gui, Y.; Chen, G.; Tian, W.; Yang, S.; Chen, J.; Wang, F.; Li, Y. Normal rice flours perform better in gluten-free bread than glutinous rice flours. J. Food Sci. 2022, 87, 554–566. [Google Scholar] [CrossRef] [PubMed]

- Wong, S.C.; Yiu, P.H.; Bong, S.T.W.; Lee, H.H.; Neoh, P.N.P.; Rajan, A. Analysis of Sarawak Bario rice diversity using microsatellite markers. Am. J. Agric. Biol. Sci. 2009, 4, 298–304. [Google Scholar] [CrossRef]

- Thomas, R.; Yeoh, T.K.; Wan-Nadiah, W.A.; Bhat, R. Quality evaluation of flat rice noodles (Kway Teow) prepared from Bario and Basmati rice. Sains Malays. 2014, 43, 339–347. Available online: http://www.ukm.edu.my/jsm/pdf_files/SM-PDF-43-3-2014/03%20Rachel%20Thomas.pdf. (accessed on 14 July 2022).

- Kevin, M.T.S.; Ahmed, O.H.; Asrina, W.Y.W.; Rajan, A.; Ahzam, M. Towards growing Bario rice on lowland soils: A preliminary nitrogen and potassium fertilization trial. Am. J. Agric. Biol. Sci. 2007, 2, 99–105. [Google Scholar] [CrossRef]

- Nicholas, D.; Hazila, K.K.; Chua, H.P.; Rosniyana, A. Nutritional value and glycemic index of Bario rice varieties. J. Trop. Agric. Food Sci. 2014, 42, 1–8. Available online: http://jtafs.mardi.gov.my/jtafs/42-1/Bario%20rice.pdf (accessed on 14 July 2022).

- Sharma, K.; Lee, Y.R. Effect of different storage temperature on chemical composition of onion (Allium cepa L.) and its enzymes. J. Food Sci. Technol. 2016, 53, 1620–1632. [Google Scholar] [CrossRef]

- Nielsen, S.S. Food Analysis Laboratory Manual, 3rd ed.; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-44127-6. [Google Scholar]

- Bolea, C.A.; Grigore-Gurgu, L.; Aprodu, I.; Vizireanu, C.; Stănciuc, N. Process-structure-function in association with the main bioactive of black rice flour sieving fractions. Foods 2019, 8, 131. [Google Scholar] [CrossRef]

- Hunter L, a, b Versus CIE 1976 L* a* b*. Available online: https://support.hunterlab.com/hc/en-us/article_attachments/201437795/an02_01.pdf (accessed on 20 July 2022).

- Coțovanu, I.; Mironeasa, S. Buckwheat Seeds: Impact of milling fractions and addition level on wheat bread dough rheology. Appl. Sci. 2021, 11, 1731. [Google Scholar] [CrossRef]

- Kraithong, S.; Lee, S.; Rawdkuen, S. Physicochemical and functional properties of Thai organic rice flour. J. Cereal Sci. 2018, 79, 259–266. [Google Scholar] [CrossRef]

- Noorfarahzilah, M.; Mansoor, A.H.; Hasmadi, M. Proximate composition, mineral content and functional properties of Tarap (Artocarpus odoratissimus) seed flour. Food Res. 2017, 1, 89–96. [Google Scholar] [CrossRef]

- Anyasi, T.A.; Jideani, A.I.; Mchau, G.R. Effects of organic acid pretreatment on microstructure, functional and thermal properties of unripe banana flour. J. Food Meas. Charact. 2017, 11, 99–110. [Google Scholar] [CrossRef] [Green Version]

- Gunaratne, A.; Wu, K.; Collado, L.; Gan, R.Y.; Arachchi, L.V.; Kumara, K.; Corke, H. Physicochemical and functional properties of Caryota urens flour as compared to wheat flour. Int. J. Food Sci. Technol. 2016, 51, 2647–2653. [Google Scholar] [CrossRef]

- Wani, I.A.; Andrabi, S.N.; Sogi, D.S.; Hassan, I. Comparative study of physicochemical and functional properties of flours from kidney bean (Phaseolus vulgaris L.) and green gram (Vigna radiata L.) cultivars grown in Indian temperate climate. Legume Sci. 2020, 2, e11. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Zhang, X.; Copeland, L.; Wang, S. Retrogradation enthalpy does not always reflect the retrogradation behavior of gelatinised starch. Sci. Rep. 2016, 6, 20965. [Google Scholar] [CrossRef]

- Islam, M.Z.; Ud-Din, M.S.; Haque, M.A. Studies on the effect of brown rice and maise flour on the quality of bread. J. Bangladesh Agric. Univ. 2011, 9, 297–304. [Google Scholar] [CrossRef]

- Muttagi, G.C.; Ravindra, U. Chemical and nutritional composition of traditional rice varieties of Karnataka. J. Pharmacogn. Phytochem. 2020, 9, 2300–2309. [Google Scholar] [CrossRef]

- Oppong, D.; Panpipat, W.; Chaijan, M. Chemical, physical, and functional properties of Thai indigenous brown rice flours. PLoS ONE 2021, 16, e0255694. [Google Scholar] [CrossRef]

- Jamal, S.; Qazi, I.M.; Ahmed, I. Comparative studies on flour proximate compositions and functional properties of selected Pakistani rice varieties. Pak. Acad. Sci. 2016, 53, 47–56. Available online: https://www.paspk.org/wp-content/uploads/2016/05/Comparative-Studies-on.pdf (accessed on 26 July 2022).

- Legal Research Board. Part VIII: Standard and Particular Labelling Requirements for Food (Cereal, Cereal Product, Starch and Bread. In Food Act 1983 (Act 281) & Regulations (Laws of Malaysia); International Law Book Services: Selangor, Malaysia, 2021; p. 99. [Google Scholar]

- USDA Foreign Agricultural Service (Rice Flour Standards and Labelling Guidelines Established). Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Rice%20Flour%20Standards%20and%20Labelling%20Guidelines%20Established_Tokyo_Japan_6-28-2017.pdf (accessed on 20 July 2020).

- Verma, D.K.; Srivastav, P.P. Proximate composition, mineral content and fatty acids analyses of aromatic and non-aromatic Indian rice. Rice Sci. 2017, 24, 21–31. [Google Scholar] [CrossRef]

- Rahman, A.N.F.; Bilang, M.; Ikawati, L.N. Physical and proximate analysis of green banana cake premix flour. IOP Conf. Ser. Earth Environ. Sci. 2020, 486, 12051. [Google Scholar] [CrossRef]

- Bello, B.K.; Hou, Y.; Zhao, J.; Jiao, G.; Wu, Y.; Li, Z.; Zhang, J. NF-YB 1-YC 12-bHLH 144 complex directly activates Wx to regulate grain quality in rice (Oryza sativa L.). Plant Biotechnol. J. 2019, 17, 1222–1235. [Google Scholar] [CrossRef] [PubMed]

- Czaja, T.; Sobota, A.; Szostak, R. Quantification of ash and moisture in wheat flour by Raman spectroscopy. Foods 2020, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Thongkaew, C.; Singthong, J. Effect of partial substitution of riceberry rice flour on rice noodles quality. Food Res. 2020, 4, 9–16. [Google Scholar] [CrossRef]

- Varastegani, B.; Zzaman, W.; Yang, T.A. Investigation on physicochemical and sensory evaluation of cookies substituted with papaya pulp flour. J. Food Qual. 2015, 38, 175–183. [Google Scholar] [CrossRef]

- Yuliana, N.D.; Akhbar, M.A. Chemical and physical evaluation, antioxidant and digestibility profiles of white and pigmented rice from different areas of Indonesia. Braz. J. Food Technol. 2020, 23, 1–13. [Google Scholar] [CrossRef]

- Singh, N.; Paul, P.; Virdi, A.S.; Kaur, P.; Mahajan, G. Influence of early and delayed transplantation of paddy on physicochemical, pasting, cooking, textural, and protein characteristics of milled rice. Cereal Chem. 2014, 91, 389–397. [Google Scholar] [CrossRef]

- Hager, A.S.; Wolter, A.; Jacob, F.; Zannini, E.; Arendt, E.K. Nutritional properties and ultra-structure of commercial gluten free flours from different botanical sources compared to wheat flours. J. Cereal Sci. 2012, 56, 239–247. [Google Scholar] [CrossRef]

- Paz, G.M.; King, J.M.; Prinyawiwatkul, W. High Protein Rice Flour in the Development of Gluten-Free Bread. J. Culin. Sci. Technol. 2021, 19, 315–330. [Google Scholar] [CrossRef]

- Puri, S.; Dhillon, B.; Sodhi, N.S. Effect of degree of milling (Dom) on overall quality of rice—A review. Int. J. Adv. Biotechnol. Res. 2014, 5, 474–489. [Google Scholar]

- Priya, T.R.; Nelson, A.R.L.E.; Ravichandran, K.; Antony, U. Nutritional and functional properties of coloured rice varieties of South India: A review. J. Ethn. Foods 2019, 6, 11. [Google Scholar] [CrossRef]

- Sapwarobol, S.; Saphyakhajorn, W.; Astina, J. Biological functions and activities of rice bran as a functional ingredient: A review. Nutr. Metab. Insights 2021, 14, 11786388211058559. [Google Scholar] [CrossRef] [PubMed]

- Araki, E.; Ashida, K.; Aoki, N.; Takahashi, M.; Hamada, S. Characteristics of rice flour suitable for the production of rice flour bread containing gluten and methods of reducing the cost of producing rice flour. Jpn. Agric. Res. Q. JARQ 2016, 50, 23–31. [Google Scholar] [CrossRef]

- Takahashi, M.; Homma, N.; Morohashi, K.; Nakamura, K.; Suzuki, Y. Effect of rice cultivar characteristics on the rice flour bread quality. Nippon. Shokuhin Kagaku Kogaku Kaishi = J. Jpn. Soc. Food Sci. Technol. 2009, 56, 394–402. [Google Scholar] [CrossRef] [Green Version]

- Yano, H.; Koda, T.; Fujita, N.; Nishioka, A. Effect of amylose content in rice flour on batter rheology and bread baking quality. J. Food Processing Preserv. 2020, 44, e14462. [Google Scholar] [CrossRef]

- Zhang, H.; Jang, S.G.; Lar, S.M.; Lee, A.R.; Cao, F.Y.; Seo, J.; Kwon, S.W. Genome-wide identification and genetic variations of the starch synthase gene family in rice. Plants 2021, 10, 1154. [Google Scholar] [CrossRef]

- Aoki, N.; Kataoka, T.; Nishiba, Y. Crucial role of amylose in the rising of gluten-and additive-free rice bread. J. Cereal Sci. 2020, 92, 102905. [Google Scholar] [CrossRef]

- Yano, H.; Fukui, A.; Kajiwara, K.; Kobayashi, I.; Yoza, K.I.; Satake, A.; Villeneuve, M. Development of gluten-free rice bread: Pickering stabilization as a possible batter-swelling mechanism. LWT-Food Sci. Technol. 2017, 79, 632–639. [Google Scholar] [CrossRef]

- Aoki, N.; Umemoto, T.; Hamada, S.; Suzuki, K.; Suzuki, Y. The amylose content and amylopectin structure affect the shape and hardness of rice bread. J. Appl. Glycosci. 2012, 59, 75–82. [Google Scholar] [CrossRef]

- Subba, D.; Katawal, S.B. Effect of particle size of rice flour on physical and sensory properties of Sel-roti. J. Food Sci. Technol. 2013, 50, 181–185. [Google Scholar] [CrossRef] [PubMed]

- Ponjanta, J.; Chomsri, N.O.; Meechoui, S. Correlation of pasting behaviors with total phenolic compounds and starch digestibility of indigenous pigmented rice grown in upper Northern Thailand. Funct. Foods Health Dis. 2016, 6, 133–143. [Google Scholar] [CrossRef]

- Huang, Y.P.; Lai, H.M. Bioactive compounds and antioxidative activity of colored rice bran. J. Food Drug Anal. 2016, 24, 564–574. [Google Scholar] [CrossRef] [PubMed]

- Rosniyana, A.; Hazila, K.K.; Syed, A.S.N. Characteristics of local rice flour (MR 220) produced by wet and dry milling methods. J. Trop. Agric. Food Sci. 2016, 44, 147–155. Available online: http://jtafs.mardi.gov.my/jtafs/44-1/characteristics.pdf (accessed on 1 August 2022).

- Martínez, M.M.; Gómez, M. Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J. Food Eng. 2017, 197, 78–86. [Google Scholar] [CrossRef]

- Thomas, R.; Bhat, R.; Kuang, Y.T.; Abdullah, W.N.W. Functional and pasting properties of locally grown and imported exotic rice varieties of Malaysia. Food Sci. Technol. Res. 2014, 20, 469–477. [Google Scholar] [CrossRef] [Green Version]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef]

- Han, H.M.; Cho, J.H.; Kang, H.W.; Koh, B.K. Rice varieties in relation to rice bread quality. J. Sci. Food Agric. 2012, 92, 1462–1467. [Google Scholar] [CrossRef]

- Cornejo, F.; Rosell, C.M. Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. Food Sci. Technol. 2015, 62, 1203–1210. [Google Scholar] [CrossRef]

- Vamadevan, V.; Bertoft, E. Observations on the impact of amylopectin and amylose structure on the swelling of starch granules. Food Hydrocoll. 2020, 103, 105663. [Google Scholar] [CrossRef]

- Wani, A.A.; Singh, P.; Shah, M.A.; Schweiggert-Weisz, U.; Gul, K.; Wani, I.A. Rice starch diversity: Effects on structural, morphological, thermal, and physicochemical properties—A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 417–436. [Google Scholar] [CrossRef]

- Li, G.; Zhu, F. Physicochemical properties of quinoa flour as affected by starch interactions. Food Chem. 2017, 221, 1560–1568. [Google Scholar] [CrossRef] [PubMed]

- Waziiroh, E.; Schoenlechner, R.; Jaeger, H.; Brusadelli, G.; Bender, D. Understanding gluten-free bread ingredients during ohmic heating: Function, effect and potential application for breadmaking. Eur. Food Res. Technol. 2022, 248, 1021–1034. [Google Scholar] [CrossRef]

- Kusumayanti, H.; Handayani, N.A.; Santosa, H. Swelling power and water solubility of cassava and sweet potatoes flour. Procedia Environ. Sci. 2015, 23, 164–167. [Google Scholar] [CrossRef]

- Suklaew, P.O.; Chusak, C.; Adisakwattana, S. Physicochemical and functional characteristics of RD43 rice flour and its food application. Foods 2020, 9, 1912. [Google Scholar] [CrossRef] [PubMed]

- Shafi, S.; Wani, I.A.; Gani, A.; Sharma, P.; Wani, H.M.; Masoodi, F.A.; Hamdani, A.M. Effect of water and ether extraction on functional and antioxidant properties of Indian horse chestnut (Aesculus indica Colebr) flour. J. Food Meas. Charact. 2016, 10, 387–395. [Google Scholar] [CrossRef]

- Thiranusornkij, L.; Thamnarathip, P.; Chandrachai, A.; Kuakpetoon, D.; Adisakwattana, S. Physicochemical properties of Hom Nil (Oryza sativa) rice flour as gluten free ingredient in bread. Foods 2018, 7, 159. [Google Scholar] [CrossRef]

- Šárka, E.; Dvořáček, V. New processing and applications of waxy starch (a review). J. Food Eng. 2017, 206, 77–87. [Google Scholar] [CrossRef]

- Hasjim, J.; Li, E.; Dhital, S. Milling of rice grains: Effects of starch/flour structures on gelatinisation and pasting properties. Carbohydr. Polym. 2013, 92, 682–690. [Google Scholar] [CrossRef]

- Amini, A.M.; Razavi, S.M.A.; Mortazavi, S.A. Morphological, physicochemical, and viscoelastic properties of sonicated corn starch. Carbohydr. Polym. 2015, 122, 282–292. [Google Scholar] [CrossRef]

- Farooq, M.A.; Murtaza, M.A.; Aadil, R.M.; Arshad, R.; Rahaman, A.; Siddique, R.; Haq, A.U. Investigating the structural properties and in vitro digestion of rice flours. Food Sci. Nutr. 2021, 9, 2668–2675. [Google Scholar] [CrossRef] [PubMed]

- Biliaderis, C.G.; Page, C.M.; Maurice, T.J.; Juliano, B.O. Thermal characterisation of rice starches: A polymeric approach to phase transitions of granular starch. J. Agric. Food Chem. 1986, 34, 6–14. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Roman, L.; Reguilon, M.P.; Gomez, M.; Martinez, M.M. Intermediate length amylose increases the crumb hardness of rice flour gluten-free breads. Food Hydrocoll. 2020, 100, 105451. [Google Scholar] [CrossRef]

- Shi, M.; Chen, Y.; Yu, S.; Gao, Q. Preparation and properties of RS III from waxy maise starch with pullulanase. Food Hydrocoll. 2013, 33, 19–25. [Google Scholar] [CrossRef]

- Chang, Q.; Zheng, B.; Zhang, Y.; Zeng, H. A comprehensive review of the factors influencing the formation of retrograded starch. Int. J. Biol. Macromol. 2021, 186, 163–173. [Google Scholar] [CrossRef] [PubMed]

- Becker, A.; Hill, S.E.; Mitchell, J.R. Relevance of amylose-lipid complexes to the behaviour of thermally processed starches. Starch-Stärke 2001, 53, 121–130. [Google Scholar] [CrossRef]

- Kang, N.; Reddy, C.K.; Park, E.Y.; Choi, H.D.; Lim, S.T. Antistaling effects of hydrocolloids and modified starch on bread during cold storage. Food Sci. Technol. 2018, 96, 13–18. [Google Scholar] [CrossRef]

- Fu, Z.; BeMiller, J.N. Effect of hydrocolloids and salts on retrogradation of native and modified maise starch. Food Hydrocoll. 2017, 69, 36–48. [Google Scholar] [CrossRef]

- Yamaguchi, Y.; Okawa, Y.; Ninomiya, K.; Kumagai, H.; Kumagai, H. Evaluation and suppression of retrogradation of gelatinised rice starch. J. Nutr. Sci. Vitaminol. 2019, 65, 134–138. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, paste, and gel properties of starch–hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

| Nutritional Compositions | TQR | Bario Adan Halus | Bario Tuan | Bario Celum | Bario Merah Sederhana |

|---|---|---|---|---|---|

| Moisture | 8.47 ± 0.05 b | 8.35 ± 0.03 c | 8.69 ± 0.05 a | 8.67 ± 0.05 a | 8.50 ± 0.02 b |

| Ash | 0.25 ± 0.01 d | 0.27 ± 0.00 d | 1.25 ± 0.06 a | 0.63 ± 0.01 c | 0.98 ± 0.02 b |

| Crude fiber | 0.13 ± 0.03 c | 0.21 ± 0.03 c | 0.87 ± 0.05 a | 0.55 ± 0.07 b | 0.62 ± 0.09 b |

| Crude protein | 7.81 ± 0.45 c | 8.97 ± 0.08 ab | 8.66 ± 0.08 b | 6.89 ± 0.01 d | 9.43 ± 0.04 a |

| Crude fat | 0.22 ± 0.07 c | 0.16 ± 0.03 c | 2.45 ± 0.08 a | 1.13 ± 0.07 b | 1.32 ± 0.11 b |

| Carbohydrate | 83.12 ± 0.35 ab | 82.04 ± 0.10 ab | 79.25 ± 1.19 c | 82.13 ± 0.01 ab | 79.17 ± 0.29 c |

| Amylose content | 32.97 ± 2.96 a | 26.67 ± 0.49 b | 36.52 ± 1.37 a | 26.68 ± 0.69 b | 32.05 ± 0.81 ab |

| Analysis | TQR | Bario Adan Halus | Bario Tuan | Bario Celum | Bario Merah Sederhana |

|---|---|---|---|---|---|

| Colour | |||||

| L* | 93.62 ± 0.04 a | 94.34 ± 0.05 b | 84.84 ± 0.07 c | 70.99 ± 0.36 d | 75.26 ± 0.04 e |

| a* | −0.15 ± 0.01 d | −0.21 ± 0.02 d | 2.12 ± 0.07 c | 2.75 ± 0.06 b | 4.80 ± 0.01 a |

| b* | 5.27 ± 0.07 d | 6.21 ± 0.03 c | 14.46 ± 0.13 a | 1.20 ± 0.05 e | 7.91 ± 0.04 b |

| WAC (g/g) | 1.20 ± 0.00 a | 1.26 ± 0.04 a | 1.24 ± 0.03 a | 1.21 ± 0.00 a | 1.21 ± 0.01 a |

| Swelling capacity (g/g) | 23.53 ± 0.10 a | 23.60 ± 0.21 a | 22.97 ± 0.0 b | 20.31 ± 0.06 c | 22.91 ± 0.20 b |

| WSI (%) | 2.32 ± 0.01c | 1.83 ± 0.08 d | 2.84 ± 0.04 b | 2.70 ± 0.10 b | 3.44 ± 0.22 a |

| Gelatinisation | |||||

| To | 77.41 ± 0.44 a | 71.43 ± 0.46 c | 74.04 ± 0.63 b | 74.89 ± 0.22 b | 76.49 ± 0.27 a |

| Tp | 80.49 ± 0.35 a | 77.03 ± 0.15 d | 78.72 ± 0.50 bc | 78.24 ± 0.41 c | 79.56 ± 0.21 ab |

| Tf | 83.22 ± 0.33 a | 80.77 ± 0.44 b | 84.45 ± 0.67 a | 81.17 ± 0.26 b | 84.38 ± 0.68 a |

| ΔHgel (J/g) | 0.79 ± 0.07 c | 2.13 ± 0.32 a | 1.77 ± 0.08 ab | 2.59 ± 0.61 a | 1.23 ± 0.16 bc |

| Retrogradation | |||||

| To | 41.80 ± 0.52 c | 44.50 ± 1.90 bc | 50.79 ± 1.35 a | 42.65 ± 1.24 c | 45.90 ± 0.29 b |

| Tp | 44.36 ± 1.55 b | 54.01 ± 1.33 a | 56.15 ± 1.27 a | 53.64 ± 1.63 a | 54.91 ± 0.63 a |

| Tf | 48.71 ± 1.37 b | 60.19 ± 1.55 a | 61.02 ± 1.32 a | 60.19 ± 1.07 a | 61.25 ± 1.89 a |

| ΔHret (J/g) | 0.13 ± 0.03 c | 0.76 ± 0.11 a | 0.19 ± 0.04 c | 0.87 ± 0.12 a | 0.42 ± 0.08 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ronie, M.E.; Abdul Aziz, A.H.; Mohd Noor, N.Q.I.; Yahya, F.; Mamat, H. Characterisation of Bario Rice Flour Varieties: Nutritional Compositions and Physicochemical Properties. Appl. Sci. 2022, 12, 9064. https://doi.org/10.3390/app12189064

Ronie ME, Abdul Aziz AH, Mohd Noor NQI, Yahya F, Mamat H. Characterisation of Bario Rice Flour Varieties: Nutritional Compositions and Physicochemical Properties. Applied Sciences. 2022; 12(18):9064. https://doi.org/10.3390/app12189064

Chicago/Turabian StyleRonie, Macdalyna Esther, Ahmad Hazim Abdul Aziz, Nor Qhairul Izzreen Mohd Noor, Faridah Yahya, and Hasmadi Mamat. 2022. "Characterisation of Bario Rice Flour Varieties: Nutritional Compositions and Physicochemical Properties" Applied Sciences 12, no. 18: 9064. https://doi.org/10.3390/app12189064

APA StyleRonie, M. E., Abdul Aziz, A. H., Mohd Noor, N. Q. I., Yahya, F., & Mamat, H. (2022). Characterisation of Bario Rice Flour Varieties: Nutritional Compositions and Physicochemical Properties. Applied Sciences, 12(18), 9064. https://doi.org/10.3390/app12189064