Criticality Effect of Fission Products

Generally, the criticality of a molten salt reactor is characterised by two different effects, the number of fissile materials, which can be changed through burning and breeding effects or feeding, and the number of neutron absorbers—fission products, which will accumulate due to burnup and can be reduced through salt clean-up.

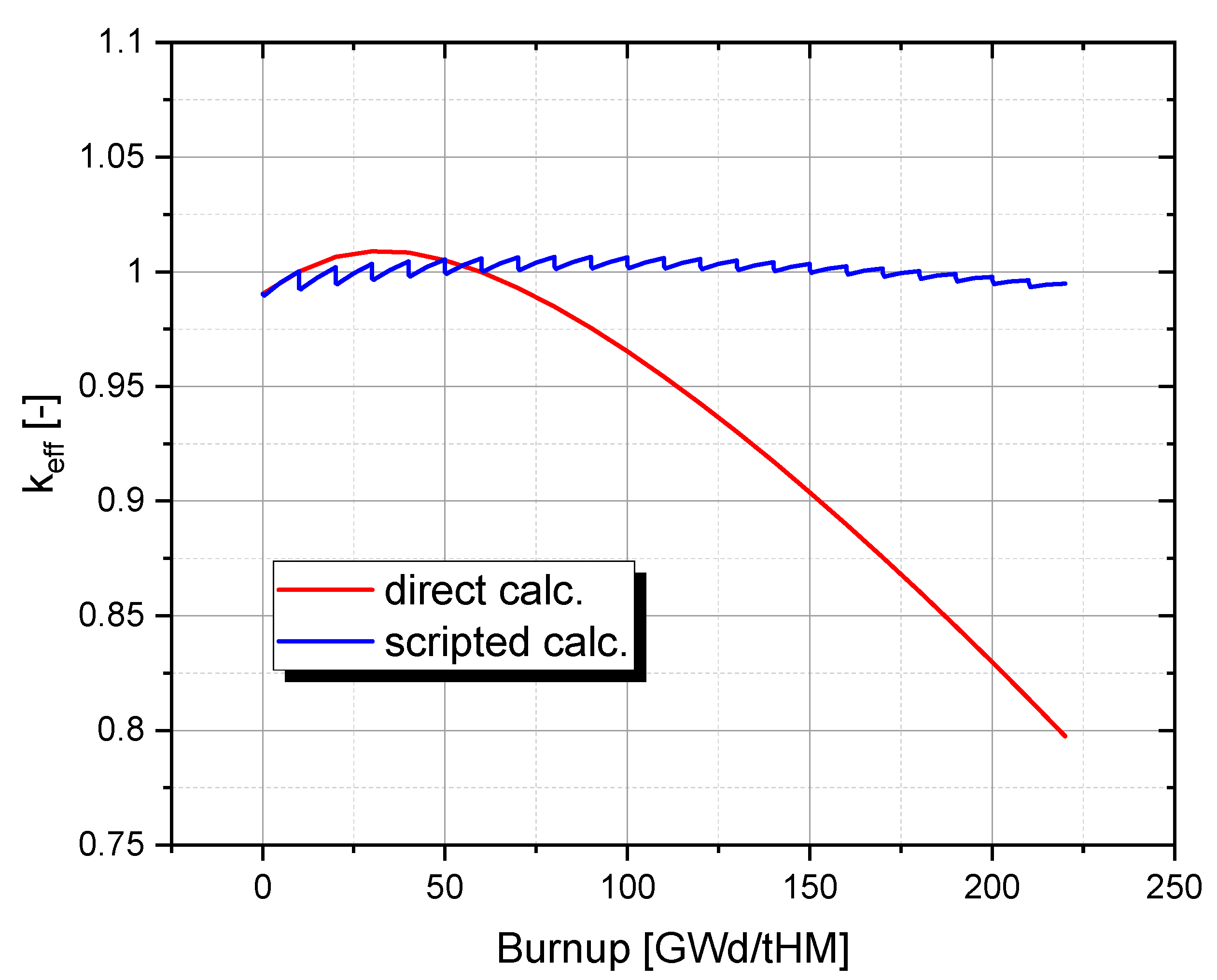

Figure 3 indicates the difference in the opportunities given through the use of a molten salt system. The red curve indicates the criticality behaviour, as would be the case in a classical, solid-fuelled reactor. In this calculation, all fission products are kept in the system; the calculation ran as one normal continuous calculation over the whole burnup period. In contrast, the blue curve is calculated using the above-described script with a cycle length of 10 GWd/tHM. After each cycle, the gaseous and volatile fission products, the elements 18, 35, 36, 53, 54, 85, are eliminated from the system, and the fuel is uniformly redistributed in the core. This first comparison already demonstrates the role of dynamic simulation in the investigation of long-term operations. While the continuous run, including all fission products produced and no redistribution of the materials, leads to improved breeding of materials at the beginning as well as a sharp drop in the criticality caused by the fission products (red curve), the dynamic simulation behaves much more stably. This difference is caused by the use of all fissile material in a comprehensive way (fuel does not stay in outer areas where it does not receive sufficient neutron flux) as well as due to the removal of the gaseous and volatile fission products through the script (blue curve). In the blue curve, each result of each HELIOS burnup step is shown, indicated by the increase in criticality through the five steps in one cycle and the followed drop in criticality caused through the redistribution of the material when the new input is generated through the PYTHON script.

As a starting point for the dynamic analysis, a continuous run to a burnup of 300 GWd/tHM has been performed to obtain an overview of the accumulation of fission products during burnup, which is used to rank the fission products based on their concentration in ppm. The results have been produced on the full isotope set available in HELIOS, leading to the ranking given below, given in

Table 1 and

Table 2.

The results of this calculation coincide well with earlier simulations based on the use of SCALE/Polaris [

16], leading to the same ranking of the concentrations, even when considering that the initial enrichment is slightly different and the POLARIS model itself is much more limited than the HELIOS model. However, the evaluation of the differences is only for some elements in very good agreement, while some elements show reasonably large differences of up to almost 30% in the worst case. Anyway, we should keep in mind that the results are for 100 GWd/tHM. This level of burnup is already almost double the standard LWR burnup, which is the normal level for the validation of such codes. The deviations show the clear demand for experimental investigation, essential for the validation of the codes for molten salt reactor application in the future when higher precision M&S results are required for detailed design considerations. For the current level of the study to support the development of separation technologies with the required basic data, the quality of the results and the coincidence of the ranking of the elements with the highest concentrations are very meaningful, even if the absolute number may deviate.

The criticality effect of the accumulation of each of the followed-up fission product elements of

Table 1 is analysed in

Table 2. For this analysis, a direct calculation has been performed without any fission product removal as well as a reference calculation has been performed using the script and the removal of the gaseous and the volatile fission products. The reference calculation has then been re-run, including the removal of 5% of the selected fission product element at the end of each 10 GWd/tHM cycle. The detailed analysis of the criticality effect and the criticality gain at the end of life of the reference case has been evaluated; see the second column. In addition, the cycle simulation was continued until the stopping criterion k < 0.995 was approached. Through interpolation, the achievable burnup for the specific case has been determined, and the third column and the result are compared to the reference solution to determine the burnup gain, which can be achieved compared to the reference case, column 4. The five leading, most influential fission product elements have been identified and marked in bold for the graphical analysis following in

Figure 4. For comparison of the gained results with the earlier published static POLARIS calculations, the ranking of the elements of the earlier calculations is given in the last column. As observed before, the main elements coincide very well between both simulation results, but the ranking is slightly different with the main difference in the ranking of Pd, which achieves in the HELIOS calculation a higher concentration resulting in this second analysis step in a stronger influence on criticality.

In general, these results indicate that the major influence on criticality up to a burnup of 200 GWd/tHM is concentrated on a comparably small number of nine elements. The influence of the remaining other elements seems to be limited but could increase with a longer operation and a higher amount of energy produced.

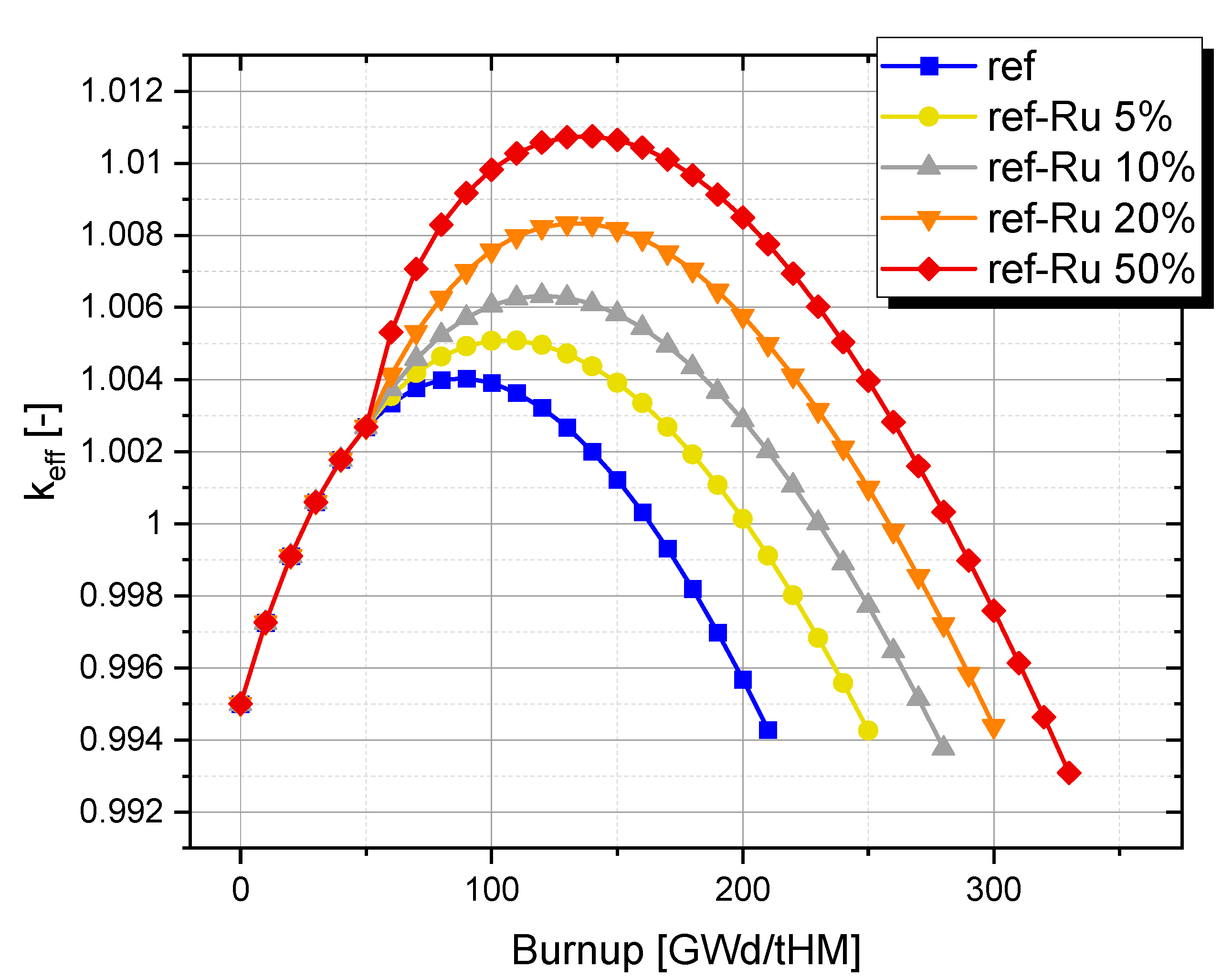

The more detailed graphical analysis of the influence of the fission products on the long-term operation is given in

Figure 4 with the analysis of the criticality curve and the potential criticality gain achievable through the cleaning out of 5% of specific fission products at the end of each of the 10 GWd/tHM cycle through the script. In contrast to

Figure 3, in

Figure 4, only the weighted average criticality of each burnup cycle is evaluated and shown as a dot to improve the readability. This approach leads to a much smoother curve compared to the presentation of all intermediate results within the cycles. The graphical analysis indicates that the influence of the fission product clean-up is very low at the beginning, which can be explained by the limited content of each of the fission product elements; thus, the reduction by 5% does not have a strong influence until a significant amount of fission product is produced. This observation leads to the next steps of the investigation; (a) what influence can we expect when the fission product clean-up is initiated at a point where a considerable amount of the specific element is allowed to accumulate? (b) will the effect of starting later maybe reduce to a kind of asymptotic limit, which would mean there will be no major penalty for starting the clean-up later in the operation of the reactor.

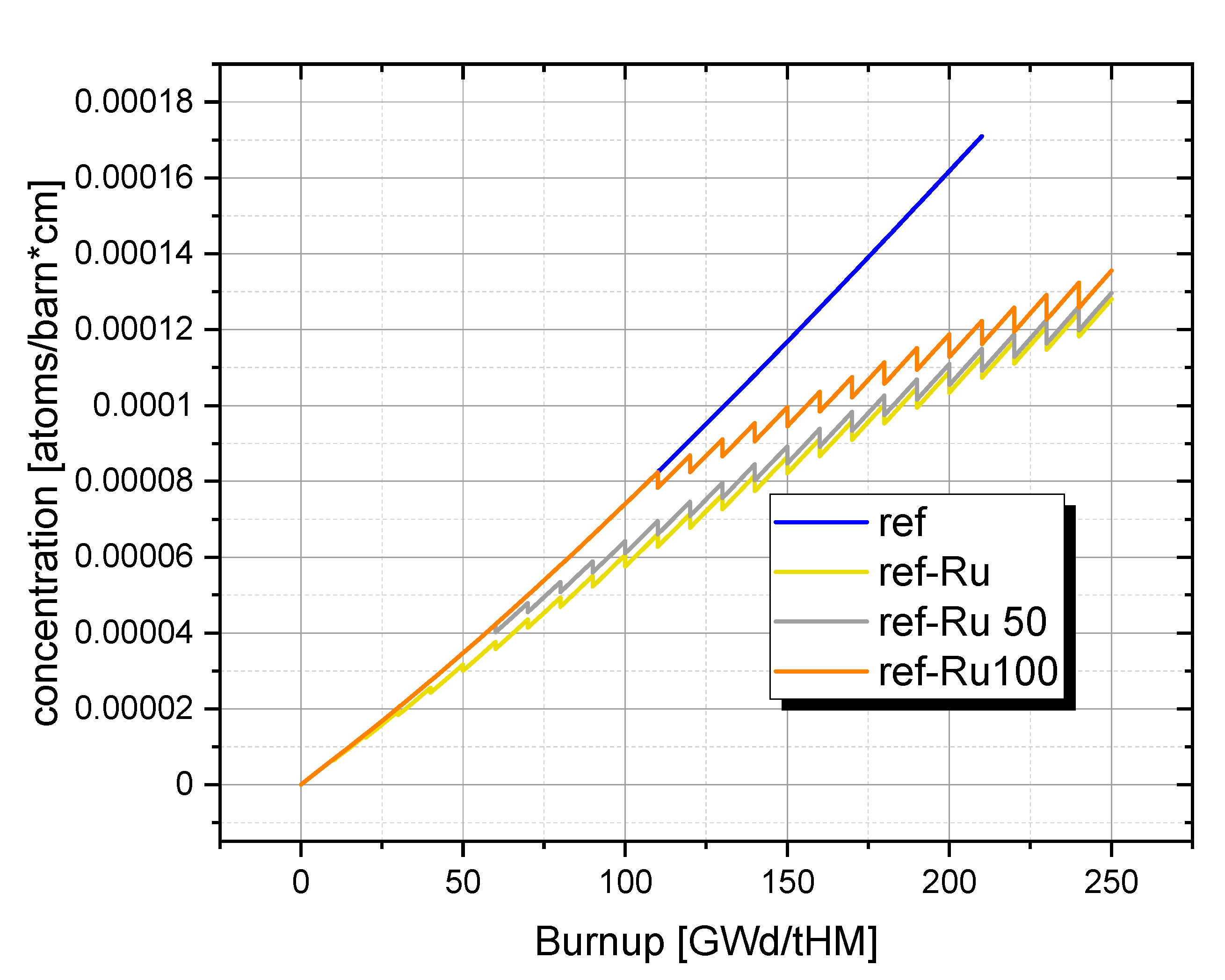

The investigation of the effect of initiation of the clean-up system at different stages of operation is given in

Figure 5 with the comparison of a set of calculations with the clean-up system initiated from the beginning, as well as at a burnup of 50 GWd/tHM and at 100 GWd/tHM, while all calculation are compared to the reference case (blue curve). The observation of the very low influence of the clean-up in the early stage of the operation taken above is confirmed in

Figure 5. There is a slight advantage in the maximum achieved criticality for the case of the initiation of the clean-up at the start of the system (red curve), but the difference in the final burnup and the criticality at the end of the observation period is very limited compared to the case with the initiation of the clean-up at 50 GWd/tHM (grey curve). The later imitation at 100 GWd/tHM yields a slightly smaller final burnup (yellow curve), but the gaps seem to close rapidly, which leads to the expectation that in the longer-term operation, the influence of the initiation of the clean-up has a limited influence and we will observe an asymptotical behaviour.

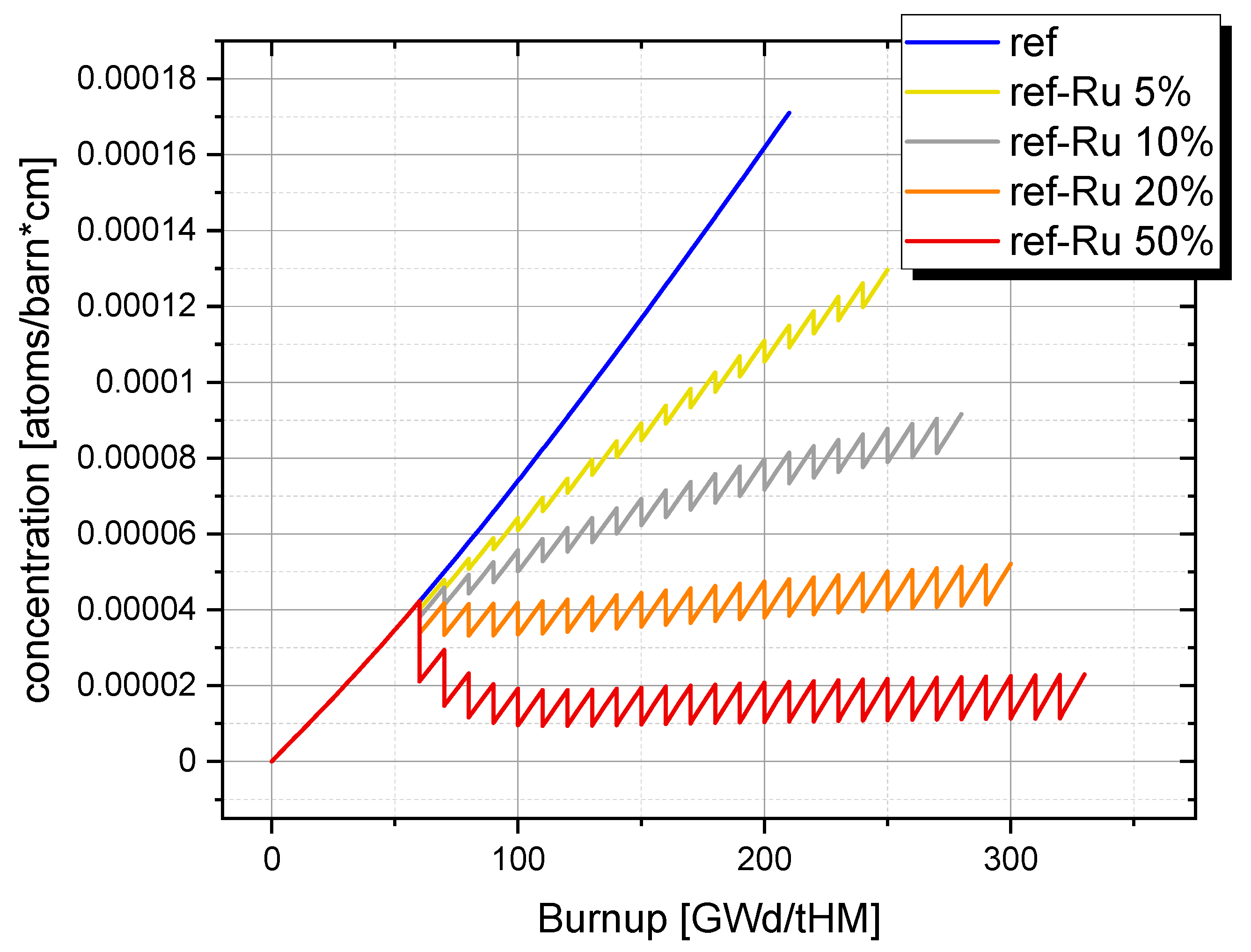

This observation is supported by the analysis of fission product concentration in the system, as analysed in

Figure 6 for Ruthenium. The general Ruthenium concentration in the system increases in a slightly exponential manner in the reference case without any clean-up (blue curve). The reduction of the Ru content is very limited in the beginning, up to 50 GWd/tHM, since the overall amount of Ru is still very limited, even if clean-up is already initiated (red curve). The initiation of the clean-up in the step after 50 GWd/tHM (grey curve) leads to a stronger reduction in the first steps since the concentration has already grown to a certain level. At the end of the observation period, the results of the initiation at 0 and at 50 GWd/tHM have almost converged, with a red and grey curve. The later initiation (yellow curve) leads to a higher final concentration, but the difference between the other results reduces over time. This supports the conclusion that with a longer operation, the effect of the initiation of the clean-up system will anneal. Based on this observation, we can get to the conclusion that there should be an ideal time point to start the clean-up. This time point will be a result of the accumulation of the fission product, the criticality effect, the efficiency of the chemical process, dependent on the concentration, and maybe the design volume for the clean-up stream. The cleaning of 5% of the volume after each calculation cycle, here 10 GWd/tHM, is just to be seen as a model for a future continuous clean-up system. However, in the current case, the Ru concentration is still growing, even if the clean-up is initiated. It will possibly achieve some asymptotic value, but obviously after a much longer time than the observed one. Based on this observation, it seems logical to investigate the influence of the cleaning stream amount in the next step.

The analysis of different clean-up volumes is given in

Figure 7 (influence on criticality) and

Figure 8 (influence on element concentration). Obviously, the clean-up volume has a clear influence on the criticality curve and as expected, increasing the clean-up volume leads to a higher criticality peak, but the effect seems to be far from linear. The gain from no clean-up to 5% volume being cleaned is ~40 GWd/tHM, and the gain between 5% and 10 % volume is ~25 GWd/tHM. Another doubling of the clean-up stream gives about 25 GWd/tHM; the step from 20% to 50% gives only ~20 GWd/tHM. Thus, we face another optimisation problem, again, especially in this case, where the gain is absolutely not linear with the salt clean-up stream. The detailed look into the development of the elementary concentrations of Ru resulting from the different clean-up streams (

Figure 8) helps to obtain a deeper understanding of the criticality and burnup effect when correlating them with the development of the Ru concentrations. It seems the greatest reduction/change in the Ru content in one step is achieved through the step from no clean-up to the 5% volume case, which correlates to the achieved burnup increase compared to the last scheme. The reduction in the other cases seems to be slightly lower, e.g., for the step from 5 to 10% and from 10 to 20%, which deliver about the same reduction and the same burnup increase, while the last step, 20 to 50%, leads to the lowest absolute reduction and the lowest burnup increase. In general, all cases seem to tend to an asymptotic value for the Ru content with a lower amount for the higher volumes in the clean-up system, which seems to be logical. However, the asymptotic value could be correlated to the ideal point to start the clean-up process, with the view that a clean-up system with a lower volumetric capacity should be started later. This could maybe lead to another optimisation approach, using a slightly larger system with stronger breeding while accepting a higher fission product content in the core versus a smaller core with less breeding and a stronger clean-up system—this will be a question of balancing the economics of the process, the cost of the reactor and the source term in the core versus the cost of the clean-up system and the source term in the clean-up system.

Following the optimisation of the separation on the hand of a single fission product element, the next is now to look into the effect of the separation of different elements as analysed in

Table 2. The most interesting and important point here will be to investigate the additivity of the effect of the separation of different elements. For this, the reference case will be calculated several times, each time separating one element more, first Ru, then Ru and Mo, followed by Ru, Mo, and Pd, and finally, Ru, Mo, Pd, and Cs, see

Figure 9. The results show not only that the effect is additive, and it seems even that the effect of cleaning out additional elements seems to be slightly self-amplifying since the burnup gain of the last steps is clearly larger than in one of the earlier steps, which is surprising since the elements which are separated first have the strongest criticality effect following

Table 2. This effect should be investigated in more detail as soon as a clean-up strategy is developed in collaboration with specialists in nuclear chemistry. Currently, the case is still a bit artificial due to the comparably high k

eff which is achieved and would not be useful in a molten salt reactor which ideally should not rely on an active control system, e.g., by relying on control rods, since the system can be controlled through temperature feedbacks [

27] and through the feeding/clean-up stream. If this operational regime is achieved, there is another problem to be thought about using the current calculation approach; in the current mode of calculation relying on criticality normalisation, the breeding will be underestimated since the normalisation artificially reduces the neutron source. However, to be able to deal with all these inter-connected effects, a much more comprehensive neutronic/thermal-hydraulic coupled modelling and simulation approach will have to be developed for the operational simulation of a molten salt reactor which allows controlling the feeding streams, the consideration of the clean-up stream composition and the potential criticality control due the thermal feedback effects in a dynamic way.

The consequences of the clean-up on the elementary concentrations of the observed fission products are given in

Figure 10. A more detailed analysis shows that there is definitively still some optimisation potential which should be leveraged in collaboration with the nuclear chemists, e.g., when observing the concentrations which are built up due to burnup. Maybe it would be the easiest and the most efficient approach to work on the elements with the highest concentration first. Thus, in this case, Mo could be cleaned first instead of tackling Ru; thus, it is maybe too straightforward to think that only the criticality effect of an element should be used to make the decision on the sequence for the clean-up and the decision for the time to initiate the cleaning of a specific element. A deeper look into

Figure 10 indicates that the separation of Pd should be started later due to the much lower concentration; otherwise, the chemical processes may be less efficient. There should some other variables be considered in the optimisation, e.g., which element can easiest be separated with the least technical effort or cost, which concentration should be accumulated before it is efficient to start the chemical processing to assure substantial separation rates. Thus, it becomes clear at this point again that there is extensive optimisation potential which has to be leveraged in close collaboration between reactor physics modelling and simulation and the nuclear chemists who develop the clean-up processes.

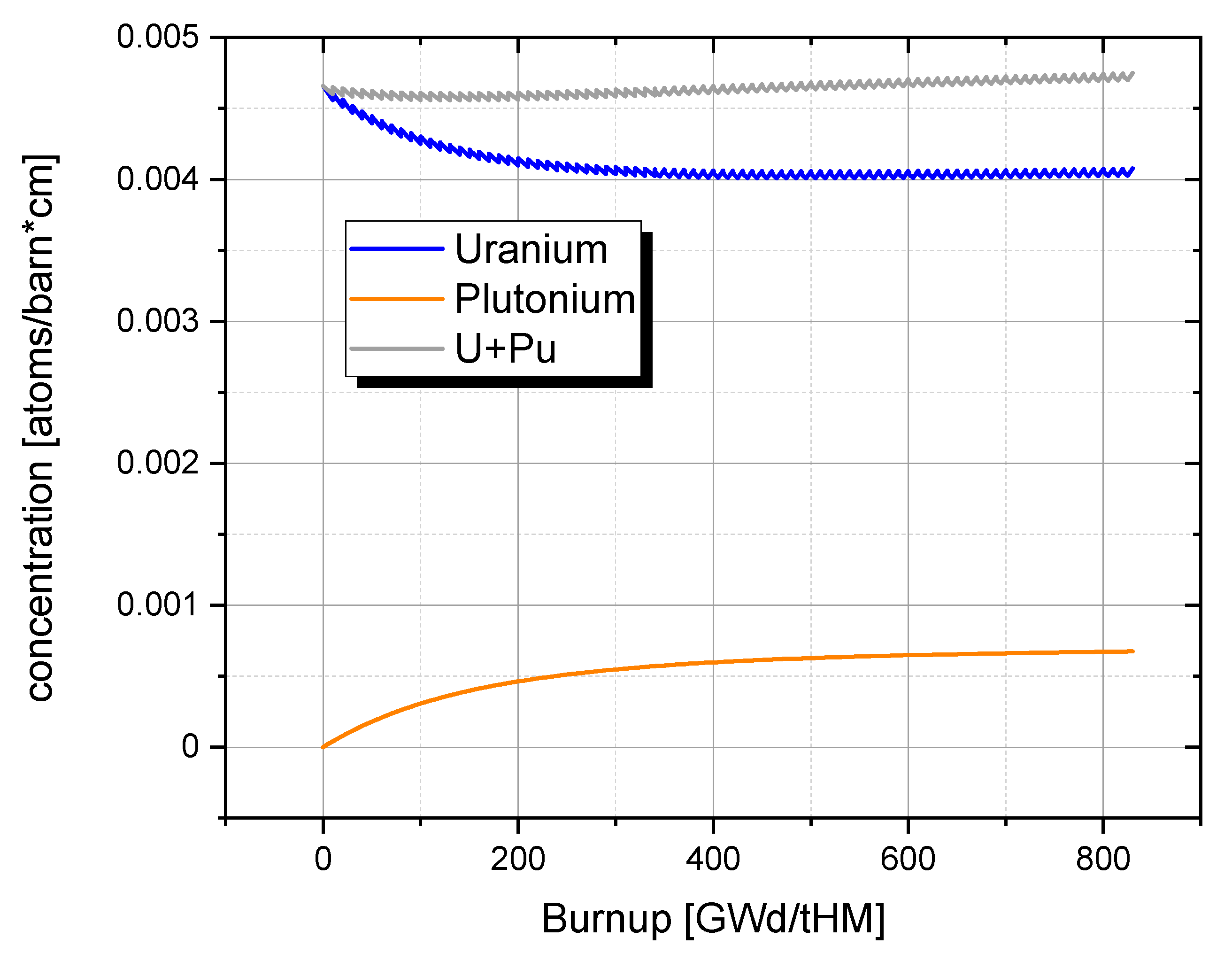

One of the core challenges of the current calculation scheme is shown in

Figure 11; it is with this scheme based on the script that it is almost impossible to keep the fissile and fertile material content constant in the core without applying an integration scheme which would slow down the whole process substantially. When operating the reactor core, which is initially based on pure Uranium fuel, the fissile component (U-235) will burn out after some time and will be replaced by Plutonium. This process will consume a part of the fertile U-238, which has to be replaced after each step. However, since the Uranium consumption is not constant, the refill can only be approximated as long as it is not iterated. The use of a constant amount of depleted Uranium makeup leads to a slight variation in the overall heavy metal content, see

Figure 11, which seems to be acceptable for the current status of the work but still has to be seen as scoping the opportunities. To obtain a better representation would require the coupled reactor physics and chemical engineering modelling tool, which has already been mentioned above. In addition, it has to be kept in mind that all performed calculations are lattice calculations, which means the results will have to be normalised using a real reactor power which is not yet determined. Thus, there is no way to determine at this point the real physical volume which will be demanded for the salt clean-up.

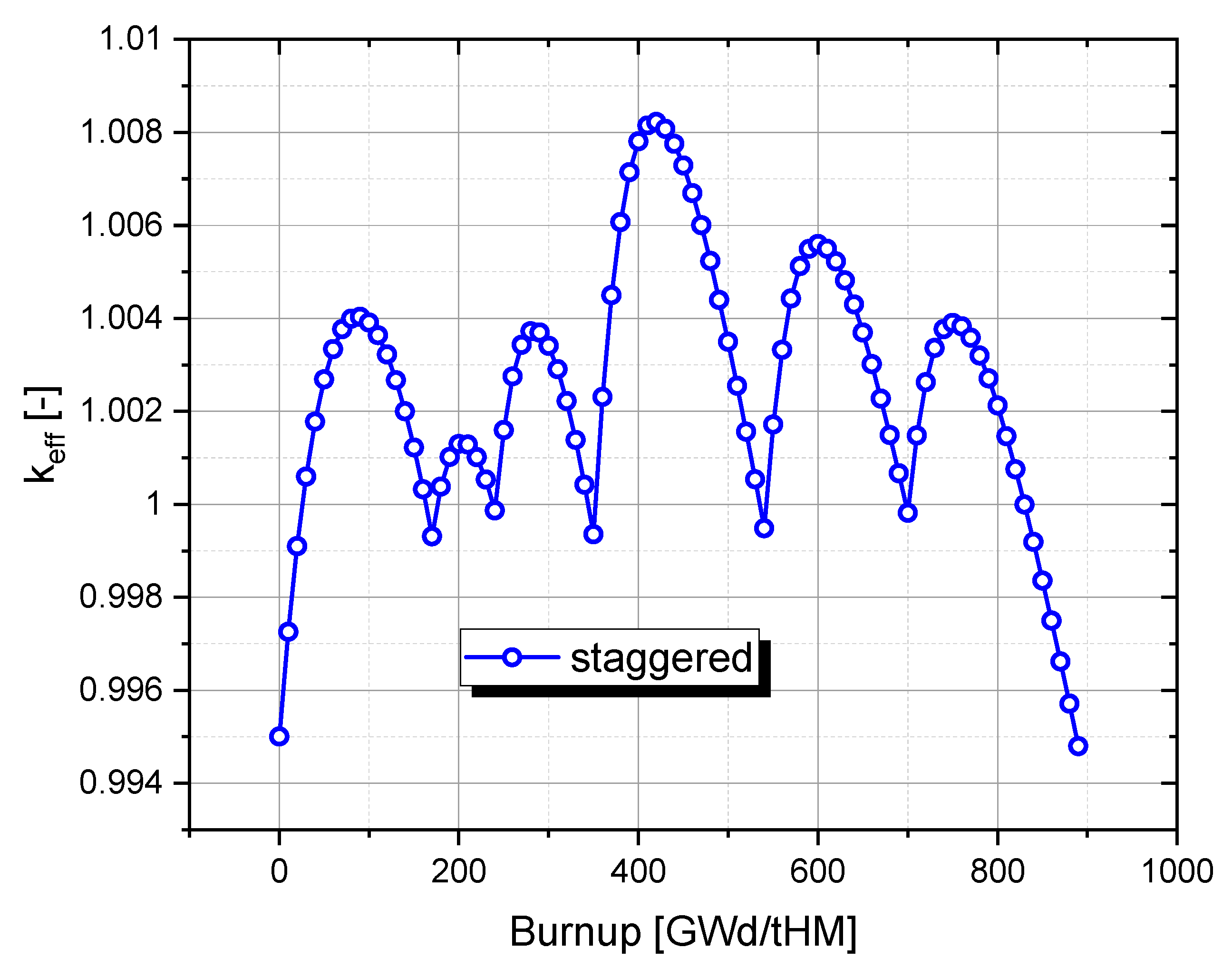

Concluding from the too high rise of the criticality in the approach shown in

Figure 9, a more reasonable and maybe promising approach for the development is given in

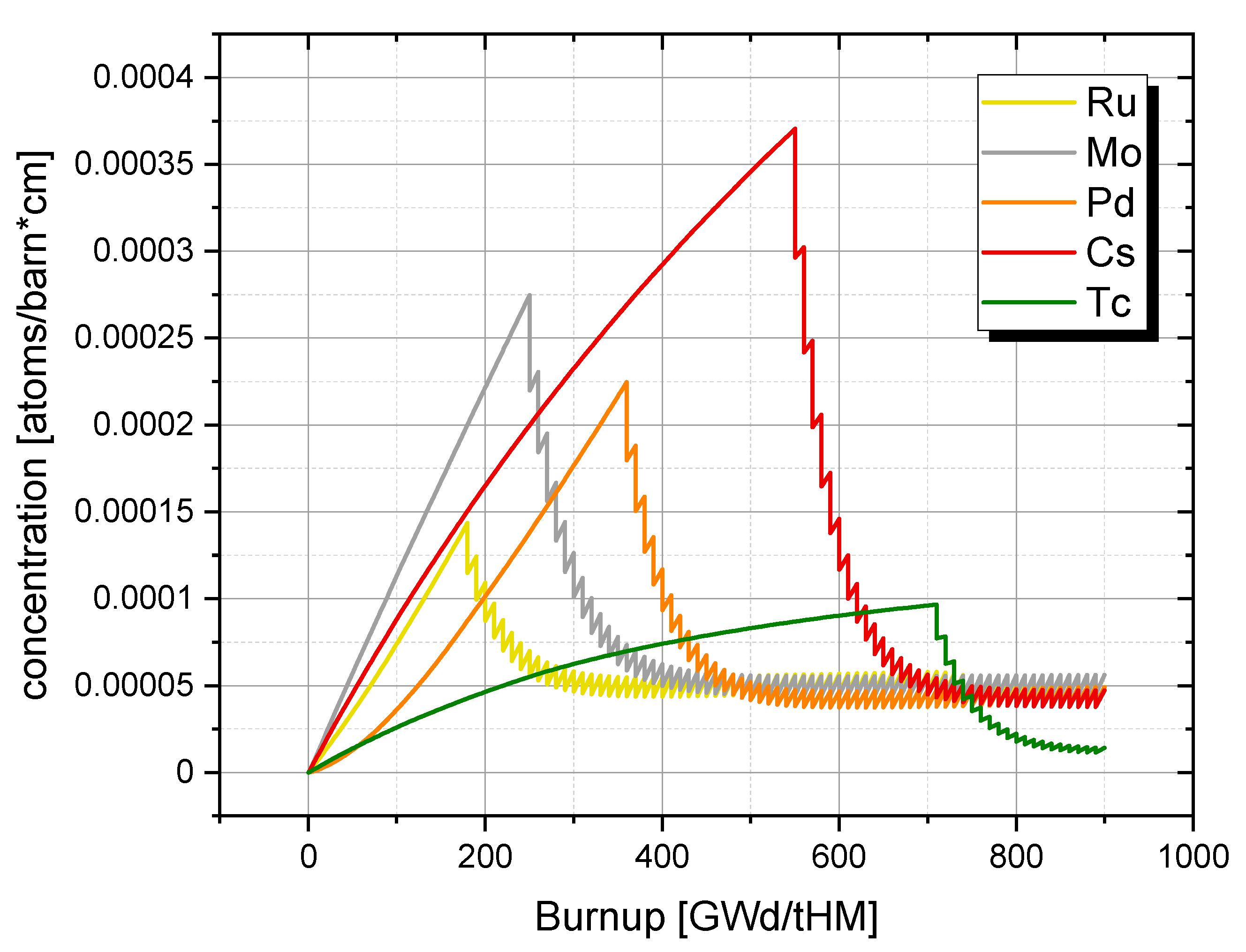

Figure 12 and

Figure 13, a stepwise start-up of the cleaning system for different elements. The idea of this approach is to operate the reactor until the criticality falls below unity; every time this happens, an additional element will be added to the list of elements to be cleaned out of the fuel by 20% at the end of each cycle. Thus, the calculation now operates on the reference case without clean-up as a start. After 180 GWd/tHM, the Ru clean-up is initiated, at 240 GWd/tHM, the Mo clean-up is initiated, at 350 GWd/tHM, the Pd clean-up is initiated, at 540 GWd/tHM, the Cs clean-up is imitated, and at 700 GWd/tHM the Tc clean-up is initiated, leading to the final burnup of ~890 GWd/tHM. This staggered approach helps to limit the excess reactivity, which has to be compensated through material exchange through the feeding system otherwise.

Analysing the elementary contents in

Figure 13 indicates the stepwise initiation of the different element clean-up approaches. The concentration of the specific elements grows almost linearly until the initiation of the clean-up and falls then rapidly following the initiation of the clean-up system. The final asymptotic value achieved using this approximation model will finally only depend on the production rate. A more realistic, sophisticated simulation, including a chemical process model, would maybe allow producing a closer-to-reality result, where the chemical separation rate and maybe different flow rates through the clean-up system will be possible and allow a different level of optimisation. One of the optimisation parameters which comes to mind first would be to have in all cases a reasonably high content of the element to be separated, but the amount which would be ideal will depend on the chemical process and the efficiency of the separation; thus, even this amount could be element specific and should thus be subject of a discussion and optimisation between reactor physics, nuclear chemistry, and process engineering.

The most important outcome of this simulation is it will be possible to start the reactor without having the salt clean-up operating from the first criticality since the elements have first to accumulate to a reasonably high concentration before a real chemistry-based clean-up should be initiated. Finally, there will be a strong demand for close interaction between the specialists to leverage the optimisation potential, which will be essential to obtaining a cost-optimised solution for this challenging problem.

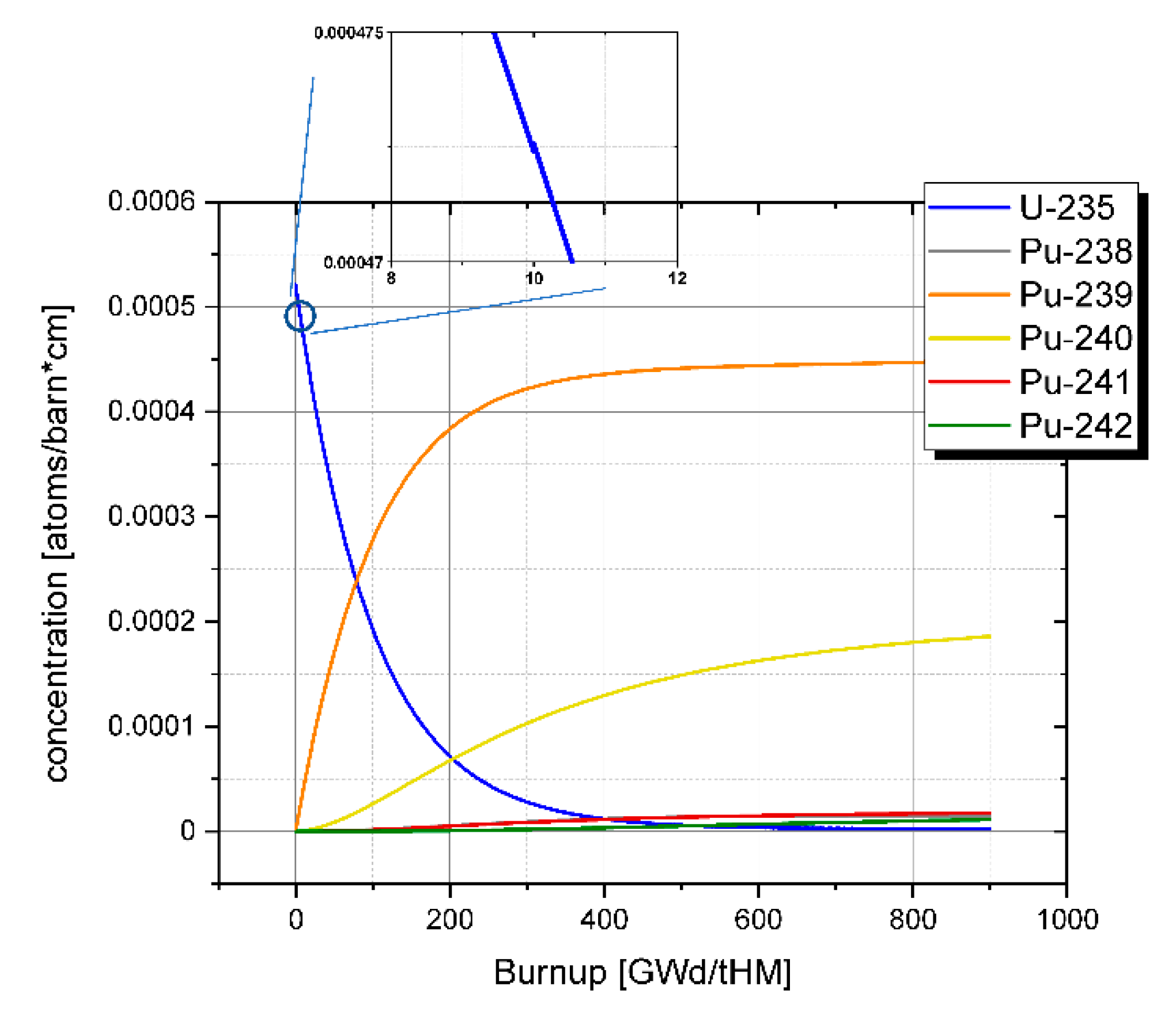

Closing the study with a final reactor physical view into the problem is given by the analysis of the evolution of the fissile material content of the reactor system,

Figure 14, the figure clearly demonstrates the change of the leading fissile material from U-235 to Pu. The very tiny feed of U-235 through the depleted Uranium in the U-235 curve is only visible in the inserted detail. However, this tiny feed is responsible such that the U-235 content will never achieve an asymptotic level of 0. In contrast, the Pu curves are completely smooth, which reflects that there is no change in the Pu production and consumption inserted via the script, only through the internal breeding processes. The Pu production is, in the beginning, almost completely dominated by Pu-239; with an increasing operational time, the production of the higher Pu isotopes becomes significant, leading to a Pu vector with 2% Pu-238, 66% Pu-239, 27% Pu-240, 3% Pu-241, 2% Pu-242 at the end of the observation period. However, only Pu-239 has achieved the asymptotic value at the end of the period, which means with longer operational time, the Pu-239 share will be reduced.