Influence of Perforated Soils on Installation of New Piles

Abstract

:1. Introduction

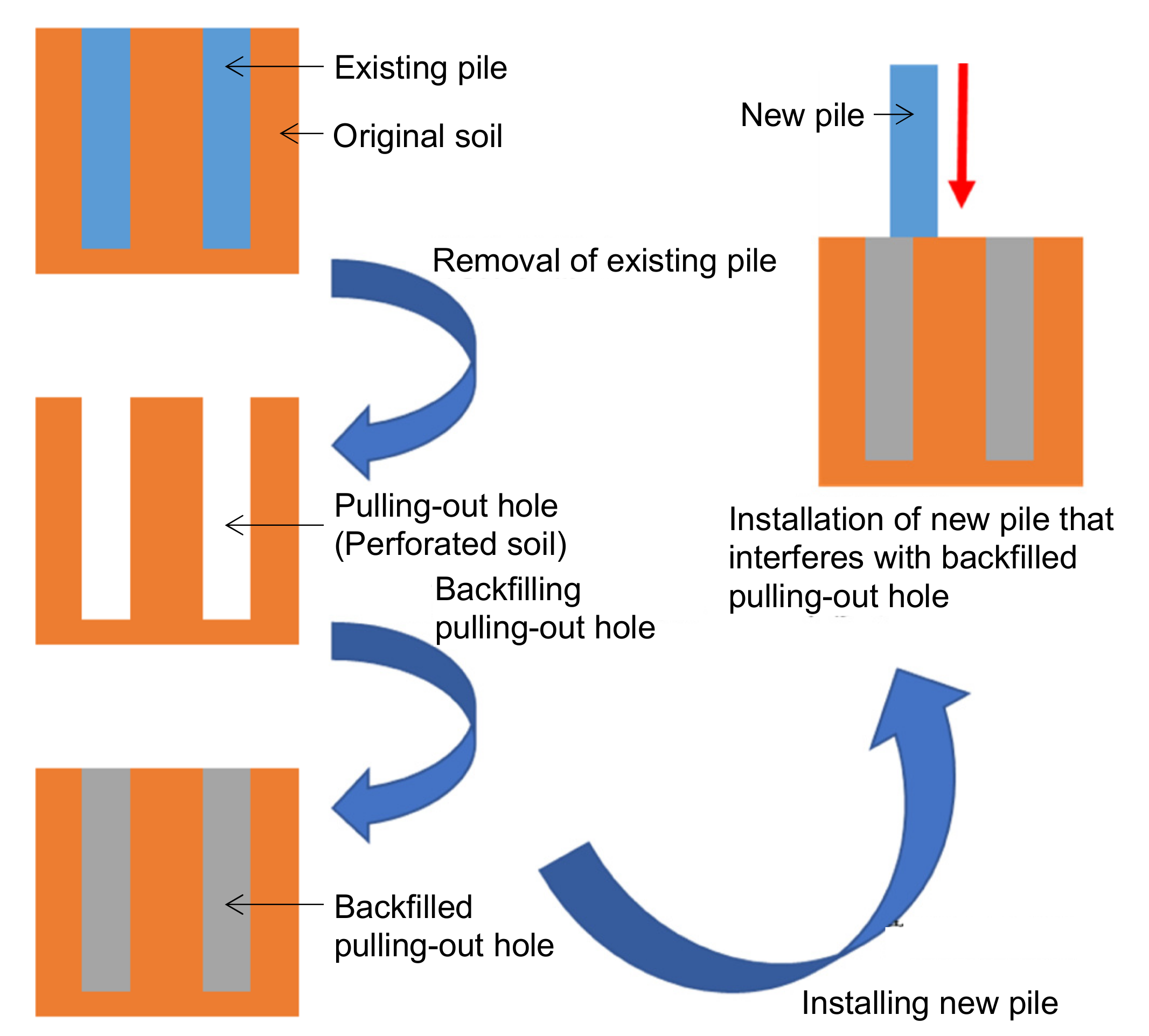

2. Removal by Pulling Out Existing Piles

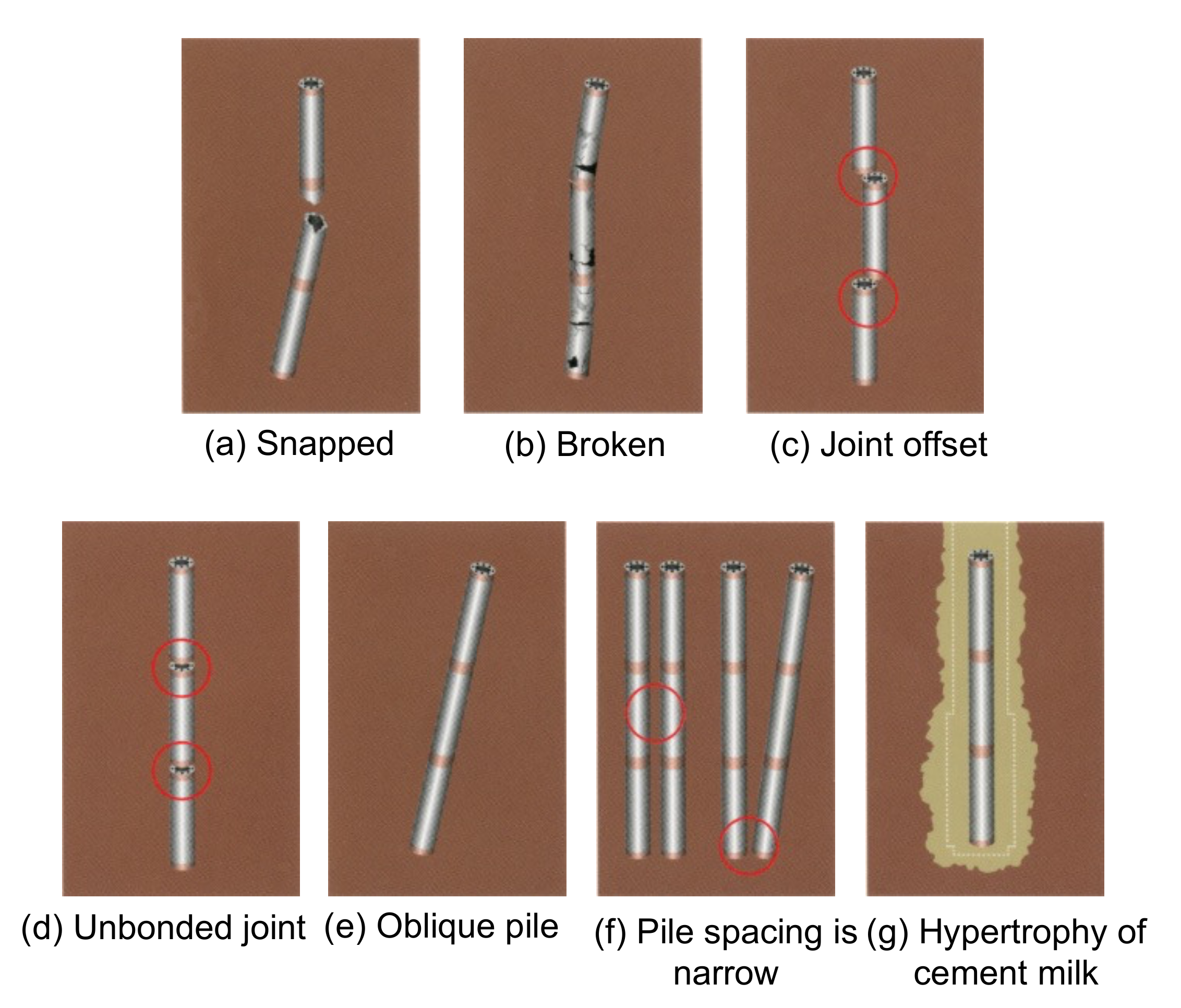

2.1. Existing Piles

2.2. Soil Condition after Removal of the Existing Piles (Pulling-Out Holes)

2.3. Removal of Existing Piles That Interfere with New Piles

3. Analysis Target and Conditions

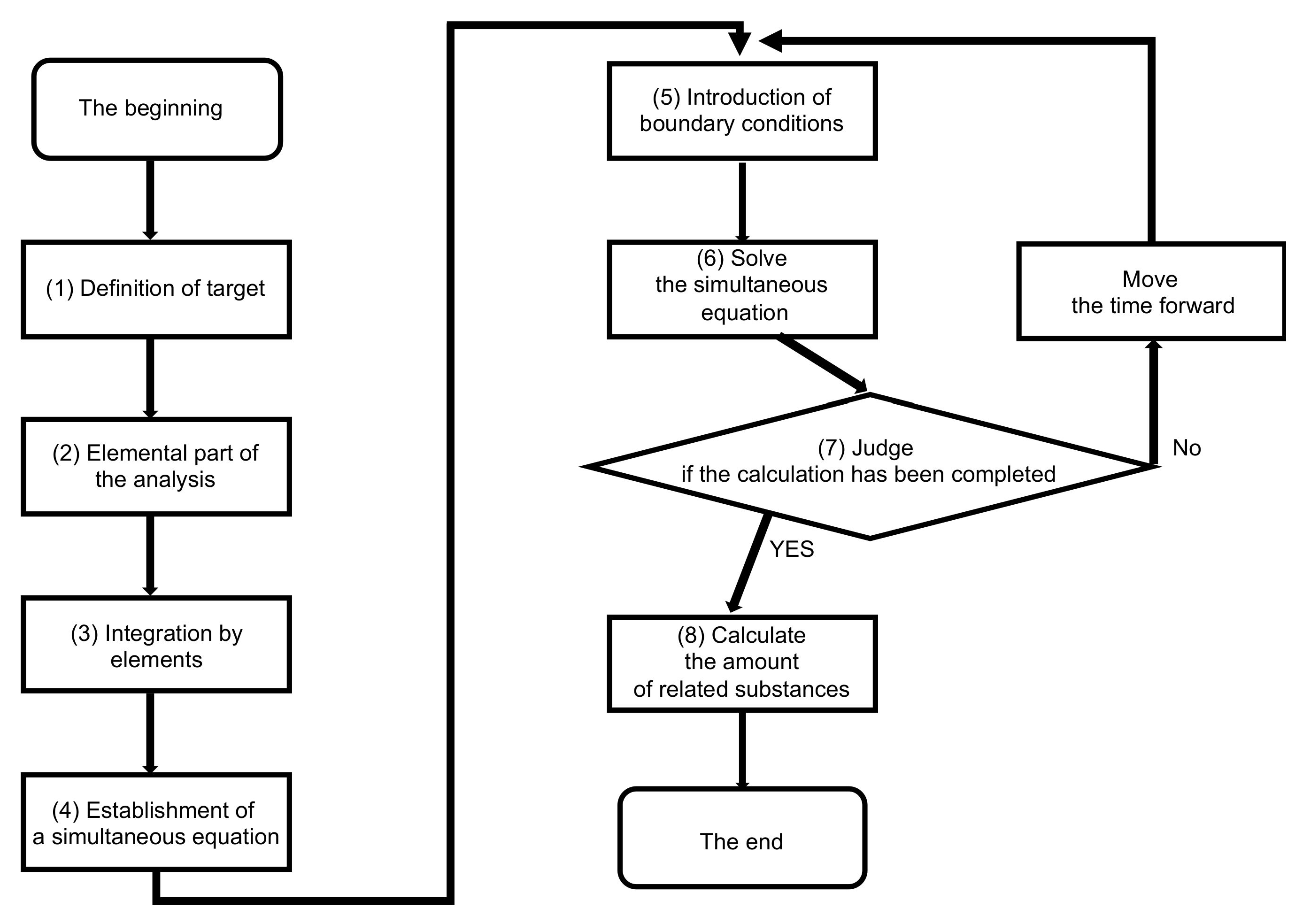

3.1. Linear Elasticity Analysis

3.2. Calculation Method for Elastic Modulus

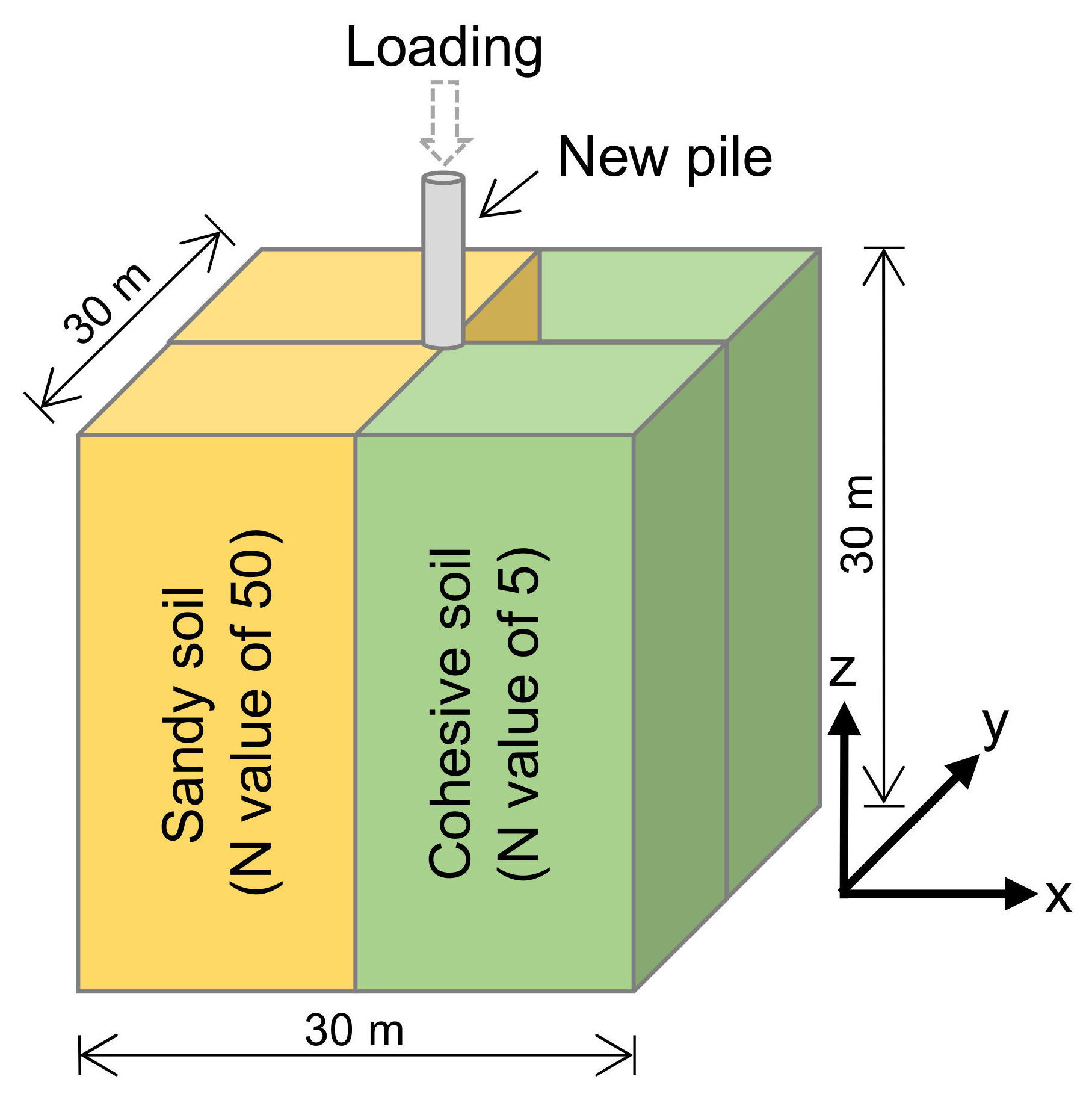

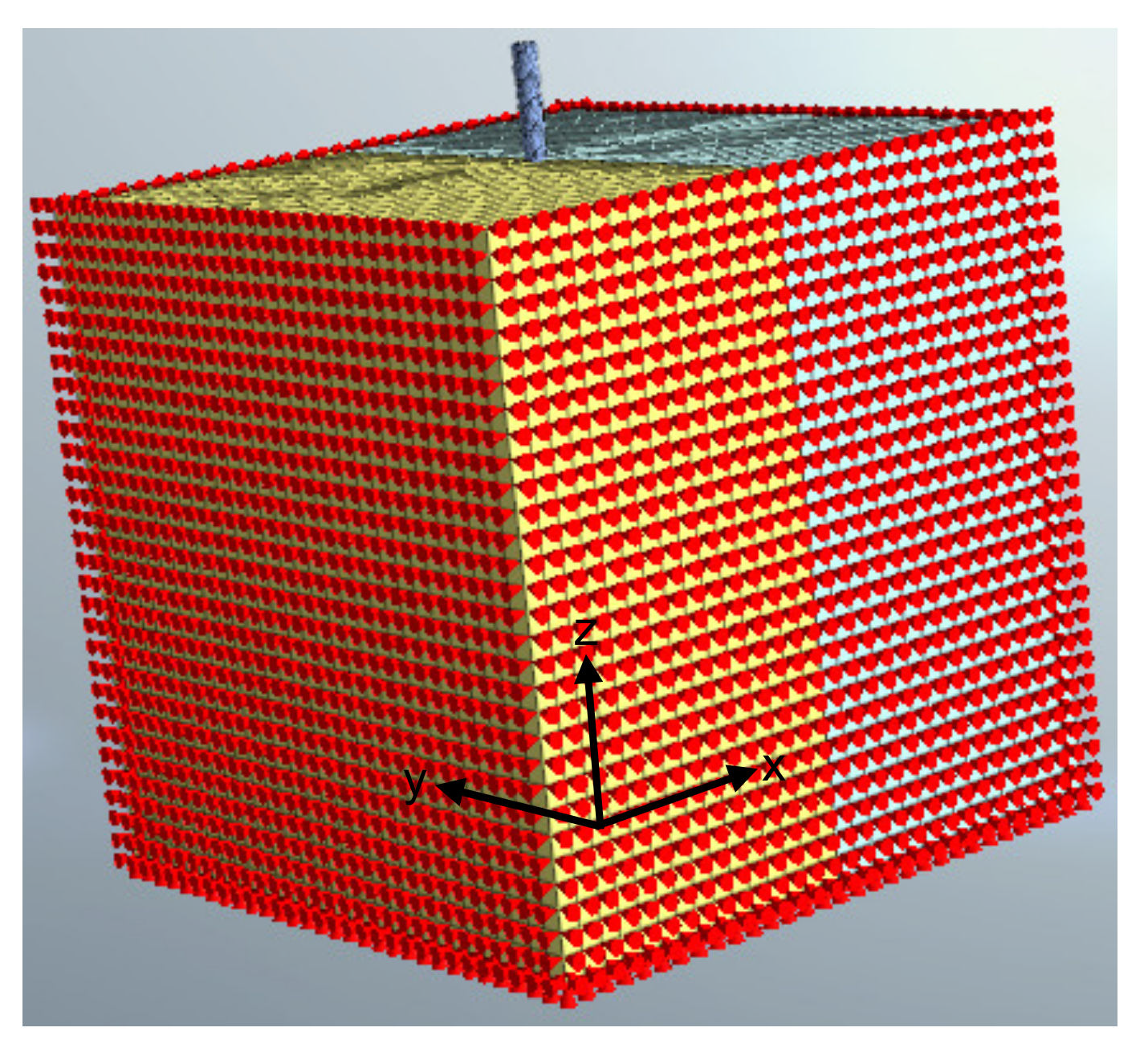

3.3. Analysis Target and Boundary Conditions

4. Analysis Results and Discussion

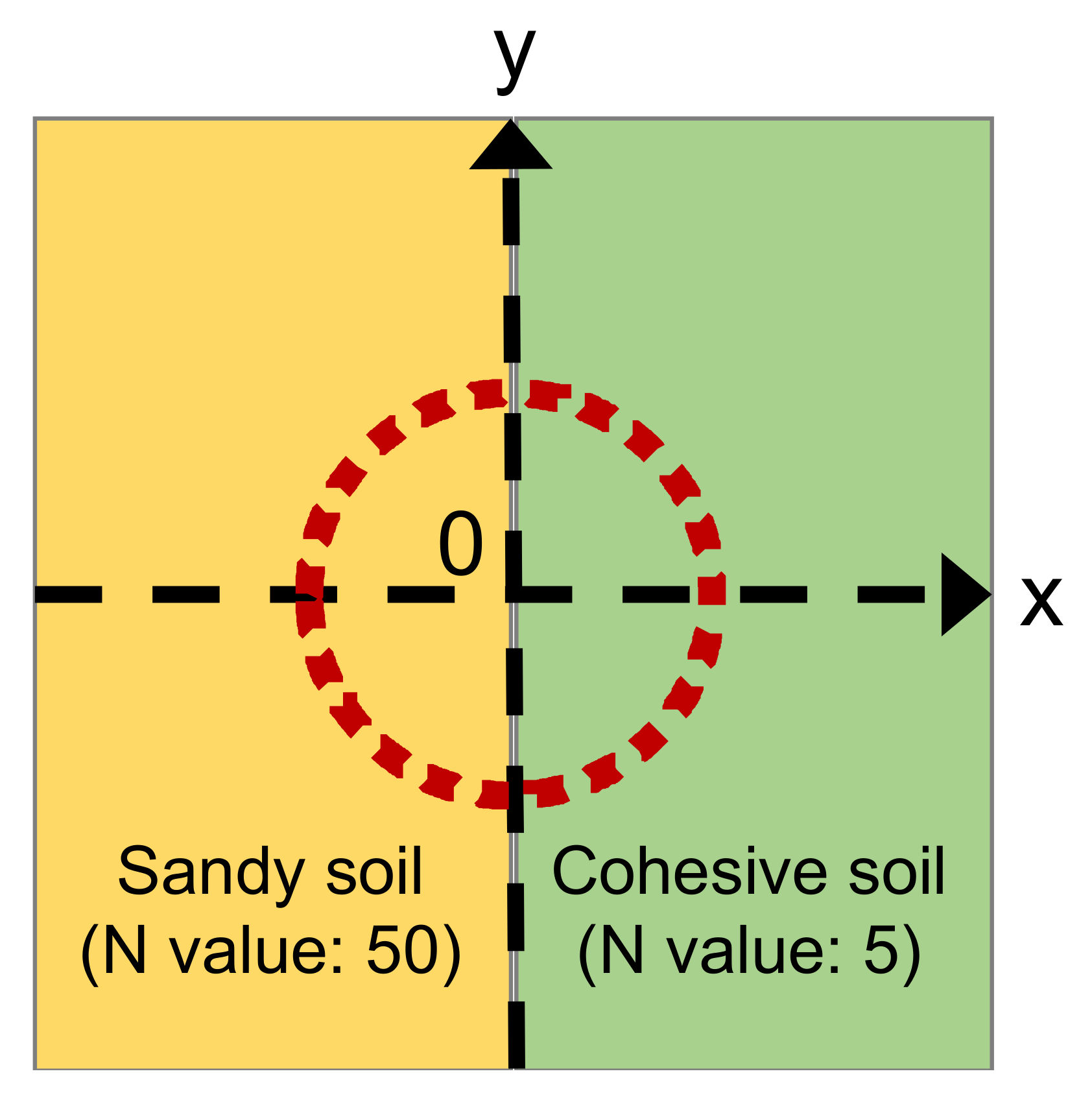

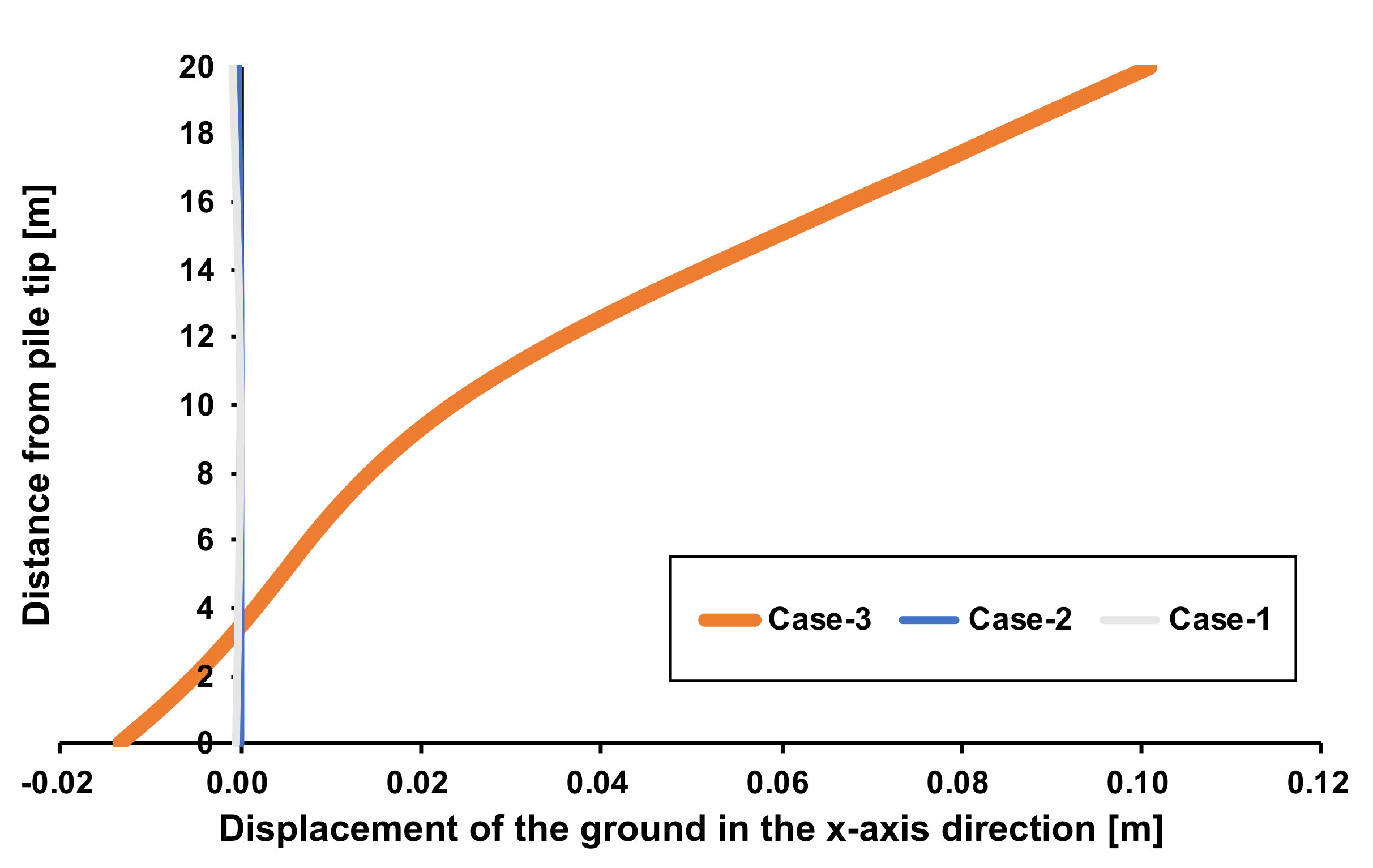

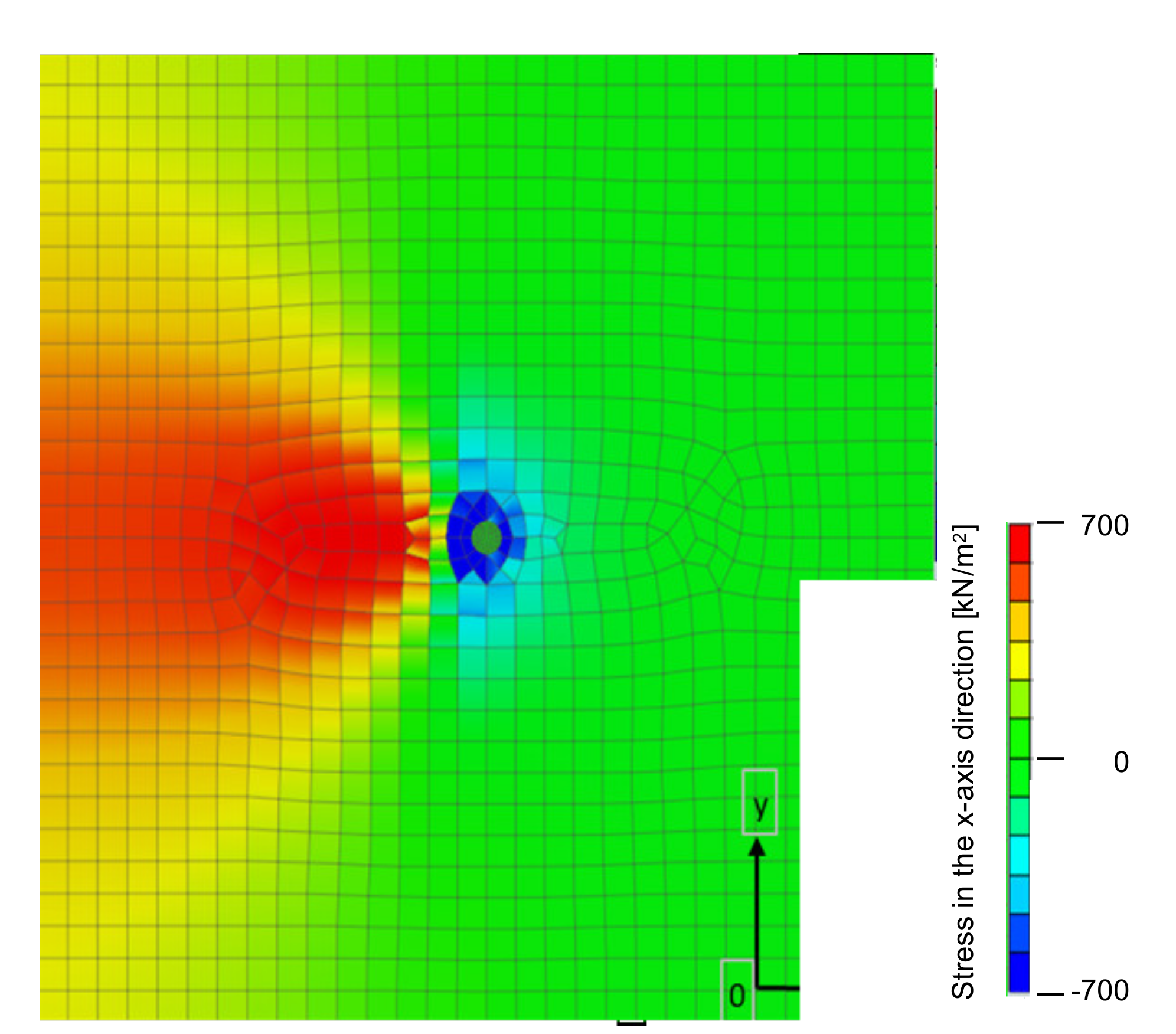

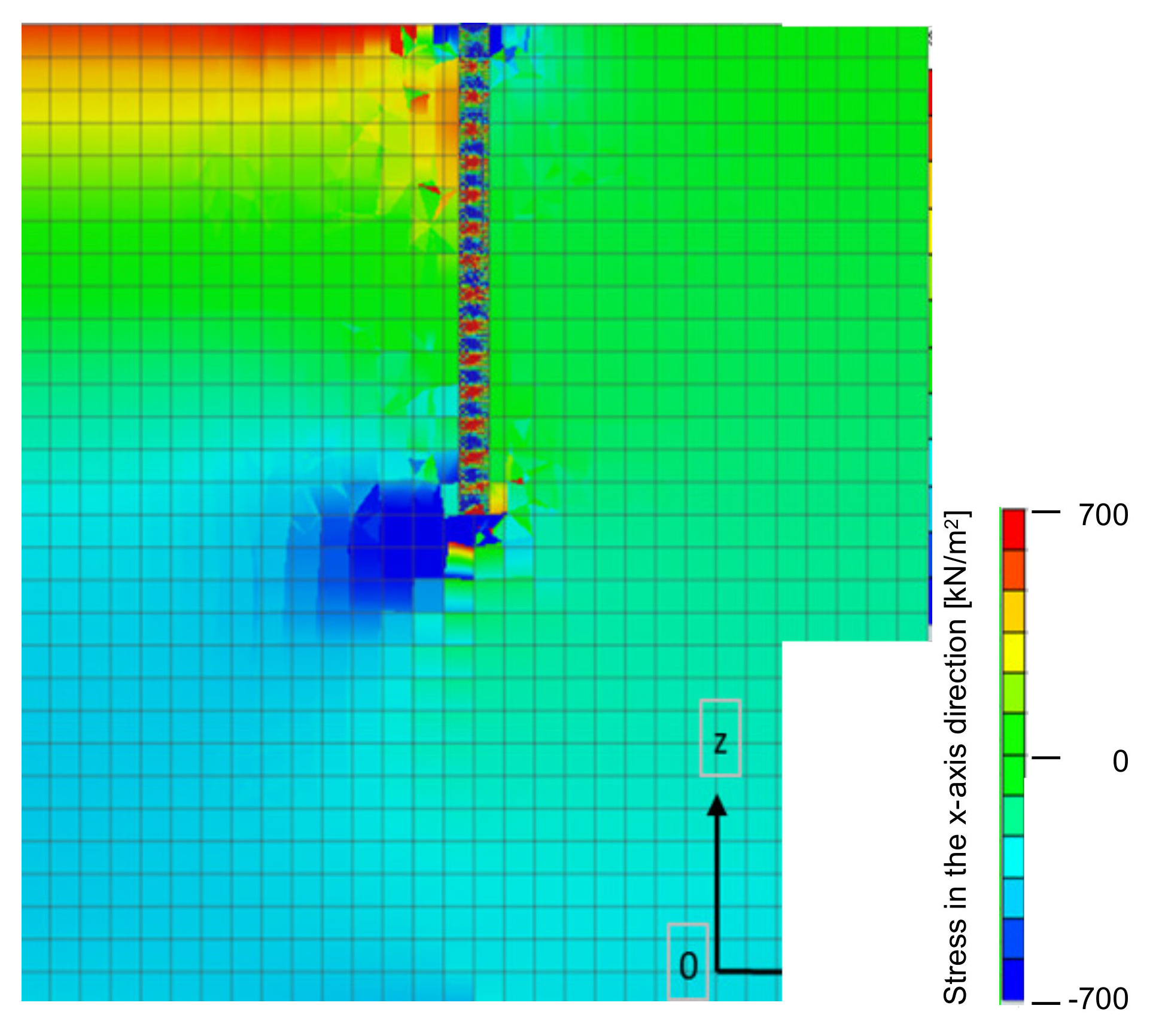

4.1. Influence of Soil with Difference in Mechanical Properties

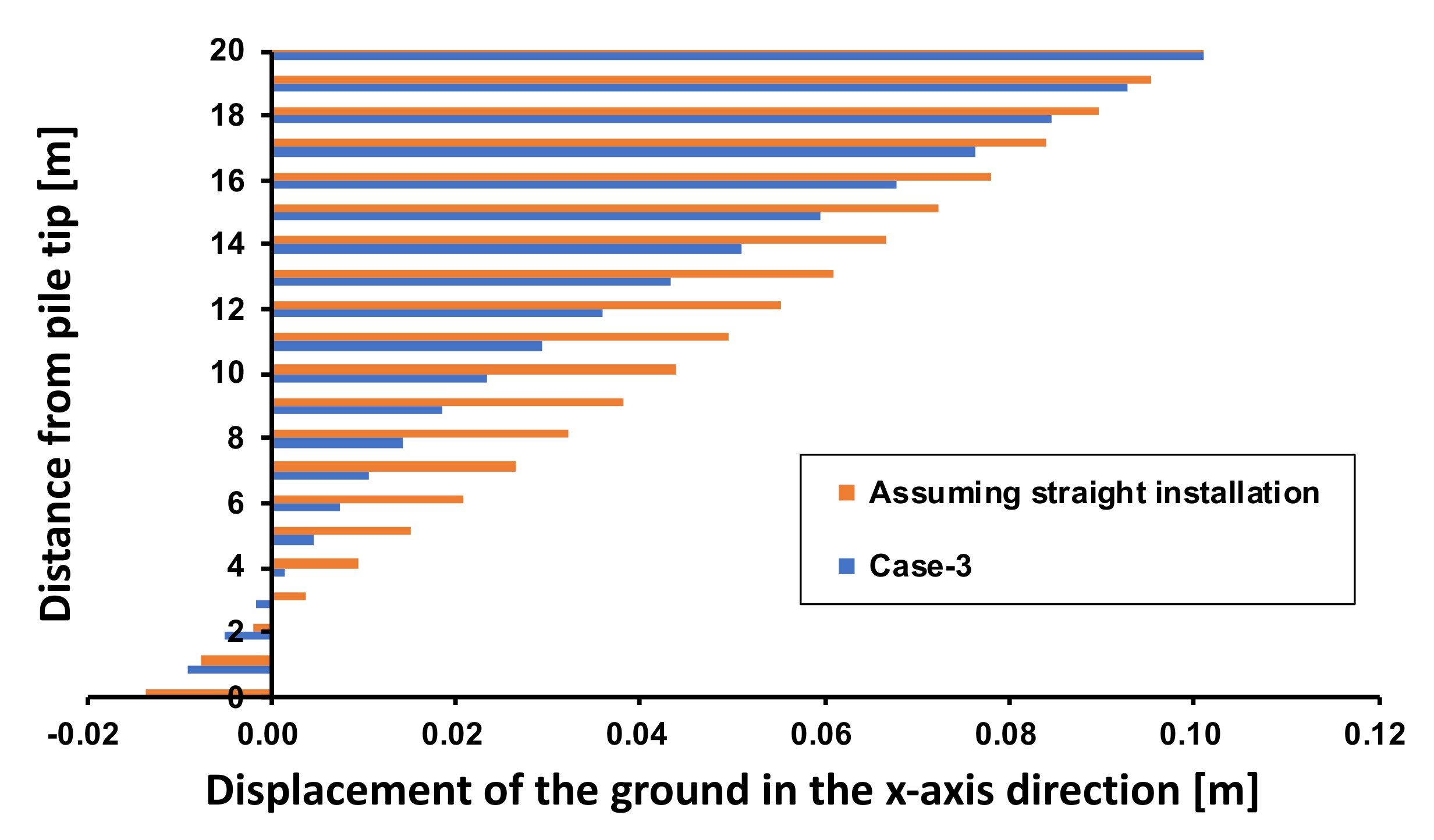

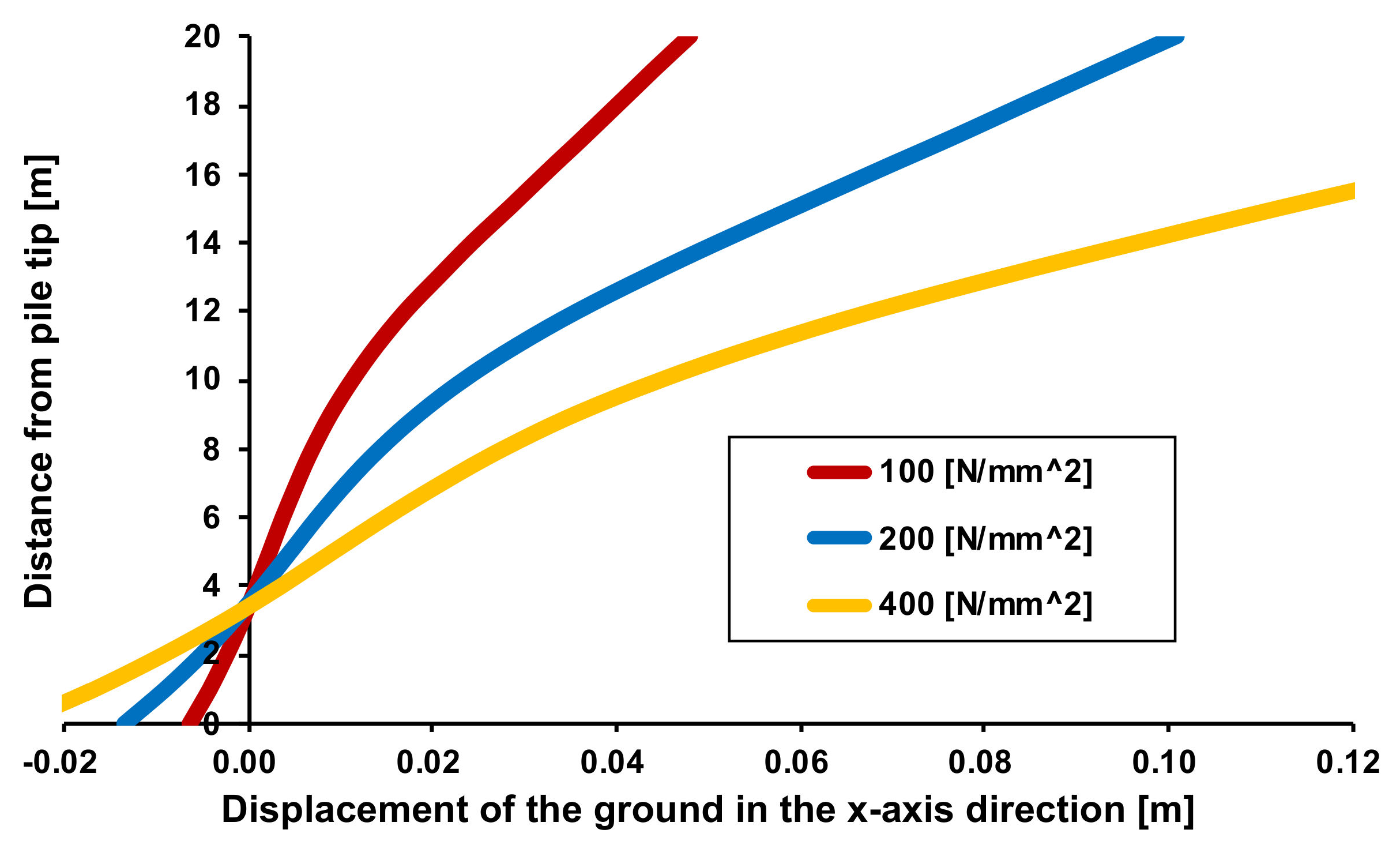

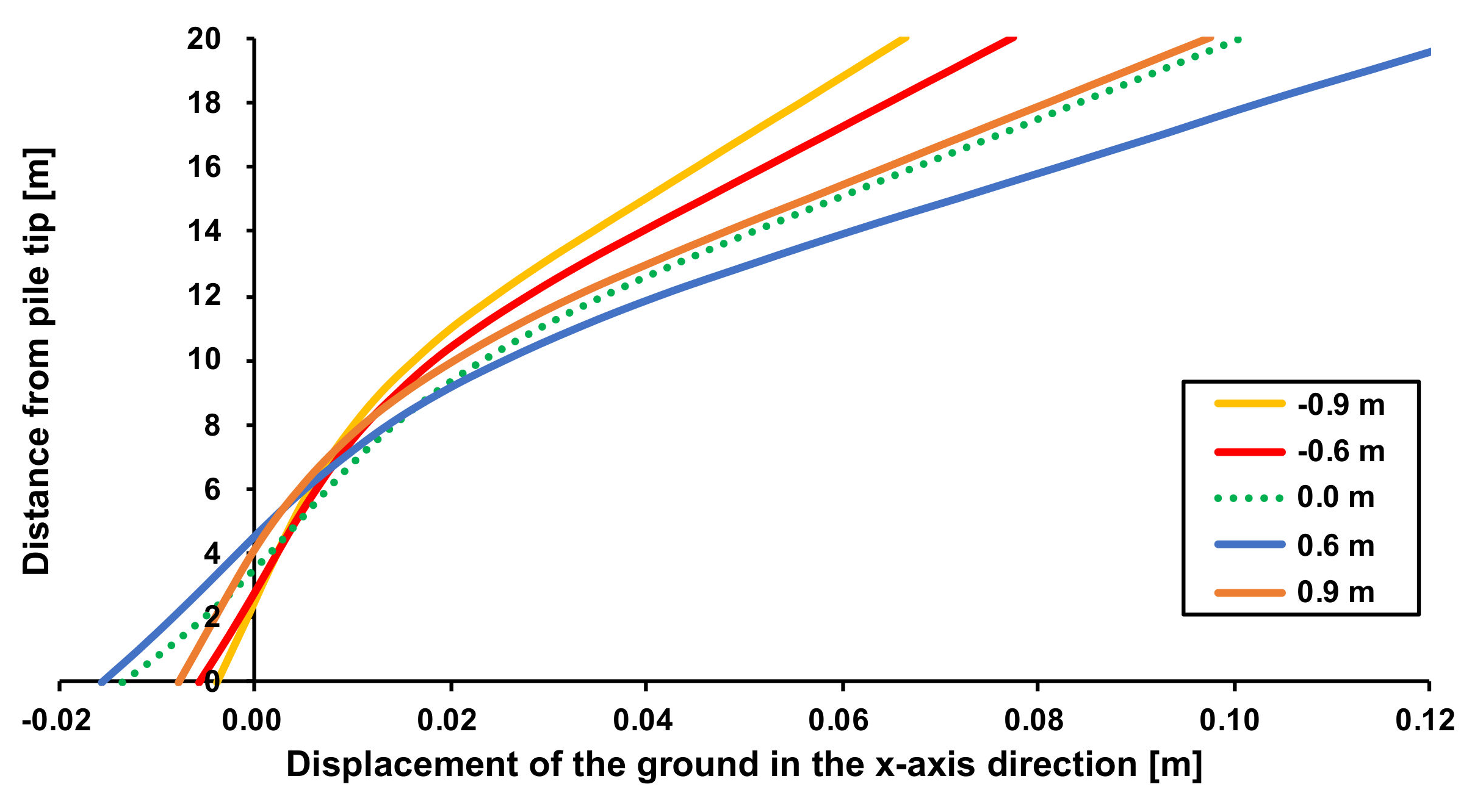

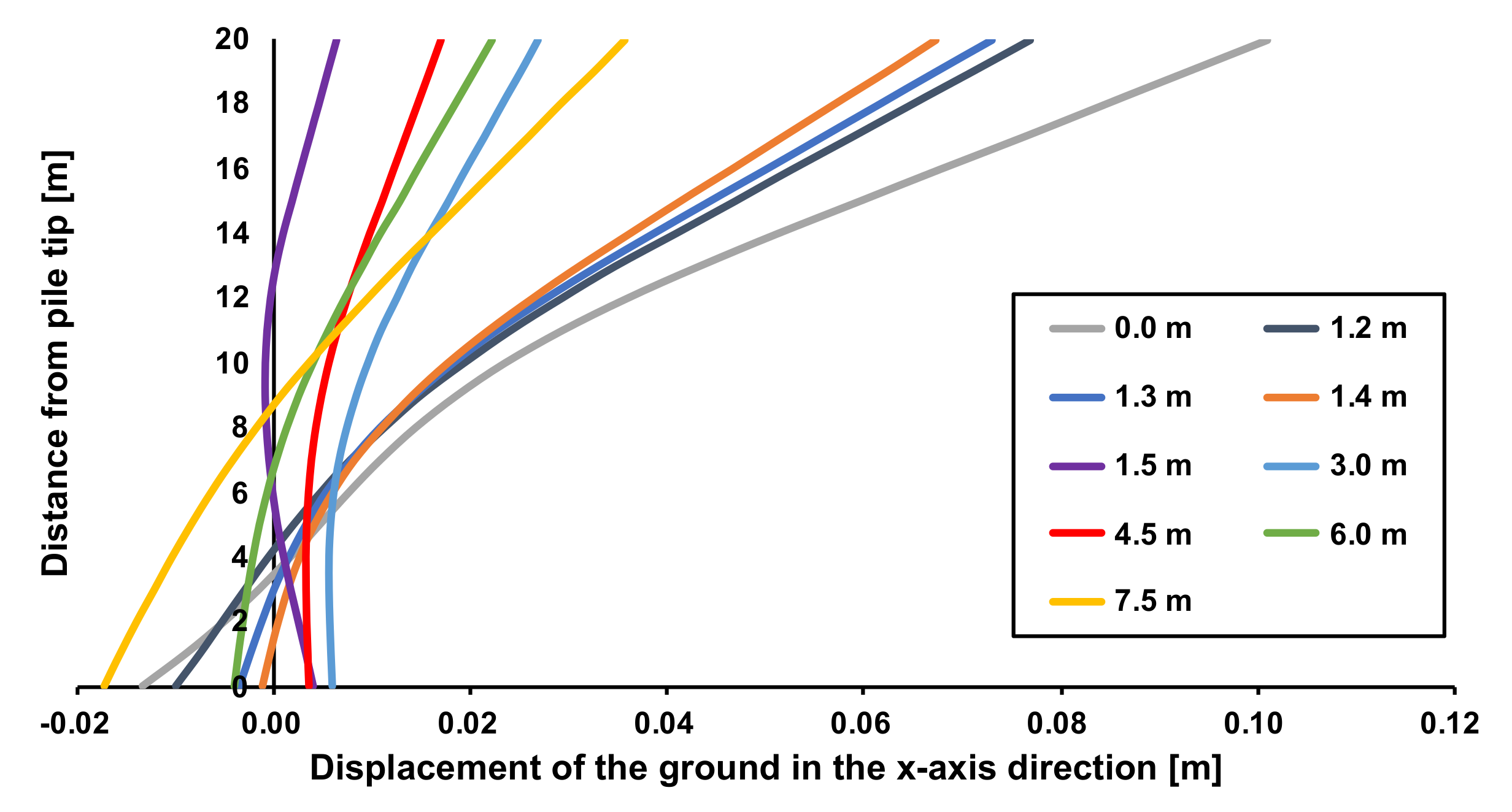

4.2. Load Acting on New Pile and Inclination of New Pile

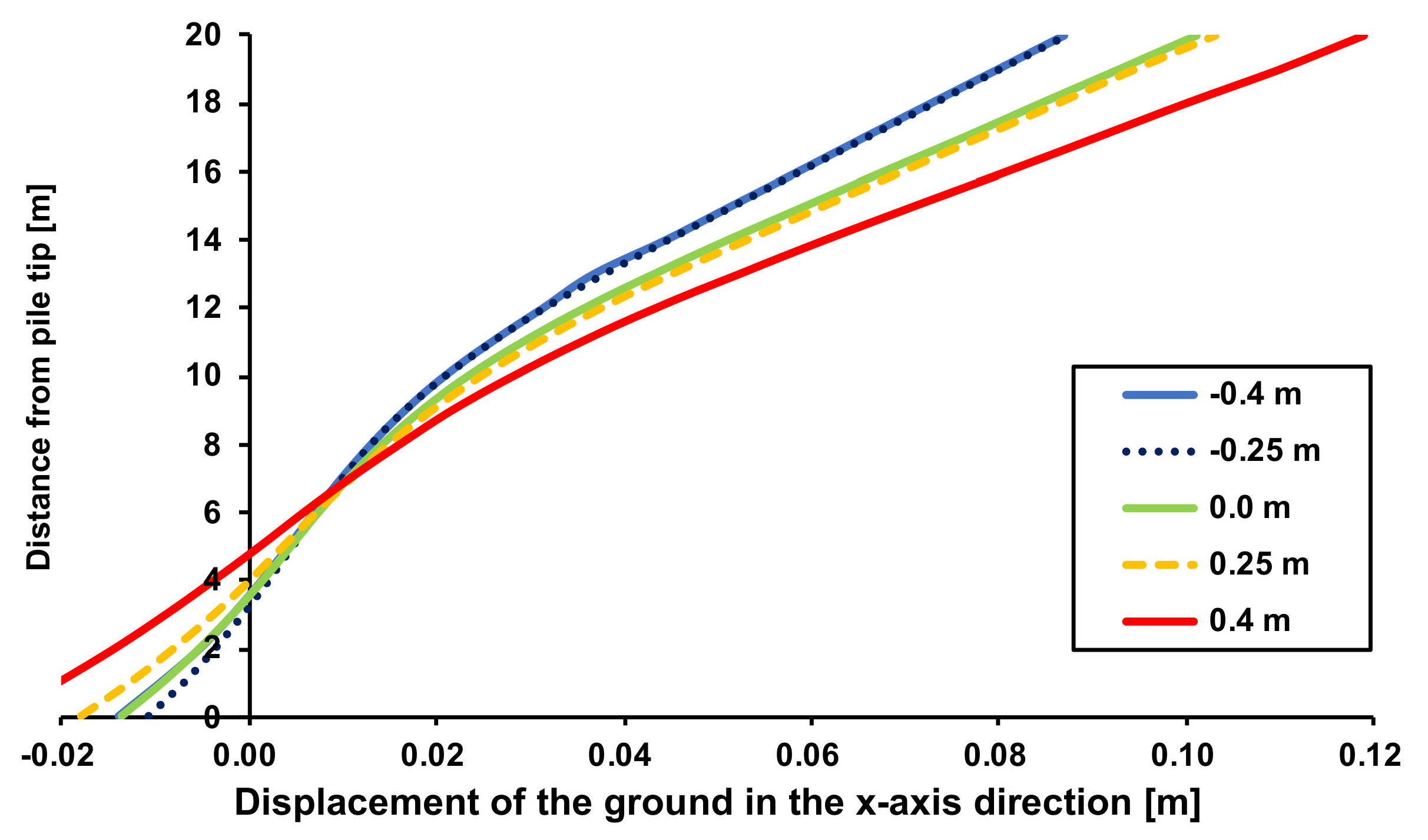

4.3. Position and Inclination of New Pile

5. Conclusions

- (1)

- When a new pile was installed at the boundary between two types of soil with different mechanical properties, most of the new pile was inclined to the soil side where the N value was relatively small.

- (2)

- When a new pile was installed at the boundary between two types of soil with different mechanical properties, the new pile warped so as to rise to the soil side where the N value was relatively large.

- (3)

- When a new pile was installed at the boundary between two types of soil with different mechanical properties, the new pile hardly inclined in the direction perpendicular to the boundary between the two types of soil.

- (4)

- When driving a new pile, the greater the load acting on the pile head, the more the new pile was inclined, and the smaller the load acting on the pile head, the less the new pile was inclined.

- (5)

- When a new pile was installed at the boundary between two types of soil with different mechanical properties, the inclination of the new pile was suppressed by increasing the distance from the boundary between the two types of soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Inazumi, S.; Namikawa, T.; Kuwahara, S.; Hamaguchi, S. Influence of pulling out existing piles on the surrounding ground. Int. J. GEOMATE Geotech. Constr. Mater. Environ. 2017, 13, 16–21. [Google Scholar] [CrossRef]

- Kuwahara, S.; Inazumi, S. Settlement of surrounding grounds due to existence of pile pulling-out holes. Int. J. GEOMATE Geotech. Constr. Mater. Environ. 2019, 16, 81–85. [Google Scholar] [CrossRef]

- Kuwahara, S.; Inazumi, S.; Jotisankasa, A.; Chaiprakaikeow, S. Influence of the condition of pullout holes on the surrounding ground. Int. J. Geo-Eng. 2020, 11, 10. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Nontananandh, S.; Jotisankasa, A.; Chaiprakaikeow, S. Numerical analysis for ground subsidence caused by extraction holes of removed piles. Appl. Sci. 2022, 12, 5481. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Jotisankasa, A.; Chaiprakaikeow, S. Improvement mechanism of sodium carbonate on traditional composite filler. Ground Improv. 2021, 174, 132–139. [Google Scholar] [CrossRef]

- Inazumi, S.; Tanaka, S.; Komaki, T.; Kuwahara, S. Effect of insertion of casing by rotation on existing piles in removal of existing pile. Geotech. Res. 2021, 8, 25–37. [Google Scholar] [CrossRef]

- Inazumi, S.; Hashimoto, R.; Shinsaka, T.; Nontananandh, S.; Chaiprakaikeow, S. Applicability of additives for ground improvement utilizing fine powder of waste glass. Materials 2021, 14, 5169. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Jotisankasa, A.; Chaiprakaikeow, S. Construction method for pulling out existing piles and influence of pulling-out holes on the surrounding ground. Geotech. Geol. Eng. 2020, 38, 6107–6123. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Jotisankasa, A.; Chaiprakaikeow, S. MPS-CAE simulation on dynamic interaction between steel casing and existing pile when pulling out existing piles. Int. J. GEOMATE Geotech. Constr. Mater. Environ. 2020, 18, 68–73. [Google Scholar] [CrossRef]

- Inazumi, S.; Kaneko, M.; Tomoda, Y.; Shigematsu, Y.; Shishido, K. Evaluation of flow-ability on fluidization treated soils based on flow analysis by MPS method. Int. J. GEOMATE Geotech. Constr. Mater. Environ. 2017, 12, 53–58. [Google Scholar] [CrossRef]

- Inazumi, S.; Kaneko, M.; Shigematsu, Y.; Shishido, K. Fluidity evaluation of fluidisation treated soils based on the moving particle semi-implicit method. Int. J. Geotech. Eng. 2018, 12, 325–336. [Google Scholar] [CrossRef]

- Inazumi, S.; Shigematsu, Y.; Nakao, K.; Shishido, K. 3-D particle flow analysis for fluidization treated soils. Am. J. Civ. Environ. Eng. 2018, 3, 59–67. [Google Scholar]

- Nakao, K.; Inazumi, S.; Takaue, T.; Tanaka, S.; Shinoi, T. Evaluation of discharging surplus soils for relative stirred deep mixing methods by MPS-CAE analysis. Sustainability 2021, 14, 58. [Google Scholar] [CrossRef]

- Nakao, K.; Inazumi, S.; Takahashi, T.; Nontananandh, S. Numerical simulation of the liquefaction phenomenon by MPSM-DEM coupled CAES. Sustainability 2022, 14, 7517. [Google Scholar] [CrossRef]

- Lees, A. Geotechnical Finite Element Analysis: A Practical Guide; ICE Publishing: London, UK, 2016. [Google Scholar]

- Saini, S.; Goyal, E.T. Analysis of piled raft foundation using MIDAS GTS NX. Int. Res. J. Eng. Technol. 2019, 6, 5491–5499. [Google Scholar]

- Skempton, A.W. Standard penetration test procedures and the effects in sands of overburden pressure, relative density, parti-cle size, ageing and overconsolidation. Geotechnique 1986, 36, 425–447. [Google Scholar] [CrossRef]

- Dung, N.T.; Chung, S.G.; Kim, S.R.; Beak, S.H. Applicability of the SPT-based methods for estimating toe bearing capacity of driven PHC piles in the thick deltaic deposits. KSCE J. Civ. Eng. 2011, 15, 1023–1031. [Google Scholar] [CrossRef]

- Intui, S.; Soralump, S.; Inazumi, S. Behavior of bearing capacity on pile foundation during fluctuating groundwater level. Int. J. GEOMATE Geotech. Constr. Mater. Environ. 2022, 22, 24–31. [Google Scholar] [CrossRef]

- Cetin, K.O.; Seed, R.B.; Kiureghian, A.D.; Tokimatsu, K.; Harder, L.F.; Kayen, R.E.; Moss, R.E.S. Standard penetration test based probabilistic and deterministic assessment of seismic soil liquefaction potential. J. Geotech. Geoenviron. Eng. 2004, 130, 1314. [Google Scholar] [CrossRef] [Green Version]

- Gang, B.; Hwang, B. Empirical estimations of soil constants using standard penetration test N value. J. Korean Geoenviron. Soc. 2018, 19, 5–12. [Google Scholar] [CrossRef]

- Huang, S.; Wang, J.; Qiu, Z.; Kang, K. Effects of cyclic wetting-drying conditions on elastic modulus and compressive strength of sandstone and mudstone. Processes 2018, 6, 234. [Google Scholar] [CrossRef] [Green Version]

- Nakao, K.; Yamaguchi, H.; Hoshino, S.; Inazumi, S. Applicability of weighting method as measure for existing manholes against uplifting during liquefaction. Appl. Sci. 2022, 12, 3818. [Google Scholar] [CrossRef]

- Hara, A.; Ohta, T.; Niwa, M.; Tanaka, S.; Banno, T. Shear modulus and shear strength of cohesive soils. Soils Found. 1974, 14, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Tarawneh, B. Predicting standard penetration test N-value from cone penetration test data using artificial neural networks. Geosci. Front. 2017, 8, 199–204. [Google Scholar] [CrossRef] [Green Version]

| N Value | Elastic Modulus [kN/m2] | Poisson’s Ratio | Wet Volume Mass [kN/m3] | |

|---|---|---|---|---|

| Sandy soil | 50 | 1.37 × 105 | 0.30 | 19.6 |

| Cohesive soil | 5 | 1.37 × 104 | 0.45 | 14.7 |

| Piles made of steel | - | 2.06 × 108 | 0.30 | 76.9 |

| Load [N/mm2] | 100 | 200 | 400 |

| Inclination based on displacements of pile tip and pile head | 1/367 | 1/175 | 1/93 |

| Inclination based on displacement of ground surface position from pile tip | 1/431 | 1/206 | 1/109 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nontananandh, S.; Kuwahara, S.; Shishido, K.-i.; Inazumi, S. Influence of Perforated Soils on Installation of New Piles. Appl. Sci. 2022, 12, 7712. https://doi.org/10.3390/app12157712

Nontananandh S, Kuwahara S, Shishido K-i, Inazumi S. Influence of Perforated Soils on Installation of New Piles. Applied Sciences. 2022; 12(15):7712. https://doi.org/10.3390/app12157712

Chicago/Turabian StyleNontananandh, Supakij, Shuichi Kuwahara, Ken-ichi Shishido, and Shinya Inazumi. 2022. "Influence of Perforated Soils on Installation of New Piles" Applied Sciences 12, no. 15: 7712. https://doi.org/10.3390/app12157712

APA StyleNontananandh, S., Kuwahara, S., Shishido, K.-i., & Inazumi, S. (2022). Influence of Perforated Soils on Installation of New Piles. Applied Sciences, 12(15), 7712. https://doi.org/10.3390/app12157712