Screening Additives for Amending Compacted Clay Covers to Enhance Diffusion Barrier Properties and Moisture Retention Performance

Abstract

:Featured Application

Abstract

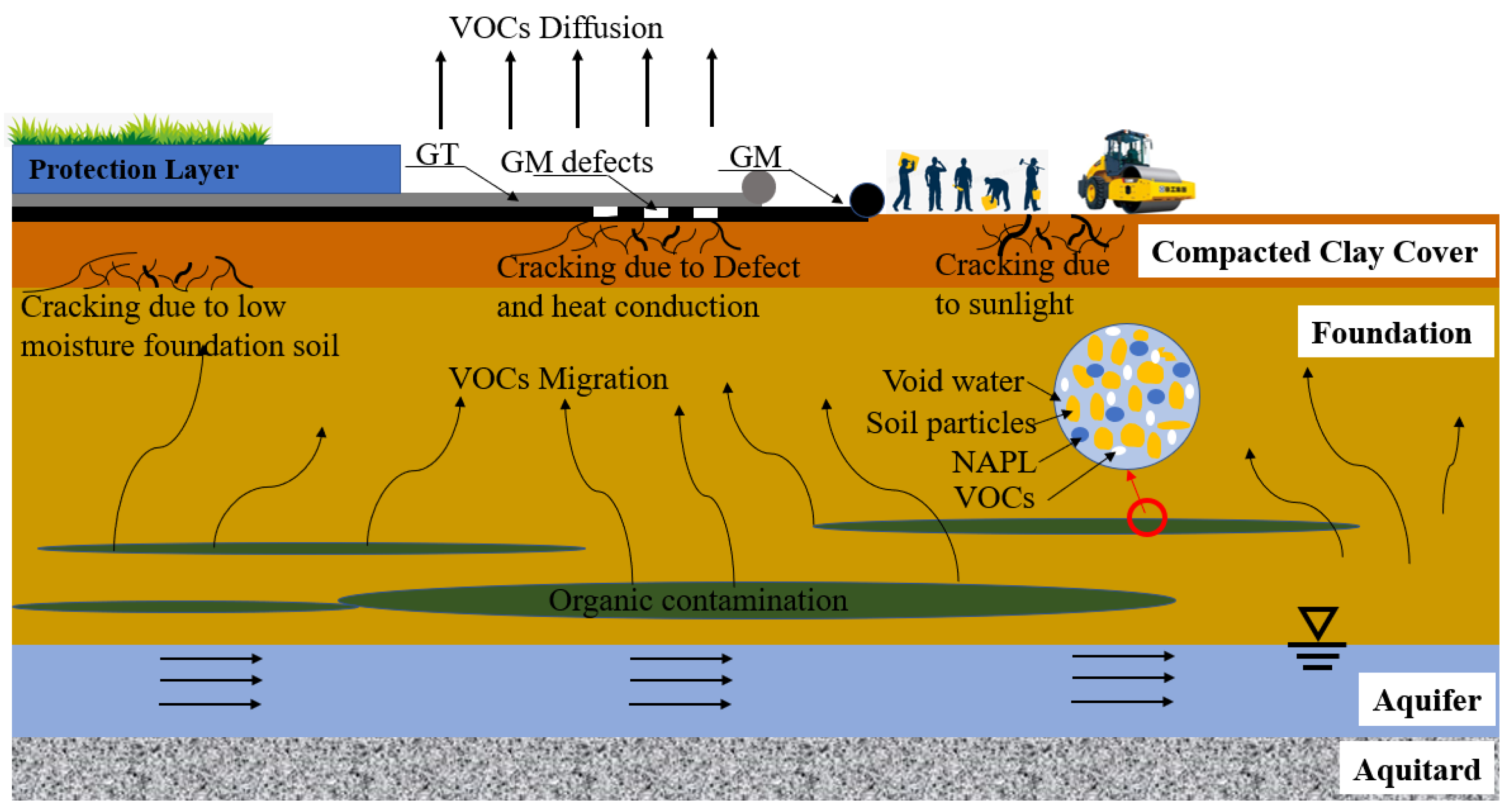

1. Introduction

2. Materials and Methods

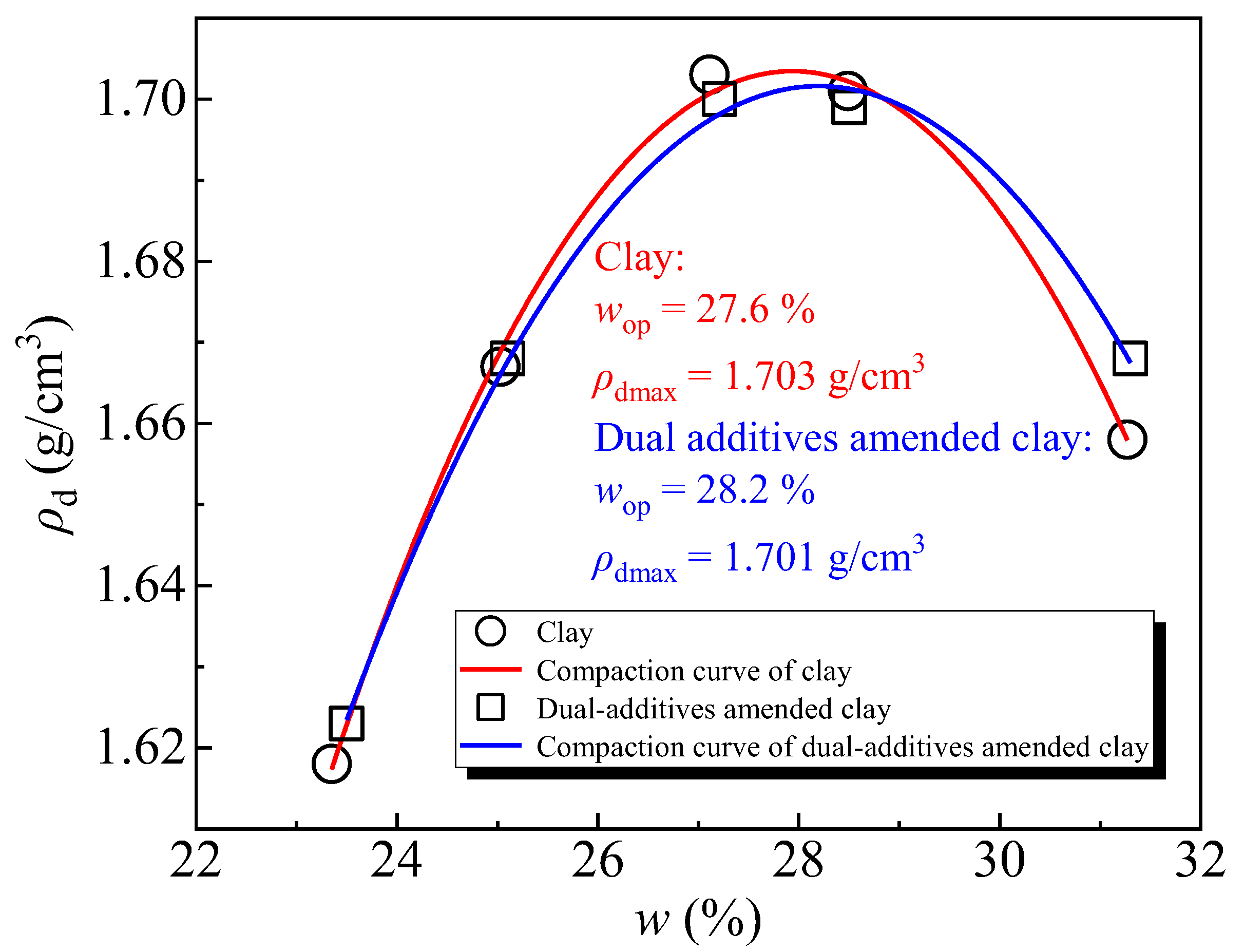

2.1. Preparation of Amended Compacted Clay

2.2. Moisture Retention Test

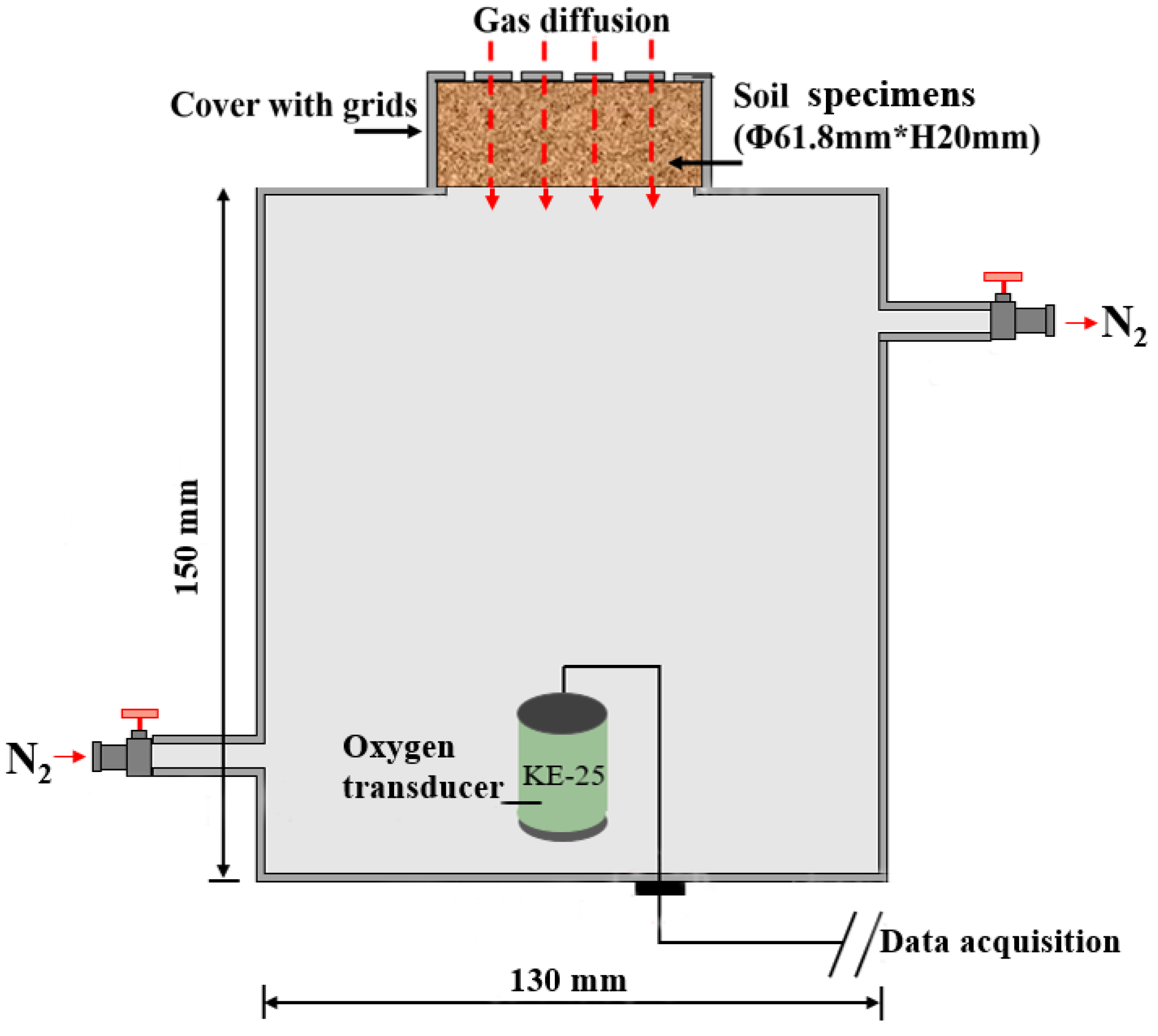

2.3. Gas Diffusion Testing Procedures and Apparatus

2.4. Flexible-Wall Hydraulic Conductivity Test

2.5. Scanning Electron Microscopy (SEM) and Mercury Intrusion Porosimetry (MIP) Tests

2.6. BET Specific Surface Area Test Method (BET) and Thermogravimetric Analysis (TGA)

3. Results and Discussion

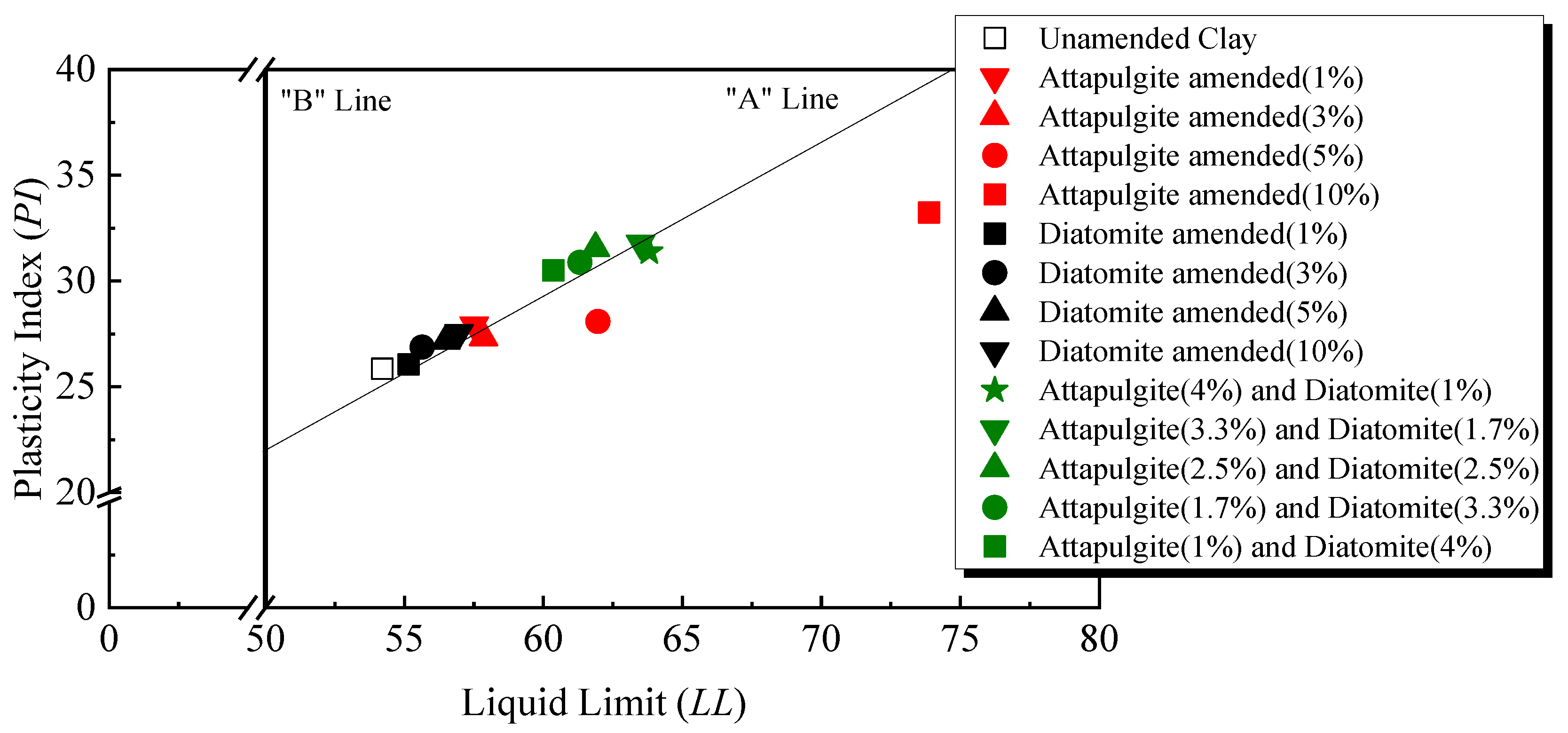

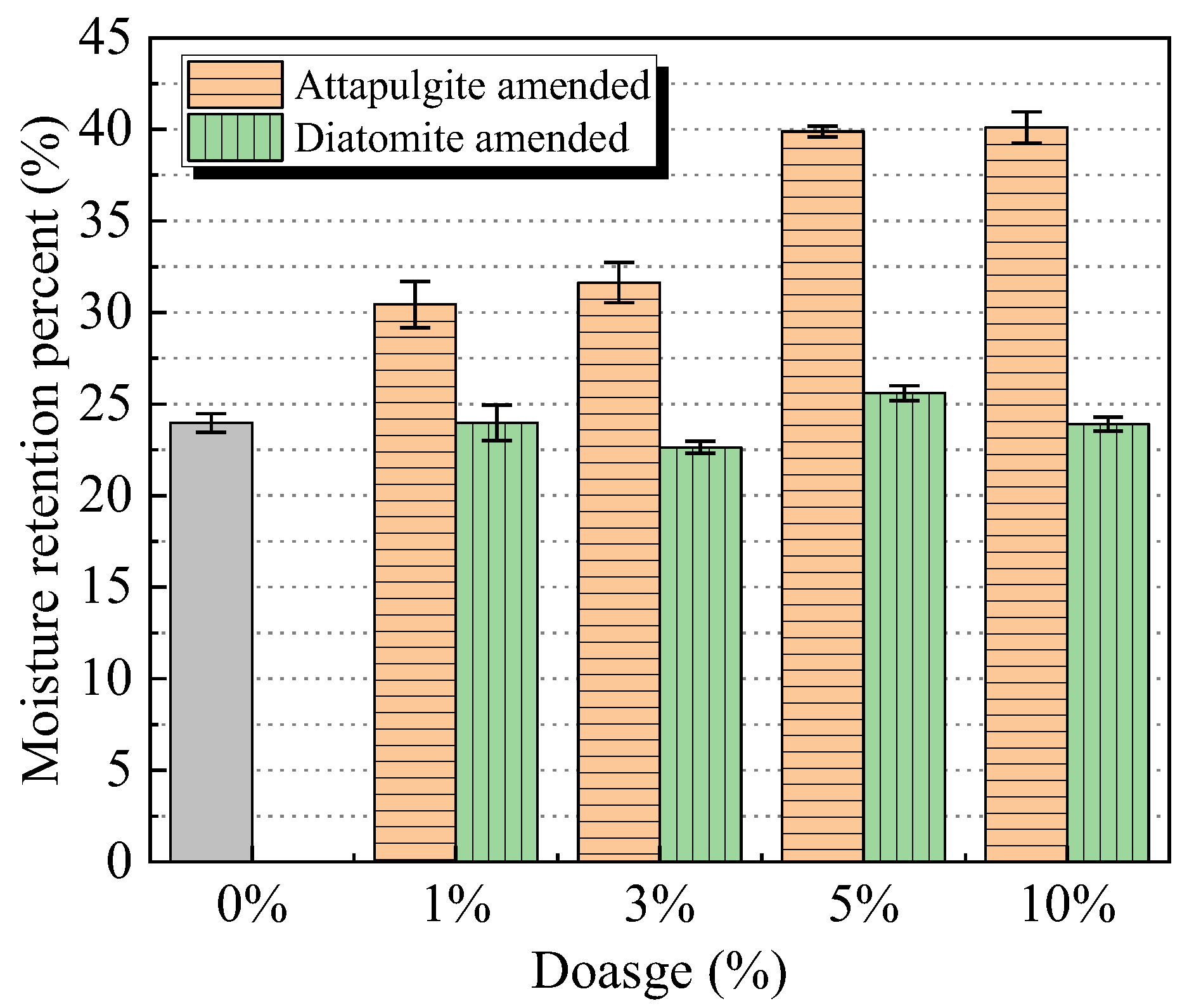

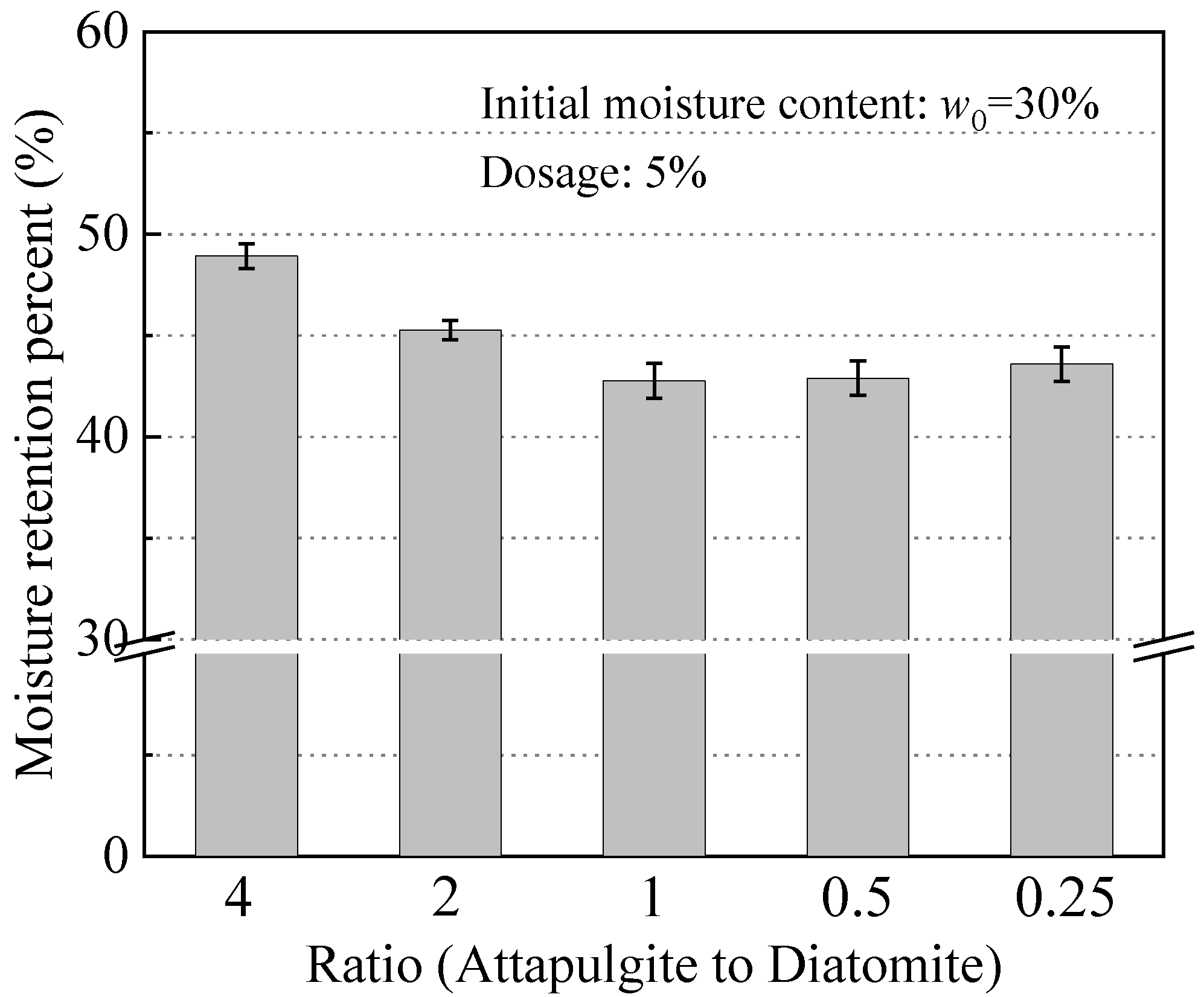

3.1. Liquid–Plastic Limit and Moisture Retention Tests Results

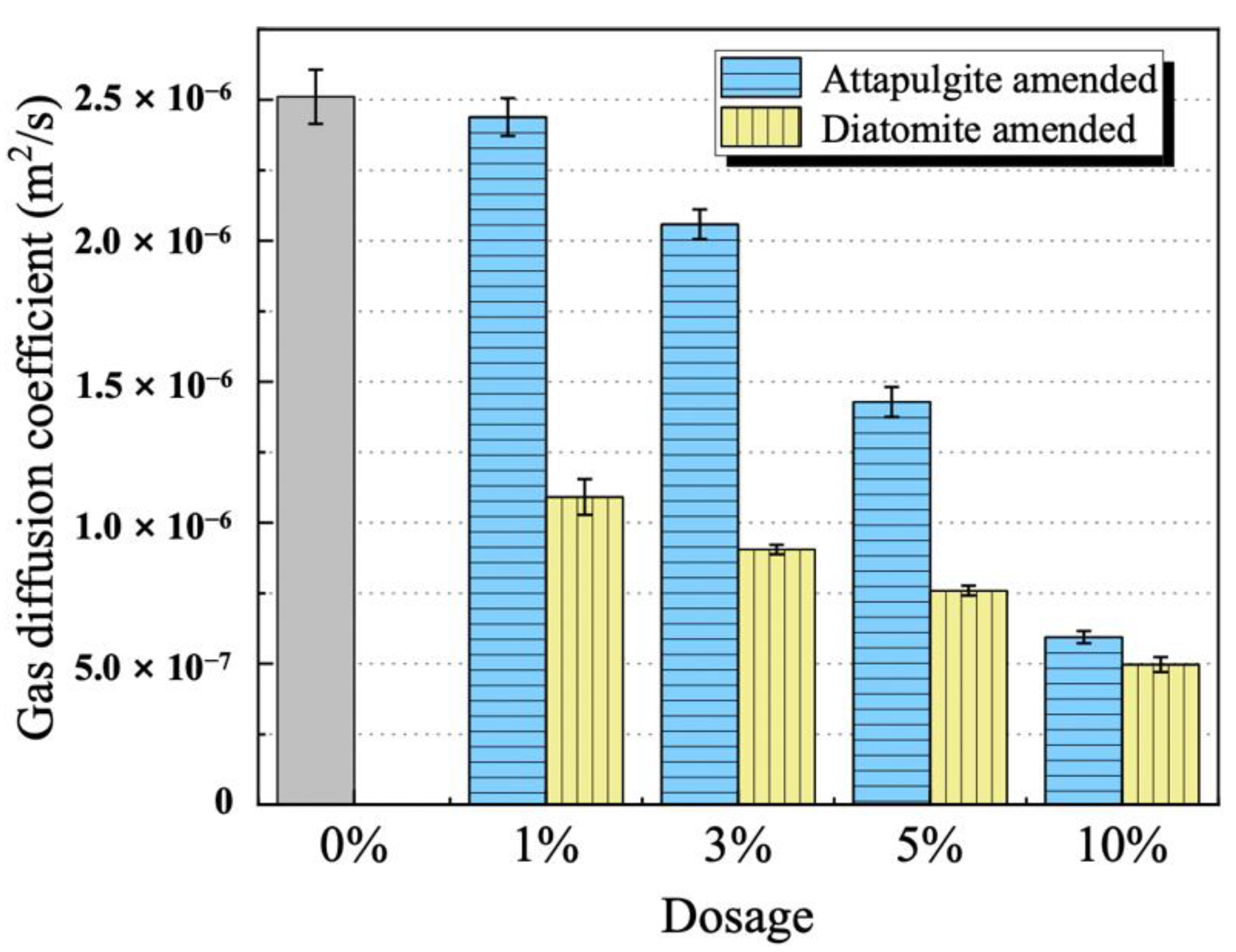

3.2. Gas Diffusion Test Results

3.3. Flexible-Wall Hydraulic Conductivity Test Results

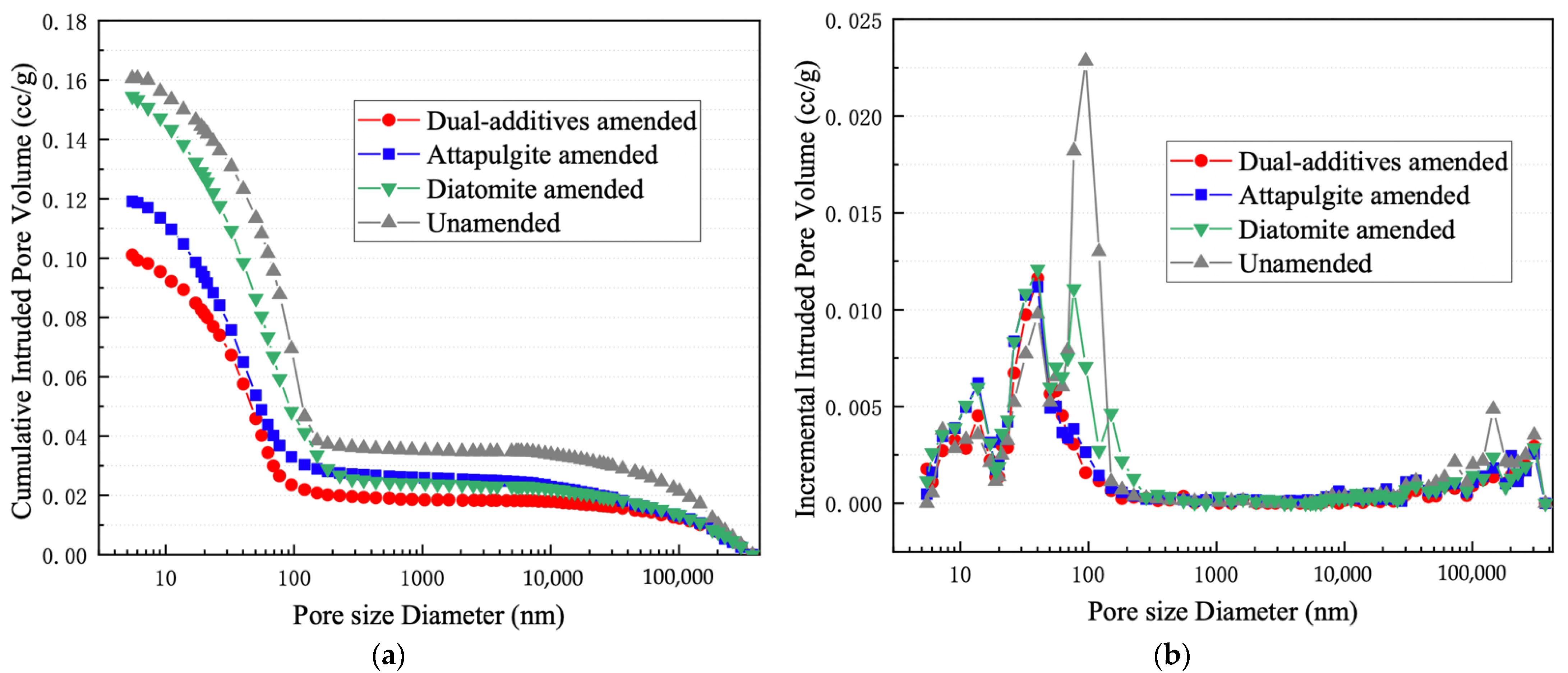

3.4. SEM, BET, MIP, and TGA Tests Results

4. Conclusions

- The attapulgite could enhance the moisture retention performance of the clay, but its effect on gas barrier performance was limited. When its dosage was 5%, its moisture retention percent was 66% higher than that of unamended clay. The enhancement mechanism behind the phenomenon is attributed to increasing the liquid limit of clay;

- The diatomite could effectively decrease the gas diffusion coefficient of clay, while it had a limited effect on the moisture retention performance. As its dosage was 5%, the moisture retention percent of clay only increased by 7%;

- Considering the moisture retention capacity, gas barrier performance, and cost, the optimal dosage of dual-additives was targeted to be 5%, and the optimal ratio of attapulgite to diatomite was 4. The moisture retention percent of the dual-additives-amended compacted clay increased by 82%, and the gas diffusion coefficient decreased by 42% compared with unamended clay. The k of enhanced compacted clay amended by attapulgite and dual-additives was 6.3 × 10−9 m/s and 5.9 × 10−9 m/s respectively, decreases of 25% and 29% compared with the unamended clay;

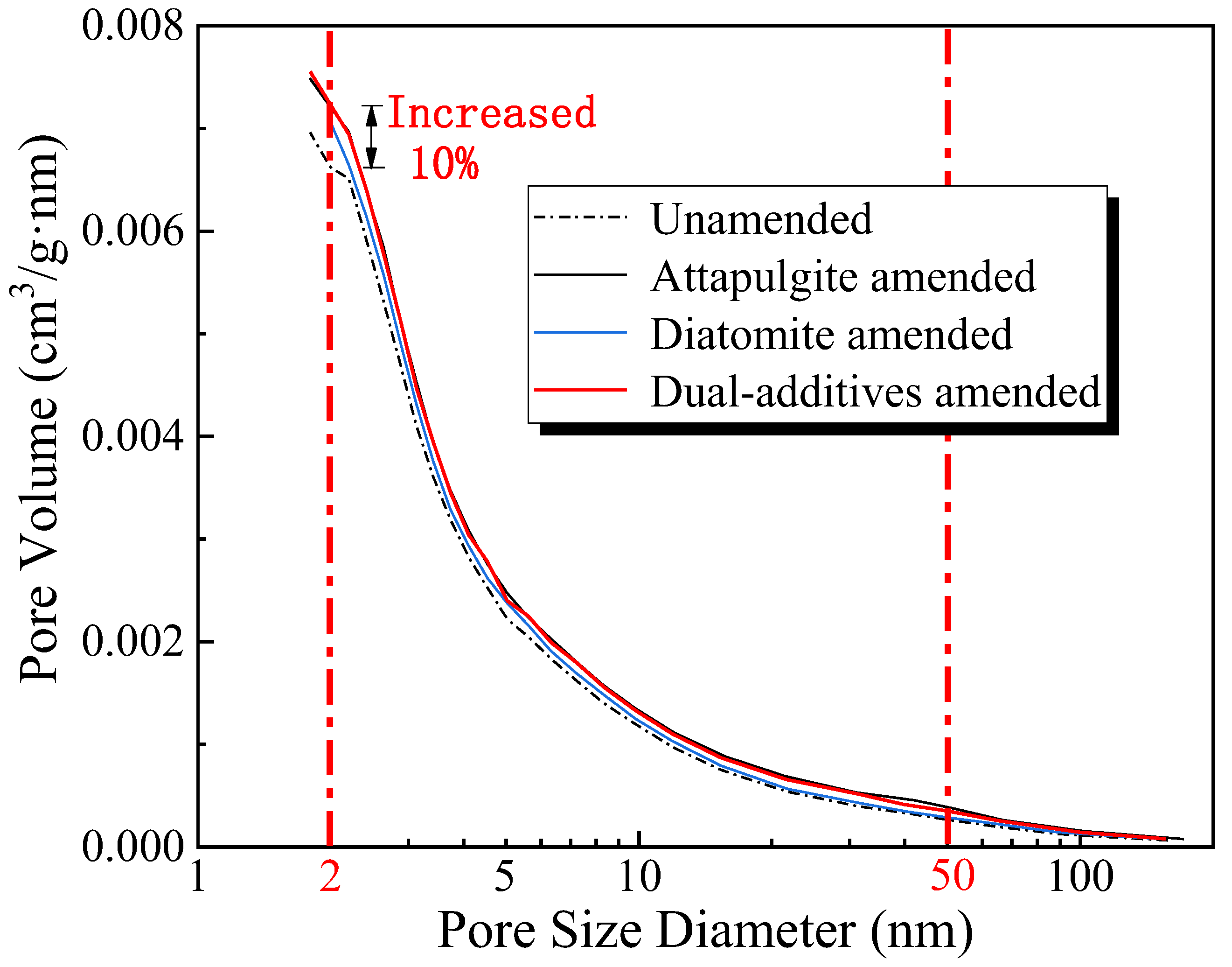

- The SEM and MIP analyses presented that dual-additives effectively filled the intergranular pores of the amended clay and micropore structure increased the gas migration path. The BET test results showed that dual-additives increased the amount of microporous to enhance the moisture retention performance of amended clay. Meanwhile, the dual-additives increased the specific surface area and decreased the average PSD. The TGA results demonstrated that dual-additives increased the temperature limit of loosely bound water to enhance the moisture retention performance of amended clay.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Kamchoom, V.; Chen, R. Landfill gas emission through compacted clay considering effects of crack pathway and intensity. Waste Manag. 2022, 143, 215–222. [Google Scholar] [PubMed]

- Albright, W.H.; Benson, C.H.; Gee, G.W.; Abichou, T.; McDonald, E.V.; Tyler, S.W.; Rock, S.A. Field performance of a compacted clay landfill final cover at a humid site. J. Geotech. Geoenviron. Eng. 2006, 132, 1393–1403. [Google Scholar]

- Ng, C.W.W.; Chen, Z.K.; Coo, J.L.; Chen, R.; Zhou, C. Gas breakthrough and emission through unsaturated compacted clay in landfill final cover. Waste Manag. 2015, 44, 155–163. [Google Scholar] [PubMed]

- Mahmoodlu, M.G.; Hassanizadeh, S.M.; Hartog, N.; Raoof, A.; van Genuchten, M.T. Evaluation of a horizontal permeable reactive barrier for preventing upward diffusion of volatile organic compounds through the unsaturated zone. J. Environ. Manag. 2015, 163, 204–213. [Google Scholar]

- Verginelli, I.; Capobianco, O.; Hartog, N.; Baciocchi, R. Analytical model for the design of in situ horizontal permeable reactive barriers (HPRBs) for the mitigation of chlorinated solvent vapors in the unsaturated zone. J. Contam. Hydrol. 2017, 197, 50–61. [Google Scholar]

- Rowe, R.K.; Brachman, R.W.I. Assessment of equivalence of composite liners. Geosynth. Int. 2004, 11, 273–286. [Google Scholar]

- Hewitt, P.J.; Philip, L.K. Problems of clay desiccation in composite lining systems. Eng. Geol. 1999, 53, 107–113. [Google Scholar]

- Omidi, G.H.; Thomas, J.C.; Brown, K.W. Effect of desiccation cracking on the hydraulic conductivity of a compacted clay liner. Water Air Soil Pollut. 1996, 89, 91–103. [Google Scholar]

- Julina, M.; Thyagaraj, T. Combined effects of wet-dry cycles and interacting fluid on desiccation cracks and hydraulic conductivity of compacted clay. Eng. Geol. 2020, 267, 105505. [Google Scholar]

- Aldaeef, A.A.; Rayhani, M.T. Hydraulic performance of compacted clay liners under simulated daily thermal cycles. J. Environ. Manag. 2015, 162, 171–178. [Google Scholar]

- Tang, C.S.; Shi, B.; Liu, C.; Suo, W.B.; Gao, L. Experimental characterization of shrinkage and desiccation cracking in thin clay layer. Appl. Clay Sci. 2011, 52, 69–77. [Google Scholar]

- Amarasiri, A.L.; Kodikara, J.K.; Costa, S. Numerical modelling of desiccation cracking. Int. J. Numer. Anal. Methods Geomech. 2011, 35, 82–96. [Google Scholar]

- Kodikara, J.K.; Choi, X. A simplified analytical model for desiccation cracking of clay layers in laboratory tests. In Unsaturated Soils, Proceedings of the UNSAT 2006 Conference, Carefree, AZ, USA, 2–6 April 2006; Miller, G.A., Zapata, C.E., Houston, S.L., Fredlund, D.G., Eds.; ASCE Geotechnical Special Publication: Carefree, AZ, USA, 2006; Volume 2, pp. 2558–2567. [Google Scholar]

- Albrecht, B.A.; Benson, C.H. Effect of desiccation on compacted natural clays. J. Geotech. Geoenviron. Eng. 2001, 127, 67–75. [Google Scholar]

- Kabiri, K.; Omidian, H.; Zohuriaan-Mehr, M.J.; Doroudiani, S. Superabsorbent hydrogel composites and nanocomposites: A review. Polym. Compos. 2011, 32, 277–289. [Google Scholar]

- Farrell, C.; Ang, X.Q.; Rayner, J.P. Water-retention additives increase plant available water in green roof substrates. Ecol. Eng. 2013, 52, 112–118. [Google Scholar]

- Polman, E.M.; Gruter, G.J.M.; Parsons, J.R.; Tietema, A. Comparison of the aerobic biodegradation of biopolymers and the corresponding bioplastics: A review. Sci. Total Environ. 2021, 753, 141953. [Google Scholar]

- Florez, C.; Restrepo-Baena, O.; Tobon, J.I. Effects of calcination and milling pre-treatments on natural zeolites as a supplementary cementitious material. Constr. Build. Mater. 2021, 310, 125220. [Google Scholar]

- Conant, B.H.; Gillham, R.W.; Mendoza, C.A. Vapor transport of trichloroethylene in the unsaturated zone: Field and numerical modeling investigations. Water Resour. Res. 1996, 32, 9–22. [Google Scholar]

- You, K.; Zhan, H. Comparisons of diffusive and advective fluxes of gas phase volatile organic compounds (VOCs) in unsaturated zones under natural conditions. Adv. Water Resour. 2013, 52, 221–231. [Google Scholar]

- Li, H.; Jiao, J.J. One-dimensional airflow in unsaturated zone induced by periodic water table fluctuation. Water Resour. Res. 2005, 41, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhan, H.; Huang, G.; You, K. Tide-induced airflow in a two-layered coastal land with atmospheric pressure fluctuations. Adv. Water Resour. 2011, 34, 649–658. [Google Scholar]

- You, K.; Zhan, H. Can atmospheric pressure and water table fluctuations be neglected in soil vapor extraction? Adv. Water Resour. 2012, 35, 41–54. [Google Scholar]

- Jiao, J.J.; Li, H. Breathing of coastal vadose zone induced by sea level fluctuations. Geophys. Res. Lett. 2004, 31, L11502. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.P.; Jiao, J.J. Numerical study of airflow in the unsaturated zone induced by sea tides. Water Resour. Res. 2008, 44, W06402. [Google Scholar] [CrossRef] [Green Version]

- You, K.; Zhan, H.; Li, J. A new solution and data analysis for gas flow to a barometric pumping well. Adv. Water Resour. 2010, 33, 1444–1455. [Google Scholar]

- You, K.; Zhan, H.; Li, J. Gas flow to a barometric pumping well in a multilayer unsaturated zone. Water Resour. Res. 2011, 47, W05522. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.W.; Smith, J.A. Geoenvironmental factors affecting organic vapor advection and diffusion fluxes from the unsaturated zone to the atmosphere under natural conditions. Environ. Eng. Sci. 2005, 22, 95–108. [Google Scholar]

- Smith, J.A.; Chiou, C.T.; Kammer, J.A.; Kile, D.E. Effect of soil moisture on the sorption of trichloroethene vapor to vadose-zone soil at Picatinny Arsenal, New Jersey. Environ. Sci. Technol. 1990, 24, 676–683. [Google Scholar]

- Batterman, S.A.; McQuown, B.C.; Murthy, P.N.; McFarland, A.R. Design and evaluation of a long-term soil gas flux sampler. Environ. Sci. Technol. 1992, 26, 709–714. [Google Scholar]

- Rowe, R.K. Environmental Geotechnics: Past, Present and Future? In Proceedings of the 8th International Congress on Environmental Geotechnics, Hangzhou, China, 28 October–1 November 2018; Springer: Singapore, 2018. [Google Scholar]

- ASTM D 698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM: West Conshohocken, PA, USA, 2012.

- ASTM D 4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2018b.

- ASTM D 854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM: West Conshohocken, PA, USA, 2014b.

- Sun, L.P.; Du, Y.M.; Shi, X.W.; Chen, X.; Yang, J.H.; Xu, Y.M. A new approach to chemically modified carboxymethyl chitosan and study of its moisture-absorption and moisture-retention abilities. J. Appl. Polym. Sci. 2006, 102, 1303–1309. [Google Scholar]

- Barajas-Ledesma, R.M.; Wong, V.N.; Little, K.; Patti, A.F.; Garnier, G. Carboxylated nanocellulose superabsorbent: Biodegradation and soil water retention properties. J. Appl. Polym. Sci. 2022, 139, 51495. [Google Scholar]

- Mi, Y.; Miao, Q.; Cui, J.; Tan, W.; Guo, Z. Novel 2-Hydroxypropyltrimethyl Ammonium Chitosan Derivatives: Synthesis, Characterization, Moisture Absorption and Retention Properties. Molecules 2021, 26, 4238. [Google Scholar] [CrossRef]

- Wang, J.; Jin, W.; Hou, Y.; Niu, X.; Zhang, H.; Zhang, Q. Chemical composition and moisture-absorption/retention ability of polysaccharides extracted from five algae. Int. J. Biol. Macromol. 2013, 57, 26–29. [Google Scholar] [PubMed]

- Taylor, S.A. Oxygen diffusion in porous media as a measure of soil aeration. Soil Sci. Soc. Am. J. 1950, 14, 55–61. [Google Scholar]

- Currie, J.A. Gaseous diffusion in porous media Part 1. A non-steady state method. Br. J. Appl. Phys. 1960, 11, 314–317. [Google Scholar]

- Su, Z.; Wu, B.; Gong, Y. Determination of gas diffusion coefficient in soils with different porosities. Trans. Chin. Soc. Agric. Eng. 2015, 31, 108–113. [Google Scholar]

- ASTM D5084; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM: West Conshohocken, PA, USA, 2016.

- Malusis, M.A.; McKeehan, M.D. Chemical compatibility of model soil-bentonite backfill containing multiswellable bentonite. J. Geotech. Geoenviron. Eng. 2013, 139, 189–198. [Google Scholar]

- Bohnhoff, G.L.; Shackelford, C.D. Hydraulic conductivity of polymerized bentonite-amended backfills. J. Geotech. Geoenviron. Eng. 2014, 140, 04013028. [Google Scholar]

- Yang, Y.L.; Reddy, K.R.; Du, Y.J.; Fan, R.D. Short-term hydraulic conductivity and consolidation properties of soil-bentonite backfills exposed to CCR-impacted groundwater. J. Geotech. Geoenviron. Eng. 2018, 144, 04018025. [Google Scholar]

- Boudriche, L.; Calvet, R.; Hamdi, B.; Balard, H. Effect of acid treatment on surface properties evolution of attapulgite clay: An application of inverse gas chromatography. Colloid. Surf. 2011, 392, 45–54. [Google Scholar]

- Duan, Z.; Zhao, Q.; Wang, S.; Yuan, Z.; Zhang, Y.; Li, X.; Wu, Y.; Jiang, Y.; Tai, H. Novel application of attapulgite on high performance and low-cost humidity sensors. Sens. Actuators B Chem. 2020, 305, 127534. [Google Scholar]

- Liu, D.B.; Li, Y.; Xiao, H.F.; Xu, L.D.; Zhou, Y.Z.; Han, W.Y.; Li, H.R.; Jiang, Y.M.; Qiu, Y.S. Attapulgite Clay and Its Application in Radionuclide Treatment: A Review. Sci. Adv. Mater. 2018, 10, 1529–1542. [Google Scholar]

- de Namor, A.F.D.; El Gamouz, A.; Frangie, S.; Martinez, V.; Valiente, L.; Webb, O.A. Turning the volume down on heavy metals using tuned diatomite. A review of diatomite and modified diatomite for the extraction of heavy metals from water. J. Hazard. Mater. 2012, 241, 14–31. [Google Scholar]

- Sun, M.; Zou, C.; Xin, D. Pore structure evolution mechanism of cement mortar containing diatomite subjected to freeze-thaw cycles by multifractal analysis. Cem. Concr. Compos. 2020, 114, 103731. [Google Scholar]

- Zheng, J.; Shi, J.; Ma, Q.; Dai, X.; Chen, Z. Experimental study on humidity control performance of diatomite-based building materials. Appl. Therm. Eng. 2017, 114, 450–456. [Google Scholar]

- Li, Y.L.; Wang, T.H.; Su, L.J. Determination of bound water content of loess soils by isothermal adsorption and thermogravimetric analysis. Soil Sci. 2015, 180, 90–96. [Google Scholar]

- Li, S.; Wang, C.; Zhang, X.; Zou, L.; Dai, Z. Classification and characterization of bound water in marine mucky silty clay. J. Soils Sediments 2019, 19, 2509–2519. [Google Scholar]

- Wang, Y.; Lu, S.; Ren, T.; Li, B. Bound water content of air-dry soils measured by thermal analysis. Soil Sci. Soc. Am. J. 2011, 75, 481–487. [Google Scholar]

- Fu, X.L.; Shen, S.Q.; Reddy, K.R.; Yang, Y.L.; Du, Y.J. Hydraulic Conductivity of Sand/Biopolymer-Amended Bentonite Backfills in Vertical Cutoff Walls Permeated with Lead Solutions. J. Geotech. Geoenviron. Eng. 2022, 148, 04021186. [Google Scholar]

- Zhuang, H.; Wang, J.; Gao, Z. Anisotropic and Noncoaxial Behavior of Soft Marine Clay under Stress Path Considering the Variation of Principal Stress Direction. Int. J. Geomech. 2022, 22, 04022062. [Google Scholar]

| Property | Standard | Constituent Material | ||

|---|---|---|---|---|

| Clay | Attapulgite | Diatomite | ||

| Specific gravity, (Gs) | ASTM D854 (2014) | 2.73 | - | - |

| Liquid limit, LL (%) | ASTM D4318 (2018) | 54 | 197 | 121 |

| Plasticity index, PI (%) | 26 | 105 | 35 | |

| Classification | ASTM D2487 (2018) | CH | MH | MH |

| Optimum moisture content, wop (%) | JTG E40 T0131-2007 | 27.6 | - | - |

| Maximum dry density, pdmax (g/cm3) | 1.7 | - | - | |

| Component | SiO2 | Al2O3 | Fe2O3 | Na2O | K2O | CaO | MgO | MnO | TiO2 | Loss | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | Attapulgite | 58.05 | 9.55 | 6.2 | 0.14 | 1.13 | 1.18 | 11.02 | 0. 61 | 0.47 | 11.65 |

| Diatomite | 90.2 | 3.4 | 1.2 | 0.5 | 0.5 | 0.4 | 0.4 | 0. 61 | 0.2 | 2.59 | |

| Specimens | The Initial Moisture Content | The Additives Dosage | Ratio (Attapulgite: Diatomite) | Test Parameter |

|---|---|---|---|---|

| Attapulgite-amended | 30% | 0%, 1%, 3%, 5%, 10% | - | Moisture retention percent (Wt); Liquid limit (LL); Plastic limit (PL); Gas diffusion coefficient (Dθ) |

| Diatomite-amended | 0%, 1%, 3%, 5%, 10% | - | ||

| Dual-additives-amended | 5% | 4, 2, 1, 0.5, 0.25 |

| Specimens | Dosage | Ratio (Attapulgite to Diatomite) | Specific Surface Area (m2/g) | DFT Pore Distribution (cm3/g) | Average Microporous Size Diameter (nm) | |

|---|---|---|---|---|---|---|

| Less than 1.863 nm | Less than 19.577 nm | |||||

| Unamended | - | - | 43.5843 | 0.01119 | 0.05508 | 0.7847 |

| Attapulgite-amended | 5% | - | 49.7271 | 0.01284 | 0.07191 | 0.7829 |

| Diatomite-amended | 5% | - | 45.4255 | 0.01201 | 0.05729 | 0.7803 |

| Dual-additives-amended | 5% | 4 | 49.3243 | 0.01284 | 0.06779 | 0.7811 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Wen, J.; Zhuang, H.; Xia, W.; Jiang, N.; Du, Y. Screening Additives for Amending Compacted Clay Covers to Enhance Diffusion Barrier Properties and Moisture Retention Performance. Appl. Sci. 2022, 12, 7341. https://doi.org/10.3390/app12147341

Wang M, Wen J, Zhuang H, Xia W, Jiang N, Du Y. Screening Additives for Amending Compacted Clay Covers to Enhance Diffusion Barrier Properties and Moisture Retention Performance. Applied Sciences. 2022; 12(14):7341. https://doi.org/10.3390/app12147341

Chicago/Turabian StyleWang, Min, Jiaming Wen, Heng Zhuang, Weiyi Xia, Ningjun Jiang, and Yanjun Du. 2022. "Screening Additives for Amending Compacted Clay Covers to Enhance Diffusion Barrier Properties and Moisture Retention Performance" Applied Sciences 12, no. 14: 7341. https://doi.org/10.3390/app12147341

APA StyleWang, M., Wen, J., Zhuang, H., Xia, W., Jiang, N., & Du, Y. (2022). Screening Additives for Amending Compacted Clay Covers to Enhance Diffusion Barrier Properties and Moisture Retention Performance. Applied Sciences, 12(14), 7341. https://doi.org/10.3390/app12147341