A Multiscale Study of Moisture Influence on the Crumb Rubber Asphalt Mixture Interface

Abstract

:1. Introduction

2. Materials and Models

2.1. Preparation of Test Materials and SCB Specimens

2.1.1. Asphalt

2.1.2. Aggregate and Gradation of CR Mixture

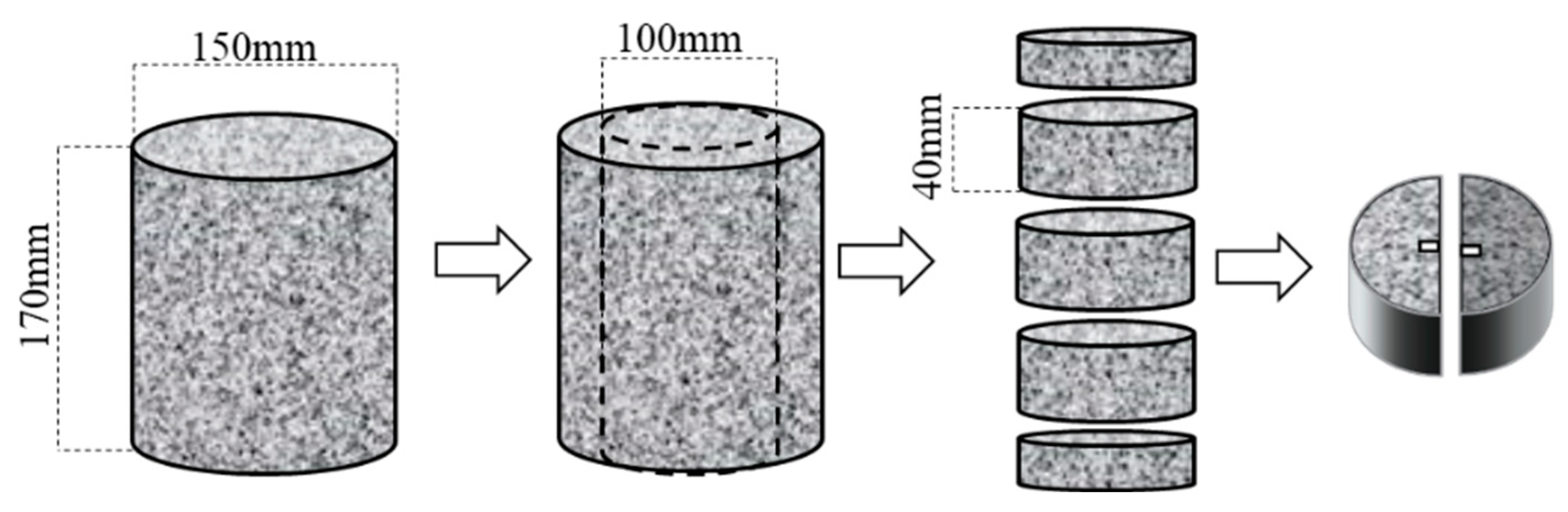

2.1.3. Preparation of SCB Specimen

2.2. Preparation of Contact Angle Measurement Sample

2.3. Construction of Models

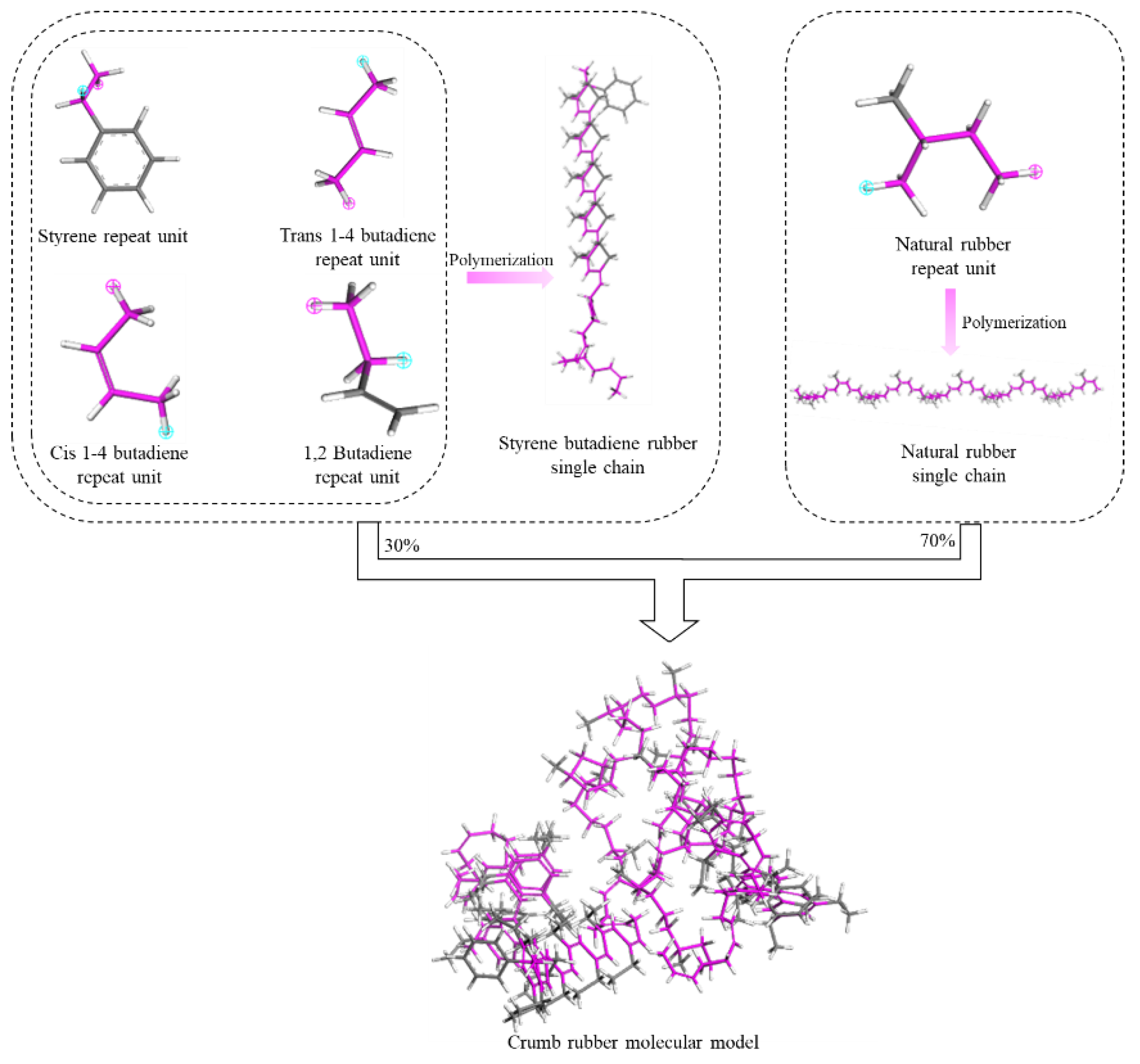

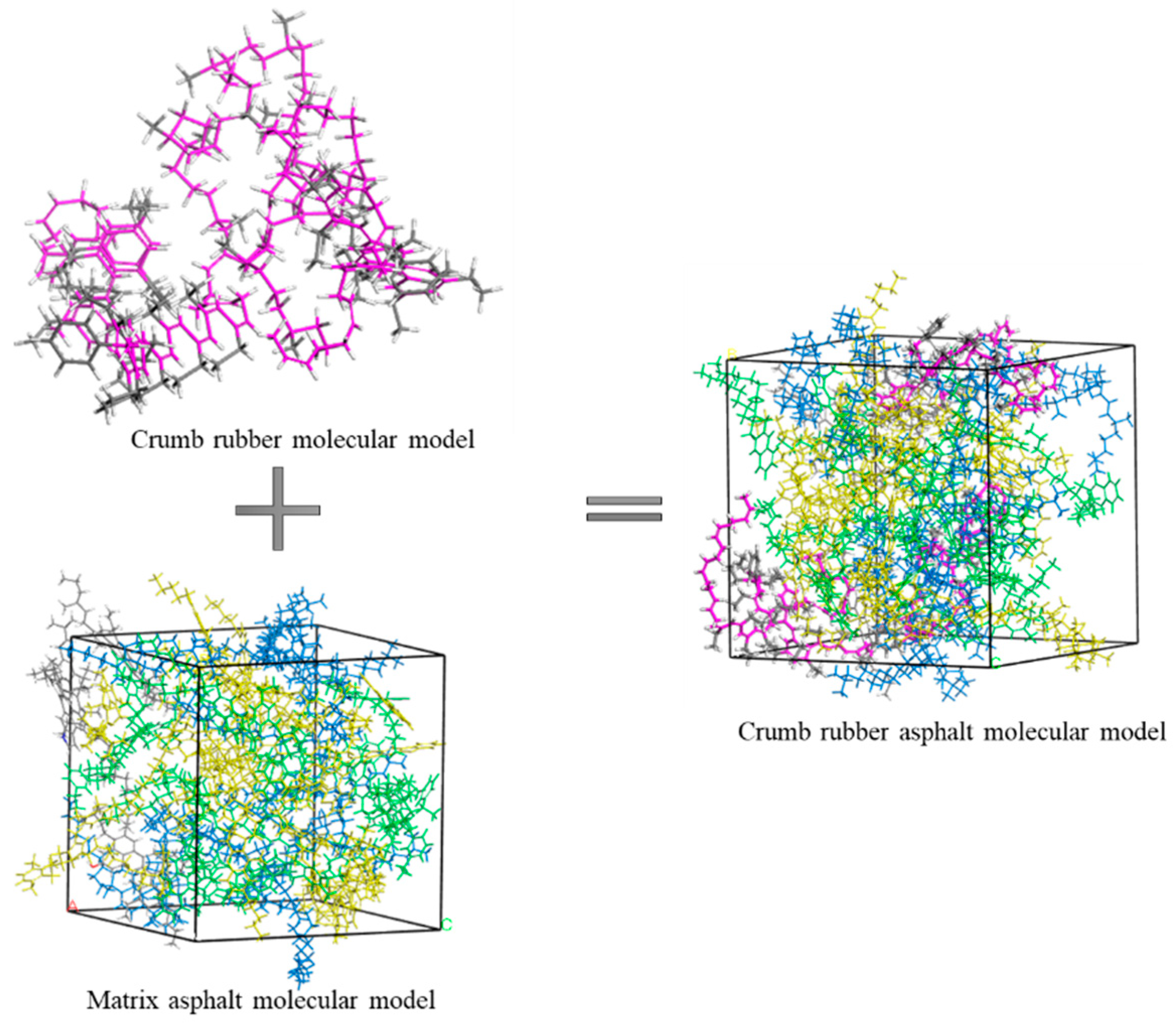

2.3.1. Model of CR

2.3.2. Model of Aggregate Mineral

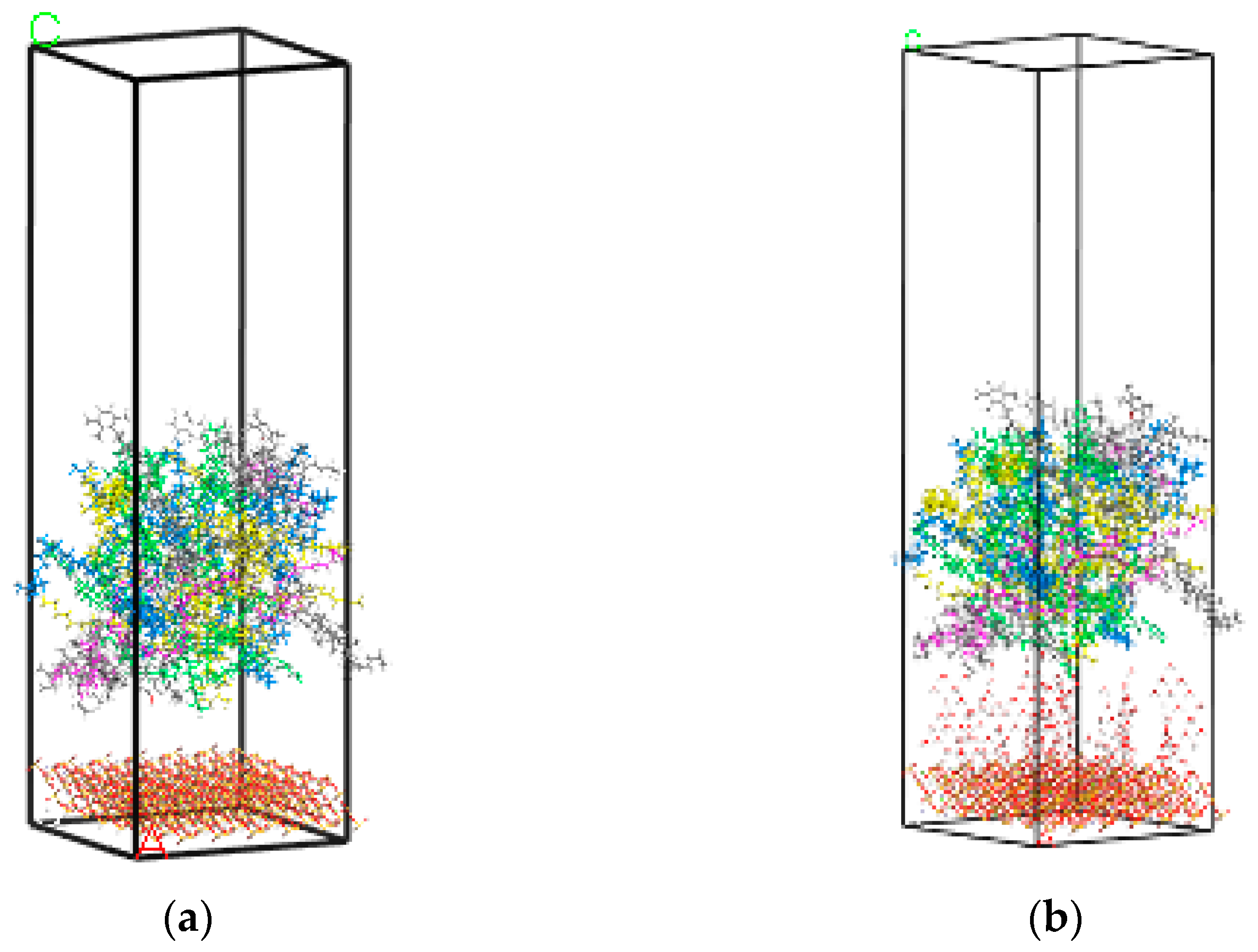

2.3.3. Interface Model of CR-Aggregate

3. Results and Analysis

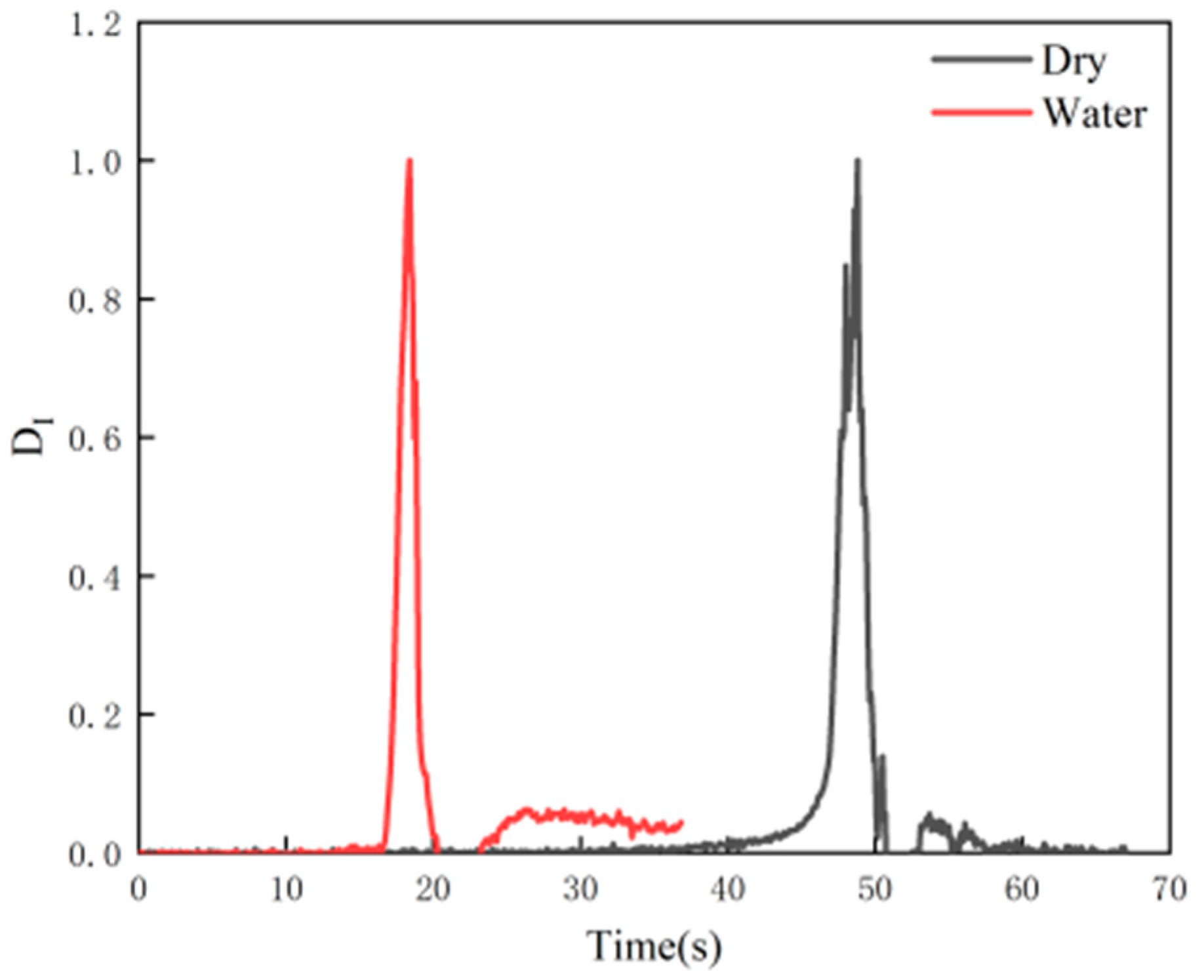

3.1. SCB Test and Analysis

3.1.1. SCB Test

3.1.2. Digital Image Measurement System

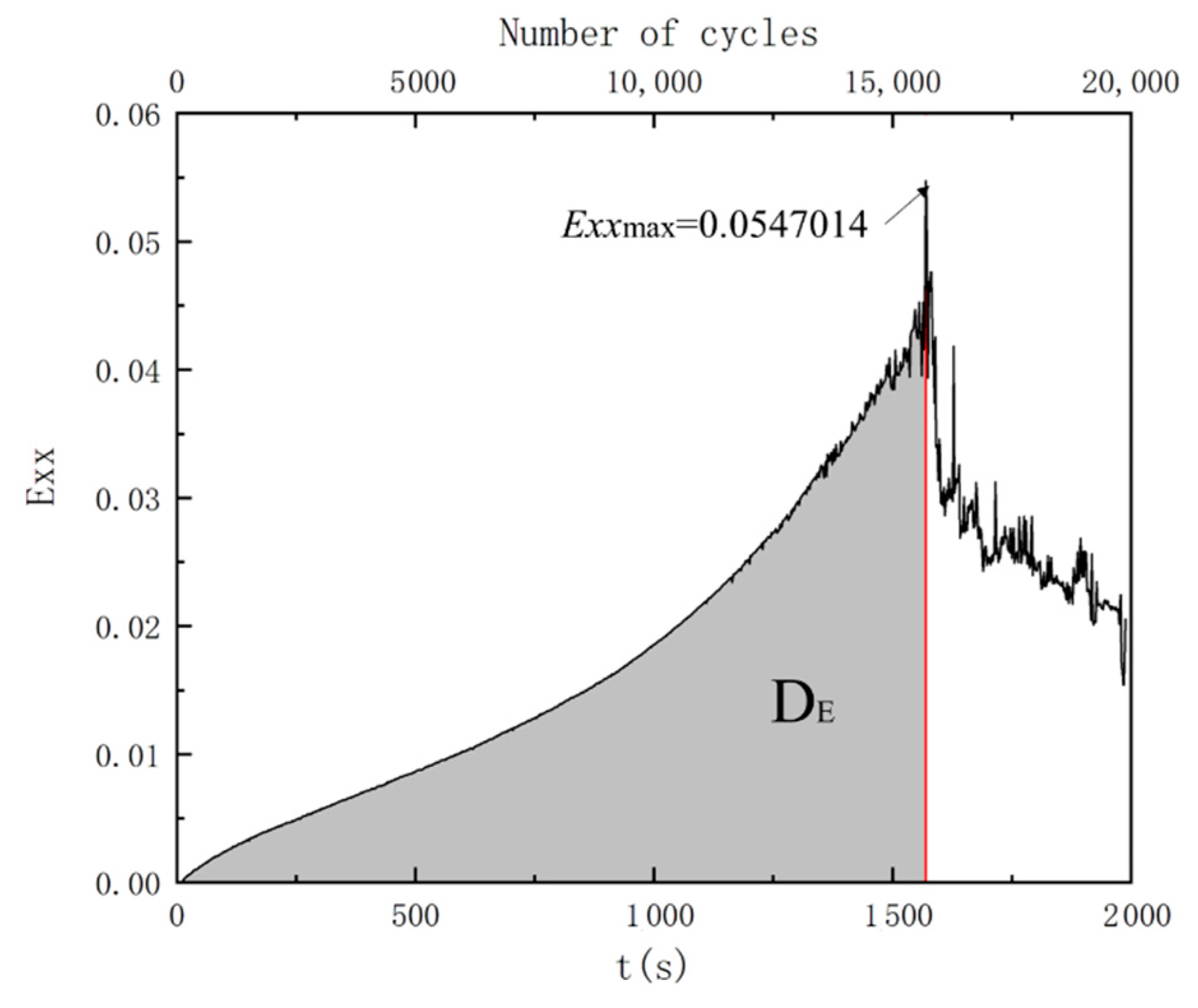

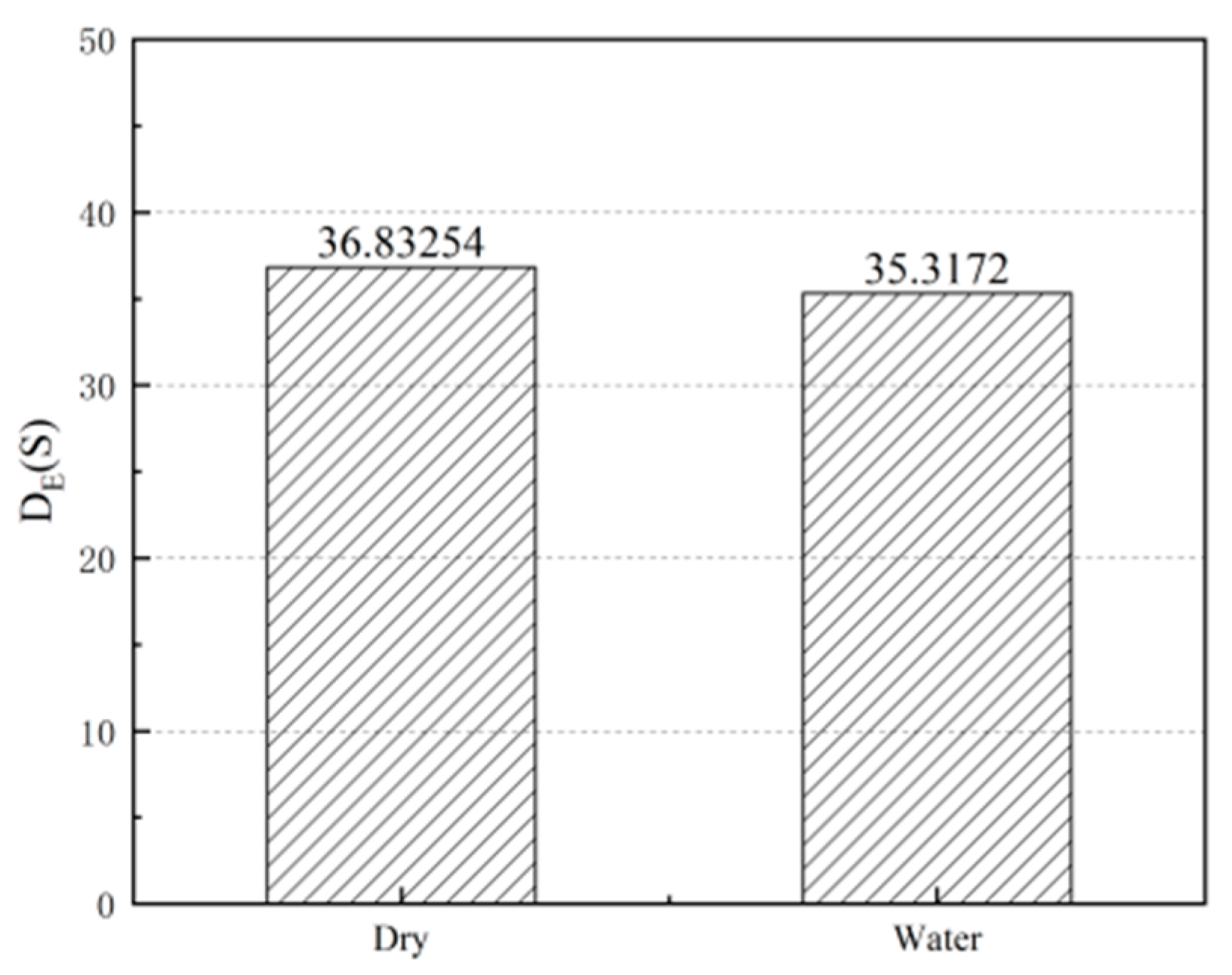

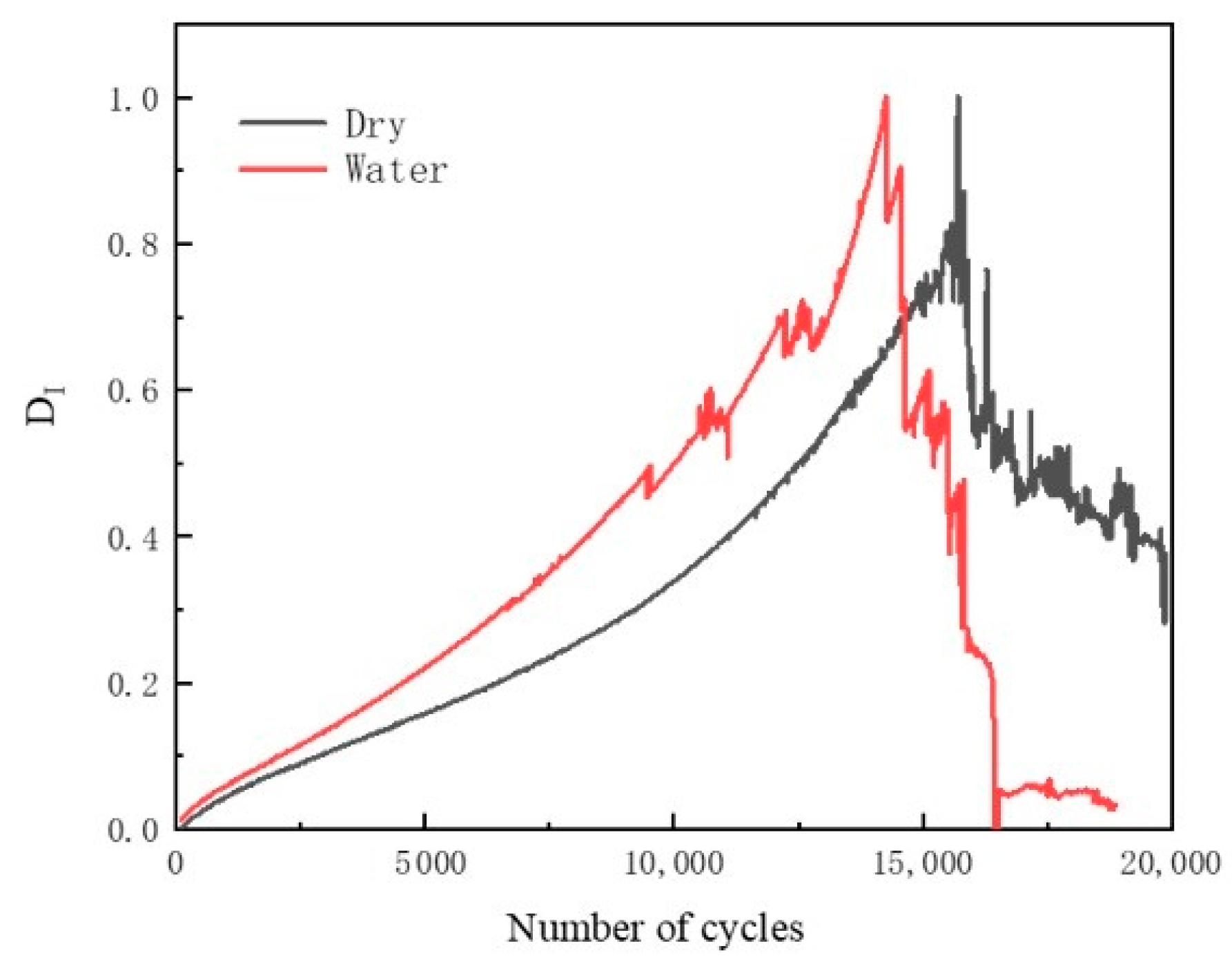

3.1.3. Strain Energy and Interfacial Damage Factor

3.1.4. Analysis of Influence of Moisture on Cracking Resistance of the CR Mixture

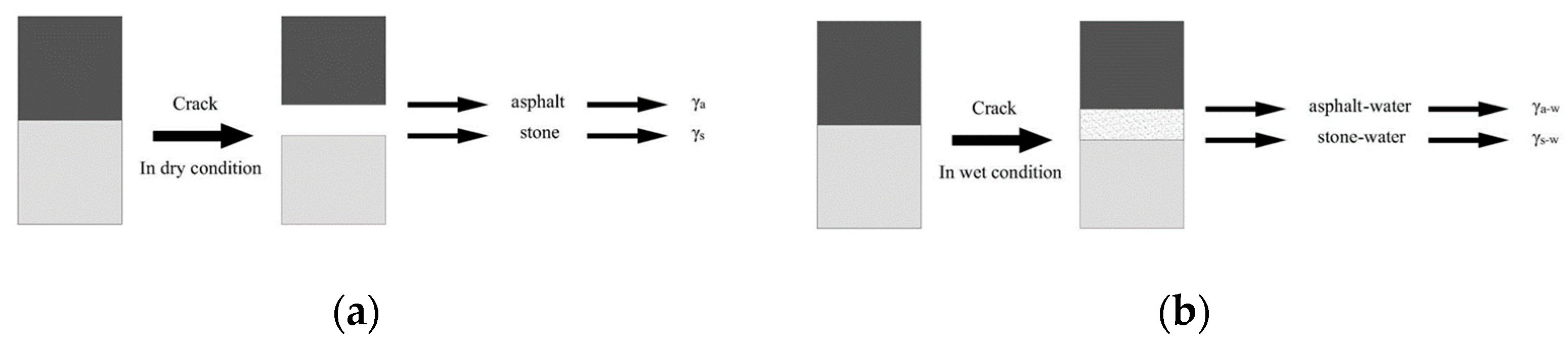

3.2. Contact Angle Measurement Test and Analysis

3.2.1. Contact Angle Measurement Test

3.2.2. Analysis of the Contact Angle Measurement Results

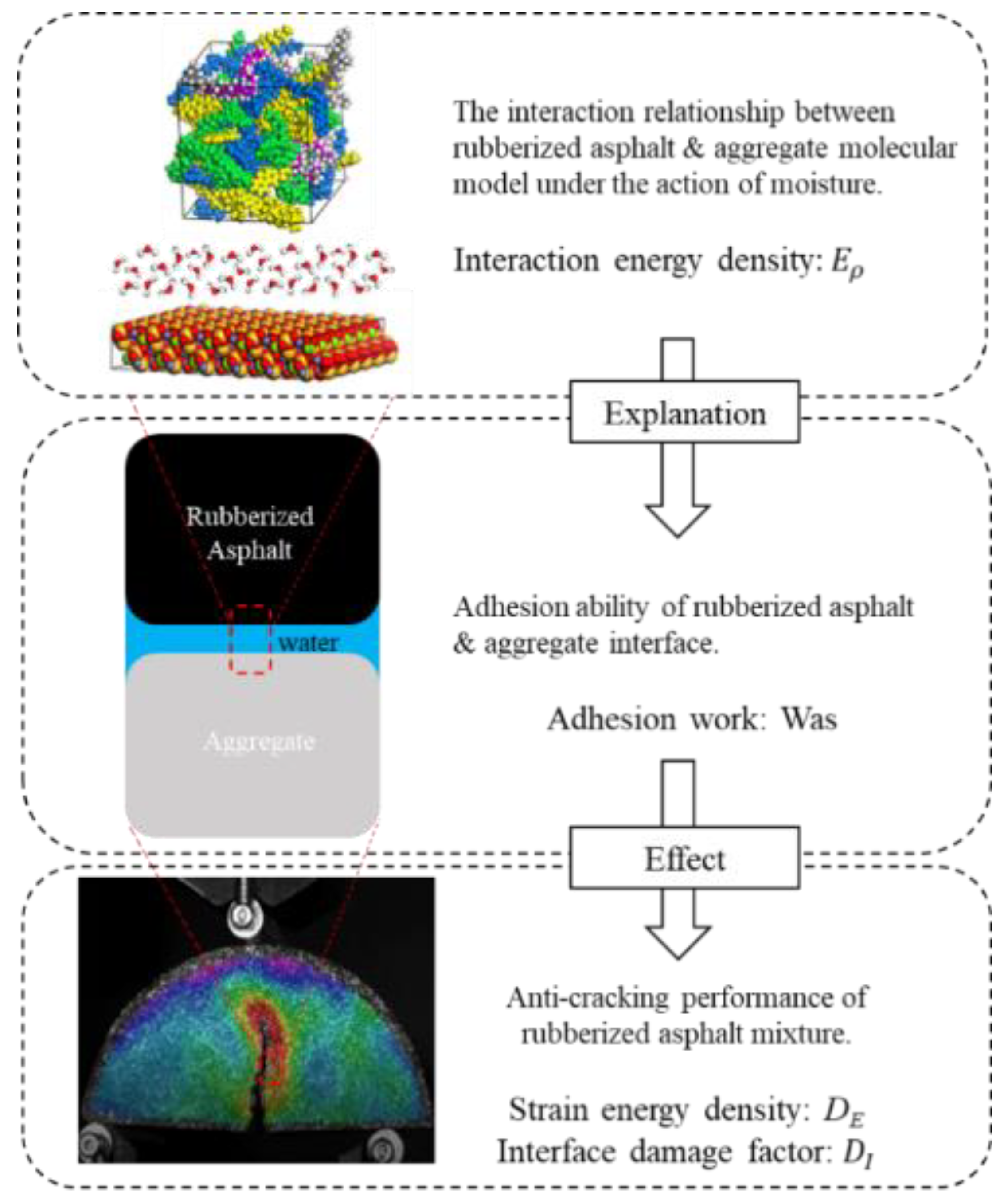

3.3. Molecular Dynamics Simulation and Analysis

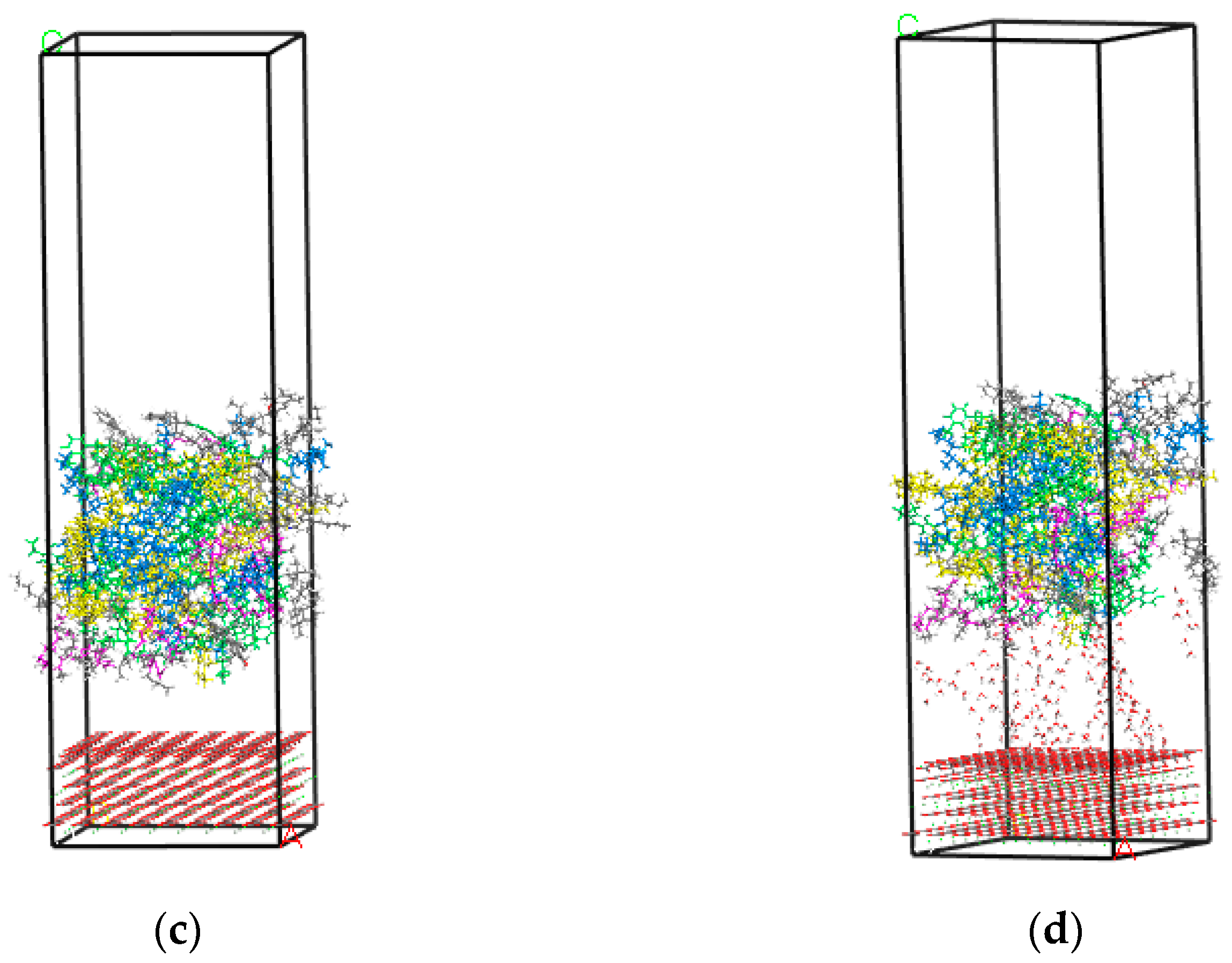

3.3.1. Optimization and Calculation of Molecular Dynamics Model

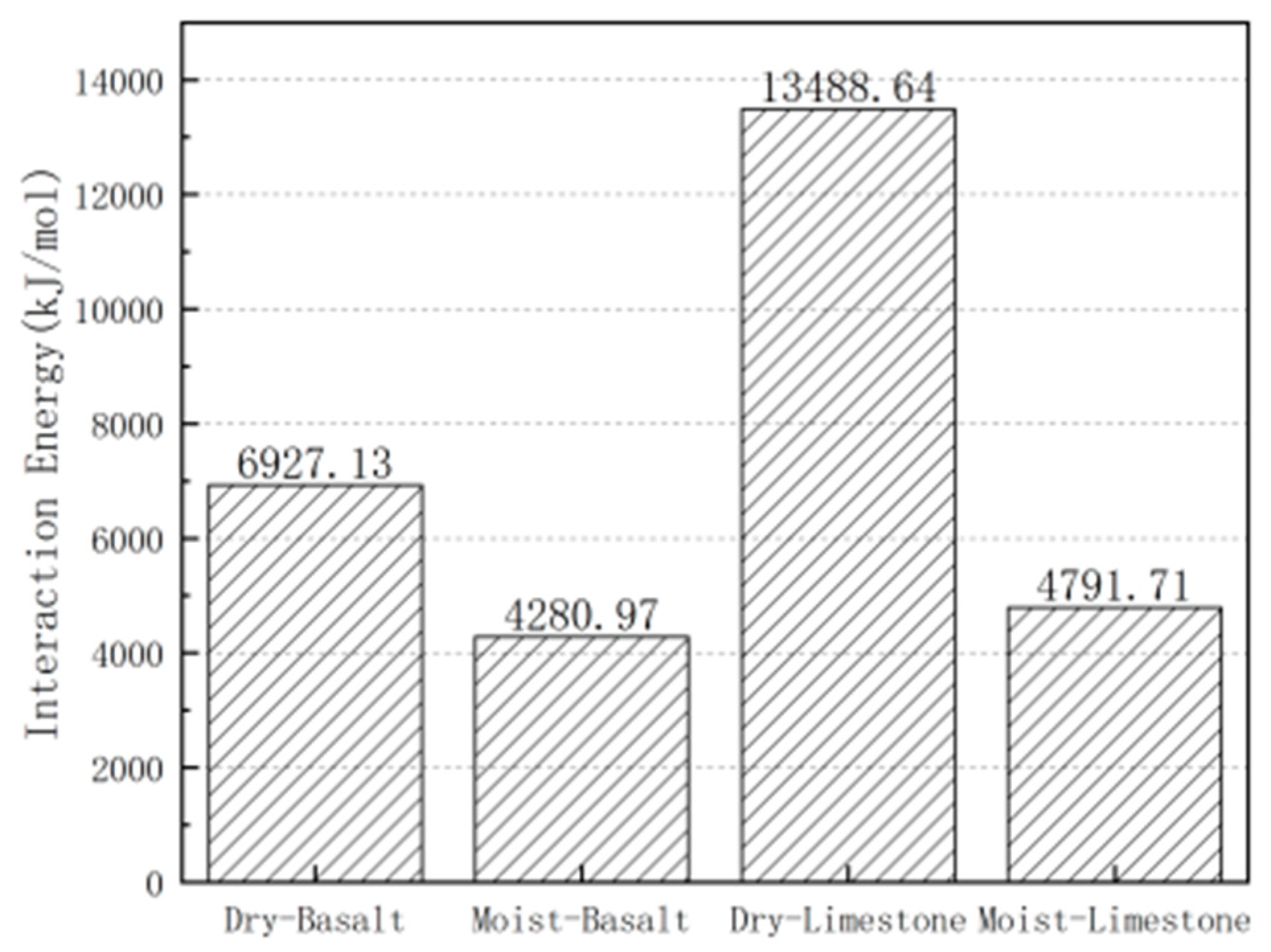

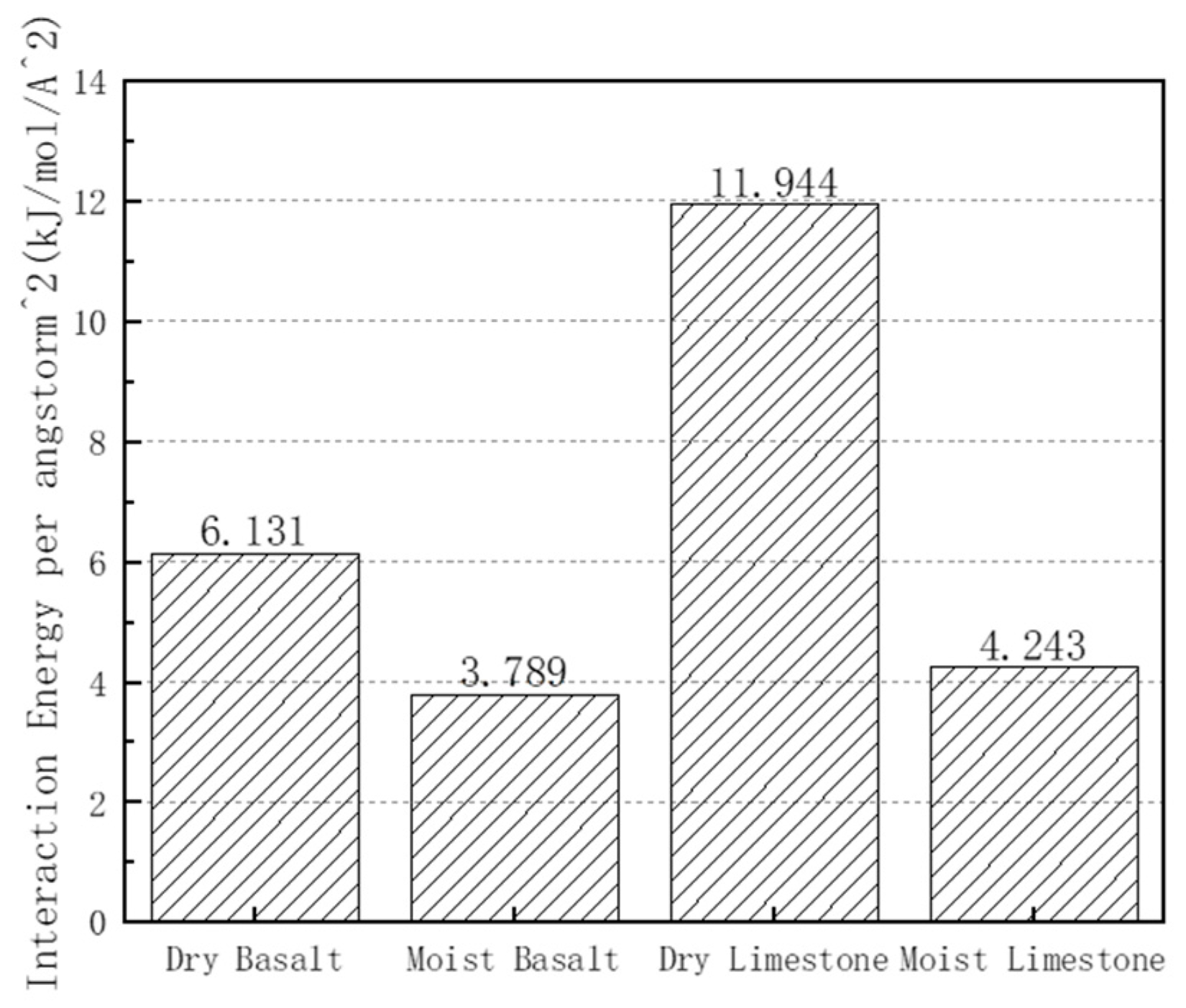

3.3.2. Intermolecular Interaction Energy

3.3.3. Analysis of Molecular Dynamics Results

3.4. Multiscale Association Analysis

4. Conclusions

- (1)

- At macroscale, water damage is more serious under low-temperature fracture damage than that of medium-temperature fatigue failure;

- (2)

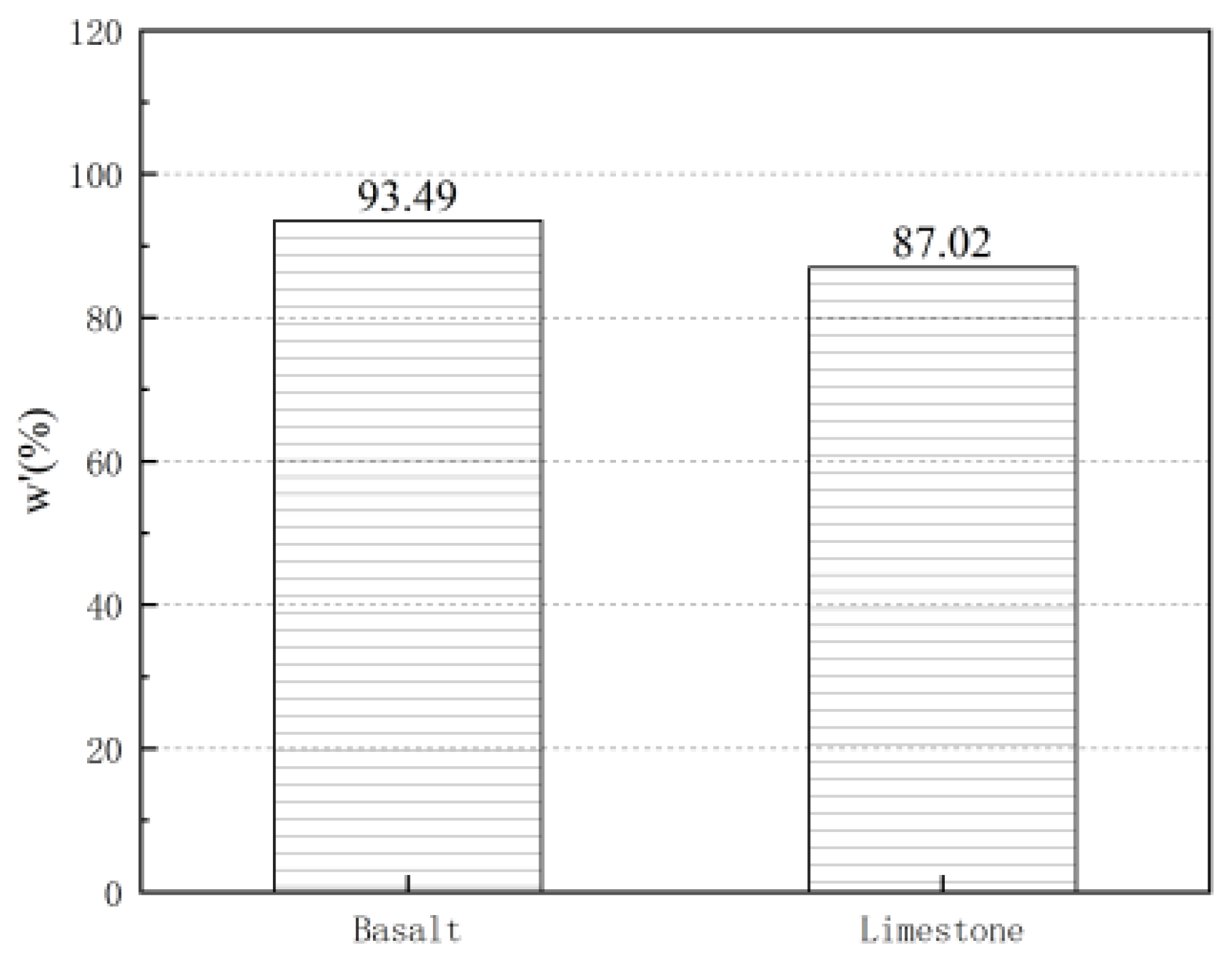

- At the microscale, the adhesion energy between the crumb rubber asphalt and aggregate decreases under wet conditions, indicating that the participation of water has a certain damage to the adhesion ability between the crumb rubber asphalt and the aggregate;

- (3)

- The adhesion ability between limestone and crumb rubber asphalt is more affected by water than by basalt;

- (4)

- The results of the molecular-scale simulation are consistent with those of the micro-adhesion test and the macrofracture test, indicating that molecular simulation has certain significance in simulating the adhesion ability of water to the interface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Shan, M.; Chang, C.; Zhou, X. The macro-and meso-cracking characteristics of warm mix crumb rubber asphalt mastics before and after aging. Constr. Build. Mater. 2020, 262, 120724. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, L.; Feng, L.; Guo, Y. Research on fatigue performance of composite crumb rubber modified asphalt mixture under freeze thaw cycles. Constr. Build. Mater. 2022, 323, 126603. [Google Scholar] [CrossRef]

- Ding, X.; Chen, L.; Ma, T.; Ma, H.; Gu, L.; Chen, T.; Ma, Y. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 2019, 203, 552–557. [Google Scholar] [CrossRef]

- Ma, T.; Wang, H.; He, L.; Zhao, Y.; Huang, X.; Chen, J. Property characterization of asphalt binders and mixtures modified by different crumb rubbers. J. Mater. Civ. Eng. 2017, 29, 04017036. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Yu, B.; Zhang, J.; Pei, J. Evaluation and optimization of asphalt binder and mixture modified with high activated crumb rubber content. Constr. Build. Materials. 2022, 314, 125676. [Google Scholar] [CrossRef]

- Asdollah-Tabar, M.; Heidari-Rarani, M.; Aliha, M.R.M. The effect of recycled PET bottles on the fracture toughness of polymer concrete. Compos. Commun. 2021, 25, 100684. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Wang, Y. Characteristics of asphalt modified by WEO/PPA: Conventional, high-temperature rheological, and mechanism properties. J. Clean. Prod. 2022, 330, 129844. [Google Scholar] [CrossRef]

- Ziari, H.; Divandari, H.; Akbar, S.M.S.A.; Hosseinian, S.M. Investigation of the effect of crumb rubber powder and warm additives on moisture resistance of SMA mixtures. Adv. Civ. Eng. 2021, 4, 6653594. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, M.; Gao, D.; Yang, T.; Huang, Y. Comparative analysis of mechanical behavior of composite modified asphalt mixture based on PG technology. Constr. Build. Mater. 2020, 259, 119771. [Google Scholar] [CrossRef]

- Aigner, E.; Lackner, R.; Pichler, C. Multiscale prediction of viscoelastic properties of asphalt concrete. J. Mater. Civ. Eng. 2009, 21, 771–780. [Google Scholar] [CrossRef] [Green Version]

- Yao, H.; Dai, Q.; You, Z. Chemo-physical analysis and molecular dynamics (MD) simulation of moisture susceptibility of nano hydrated lime modified asphalt mixtures. Constr. Build. Mater. 2015, 101, 536–547. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Xie, J.; Xiao, Y.; Chen, J.; Wu, S. Characteristics of bonding behavior between basic oxygen furnace slag and asphalt binder. Constr. Build. Mater. 2014, 64, 60–66. [Google Scholar] [CrossRef]

- Wang, L.; Shen, A.; Yao, J. Effect of different coarse aggregate surface morphologies on cement emulsified asphalt adhesion. Constr. Build. Mater. 2020, 262, 120030. [Google Scholar] [CrossRef]

- Wei, J.; Dong, F.; Li, Y.; Zhang, Y. Relationship analysis between surface free energy and chemical composition of asphalt binder. Constr. Build. Mater. 2014, 71, 116–123. [Google Scholar] [CrossRef]

- Azarhoosh, A.R.; Nejad, F.M.; Khodaii, A. Using the surface free energy method to evaluate the effects of nanomaterial on the fatigue life of hot mix asphalt. J. Mater. Civ. Eng. 2016, 28, 04016098. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Jiao, Y.; Tan, Y.; Yu, J.; Luo, D. Effect of aging and rejuvenation on adhesion properties of modified asphalt binder based on AFM. J. Microsc. 2021, 284, 244–255. [Google Scholar] [CrossRef]

- Zhang, W.G.; Luan, Y.C.; Ma, T.; Wang, S. Multilevel analysis of the aging mechanisms and performance evolution of rubber-modified asphalt. J. Mater. Civ. Eng. 2021, 33, 04021365. [Google Scholar] [CrossRef]

- Cong, P.H.; van Thom, D.; Duc, D.H. Phase field model for fracture based on modified couple stress. Eng. Fract. Mech. 2022, 269, 108534. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Bashandeh-Khodaei-Naeini, K. Micromechanics based damage model for predicting compression behavior of polymer concretes. Mech. Mater. 2018, 117, 126–136. [Google Scholar] [CrossRef]

- Doan, D.H.; Van Do, T.; Nguyen, N.X.; Van Vinh, P.; Trung, N.T. Multi-phase-field modelling of the elastic and buckling behaviour of laminates with ply cracks. Appl. Math. Model. 2021, 94, 68–86. [Google Scholar] [CrossRef]

- Wang, H.; Lin, E.; Xu, G. Molecular dynamics simulation of asphalt-aggregate interface adhesion strength with moisture effect. Int. J. Pavement Eng. 2015, 18, 414–423. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Liu, Y. Study on compatibility of rubber powder and asphalt in rubber powder modified asphalt by molecular dynamics. J. Build. Mater. 2018, 21, 689–694. (In Chinese) [Google Scholar]

- Wang, L.; Zhang, L.; Liu, Y. Molecular dynamics study on compatibility of asphalt and rubber powders before and after aging. J. Build. Mater. 2019, 22, 474–479. (In Chinese) [Google Scholar]

- Wang, L.; Liu, Y.; Zhang, L. Micro/nanoscale study on the effect of aging on the performance of crumb rubber modified asphalt. Math. Probl. Eng. 2020, 2020, 1924349. [Google Scholar] [CrossRef]

- Rinaldini, E.; Schuetz, P.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Investigating the blending of reclaimed asphalt with virgin materials using rheology, electron microscopy and computer tomography. Compos. Part B 2014, 67, 579–587. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Mogawer, W.; Austerman, A.; Abu Qtaish, L.; Kaya, S. Multi-scale evaluation of the effect of rejuvenators on the performance of high RAP content mixtures. Constr. Build. Mater. 2015, 101, 50–56. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Holcombe, E.; Kim, S.S.; Abbas, A.; Kaya, S. Multi-scale evaluation of the effect of ras on the fracture properties of asphalt mixtures. Constr. Build. Mater. 2018, 175, 126–133. [Google Scholar] [CrossRef]

- Samieadel, A.; Oldham, D.; Fini, E.H. Multi-scale characterization of the effect of wax on intermolecular interactions in asphalt binder. Constr. Build. Mater. 2017, 157, 1163–1172. [Google Scholar] [CrossRef]

- Yang, S.Q.; Sun, S.; Qin, L.S.; Li, Q. Microstructure and meso-mechanical properties of asphalt mixture modified by rubber powder under a multi-scale effect. Coatings 2021, 11, 1321. [Google Scholar] [CrossRef]

- Zhang, L.; Long, N.; Liu, Y.; Wang, L. Cross-scale study on the influence of moisture-temperature coupling conditions on adhesive properties of rubberized asphalt and steel slag. Constr. Build. Mater. 2022, 332, 127401. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Liu, Y. Molecular dynamics study on the effect of mineral composition on the interface interaction between rubberized asphalt and aggregate. J. Mater. Civ. Eng. 2022, 34, 04022032. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixture for Highway Engineering. People Transportation Press: Beijing, China, 2011.

- JTG E42-2005; Highway Engineering Aggregate Test Regulations. People Transportation Press: Beijing, China, 2005.

- JTG F40-2004; Technical Specification for Construction of Asphalt Pavement in Highway Engineering. People Transportation Press: Beijing, China, 2004.

- Aliha, M.R.M.; Heidari-Rarani, M.; Shokrieh, M.M.; Ayatollahi, M.R. Experimental determination of tensile strength and KIc of polymer concretes using semi-circular bend (SCB) specimens. Struct. Eng. Mech. 2012, 43, 823–833. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Wang, L.; Shan, M.; Li, C. The cracking characteristics of the polymer-modified asphalt mixture before and after aging based on the digital image correlation technology. Constr. Build. Mater. 2020, 260, 119802. [Google Scholar] [CrossRef]

- Wang, L.; Cui, S.; Feng, L. Research on the influence of ultraviolet aging on the interfacial cracking characteristics of warm mix crumb rubber modified asphalt mortar. Constr. Build. Mater. 2021, 281, 122556. [Google Scholar] [CrossRef]

- Fowkes, F.M. Dispersion force contributions to surface and interfacial tensions, contact angles, and heats of immersion. Adv. Chem. Ser. 1964, 43, 99–111. [Google Scholar]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. Apply Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Bhasin, A.; Masad, E.; Little, D.; Lytton, R. Limits on adhesive bond energy for improved resistance of hot-mix asphalt to moisture damage. Transp. Res. Rec. 2006, 1970, 2–13. [Google Scholar] [CrossRef]

- Golzar, K. Molecular simulation study of penetrant gas trans-port properties into the pure and nanosized silica particles filled poly-sulfone membranes. J. Membr. Sci. 2014, 451, 117–134. [Google Scholar] [CrossRef]

| Technical Index | CR | Matrix Asphalt |

|---|---|---|

| Penetration (25,100 g, 5 s) (0.1 mm) | 68.2 | 91.5 |

| Softening Point/°C (Ring and ball test) | 57.3 | 51.5 |

| Ductility (5 cm/min,10 °C)/cm | 17.2 | 9.4 |

| Asphalt Components | Asphaltene | Saturate | Aromatic | Resin |

|---|---|---|---|---|

| Mass percentage (w/%) | 9.4 | 25.2 | 28.8 | 36.6 |

| Item | Unit | Specification | Test Result | Method | ||

|---|---|---|---|---|---|---|

| 10~20 mm | 5~10 mm | 3~5 mm | ||||

| Crushing value of stone | % | ≤26 | 13.0 | 11.0 | T0316 | |

| LA abrasion value | % | ≤28 | 9.5 | 10.5 | T0317 | |

| Soundness | % | ≤12 | 1.5 | 1.6 | T0314 | |

| Soft stone content | % | ≤2 | 1.1 | 1.0 | 2.0 | T0320 |

| Water absorption | % | ≤2 | 0.8 | 0.9 | 0.9 | T0304 |

| Water washing method <0.075 content | % | ≤1 | 0.1 | 0.3 | 0.4 | T0310 |

| Item | Unit | Specification | Test Result | Method |

|---|---|---|---|---|

| Apparent relative density | g/cm3 | ≥2.5 | 2.734 | T0328 |

| Soundness (>0.3) | % | ≥12 | 25 | T0340 |

| Mud content (<0.075 mm) | % | ≤3 | 0.4 | T0333 |

| Sand equivalent | % | ≥60 | 88 | T0334 |

| Methylene blue value | g/kg | ≤25 | 1.8 | T0346 |

| Item | Unit | Specification | Test Result | Method | |

|---|---|---|---|---|---|

| Appearance | — | No agglomerate | No agglomerate | — | |

| Water content | % | ≤1 | 0.5 | T0103 | |

| Apparent density | t/m3 | ≥2.5 | 2.686 | T0352 | |

| Hydrophilic coefficient | — | <1 | 0.5 | T0353 | |

| Plasticity index | % | <4 | 2.1 | T0354 | |

| Heating stability | — | Actual observation record | No deterioration | T0355 | |

| Particle size range | <0.6 mm | % | 100 | 100 | T0351 |

| <0.15 mm | % | 90~100 | 100 | ||

| <0.075 mm | % | 75~100 | 99.6 | ||

| Particle size (mm) | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Synthetic gradation | 100 | 94.2 | 83.6 | 71.8 | 48.5 | 33.6 | 25.4 | 18.6 | 12.9 | 9.6 | 6.6 |

| Components | Number of Molecules | Mass Ratio | Simulated Mass Ratio | Experimental Mass Ratio | |

|---|---|---|---|---|---|

| Asphaltene | AS-1 | 1 | 3.9% | 9.5% | 9.4% |

| AS-2 | 1 | 2.5% | |||

| AS-3 | 1 | 3.1% | |||

| Resin | R-1 | 4 | 9.7% | 36.7% | 36.6% |

| R-2 | 3 | 7.3% | |||

| R-3 | 4 | 5.1% | |||

| R-4 | 3 | 7.3% | |||

| R-5 | 4 | 7.3% | |||

| Aromatic | Ar-1 | 8 | 15.8% | 28.3% | 28.8% |

| Ar-2 | 7 | 12.5% | |||

| Saturate | S-1 | 6 | 12.7% | 25.7% | 25.2% |

| S-2 | 7 | 13% | |||

| Styrene | Trans 1-4 Butadiene | Cis 1-4 Butadiene | 1,2-Butadiene | Others |

|---|---|---|---|---|

| 23.5 | 58 | 5.5 | 12 | 1 |

| Mineral Type | Cell Model | Lattice Parameters | Molecular Model |

|---|---|---|---|

| Augite |  | a = 9.7 Å b = 8.9 Å c = 5.3 Å α = 90° β = 106.8° γ = 90° |  |

| Calcite |  | a = 5.0 Å b = 5.0 Å c = 17.1 Å α = 90° β = 90° γ = 120° |  |

| Temperature/°C | Control Mode | Loading Mode | |

|---|---|---|---|

| Medium-temperature fatigue failure test | 20 | Stress control | Repeated load: 10 Hz sine wave, loading range 50–500 N |

| Low-temperature fracture test | −10 | Displacement control | Uniform load: 1 mm/min |

| γ | γd | γp | γ+ | γ− | |

|---|---|---|---|---|---|

| CR | 22.80 | 21.94 | 0.86 | 0.17 | 1.10 |

| Basalt | 32.39 | 24.64 | 6.75 | 1.08 | 10.56 |

| Limestone | 37.74 | 31.77 | 5.97 | 0.75 | 11.89 |

| Distilled water | 72.8 | 21.8 | 51.0 | 25.5 | 25.5 |

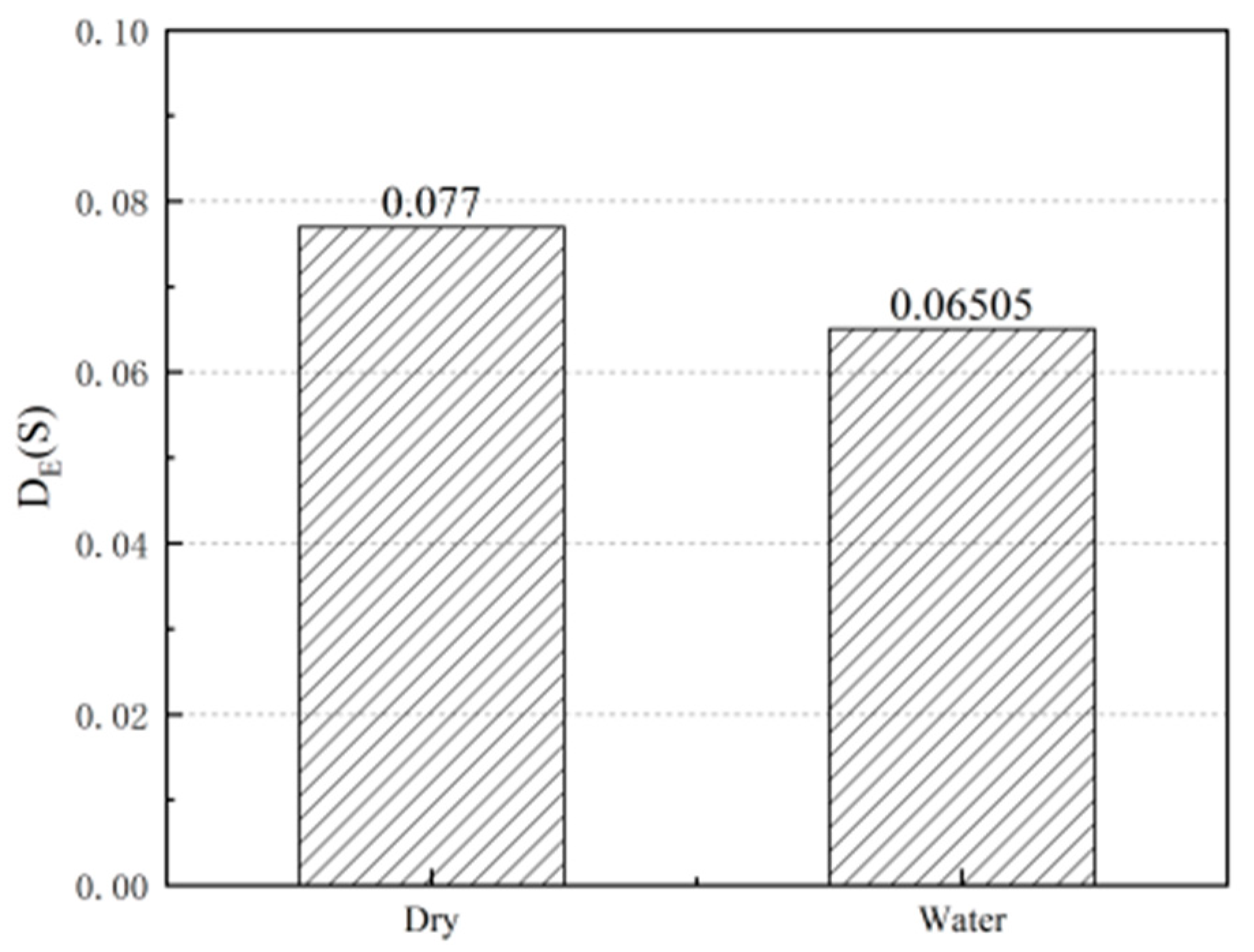

| Scales | Indexes | Unit | Dry | Wet |

|---|---|---|---|---|

| Molecular scale | (kJ/mol/A2) | 6.131 | 3.789 | |

| (kJ/mol/A2) | 11.944 | 4.243 | ||

| Micro scale | (%) | 100 | 93.49 | |

| (%) | 100 | 87.02 | ||

| Macro scale | Medium temperature fatigue failure DE | - | 36.83254 | 35.3172 |

| Low temperature fracture DE | - | 0.077 | 0.06505 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Liu, Y.; Zhang, L. A Multiscale Study of Moisture Influence on the Crumb Rubber Asphalt Mixture Interface. Appl. Sci. 2022, 12, 6940. https://doi.org/10.3390/app12146940

Wang L, Liu Y, Zhang L. A Multiscale Study of Moisture Influence on the Crumb Rubber Asphalt Mixture Interface. Applied Sciences. 2022; 12(14):6940. https://doi.org/10.3390/app12146940

Chicago/Turabian StyleWang, Lan, Yang Liu, and Le Zhang. 2022. "A Multiscale Study of Moisture Influence on the Crumb Rubber Asphalt Mixture Interface" Applied Sciences 12, no. 14: 6940. https://doi.org/10.3390/app12146940

APA StyleWang, L., Liu, Y., & Zhang, L. (2022). A Multiscale Study of Moisture Influence on the Crumb Rubber Asphalt Mixture Interface. Applied Sciences, 12(14), 6940. https://doi.org/10.3390/app12146940