Efficiency of Pulsating Base Bleeding to Control Trailing Edge Flow Configurations

Abstract

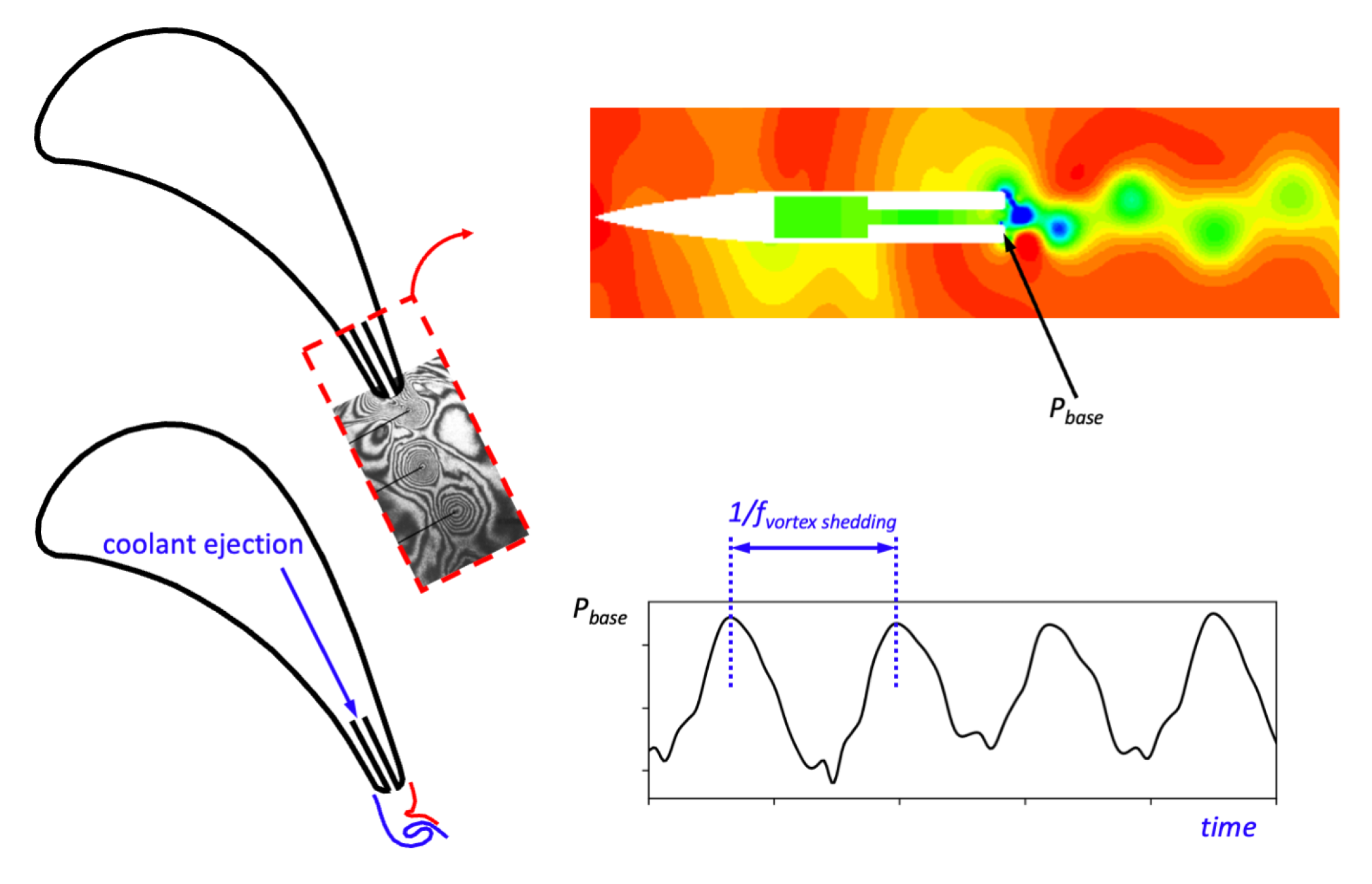

:1. Introduction

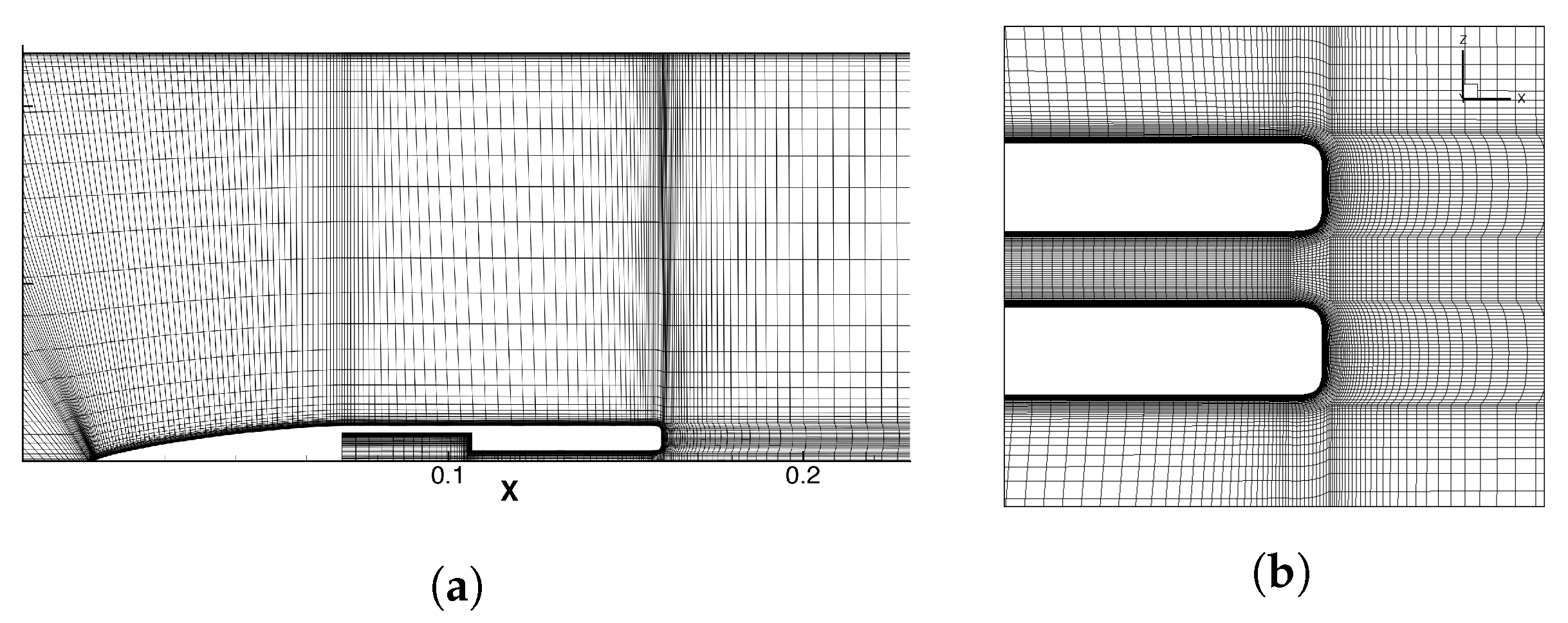

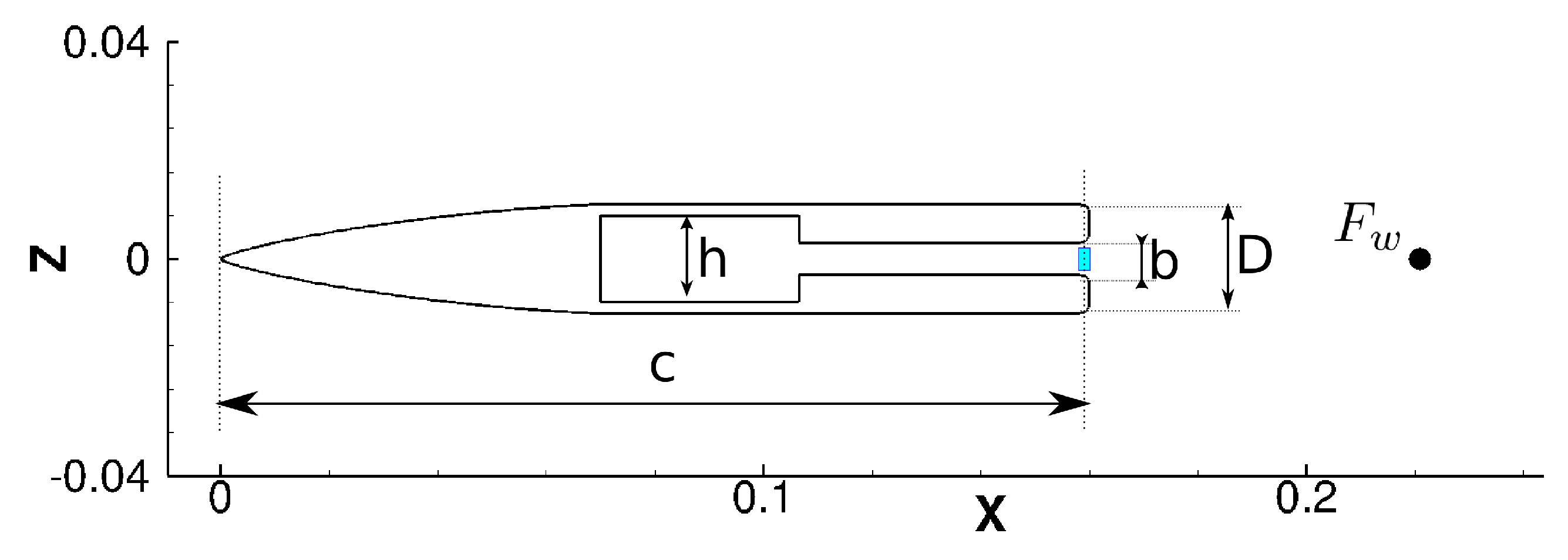

2. Computational Set-Up

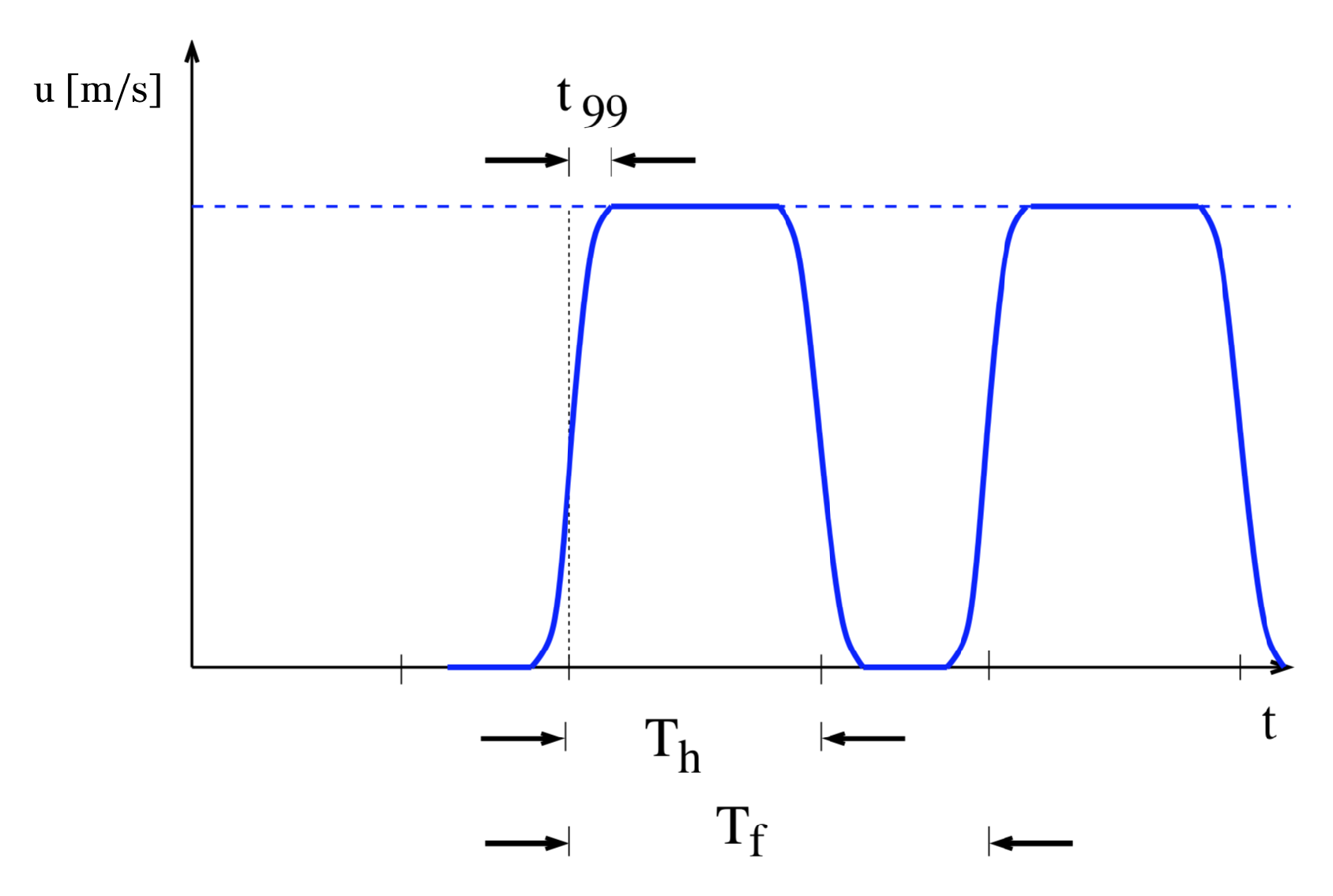

Actuation Details

3. Results and Discussion

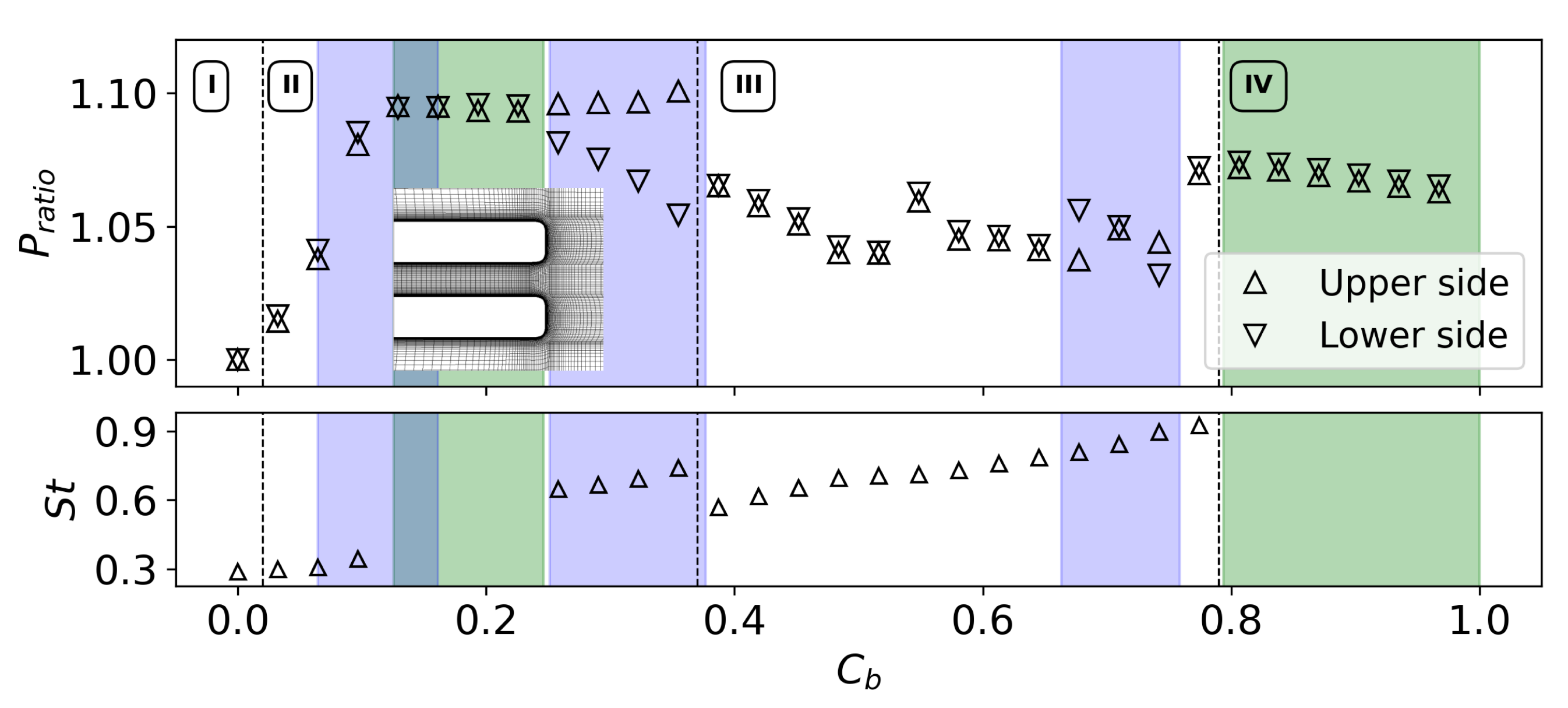

3.1. Trailing Edge Steady Actuation

- Phase I.

- . Vortices shed in an alternate manner from the trailing edge when no base bleed is applied. We refer to this stage as a non-blowing configuration.

- Phase II.

- . Base pressure increases due to an initial “filling” effect, raising the maximum base pressure value to , with a slight increment in the frequency associated to the vortices. Under these conditions, the base bleed introduces a source of asymmetry on the wake downstream, followed by a neutralization of the vortex shedding.

- Phase III.

- . At this stage, the base pressure rapidly decays, almost eliminating the observed gains produced by a lower intensity trailing edge actuation. These changes are also accompanied by a reduction of the dominant wake flow frequency. While the trailing edge flow initially behaves as symmetric when it is time averaged, higher blowing intensities promote the onset of a non-symmetric flow topology.

- Phase IV.

- . Elevated ejected mass flows eventually force a symmetric trailing edge flow, weakening any oscillation and increasing the base pressure towards a final plateau of . Further increments in the base bleed intensity do not produce significant changes in the flow topology.

3.2. Trailing Edge Pulsating Actuation

- 1.

- Airfoil drag force.

- 2.

- Airfoil lift force, monitoring characteristic frequencies and extreme values.

- 3.

- Onset of a base region Coanda effect.

- 4.

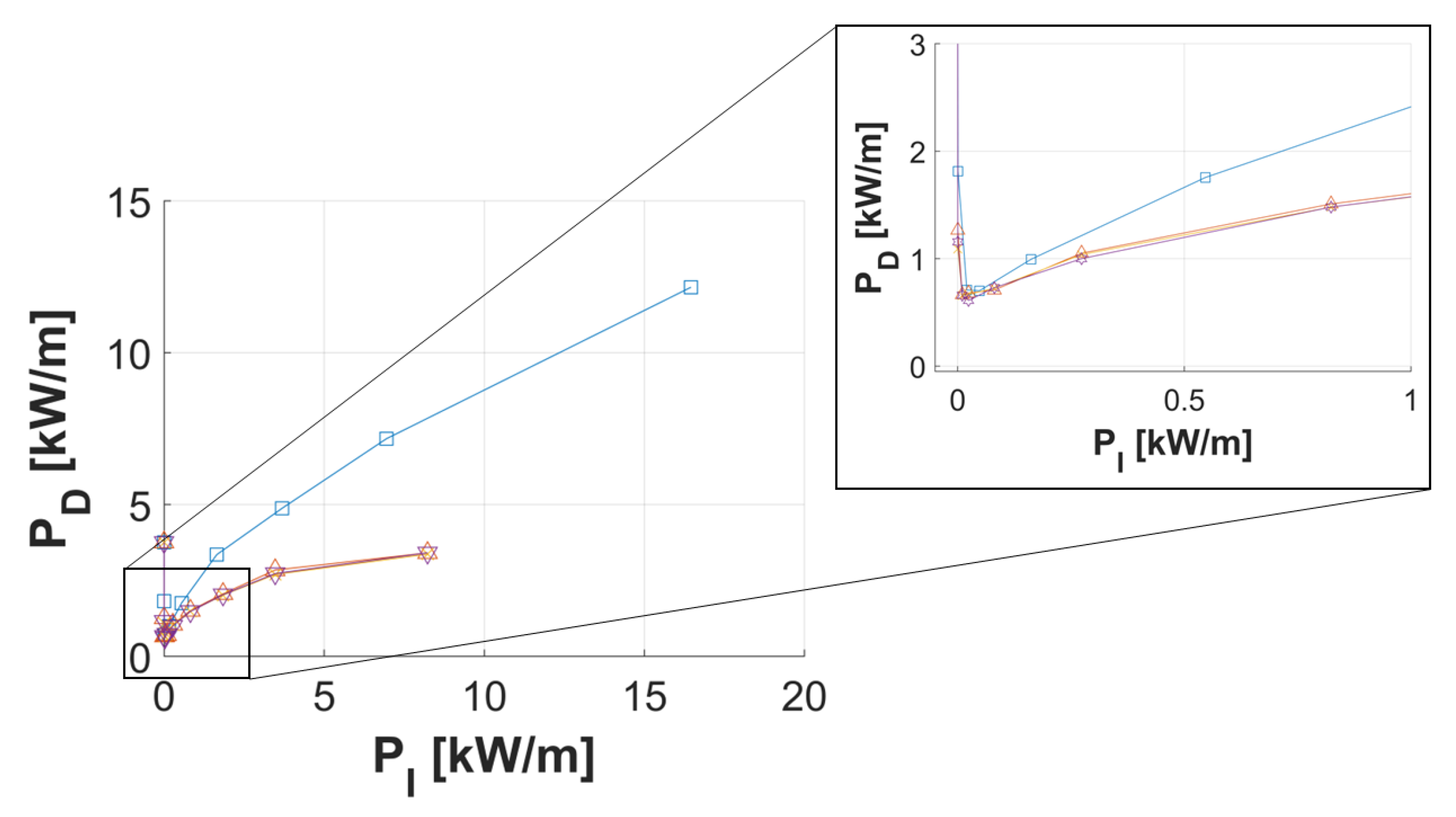

- Energy efficiency of the trailing edge actuation.

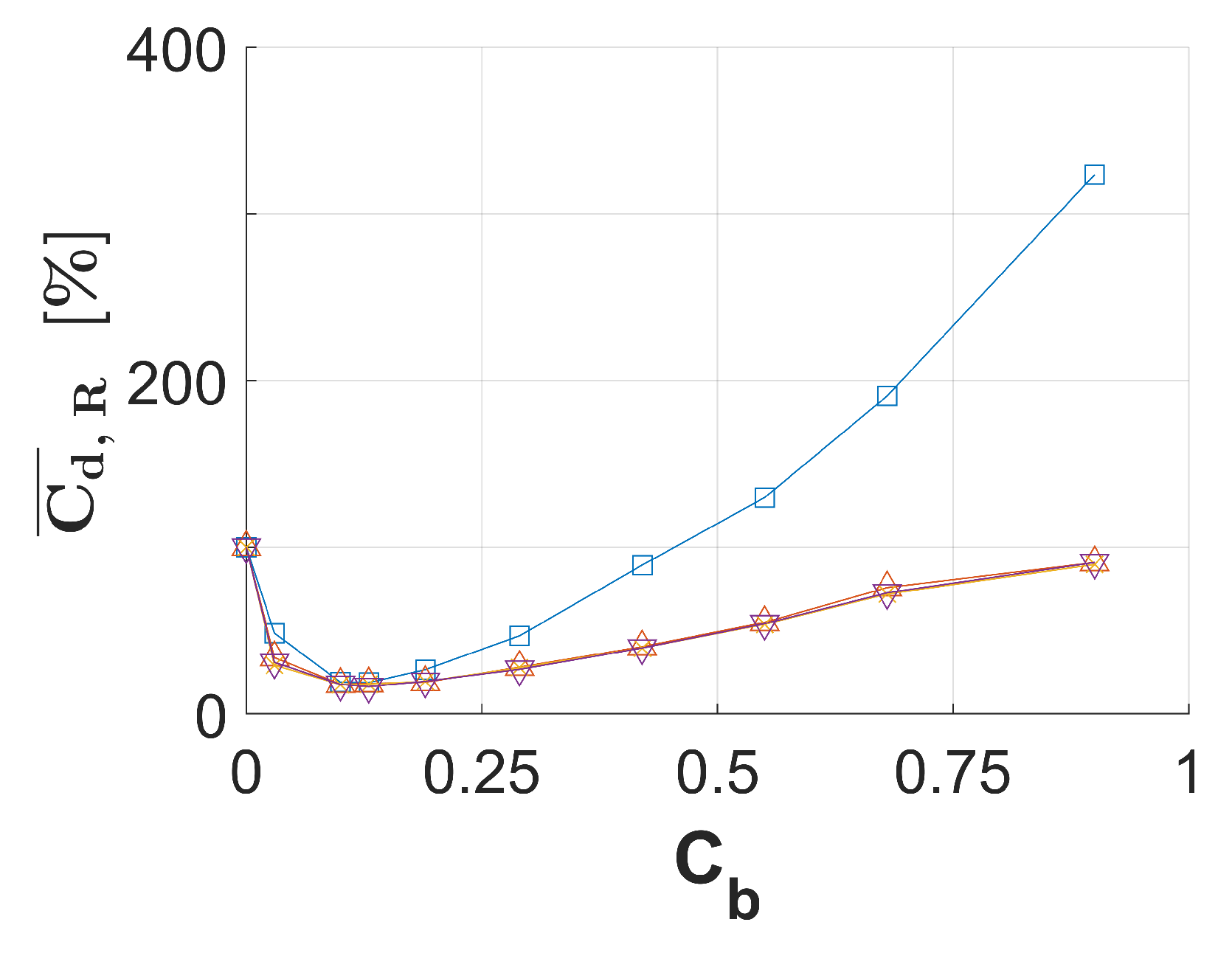

3.2.1. Airfoil Drag Force

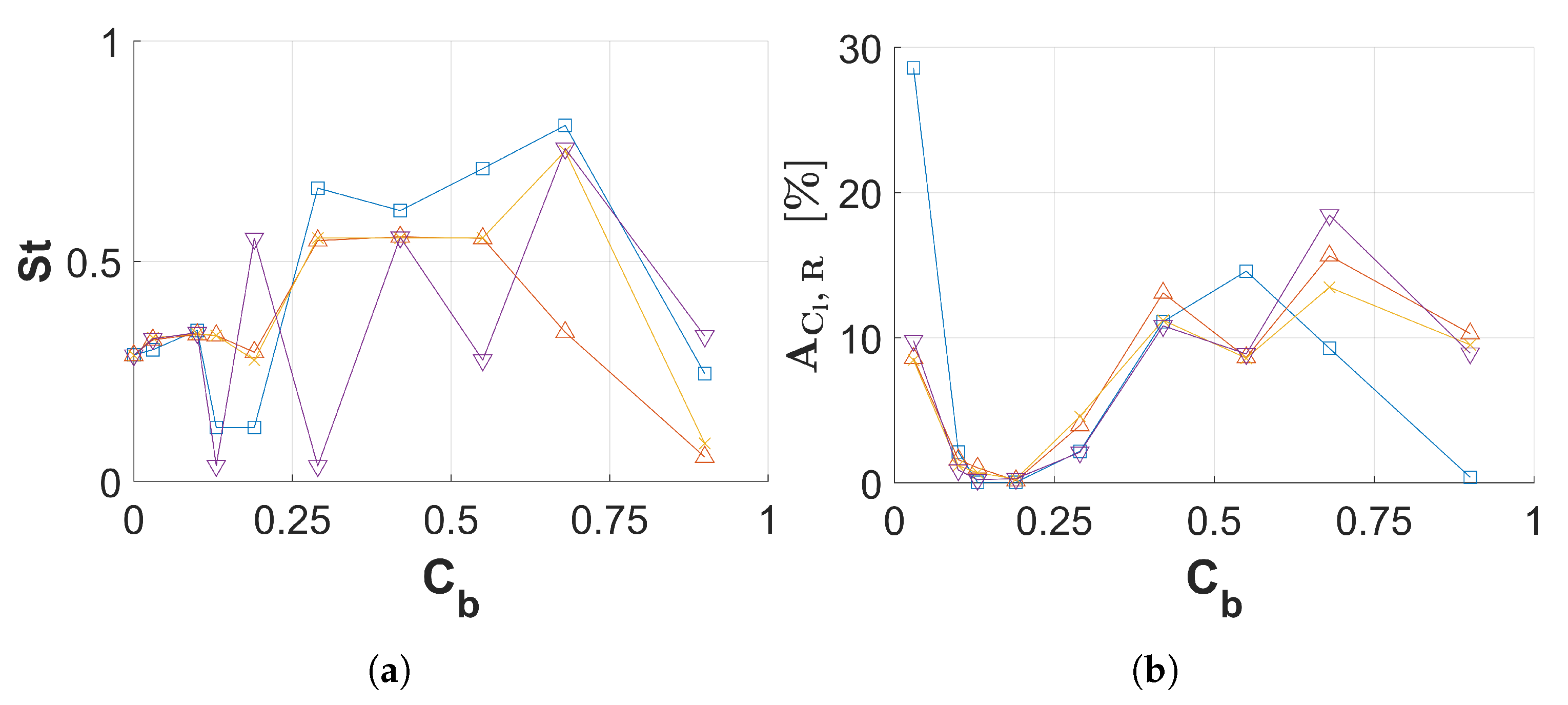

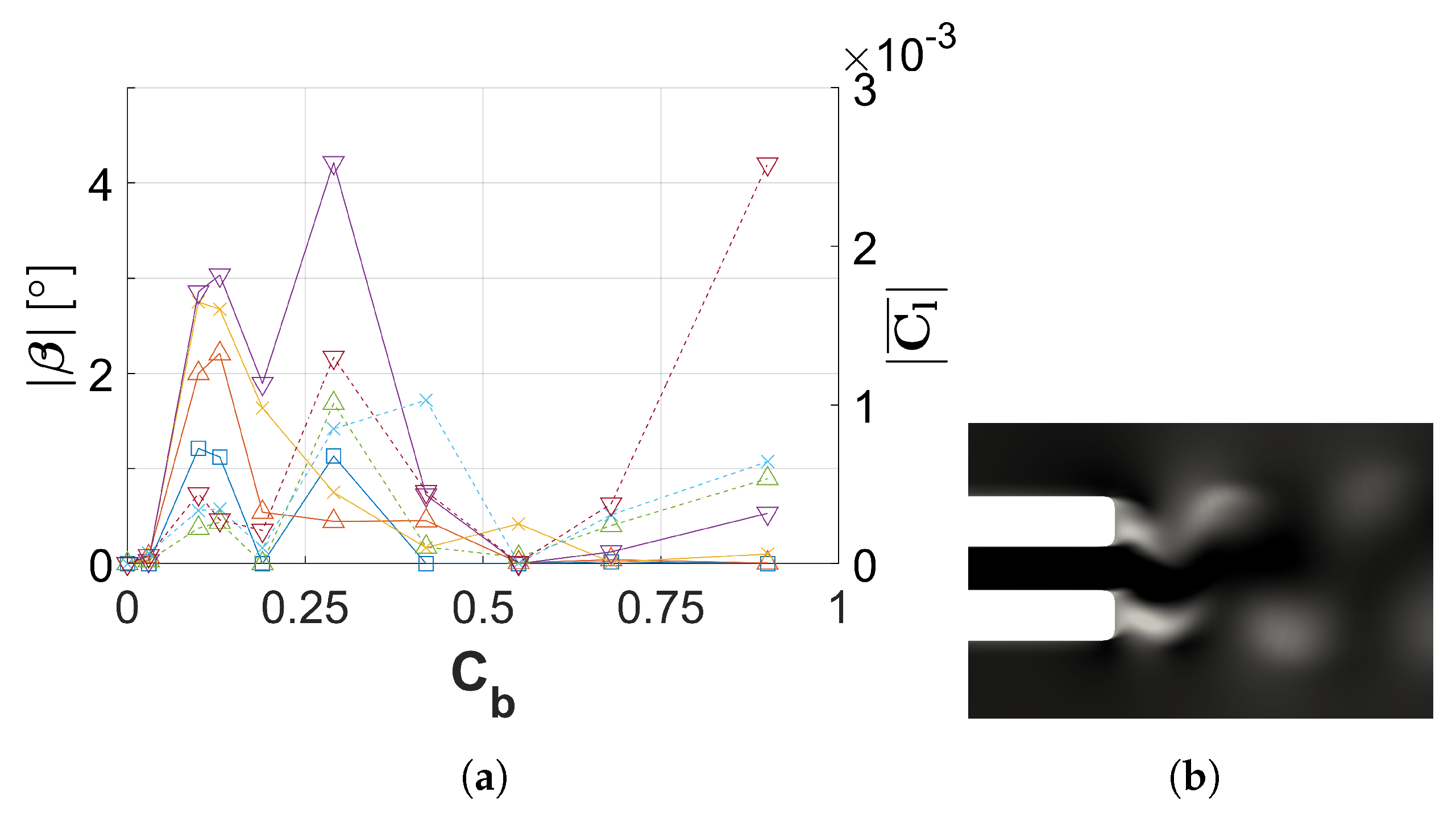

3.2.2. Airfoil Lift Force

- 1.

- Vortex shedding phenomenon

- 2.

- Oscillations of the jet angle

- 3.

- Injection frequency

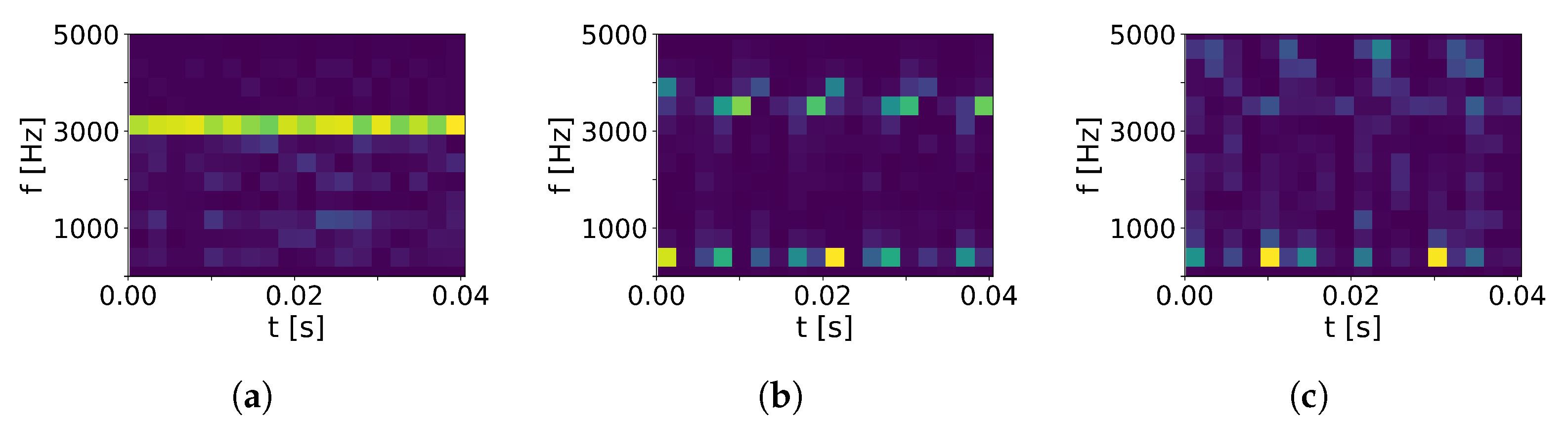

3.2.3. Base Region Coanda Effect

3.2.4. Efficiency Gain

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paniagua, G.; Szokol, S.; Kato, H.; Manzini, G.; Varvill, R. Contra-rotating turbine aero-design for an advanced hypersonic propulsion system. J. Propuls. Power 2008, 24, 1269–1277. [Google Scholar] [CrossRef]

- Sieverding, C.H.; Heinemann, H. The influence of boundary layer state on vortex shedding from flat plates and turbine cascades. ASME J. Turbomach. 1990, 112, 181–187. [Google Scholar] [CrossRef]

- Sousa, J.; Paniagua, G.; Collado, E. Supersonic turbine design suitable for detonation based engines. Chin. J. Aeronaut. 2022, in press. [Google Scholar] [CrossRef]

- Denton, J.D. Loss Mechanisms in Turbomachinery. ASME J. Turbomach. 1993, 115, 621–656. [Google Scholar] [CrossRef]

- Nash, J.F. A Review of Research on Two-Dimensional Base Flow. ARC R&M 1963, 1–25. [Google Scholar]

- Sieverding, C.H. The influence of trailing edge ejection on the base pressure in transonic turbine cascades. Proc. ASME Turbo Expo 1983, 105, 215–222. [Google Scholar] [CrossRef]

- Motallebi, F.; Norbury, J. The effect of base bleed on vortex shedding and base pressure in compressible flow. J. Fluid Mech. 1981, 110, 273–292. [Google Scholar] [CrossRef]

- Barigozzi, G.; Armellini, A.; Mucignat, C.; Casarsa, L. Experimental investigation of the effects of blowing conditions and Mach number on the unsteady behavior of coolant ejection through a trailing edge cutback. Int. J. Heat Fluid Flow 2012, 37, 37–50. [Google Scholar] [CrossRef]

- Rehder, H.J. Investigation of trailing edge cooling concepts in a high pressure turbine cascade-aerodynamic experiments and loss analysis. J. Turbomach. 2012, 134, 51029-1–51029-11. [Google Scholar] [CrossRef]

- Li, Y.; Xu, H.; Wang, J.; Zhu, J.; Su, H. Numerical study of unsteady flow and cooling characteristics of turbine blade cutback trailing edges integrated with pin fins and film holes. Aerosp. Sci. Technol. 2022, 126, 107604. [Google Scholar] [CrossRef]

- Kost, F.H.; Holmes, A.T. Aerodynamic effect of coolant ejection in the rear part of transonic rotor blades. In AGARD Heat Transfer and Cooling in Gas Turbines (SEE N86-29823 21-07); AGARD: Neuilly Sur Seine, France, 1985. [Google Scholar]

- Raffel, M.; Kost, F. Investigation of aerodynamic effects of coolant ejection at the trailing edge of a turbine blade model by PIV and pressure measurements. Exp. Fluids 1998, 24, 447–461. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, H. An experimental investigation on the trailing edge cooling of turbine blades. Propuls. Power Res. 2012, 1, 36–47. [Google Scholar] [CrossRef] [Green Version]

- Saracoglu, B.H.; Paniagua, G.; Sanchez, J.; Rambaud, P. Effects of blunt trailing edge flow discharge in supersonic regime. Comput. Fluids 2013, 88, 200–209. [Google Scholar] [CrossRef] [Green Version]

- Saracoglu, B.H.; Paniagua, G.; Salvadori, S.; Tomasoni, F.; Duni, S.; Yasa, T.; Miranda, A. Trailing edge shock modulation by pulsating coolant ejection. Appl. Therm. Eng. 2012, 48, 1–10. [Google Scholar] [CrossRef]

- Bernardini, C.; Salvadori, S.; Martelli, F.; Paniagua, G.; Saracoglu, B.H. Pulsating Coolant Ejection Effects Downstream of Supersonic Trailing Edge. Eng. Appl. Comput. Fluid Mech. 2013, 7, 250–260. [Google Scholar] [CrossRef] [Green Version]

- Saavedra, J.; Paniagua, G.; Saracoglu, B.H. Experimental Characterization of the Vane Heat Flux Under Pulsating Trailing-Edge Blowing. J. Turbomach. 2017, 139, 061004. [Google Scholar] [CrossRef]

- Martinez-Cava, A.; Wang, Y.; de Vicente, J.; Valero, E. Pressure Bifurcation Phenomenon on Supersonic Blowing Trailing Edges. AIAA J. 2019, 57, 153–164. [Google Scholar] [CrossRef]

- Martinez-Cava, A.; Rodríguez, D.; Valero, E.; Paniagua, G. Characterization of base bleed effects on subsonic trailing edge flows. Aerosp. Sci. Technol. 2021, 113, 106730. [Google Scholar] [CrossRef]

- Perkins, E.W.; Jorgensen, L.H.; Sommer, S.C. NACA-TR-1386: Investigation of the Drag of Various Axially Symmetric Nose Shapes of Fineness Ratio 3 for Mach Numbers from 1.24 to 7.4; Technical Report; National Advisory Committee for Aeronautics; Ames Aeronautical Lab.: Moffett Field, CA, USA, 1958. [Google Scholar]

- Schwamborn, D.; Gerhold, T.; Heinrich, R. The DLR Tau-code: Recent applications in research and industry. In Proceedings of the ECCOMAS CFD 2006: European Conference on Computational Fluid Dynamics, Egmond aan Zee, The Netherlands, 5–8 September 2006; Delft University of Technology: Edmond aan Zee, The Netherlands, 2006. [Google Scholar]

- Wilcox, D.C. Formulation of the k-w Turbulence Model Revisited. AIAA J. 2008, 46, 2823–2838. [Google Scholar] [CrossRef] [Green Version]

- Clark, J.P.; Grover, E.A. Assessing convergence in predictions of periodic-unsteady flowfields. In Turbo Expo: Power for Land, Sea, and Air; Paper No: GT2006-90735; International Gas Turbine Institute: Barcelona, Spain, 2006; pp. 1831–1841. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carbajosa, C.; Martinez-Cava, A.; Valero, E.; Paniagua, G. Efficiency of Pulsating Base Bleeding to Control Trailing Edge Flow Configurations. Appl. Sci. 2022, 12, 6760. https://doi.org/10.3390/app12136760

Carbajosa C, Martinez-Cava A, Valero E, Paniagua G. Efficiency of Pulsating Base Bleeding to Control Trailing Edge Flow Configurations. Applied Sciences. 2022; 12(13):6760. https://doi.org/10.3390/app12136760

Chicago/Turabian StyleCarbajosa, Carlos, Alejandro Martinez-Cava, Eusebio Valero, and Guillermo Paniagua. 2022. "Efficiency of Pulsating Base Bleeding to Control Trailing Edge Flow Configurations" Applied Sciences 12, no. 13: 6760. https://doi.org/10.3390/app12136760

APA StyleCarbajosa, C., Martinez-Cava, A., Valero, E., & Paniagua, G. (2022). Efficiency of Pulsating Base Bleeding to Control Trailing Edge Flow Configurations. Applied Sciences, 12(13), 6760. https://doi.org/10.3390/app12136760