Influence of Wake Intensity on the Unsteady Flow Characteristics of the Integrated Aggressive Interturbine Duct

Abstract

:1. Introduction

2. Numerical Methods

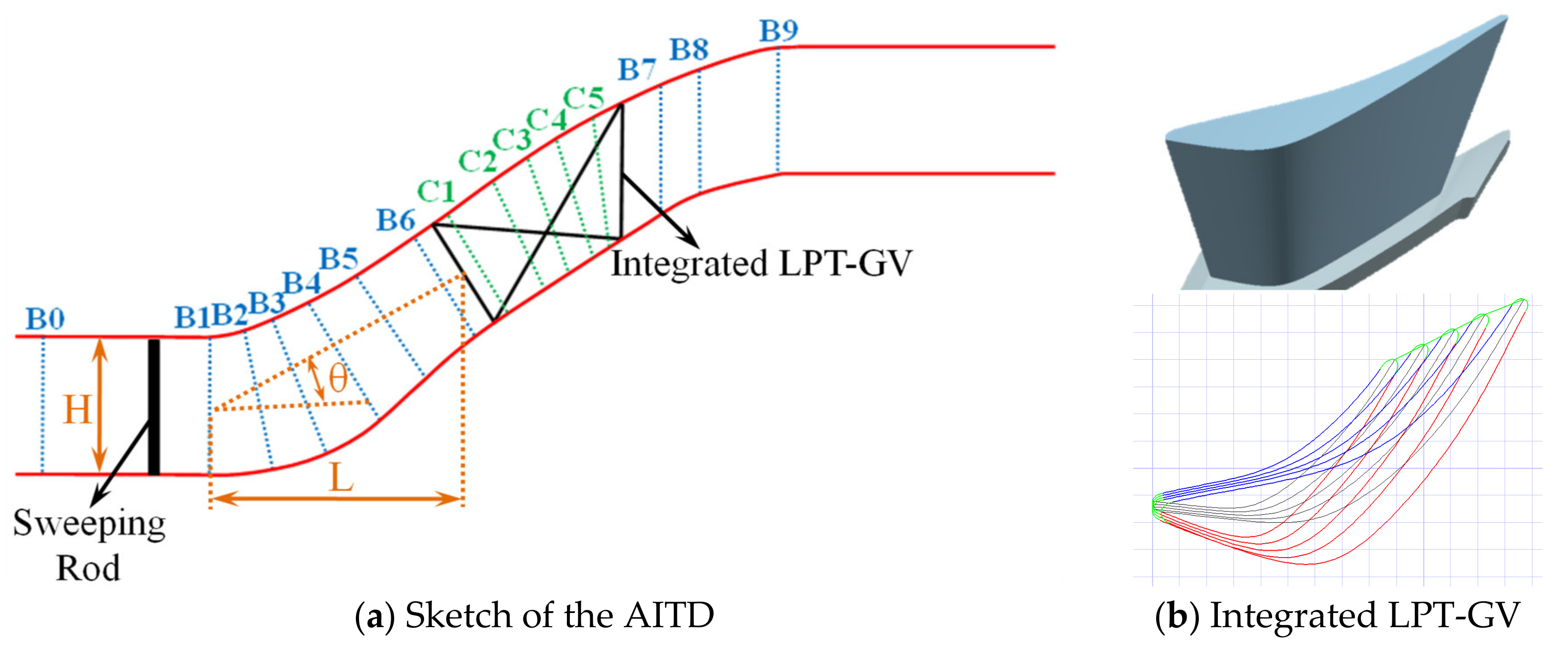

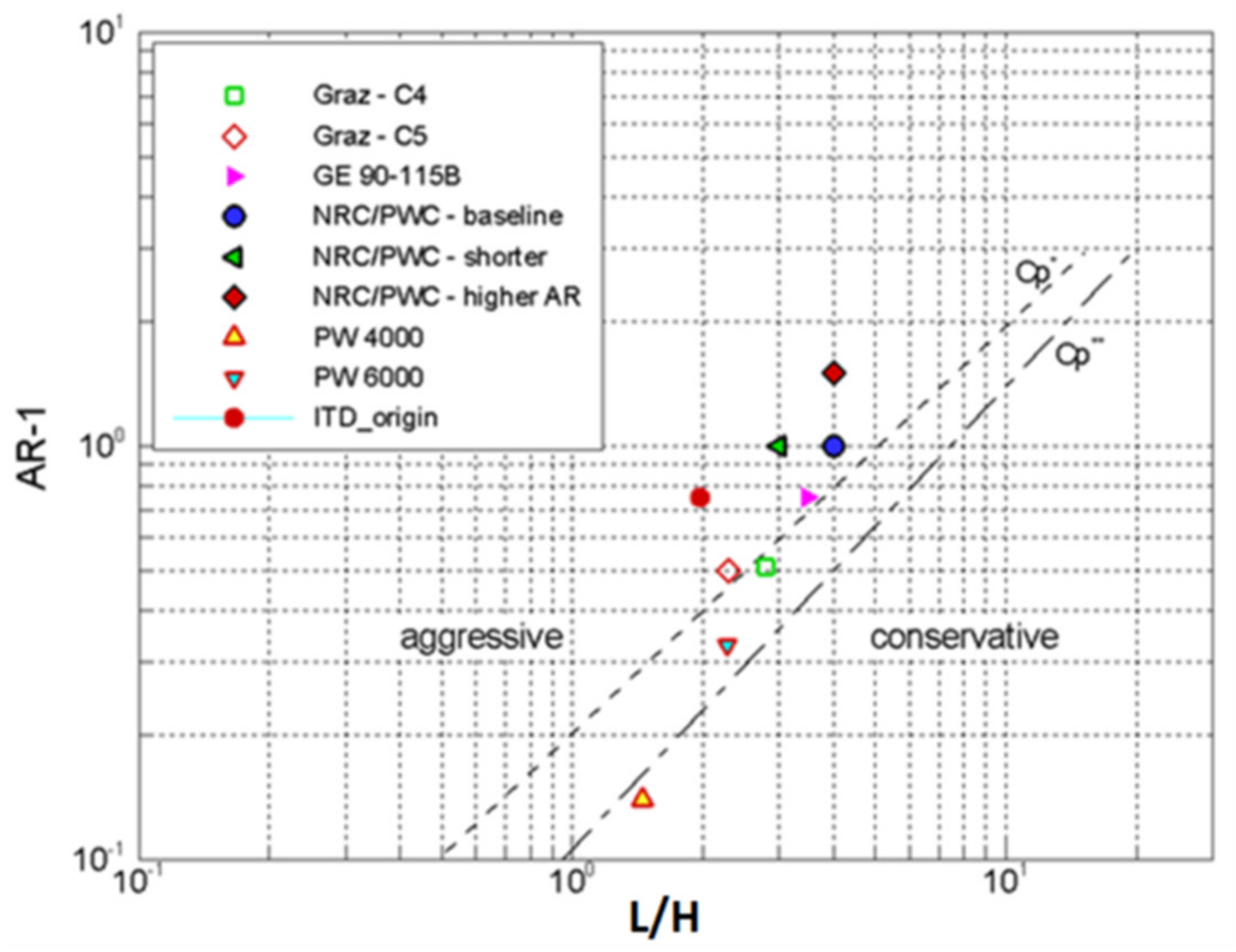

2.1. Integrated AITD

2.2. Boundary Conditions and Grid Independence

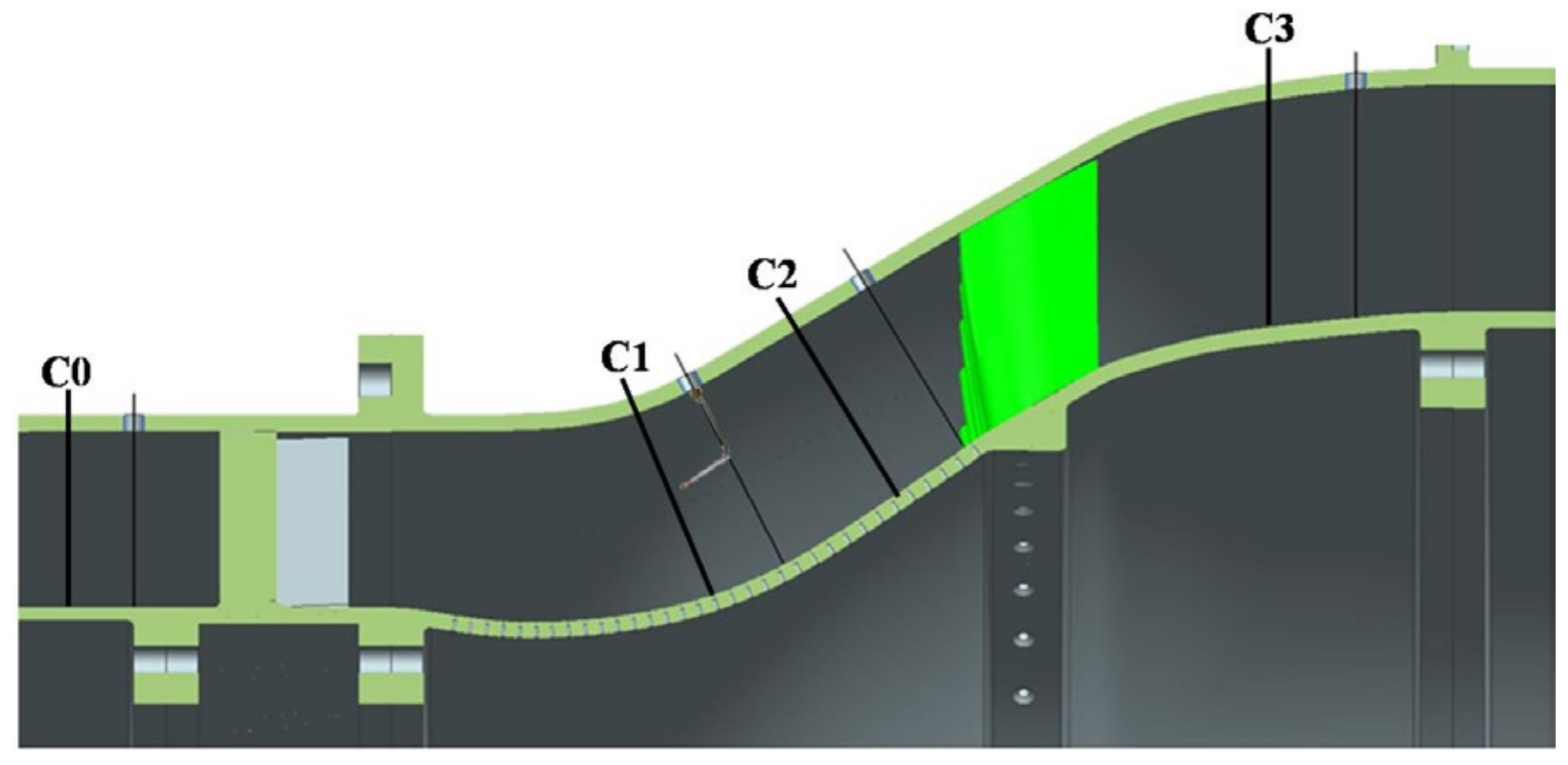

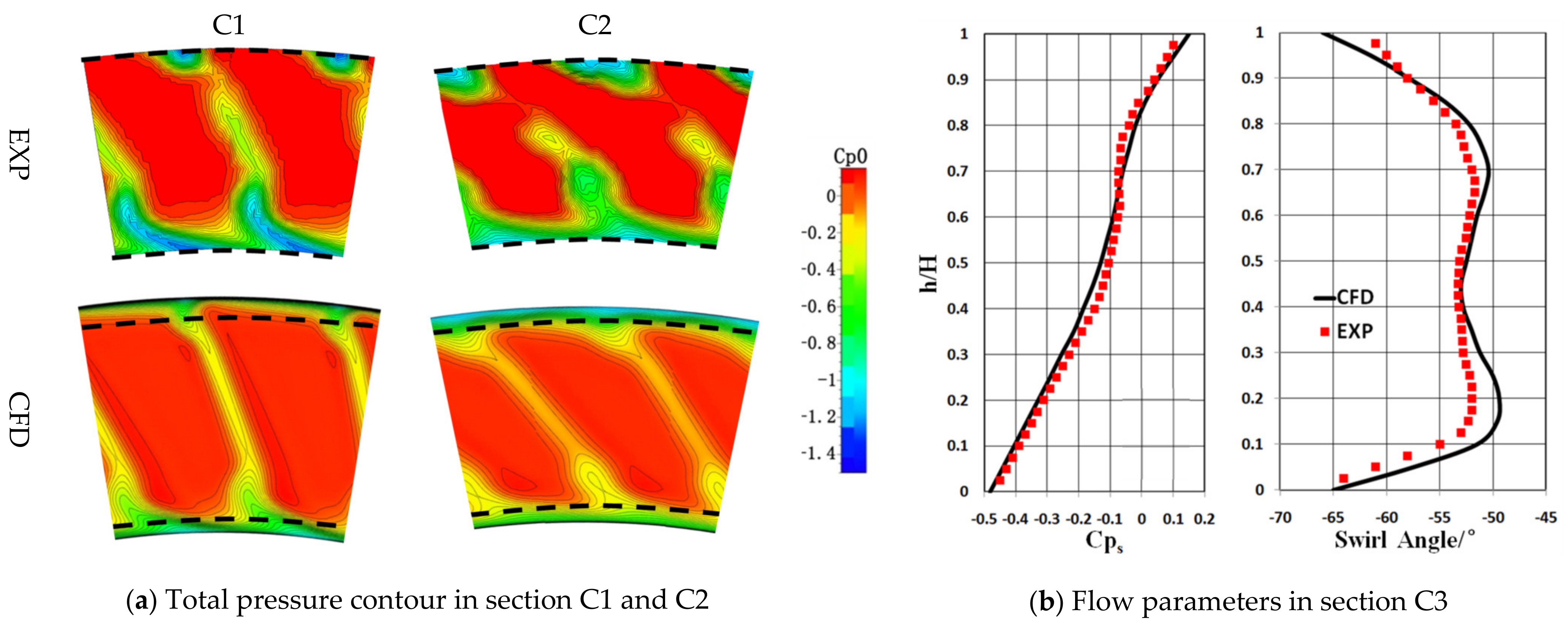

2.3. Validation

3. Results and Discussion

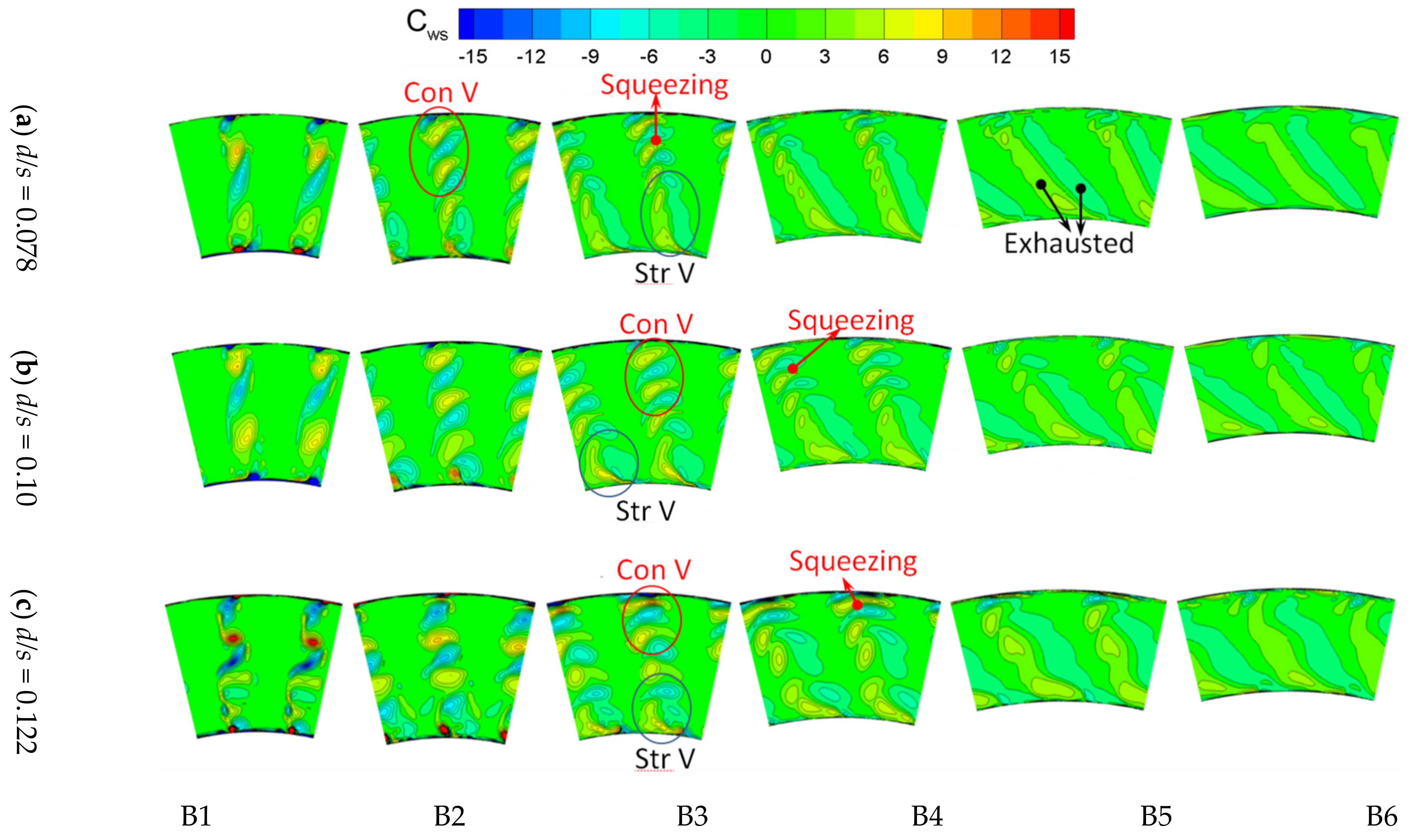

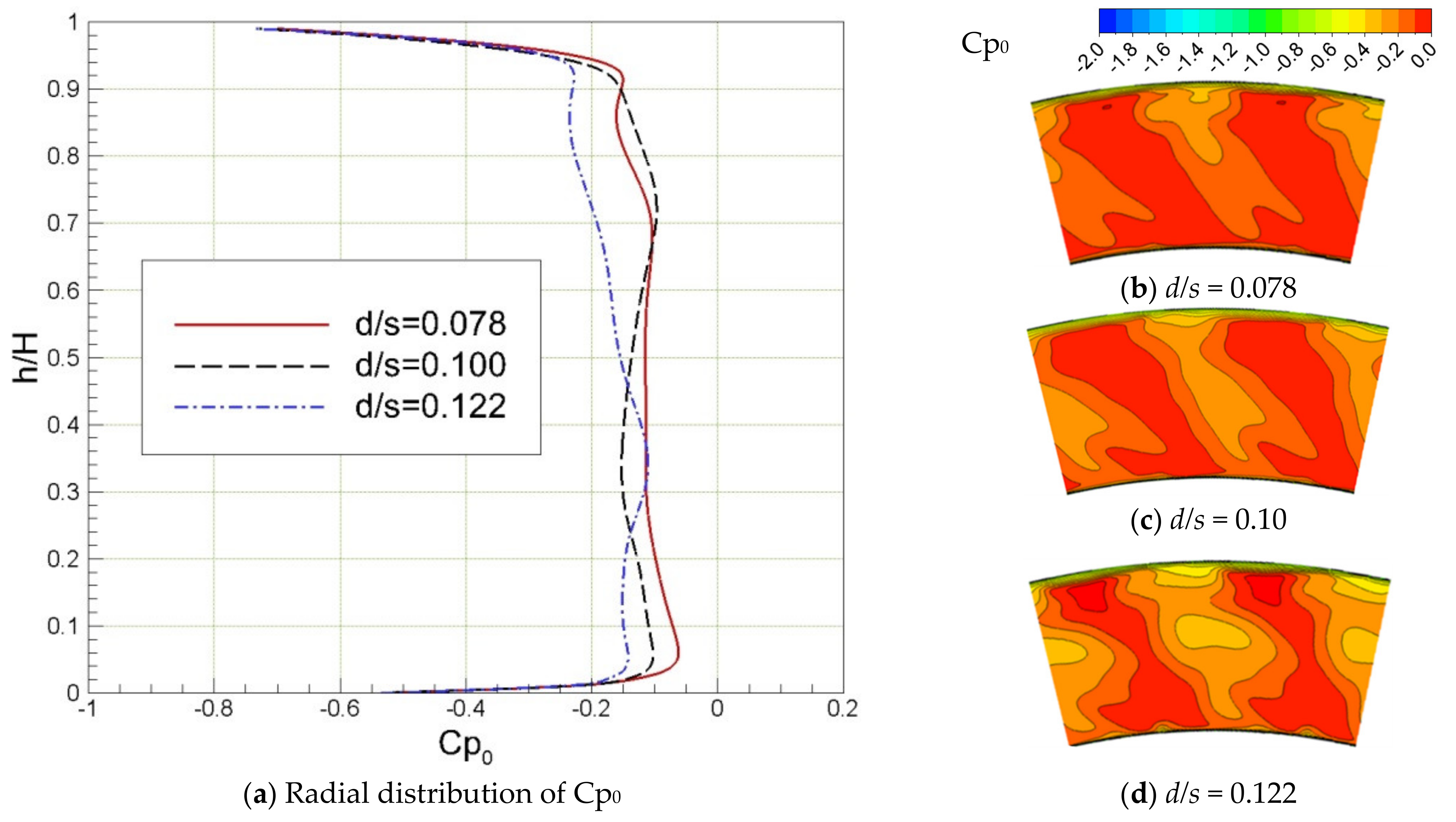

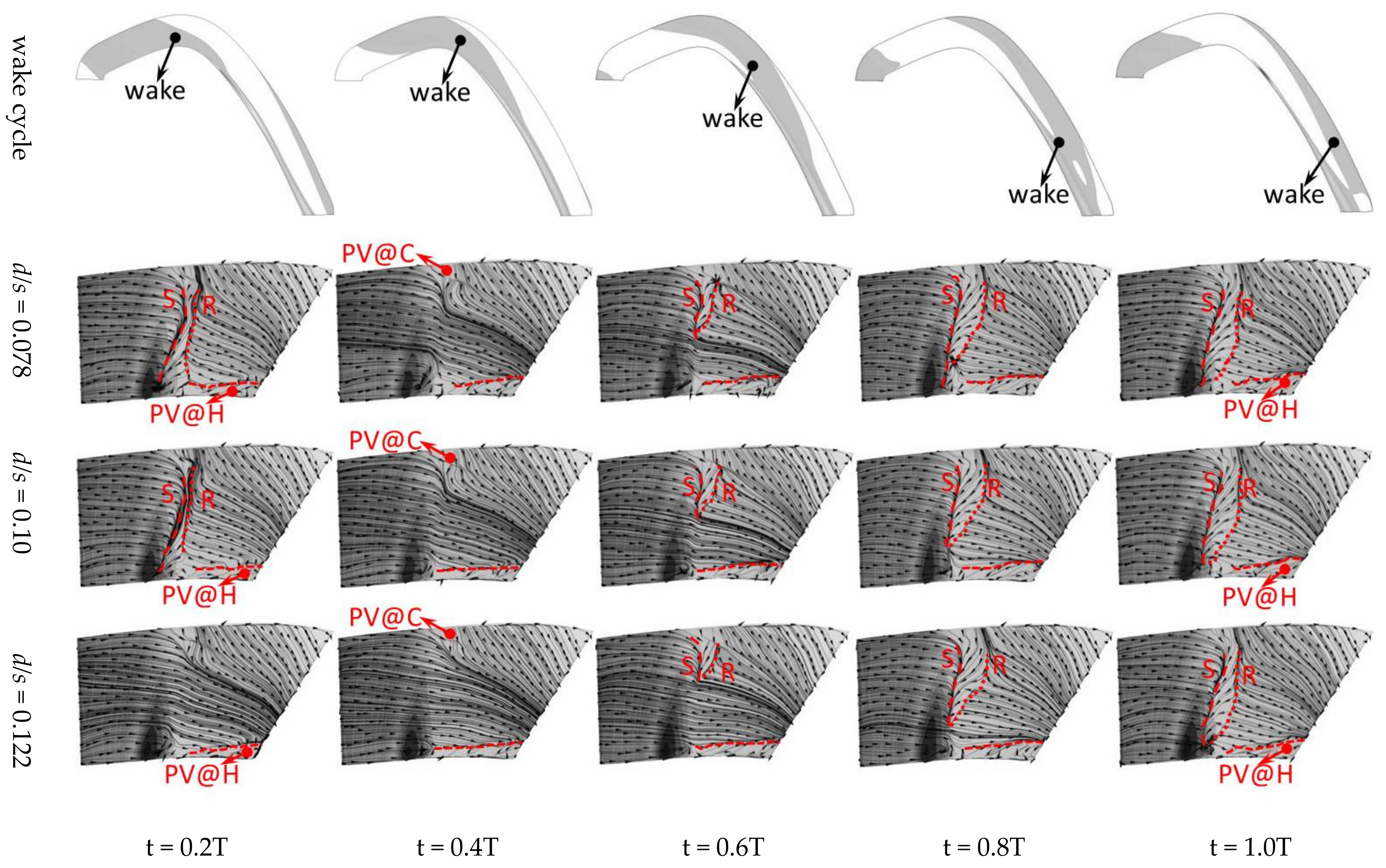

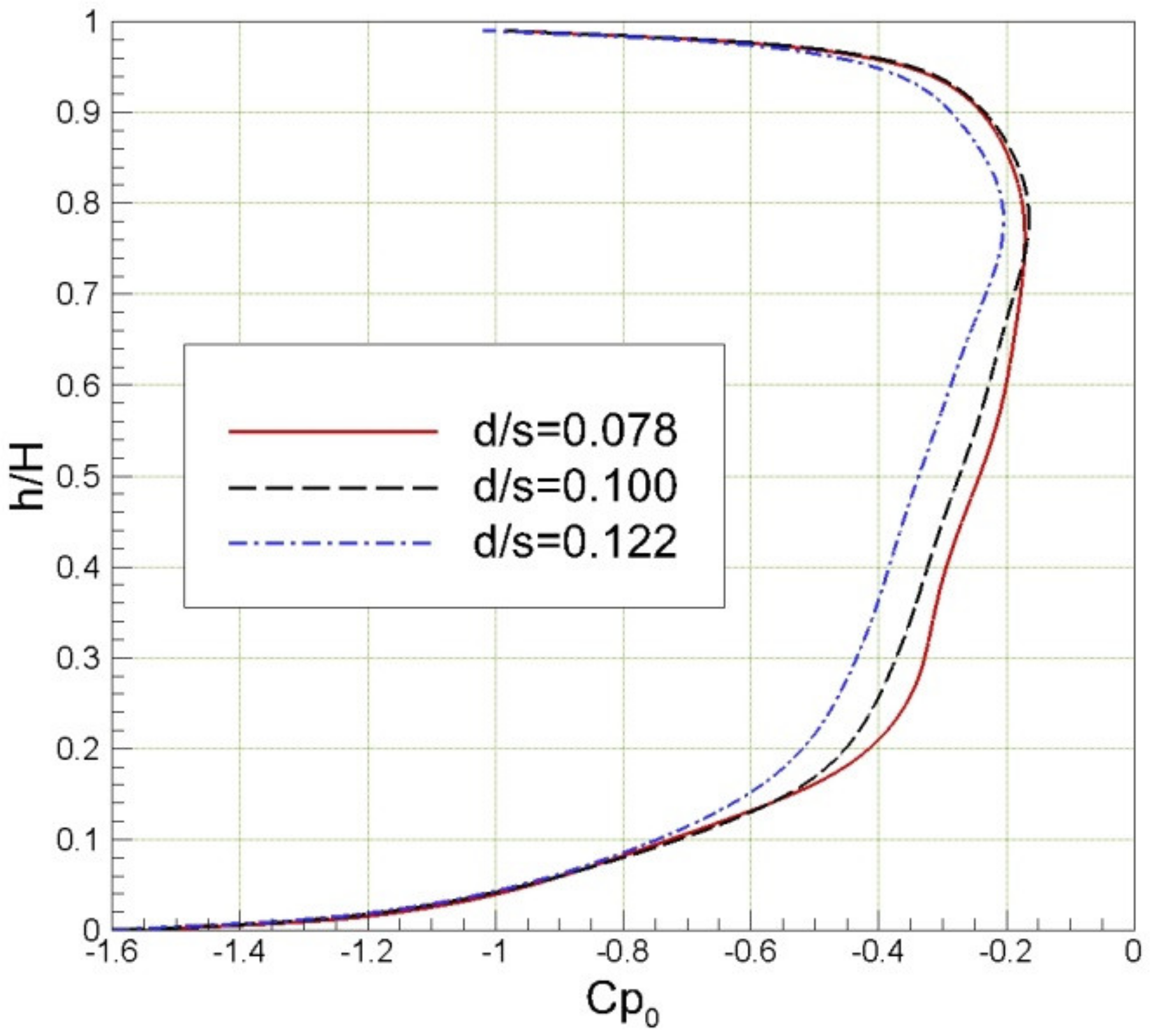

3.1. Influence on Unsteady Wake Transport in AITD

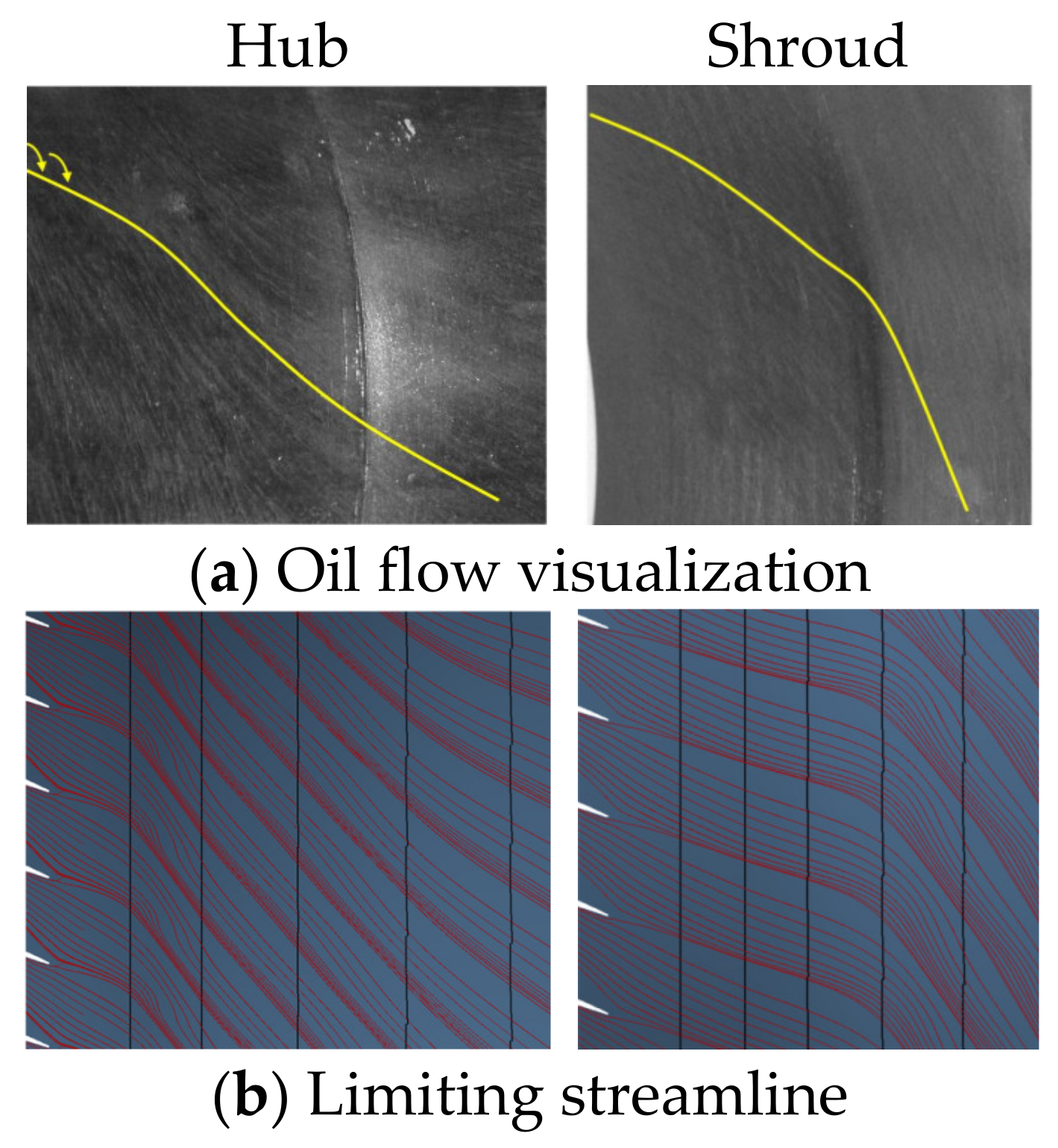

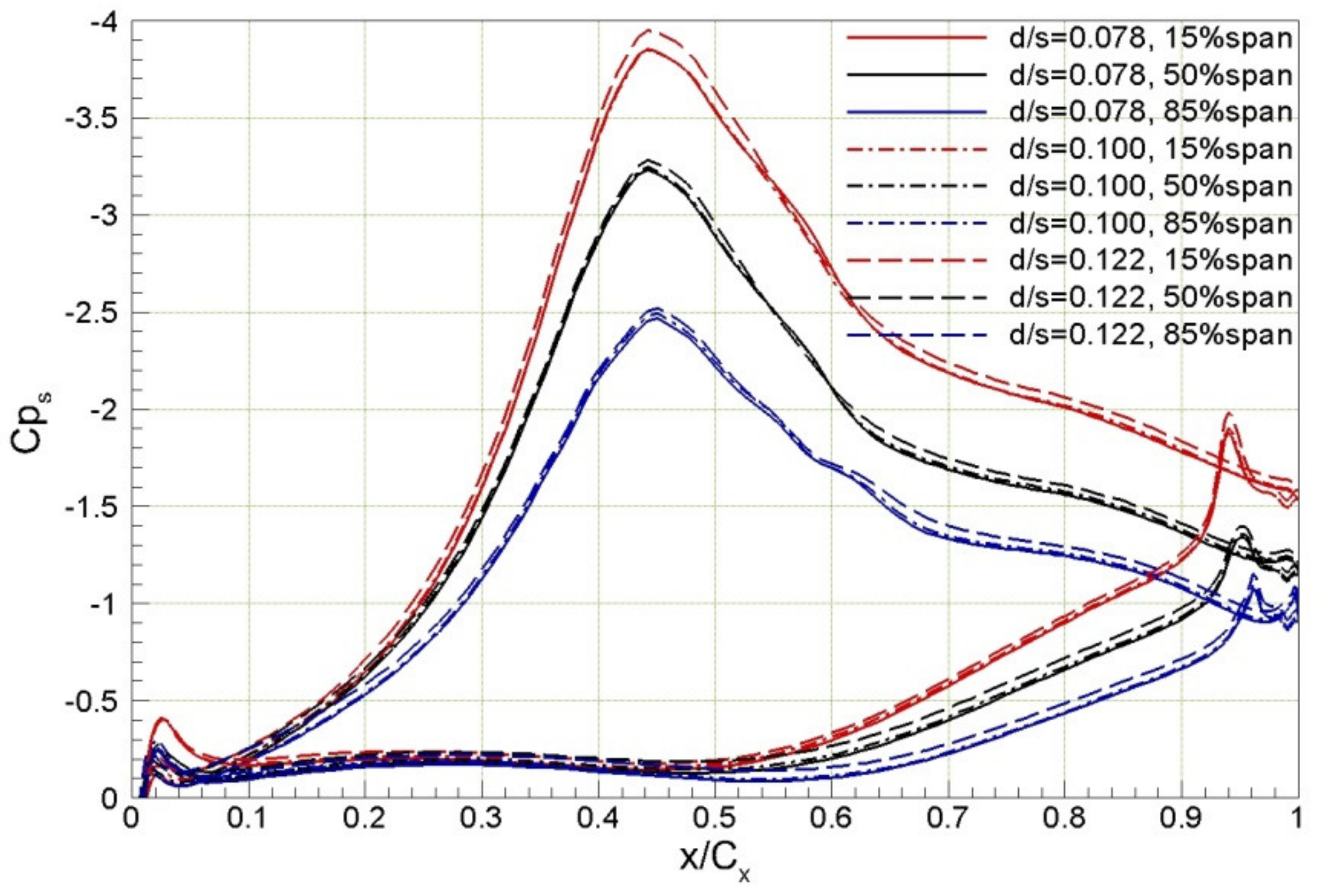

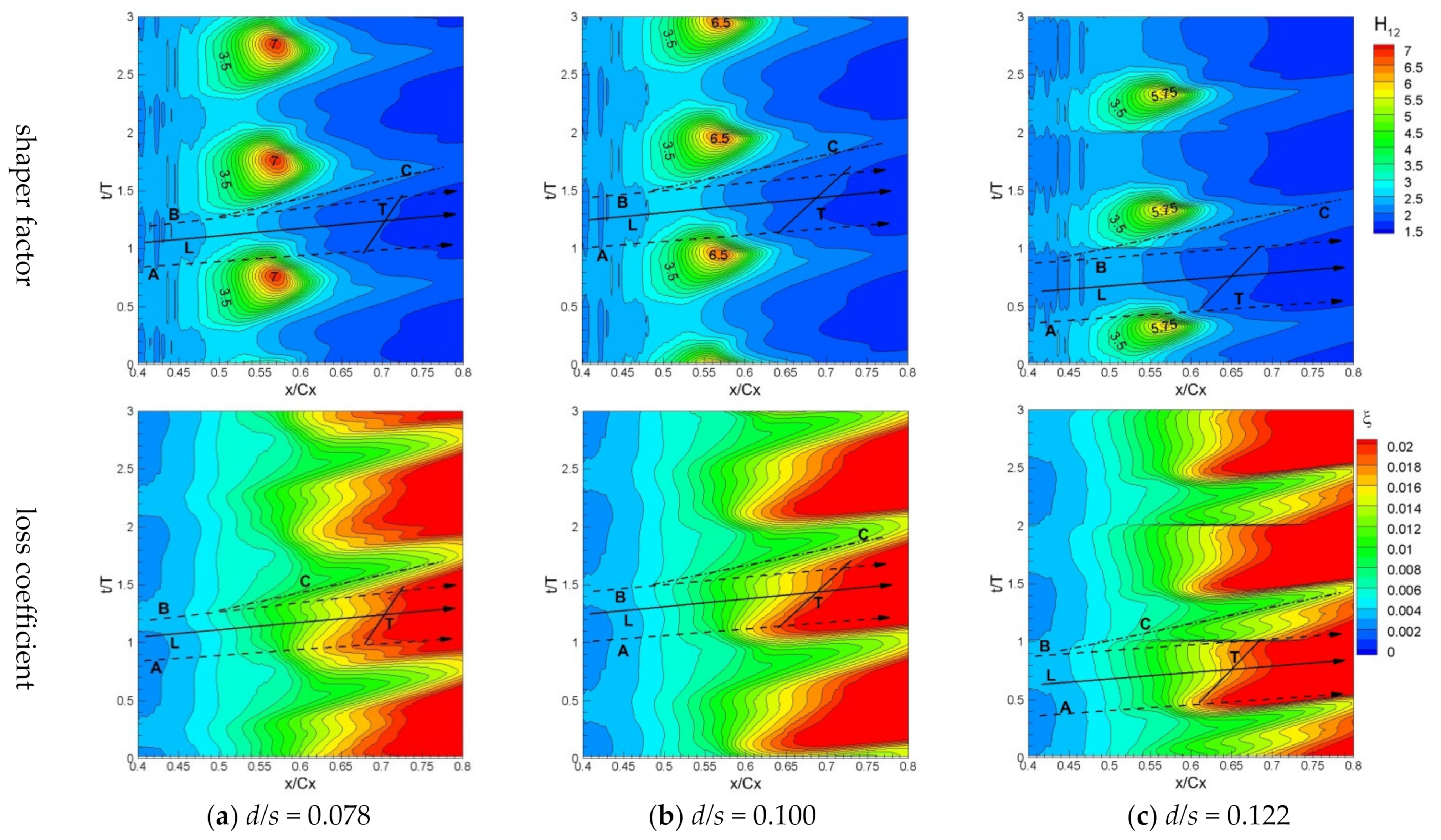

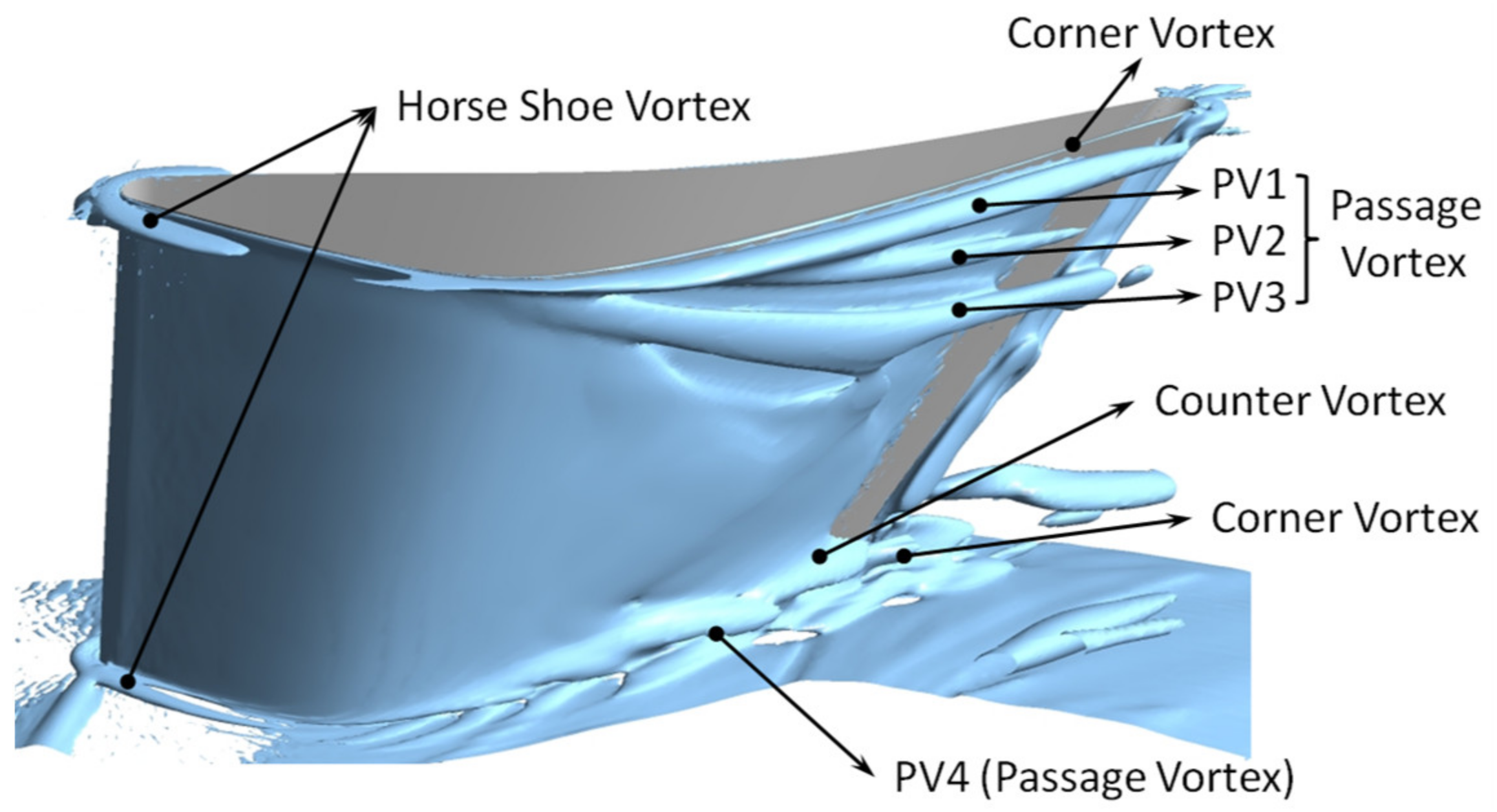

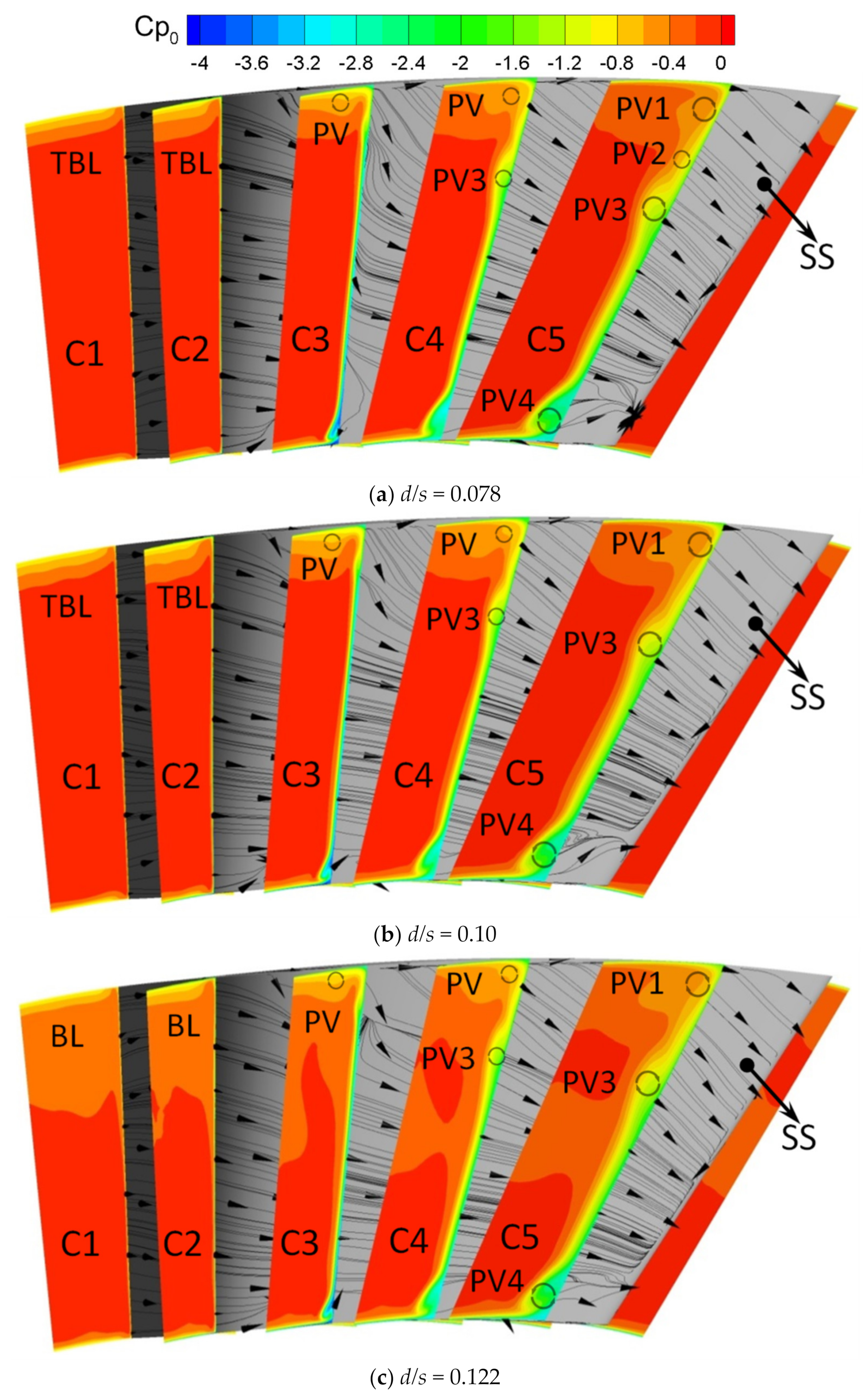

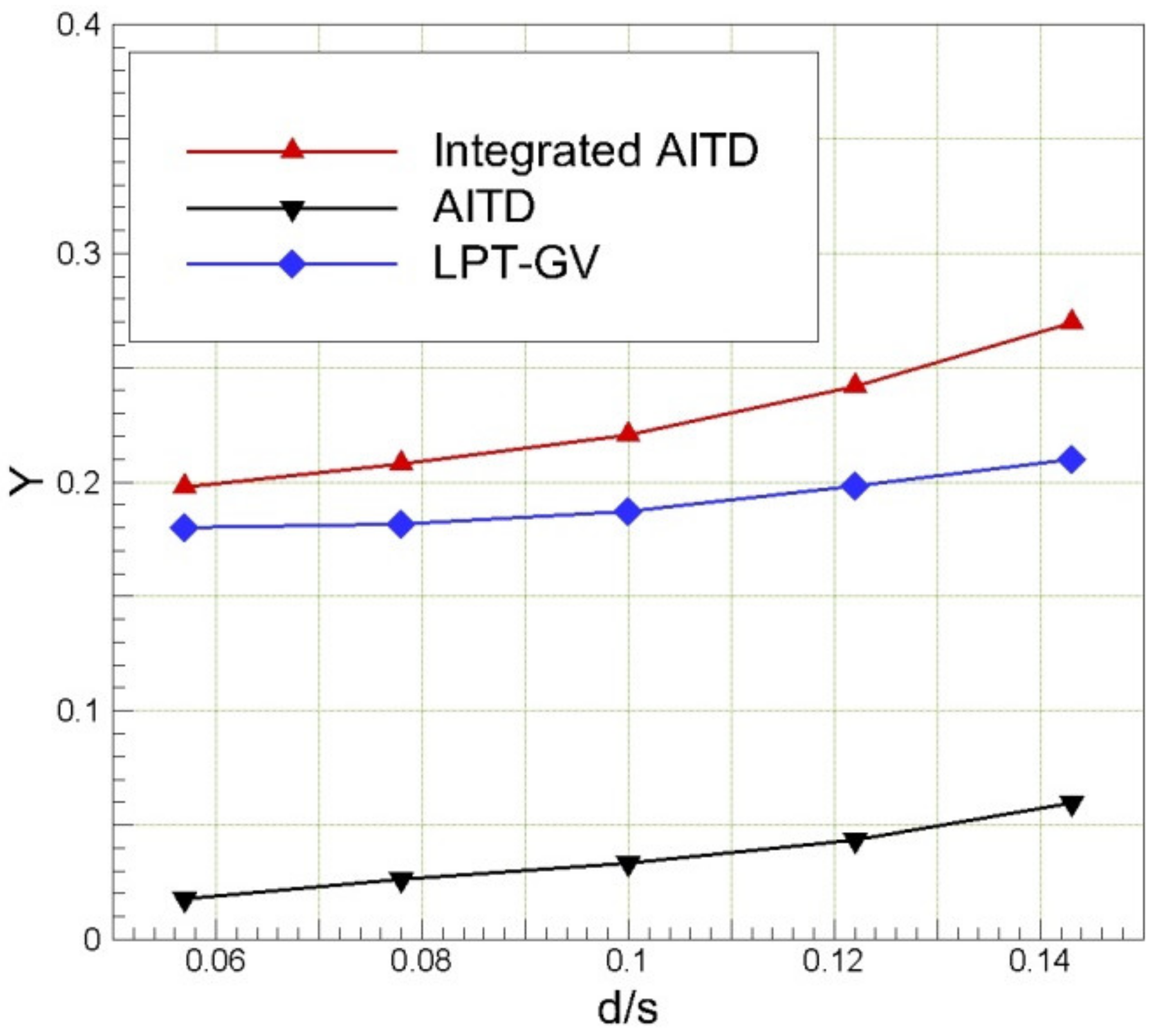

3.2. Effect of Wake on the Integrated LPT-GV

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AR: outlet-to-inlet area ratio |

| AITD: aggressive Interturbine transition duct |

| : resistance coefficient of the sweeping rod |

| : total pressure coefficient |

| : static pressure coefficient |

| : streamwise vorticity coefficient |

| : axial chord |

| : diameter of the sweeping rod |

| : nondimensional diameter of the sweeping rod |

| : reduced frequency |

| : passing frequency of the HPT rotor |

| FSTI: free stream turbulence intensity |

| : height relative to hub |

| : annulus height of the ITD inlet |

| : shape factor |

| HP: high pressure |

| HPT: high pressure turbine |

| ITD: Interturbine transition duct |

| L: axial length of ITD |

| L/H: nondimensional axial length of ITD |

| LP: low pressure |

| LPT: low pressure turbine |

| LPT-GV: low pressure turbine-guide vane |

| : radius of hub at the ITD’s inlet |

| : radius of casing at the ITD’s inlet |

| : reference plane (Plane B0) |

| : pitch of LPT-GV at midspan |

| : the sweeping rod spacing at midspan |

| T: the time of full cycle sweeping wake |

| : turbulence intensity |

| : mass-averaged exit velocity |

| : width of wake |

| : nondimensional width of wake |

| : total pressure loss |

| : nondimensional thichness of the first layer grid on the wall |

| : cosecant of the relative flow angle at HPT outlet |

| : mean rise angle/momentum thickness |

| : the exit flow angle |

| : loss coefficient |

| : the minimum physical time step |

References

- Dominy, R.G.; Kirkham, D.A. The Influence of Blade Wakes on the Performance of Inter-turbine Diffusers. J. Turbomach. 1996, 118, 347–352. [Google Scholar] [CrossRef]

- Dominy, R.G.; Kirkham, D.A.; Smith, A.D. Flow Development through Inter-turbine Diffusers. J. Turbomach. 1998, 120, 298–304. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, S.; Benner, M.; Gostelow, P.; Vlasic, E. Experimental and Numerical Study on an Inter-turbine Duct. In Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition, Vancouverm, BC, Canada, 12–18 November 2010; Paper No.: IMECE2010-37322. pp. 679–690. [Google Scholar]

- Miller, R.J.; Moss, R.W.; Ainsworth, R.W.; Harvey, N.W. The Development of Turbine Exit Flow in a Swan-Necked Inter-stage Diffuser. In Proceedings of the ASME Turbo Expo 2003: Power for Land, Sea, and Air, Atlanta, GA, USA, 16–19 June 2003; Paper No.: GT2003-38174. pp. 863–875. [Google Scholar]

- Norris, G.; Dominy, R.G. Diffusion Rate Influences on Inter-Turbine Diffusers. Proc. Inst. Mech. Eng. Part A J. Power Energy 1997, 211, 235–242. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, S.; Mahallati, A.; Zhang, X.; Vlasic, E. Effects of Area Ratio and Mean Rise Angle on the Aerodynamics of Inter-Turbine Ducts. J. Turbomach. 2018, 140, 091006. [Google Scholar] [CrossRef]

- Axelsson, L.U.; Osso, C.A.; Cadrecha, D.; Johansson, T.G. Design, Performance Evaluation and Endwall Flow Structure Investigation of an S-shaped Intermediate Turbine Duct. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; Paper No.: GT2007-27650. pp. 693–701. [Google Scholar]

- Axelsson, L.U.; Johansson, T.G. Experimental Investigation of the Time-Averaged Flow in an Intermediate Turbine Duct. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Paper No.: GT2008-50829. pp. 1313–1322. [Google Scholar]

- Axelsson, L.U.; George, W.K. Spectral Analysis of the Flow in an Intermediate Turbine Duct. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Paper No.: GT2008-51340. pp. 1419–1426. [Google Scholar]

- Göttlich, E.; Marn, A.; Pecnik, R.; Malzacher, F.; Schennach, O.; Pirker, H. The Influence of Blade Tip Gap Variation on the Flow through an Aggressive S-Shaped Intermediate Turbine Duct Downstream a Transonic Turbine Stage: Part II—Time-Resolved Results and Surface Flow. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; Paper No.: GT2007-28069. pp. 843–853. [Google Scholar]

- Marn, A.; Göttlich, E.; Pecnik, R.; Malzacher, F.; Schennach, O.; Pirker, H. The Influence of Blade Tip Gap Variation on the Flow through an Aggressive S-Shaped Intermediate Turbine Duct Downstream a Transonic Turbine Stage: Part I—Time-Averaged Results. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; Paper No.: GT2007-27405. pp. 575–585. [Google Scholar]

- Göttlich, E.; Heitmeir, F.; Malzacher, F.; Marn, A. Comparison between the Flow through an Aggressive and a Super-Aggressive Intermediate Turbine Duct. In Proceedings of the International Symposium on Air Breathing Engines, Montreal, QC, Canada, 7–11 September 2009. Paper No.: ISABE-2009-1259. [Google Scholar]

- Marn, A.; Göttlich, E.; Malzacher, F.; Pirker, H. The Effect of Rotor Tip Clearance Size onto the Separated Flow through a Super-Aggressive S-Shaped Intermediate Turbine Duct Downstream of a Transonic Turbine Stage. J. Turbomach. 2012, 134, 051019. [Google Scholar] [CrossRef]

- Dominy, R.G.; Kirkham, D.A. The Influence of Swirl on the Performance of Inter-Turbine Diffusers. VDI Berichte. 1995, 1186, 107–122. [Google Scholar]

- Hu, S.; Zhang, Y.; Zhang, X.; Vlasic, E. Influences of Inlet Swirl Distributions on an Inter-Turbine Duct: Part I—Casing Swirl Variation. In Proceedings of the ASME Turbo Expo 2011: Power for Land, Sea, and Air, Vancouver, BC, Canada, 6–10 June 2010; Paper No.: GT2011-45554. pp. 619–630. [Google Scholar]

- Zhang, Y.; Hu, S.; Zhang, X.; Vlasic, E. Influences of Inlet Swirl Distributions on an Inter-Turbine Duct: Part II—Hub Swirl Variation. In Proceedings of the ASME Turbo Expo 2011: Power for Land, Sea, and Air, Vancouver, BC, Canada, 6–10 June 2010; Paper No.: GT2011-45555. pp. 631–641. [Google Scholar]

- Bailey, D.W.; Carrotte, J.F. The Influence of Inlet Swirl on the Flow within an Annular S-Shaped Duct. In Proceedings of the International Gas Turbine and Aeroengine Congress and Exhibition, Birmingham, UK, 10–13 June 1996. Paper No.: 96-GT-060. [Google Scholar]

- Schennach, O.; Pecnik, R.; Paradiso, B.; Göttlich, E.; Marn, A.; WoisetschläGer, J. The Effect of Vane Clocking on the Unsteady Flow Field in a One-and-a-Half Stage Transonic Turbine. J. Turbomach. 2008, 130, 031022. [Google Scholar] [CrossRef]

- Norris, G.; Dominy, R.G.; Smith, A.D. Strut Influences within a Diffusing Annular S-Shaped Duct. In Proceedings of the International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998. Paper No.: 98-GT-425. [Google Scholar]

- Norris, G.; Dominy, R.G.; Smith, A.D. Flow Instability within a Diffusing, Annular S-Shaped Duct. In Proceedings of the International Gas Turbine and Aeroengine Congress and Exhibition, Indianapolis, IN, USA, 7–10 June. Paper No.: 99-GT-070.

- Miller, R.J.; Moss, R.W.; Ainsworth, R.W.; Harvey, N.W. The Effect of an Upstream Turbine on a Low-Aspect Ratio Vane. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 14–17 June 2004; Paper No.: GT2004-54017. pp. 1417–1428. [Google Scholar]

- Walker, A.D.; Barker, A.G.; Mariah, I.; Peacock, G.L.; Northall, R. An Aggressive S-Shaped Compressor Transition Duct with Swirling Flow and Aerodynamic Lifting Struts. In Proceedings of the ASME Turbo Expo 2014: Power for Land, Sea, and Air, Düsseldorf, Germany, 16–20 June 2014. Paper No.: GT2014-25844. [Google Scholar]

- Lengani, D.; Santner, C.; Spataro, R.; Paradiso, B.; Göttlich, E. Experimental Investigation of the Unsteady Flow Field Downstream of a Counter-Rotating Two-Spool Turbine Rig. In Proceedings of the ASME Turbo Expo 2012: Power for Land, Sea, and Air, Copenhagen, Denmark, 11–15 June 2012; Paper No.: 2545-2554. pp. 2545–2554. [Google Scholar]

- Lengani, D.; Santner, C.; Spataro, R.; Ttlich, E.G. Analysis Tools for the Unsteady Interactions in a Counter-Rotating Two-Spool Turbine Rig. Exp. Therm. Fluid Sci. 2012, 42, 248–257. [Google Scholar] [CrossRef]

- Marn, A.; Göttlich, E.; Cadrecha, D.; Pirker, H.P. Shorten the Intermediate Turbine Duct Length by Applying an Integrated Concept. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Paper No.: GT2008-50269. pp. 1041–1051. [Google Scholar]

- Spataro, R.; Santner, C.; Lengani, D.; Göttlich, E. On the Flow Evolution through a LP Turbine with Wide-Chord Vanes in an S-Shaped Channel. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; Paper No.: GT2012-68178. pp. 1011–1020. [Google Scholar]

- Bader, P.; Sanz, W.; Spataro, R.; Göttlich, E. Flow Evolution through a Turning Mid Turbine Frame with Embedded Design. In Proceedings of the ASME Turbo Expo 2014: Power for Land, Sea, and Air, Düsseldorf, Germany, 16–20 June 2014. Paper No.: GT2014-25009. [Google Scholar]

- Faustmann, C.; Zerobin, S.; Spataro, R.; Marn, A.; Heitmeir, F.; Göttlich, E. On the Acoustics of a Turning Mid Turbine Frame with Embedded Design in a Two-Stage Test-Turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2015, 229, 529–538. [Google Scholar] [CrossRef]

- Du, Q.; Wang, P.; Gong, J.; Zhu, J. Design Performance Evaluation and Vortex Structure Investigation of Different S-Shaped Intermediate Turbine Ducts. Sci. China Technol. Sci. 2012, 55, 3510–3520. [Google Scholar] [CrossRef]

- Wang, P. Design and Flow Mechanism of Integrated Aggressive Intermediate Turbine Duct; Institute of Engineering Thermophysics, C.A.S.: Beijing, China, 2014. [Google Scholar]

- Liu, J.; Wang, P.; Du, Q.; Liu, G.; Zhu, J. Effects of Rising Angle on Upstream Blades and Intermediate Turbine Duct. J. Therm. Sci. 2016, 25, 293–301. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, P.; Du, Q.; Liu, J.; Liu, G. Effects of Axial Length and Integrated Design on the Aggressive Intermediate Turbine Duct. Proc. IMechE Part A J. Power Energy 2018, 233, 443–456. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Ji, L.; Du, Q.; Liu, G.; Wang, P. Influence of Reynolds Number on the Unsteady Aerodynamics of Integrated Aggressive Intermediate Turbine Duct. J. Therm. Sci. 2018, 27, 294–303. [Google Scholar] [CrossRef]

- Mahallati, A. Aerodynamics of a Low Pressure Turbine Airfoil Under steady and Periodically Unsteady Conditions. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2004. [Google Scholar]

- Meyer, R.J. The Effect of Wakes on the Transient Pressure and Velocity Distributions in Turbomachines. ASME J. Basic Eng. 1958, 80, 1544–1552. [Google Scholar] [CrossRef]

- Stieger, R.D. The Effects of Wakes on Separating Boundary Layers in Low Pressure Turbines. Ph.D. Thesis, Cambridge University, Cambridge, UK, 2002. [Google Scholar]

- Zhong, S.; Kittichaikarn, C.; Hodson, H.P.; Ireland, P. A study of unsteady wake-induced boundary layer transition with thermochromic liquid crystals. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1999, 213, 163–171. [Google Scholar] [CrossRef]

- Roberts, S.K.; Yaras, M.I. Large-Eddy Simulation of Transition in a Separation Bubble. ASME J. Fluids Eng. 2006, 128, 232–238. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Du, Q.; Liu, G.; Wang, P. Unsteady Flow Mechanism of the integrated Aggressive Inter-turbine Duct in Low Reynolds number condition. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2020, 234, 1507–1517. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Du, Q.; Liu, G.; Wang, P. Impact of Turbulence Intensity on the Unsteady Flow Characteristics of the integrated Aggressive Inter-turbine Duct. Proc. Inst. Mech. Eng. Part A J. Power Energy 2020, 234, 490–499. [Google Scholar] [CrossRef]

- Jeon, W.; Shin, C.B. Design and Simulation of Passive Mixing in Microfluidic Systems with Geometric Variations. Chem. Eng. J. 2009, 152, 575–582. [Google Scholar] [CrossRef]

| Chord (mm) | Leading-Edge Radius (mm) | Trailing-Edge Radius (mm) | Stagger Angle (°) | Inlet Metal Angle (°) | Outlet Metal Angle (°) | Tmax/Chord | Throat/Pitch | Solidity | |

|---|---|---|---|---|---|---|---|---|---|

| Root | 74.5 | 3.5 | 2.5 | 35° | −6° | 62° | 0.200 | 0.444 | 1.348 |

| Midspan | 94.1 | 3.5 | 2.5 | 35° | −6° | 62° | 0.197 | 0.427 | 1.457 |

| Tip | 112.8 | 3.5 | 2.5 | 35° | −6° | 62° | 0.194 | 0.410 | 1.566 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Z.; Liu, H.; Li, G.; Gong, J.; Zhang, Y.; Lu, X.; Xu, G.; Zhu, J. Influence of Wake Intensity on the Unsteady Flow Characteristics of the Integrated Aggressive Interturbine Duct. Appl. Sci. 2022, 12, 6655. https://doi.org/10.3390/app12136655

Lei Z, Liu H, Li G, Gong J, Zhang Y, Lu X, Xu G, Zhu J. Influence of Wake Intensity on the Unsteady Flow Characteristics of the Integrated Aggressive Interturbine Duct. Applied Sciences. 2022; 12(13):6655. https://doi.org/10.3390/app12136655

Chicago/Turabian StyleLei, Zhijun, Hongrui Liu, Gang Li, Jianbo Gong, Yanfeng Zhang, Xingen Lu, Gang Xu, and Junqiang Zhu. 2022. "Influence of Wake Intensity on the Unsteady Flow Characteristics of the Integrated Aggressive Interturbine Duct" Applied Sciences 12, no. 13: 6655. https://doi.org/10.3390/app12136655

APA StyleLei, Z., Liu, H., Li, G., Gong, J., Zhang, Y., Lu, X., Xu, G., & Zhu, J. (2022). Influence of Wake Intensity on the Unsteady Flow Characteristics of the Integrated Aggressive Interturbine Duct. Applied Sciences, 12(13), 6655. https://doi.org/10.3390/app12136655