Machine-Learning-Based Digital Twin in Manufacturing: A Bibliometric Analysis and Evolutionary Overview

Abstract

:1. Introduction

- ML-enabled DT is a subset of AI-enabled DT.

- ML-enabled DT involves algorithms such as ANN, RF, kNN, whereas AI-enabled DT involves algorithms such as genetic algorithm, ant colony optimization, and particle swarm optimization, in addition to ML algorithms.

- ML-enabled DT is primarily used for process control, scheduling and prediction, whereas AI-enabled DT is primarily used for optimization, scheduling, and resource allocation.

- ML-enabled DT is more abundant than AI-enabled DT

- DT in the manufacturing life cycle.

- -

- Manufacturing design.

- -

- Manufacturing service.

- -

- Manufacturing process management.

- Simulation of manufacturing process.

- Big data associated with manufacturing.

- Cyberphysical system.

- Human-integrated manufacturing.

2. Related Review Studies

- DT in product design,

- Manufacturing,

- Product service,

- Digital twin-driven sustainable intelligent manufacturing etc.

Difference between Proposed Literature Review Study and State-of-the-Art Studies

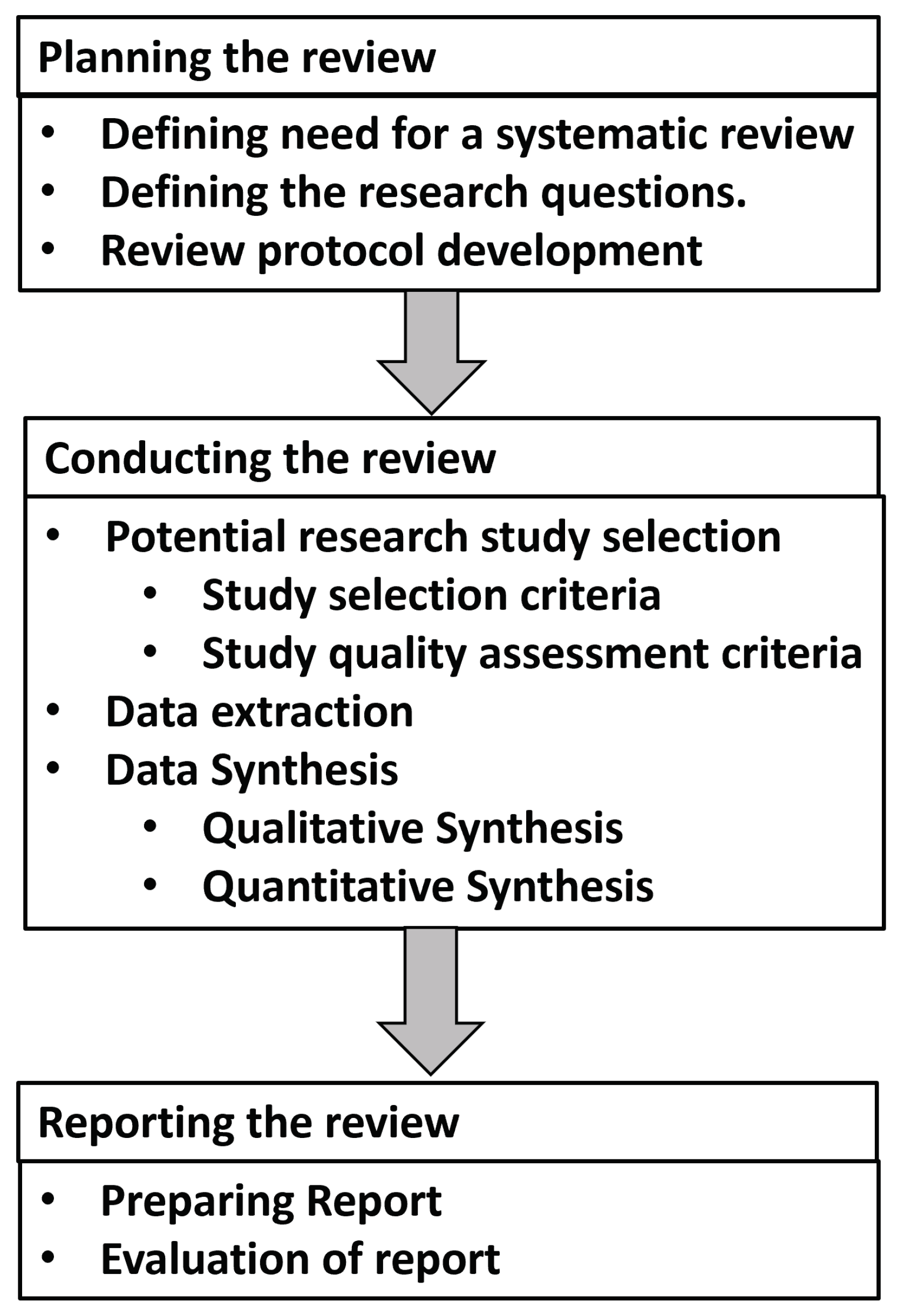

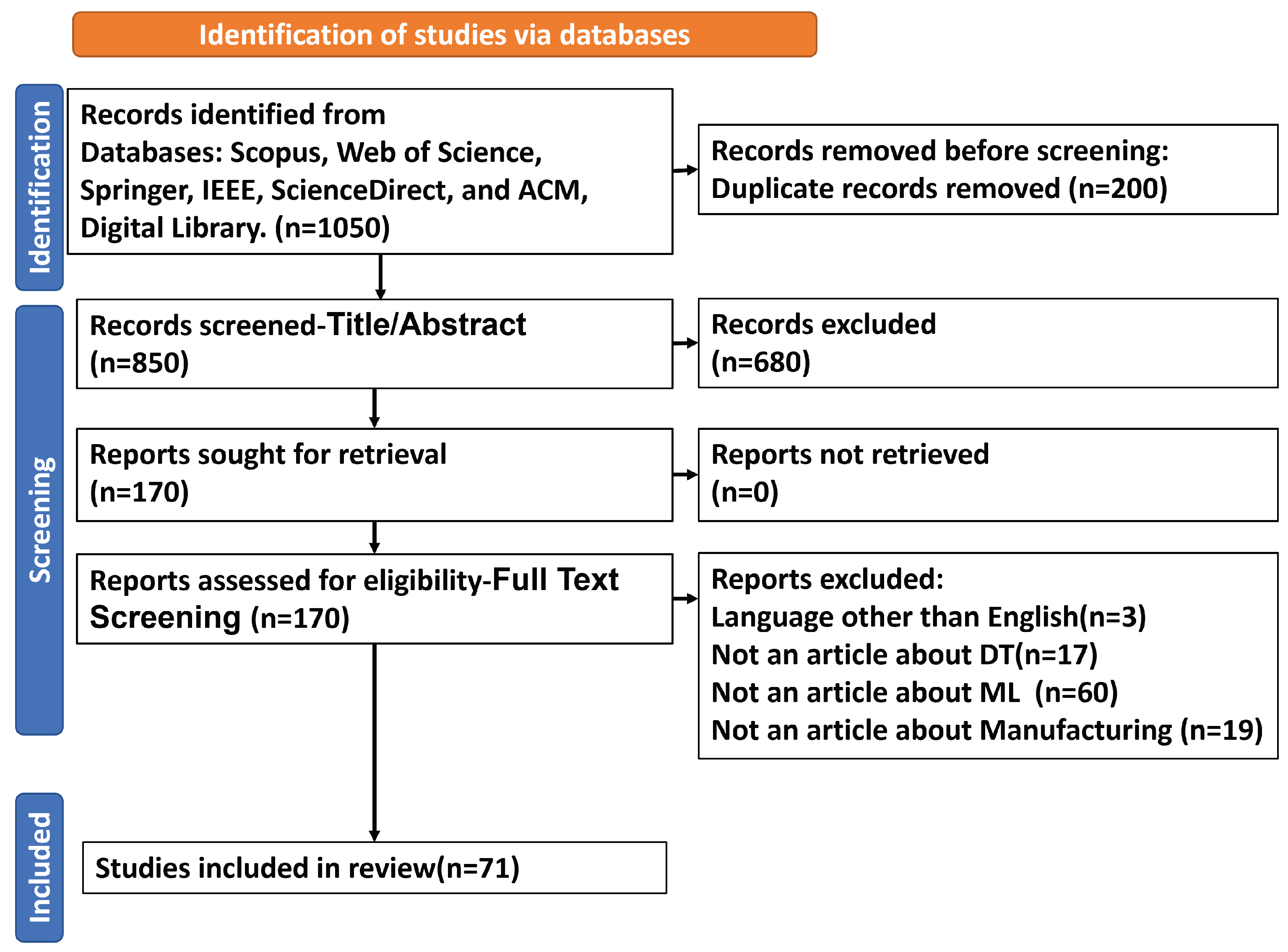

3. Methodology

- Planning the review,

- Conducting the review,

- Reporting the review.

Research Questions

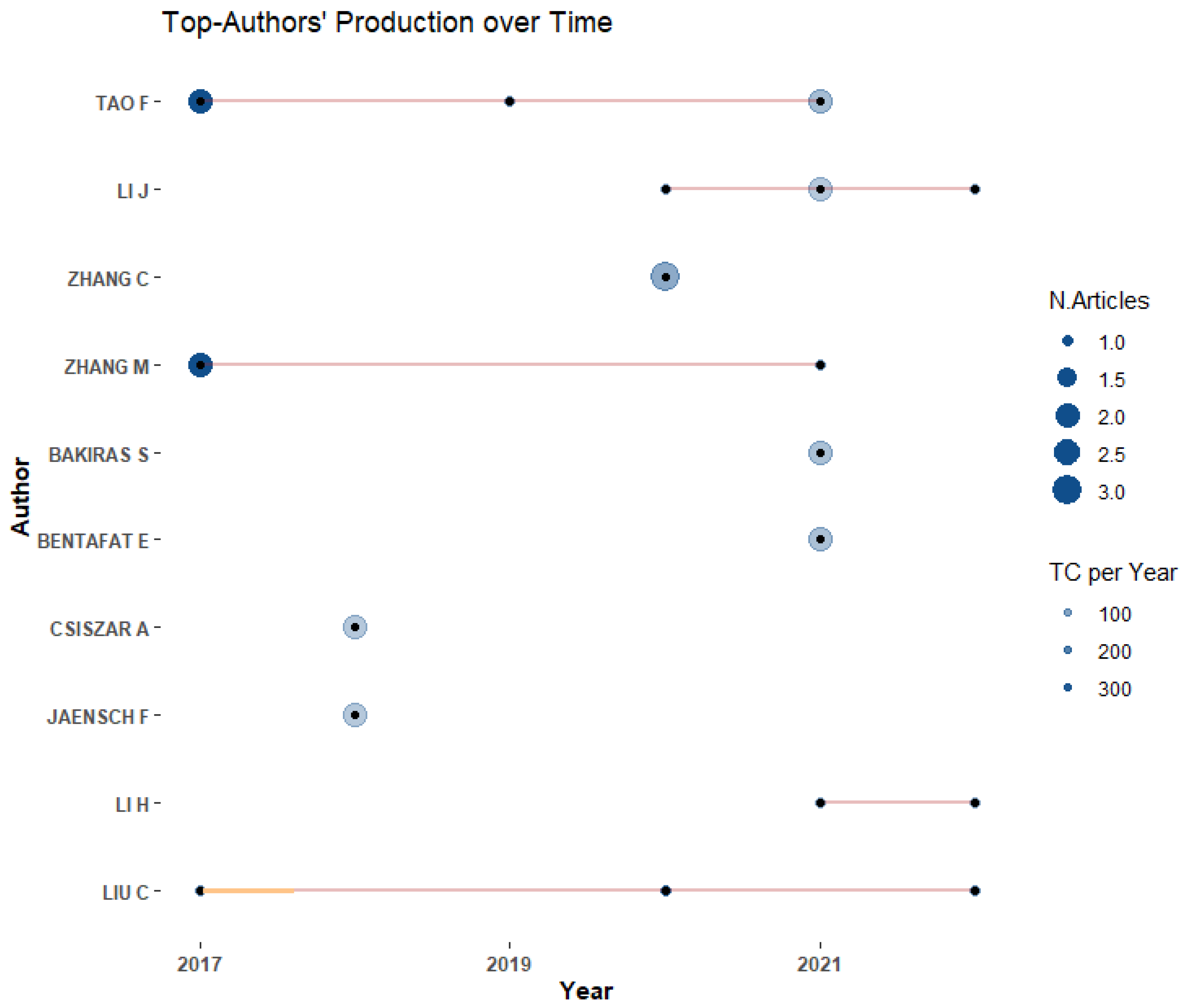

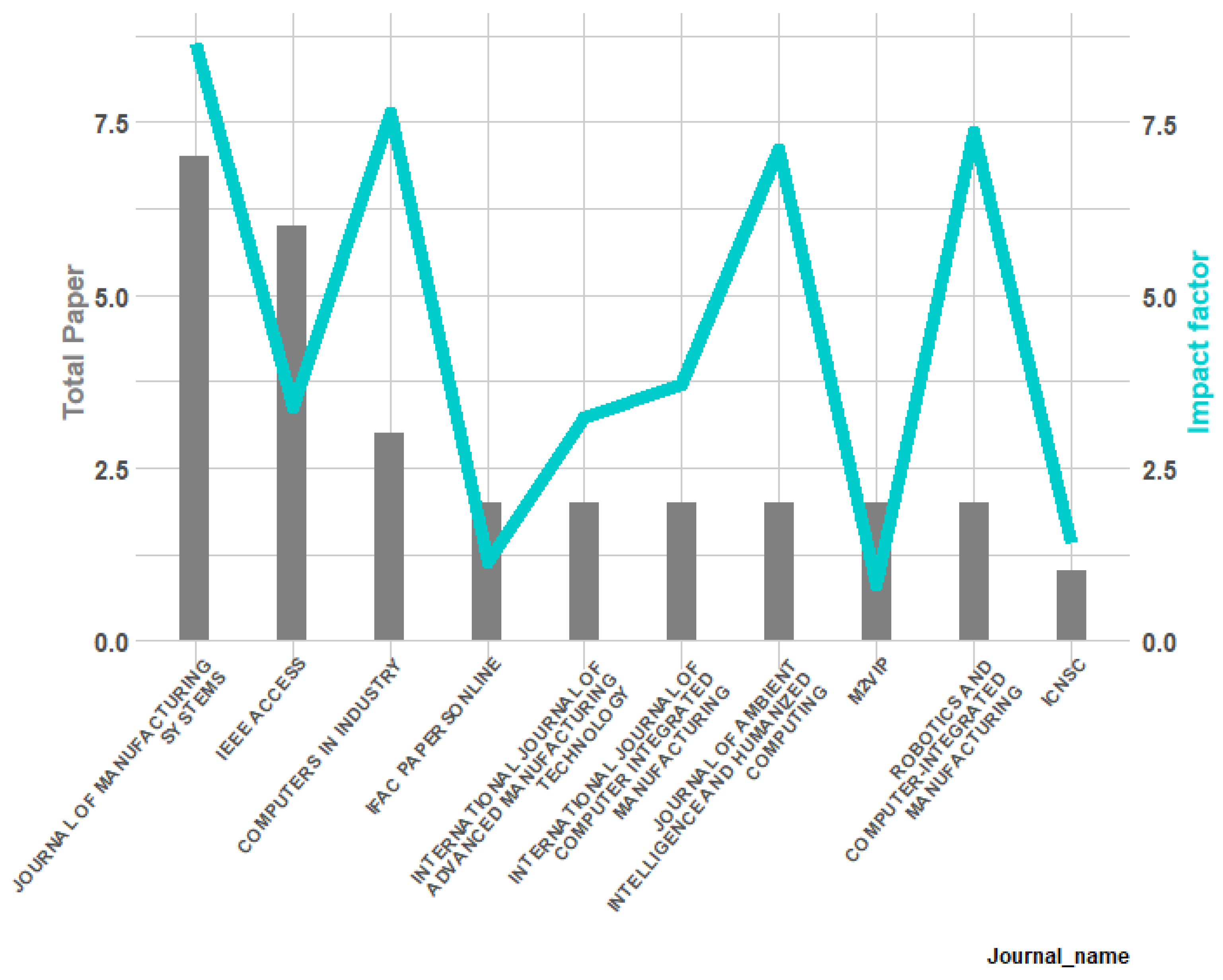

- RQ1: What are the quantitative statistics, such as citation trends, author productivity, journal productivity, and qualitative trends, such as thematic evolution and topic clusters associated with ML-based DT of manufacturing systems?

- RQ2: What tasks are performed by ML in the ML-based DT of manufacturing systems?

- -

- RQ2.1 Which ML algorithms are used? How are these algorithms evolving over time?

- RQ3: What is the role of ML in developing the DT?

- -

- RQ3.1 What DT dimensions are enhanced by ML?

- -

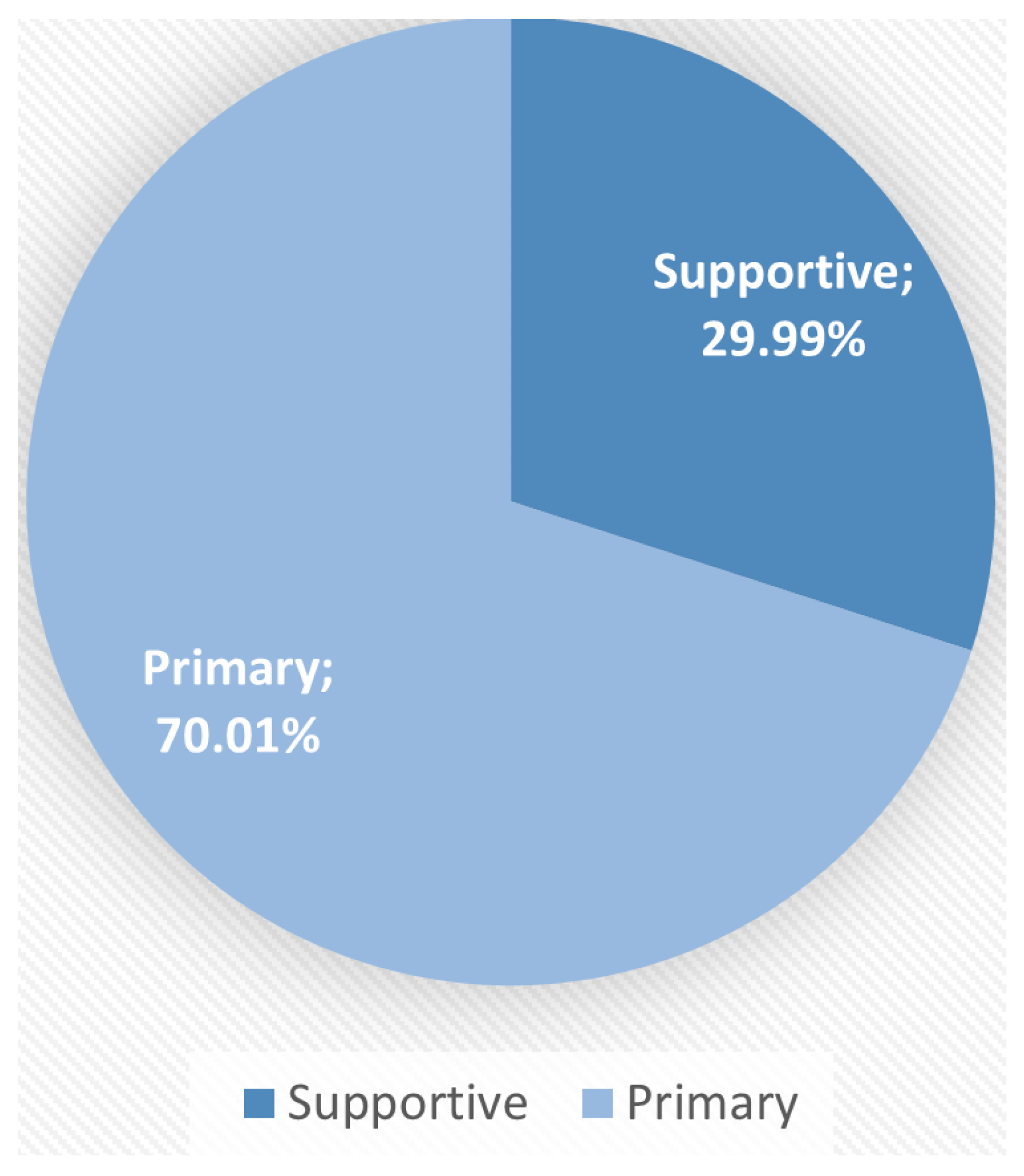

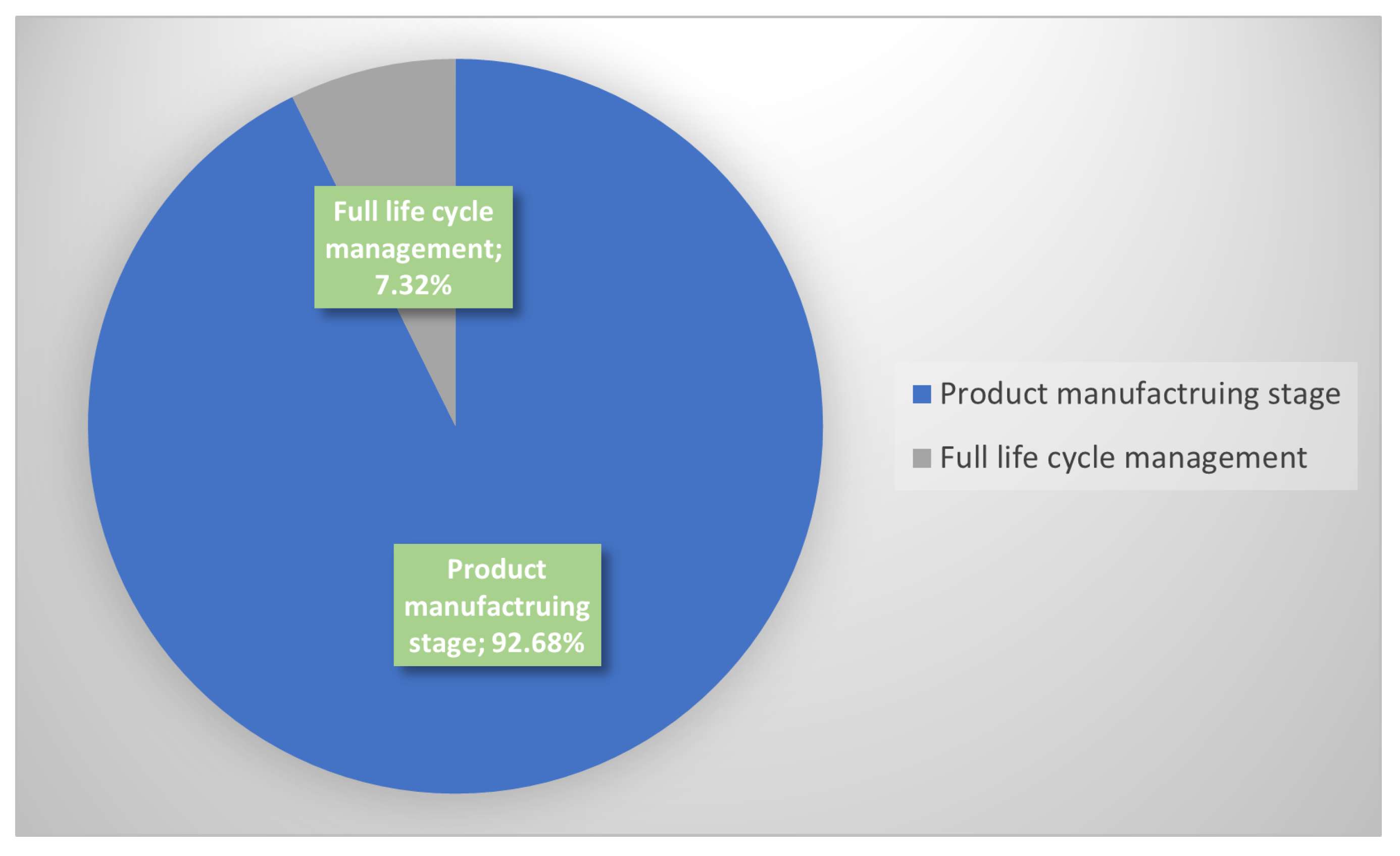

- RQ3.2 What is the contribution of ML-based DT in Manufacturing Product lifecycle management (PLM)?

- RQ4: How do open issues associated with ML-based DT evolve over time? What are the possibilities for future research?

4. Research Question Results

4.1. First Research Question

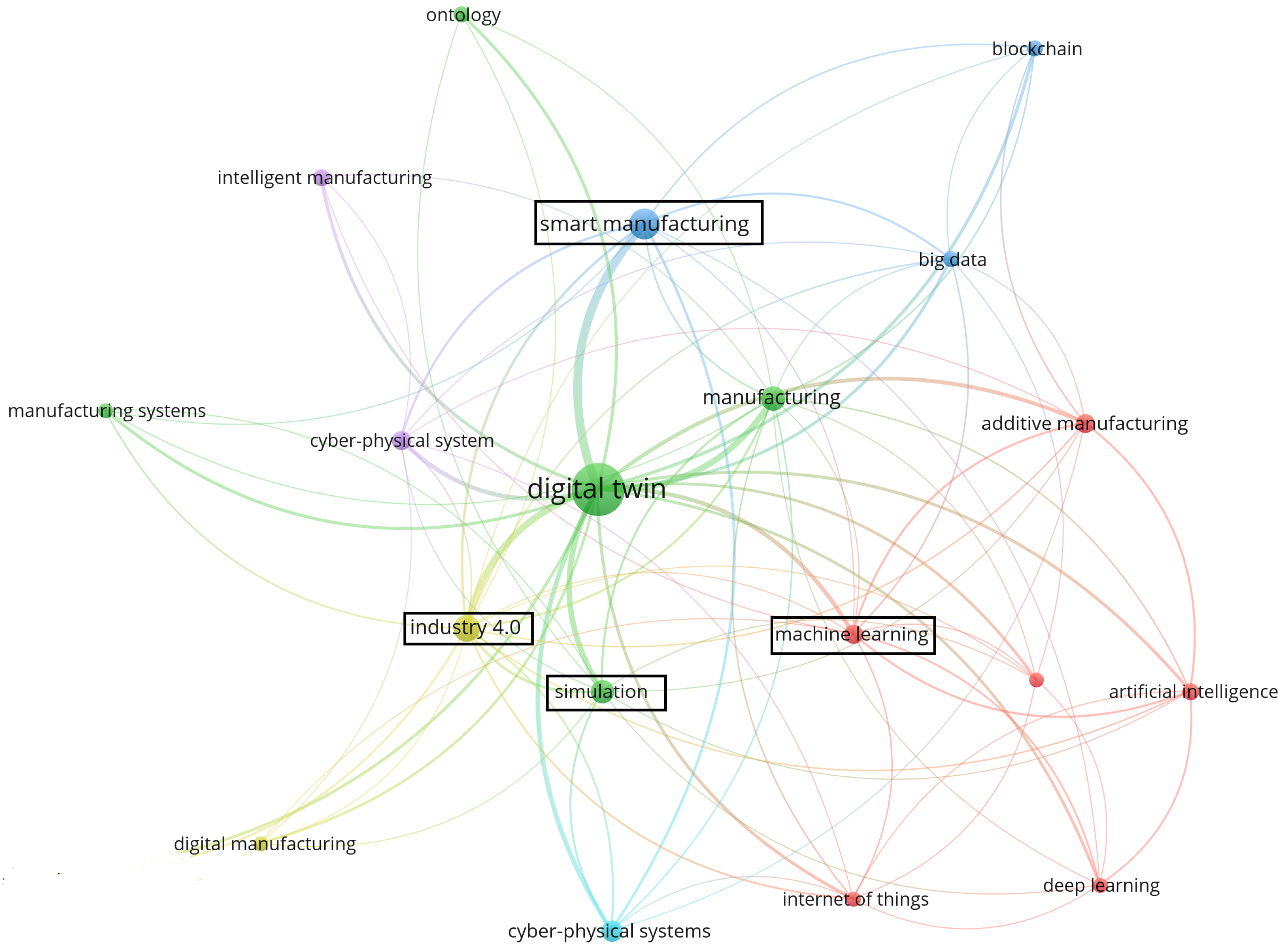

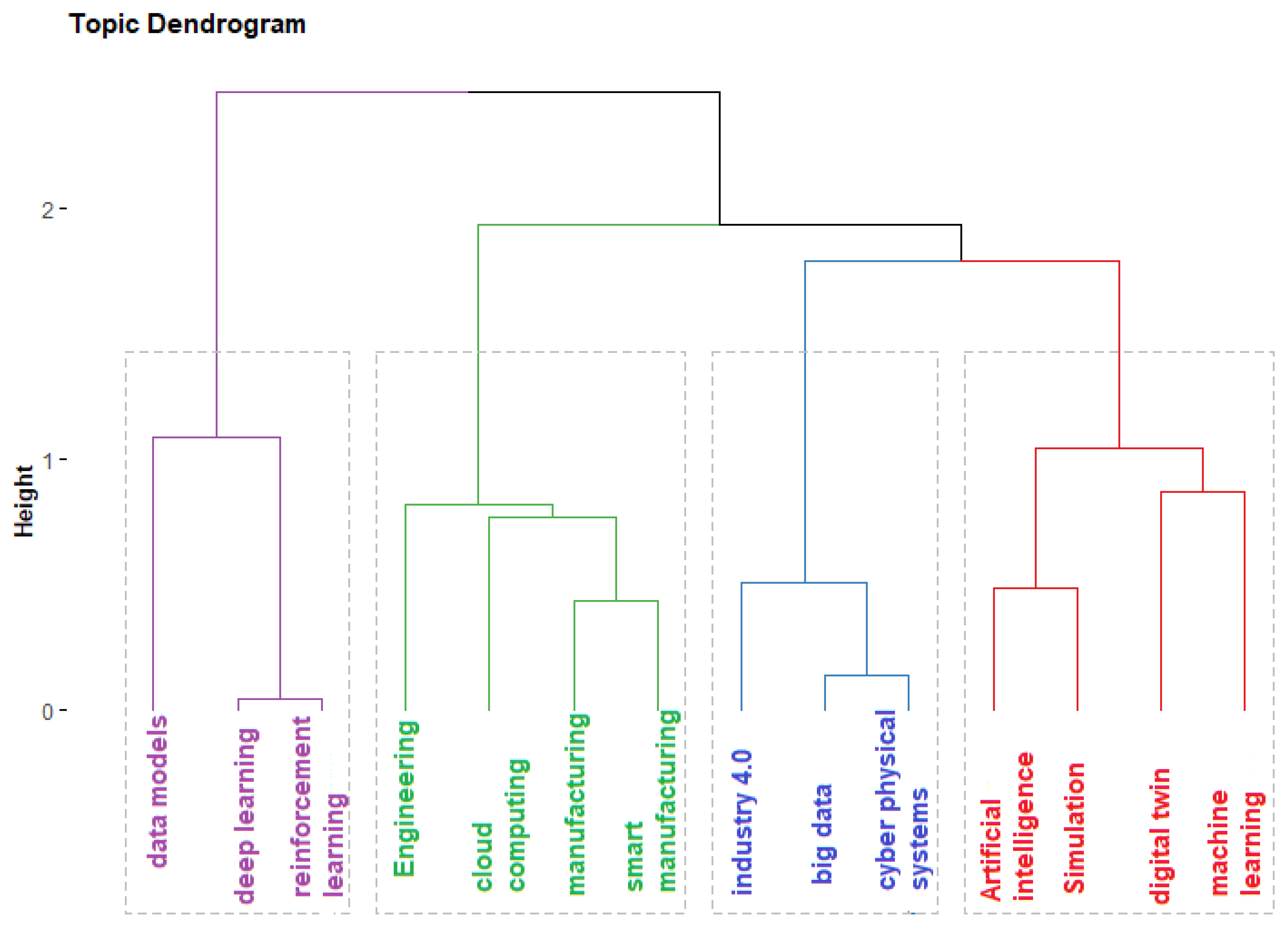

4.1.1. Topic Cluster

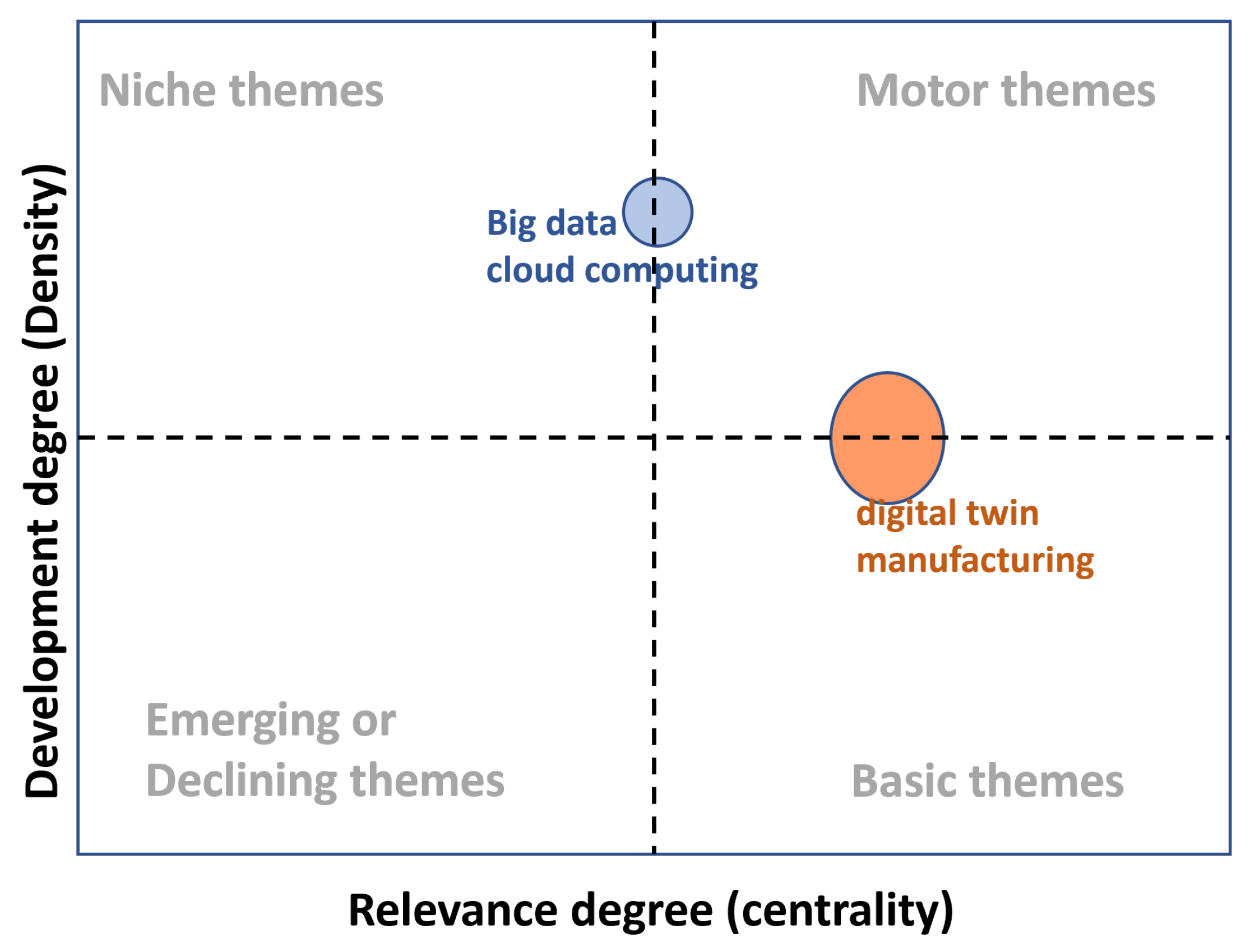

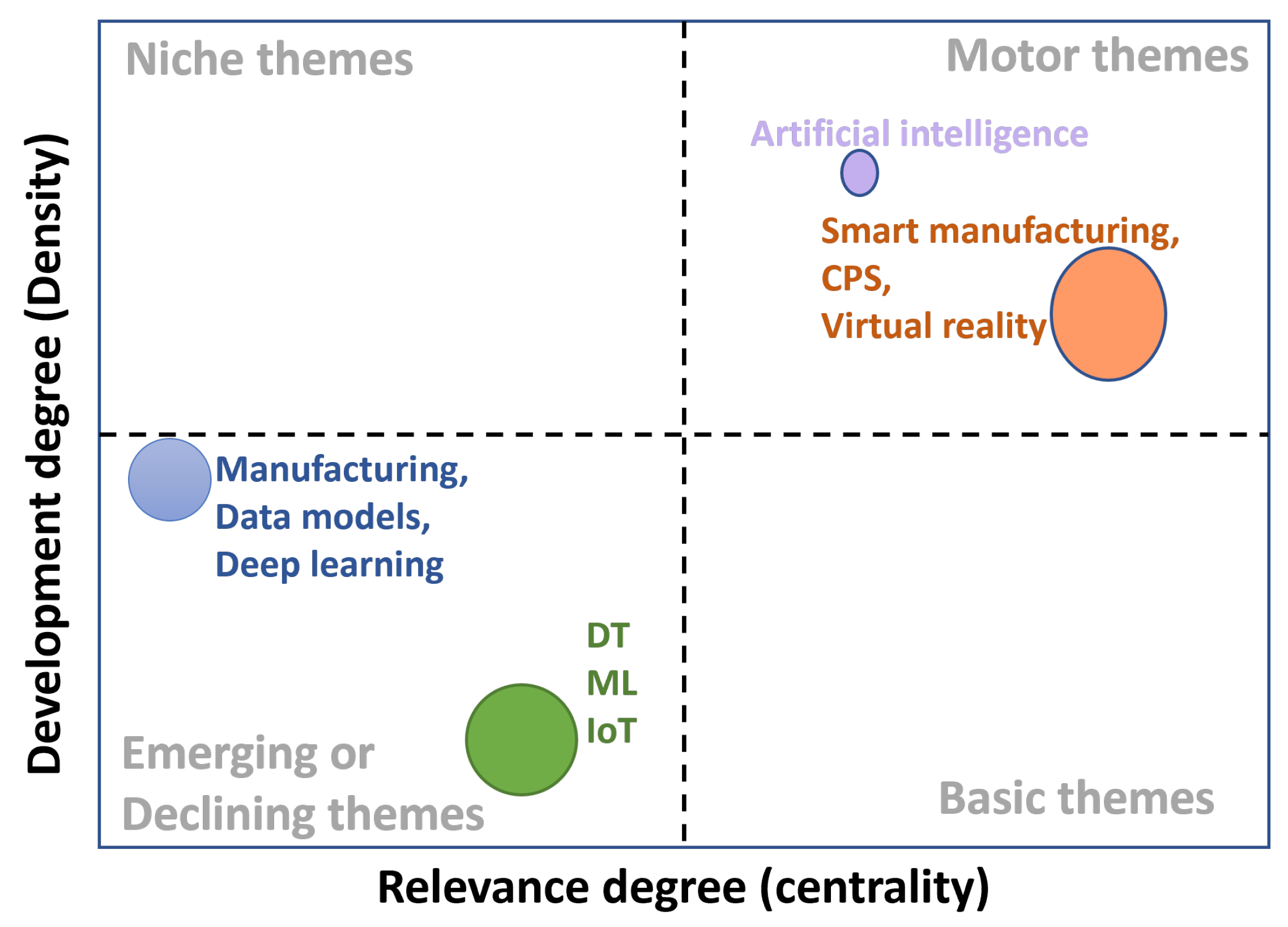

4.1.2. Thematic Evolution

- Upper-right quadrant: motor themes—higher values of development and relevance define motor themes. These themes are well-developed and relevant to the domain.

- Lower-right quadrant: basic themes—higher values of relevance and lower values of development define basic themes. These themes are significant for the domain; however, they are not well-developed.

- Lower-left quadrant: emerging or declining themes—lower values for relevance and development define emerging or declining themes. These themes are not directly connected to the domain, and full development has not been achieved.

- Upper-left quadrant: very specialized/niche themes—lower-relevance values and higher development values define niche themes. These themes are highly developed, but their relevance to the domain is marginal.

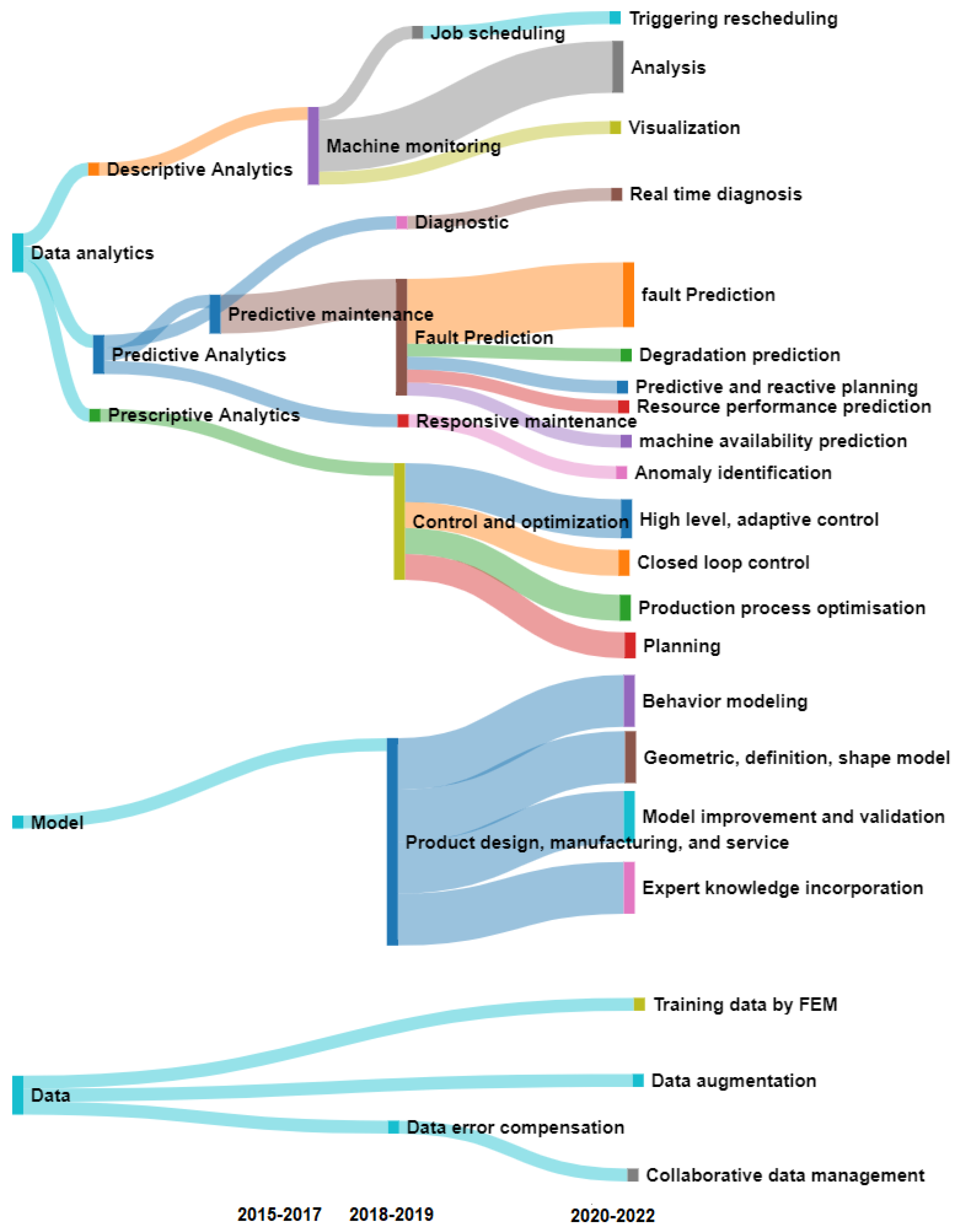

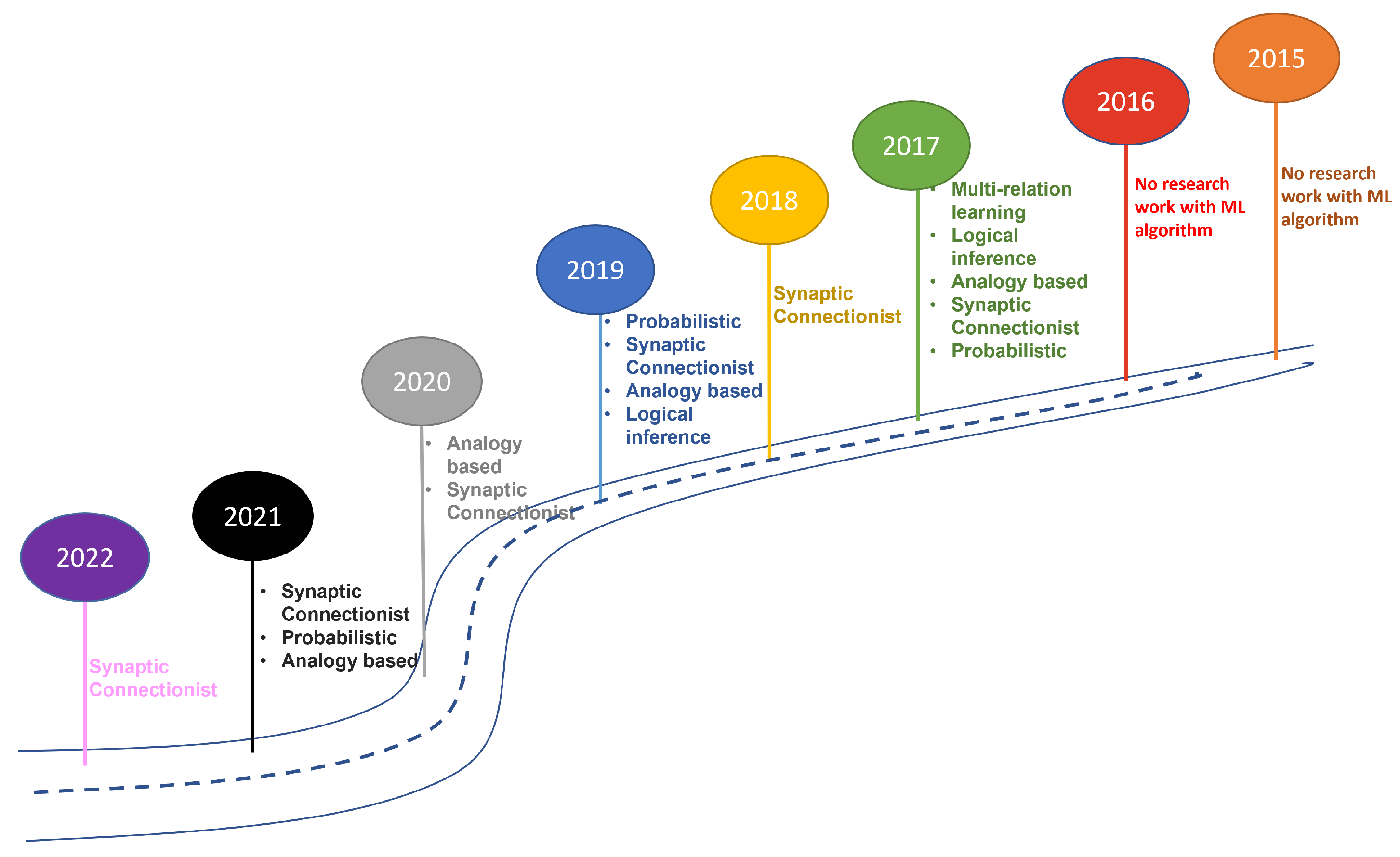

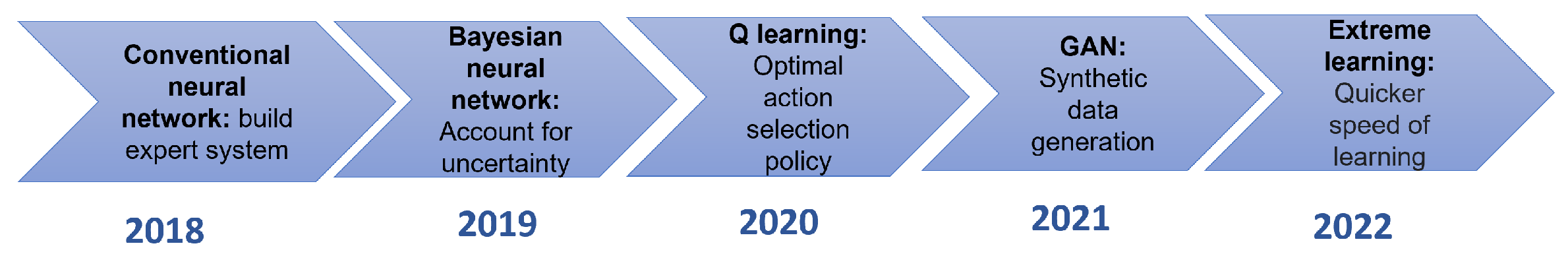

4.2. Second Research Question

- Data analytics.

- -

- Predictive data analytics.

- -

- Descriptive data analytics.

- -

- Prescriptive data analytics.

- Model-based task.

- Data-based task.

4.3. Third Research Question

4.4. Fourth Research Question

- Data analytics.

- -

- Predictive data analytics.

- -

- Prescriptive data analytics.

- Model-based task.

- Data-based task.

5. Discussion and Conclusions

- Based on the bibliometric analysis, it can be concluded that there has been a reciprocal increase in interest in ML-based DT. However, the improvements introduced in ML-based DT are focused primarily on the ML part rather than complete DT architecture or manufacturing processes. A collaborative work between authors with ML and manufacturing backgrounds can create a consolidated ML-based DT for use in manufacturing.

- It can also be concluded that ML tasks are becoming more advanced over time in ML-based DT. The sole application of ML in manufacturing is no longer considered as a significant contribution to the state of the art. However, the advancement in ML tasks needs quantification and comparison with other domains such as healthcare.

- Additionally, it can be concluded that ML acts as the main player in cyberphysical system intelligence enhanced by ML-based DT. ML has potential in enhancing each dimension of DT. In the future, industrial application and encapsulation of dynamic processes will be focused on primarily.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Definitions

References

- Mazhar Rathore, M.; Shah, S.A.; Shukla, D.; Bentafat, E.; Bakiras, S. The Role of AI, Machine Learning, and Big Data in Digital Twinning: A Systematic Literature Review, Challenges, and Opportunities. IEEE Access 2021, 9, 32030–32052. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Digital Twin Driven Smart Manufacturing; Academic Press: London, UK, 2019. [Google Scholar]

- Luo, W.; Hu, T.; Zhu, W.; Tao, F. Digital twin modeling method for CNC machine tool. In Proceedings of the IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–4. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Kong, Z.; Liu, X.; Snoussi, H.; Lv, H. Digital twin improved via visual question answering for vision-language interactive mode in human-machine collaboration. J. Manuf. Syst. 2021, 58, 261–269. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Li, D.; Wang, S.; Liu, C.; Abbas, H.; Vasilakos, A.V. A Manufacturing Big Data Solution for Active Preventive Maintenance. IEEE Trans. Ind. Inform. 2017, 13, 2039–2047. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Yan, Q. Digital twin-driven cyber-physical production system towards smart shop-floor. J. Ambient. Intell. Humaniz. Comput. 2018, 10, 4439–4453. [Google Scholar] [CrossRef]

- Cunbo, Z.; Liu, J.; Xiong, H. Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar]

- Piros, A.; Trautmann, L.; Baka, E. Error handling method for digital twin-based plasma radiation detection. Fusion Eng. Des. 2020, 156, 111592. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital twin—The simulation aspect. In Mechatronic Futures; Springer International Publishing: Cham, Switzerland, 2016; pp. 59–74. [Google Scholar]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems; Springer International Publishing: Cham, Switzerland, 2016; pp. 85–113. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Reifsnider, K.; Majumdar, P. Multiphysics stimulated simulation digital twin methods for fleet management. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; p. 1578. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. In Proceedings of the IFAC PapersOnLine, Shenyang, China, 25–27 July 2018; Volume 51, pp. 1016–1022. [Google Scholar]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Keele, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; Report; Citeseer: Princeton, NJ, USA, 2007. [Google Scholar]

- Busalim, A.H. Understanding social commerce: A systematic literature review and directions for further research. Int. J. Inf. Manag. 2016, 36, 1075–1088. [Google Scholar] [CrossRef]

- Zhang, M.; Tao, F.; Nee, A. Digital Twin Enhanced Dynamic Job-Shop Scheduling. J. Manuf. Syst. 2021, 58, 146–156. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Deng, Y.; Wang, C.; Snoussi, H.; Tao, F. Digital twin for human-machine interaction with convolutional neural network. Int. J. Comput. Integr. Manuf. 2021, 34, 888–897. [Google Scholar] [CrossRef]

- Zhang, S.; Kang, C.; Liu, Z.; Wu, J.; Ma, C. A Product Quality Monitor Model With the Digital Twin Model and the Stacked Auto Encoder. IEEE Access 2020, 8, 113826–113836. [Google Scholar] [CrossRef]

- Gaikwad, A.; Yavari, R.; Montazeri, M.; Cole, K.; Bian, L.; Rao, P. Toward the digital twin of additive manufacturing: Integrating thermal simulations, sensing, and analytics to detect process faults. IISE Trans. 2020, 52, 1204–1217. [Google Scholar] [CrossRef]

- Lugaresi, G.; Matta, A. Automated manufacturing system discovery and digital twin generation. J. Manuf. Syst. 2021, 59, 51–66. [Google Scholar] [CrossRef]

- Cronrath, C.; Aderiani, A.R.; Lennartson, B. Enhancing Digital Twins through Reinforcement Learning. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 293–298. [Google Scholar]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 19990–19999. [Google Scholar] [CrossRef]

- Lacueva-Perez, F.J.; Hermawati, S.; Amoraga, P.; Salillas-Martinez, R.; Del Hoyo Alonso, R.; Lawson, G. SHION: Towards An Interactive Digital Twin Supporting Shopfloor Operations on Real Time. IEEE Internet Comput. 2020. [Google Scholar] [CrossRef]

- Callon, M.; Courtial, J.P.; Laville, F. Co-word analysis as a tool for describing the network of interactions between basic and technological research: The case of polymer chemsitry. Scientometrics 1991, 22, 155–205. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. An approach for detecting, quantifying, and visualizing the evolution of a research field: A practical application to the Fuzzy Sets Theory field. J. Inf. 2011, 5, 146–166. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Ali, M.A.; Guan, Q.; Umer, R.; Cantwell, W.J.; Zhang, T. Deep learning based semantic segmentation of mu CT images for creating digital material twins of fibrous reinforcements. Compos. Part A-Appl. Sci. Manuf. 2020, 139, 106131. [Google Scholar] [CrossRef]

- Zotov, E.; Tiwari, A.; Kadirkamanathan, V. Conditional StyleGAN modelling and analysis for a machining digital twin. Integr. Comput. Aided Eng. 2021, 28, 399–415. [Google Scholar] [CrossRef]

- Li, H.; Yang, D.; Cao, H.; Ge, W.; Chen, E.; Wen, X.; Li, C. Data-driven hybrid petri-net based energy consumption behaviour modelling for digital twin of energy-efficient manufacturing system. Energy 2022, 239, 122178. [Google Scholar] [CrossRef]

- Ringsquandl, M.; Lamparter, S.; Lepratti, R.; Kroeger, P. Knowledge fusion of manufacturing operations data using representation learning. In Advances in Production Management Systems: The Path to Intelligent, Collaborative and Sustainable Manufacturing; Lodding, H., Riedel, R., Thoben, K., VonCieminski, G., Kiritsis, D., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 514, pp. 302–310. [Google Scholar]

- Stieber, S.; Hoffmann, A.; Schiendorfer, A.; Reif, W.; Beyrle, M.; Faber, J.; Richter, M.; Sause, M. Towards real-time process monitoring and machine learning for manufacturing composite structures. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), New York, NY, USA, 8–11 September 2020; pp. 1451–1454. [Google Scholar]

- Borangiu, T.; Trentesaux, D.; Leitão, P.; Cardin, O.; Lamouri, S. Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future: Proceedings of SOHOMA 2020, Paris, France, 1–2 October 2020; Springer: Berlin/Heidelberg, Germany, 2021; Volume 952. [Google Scholar]

- Borangiu, T.; Răileanu, S.; Silişteanu, A.; Anton, S.; Anton, F. Smart manufacturing control with cloud-embedded digital twins. In Proceedings of the 24th International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 8–10 October 2020; pp. 915–920. [Google Scholar]

- Park, K.T.; Son, Y.H.; Ko, S.W.; Noh, S.D. Digital Twin and Reinforcement Learning-Based Resilient Production Control for Micro Smart Factory. Appl. Sci. 2021, 11, 2977. [Google Scholar] [CrossRef]

- Selvaraj, H.; Chmaj, G.; Zydek, D. Lecture Notes in Networks and Systems. In Proceedings of the 27th International Conference on Systems Engineering, ICSEng 2020, Las Vegas, NV, USA, 25–27 August 2020; Springer: Berlin/Heidelberg, Germany, 2021; Volume 182. [Google Scholar]

- Vrabic, R.; Erkoyuncu, J.A.; Farsi, M.; Ariansyah, D. An intelligent agent-based architecture for resilient digital twins in manufacturing. CIRP Ann. Manuf. Technol. 2021, 70, 349–352. [Google Scholar] [CrossRef]

- Liu, J.; Gui, H.; Ma, C. Digital twin system of thermal error control for a large-size gear profile grinder enabled by gated recurrent unit. J. Ambient. Intell. Humaniz. Comput. 2021. [Google Scholar] [CrossRef]

- Sommer, M.; Stjepandic, J.; Stobrawa, S. Automated generation of a digital twin of a manufacturing system by using scan and convolutional neural networks. In Proceedings of the 27th ISTE International Conference on Transdisciplinary Engineering, Warsaw, Poland, 1–10 July 2020; Volume 12, p. 363. [Google Scholar]

- Liu, C.; Le Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2022, 62, 857–874. [Google Scholar] [CrossRef]

- Lin, T.Y.; Jia, Z.; Yang, C.; Xiao, Y.; Lan, S.; Shi, G.; Zeng, B.; Li, H. Evolutionary digital twin: A new approach for intelligent industrial product development. Adv. Eng. Inform. 2021, 47, 101209. [Google Scholar] [CrossRef]

- Qiao, Q.; Wang, J.; Ye, L.; Gao, R.X. Digital Twin for Machining Tool Condition Prediction. In Proceedings of the 52nd CIRP Conference on Manufacturing Systems (CMS), Ljubljana, Slovenia, 12–14 June 2019; pp. 1388–1393. [Google Scholar] [CrossRef]

- Scheffel, R.M.; Frohlich, A.A.; Silvestri, M. Automated fault detection for additive manufacturing using vibration sensors. Int. J. Comput. Integr. Manuf. 2021, 34, 500–514. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot.-Comput.-Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Eirinakis, P.; Kalaboukas, K.; Lounis, S.; Mourtos, I.; Rožanec, J.M.; Stojanovic, N.; Zois, G. Enhancing Cognition for Digital Twins. In Proceedings of the IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020; pp. 1–7. [Google Scholar]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G.; Hu, J.; Li, J. Deep learning-enabled intelligent process planning for digital twin manufacturing cell. Knowl.-Based Syst. 2020, 191, 105247. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-driven digital twin manufacturing cell towards intelligent manufacturing. Int. J. Prod. Res. 2020, 58, 1034–1051. [Google Scholar] [CrossRef]

- Jaensch, F.; Csiszar, A.; Scheifele, C.; Verl, A. Digital Twins of Manufacturing Systems as a Base for Machine Learning. In Proceedings of the 25th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Stuttgart, Germany, 20–22 November 2018; pp. 7–12. [Google Scholar]

- Lee, J.; Azamfar, M.; Singh, J.; Siahpour, S. Integration of digital twin and deep learning in cyber-physical systems: Towards smart manufacturing. IET Collab. Intell. Manuf. 2020, 2, 34–36. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Chhetri, S.R.; Faezi, S.; Canedo, A.; Al Faruque, M.A. QUILT: Quality inference from living digital twins in IoT-enabled manufacturing systems. In Proceedings of the International Conference on Internet of Things Design and Implementation (IoTDI), Montreal, QC, Canada, 15–18 April 2019. [Google Scholar] [CrossRef]

- Latif, H.; Shao, G.; Starly, B. A Case Study of Digital Twin for a Manufacturing Process Involving Human Interactions. In Proceedings of the 2020 Winter Simulation Conference (WSC), Orlando, FL, USA, 14–18 December 2020; pp. 2659–2670. [Google Scholar]

- Ladj, A.; Wang, Z.; Meski, O.; Belkadi, F.; Ritou, M.; Da Cunha, C. A knowledge-based Digital Shadow for machining industry in a Digital Twin perspective. J. Manuf. Syst. 2021, 58, 168–179. [Google Scholar] [CrossRef]

- Mueller-Zhang, Z.; Antonino, P.O.; Kuhn, T. Integrated Planning and Scheduling for Customized Production using Digital Twins and Reinforcement Learning. IFAC Pap. 2021, 54, 408–413. [Google Scholar] [CrossRef]

- Ren, Z.; Wan, J. Strengthening Digital Twin Applications based on Machine Learning for Complex Equipment. In Proceedings of the Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 1–5 February 2021; pp. 609–614. [Google Scholar]

- Friederich, J.; Francis, D.P.; Lazarova-Molnar, S.; Mohamed, N. A framework for data-driven digitial twins of smart manufacturing systems. Comput. Ind. 2022, 136, 103586. [Google Scholar] [CrossRef]

- Ren, Z.; Wan, J.; Deng, P. Machine-Learning-Driven Digital Twin for Lifecycle Management of Complex Equipment. IEEE Trans. Emerg. Top. Comput. 2022, 10, 9–22. [Google Scholar] [CrossRef]

- Schönfuß, B.; McFarlane, D.; Athanassopoulou, N.; Salter, L.; Silva, L.d.; Ratchev, S. Prioritising low cost digital solutions required by manufacturing SMEs: A shoestring approach. In Proceedings of the International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing, Paris, France, 1–2 October 2019; pp. 290–300. [Google Scholar]

- Farsi, M.; Daneshkhah, A.; Hosseinian-Far, A.; Jahankhani, H. Digital Twin Technologies and Smart Cities; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Abideen, A.Z.; Sundram, V.P.K.; Pyeman, J.; Othman, A.K.; Sorooshian, S. Digital Twin Integrated Reinforced Learning in Supply Chain and Logistics. Logistics 2021, 5, 84. [Google Scholar] [CrossRef]

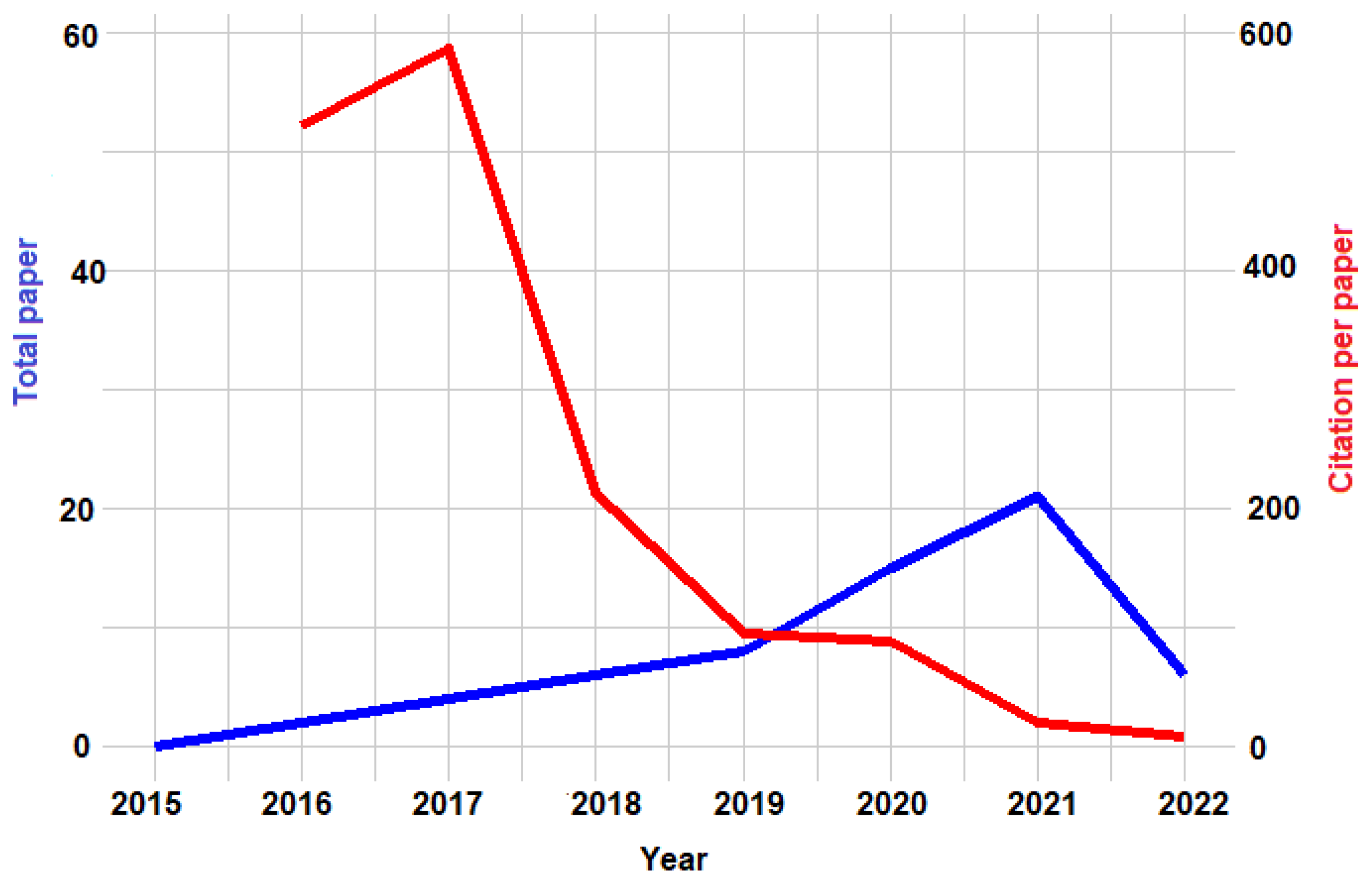

| Timespan | 2015–2022 |

|---|---|

| Documents | 71 |

| Sources | 47 |

| Annual Growth Rate % | 20.09 |

| Document Average Age | 2.11 |

| Average citations per documents | 104.5 |

| Average citations per year per document | 27.56 |

| Keywords Plus (ID) | 61 |

| Author’s Keywords (DE) | 249 |

| Authors | 246 |

| Authors of single-authored documents | 3 |

| Authors of multi-authored documents | 68 |

| Docs with international collab % | 12.68 |

| DT 8 Dimensions | Dimension Criteria | ML Contributing to DT Dimensions |

|---|---|---|

| Integration breadth | Interaction of physical world with virtual world in the form of data acquisition and scheduling | Data acquisition: acquire process knowledge. Scheduling: schedule manufacturing tasks, identify optimal actions [53] |

| Connectivity mode | Context-aware, bidirectional or unidirectional connection in between physical and virtual word | Context-aware connection: fault diagnosis, deep transfer learning (DFDD), real-time monitoring, and predictive maintenance. [30] Real-time controlling instruction [34], optimal process plan. Bidirectional connection: real-time synchronisation [54] |

| Update frequency | Event-driven, hourly, daily or monthly update of digital model | Event-driven update: real-time controlling instruction [34] |

| CPS intelligence | Cyberphysical System enhanced by AI, cognition, and automation | AI: rule mining, data fusion [12], fault prediction [3], predicting energy efficiency [37], predictive maintenance, feature extraction [30], compensating data errors in DT [29], failure prediction [31], prediction [39], resource performance prediction [41], cutting tool wear prediction [51], prediction [39]; Cognition and automation: product quality inference, accuracy evaluation [59], layer defect analysis [47], optimal process plan [54], improved decision [60], process-parallel monitoring [46], providing cognitive abilities [52], production quality classification [26], real-time monitoring [30], visualization [39], production control and resource maintenance [41], classification [27], behavior analysis [25], adaptively control manipulated variables [53], data analytics [61], tool wear analysis [24], optimized process plans and workflows [62], and visualization [39]. |

| Simulation capabilities | Simulation of physical process on ad hoc or continuous basis | process simulation [63], automated simulation model generation, [64] |

| Digital model richness | Robustness, resilience, self-adaption, fidelity of virtual model | Robustness, resilience, self-adaption, fidelity [44], DT fidelity [53], fidelity [61], DT behaviour model [37], high-fidelity of DTs [64] |

| Human interaction | Bridging human and machine | Human–machine collaboration [5], bridges a human user and robot [25] |

| Product life-cycle | Product design, manufacturing and service | Service stage: service, data analytics [38], Full product life-cycle management [37,63,65], Manufacturing stage: fault prediction [3], predicting energy efficiency [37], predictive maintenance, feature extraction [30] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheuly, S.S.; Ahmed, M.U.; Begum, S. Machine-Learning-Based Digital Twin in Manufacturing: A Bibliometric Analysis and Evolutionary Overview. Appl. Sci. 2022, 12, 6512. https://doi.org/10.3390/app12136512

Sheuly SS, Ahmed MU, Begum S. Machine-Learning-Based Digital Twin in Manufacturing: A Bibliometric Analysis and Evolutionary Overview. Applied Sciences. 2022; 12(13):6512. https://doi.org/10.3390/app12136512

Chicago/Turabian StyleSheuly, Sharmin Sultana, Mobyen Uddin Ahmed, and Shahina Begum. 2022. "Machine-Learning-Based Digital Twin in Manufacturing: A Bibliometric Analysis and Evolutionary Overview" Applied Sciences 12, no. 13: 6512. https://doi.org/10.3390/app12136512

APA StyleSheuly, S. S., Ahmed, M. U., & Begum, S. (2022). Machine-Learning-Based Digital Twin in Manufacturing: A Bibliometric Analysis and Evolutionary Overview. Applied Sciences, 12(13), 6512. https://doi.org/10.3390/app12136512