Triaxial Compression Fracture Characteristics and Constitutive Model of Frozen–Thawed Fissured Quasi-Sandstone

Abstract

:1. Introduction

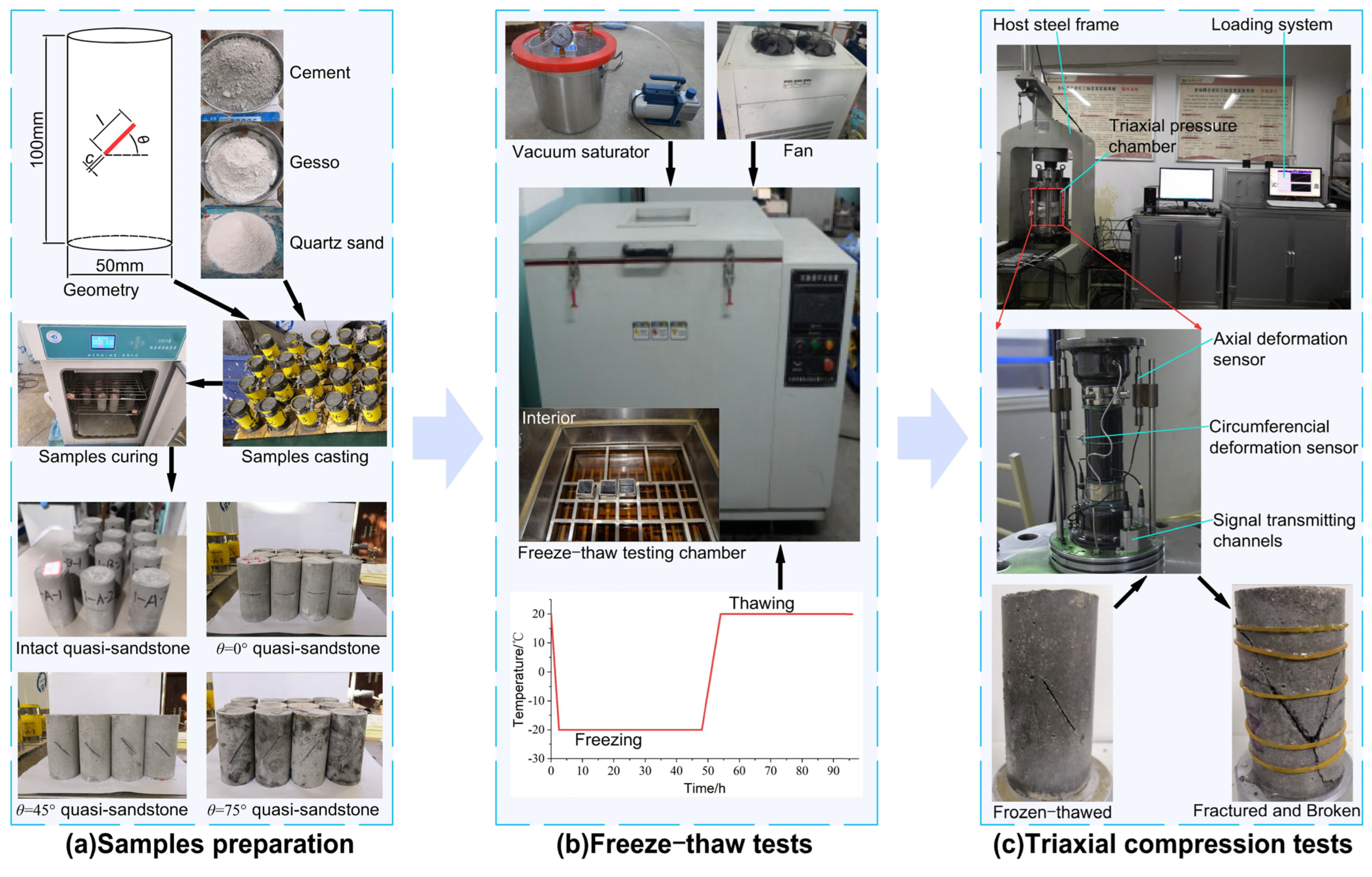

2. Materials and Method

2.1. Quasi-Sandstone Materials

2.2. Preparation of Intact and Single-Fissured Samples

2.3. Basic Physical and Mechanical Parameter Test

2.4. Testing Scheme

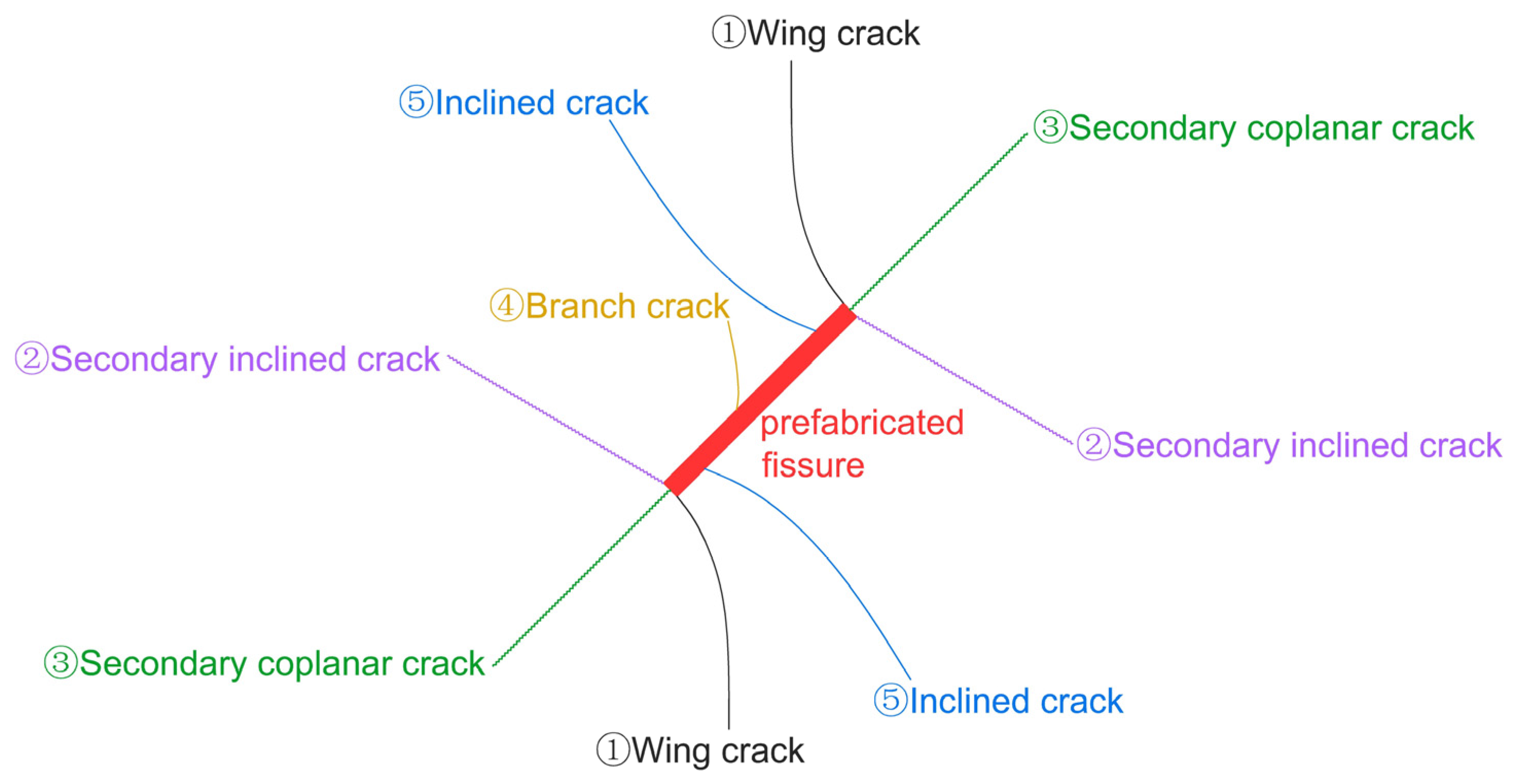

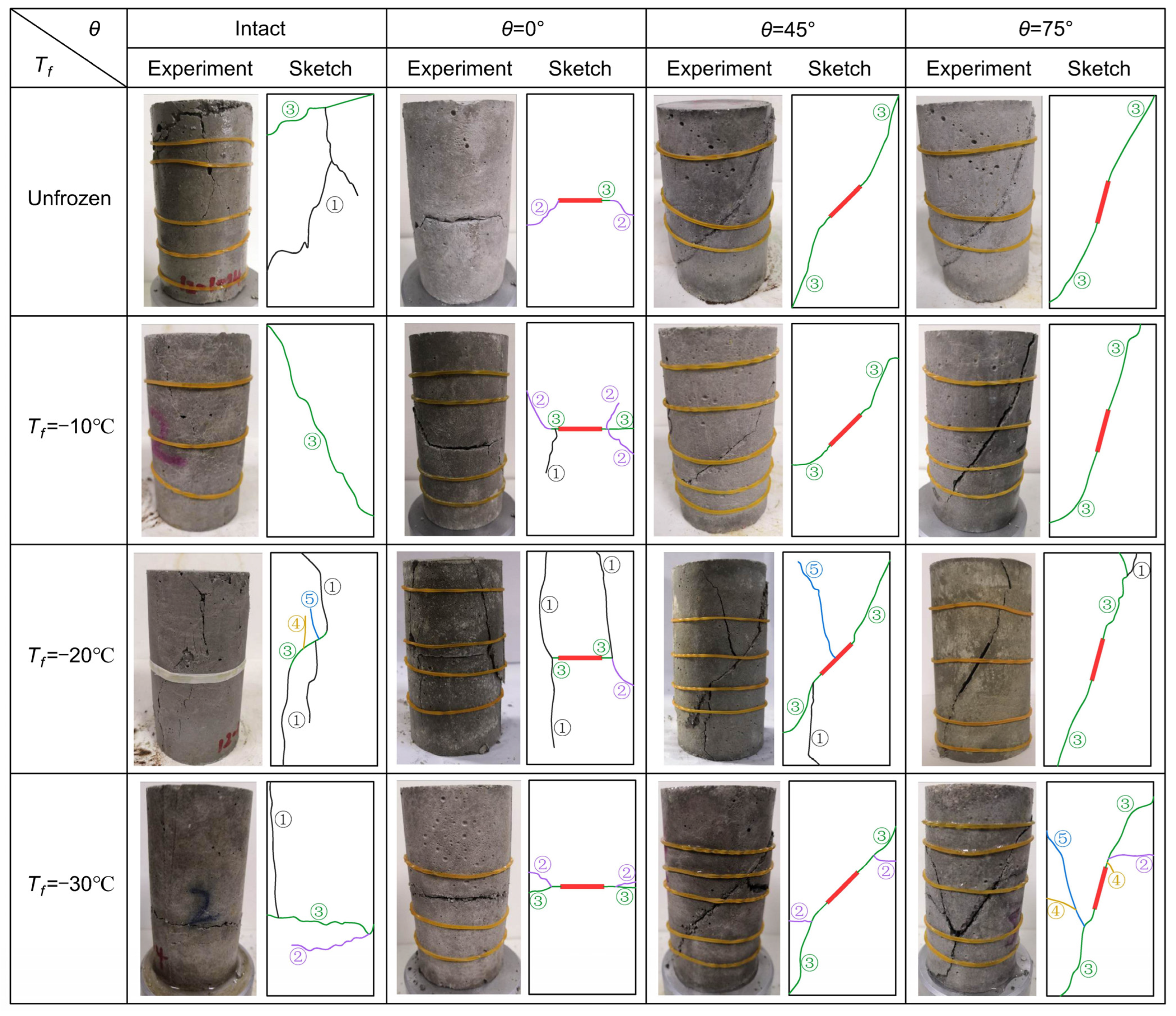

3. Fracture Characteristics

3.1. Damage Behaviour after Freezing–Thawing

3.2. Fracture Characteristics after Freeze–Thaw and Triaxial Compression

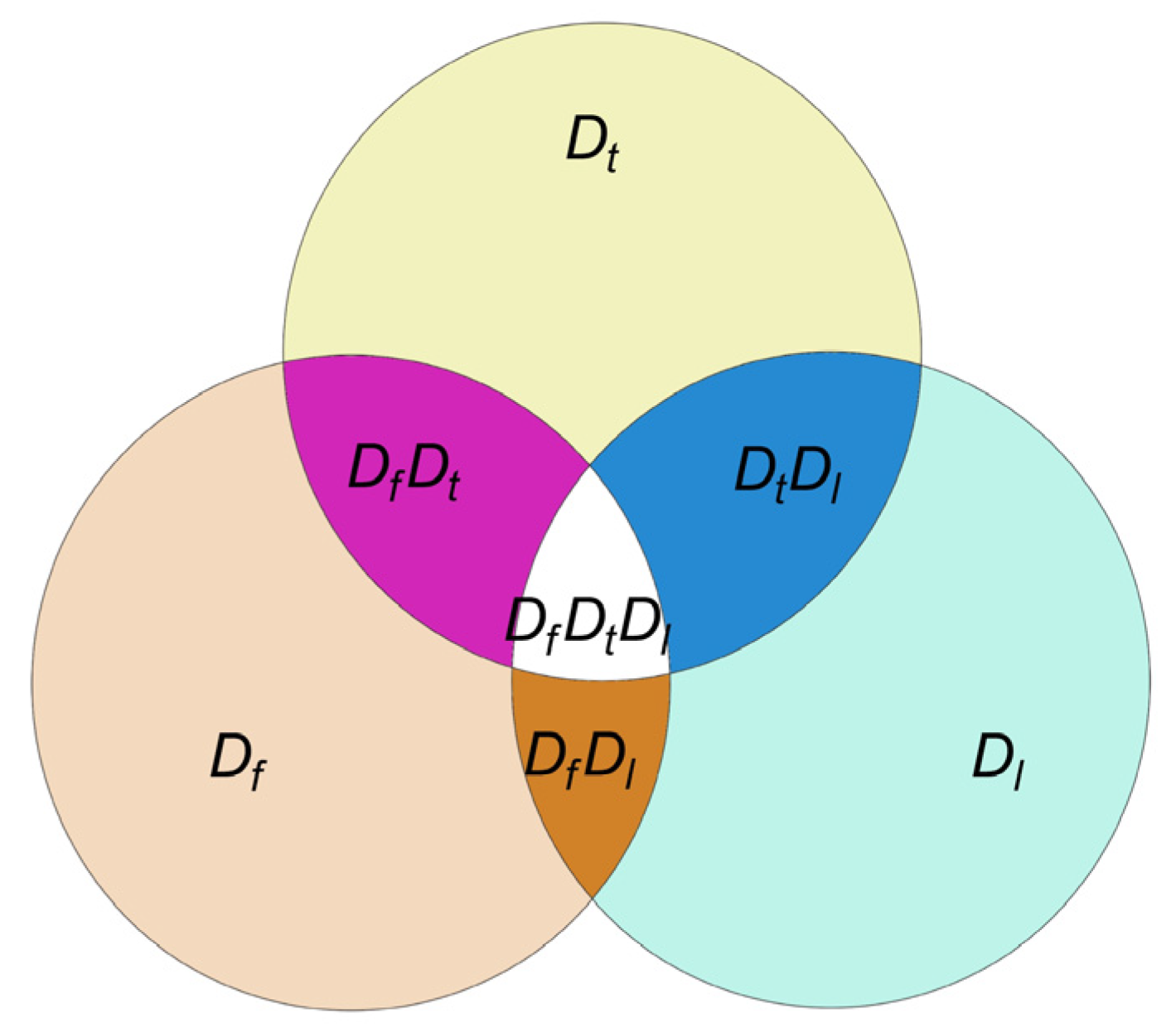

4. Damage Constitutive Model and Damage Evolution Law

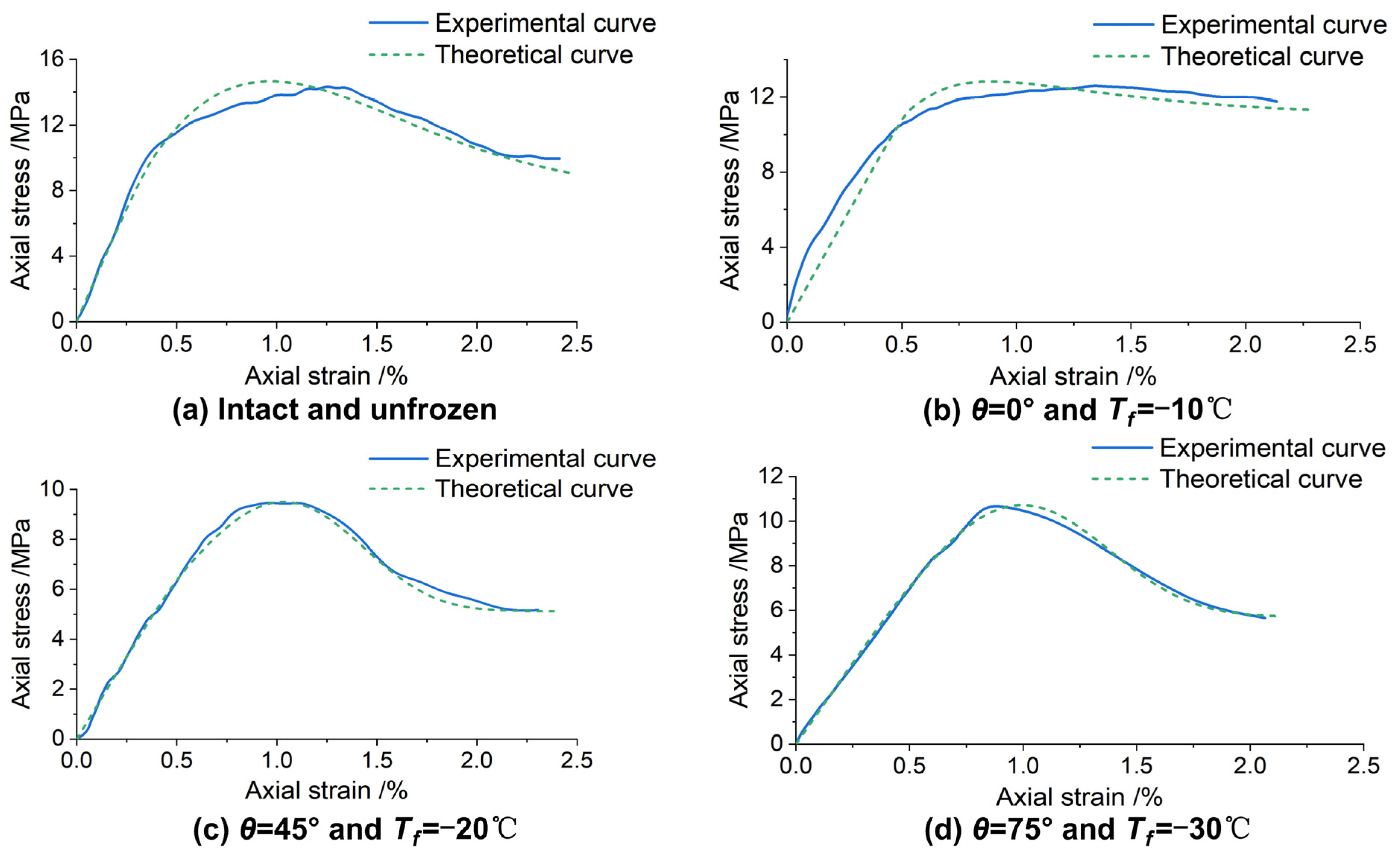

4.1. Constitutive Model of Single-Fissured Quasi-Sandstone Subjected to Freezing–Thawing and Load Considering Residual Strength

4.1.1. Establishment of Constitutive Equation

4.1.2. Determining Model Parameters

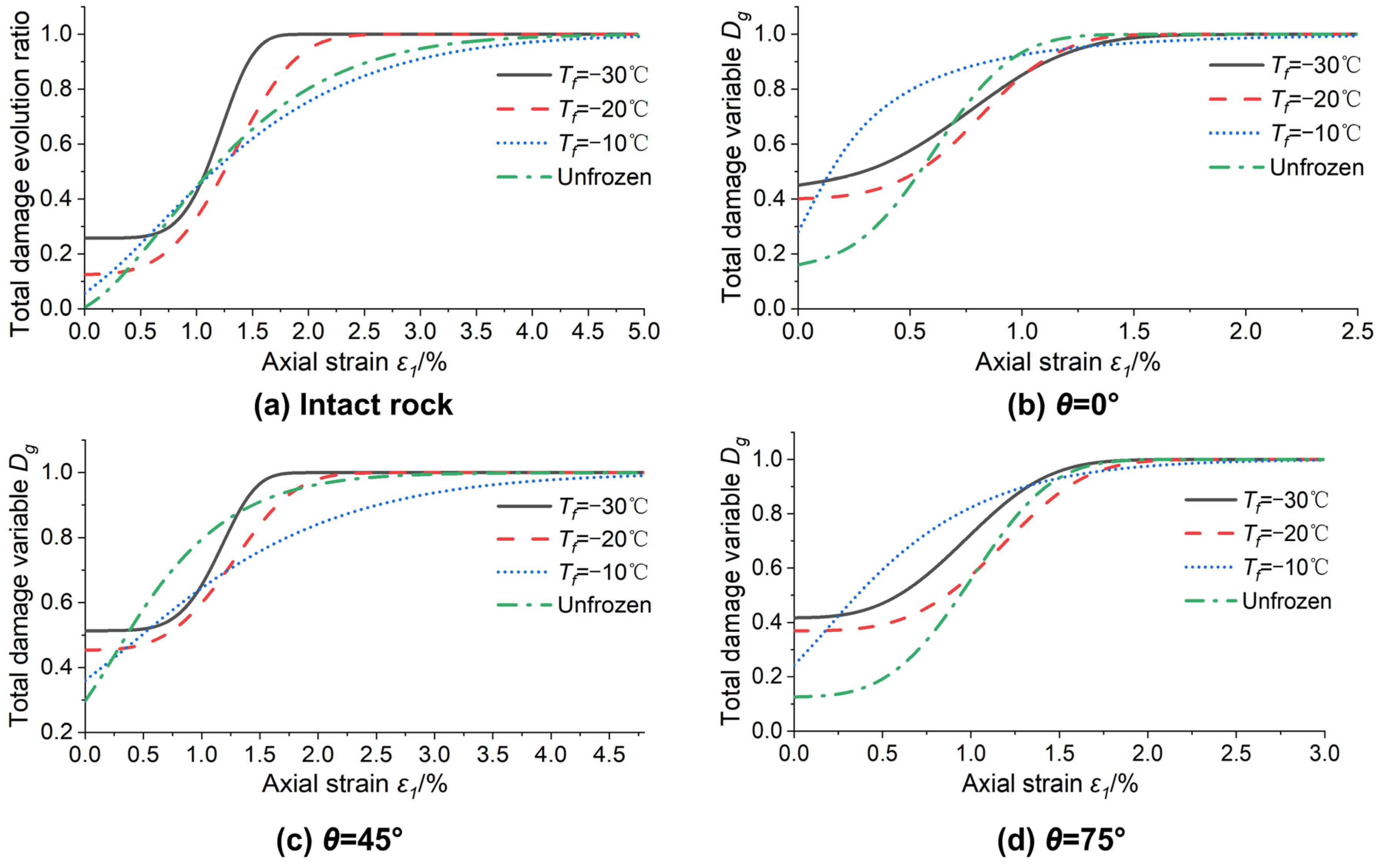

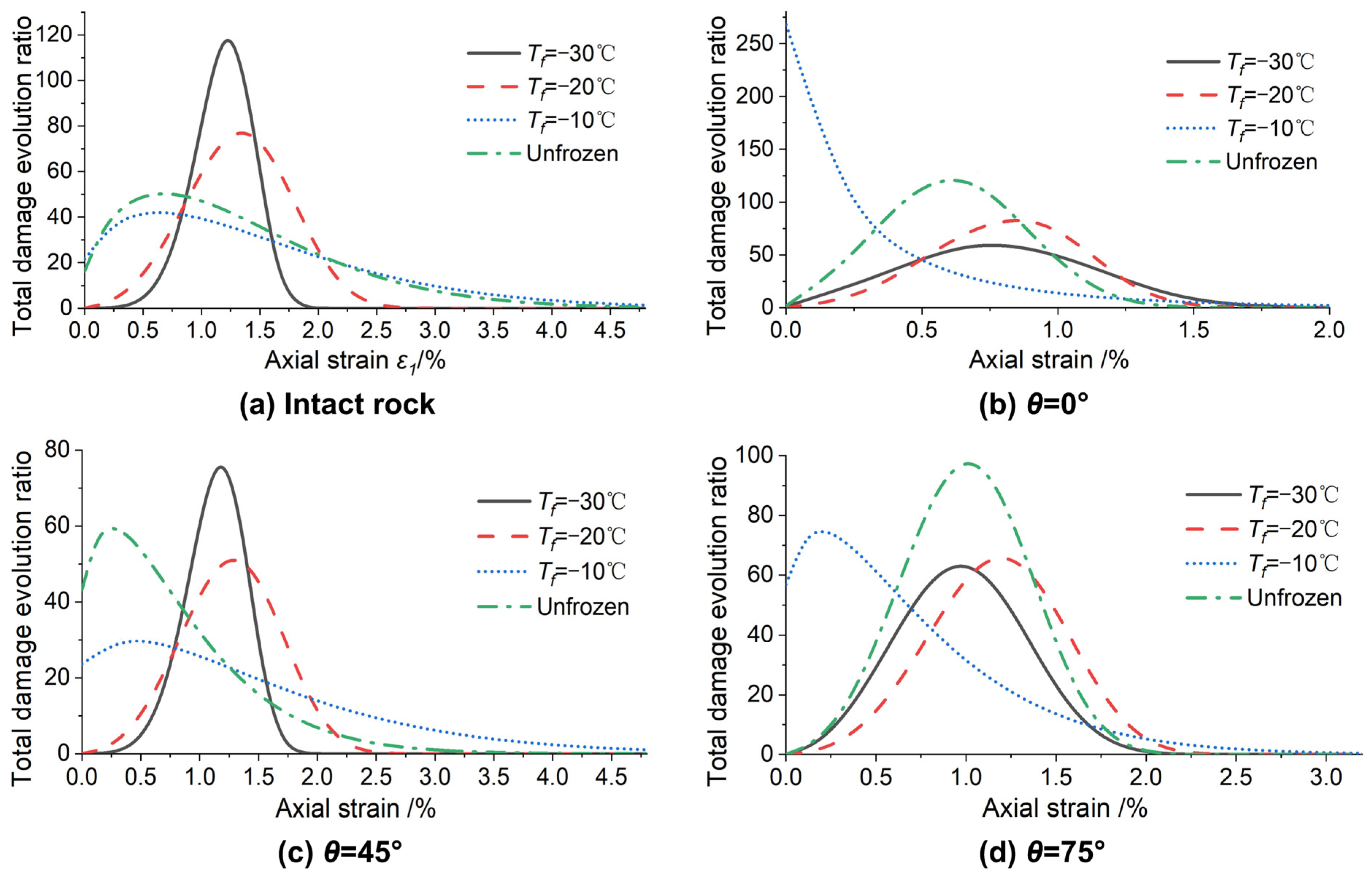

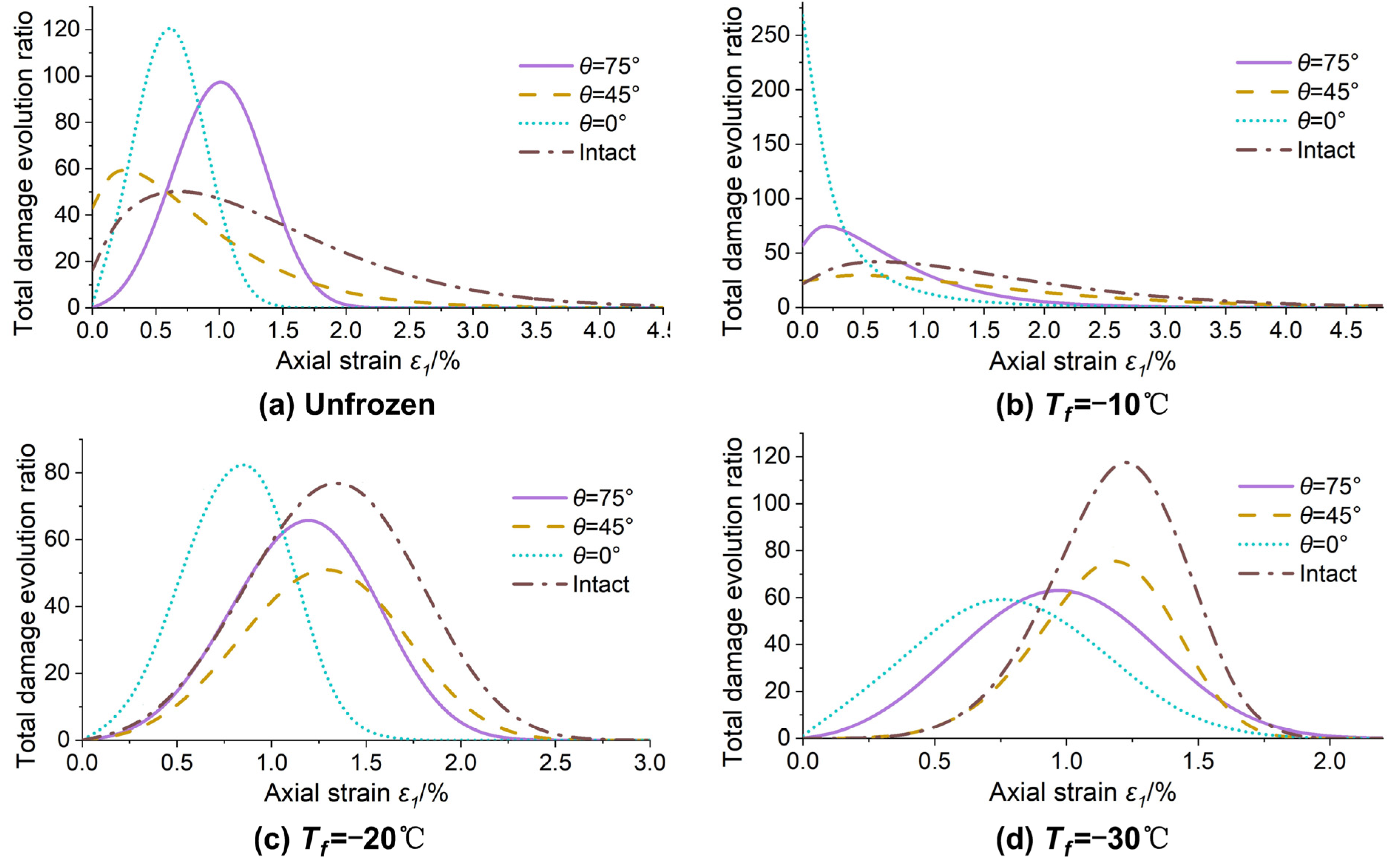

4.2. Evolution Law of Loading Damage of Single-Fissured Quasi-Sandstone after Freezing–Thawing

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cai, H.B.; Yao, F.X.; Hong, R.B.; Lin, J.; Zeng, K. Multi-loop pipe freezing optimization of deep shaft considering seepage effect. Arab. J. Geosci. 2022, 15, 153. [Google Scholar] [CrossRef]

- Ren, J.X.; Sun, J.L.; Zhang, K.; Wang, J.; Wang, D.X. Mechanical properties and temperature field of inclined frozen wall in water-rich sand stratum. Rock Soil Mech. 2017, 38, 1405–1412. [Google Scholar]

- Alzoubi, M.A.; Xu, M.H.; Hassani, F.P.; Poncet, S.; Sasmito, A.P. Artificial ground freezing: A review of thermal and hydraulic aspects. Tunn. Undergr. Space Technol. 2020, 104, 103534. [Google Scholar] [CrossRef]

- Kodama, J.; Goto, T.; Fujii, Y.; Hagan, P. The effects of water content, temperature and loading rate on strength and failure process of frozen rocks. Int. J. Rock Mech. Min. Sci. 2013, 62, 1–13. [Google Scholar] [CrossRef]

- Liu, B.; Sun, Y.D.; Wang, J.; Zhang, G. Characteristic analysis of crack initiation and crack damage stress of sandstone and mudstone under low-temperature condition. J. Cold Reg. Eng. 2020, 34, 04020020. [Google Scholar] [CrossRef]

- Wang, P.S.; Zhou, G.Q. Frost-heaving pressure in geotechnical engineering materials during freezing process. Int. J. Min. Sci. Technol. 2018, 28, 287–296. [Google Scholar] [CrossRef]

- Levin, L.; Golovatyi, I.; Zaitsev, A.; Pugin, A.; Semin, M. Thermal monitoring of frozen wall thawing after artificial ground freezing: Case study of Petrikov Potash Mine. Tunn. Undergr. Space Technol. 2021, 107, 103685. [Google Scholar] [CrossRef]

- Sun, J.L.; Chen, X.Z.; Qiu, M.M.; Cao, X.Y.; Chen, S.J. Physical model test of artificial freezing-inclined shaft. Adv. Civ. Eng. 2021, 2021, 6640722. [Google Scholar] [CrossRef]

- Wu, T.; Zhou, X.M.; Zhang, L.G.; Zhang, X.J.; He, X.N. Theory and technology of real-time temperature field monitoring of vertical shaft frozen wall under high-velocity groundwater conditions. Cold Reg. Sci. Technol. 2021, 189, 103337. [Google Scholar] [CrossRef]

- Lin, H.; Lei, D.X.; Zhang, C.S.; Wang, Y.X.; Zhao, Y.L. Deterioration of non-persistent rock joints: A focus on impact of freeze–thaw cycles. Int. J. Rock Mech. Min. Sci. 2020, 135, 104515. [Google Scholar] [CrossRef]

- Jia, H.L.; Ding, S.; Wang, Y.; Zi, F.; Sun, Q.; Yang, G.S. An NMR-based investigation of pore water freezing process in sandstone. Cold Reg. Sci. Technol. 2019, 168, 102893. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Y.J.; Liu, N.; Han, Y.H.; Li, D.Y.; Deng, H.L. Investigation of pore structure changes in Mesozoic water-rich sandstone induced by freeze-thaw process under different confining pressures using digital rock technology. Cold Reg. Sci. Technol. 2019, 161, 137–149. [Google Scholar] [CrossRef]

- Zhou, X.P.; Niu, Y.; Zhang, J.Z.; Shen, X.C.; Zheng, Y.; Berto, F. Experimental study on effects of freeze-thaw fatigue damage on the cracking behaviors of sandstone containing two unparallel fissures. Fatigue Fract Eng. Mater. Struct. 2019, 42, 1322–1340. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Chen, G.Q.; Xu, Z.X.; Yang, Y.; Lin, Z.H. Crack failure characteristics of different rocks under the action of frost heaving of fissure water. Front. Earth Sci. 2020, 8, 13. [Google Scholar] [CrossRef]

- Maji, V.; Murton, J.B. Experimental observations and statistical modeling of crack propagation dynamics in limestone by acoustic emission analysis during freezing and thawing. J. Geophys. Res. Earth Surf. 2021, 126, e2021JF006127. [Google Scholar] [CrossRef]

- Wang, T.T.; Tang, C.A.; Tang, S.B.; Bao, C.Y.; Li, Y.; Fan, N. The mechanism of crack propagation during frost heave damage in fractured rock mass at low temperature. Arab. J. Geosci. 2021, 14, 1882. [Google Scholar] [CrossRef]

- Han, C.H.; Xu, J.G.; Zhang, W.J.; Wei, J.C.; Yang, F.; Yin, H.Y.; Xie, D.L. Assessment and grouting of water inrush induced by shaft-freezing holes in the Yingpanhao Coal Mine, Inner Mongolia, China. Mine Water Environ. 2022, 41, 16–29. [Google Scholar] [CrossRef]

- Chen, L.; Wu, P.; Chen, Y.; Zhang, W. Experimental study on physical-mechanical properties and fracture behaviors of saturated yellow sandstone considering coupling effect of freeze-thaw and specimen inclination. Sustainability 2020, 12, 1029. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Gao, S.H.; Li, C.H.; Han, J.Q. Energy dissipation and damage evolution for dynamic fracture of marble subjected to freeze-thaw and multiple level compressive fatigue loading. Int. J. Fatigue 2020, 142, 105927. [Google Scholar] [CrossRef]

- Yahaghi, J.; Liu, H.Y.; Chan, A.; Fukuda, D. Experimental and numerical studies on failure behaviours of sandstones subject to freeze-thaw cycles. Transp. Geotech. 2021, 31, 100655. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Cai, Y.T.; Huang, S.B.; Guo, Y.L.; Liu, G.F. Effect of water saturation on uniaxial compressive strength and damage degree of clay-bearing sandstone under freeze-thaw. Bull. Eng. Geol. Environ. 2019, 79, 2021–2036. [Google Scholar] [CrossRef]

- Che, Y.X.; Song, Y.J.; Ren, J.X.; Chen, J.X.; Guo, X.X.; Tan, H.; Hu, M. Creep characteristics of different saturated states of red sandstone after freeze-thaw cycles. Geofluids 2021, 2021, 13. [Google Scholar] [CrossRef]

- Niu, Y.; Zhou, X.P.; Zhang, J.Z.; Qian, Q.H. Experimental study on crack coalescence behavior of double unparallel fissure-contained sandstone specimens subjected to freeze-thaw cycles under uniaxial compression. Cold Reg. Sci. Technol. 2019, 158, 166–181. [Google Scholar] [CrossRef]

- Shen, Y.J.; Yang, H.W.; Jin, L.; Zhang, H.; Yang, G.S.; Zhang, J.Y. Fatigue deformation and energy change of single-joint sandstone after freeze-thaw cycles and cyclic loadings. Front. Earth Sci. 2019, 7, 333. [Google Scholar] [CrossRef] [Green Version]

- Cao, R.H.; Wang, C.S.; Yao, R.B.; Hu, T.; Lei, D.X.; Lin, H.; Zhao, Y.L. Effects of cyclic freeze-thaw treatments on the fracture characteristics of sandstone under different fracture modes: Laboratory testing. Theor. Appl. Fract. Mech. 2020, 109, 102738. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.H.; Liu, H.; Han, J.Q. Fracture failure analysis of freeze–thawed granite containing natural fracture under uniaxial multi-level cyclic loads. Theor. Appl. Fract. Mech. 2020, 110, 102782. [Google Scholar] [CrossRef]

- Ke, B.; Zhang, J.; Deng, H.W.; Yang, X.R. Dynamic characteristics of candstone under coupled static-dynamic loads after freeze-thaw cycles. Appl. Sci. 2020, 10, 3351. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, S.H.; Li, C.H.; Han, J.Q. Investigation on fracture behaviors and damage evolution modeling of freeze-thawed marble subjected to increasing- amplitude cyclic loads. Theor. Appl. Fract. Mech. 2020, 109, 102679. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, B.; Gao, S.H.; Li, C.H. Investigation on the effect of freeze-thaw on fracture mode classification in marble subjected to multi-level cyclic loads. Theor. Appl. Fract. Mech. 2020, 111, 102847. [Google Scholar] [CrossRef]

- Gao, J.W.; Xu, C.; Xi, Y.; Fan, L.F. Degradation of mechanical behavior of sandstone under freeze-thaw conditions with different low temperatures. Appl. Sci. 2021, 11, 10653. [Google Scholar] [CrossRef]

- Wang, Y.; Song, Z.; Mao, T.; Zhu, C. Macro–Meso fracture and instability behaviors of hollow-cylinder granite containing fissures subjected to freeze–thaw–fatigue loads. Rock Mech. Rock Eng. 2022, 45, 1–21. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, W.K.; Wang, H.J.; Li, C.H.; Hou, Z.Q. Rock bridge fracturing characteristics in granite induced by freeze-thaw and uniaxial deformation revealed by AE monitoring and post-test CT scanning. Cold Reg. Sci. Technol. 2020, 177, 103115. [Google Scholar] [CrossRef]

- Song, Y.J.; Tan, H.; Yang, H.M.; Chen, S.J.; Che, Y.X.; Chen, J.X. Fracture evolution and failure characteristics of sandstone under freeze-thaw cycling by computed tomography. Eng. Geol. 2021, 294, 106370. [Google Scholar] [CrossRef]

- Liu, T.Y.; Zhang, C.Y.; Cao, P.; Zhou, K.P. Freeze-thaw damage evolution of fractured rock mass using nuclear magnetic resonance technology. Cold Reg. Sci. Technol. 2020, 170, 102951. [Google Scholar] [CrossRef]

- Wang, F.; Cao, P.; Wang, Y.X.; Hao, R.Q.; Meng, J.J.; Shang, J.L. Combined effects of cyclic load and temperature fluctuation on the mechanical behavior of porous sandstones. Eng. Geol. 2020, 266, 105466. [Google Scholar] [CrossRef]

- Li, H.R.; Dong, Z.K.; Yang, Y.; Liu, B.; Chen, M.Y.; Jing, W.J. Experimental study of damage development in salt rock under uniaxial stress using ultrasonic velocity and acoustic emissions. Appl. Sci. 2018, 8, 553. [Google Scholar] [CrossRef] [Green Version]

- Si, K.; Cui, Z.D.; Peng, R.D.; Zhao, L.L.; Zhao, Y. Crack propagation process and seismogenic mechanisms of rock due to the influence of freezing and thawing. Appl. Sci. 2021, 11, 9601. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, H.N.; Han, J.Q.; Zhu, C. Effect of rock bridge length on fracture and damage modelling in granite containing hole and fissures under cyclic uniaxial increasing-amplitude decreasing-frequency (CUIADF) loads. Int. J. Fatigue 2022, 158, 106741. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yang, S.Q.; Tian, W.L. Crack coalescence behavior of sandstone specimen containing two pre-existing flaws under different confining pressures. Theor. Appl. Fract. Mech. 2019, 99, 118–130. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Liu, X.R.; Huang, Y.H.; Yang, J. An experimental study on failure mechanical behavior and cracking mechanism of rectangular solid sandstone containing two non-coplanar fissures under conventional triaxial compression. Theor. Appl. Fract. Mech. 2021, 114, 102975. [Google Scholar] [CrossRef]

- Song, Z.Y.; Wu, Y.F.; Yang, Z.; Cai, X.; Jia, Y.Z.; Zhang, M. Mechanical responses of a deeply buried granite exposed to multilevel uniaxial and triaxial cyclic stresses: Insights into deformation behavior, energy dissipation, and hysteresis. Adv. Mater. Sci. Eng. 2021, 2021, 3160968. [Google Scholar] [CrossRef]

- Bai, Y.; Shan, R.L.; Ju, Y.; Wu, Y.X.; Tong, X.; Han, T.Y.; Dou, H.Y. Experimental study on the strength, deformation and crack evolution behaviour of red sandstone samples containing two ice-filled fissures under triaxial compression. Cold Reg. Sci. Technol. 2020, 174, 103061. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, X.F.; Gao, S.H.; Liu, H. Laboratory Investigation on the Effects of Natural Fracture on Fracture Evolution of Granite Exposed to Freeze-Thaw-Cyclic (FTC) Loads. Geofluids 2021, 2021, 6650616. [Google Scholar] [CrossRef]

- Chen, Y.L.; Xiao, P.; Du, X.; Wang, S.R.; Fernandez-Steeger, T.M.; Azzam, R. Study on damage constitutive model of rock under freeze-thaw-confining pressure-acid erosion. Appl. Sci. 2021, 11, 9431. [Google Scholar] [CrossRef]

- Huang, S.B.; Liu, Q.S.; Cheng, A.P.; Liu, Y.Z. A statistical damage constitutive model under freeze-thaw and loading for rock and its engineering application. Cold Reg. Sci. Technol. 2017, 145, 142–150. [Google Scholar] [CrossRef]

- Zhang, H.M.; Yuan, C.; Yang, G.S.; Wu, L.Y.; Peng, C.; Ye, W.; Shen, Y.; Moayedi, H. A novel constitutive modelling approach measured under simulated freeze–thaw cycles for the rock failure. Eng. Comput. 2019, 37, 779–792. [Google Scholar] [CrossRef]

- Zhang, H.M.; Meng, X.Z.; Yang, G.S. A study on mechanical properties and damage model of rock subjected to freeze-thaw cycles and confining pressure. Cold Reg. Sci. Technol. 2020, 174, 103056. [Google Scholar] [CrossRef]

- Dong, X.H.; Yang, G.S.; Liu, S. Experimental study on AE response and damage evolution characteristics of frozen sandstone under uniaxial compression. Cold Reg. Sci. Technol. 2021, 193, 103424. [Google Scholar] [CrossRef]

- Liu, S.; Yang, G.S.; Dong, X.H.; Shen, Y.J. Energy characteristics and damage constitutive model of frozen sandstone under triaxial compression. J. Cold Reg. Eng. 2022, 36, 04021021. [Google Scholar] [CrossRef]

- Li, Z.Y.; Yang, G.S. Constitutive model of frozen red sandstone based on ice-solid binary medium. Arab J. Geosci. 2021, 14, 1616. [Google Scholar] [CrossRef]

- Chen, Q.; Li, C.H.; Wang, Y.; Yang, H.P.; Song, Z.Y. Research on macro and meso damage model of pre-flawed granites subjected to coupling action of freeze-thaw and loading. Arab J. Geosci. 2021, 14, 1083. [Google Scholar]

- Huang, S.B.; Liu, Y.Z.; Guo, Y.L.; Zhang, Z.L.; Cai, Y.T. Strength and failure characteristics of rock-like material containing single crack under freeze-thaw and uniaxial compression. Cold Reg. Sci. Technol. 2019, 162, 1–10. [Google Scholar] [CrossRef]

- Xiao, T.L.; Huang, M.; Cheng, C.; He, Y.L. Experimental investigation on the mechanical characteristics and deformation behaviour of fractured rock-like material with one single fissure under the conventional triaxial compression. Shock Vib. 2018, 2018, 2608639. [Google Scholar] [CrossRef] [Green Version]

- Xiao, T.L.; Li, X.P.; Guo, Y.H. Experimental study of failure characteristic of single jointed rock mass under triaxial compression tests. Rock Soil Mech. 2012, 33, 3251–3256. [Google Scholar]

- Lu, Y.N.; Li, X.P.; Wu, X.H. Fracture coalescence mechanism of single flaw rock specimen due to freeze-thaw under triaxial compression. Rock Soil Mech. 2014, 35, 1579–1584. [Google Scholar]

- Zhao, T.; Yang, G.; Xi, J.M.; Shen, Y.J.; Song, K.-I. Factorial experiment study on the mechanical properties of sandstone-concrete specimens under different freeze-thaw conditions. Front. Phys. 2020, 8, 322. [Google Scholar] [CrossRef]

- Liu, Q.S.; Huang, S.B.; Kang, Y.S.; Cui, X.Z. Advance and review on freezing-thawing damage of fractured rock. Chin. J. Rock. Mech. Eng. 2015, 34, 452–471. [Google Scholar]

- Wang, H.; Wang, X.D.; Cao, Z.B.; Xu, G.G.; Yang, D. Mechanism and prevention technology of water inrush and sand inrush occurred in thawing process of mine freezing shaft wall. Coal Sci. Technol. 2019, 47, 21–26. [Google Scholar]

- Zhu, T.T.; Chen, J.X.; Huang, D.; Luo, Y.B.; Li, Y.; Xu, L.F. A DEM-based approach for modeling the damage of rock under freeze–thaw cycles. Rock Mech. Rock Eng. 2021, 54, 2843–2858. [Google Scholar] [CrossRef]

- Feng, Q.; Jin, J.C.; Zhang, S.; Liu, W.W.; Yang, X.X.; Li, W.T. Study on a damage model and uniaxial compression simulation method of frozen–thawed rock. Rock Mech. Rock Eng. 2022, 55, 187–211. [Google Scholar] [CrossRef]

- Srinivasan, S.; Hyman, J.; Karra, S.; O’Malley, D.; Viswanathan, H.; Srinivasan, G. Robust system size reduction of discrete fracture networks a multi-fidelity method that preserves transport characteristics. Comput. Geosci. 2018, 22, 1515–1526. [Google Scholar] [CrossRef]

- Viswanathan, H.S.; Hyman, J.D.; Karra, S.; O’Malley, D.; Srinivasan, S.; Hagberg, A.; Srinivasan, G. Advancing graph-based algorithms for predicting flow and transport in fractured rock. Water Resour. Res. 2018, 54, 6085–6099. [Google Scholar] [CrossRef]

- Srinivasan, S.; O’Malley, D.; Hyman, J.D.; Karra, S.; Viswanathan, H.S.; Srinivasan, G. Transient flow modeling in fractured media using graphs. Phys. Rev. E 2020, 102, 052310. [Google Scholar] [CrossRef] [PubMed]

- Greer, S.Y.; Hyman, J.D.; O’Malley, D. A comparison of linear solvers for resolving flow in three-dimensional discrete. Water Resour. Res. 2022, 58. [Google Scholar] [CrossRef]

| Materials | Dry Density/g·cm−3 | Saturated Density/g·cm−3 | Longitudinal Wave Velocity/km·s−1 | Porosity/% | Uniaxial Strength/MPa | Poisson Ratio | Elastic Modulus/GPa |

|---|---|---|---|---|---|---|---|

| Luohe Formation sandstone | 2.04 | 2.25 | 1.91 | 20.48 | 11.19 | 0.32 | 1.63 |

| Intact quasi-sandstone | 1.70 | 2.05 | 2.06 | 27.64 | 10.51 | 0.36 | 1.91 |

| Similar ratio | 0.83 | 0.91 | 1.07 | 1.35 | 0.94 | 1.12 | 1.17 |

| θ = 0° quasi-sandstone | 1.69 | 2.02 | 2.1 | 28.52 | 9.06 | 0.31 | 1.82 |

| θ = 45° quasi-sandstone | 1.6765 | 2.03 | 2.17 | 29.71 | 7.79 | 0.37 | 1.64 |

| θ = 75° quasi-sandstone | 1.78 | 2.09 | 2.27 | 26.99 | 10.08 | 0.30 | 1.86 |

| Groups | Freezing Temperature Tf/°C | Melting Temperature Tm/°C | Fissure Angle θ/(°) | |

|---|---|---|---|---|

| A | Unfrozen | Unfrozen | No, 0, 45, 75 | 2 |

| B | −10 | 20 | No, 0, 45, 75 | 2 |

| C | −20 | 20 | No, 0, 45, 75 | 2 |

| D | −30 | 20 | No, 0, 45, 75 | 2 |

| Fissure Angle θ/° | Freezing Temperature Tf/°C | Elastic Modulus E/GPa | |||

|---|---|---|---|---|---|

| Intact | Unfrozen | 1.35 | 14.30 | 2.67 | 0.220 |

| −10 | 1.98 | 13.21 | 2.55 | 0.234 | |

| −20 | 1.23 | 11.67 | 2.34 | 0.259 | |

| −30 | 1.02 | 10.15 | 1.99 | 0.272 | |

| 0 | Unfrozen | 0.71 | 13.17 | 2.33 | 0.247 |

| −10 | 1.31 | 12.63 | 2.16 | 0.289 | |

| −20 | 0.87 | 11.49 | 1.91 | 0.302 | |

| −30 | 0.88 | 10.36 | 1.78 | 0.327 | |

| 45 | Unfrozen | 1.06 | 11.34 | 2.27 | 0.319 |

| −10 | 1.95 | 10.31 | 2.08 | 0.317 | |

| −20 | 1.08 | 9.49 | 1.72 | 0.338 | |

| −30 | 0.98 | 8.48 | 1.53 | 0.367 | |

| 75 | Unfrozen | 1.01 | 13.19 | 2.50 | 0.260 |

| −10 | 0.92 | 12.62 | 2.21 | 0.309 | |

| −20 | 1.03 | 11.72 | 1.80 | 0.319 | |

| −30 | 0.86 | 10.68 | 1.67 | 0.334 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Ren, J.; Caoxi, T.; Chen, X.; Yun, M. Triaxial Compression Fracture Characteristics and Constitutive Model of Frozen–Thawed Fissured Quasi-Sandstone. Appl. Sci. 2022, 12, 6454. https://doi.org/10.3390/app12136454

Xie Y, Ren J, Caoxi T, Chen X, Yun M. Triaxial Compression Fracture Characteristics and Constitutive Model of Frozen–Thawed Fissured Quasi-Sandstone. Applied Sciences. 2022; 12(13):6454. https://doi.org/10.3390/app12136454

Chicago/Turabian StyleXie, Yi, Jianxi Ren, Tailang Caoxi, Xu Chen, and Mengchen Yun. 2022. "Triaxial Compression Fracture Characteristics and Constitutive Model of Frozen–Thawed Fissured Quasi-Sandstone" Applied Sciences 12, no. 13: 6454. https://doi.org/10.3390/app12136454

APA StyleXie, Y., Ren, J., Caoxi, T., Chen, X., & Yun, M. (2022). Triaxial Compression Fracture Characteristics and Constitutive Model of Frozen–Thawed Fissured Quasi-Sandstone. Applied Sciences, 12(13), 6454. https://doi.org/10.3390/app12136454