Strategy Based on Two Stages for IR Thermographic Inspections of Photovoltaic Plants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

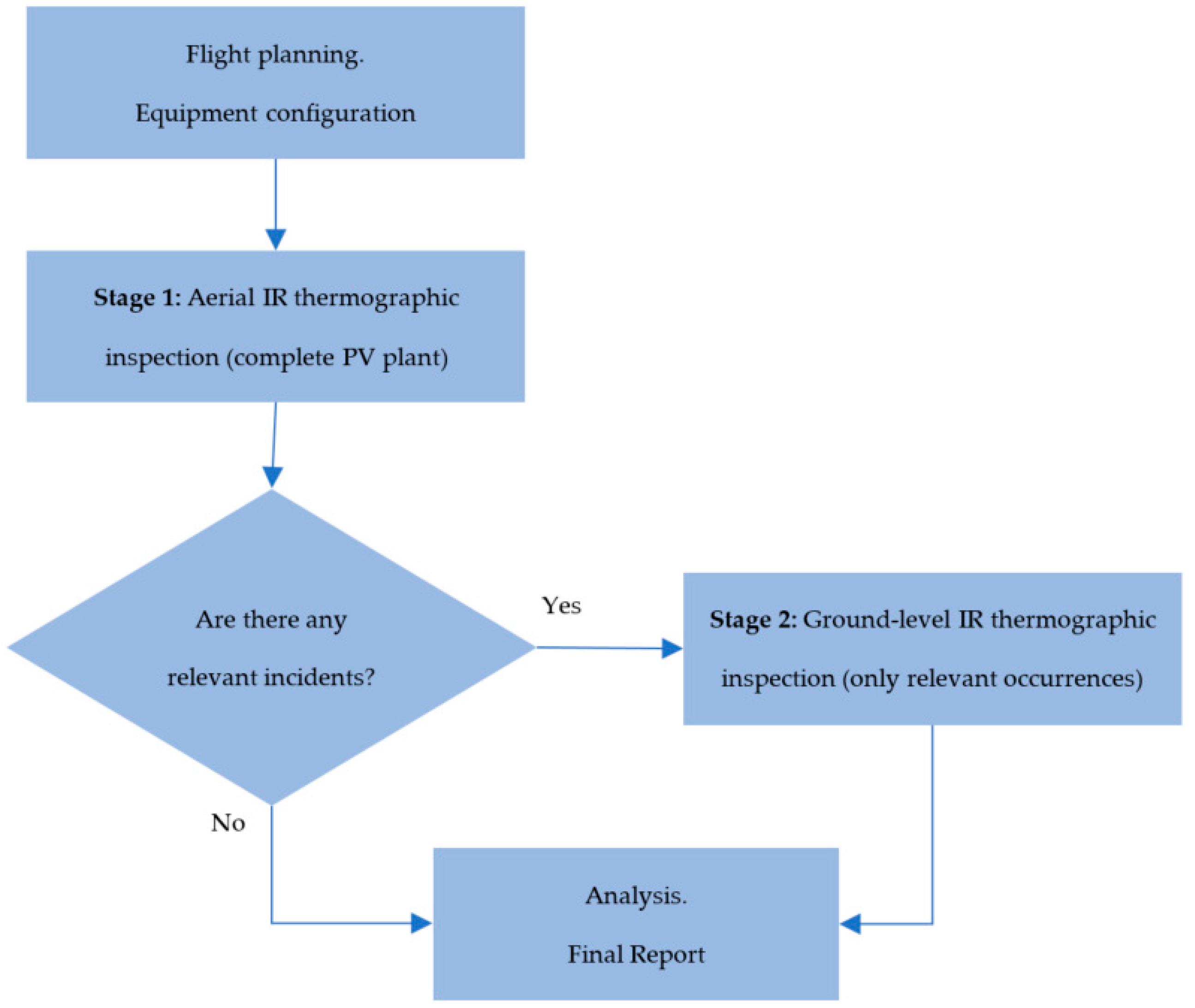

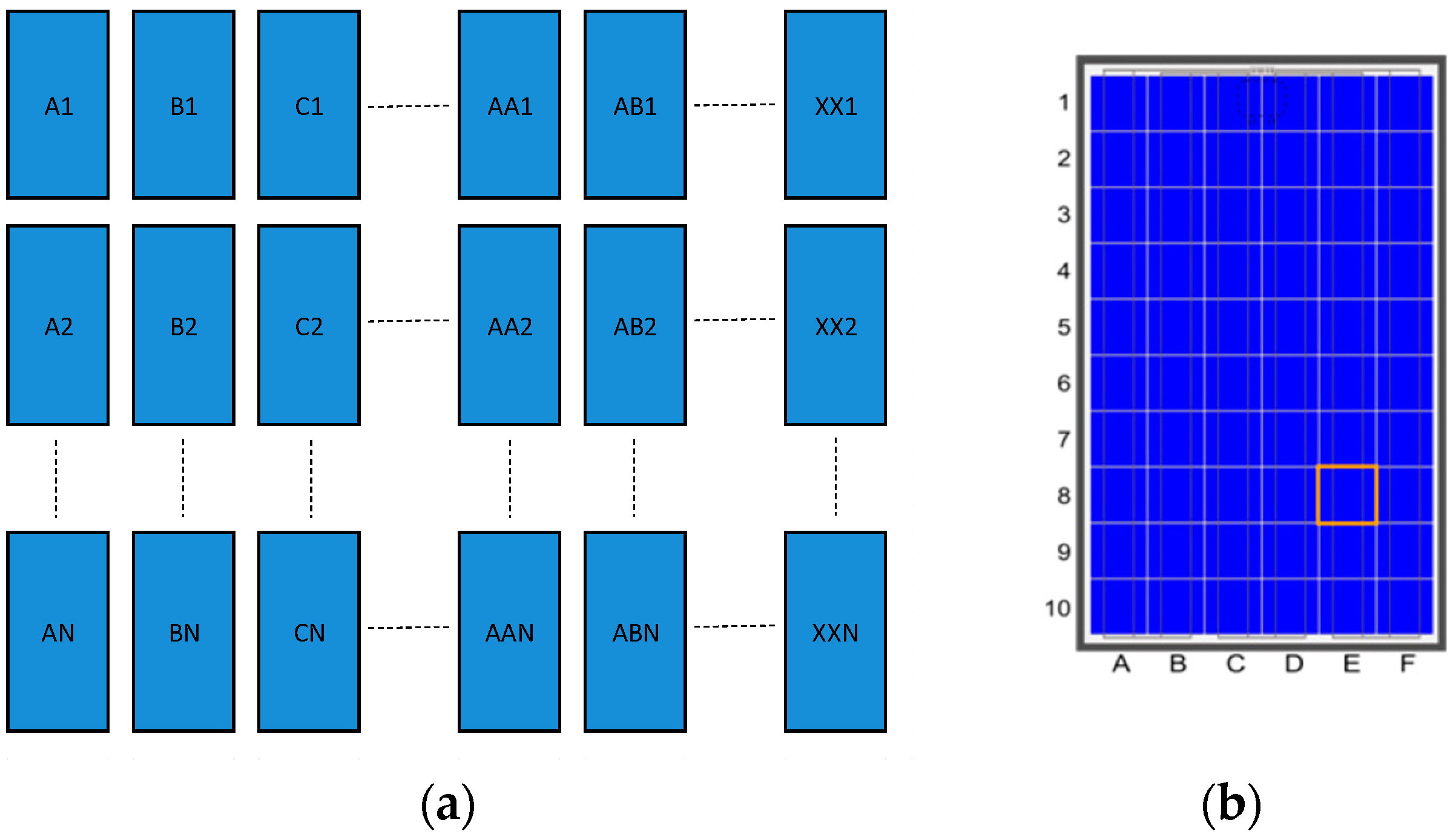

2.2. Methods

2.3. Case Study

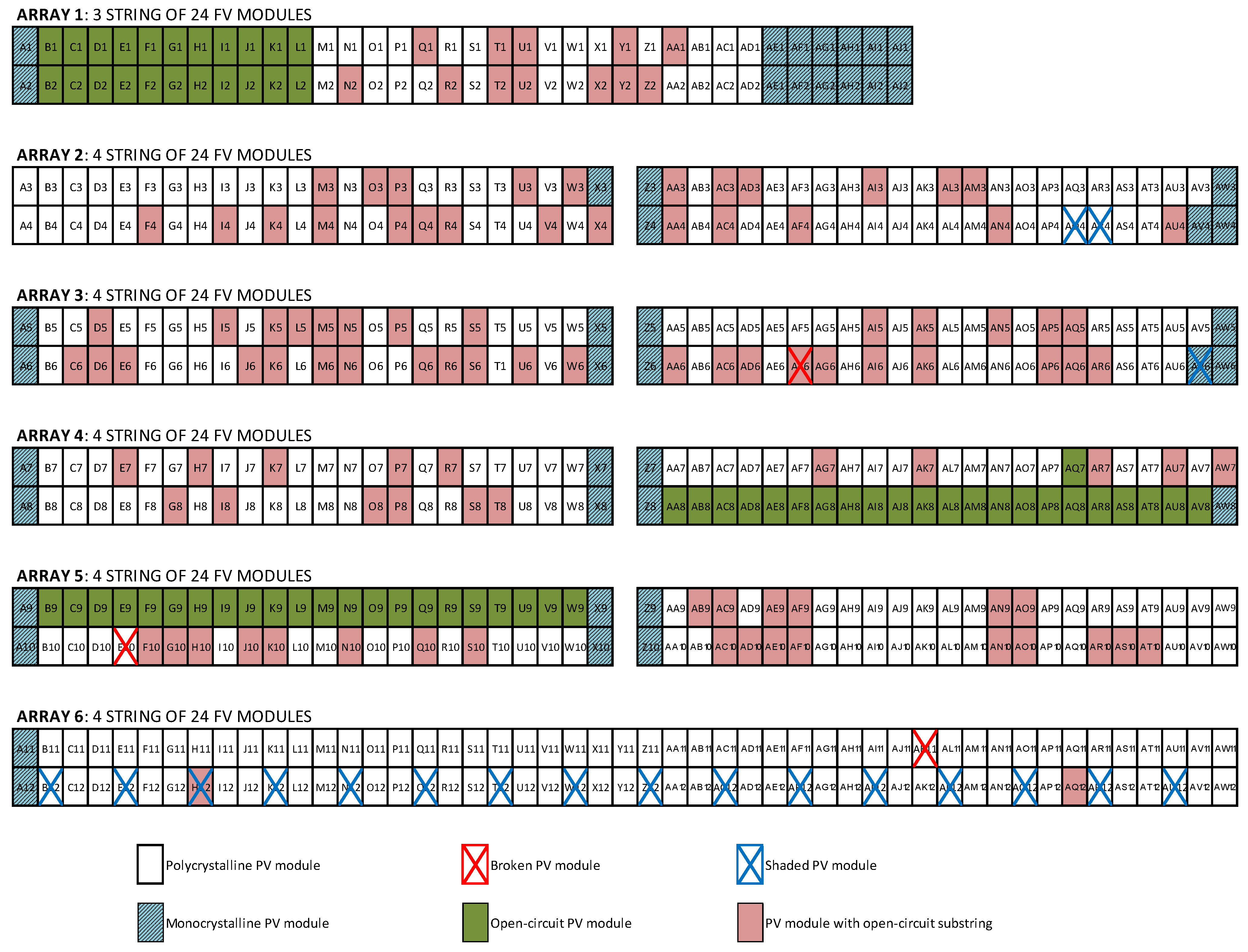

3. Results

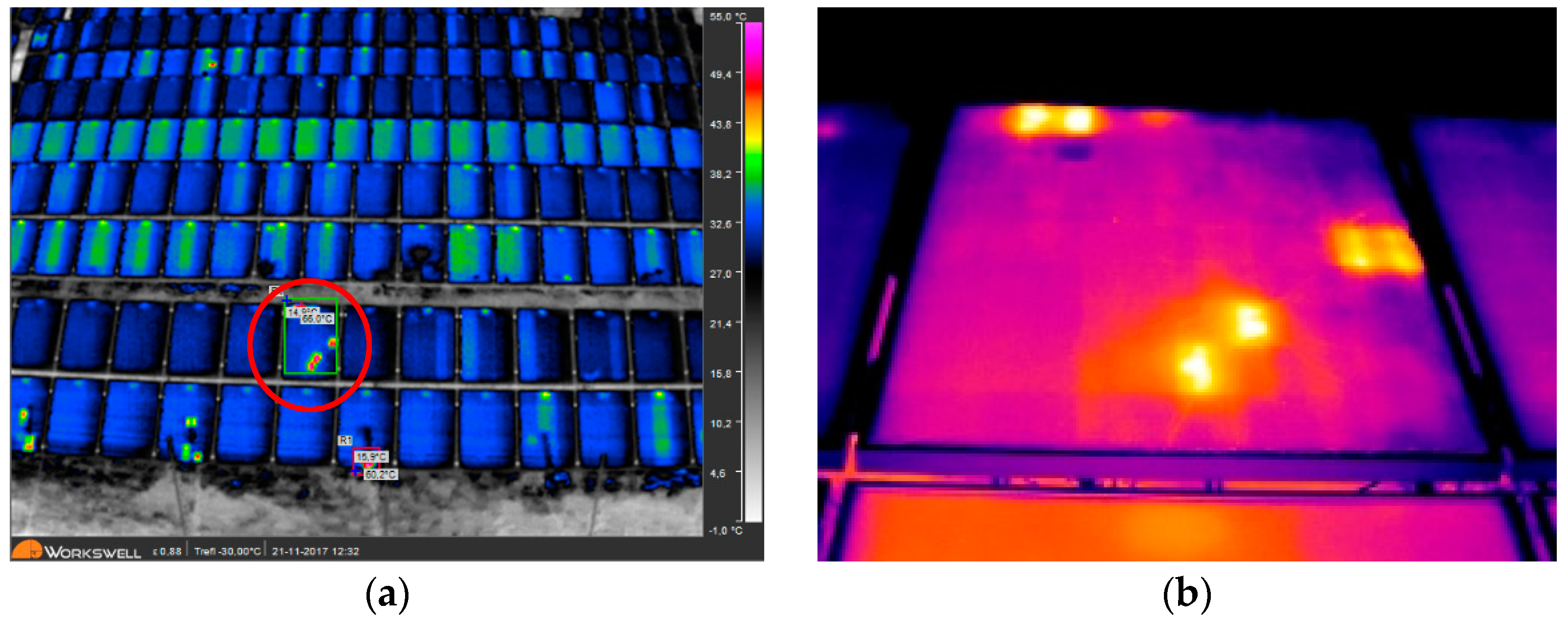

- Incidents with broken glass in PV module.

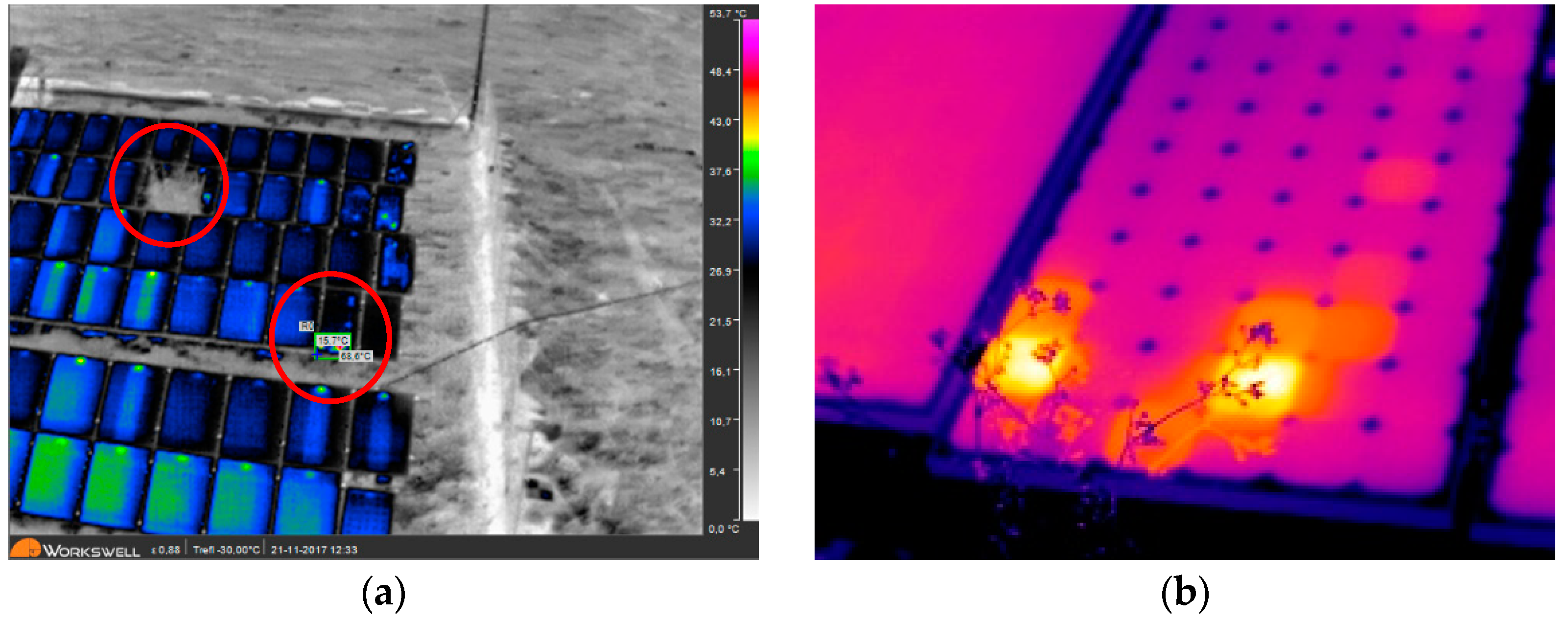

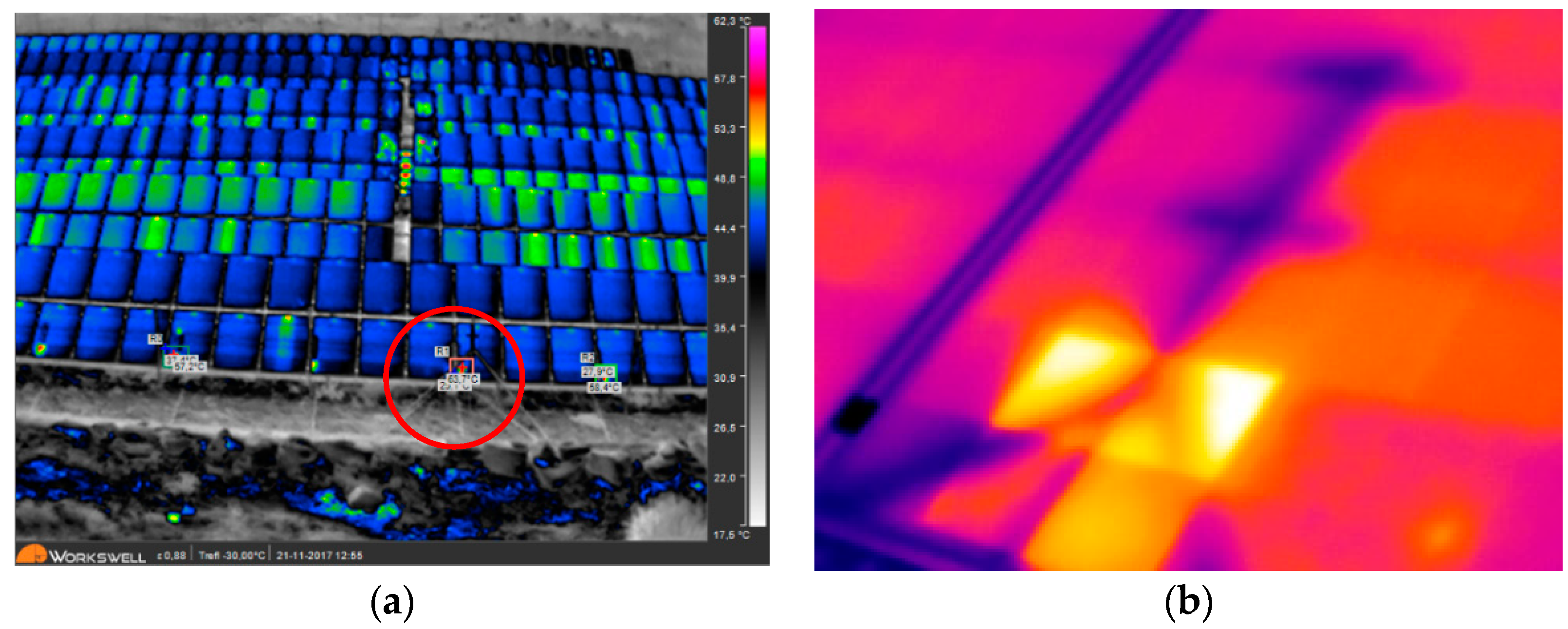

- Incidents involving partial shading.

- Incidents involving PV module technology.

- Incidents with open-circuit PV modules.

- Other incidents.

- Incidents with broken glass in PV module

- 2.

- Incidents involving partial shading

- 3.

- Incidents involving PV module technology

- 4.

- Incidents with open-circuit PV modules

- 5.

- Other incidents

4. Discussion

- For one-off incidents due to hotspots, spatial resolution may be insufficient with aerial IR thermography. Ground-level IR thermography enables greater precision for determining thermal behaviour.

- Heat incidents from shading may be totally or partially concealed by the item causing the shadow (vegetation or post) with aerial IR thermography. Ground-level IR thermography prevents any possible blocking.

- PV modules with technology different from m-Si reveal an irregular temperature pattern. This pattern is characteristic of a module in a short circuit. For this reason, all m-Si type PV modules are operating in a state close to a short circuit as a consequence of the intensity values produced by the p-Si type PV modules, which are series connected within each string. This incident is seen indistinctly by both thermography types, although at ground level the behaviour is viewed with greater sharpness and definition.

- For PV modules in open circuit, the thermal behaviour is some 5 to 7 °C higher than temperatures in operational modules. These modules do not produce power. This incident does not depend on the thermography type.

- For PV modules with open-circuit substrings, thermal behaviour is some 5 to 7 °C higher than operational substrings. These PV modules’ power production at the PV plant is very limited. This incident is observed interchangeably in both thermography types.

- In the stage one of the thermographic inspection, it is necessary to determine the specific location of the PV modules with faults and to identify them correctly. This is essential for the success of the stage two and for the documentation of the final report.

- The stage two of thermographic inspection can also be performed aerially, but at a reduced distance to allow for the necessary thermal resolution. This may require the scheduling of two flight plans. The second flight plan would be conditioned by the results of the first flight plan. This will simplify the thermographic equipment to be used and the subsequent analysis. This may be the subject of future research.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| IFOV | Instantaneous Field of View |

| IR | Infrared |

| PV | Photovoltaic |

| STC | Standard Test Conditions |

| UAVs | Unmanned Aerial Vehicles |

References

- Solar Power Europe. Global Market Outlook for Solar Power 2021–2025; Solar Power Europe: Brussels, Belgium, 2021; p. 135. [Google Scholar]

- Jäger-Waldau, A. Snapshot of photovoltaics—March 2021. EPJ Photovolt. 2021, 12, 2. [Google Scholar] [CrossRef]

- SolarPower Europe. Operation & Maintenance. Best Practice Guidelines/Version 4.0; SolarPower Europe: Brussels, Belgium, 2019; p. 120. [Google Scholar]

- Hernández-Callejo, L.; Gallardo-Saavedra, S.; Gómez, V.A. A review of photovoltaic systems: Design, operation and maintenance. Sol. Energy 2019, 188, 426–440. [Google Scholar] [CrossRef]

- IEA-PVPS Task 13. Review of Failures of Photovoltaic Modules. Report IEA-PVPS T13-01. 2014. Available online: https://iea-pvps.org/key-topics/review-of-failures-of-photovoltaic-modules-final/ (accessed on 7 June 2022).

- Libra, M.; Daneček, M.; Lešetický, J.; Poulek, V.; Sedláček, J.; Beránek, V. Monitoring of Defects of a Photovoltaic Power Plant Using a Drone. Energies 2019, 12, 795. [Google Scholar] [CrossRef] [Green Version]

- IEC 61724; Photovoltaic System Performance—Part 1: Monitoring. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2017; p. 68.

- Tsanakas, J.A.; Ha, L.; Buerhop, C. Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: A review of research and future challenges. Renew. Sustain. Energy Rev. 2016, 62, 695–709. [Google Scholar] [CrossRef]

- Buerhop, C.; Jahn, U.; Hoyer, U.; Lercher, B.; Wittmann, S. Abschlussbericht Machbarkeitsstudie Überprüfung der Qualität von Photovoltaik-Modulen Mittels Infrarot-Aufnahmen. 2007, pp. 1–46. Available online: https://www.sev-bayern.de/wp-content/uploads/2018/12/IR-Handbuch.pdf (accessed on 7 June 2022).

- Buerhop, C.; Schlegel, D.; Niess, M.; Vodermayer, C.; Weißmann, R.; Brabec, C.J. Reliability of IR-imaging of PV-plants under operating conditions. Sol. Energy Mater. Sol. Cells 2012, 107, 154–164. [Google Scholar] [CrossRef]

- Spagnolo, G.S.; Del Vecchio, P.; Makary, G.; Papalillo, D.; Martocchia, A. A review of IR thermography applied to PV systems. In Proceedings of the 11th International Conference on Environment and Electrical Engineering, Venice, Italy, 18–25 May 2012; pp. 879–884. [Google Scholar] [CrossRef]

- IEC TS 62446-3; Photovoltaic (PV) Systems—Requirements for Testing, Documentation and Maintenance—Part 3: Outdoor Infrared Thermography of Photovoltaic Modules and Plants. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2017.

- IEA-Photovoltaic Power Systems Programme. Review on Infrared (IR) and Electroluminescence (EL) Imaging for Photovoltaic Field Applications. Report IEA-PVPS T13-10:2018. 2018, pp. 1–94. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/Review_on_IR_and_EL_Imaging_for_PV_Field_Applications_by_Task_13.pdf (accessed on 7 June 2022).

- Buerhop-Lutz, C.; Weißmann, R.; Scheuerpflug, H.; Auer, R.; Brabec, C. Quality Control of PV-Modules in the Field Using a Remote-Controlled Drone with an Infrared Camera. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition (EU PVSEC 2012), Frankfurt, Germany, 24–28 September 2012; pp. 3370–3373. [Google Scholar] [CrossRef]

- Quater, P.B.; Grimaccia, F.; Leva, S.; Mussetta, M.; Aghaei, M. Light Unmanned Aerial Vehicles (UAVs) for Cooperative Inspection of PV Plants. IEEE J. Photovolt. 2014, 4, 1107–1113. [Google Scholar] [CrossRef] [Green Version]

- Rahaman, S.A.; Urmee, T.; Parlevliet, D.A. PV system defects identification using Remotely Piloted Aircraft (RPA) based infrared (IR) imaging: A review. Sol. Energy 2020, 206, 579–595. [Google Scholar] [CrossRef]

- Gallardo-Saavedra, S.; Hernández-Callejo, L.; Duque-Perez, O. Technological review of the instrumentation used in aerial thermographic inspection of photovoltaic plants. Renew. Sustain. Energy Rev. 2018, 93, 566–579. [Google Scholar] [CrossRef]

- Gallardo-Saavedra, S.; Hernandez-Callejo, L.; Duque-Perez, O.; Hermandez, L. Image Resolution Influence in Aerial Thermographic Inspections of Photovoltaic Plants. IEEE Trans. Ind. Inform. 2018, 14, 5678–5686. [Google Scholar] [CrossRef]

- Coello, J.; Perez, L.; Parra, V.; Gomez, R. IR Thermography Inspection of PV modules in large PV Plants with UAV. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015. [Google Scholar]

- Henry, C.; Poudel, S.; Lee, S.-W.; Jeong, H. Automatic Detection System of Deteriorated PV Modules Using Drone with Thermal Camera. Appl. Sci. 2020, 10, 3802. [Google Scholar] [CrossRef]

- De Oliveira, A.K.V.; Bracht, M.K.; Melo, A.P.; Lamberts, R.; Ruther, R. Evaluation of Faults in a Photovoltaic Power Plant using Orthomosaics based on Aerial Infrared Thermography. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Virtual Meeting, 20–25 June 2021; pp. 2604–2610. [Google Scholar] [CrossRef]

- Lee, D.H.; Park, J.H. Developing Inspection Methodology of Solar Energy Plants by Thermal Infrared Sensor on Board Unmanned Aerial Vehicles. Energies 2019, 12, 2928. [Google Scholar] [CrossRef] [Green Version]

- Dalsass, M.; Scheuerpflug, H.; Fecher, F.W.; Buerhop-Lutz, C.; Camus, C.; Brabec, C.J. Correlation between the generated string powers of a photovoltaic: Power plant and module defects detected by aerial thermography. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; Volume 83, pp. 3113–3118. [Google Scholar] [CrossRef]

- de Oliveira, A.K.V.; Aghaei, M.; Rüther, R. Automatic Inspection of Photovoltaic Power Plants Using Aerial Infrared Thermography: A Review. Energies 2022, 15, 2055. [Google Scholar] [CrossRef]

- Ortiz-Sanz, J.; Gil-Docampo, M.; Arza-García, M.; Cañas-Guerrero, I. IR Thermography from UAVs to Monitor Thermal Anomalies in the Envelopes of Traditional Wine Cellars: Field Test. Remote Sens. 2019, 11, 1424. [Google Scholar] [CrossRef]

- Feroz, S.; Abu Dabous, S. UAV-Based Remote Sensing Applications for Bridge Condition Assessment. Remote Sens. 2021, 13, 1809. [Google Scholar] [CrossRef]

- WIRIS. Workswell 2a Gen. User Manual Revision 2.0; Workswell: Prague, Czech Republic, 2017; pp. 1–8. [Google Scholar]

- FLIR Systems. ThermaCAM TM S60. User Manual Revision a35; FLIR Systems: Danderyd, Sweden, 2004; pp. 1–200. [Google Scholar]

- Álvarez-Tey, G.; Jiménez-Castañeda, R.; Carpio, J. Analysis of the configuration and the location of thermographic equipment for the inspection in photovoltaic systems. Infrared Phys. Technol. 2017, 87, 40–46. [Google Scholar] [CrossRef]

- Krenzinger, A.; de Andrade, A. Accurate outdoor glass thermographic thermometry applied to solar energy devices. Sol. Energy 2007, 81, 1025–1034. [Google Scholar] [CrossRef]

| Incident Type | Affected PV Modules | Temperature Value (°C) | Irradiance Value (W/m2) | Temperature Value Extrapolated at 1000 W/m2 | Comment |

|---|---|---|---|---|---|

| Broken cover | AF6 | 55.6 | 890 | 61.2 | Required replacement of PV modules |

| E10 | 86.6 | 922 | 94.6 | ||

| AK11 | 89.6 | 940 | 97.9 | ||

| Partial shade | AL12 | 60.2 | 921 | 66.2 | Post |

| AV6 | 111.8 | 941 | 118.5 | Vegetation | |

| AQ4 | 49.6 | 941 | 54.6 | Vegetation | |

| AR4 | 49.6 | 941 | 54.6 | Vegetation | |

| AC12 | 77.5 | 945 | 85.3 | Post | |

| Several array 6 | - | - | - | Post | |

| PV module technology | All m-Si type PV modules | 63.5 | 944 | 69.9 | Measurement of max. temperature |

| Open circuit | String in arrays 1, 4 and 5 | 2 to 7 °C for operational PV modules | 2 to 7 °C for operational PV modules | Electrical verification required | |

| Open-circuit substrings | Many p-Si type PV modules | 2 to 7 °C for adjacent substring | - | 2 to 7 °C for adjacent substring | Electrical verification required |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Tey, G.; García-López, C. Strategy Based on Two Stages for IR Thermographic Inspections of Photovoltaic Plants. Appl. Sci. 2022, 12, 6331. https://doi.org/10.3390/app12136331

Álvarez-Tey G, García-López C. Strategy Based on Two Stages for IR Thermographic Inspections of Photovoltaic Plants. Applied Sciences. 2022; 12(13):6331. https://doi.org/10.3390/app12136331

Chicago/Turabian StyleÁlvarez-Tey, Germán, and Carmen García-López. 2022. "Strategy Based on Two Stages for IR Thermographic Inspections of Photovoltaic Plants" Applied Sciences 12, no. 13: 6331. https://doi.org/10.3390/app12136331

APA StyleÁlvarez-Tey, G., & García-López, C. (2022). Strategy Based on Two Stages for IR Thermographic Inspections of Photovoltaic Plants. Applied Sciences, 12(13), 6331. https://doi.org/10.3390/app12136331