Optimal Placement of Vibration Sensors for Industrial Robots Based on Bayesian Theory

Abstract

:1. Introduction

1.1. Background and Significance of the Study

1.2. Related Work

2. Sensor Placement Method

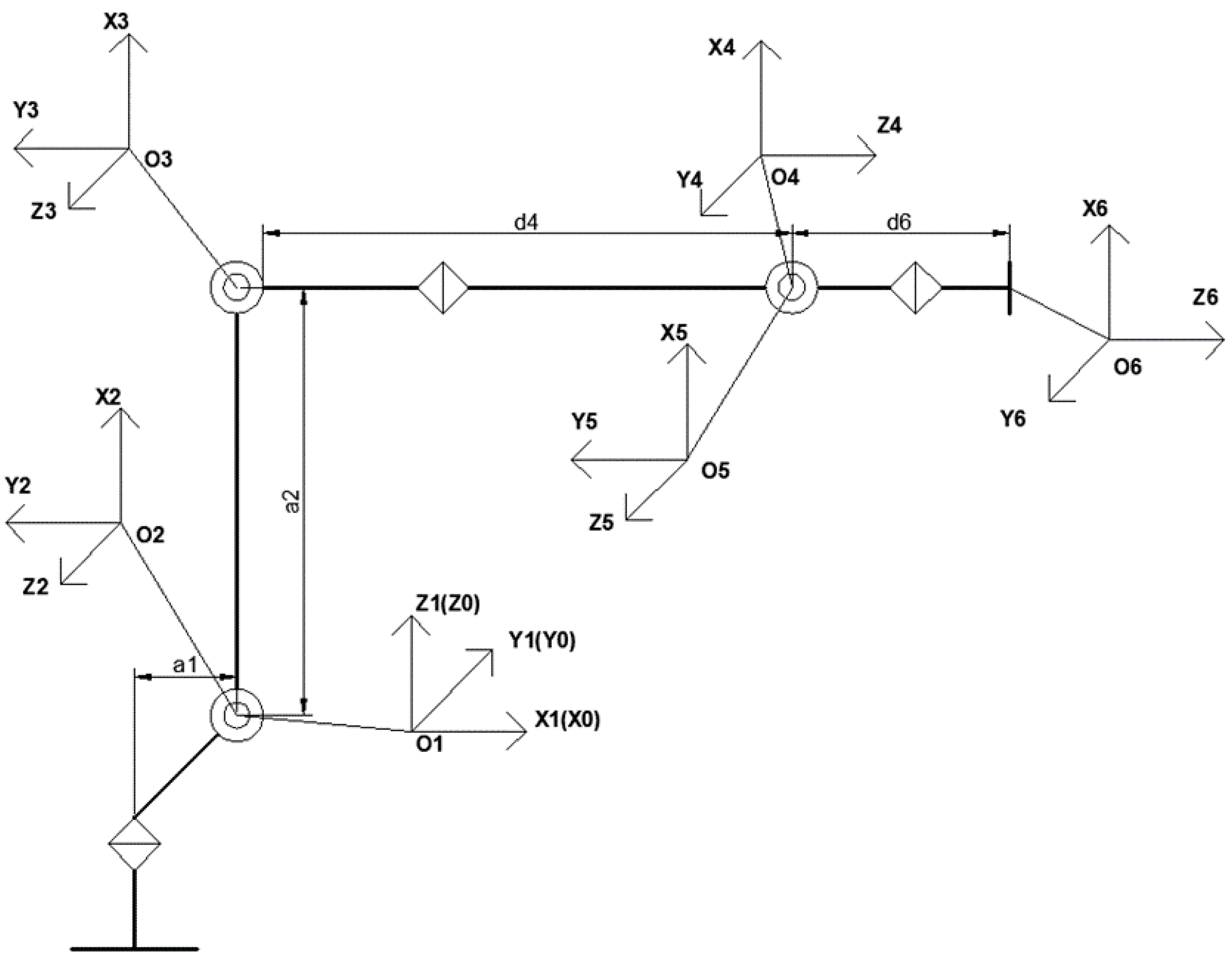

2.1. Derivation of Forward Kinematics of Industrial Robots

- 1.

- Link length : along the axis, the distance from to ;

- 2.

- The torsion angle of the connecting rod: the angle from to around the axis;

- 3.

- Link offset : along the axis, the distance from to ;

- 4.

- Joint angle : the angle of rotation from to around the axis.

2.2. Numerical Method of Velocity

2.3. Simulation Analysis of Industrial Robot

2.4. Optimal Sensor Placement Based on Bayesian

2.4.1. Bayesian Estimation of Motion Joint Position

2.4.2. Optimal Sensor Placement for Industrial Robots Based on Information Gain

2.5. Constraint Equation

3. Experiment

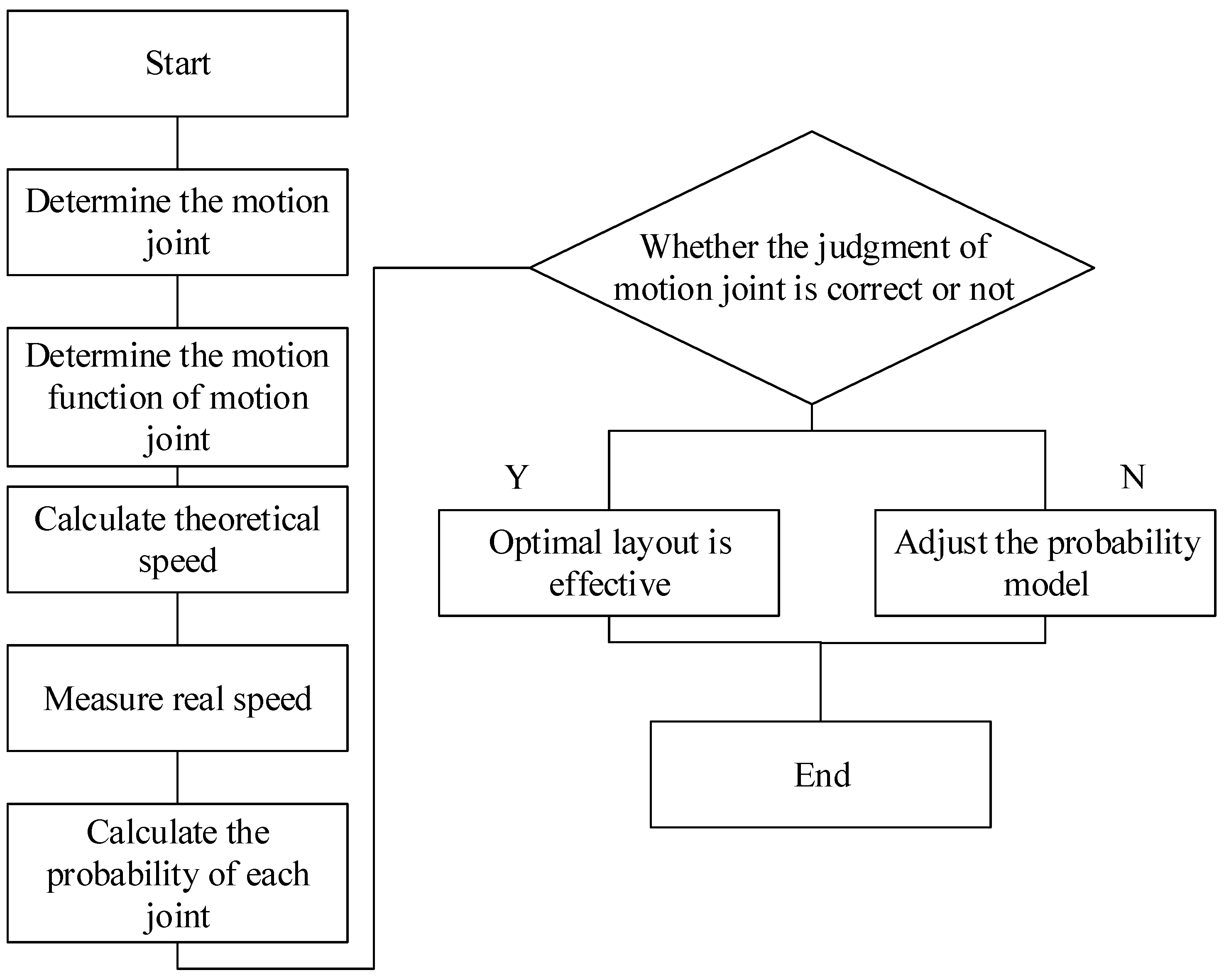

3.1. Verification Method for Layout

- According to the given initial position, sensors are arranged in the corresponding position of the real industrial robot;

- Set the joint speed of the industrial robot as a fixed speed, make the industrial robot move accordingly, and collect the acceleration of sensor distribution in the process of motion;

- The acceleration signal is processed to get the velocity of each point, and the probability of motion from each joint is calculated by using the probability model;

- Compare the probability of each joint with the real motion joint to determine whether the maximum probability corresponds to the real motion joint. If so, it is considered that the sensor layout can obtain the whole machine state.

| Algorithm 1: Optimal sensor placement based on Bayesian and Constraint equation | |

| Input: the measured velocity and the predicted velocity of the sensor. | |

| Output: optimal sensor placement s_best. | |

| 1 | rn = 3; |

| 2 | if sn = 1 do |

| 3 | for i = 1 to rn do |

| 4 | for j = 1 to le do |

| 5 | compute p(i,j);//according to Equation (16). |

| 6 | end |

| 7 | end |

| 8 | for i = 1 to rn do |

| 9 | for j = 1 to le do |

| 10 | compute U(i,j);//according to Equation (19) |

| 11 | end |

| 12 | end |

| 13 | for i = 1 to rn do |

| 14 | compute Us(i);//sum U(i,j) |

| 15 | end |

| 16 | s_best = s(max(Us)); |

| 17 | else |

| 18 | sn = sn + 1; |

| 19 | for i = 1 to rn do |

| 20 | for j = 1 to le do |

| 21 | compute p(i,j);//according to Equation (16) |

| 22 | end |

| 23 | end |

| 24 | for i = 1 to rn do |

| 25 | for j = 1 to le do |

| 26 | compute U(i,j);//according to Equation (19) |

| 27 | end |

| 28 | end |

| 29 | for i = 1 to rn do |

| 30 | compute Us(i);//sum U(i,j) |

| 31 | end |

| 32 | s_best = snew(max(Us)); |

| 33 | for i = 1 to rn do |

| 34 | compute n_best;//according to Equation (21) |

| 35 | end |

| 36 | s_best = s_best(n_best);//optimal sensor placement |

| 37 | end |

| 38 | //rn—number of joints; |

| 39 | //s—initial Sensor placement; |

| 40 | //sn—number of sensors currently optimized; |

| 41 | //le—number of sensors in the initial layout; |

| 42 | //p(i j)—the likelihood function; |

| 43 | //U(i,j)—the sensor placement evaluation function according to Equation (19); |

| 44 | //Us(i)—sum of regression values of each sensor coordinate; |

| 45 | //snew—the new sensor placement based on heuristic sequential sensor placement; |

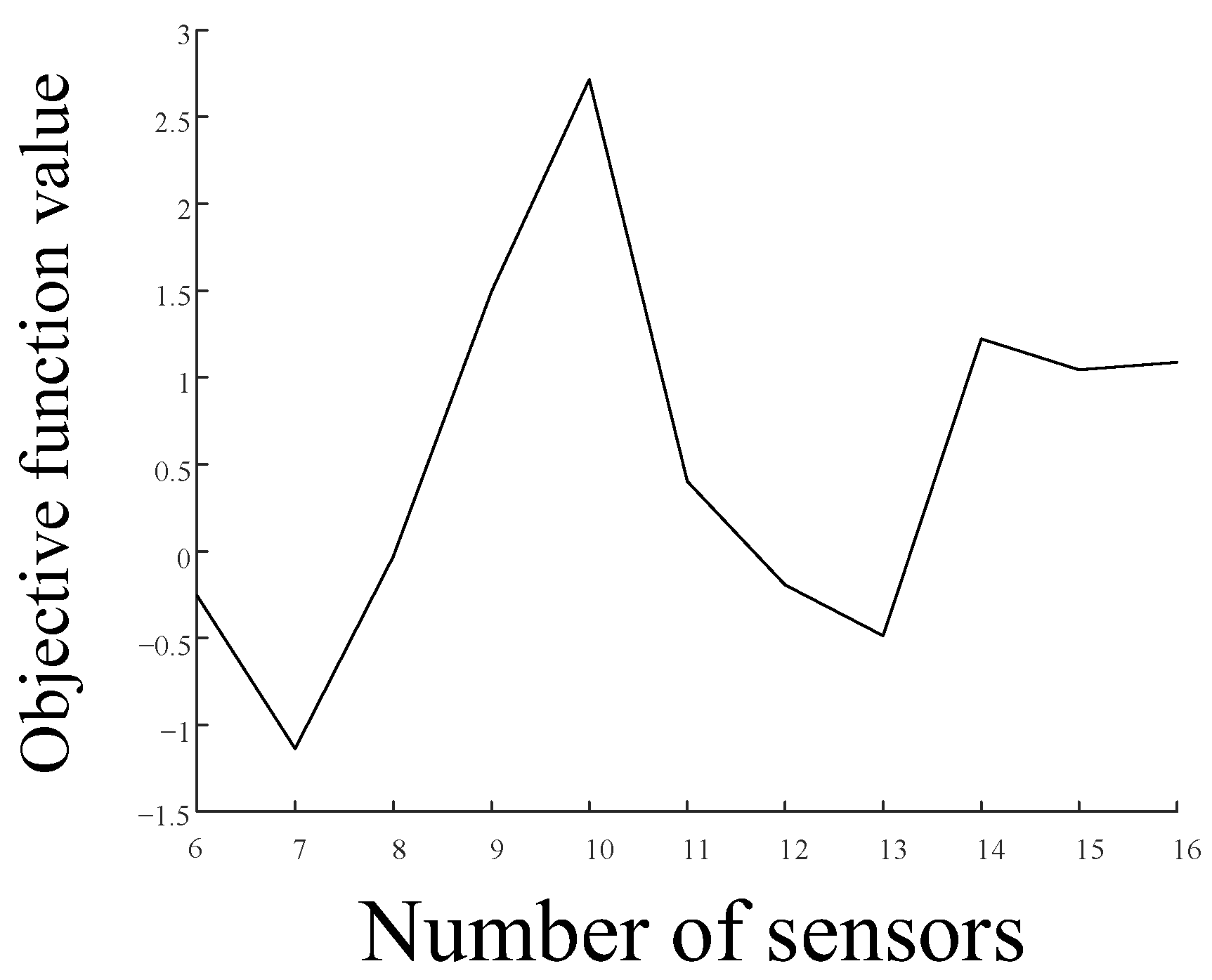

| 46 | //n_best—the optimal number of sensors according to the change of the objective function; |

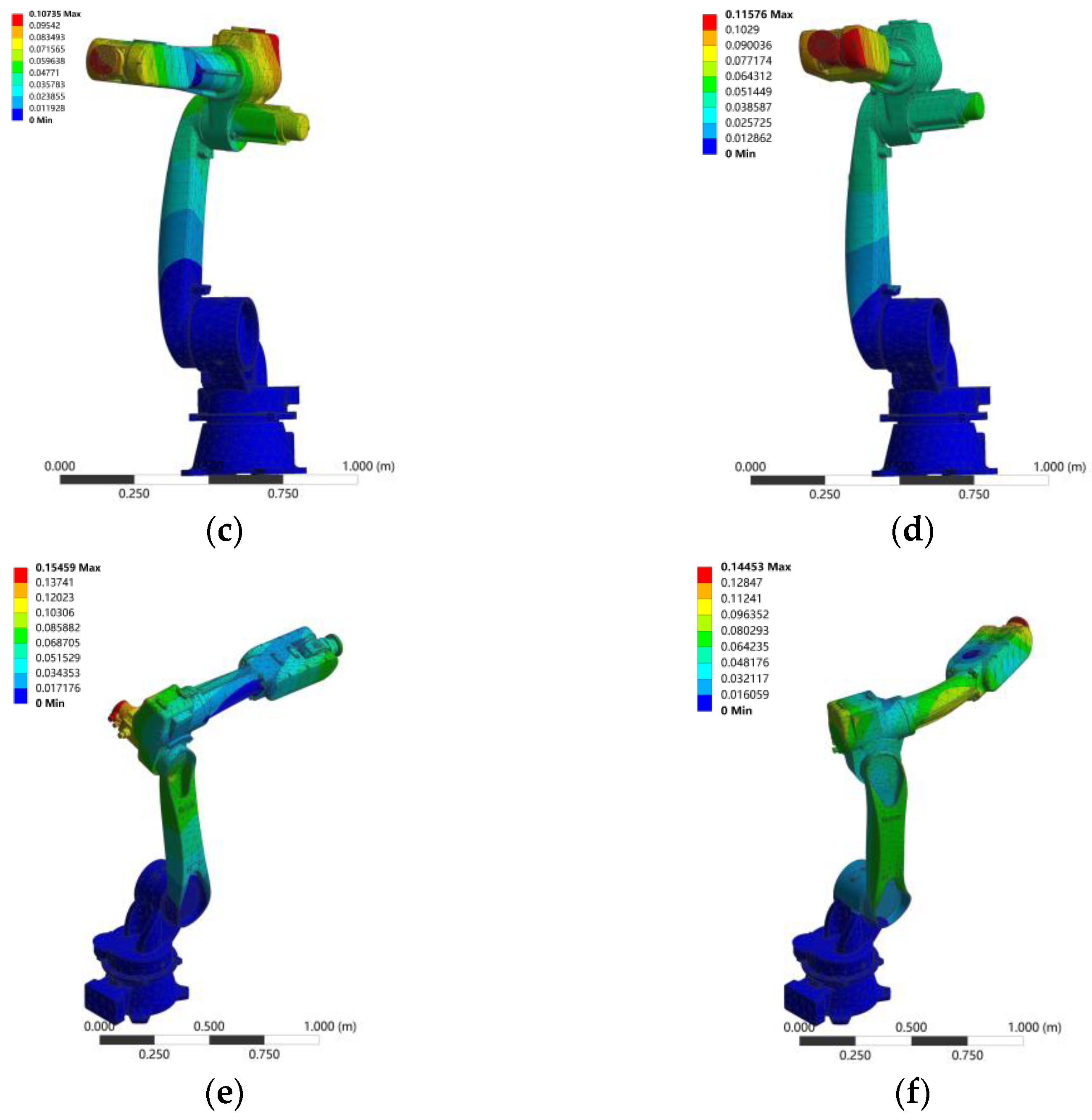

3.2. Verification of Optimal Sensor Placement for Industrial Robots Based on the Simulation Model

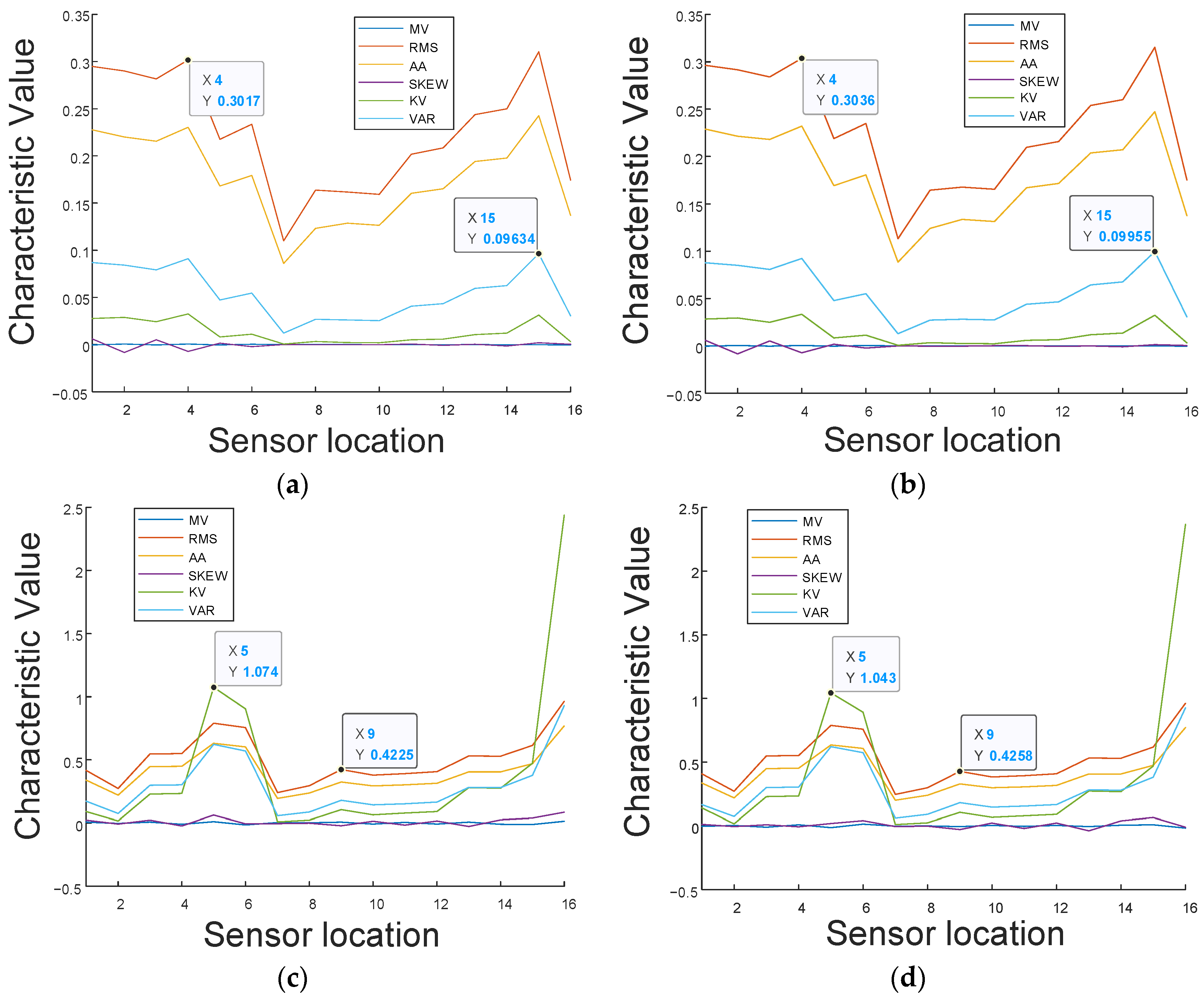

3.3. Optimal Sensor Placement Method and Verification of Industrial Robots without Simulation Models

3.4. Result

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, H.; Lin, Y.; Gu, L.; Xu, Y.; Gu, F. Vibration Analysis Based Condition Monitoring for Industrial Robots. In IncoME-V 2020: Proceedings of IncoME-V & CEPE Net-2020; Zhen, D., Wang, D., Wang, T., Wang, H., Huang, B., Sinha, J.K., Ball, A.D., Eds.; Mechanisms and Machine Science; Springer International Publishing: Cham, Switzerland, 2021; Volume 105, pp. 186–195. ISBN 978-3-030-75792-2. [Google Scholar]

- Xue, B. Remote Infrared Monitoring Method for Faults of Indoor Patrol Robot in Substation. In Proceedings of the 2021 7th International Symposium on Mechatronics and Industrial Informatics (ISMII), Zhuhai, China, 22–24 January 2021; pp. 24–27. [Google Scholar]

- Hou, Z.; Chen, J. Research Review of Remote Monitoring and Fault Diagnosis of Industrial Robots. Mach. Tool Hydraul. 2018, 46, 168, 172–176. [Google Scholar]

- Mi, Y.; Xu, F.; Tan, J.; Wang, X.; Liang, B. Fault-Tolerant Control of a 2-DOF Robot Manipulator Using Multi-Sensor Switching Strategy. In Proceedings of the 2017 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017; pp. 7307–7314. [Google Scholar]

- Neyens, G.; Zampunieris, D. Proactive Middleware for Fault Detection and Advanced Conflict Handling in Sensor Fusion. In Artificial Intelligence and Soft Computing; Rutkowski, L., Scherer, R., Korytkowski, M., Pedrycz, W., Tadeusiewicz, R., Zurada, J.M., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2019; Volume 11509, pp. 643–653. ISBN 978-3-030-20914-8. [Google Scholar]

- Zhou, Y.; Luo, J.; Wang, M. Dynamic Manipulability Analysis of Multi-Arm Space Robot. Robotica 2021, 39, 23–41. [Google Scholar] [CrossRef]

- Xu, P.; Cheung, C.-F.; Li, B.; Ho, L.-T.; Zhang, J.-F. Kinematics Analysis of a Hybrid Manipulator for Computer Controlled Ultra-Precision Freeform Polishing. Robot. Comput. Integr. Manuf. 2017, 44, 44–56. [Google Scholar] [CrossRef]

- Erkaya, S. Effects of Joint Clearance on the Motion Accuracy of Robotic Manipulators. Stroj. Vestn./J. Mech. Eng. 2018, 64, 82–94. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, G.; Wang, L.; Wang, J.; Wang, H. Multi-Degree-of-Freedom Joint Nonlinear Motion Control with Considering the Friction Effect. In Proceedings of the 2021 IEEE 19th World Symposium on Applied Machine Intelligence and Informatics (SAMI), Herl’any, Slovakia, 21 January 2021; pp. 000211–000216. [Google Scholar]

- Long, J.; Mou, J.; Zhang, L.; Zhang, S.; Li, C. Attitude Data-Based Deep Hybrid Learning Architecture for Intelligent Fault Diagnosis of Multi-Joint Industrial Robots. J. Manuf. Syst. 2021, 61, 736–745. [Google Scholar] [CrossRef]

- Zhang, J.; Maes, K.; De Roeck, G.; Reynders, E.; Papadimitriou, C.; Lombaert, G. Optimal Sensor Placement for Multi-Setup Modal Analysis of Structures. J. Sound Vib. 2017, 401, 214–232. [Google Scholar] [CrossRef]

- Gao, Q.; Cui, K.; Li, J.; Guo, B.; Liu, Y. Optimal Layout of Sensors in Large-Span Cable-Stayed Bridges Subjected to Moving Vehicular Loads. Int. J. Distrib. Sens. Netw. 2020, 16, 155014771989937. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.-H.; Xu, Y.-L.; Zhu, S.; Zhan, S. Dual-Type Sensor Placement for Multi-Scale Response Reconstruction. Mechatronics 2014, 24, 376–384. [Google Scholar] [CrossRef]

- Yi, T.; Zhang, X.; Li, H.-N. Modified Monkey Algorithm and Its Application to the Optimal Sensor Placement. Appl. Mech. Mater. 2012, 178–181, 2699–2702. [Google Scholar] [CrossRef]

- Hanis, T.; Hromcik, M. Optimal Sensors Placement and Spillover Suppression. Mech. Syst. Signal Process. 2012, 28, 367–378. [Google Scholar] [CrossRef]

- Castro-Triguero, R.; Murugan, S.; Gallego, R.; Friswell, M.I. Robustness of Optimal Sensor Placement under Parametric Uncertainty. Mech. Syst. Signal Process. 2013, 41, 268–287. [Google Scholar] [CrossRef]

- Li, D.S.; Li, H.N.; Fritzen, C.P. The Connection between Effective Independence and Modal Kinetic Energy Methods for Sensor Placement. J. Sound Vib. 2007, 305, 945–955. [Google Scholar] [CrossRef]

- Kammer, D.C. Sensor Placement for On-Orbit Modal Identification and Correlation of Large Space Structures. In Proceedings of the 1990 American Control Conference, San Diego, CA, USA, 23–25 May 1990; pp. 2984–2990. [Google Scholar]

- Li, D.-S.; Li, H.-N.; Fritzen, C.-P. Load Dependent Sensor Placement Method: Theory and Experimental Validation. Mech. Syst. Signal Process. 2012, 31, 217–227. [Google Scholar] [CrossRef]

- Brehm, M.; Zabel, V.; Bucher, C. Optimal Reference Sensor Positions Using Output-Only Vibration Test Data. Mech. Syst. Signal Process. 2013, 41, 196–225. [Google Scholar] [CrossRef]

- Moreno-Salinas, D.; Pascoal, A.; Aranda, J. Optimal Sensor Placement for Acoustic Underwater Target Positioning With Range-Only Measurements. IEEE J. Ocean. Eng. 2016, 41, 620–643. [Google Scholar] [CrossRef]

- Flynn, E.B.; Todd, M.D. A Bayesian Approach to Optimal Sensor Placement for Structural Health Monitoring with Application to Active Sensing. Mech. Syst. Signal Process. 2010, 24, 891–903. [Google Scholar] [CrossRef]

- Papadimitriou, C.; Lombaert, G. The Effect of Prediction Error Correlation on Optimal Sensor Placement in Structural Dynamics. Mech. Syst. Signal Process 2012, 28, 105–127. [Google Scholar] [CrossRef]

- Sun, H.; Büyüköztürk, O. Optimal Sensor Placement in Structural Health Monitoring Using Discrete Optimization. Smart Mater. Struct. 2015, 24, 125034. [Google Scholar] [CrossRef]

- Vincenzi, L.; Simonini, L. Influence of Model Errors in Optimal Sensor Placement. J. Sound Vib. 2017, 389, 119–133. [Google Scholar] [CrossRef]

- Huan, X.; Marzouk, Y.M. Simulation-Based Optimal Bayesian Experimental Design for Nonlinear Systems. J. Comput. Phys. 2013, 232, 288–317. [Google Scholar] [CrossRef] [Green Version]

| When the axis of joint intersects with the axis of joint , the intersection point is taken | Coincides with the axis of joint | If the joint axis intersects , it is perpendicular to the plane where the joint axis and are located | Determined by the right-hand rule |

| When the axis of joint is out of plane with the axis of joint , take the intersection of the common perpendicular of the two axes and the axis of joint | On the common perpendicular of the links and , its direction is from to | ||

| When the axis of joint is parallel to the axis of joint , take the intersection of the common perpendicular of the axis of joint and the axis of joint with the axis of joint |

| Link\Parameters | ||||

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | |

| 2 | 0 | |||

| 3 | 0 | 0 | ||

| 4 | 0 | |||

| 5 | 0 | 0 | ||

| 6 | 0 |

| Project | Type | Number of Axes | Driving Mode | Repeat Positioning Accuracy | Range of Motion |

|---|---|---|---|---|---|

| Parameter | RB13 | 6 | AC servo | 0.07 mm | R499~R1404 mm |

| Order | 1 | 2 | 3 | 4 | 5 | 6 |

| Natural frequency/Hz | 12.6 | 20.0 | 30.0 | 70.3 | 116.7 | 338.3 |

| Maximum relative amplitude/m | 0.11 | 0.09 | 0.10 | 0.12 | 0.15 | 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Q.; Zhang, Y.; Xie, X.; Su, W.; Li, Y.; Shan, L.; Yu, X. Optimal Placement of Vibration Sensors for Industrial Robots Based on Bayesian Theory. Appl. Sci. 2022, 12, 6086. https://doi.org/10.3390/app12126086

Hu Q, Zhang Y, Xie X, Su W, Li Y, Shan L, Yu X. Optimal Placement of Vibration Sensors for Industrial Robots Based on Bayesian Theory. Applied Sciences. 2022; 12(12):6086. https://doi.org/10.3390/app12126086

Chicago/Turabian StyleHu, Qiao, Yangkun Zhang, Xingju Xie, Wenbin Su, Yangyang Li, Liuhao Shan, and Xiaojie Yu. 2022. "Optimal Placement of Vibration Sensors for Industrial Robots Based on Bayesian Theory" Applied Sciences 12, no. 12: 6086. https://doi.org/10.3390/app12126086

APA StyleHu, Q., Zhang, Y., Xie, X., Su, W., Li, Y., Shan, L., & Yu, X. (2022). Optimal Placement of Vibration Sensors for Industrial Robots Based on Bayesian Theory. Applied Sciences, 12(12), 6086. https://doi.org/10.3390/app12126086