1. Introduction

The increasing world population and the improvement of people’s living conditions have caused a significant increase in global energy needs. The worldwide energy consumption by the building sector has increased and currently accounts for 40% of the world’s energy consumption and for approximately 36% of the greenhouse gas emissions [

1,

2,

3], making it a key sector in which to promote more sustainable energy consumption.

The topic of energy efficiency in buildings has been the center of a broad technical and scientific discussion in recent years concerning the decarbonization or carbon neutrality of the building sector. In that sense, several innovative materials for opaque and transparent [

4] elements of building envelopes, high-performant lighting systems, and more efficient heating and cooling systems that maximize energy savings have been investigated and developed in the last decades.

When compared with opaque elements, glazed elements of a building envelope usually have a lower performance due to their higher thermal and solar transmittance. However, glazed elements can positively impact the luminous quality of the indoor environment since they provide occupants with an outdoor view and make it possible to benefit from daylight. Therefore, glazing systems are one of the most significant elements concerning the thermal and visual comfort, and energy efficiency in buildings [

5,

6,

7].

Since modern buildings tend to have large glazing areas, and conventional glazing is responsible for significant heat exchanges between the indoor and outdoor environments and for high indoor illuminance levels that can lead to discomfort glare, it is important to promote solar control solutions that can enhance the performance of windows. Some of these more conventional solutions, such as overhangs, blinds and louvers, have, as drawbacks, the requirement of altering the type or structure of the existing glazing/fenestration and the possible blocking of the outdoor view.

Research and development in the field of glazing systems have experienced a rapid evolution with several innovative breakthroughs, such as laminated glass panes in the 1920s and coated products in the 1970s. Since then, the traditional clear single-glass window, which has a poor performance, has evolved to produce more efficient solutions such as double or triple glazing, low-emittance windows with low thermal transmittance, vacuum glazing, electrochromic windows [

8,

9], thermotropic materials [

10,

11], silica aerogels [

12] and transparent insulation materials. More recently, the development of transparent selective coatings and films [

13,

14,

15] provides a wide range of solar optical properties for glazing surfaces, admitting high daylight levels while preventing excessive heat gains through the glazing.

Some of these innovative and modern window technologies [

8,

10,

11] can dynamically alter their properties to control the amount of incoming light and heat by responding to environmental stimuli or user requirements. As a result, these smart window technologies can improve the building’s global performance by optimizing energy use, peak demand and indoor comfort in real time.

Smart window technologies have undergone rapid development in the last years, particularly in windows that respond to electro-, thermos-, mechano- and photo- stimuli [

4]. Electrochromic windows are a promising and attractive window technology from research, design and user perspectives, with several products currently available on the market. This type of smart window has a better performance in climates with different needs for winter and summer seasons and different façade orientations [

9,

16]. Photochromic and thermotropic passive smart windows that react to light and heat stimuli, respectively, are also attractive solutions with a lower economic cost than active windows [

10,

11,

17]. Nevertheless, these passive smart windows have the absence of control by the user as a disadvantage.

The main issues involved in the application of smart windows are: the high cost and associated long payback period; the materials and devices must be highly durable; the optimization of the solar modulation properties to achieve maximum energy savings; the potential presence of the haze effect, usually caused by disperse particle technology.

The installation of static solar control films (SCFs) is an alternative and effective solution to reduce heat gains through glazing systems by altering their solar optical and thermal properties. With an easy application method that does not require façade alteration, these films act as refurbishment solutions that promote the improvement of the thermal, luminous and energy performance of building glazing, while reducing potential glare and the transmittance of ultraviolet (UV) radiation. Furthermore, these static films present a lower economic cost than the dynamic window technologies previously mentioned.

This paper presents a literature review of the performance of static SCFs when installed in building glazing systems consisting of: an overview of window films with the characterization of the different types, installation position and main properties; the characterization of SCFs in terms of existing types and their impact on the properties of the glazing system they are applied to; an in-depth literature review of research studies that assess the performance of SCFs in buildings; a discussion of the data, methodology and findings of the studies; and the main conclusions and recommendation of future studies on the topic. To the best of the authors’ knowledge, there is no evidence reported in the literature of a study addressing a comprehensive review of the performance of static SCFs when installed in the glazing systems of buildings. Innovative window coatings [

13] are not considered in the present review.

The added value of the present work lies in collecting and analyzing the existing studies in the literature that address the performance of static SCFs applied to building glazing, comparing research approaches and the main findings. Moreover, research gaps and future studies are listed to help establish guidelines for research and design on the topic.

2. Window Films

Window films, composed of transparent, tinted or metalized laminated polyester layers, are designed to be installed in glazing systems to change their thermal and solar optical properties and they usually increase their performance by reflecting or absorbing part of the incident solar radiation. This section briefly introduces window films, describing a typical layout and listing the different types of films and the main solar optical and thermal properties used to characterize these materials. The background information gathered in this section helps to better contextualize solar control films (the solution focused on in the present study).

The first window films were developed in the 1960s. They had the primary purpose of balancing heat exchanges through glazing by blocking radiation throughout the entire range of wavelengths of the solar spectrum [

18]. Even though this was a significant discovery with a high potential to promote visual and thermal comfort in buildings, drawbacks in terms of reducing outdoor visibility, excessive artificial lighting and heating energy consumption instigated new research and product development.

With the improvement and development of the concept of a window film, the demand for colored films that could provide privacy and sun control, while complementing the architectural design of the building, increased.

In the 1970s, when the industrial revolution was at its peak, new products and materials that improved indoor thermal comfort and energy efficiency in buildings were investigated and developed. The incorporation of polyester membranes in window films made it possible to manufacture films with higher energy efficiency for cold climates, due to the higher absorption coefficient and reradiation of long wave infrared heat, thus reducing heat losses towards the outdoor environment without decreasing the visible transmittance through the glass and film system [

18].

Metalized films, which had a metallic coating that reflected solar heat and UV radiation, were introduced in the 1990s.

More recently, innovative ceramic window films were introduced to the market. These films have a significantly high performance, blocking up to 99% of UV radiation and efficiently decreasing glare and solar gains. Ceramic films have a higher resistance to corrosion than other window films.

2.1. Typical Layout of Window Films

Window films are made of several membranes of different intercalated materials that can reach up to eight different layers and undergo seven different manufacturing procedures [

19].

Figure 1 shows a typical layout of a window film [

19,

20] installed on the internal surface of the glass, constituted by the following layers:

1. Scratch resistant coating: a hard acrylic coating finishing layer that is in contact with the indoor environment and aims to protect the film from abrasion and scratching.

2. and 5. Polyester: polyester layers that introduce good mechanical, thermal, optical, physical and chemical characteristics to the film, and that are very durable, flexible, resistant and have the capacity to withstand high and low temperatures. The lamination of several layers of polyester using adhesives increases the film’s absorption and solar front reflectance. This layer can have different finishing types, such as UV resin or adhesives.

3. Metal: oxide metals are incorporated into the polyester layers of window films and have the purpose of reducing solar heat gains through the glazing. Usually, aluminum is used to reduce solar heat gains and visible transmittance by about 80% and 15–70%, respectively. Modern films based on nanotechnology are manufactured without metal oxides, resulting in thin window films with high visible transmittance and low solar front reflectance.

4. Lamination adhesive: combines several membranes of polyester through lamination processes and can sometimes be embedded directly in the polyester layers.

6. High performance UV resin: can be incorporated into the adhesives or the polyester membranes to block UV radiation, protect the polyester layers and lamination adhesives, and protect the indoor environment, occupants and materials from exposure to UV radiation.

7. Adhesive: window films can be applied to glazing using pressure-sensitive or water-activated adhesives. Pressure-sensitive adhesives adhere to the surface of the glass by applying pressure forces without the need to use any type of solvent, water, or heat. Water-activated adhesives need water to form a correct adherence to the glass through chemical bonds, which guarantees higher durability and a more transparent appearance. However, using water-activated adhesives can make the removal or replacement of the film difficult.

8. Protective release liner: a removable polyester film that shields the adhesive from contamination. The protective liner should only be removed right before applying the film.

The production of window films usually requires the following high-quality manufacturing procedures [

18]:

Coating: the material is transferred from a container to a large roller and then onto the surface of the polyester film. This process is typically used to apply adhesives and scratch resistant layers.

Laminating: a film that is coated with adhesive is adhered to an uncoated film by using a roller system that presses the two films together.

Metallizing: under vacuum conditions, a polyester roll is wound round a water-cooled roller in a large metal chamber while a metal, typically aluminum, is evaporated onto the cold film surface.

Sputtering: the equipment needed for this process is very similar to that used for metallizing, but in the sputtering process, a metal or alloy target is bombarded with positive ions to sputter atoms of metal onto the cold film surface. Some metals used in sputtering, such as nickel, can give extra corrosion resistance to films. This process is more time consuming than metallizing.

Coloring: color can be added to adhesives before coating, or the polyester film can be deep dyed through this process. The resulting color is usually a mixture of different dyes and, generally, a higher durability is obtained using deep dyeing processes.

2.2. Types of Window Films

Currently, there is a wide range of films designed to be applied to the interior or exterior of glazed windows for different purposes. The following types of window films are listed in EN 15752-1 [

20]:

Solar control films (the focus of this paper): their purpose is to decrease the solar gains by reducing the solar factor of the glass substrate. These films can be applied on the interior or exterior surface of the glazing.

Low emissivity (low-E) films: their purpose is to promote thermal insulation by reducing the thermal transmittance of the glass pane. These films should be applied on the exterior (hot climates) or interior (cold climates) glazing surfaces in contact with the air chamber to obtain a better performance when applied to double-glazed windows.

Low ultraviolet transmittance films: the reduction in the UV radiation transmittance through the glazing (up to 99.9%), is the purpose of this type of window film.

Privacy films: their goal is to reduce the vision through the glass pane by decreasing its visible light transmittance. This goal can be achieved by increasing the visible light reflectance of the glass pane on the outside (usually the public side) or by applying opaque or decorative features to the glass substrate.

Decorative films: the goal of these films is to change the appearance of the glass substrate by incorporating patterns, textures, or colors.

Protection films: their purpose is to increase the resistance of the glass pane to intentional or accidental impacts and to reduce the amount and size of possible glass fragments, protecting occupants and material goods by keeping most fragments attached to the film.

Safety films: while the previous type of window films increase the resistance of the glass pane to impacts, the purpose of safety films is to offer resistance to shock waves from explosions and/or ballistic attacks.

Protection of radio frequency and electromagnetic frequency films: their goal is to attenuate the transmittance of frequencies over the range of 30 MHz to 15 GHz by ≥20 dB.

Anti-graffiti films: their purpose is to protect the surface of the glass pane against scratching, graffiti, and painting. These films present a resistant anti-scratch layer that prevents the glass from having to be replaced.

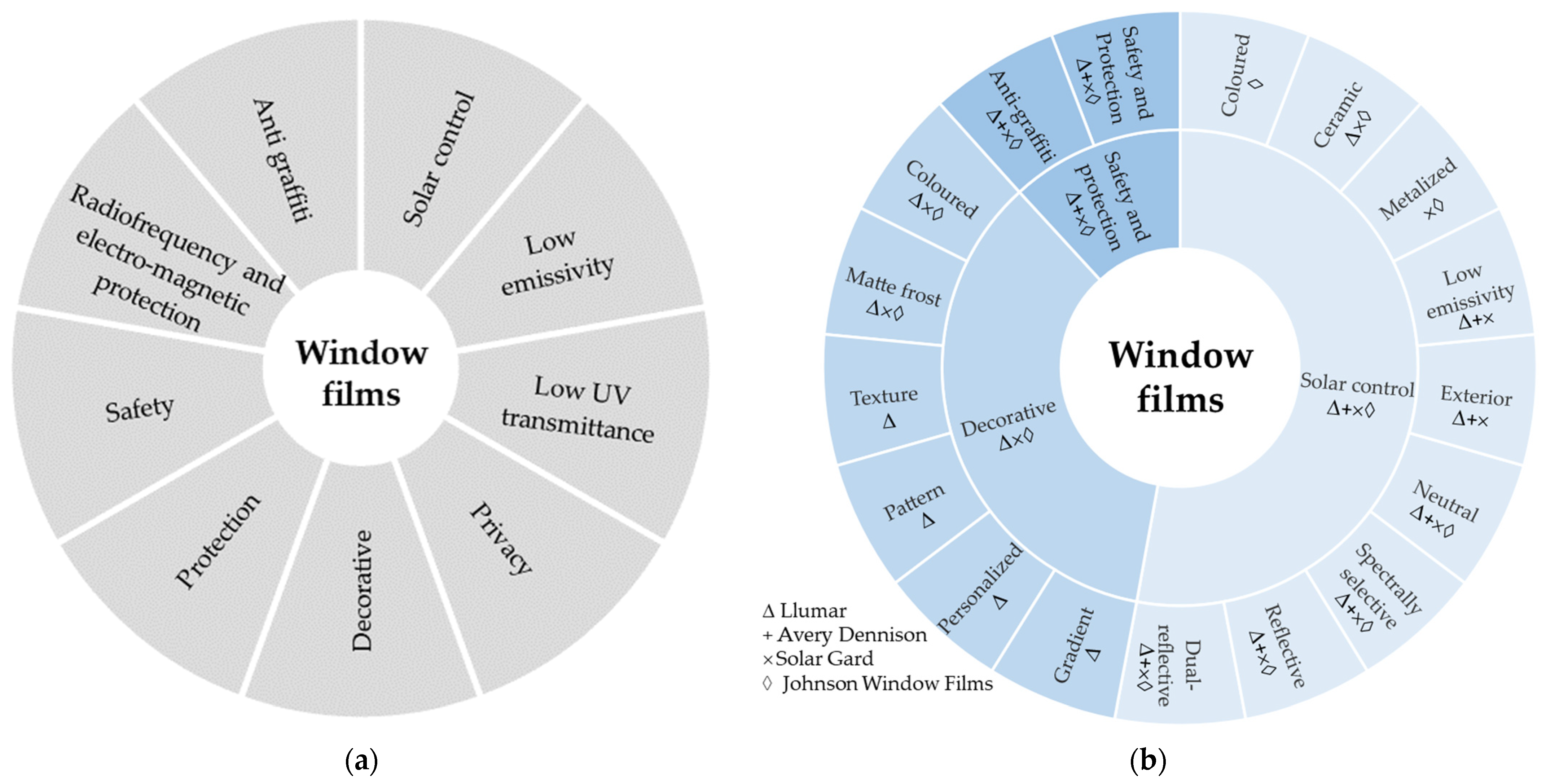

The industry presents window films in a different way to allow a better perception of the films available on the market and to help the comparison between them by customers. The different types of window films listed by EN 15752-1 [

20] and presented on the market by some of the main industry players are shown in

Figure 2.

2.3. Main Properties of Window Films

The performance characteristics and properties of window films are described in relation to their class and type of film.

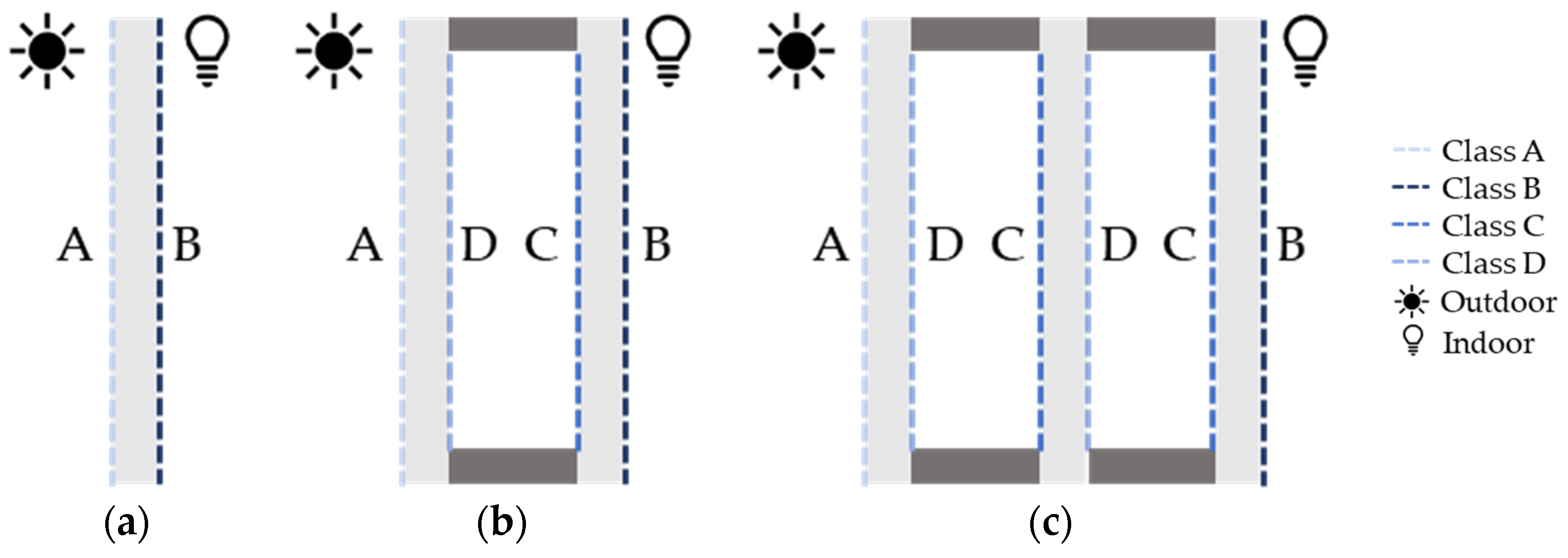

The class of window films corresponds to which glass surface they can be applied to. The following classes are listed in EN 15752-1 [

20]:

Class A: the window film is designed to be applied to the external glass surface in contact with the outdoor environment. These films are usually described as external films.

Class B: the window film is designed to be applied to the internal glass surface in contact with the indoor environment. These films are usually described as internal films.

Class C: the window film is designed to be applied as an external film to the glass surface within the cavity of an insulating glass unit facing the outdoor environment.

Class D: the window film is designed to be applied as an internal film to the glass surface within the cavity of an insulating glass unit facing the indoor environment.

Figure 3 illustrates the different installation positions of each class of window films. Films with external application on the glass surface present lower durability than those with internal application because they are exposed to weather elements and possible damage induced by people or objects for glazing surfaces at the ground level. In addition, inappropriate cleaning tasks or insufficient maintenance routines have proven to decrease the life span of the films.

The determination and knowledge of the thermal and solar optical properties of glazing systems are essential to ensure a good thermal and energy performance of buildings, particularly in building envelopes with high ratios of glazed to opaque areas. A suitable choice of glazing system at the design stage of a building should enhance occupants’ thermal and visual comfort and, consequently, the energy efficiency of the building.

According to EN 15752-1 [

20], window films are defined based on their reflectance (interior and exterior) and their transmittance properties for the different radiation ranges: UV, solar, visible and thermal ranges. The following solar optical properties are listed in EN 15752-1 [

20] to characterize a glass and film system:

Solar transmittance (): fraction of solar radiation passing through the glass and film system.

Solar reflectance (): fraction of solar radiation reflected by the glass and film system.

Solar absorptance (): fraction of solar radiation absorbed by the glass and film system.

Visible light transmittance (): fraction of visible radiation passing through the glass and film system.

Exterior visible light reflectance (): fraction of visible radiation reflected by the exterior surface of the glass and film system.

Interior visible light reflectance (): fraction of visible radiation reflected by the interior surface of the glass and film system.

Total solar energy transmittance factor or solar factor (g): ratio between the total amount of radiation (transmitted directly and after being absorbed) flowing into the indoor environment and the global incident solar radiation on the glass and film system.

Total shading coefficient (SC): ratio between the gain of solar heat through a glass and film system and the gain of solar heat through a double-resistant transparent glass system.

UV transmittance (): fraction of UV radiation passing through the glass and film system.

General color rendering index (): degree of reliability of the light source that permeates the film revealing the colors of the illuminated objects, compared to their appearance when illuminated by natural daylight.

The values of the abovementioned properties are determined in accordance with EN 410 [

21] and can be expressed as decimal or percentage values except for the total SC and the

index, which should only be expressed using decimal values [

20].

The following thermal properties referred to in EN 15752-1 [

20] are also used to describe a glass and film system, particularly in the case of low emissivity films:

Thermal transmittance coefficient (U-value): quantifies the heat flow [W/m

2·K] that passes in one hour through 1 m

2 of the glass and film system separating two environments (outdoor and indoor) with a temperature difference of 1 °C. U-value shall be determined in accordance with EN 673 [

22].

Emissivity (

ε): the ratio between the energy emitted by the glass pane and film system and the energy emitted by the blackbody at the same temperature. Emissivity shall be determined in accordance with EN 12898 [

23].

3. Solar Control Films

A solar control film (SCF), as previously referred to, is a thin laminate film that is applied to glazing systems to modify their solar optical and thermal properties in order to increase their performance. Currently, there is a broad variety of SCFs for new and retrofitted glass, with application on both internal and external glass surfaces, that are suitable for cold and hot climates.

This section summarizes the existing types of SCFs and their impact on the main solar optical and thermal properties of the glazing systems they are applied to. The information present in this section is relevant to later discussion about which types of SCFs are less studied and to better comprehend the impact these films have on the properties of the glazing system when installed in single and double clear glazing (representative of the most common glazing solutions).

3.1. Types of Solar Control Films

The main industry players of window films (such as 3M [

24]; Llumar [

25]; Avery Dennison [

26]; Solar Gard [

27]; and Johnson Window Films [

28]) offer a large variety of each type of SCF to be installed in different positions of the glazing system. Depending on their purpose, SCFs can be divided into the following types:

Reflective: these films have reflective properties on both sides that provide high heat, glare and UV control. They give a silvery/mirrored look to the glazing when viewed with indoor lighting or outdoor daylight.

Dual-reflective: these films have a reflective outside-facing layer with a subtler inside-facing layer, meaning they can provide significant solar control during the day and maintain a clear outside view at night.

Neutral: these films control solar gains through the glass while maintaining the original appearance of the glazing system.

Low emissivity: these films reduce the thermal transmittance coefficient (U-value) of the glazing system, increasing its thermal insulation and heat-rejection properties during the four seasons (suitable for temperate regions).

Spectrally selective: these films offer an excellent heat rejection with a virtually invisible appearance. Contrary to neutral SCFs, spectrally selective films can block specific regions of the solar spectrum associated with solar heat gains while not penalizing the transmittance of daylight through the glazing.

Ceramic: these films offer solar control without a metal layer, maintaining a low visible reflectivity and a high resistance to corrosion (suitable for coastal areas).

Safety and protection: these films can control excessive solar heat gains and, at the same time, increase the resistance of the glass pane to intentional or accidental impacts. In addition, this type of film reduces the amount and dimension of potential glass fragments and/or offers higher resistance to the glass to support shock waves from explosions and/or ballistic attacks.

Information on the thermal and solar optical properties of the SCFs available on the market was gathered in this work to better understand the range of values of each property and help to highlight the differences between the multiple types of SCFs. The properties of the SCFs present in the International Glazing Database were collected using Optics [

29] and Window [

30] software.

The International Glazing Database (IGDB) [

31] encompasses the most extensive collection of products used for the construction of windows, namely: different types of glass, films, lamination adhesives, window frames, and filling gasses. It also contains detailed solar optical and thermal information on these products.

The addition of products into the IGDB database follows a set of standards issued by the National Fenestration Rating Council. Adding a new film into this database requires that manufacturers provide film samples applied to single uncoated glass substrates with solar and optical transmittances greater than 0.83 and 0.89, respectively. These specifications ensure that the film has transmittance values similar to or lower than those of the glass to which it will be applied to [

32]. The glass that meets these criteria: 3 mm single glass; 3 mm single glass with low iron content; and 6 mm single glass with low iron content. Additionally, manufacturers must submit samples of the same glass without the film, so that the thermal and solar optical properties of the glass can be determined separately.

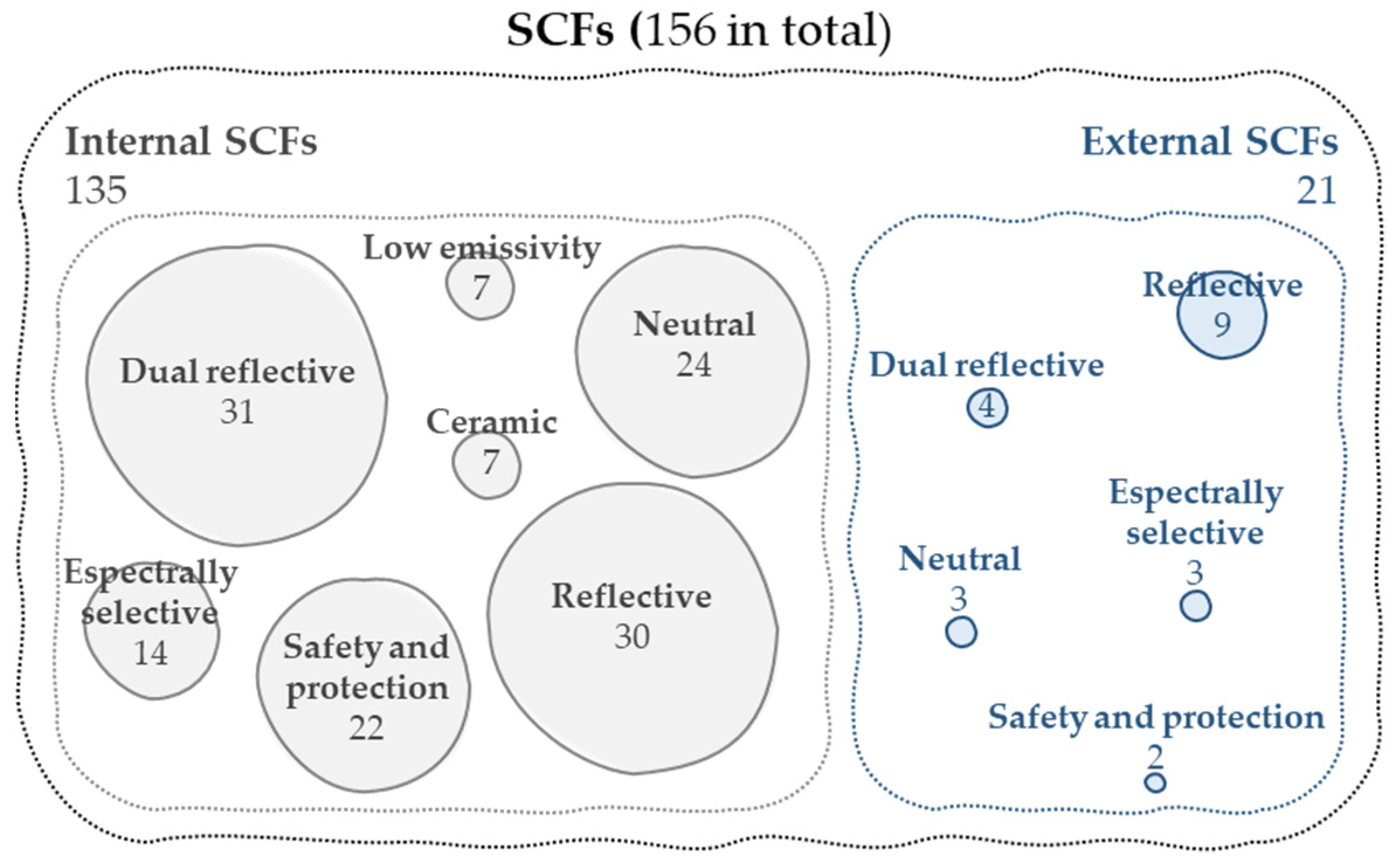

The version (v72.0) of the IGDB database [

31] used for this work has, in total, 156 SCFs manufactured by some of the main industry players of window films (3M [

24]; Llumar [

25]; Avery Dennison [

26]; Solar Gard [

27]; and Johnson Window Films [

28]).

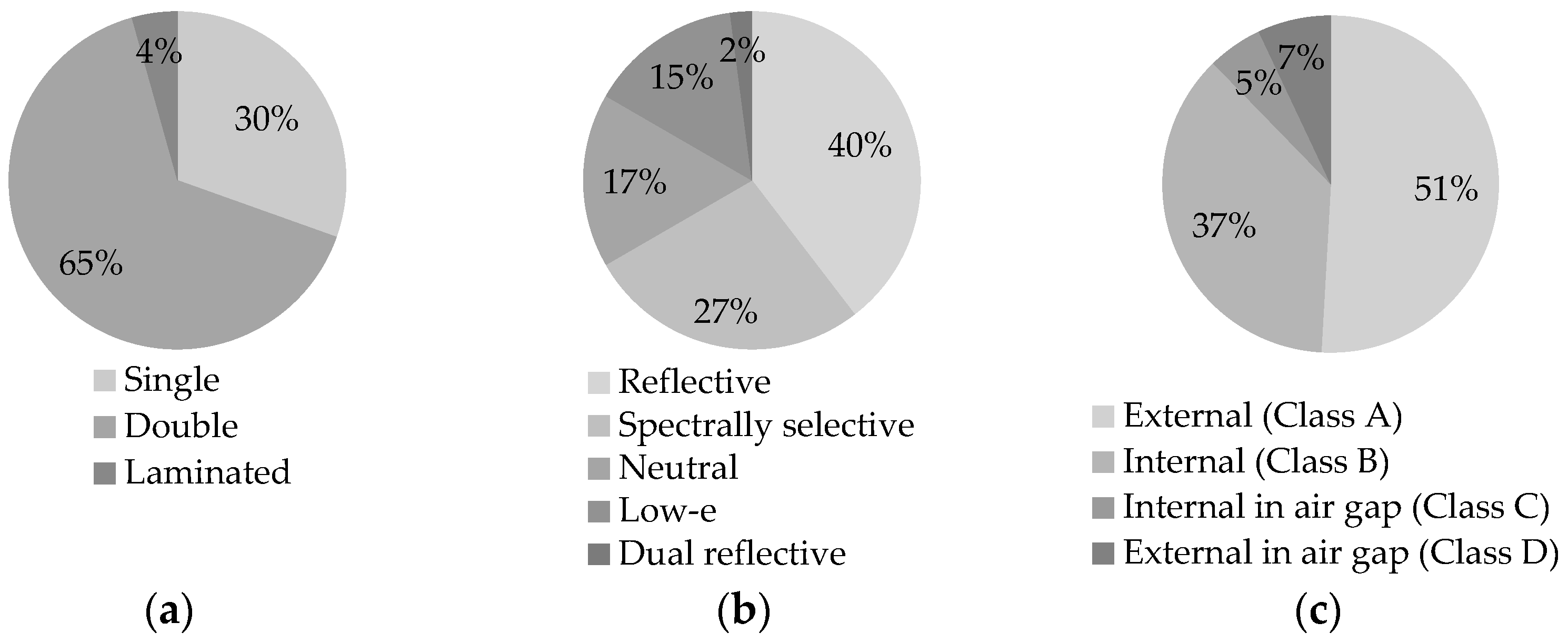

Figure 4 shows the quantity of SCFs assembled, grouped by film type.

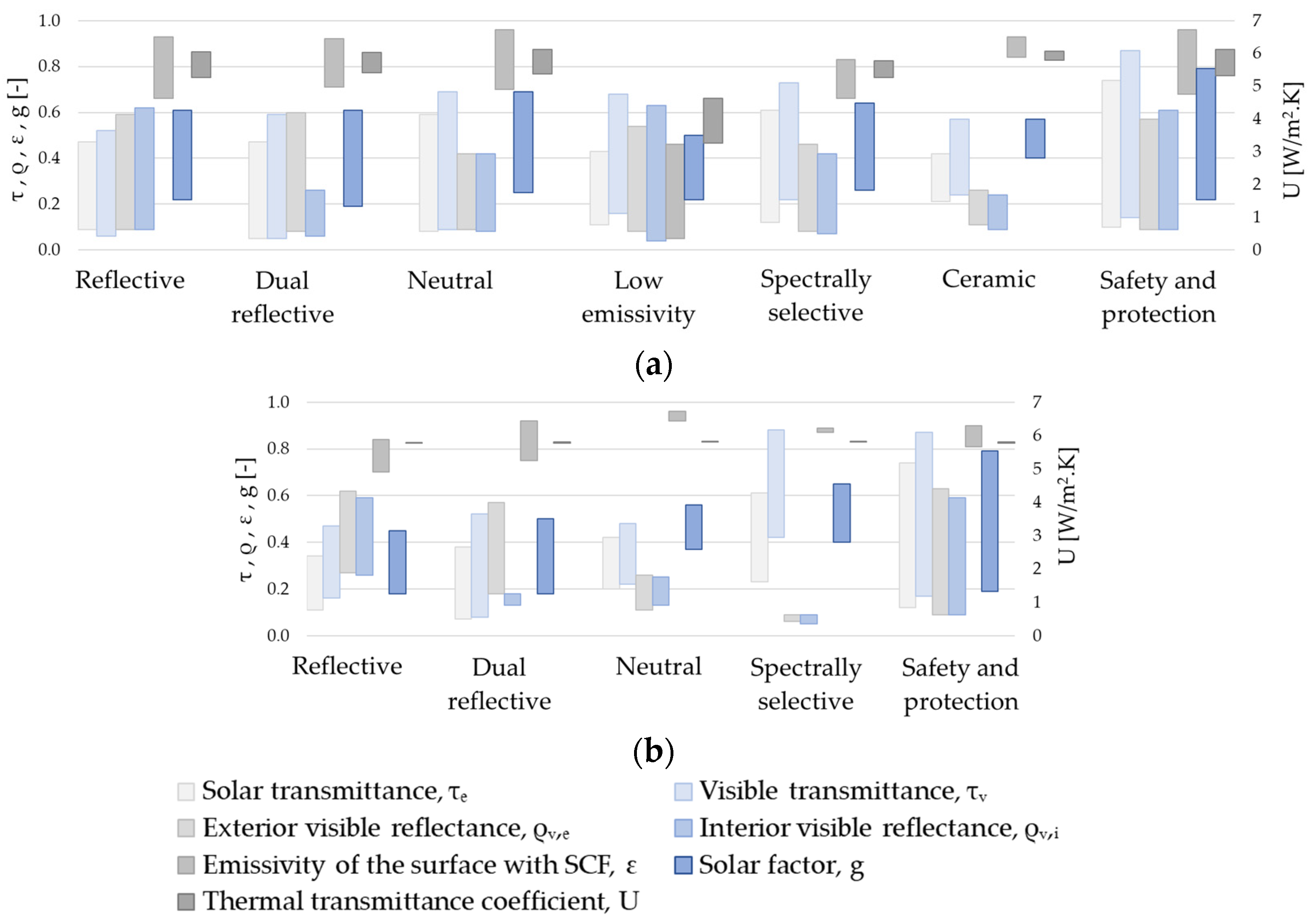

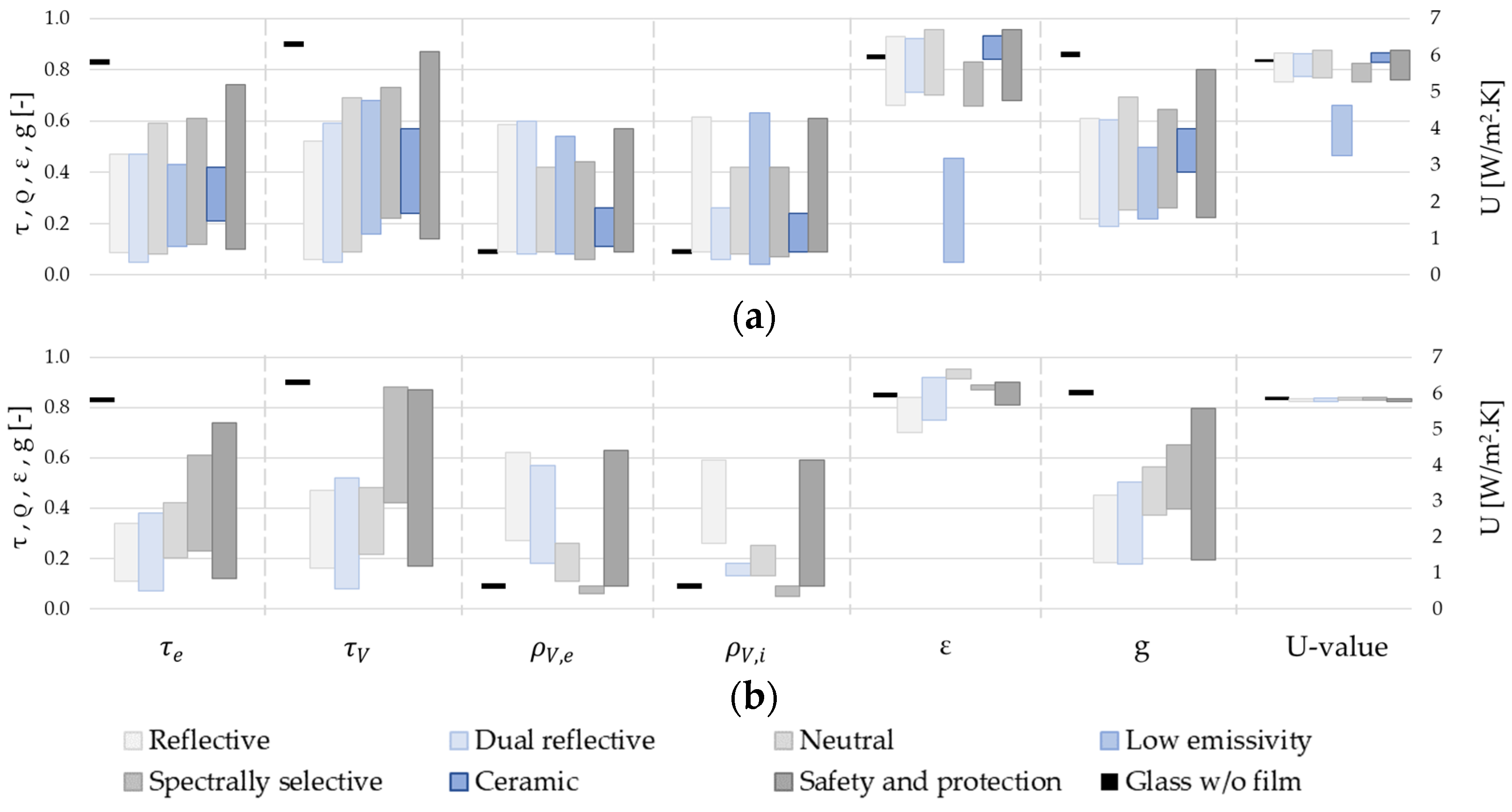

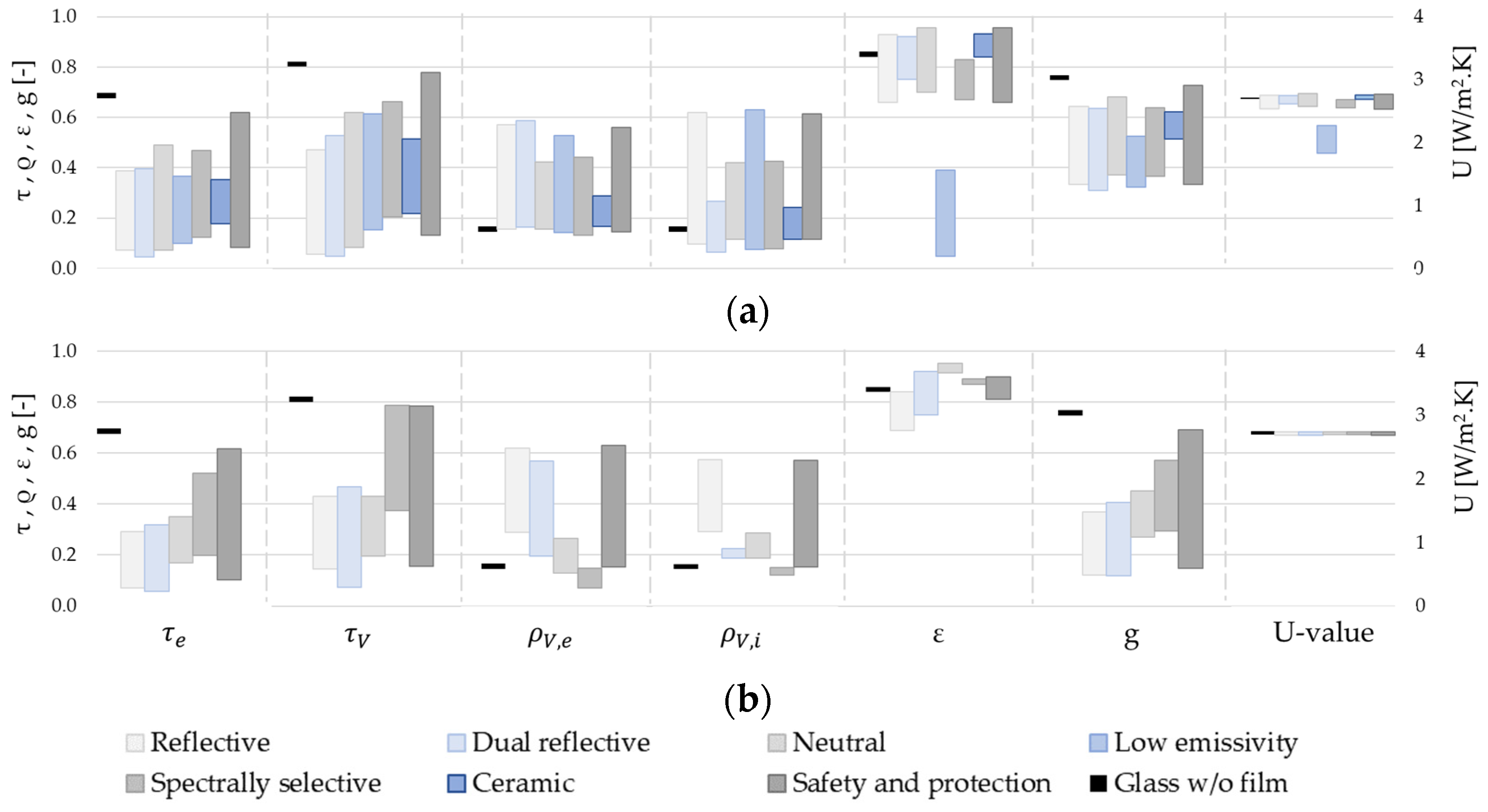

Figure 5 shows the ranges of the thermal and solar optical properties of different types of SCFs, present in the IGDB database [

31], when applied to clear single glass (6 mm). The thermal and solar optical properties of these SCFs, when installed in single clear glazing (6 mm), were computed using Optics [

29] and Window [

30] software. It is possible to note the variety of values for the different properties of the different types of SCF. Reflective and dual reflective SCFs show similar ranges of the main properties’ values, except the interior visible reflectance that is significantly lower for dual reflective films. Neutral, spectrally selective and ceramic SCFs show lower reflectance values. Low emissivity SCFs show a noteworthy reduction in the surface emissivity and of the U-value of the glazing system. Safety and protection SCFs show a higher amplitude of values.

3.2. Impact of Solar Control Films on the Main Thermal and Solar Optical Properties of Clear Glass

The performance of SCFs depends on their thermal and solar optical properties, as well as on the properties of the glass substrate to which they have been applied to, as referred in EN 15755-1 [

33]. It is important to highlight that there are limitations when SCFs are applied to specific types of glazing due to potential thermal shock breakage of the glass substrate that is usually promoted by the increasing solar absorptance by the film. As a result, a careful analysis should be carried out prior to applying SCFs.

The impact of different types of SCFs on the main thermal and solar optical properties of two glass substrates representative of common building glazing solutions (clear single and double glazing) is assessed in the present section. The selected glass substrates (

Table 1) are composed of clear glass panes with a thickness of 6 mm and a gas filling chamber with 16 mm of thickness in the case of the double-glazing solution. The SCFs previously assembled were considered for the impact assessment conducted in this section. The ranges of values of the main thermal and solar optical properties of the clear glazing solutions with and without different types of SCFs presented in this section were computed through Optics [

29] and Window [

30] software.

Figure 6a shows the ranges of values of the main thermal and solar optical properties of clear single-glazing, with and without different types of SCFs applied to the internal glass surface. All types of SCFs made it possible to reduce the solar and visible transmittance values of the glazing, particularly reflective and dual reflective films (by up to 94%). The visible reflectance values increased (up to

= 0.63) in the presence of all types of SCFs. Low-E films drastically reduce the emissivity (lowest

ε of 0.05) of the glazing and, consequently, the thermal transmittance coefficient (down to U = 3.26 W/(m

2·K), equivalent to a reduction of 44%) of the window.

Figure 6b shows the ranges of values of the main thermal and solar optical properties of clear single-glazing, with and without different types of SCFs applied to the external glass surface. The types of SCFs with external applications are more restricted than those available for internal applications. The ranges of values of the properties tend to be shorter and tend to include lower values in the presence of SCFs with external application, when compared with SCFs with internal application. However, this could be explained by the scarce number of SCFs with external application considered in this study. The main properties of the safety and protection SCFs are similar when comparing internal versus external application. The thermal transmittance coefficient remained unchanged with the application of external SCFs.

Figure 7a shows the ranges of the main thermal and solar optical properties values of clear double glazing with and without different types of SCFs applied to the internal glass surface. SCFs modified the values of the properties of the double-glazing in a similar way to that previously observed with the single-glazing (solar and visible transmittance reduced by 94%). However, the application of SCFs to double-glazing did not result in significant reductions in the solar factor (lowest g of 0.31, equivalent to a reduction of 59%) and the thermal transmittance coefficient (lowest U of 1.83 W/(m

2·K), equivalent to a reduction of 32%), as previously obtained with single glazing.

Figure 7b shows the ranges of the main thermal and solar optical property values of clear double glazing with and without different types of SCFs applied to the external glass surface. The changes obtained in the presence of SCFs are similar, but of less magnitude, than those obtained with single-glazing.

The ranges of values presented in

Figure 6 and

Figure 7 are relevant to better understanding the impact of the different types of SCFs on each clear single and double-glazing property. Selecting the type of SCFs to install in a specific glazing system depends on the solar control purpose (to increase or reduce specific glazing properties) and on the installation position (internal or external). Reflective and dual reflective SCFs should be installed in glazing systems to increase their solar and visible transmittance and, consequently, reduce solar heat gains and potential glare. Neutral, spectrally selective and ceramic films are advised to maintain the neutral appearance of the glazing (lower impact on increasing the reflectance of the glass substrate). Low emissivity films should be installed in cases where the main aim is to drastically reduce the emissivity and U-value of the glazing. The impact of SCFs on the main properties of clear glazing is more noteworthy in the case of the single-glazing substrate.

4. Existing Studies on the Performance of Solar Control Films

A web-based search of existing studies was carried out covering scientific engineering databases such as Science Direct, Scopus and Google Scholar. Very scarce studies have investigated the impact of solar control films (SCFs) on the performance of buildings using numerical [

34,

35,

36,

37,

38,

39,

40], experimental [

19,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51] or computer simulation [

35,

43,

44,

45,

46,

48,

49,

52,

53,

54,

55,

56,

57] approaches, singly or in combination.

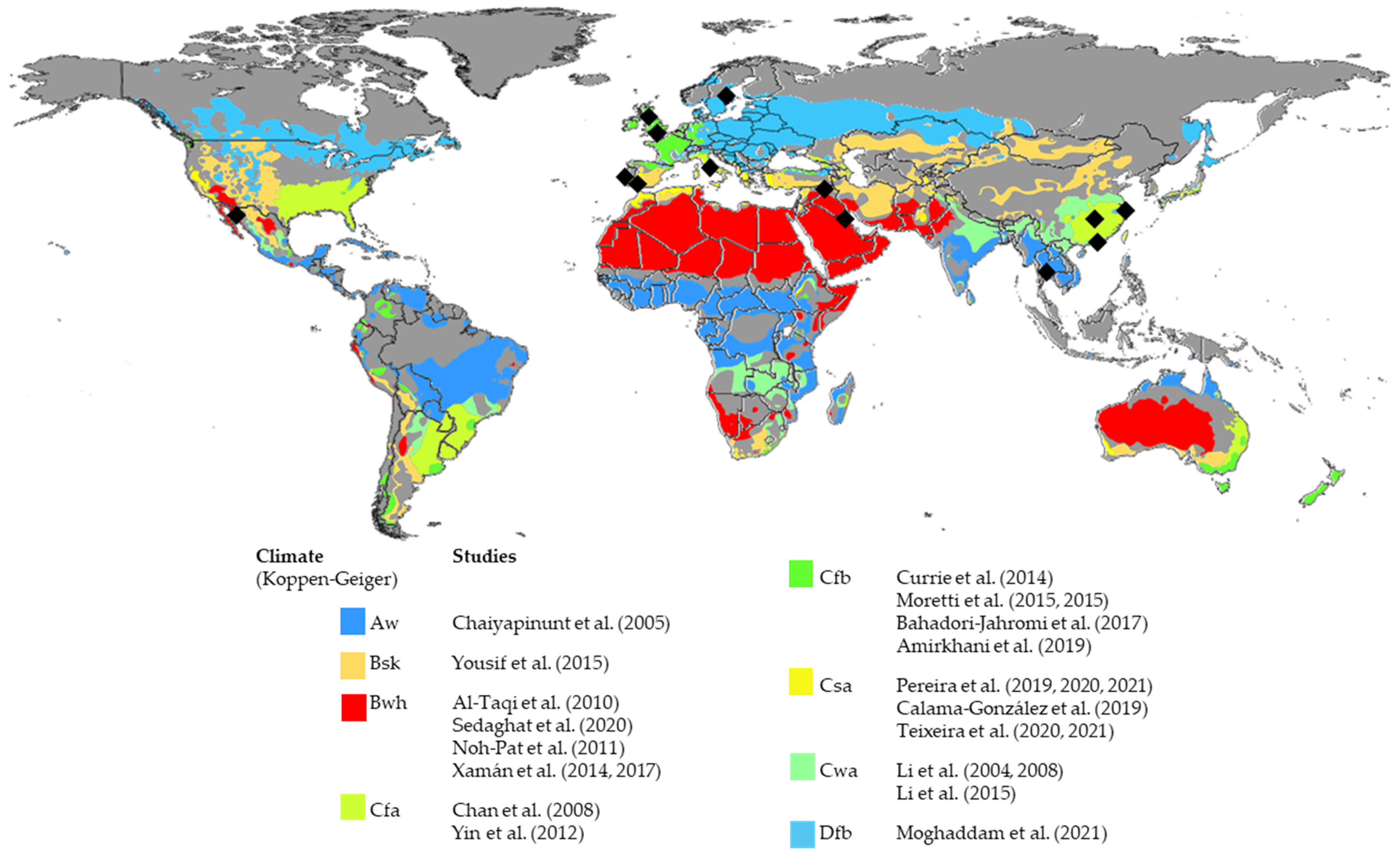

Table 2 resents a brief description of the existing studies that assess the performance of SCFs installed in building glazing organized by the type of climate (Köppen–Geiger climate classification [

58]: Aw, tropical monsoon; Bsk, cold arid steppe; Bwh, hot desert; Cfa, humid subtropical with a hot summer; Cfb, temperate oceanic; Csa, hot-summer Mediterranean; Cwa, monsoon-influenced humid subtropical; Dfb, warm-summer humid continental). These studies generally conclude that the presence of SCFs increases the energy efficiency of buildings and improves the thermal and visual comfort of occupants due to the reduction in extreme solar gains and control of potential glare.

This section comprises the main findings of previous research studies regarding the thermal, luminous, energy, economic and environmental performance and comfort assessment of SCFs when installed in building glazing systems.

4.1. Thermal and Luminous Performance Assessment of Glazing Systems with Solar Control Films

The number of research studies that address the thermal performance of building glazing systems with SCFs is higher than those that assess the luminous performance. Only a scarce number of studies contemplates both the thermal and luminous performance [

43,

44,

46,

50,

51,

53].

The heat transmission of different types of glass (single and double-glazing: clear, dark tinted, reflective, and low-E), with and without SCFs, were analyzed in view of an analytical study by Chaiyapinunt et al. [

34], conducted under a tropical monsoon climate (Aw [

58]). The results show that SCFs reduced the thermal gains due to solar radiation in the same proportion as the change in the optical properties of the film; therefore, a minimal effect on thermal gains by thermal conduction was obtained. The single and double reflective glazing presented the lowest relative heat gain value due to the high reflectance values of the glass with a film.

Yousif [

35] experimentally assessed the performance of a single glazed window with and without an SCF installed, in a south-oriented glazing system of two wood cells under the cold arid steppe climate of Iraq (Bsk [

58]). A reduction in the peak indoor air temperature of 11.5 °C at 2.00 pm (from 68.5 °C to 57 °C) and a reduction of 10–90% of the solar irradiance transmitted through the glazing were obtained.

The thermal performance of SCFs under the hot desert climate (Bwh [

58]) was analyzed by Sedaghat et al. [

51] and Xamán et al. [

36,

37,

38]. The performance of neutral SCFs installed in double glazed windows of office rooms, in actual working conditions, was experimentally assessed during summer by Sedaghat et al. [

51]. The presence of SCFs made it possible to preserve indoor relative humidity levels and decrease the indoor air temperature by 2 °C to 5 °C. When analytically analyzing the performance of a double-glazing system with and without an SCF installed in hot and cold climates, Xamán et al. [

36,

37,

38] concluded that the application of the SCF on double-glazing reduced solar gains through the glazing by 52% and 10% in hot and cold climates, respectively. Due to the results, the authors strongly recommend using an SCF in hot climates and using reversible windows with SCFs in temperate climates.

Some of the existing studies [

42,

43,

53] evaluated the thermal and luminous performance of SCFs under the temperate oceanic climate (Cfb [

58]).

A study by Currie et al. [

42] analyzed the installation of blinds against the application of a low-E SCF as rehabilitation solutions to reduce solar gains in a 18th century building in Scotland. Even though the thermal transmission coefficient in the presence of blinds (1.1 W/m

2·K if fully closed) was lower than the value calculated for a window with an SCF, the luminous comfort and the outdoor view would be compromised due to the almost closed position of the blind. The authors concluded that the SCF had a slightly better performance than the blinds to maintain a balance between the thermal and luminous comfort and take advantage of the benefits inherent to solar gains.

Moretti et al. [

43,

53] analyzed, experimentally and numerically, the performance of a double-pane window in the southwest façade with and without a reflective SCF, using two similar offices in Italy as a case study. The mean and peak values of incoming solar radiation were reduced by 46% to 66% in the presence of the SCF, resulting in a reduction in the glass surface temperature by 10 °C and the indoor air temperature by 2 °C on sunny days without climate control. Indoor illuminance levels decreased by 50% to 60% during sunny and cloudy days, respectively, in the presence of the SCF.

The performance of SCFs when installed in single- and double-glazing systems of office rooms in Portugal (hot summer, Mediterranean climate (Csa [

58])) was assessed by Pereira et al. [

44] and Teixeira et al. [

46,

50], respectively. The authors concluded that external reflective films have a better thermal performance.

Also, considering a hot summer, Mediterranean climate (Csa [

58]), Calama-González et al. [

45] assessed the performance of a double-glazed window with and without a reflective SCF installed on the exterior glass surface by monitoring a southwest-oriented hospital room located in Spain. An experimental campaign was conducted throughout a whole year considering real operation and use conditions. The SCF made it possible to reduce indoor illuminance levels by 46.3%.

Li et al. [

47,

48] experimentally and numerically assessed the performance of SCFs installed in the glazing systems of office rooms in Hong Kong, under a monsoon-influenced, humid subtropical climate (Cwa [

58]). A reduction in solar gains of up to 30% was obtained when considering only the diffuse component of solar radiation, and above 50% when considering the direct component [

47]. The film drastically reduced the occurrence of high illuminance levels (>5.5 klx) by 30% on sunny days.

Also, considering the monsoon-influenced, humid subtropical climate (Cwa [

58]), Li et al. [

49] conducted an experimental study in two test cells with different combinations of glazing systems and SCFs facing southwest. The authors reported that installing SCFs on single glass induces higher indoor glass surface temperatures for clear glass (increase of up to 10 °C) than for tinted or laminated clear glass, proving the higher ability of solar films in absorbing and reflecting radiation when applied to clear glazing.

The only research study that addresses the performance of SCFs in a cold climate (warm summer, humid continental climate (Dfb [

58])) was conducted by Moghaddam et al. [

57]. The authors assessed the performance of low-E films installed in double-glazing systems of a building, concluding that the films reduced heat loss through the glazing in winter and unwanted heat gains in summer by almost 36% and 35%, respectively.

4.2. Energy, Economic and Environmental Performance Assessment of Glazing Systems with Solar Control Films

Even though the energy performance of SCFs is commonly evaluated, there are scarce studies that investigate the economic and environmental performance of building glazing with SCFs.

Al Taqi [

40] assessed the performance of an SCF installed in a residential building located in a tropical monsoon climate (Bwh [

58]). The film reduced the peak cooling demand by 7% and the peak energy consumption of the climate control system by 5%. Even though annual energy consumption was significantly reduced, the high local costs of electricity contributed to extending the payback period (over 40 years).

Chan et al. [

41] assessed the performance of hotel rooms with and without an SCF installed on the glazing under a humid subtropical with a hot summer climate in China (Cfa [

58]). The authors obtained annual energy savings of 155 kWh due to the reduction in cooling energy needs. Considering different scenarios for a cost–benefit analysis, a payback period of between 3.5 and 4.7 years was obtained.

In addition, in a humid subtropical climate, Yin et al. [

52] simulated the energy performance of the double-glazing of a museum building with and without SCFs. Building cooling energy savings between 44% and 56% were obtained due to the reduction in solar transmittance, having achieved an average reduction in the cooling needs of about 50%. Even with the increased heating needs with SCFs, the energy efficiency of the building improved.

A whole building performance evaluation in the presence of SCFs was conducted by Currie et al. [

42], Bahadori-Jahromi [

54] and Amirkhani et al. [

55] under a temperate oceanic climate (Cfb [

58]).

Currie et al. [

42] assessed the performance of a low-E film against the installation of blinds as solutions to reduce solar heat gains in a 18th century building located in the temperate oceanic climate (Cfb [

58]) of Scotland. After conducting experimental work, a best-case model was simulated, and a reduction of 30% of the heating energy cost was obtained, in addition to a significant reduction in carbon dioxide emissions due to heating energy consumption.

The performance of spectrally selective and low-E SCFs, when installed in a hotel in a temperate climate, was studied by Bahadori-Jahromi [

54] and Amirkhani et al. [

55]. Heating and cooling energy consumption was reduced by 3% and 20% in the presence of low-E films. Even though spectrally selective films are more effective in reducing cooling energy consumption, low-E films were found to be a better solution for the heating-dominated climate of the case study.

Also, considering the temperate oceanic climate, the performance of double-glazing, with and without SCF, in office rooms in Italy was studied by Moretti et al. [

43,

53]. The authors concluded that the reduction in the indoor temperature due to the application of the film resulted in the reduction in the cooling needs of between 29% and 40%. However, an increase in the heating needs of between 15% and 33% was obtained, particularly during the heating season.

The energy performance of SCFs applied to glazing systems of a hospital room and office rooms under the hot-summer Mediterranean climate was evaluated by Calama-González et al. [

45] and Pereira and Teixeira et al. [

44,

46,

50], respectively.

Calama-González et al. [

45] evaluated the performance of an external reflective film installed in a glazing system of a hospital room located in the hot-summer Mediterranean climate (Cfa [

58]). The combined use of the film with shading shutters reduced artificial lighting energy consumption by 12%. The presence of the film during winter penalized energy consumption.

Pereira et al. [

44] and Teixeira et al. [

46,

50] analyzed the performance of different SCFs installed in the single- and double-glazing systems of office rooms in the hot-summer Mediterranean climate of the city of Lisbon (Csa [

58]). Reflective films were found to have a better energy performance, with a significant reduction in the cooling energy consumption that surpasses energy increases with artificial lighting. The annual energy use was reduced by 68% and 38% when considering the installation of SCFs in single- and double-glazing, respectively, oriented south.

Considering a whole building performance evaluation, also in the climate of Lisbon, Pereira et al. [

56] assessed the energy, economic and environmental performance of SCFs (one reflective and two spectrally selective) against the replacement of the existing window. Higher energy savings during the use stage were obtained in the presence of the retrofitting solutions with higher light-to-solar gain ratios because of the higher reduction in solar gains compared with the reduction in the visible transmittance. The spectrally selective film with high solar transmittance was found to be the best retrofitting solution with a life cycle energy (including embodied and operational energy) and a carbon footprint of 4447 MJ and 380 kgCO

2eq per square meter of floor, considering a life cycle of 40 years. The replacement of the existing window showed a life cycle energy 1.5 times higher than the average values obtained for the different SCFs.

The energy performance of SCFs installed in building glazing systems under a monsoon-influenced humid subtropical climate (Cwa [

58]) was evaluated by Li et al. [

47,

48] and Li et al. [

49].

The performance of office spaces located in Hong Kong (monsoon-influenced humid subtropical climate (Cwa [

58])), with and without SCFs, was evaluated by Li et al. [

47,

48]. Considering single-cell office rooms, the daily cooling energy consumption was reduced by 68 Wh per square meter of floor in the presence of the film, whereas the artificial lighting consumption increased by 13 Wh/m

2 of floor, resulting in total energy savings of 55 Wh/m

2 of floor [

47]. Considering an open-plan office space with dimmable lighting controls and an SCF installed on the glazing system, artificial lighting and cooling energy savings of about 21% and 7%, respectively, were obtained.

Also, in the climate of the city of Hong Kong, Li et al. [

49] evaluated the energy performance of different types of buildings (office, shopping center and hotel room) through a computer simulation model, considering glass and film systems previously experimentally assessed. The authors obtained annual energy savings between 77 and 90 kWh per unit area of SCF installed in the west-oriented single-glazing of an office space. Regarding the shopping center and hotel room, annual energy savings between 44 and 57 kWh per unit area of SCF were obtained.

Considering the warm-summer humid continental climate (Dfb [

58]), Moghaddam [

57] analyzed the performance of low emissivity films applied to double-glazing. The application of SCFs made it possible to reduce the annual energy consumption of the building for heating by 6%. However, when performing a life cycle cost analysis, the authors concluded that the high price of the low-E films and the contrasting low price of district heating resulted in an extremely long payback period of 30 years.

4.3. Comfort Assessment of Glazing Systems with Solar Control Films

A scarce number of the existing studies assess the thermal [

34,

43,

46,

50,

53,

55,

57] and visual [

19,

43,

46,

50,

53] comfort in the presence of SCFs installed in building glazing systems. Some studies evaluated both the indoor thermal and visual comfort, considering the same case study [

43,

46,

50,

53], to help differentiate the thermal and visual impact of SCFs. Comfort assessment has been scarcely explored in real occupancy conditions using experimental data, with the majority of the studies conducting computer simulation analyses.

Chaiyapinunt et al. [

34] used the predicted percentage of discomfort (PPD) values, due to the solar radiation effect and glass surface temperature, to evaluate thermal comfort in the presence of different combinations of glazing and SCFs, under a humid tropical climate (Aw [

58]). The analysis and comparison, considering these different combinations of glazing and SCFs, are of high importance as background information and to help guide/predict the performance of existing scenarios. All glazing, with or without films, except for reflective glazing, showed that the PPD due to solar radiation was higher than the PPD due to the glass surface temperature.

Moretti et al. [

43,

53] evaluated the thermal and visual comfort of a reflective SCF applied to the double-glazing of an office room located in a temperate oceanic climate (Cfb [

58]). Even though occupants still feel warm/hot in the office with SCF during summer, according to the computed PMV values, the reflective film made it possible to reduce the PPD values by 20–50% when compared with the office room without SCF.

Amirkhani et al. [

55] evaluated the thermal comfort of a building with low-E films by analyzing indoor operative temperature values, computed using a simulation model. During summer, the low-E films reduced the percentage of hours with excessive temperature levels (higher than 25 °C) by 5% compared with the original clear glazing.

Teixeira et al. [

46,

50] assessed the thermal and visual comfort of office rooms with double-glazing with different types of SCFs, under the hot-summer Mediterranean climate (Csa [

58]) of the city of Lisbon. This study evaluates indoor visual and thermal comfort under real occupancy conditions. A highly reflective solar control film was found to significantly reduce potential glare (43% of working hours with comfortable glare levels) when analyzing the computed daylight glare index values. SCFs increased the percentage of working hours within comfort levels of operative temperature by 25% compared with the original clear glazing (10% of working hours within thermal comfort).

Also, in the city of Lisbon, Pereira et al. [

19] experimentally analyzed the indoor illuminance levels and distribution on the horizontal work plane in the presence of south-oriented single-glazing with highly reflective and spectrally selective SCFs. Field experiments were conducted in a small-scale model, under clear sky conditions during summer and winter solstice. SCFs showed a better visual performance in summer, decreasing excessive illuminance levels and promoting a more extensive spatial distribution of acceptable levels of daylight availability. The lower solar altitude during winter, that increased solar radiation perpendicular to the glazing, had a negative impact on the visual performance of SCFs. A highly reflective film was found to be the best solution to provide useful illuminance levels and prevent potential flare. This study is relevant to better understand the influence of SCFs on the indoor daylight distribution under clear sky conditions.

Indoor thermal comfort in the presence of a low-E SCF installed in the double-glazing system of a building located in a cold climate was assessed by Moghaddam et al. [

57]. PPD values were reduced up to 5% in the presence of the low-E film installed in the northwest and southwest glazing. Even though the low-E film slightly reduced thermal discomfort when installed in the southeast-oriented glazing, the PPD values often surpass the limit value of 10%. The reduction in working hours with thermal discomfort is insufficient for the building to fully meet the existing thermal comfort requirements, so the low-E film should be complemented with other supplementary strategies.

5. Discussion of Existing Studies on the Performance of Solar Control Films

Based on the findings of the existing studies on the performance assessment of SCFs in building glazing systems, it is possible to note that the performance and efficiency of SCFs depend on different conditioning factors such as the: type and size of the glazing; local weather conditions; installation position of the film; solar orientation of the glazing; existing shading systems; type and efficiency of existing climate control systems; and cleaning and maintenance practices of the building.

This section briefly discusses the conditioning factors and compares research approaches and performance assessments conducted by the research studies reported in the literature review.

5.1. Building Type, Geometry and Solar Orientation

The heterogeneity of wall and glazing materials, floor area, room geometry, and building requirements and regulations between existing studies makes it difficult to compare results.

Regarding building type, all existing studies were based on the performance of SCFs when installed in commercial (shopping mall) or service (office, hospital, school, hotel) buildings, with the exception of the study conducted by Al-Taqi et al. [

40] that considered a residential building. The large glazing areas of the facade of commercial and service buildings, which may lead to a higher risk of overheating of the indoor environment, could justify the predominance of this building type. In addition, residential buildings tend to have more restricted occupancy schedules, particularly during the daytime, and lower heating, cooling and artificial lighting energy needs, so the potential benefits of applying SCFs are smaller when compared with commercial and service buildings.

Single rectangular cell rooms are the dominant type of building geometry scenario that is assessed by existing studies, as opposed to the impact of SCFs on the performance of the whole building [

40,

42,

52,

54,

55,

56]. The performance of SCFs installed in open plan spaces [

48] is poorly investigated, so future studies should evaluate this research gap, particularly the impact of SCFs on daylight availability due to light scattering in multiple zone spaces that tend to have bright perimeter zones and a sharp light reduction away from the windows. Some experimental studies assessed the performance of SCFs through small scale models [

19] and test cells [

35,

49].

The fact that south-oriented glazing systems are usually responsible for higher solar heat gains may justify the high number of case studies with windows facing south in the literature review. When assessing the same glass and film system facing different solar orientations, existing studies conclude that the best performance is achieved with south-oriented glazing, the performance is similar for east- and west- oriented glazing, and the worst performance is obtained for north-oriented glazing [

44,

46,

49]. The reduction in solar heat gains through glazing with SCF oriented north penalizes its performance, particularly during the winter season and when considering individual rooms without other glazed surfaces.

5.2. Glazing Type, Film Type and Installation Position

Figure 8 shows, in terms of percentage, the different types of glazing substrates, types of SCFs and respective installation positions assessed by the existing studies reported in the literature review.

Double-glazing is the most common type of glazing substrate used to assess the performance of SCFs, followed by single-glazing. The majority of the studies considered clear glazing without film as the reference scenario to compare with the results obtained in the presence of SCFs, with the exception of the studies conducted by Chaiyapinunt et al. [

34] and Li et al. [

49] that considered the installation of films in tinted glazing.

Reflective and spectrally selective SCFs are commonly evaluated by existing studies, followed by neutral and low-E films. These types of SCFs cover the majority of films available on the market and usually installed in building glazing. Existing studies tend to focus on SCFs with external application, followed by internal SCFs. The scarce number of studies on the performance assessment of SCFs installed in the air gap, corresponding to the installation of low-E films, could be explained by the fact that SCFs are usually used as rehabilitation solutions and, as a result, the installation tends to be restricted to the internal and external glass surfaces.

5.3. Climate

SCFs initially emerged on the market with the main aim of reducing excessive solar heat gains through glazing systems. As a result, the majority of the research studies evaluate the performance of SCFs when installed in buildings located in hot climates with high solar radiation levels. As previously mentioned, the window film market has been evolving and new types of SCFs that aim to balance different performance aspects (such as visual and thermal comfort) and increase the glass performance during the cold season, other than reducing excessive solar gains, have been developed. Hence, the evaluation of the performance of SCFs should also be carried out for temperate and cold climates.

Figure 9 shows the location and respective climate of the existing research studies on the performance of SCFs when installed in building glazing. The existing studies reported in the literature review considered case studies located on tropical (tropical monsoon [

34]), arid (cold arid steppe [

35]; hot desert [

36,

37,

38,

40,

51]), temperate (humid subtropical with a hot summer [

41,

52]; temperate oceanic [

42,

43,

53,

54,

55]; hot-summer Mediterranean [

19,

44,

45,

46,

50,

56]; monsoon-influenced humid subtropical [

47,

48,

49]) and cold (warm-summer humid [

57]) zones, in accordance with the Köppen–Geiger climate classification [

58].

SCFs show a better performance when installed in hot climates, particularly during the hot season (higher temperature and solar radiation levels) when the reduction in excessive solar heat gains is more significant. The performance of SCFs is less noteworthy when installed in cold climates and/or during the cold season because they can promote an increase in the heating energy needs due to the reduction in solar heat gains through the glazing. Low-E films are more adequate for temperate or cold climates since they can better balance heat gain/losses through the glazing system to meet the different required indoor comfort conditions throughout the year.

The performance of SCFs, when installed in different locations than the ones considered by existing studies, can be deduced based on the findings obtained for a specific climate condition and latitude (similar incident solar radiation levels) and similar conditioning factors. Even though the existing studies cover the main types of climate, all the case studies were located in the northern hemisphere. For this reason, an assessment of the performance of SCFs considering locations in the southern hemisphere is strongly recommended for future studies to better represent their performance globally.

5.4. Research Approach

Existing studies reported in the literature used numerical [

34,

35,

36,

37,

38,

39,

40], experimental [

19,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50] and computer simulation [

35,

43,

44,

45,

46,

48,

49,

52,

53,

54,

55,

56] models, singly or in combination, as research approaches to assess the performance of SCFs.

Chaiyapinunt et al. [

34] and Xáman et al. [

36,

37,

38] used analytical models to assess the performance of glazing systems with SCFs. This research approach is more time-consuming compared to the computer simulation approach and, for this reason, it is more suited to evaluate less complex case studies.

The following variables are usually measured in the outdoor and indoor environments when conducting experimental studies: air temperature; surface temperature of the glazing and film system; solar radiation (global and/or diffuse, vertical and/or horizontal plane); illuminance (vertical and/or horizontal plane); heat flows through opaque or glazed elements; relative humidity; air speed; and electricity consumption. Even though the majority of the research studies conducted experimental campaigns under real occupation and operating conditions, small scale models [

19] and test units [

35,

49] were also used.

Building simulation programs such as EnergyPlus [

59], IDA ICE [

60], EDSL TAS [

61] and eQUEST [

62] were used by existing studies to assess the performance of SCFs installed in building glazing systems. In addition, Optics [

29] and Window [

30] software, developed by the Lawrence Berkeley National Laboratory, were common complementary simulation tools to compute the thermal and solar optical properties of the glazing systems with and without SCFs [

19,

34,

35,

44,

46,

50,

56].

The computer simulation models used by the reported studies were usually calibrated with experimental data, involving the comparison and subsequent approximation of the simulated values to the ones experimentally collected. The most common calibration variables are indoor air and/or glass surface temperature and energy consumption. The statistical parameters normalized mean bias error (NMBE) and coefficient of variation of the root mean square error (Cv(RMSE)) are usually computed to assess the quality of the calibration of the simulation models [

44,

46,

49,

57]. After a successful calibration, the computer simulation model is considered to accurately reproduce the case study and thus suitable to perform trusting simulations of the performance of the glazing systems.

5.5. Performance Assessment

When assessing the potential of the application of SCFs to building glazing, existing studies focus on the following types of performance: thermal, luminous, energy, economic and environmental.

To assess the thermal performance of building glazing with SCFs, existing studies commonly analyze the indoor air temperature and the indoor/outdoor glass surface temperature with and without SCFs. Indoor temperature levels are lower in the presence of SCFs due to the reduction in the transmittance of solar radiation through the glazing. However, external SCFs are found to have better thermal performance since internal films can absorb and irradiate heat towards the indoor environment and contribute to temperature increase [

44,

46,

49,

50]. SCFs increase the surface temperature of the glass they are applied to due to the absorption of solar radiation, particularly in clear glazing [

46,

49,

50].

The research studies evaluate the luminous performance of SCFs through the analysis and comparison of indoor illuminance levels with and without films, and indoor and outdoor levels. Vertical illuminance levels, related to potential glare, are rarely measured and/or computed by existing studies. Even though some studies suggest that SCFs have higher efficiency in reducing solar radiation through the glazing under a clear sky than an overcast sky [

43,

48,

50], no existing research study focuses on the luminous performance assessment of SCFs under different sky conditions. The horizontal distribution of illuminance levels on the indoor environment, which is of particular importance for large plan spaces, is poorly explored in the literature.

In terms of energy performance, existing studies analyze energy needs, energy consumption and peak values with and without SCFs. Cooling and heating energy needs are commonly analyzed to better comprehend the impact of SCFs on the need of climate control. The discrepancy between thermal setpoints, type of climate control devices and respective efficiency make the comparison of results between studies difficult. Since SCFs can reduce indoor daylight levels, some studies also consider artificial lighting needs/consumption, in addition to climate control needs/consumption. Pereira et al. [

56] conducted a more complex study, computing the life cycle energy of different SCFs against a new window and concluding that films presented a life cycle energy value up to 40% lower than the new window.

To evaluate the economic performance of SCFs, the research studies followed different approaches. Some studies [

46,

52,

54,

55] conducted a simple analysis by calculating the cost of the energy consumed (or energy savings) using prices and charges of the local energy suppliers. Al-Taqi et al. [

40] and Chan et al. [

41] conducted a cost–benefit analysis considering the film cost, in addition to the energy cost, assessing different scenarios and determining payback periods. Pereira et al. [

56] and Moghaddam et al. [

57] conducted more complex studies by performing a life cycle cost analysis of buildings with SCFs installed. Moghaddam et al. [

57] concluded that the relatively high price of low-E films and the contrasting low price of district heating resulted in a long payback period of around 30 years, which is longer than the service life of these films. Pereira et al. [

56] concluded that a reflective film exhibited lower economic costs, but it has a worse energy and environmental performance compared with the other alternatives (spectrally selective films and new window).

Regarding the assessment of the environmental performance of SCFs, the majority of the existing studies [

35,

41,

46,

54,

55] poorly explore the topic by simply calculating the emissions of carbon dioxide that result from the energy consumption with and without SCFs. Pereira et al. [

56] conducted a more correct and complex study by performing a life cycle analysis considering different SCFs versus the replacement of the existing window. The authors concluded that the carbon footprint of manufacturing the new window was two times higher than that of producing the films. The carbon footprints of the SCFs, considering the product, construction and use stages, vary between 38 and 46 kgCO

2eq per square meter of floor area and a life cycle of 40 years.

5.6. Comfort Assessment

A minority of research studies analyze the impact of SCFs on occupants’ thermal [

34,

43,

46,

50,

53,

55,

57] and visual [

19,

43,

46,

50,

53] comfort, considering different standards and metrics.

Existing studies usually analyzed thermal comfort through the PPD and PMV thermal indexes developed by Fanger [

63]. Few studies [

46,

55,

57] use indoor operative temperature levels to assess thermal comfort. No existing research study considers adaptive thermal comfort models to assess indoor thermal comfort in the presence of SCFs.

In terms of visual comfort, existing studies used the useful daylight illuminance (UDI) metric [

64,

65] to determine the percentage of working hours with useful illuminance levels (between 0.1 and 3.0 klx). The assessment of the indoor UDI levels performed by the existing studies is rather limited since they only consider up to two indoor points to compute and compare illuminance levels with and without SCFs. On the contrary, Pereira et al. [

19] conducted an experimental study that focused on the impact of SCFs on daylight availability under clear sky conditions (measurements from winter and summer solstice) using small scale-models. The authors mapped the horizontal daylight distribution inside the models, considering the absolute illuminance values and the ranges of the UDI metric, concluding that SCFs decreased illuminance levels below critical values and provided a more extensive spatial distribution of acceptable daylight availability levels compared with the clear single-glazing without a film.

Still, regarding visual comfort, only the study conducted by Teixeira et al. [

46] assessed indoor glare in the presence of SCFs. The authors used the daylight glare index (DGI) metric and concluded that highly reflective SCFs could significantly reduce potential glare and promote comfortable glare levels (DGI < 22) during 43% of working hours. However, recent studies suggest that the daylight glare probability metric is more suitable to assess glare in daylight-dominated indoor spaces.

Since people spend a significant amount of time indoors [

66], the assessment of the impact of SCFs on indoor thermal and visual comfort becomes of extreme importance. For this reason, future research on the topic is strongly advised and should help fill the identified research gaps.

6. Main Conclusions, Research Gaps and Recommendations

Research studies on the performance of solar control films (SCFs) installed in building glazing systems were collected and thoroughly analyzed for this literature review article.

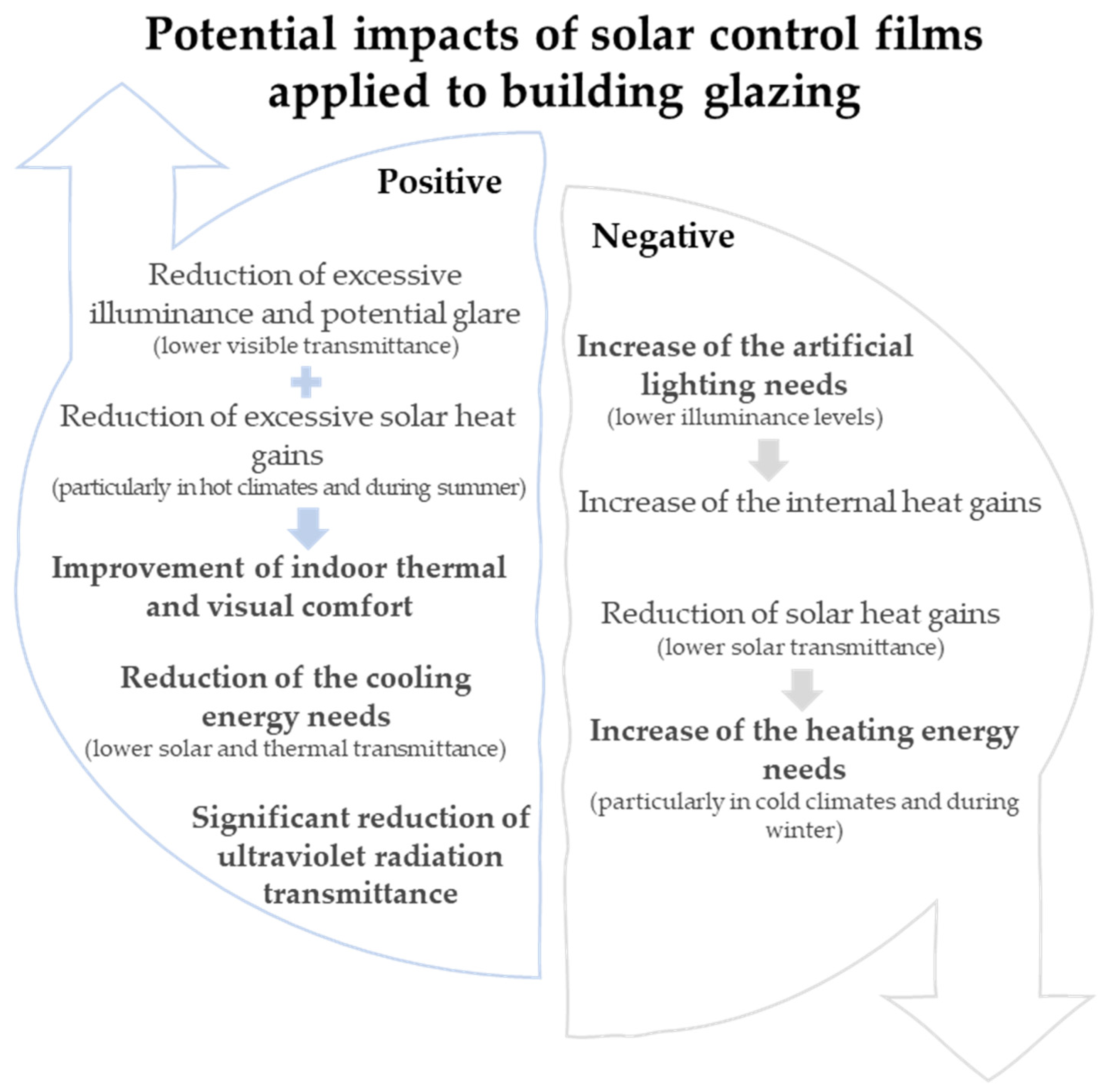

As stated in the comprehensive literature review, the impact of SCFs on the performance of the transparent elements of building facades is a somewhat recent research topic with multiple subjects of interest. As a result, it has a large potential for investigation. The consulted research studies show that the application of SCFs to building glazing has numerous advantages as a rehabilitation solution. In fact, this recent glazing technology, which is continuously under development and investigation to create new and improved products, aims to increase the energy efficiency of the glazing and promote indoor thermal and visual comfort for the occupants. The potential impacts resulting from the application of SCFs are shown in

Figure 10.

The assessment of the performance of SCFs is disperse in terms of methodology, analyzed variables and performance indices used. Moreover, most of the case studies of the existing literature are located in Europe and in East and Southeast Asia, corresponding to temperate, arid and tropical climate zones. It is also important to note that the performance of a given SCF depends on multiple conditioning factors such as the substrate to which it has been applied, solar orientation, type of air conditioning system and its energy efficiency, comfort conditions, existing shading and type of climate. Thus, the analysis of the performance of SCFs in existing glazing should consider these factors that directly affect the performance of the film. Even though some studies present a more complete analysis considering the evaluation of these conditioning factors on the film performance, the large majority is rather limited. Comfort assessment with SCFs installed in building glazing systems is also scarce in the existing literature, missing indoor glare analysis and thermal comfort analysis using adaptive models.

Having identified the existing research gaps on the topic, future research considering the following potential studies should be conducted, singly and in combination, to further explore the potential of SCFs on building glazing:

Performance of SCFs considering whole building scenarios;

Daylight assessment in the presence of SCFs installed in open plan spaces;

Visual comfort assessment in the presence of SCFs, including glare analysis;

Thermal comfort assessment in the presence of SCFs considering adaptive thermal comfort models;

Sensitivity analysis of the conditioning factors such as film type and properties, film installation position, glazing type and properties, type of building, climate and solar orientation;

A holistic analysis assessing the global performance of SCFs consisting of the thermal, luminous, energy, environment and economic performance assessment considering the conditioning factors with the highest potential impact;

Single and multi-objective analysis of the performance of SCFs considering different conditioning factors.

This literature review should positively aid in enhancing the limitations of existing studies and provide guidance for future research on the topic.