The Properties of Materials and Structures of Fluted PVC Panels for the Transmission of Airborne Sound

Abstract

:1. Introduction

2. Materials and Methods

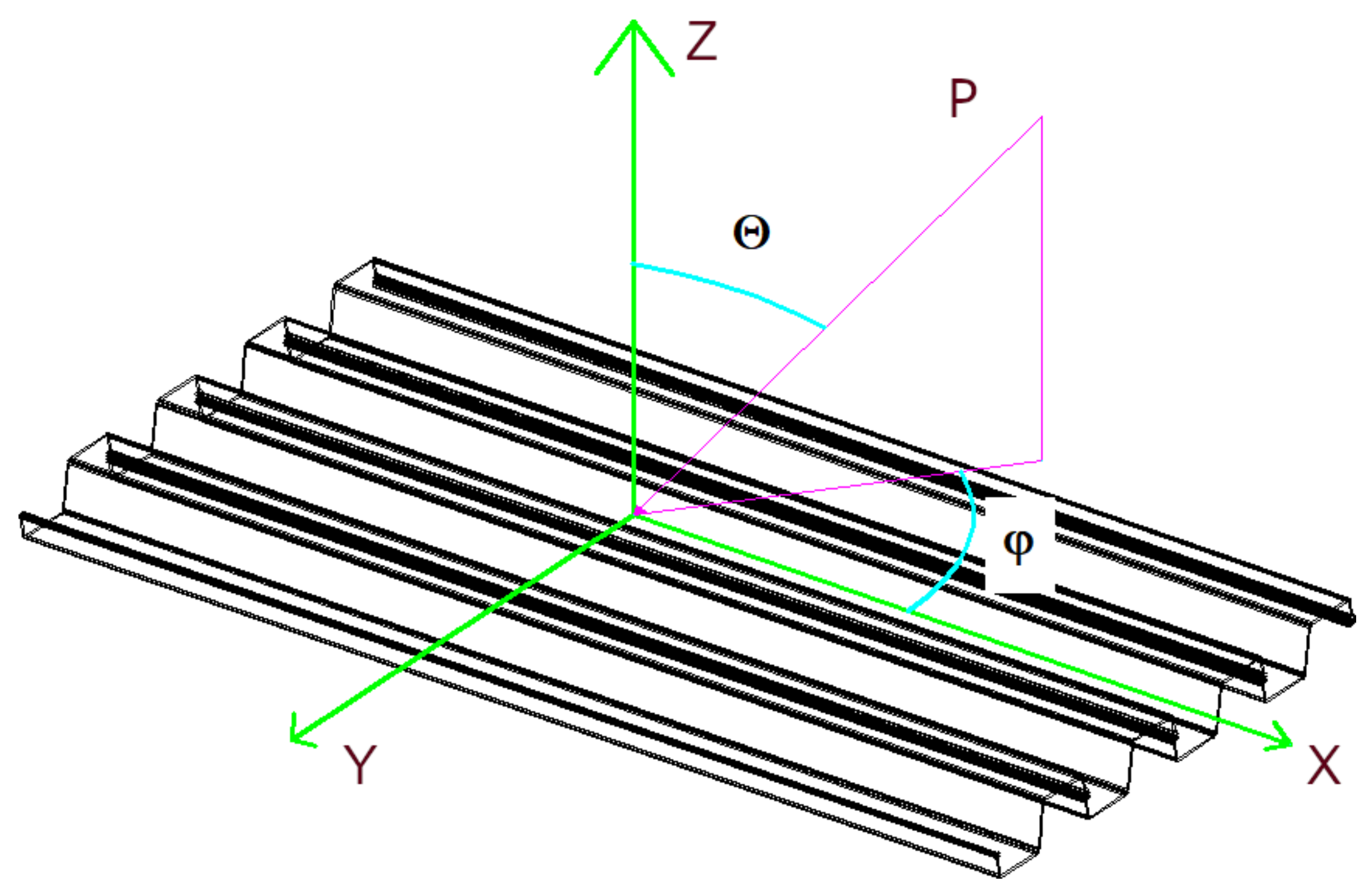

2.1. Analytical Model for Infinite and Finite Homogeneous Orthotropic Panel

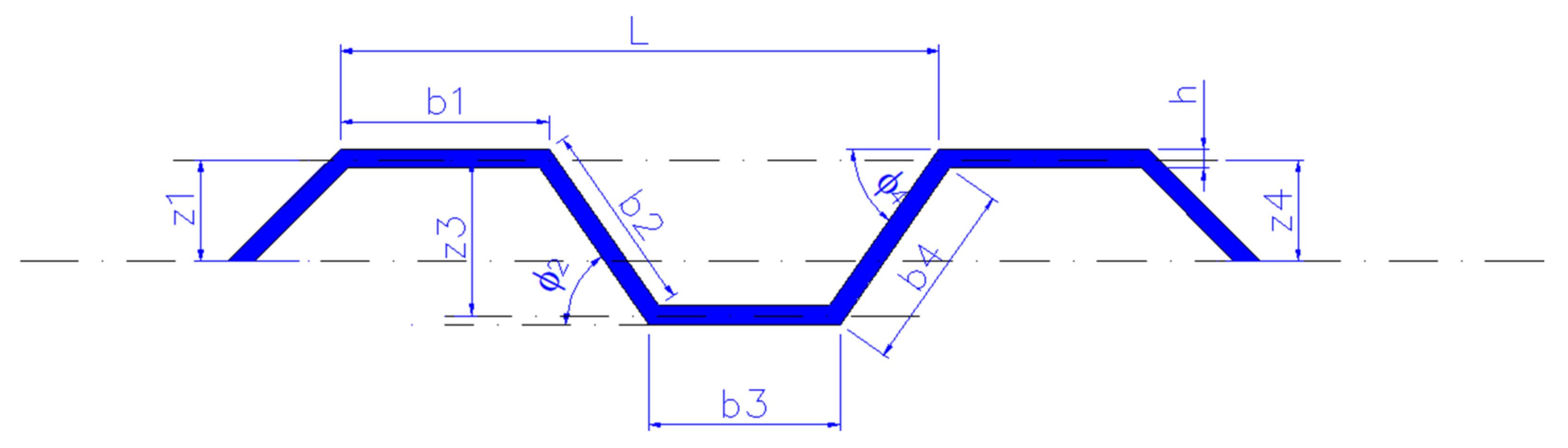

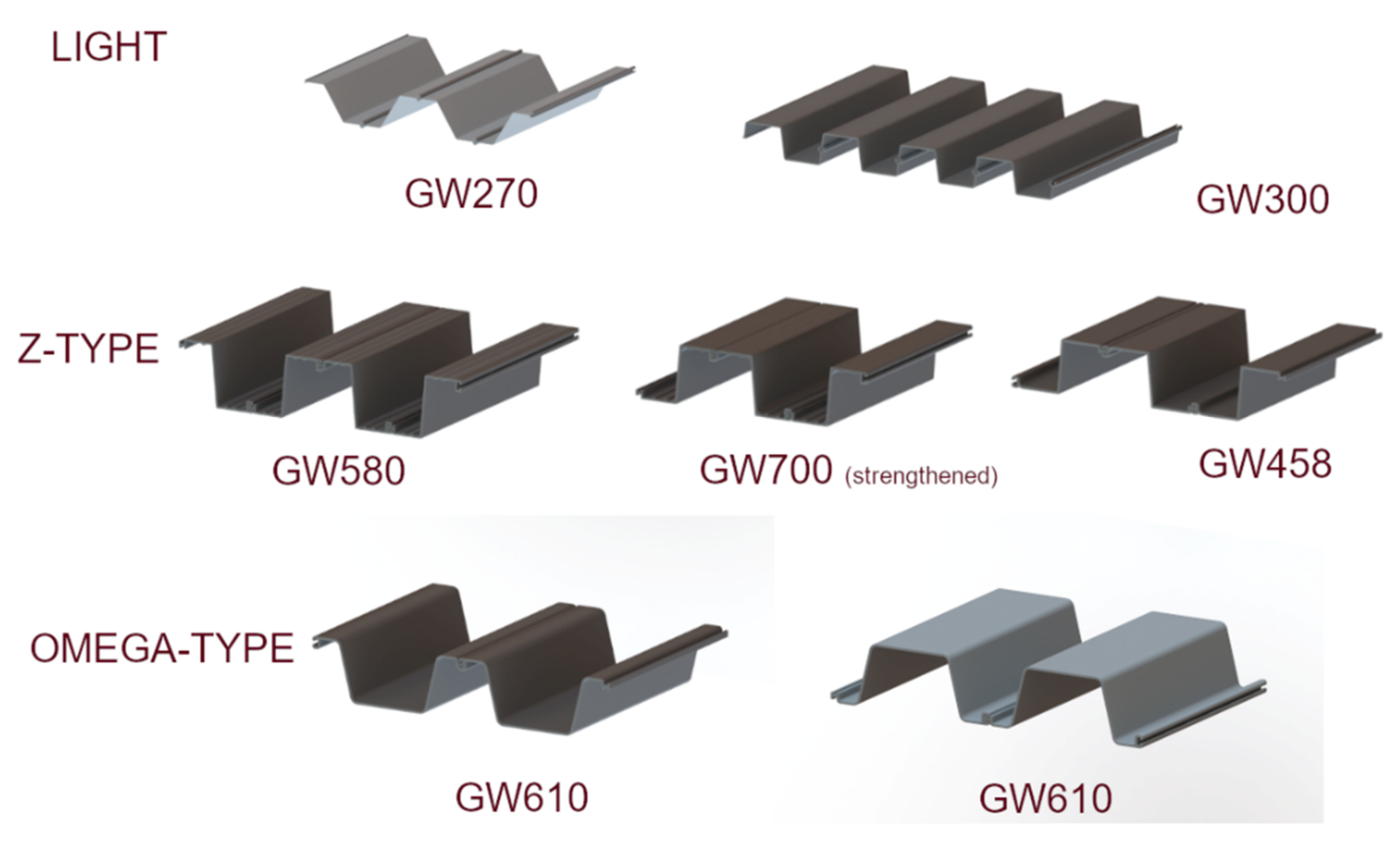

2.2. Studied Panels

2.3. Transmission Loss Measurements

2.4. Sound Absorption Measurements

- when the reverberation room was empty;

- when the studied panels were inside.

3. Results and Discussion

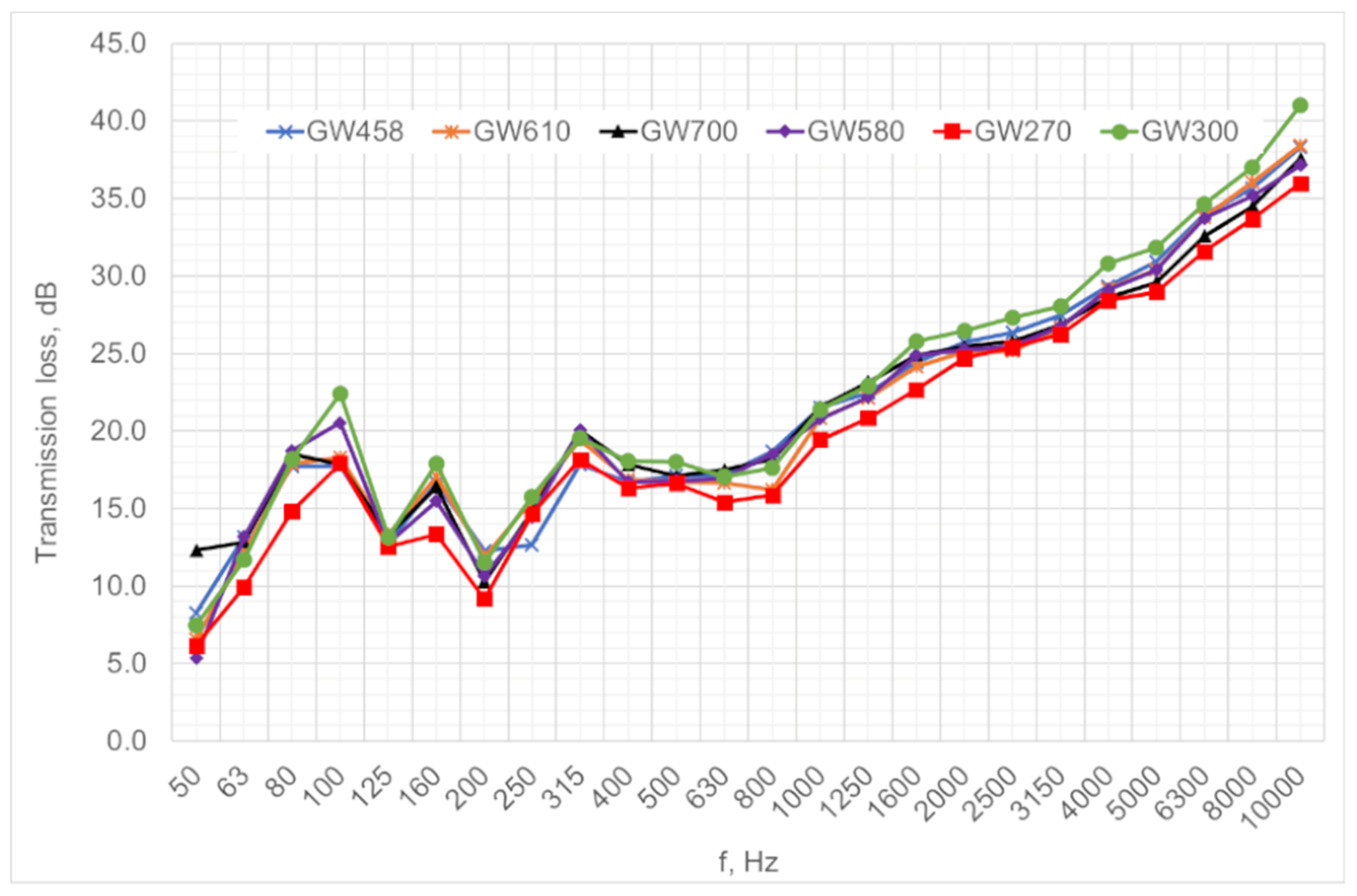

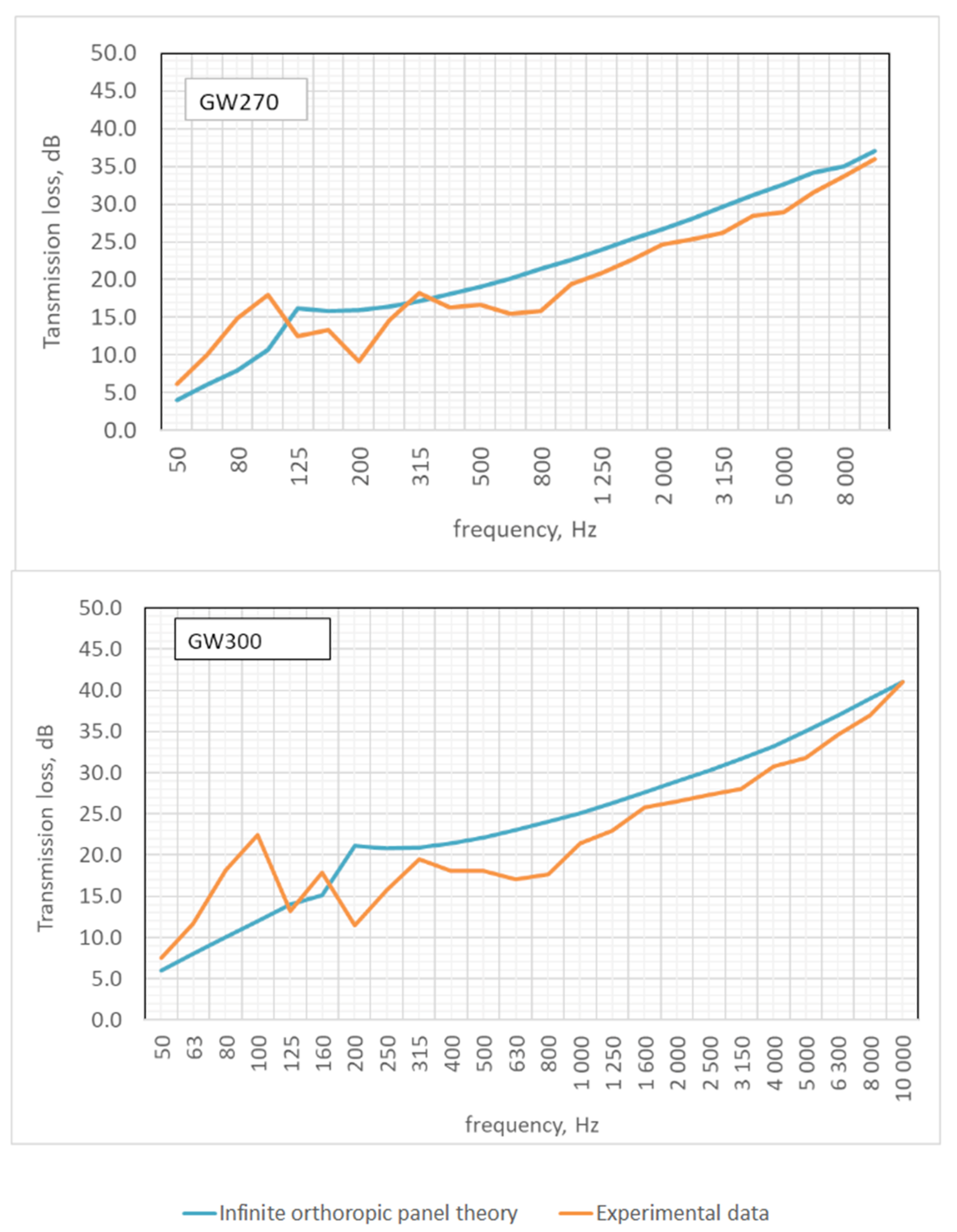

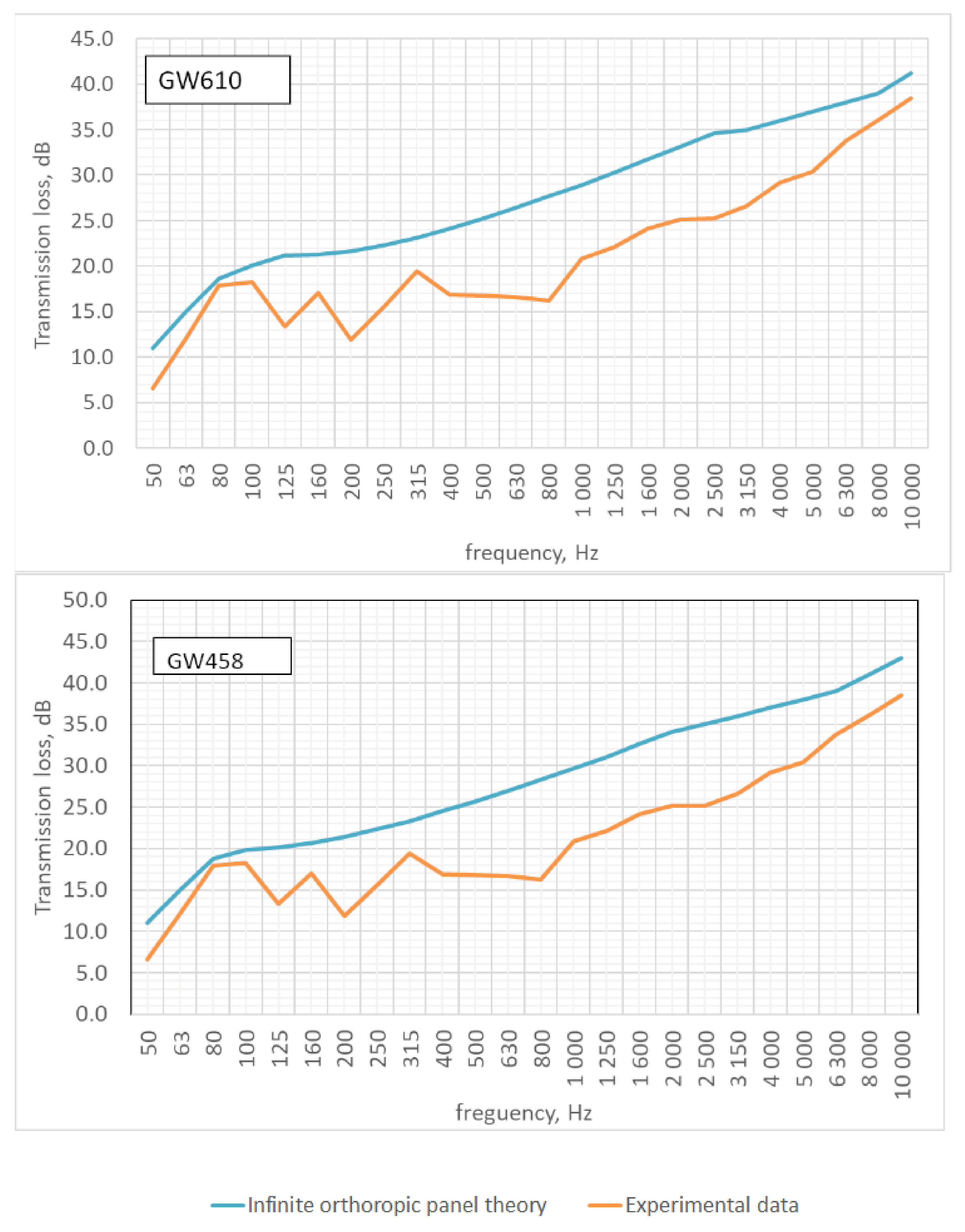

3.1. Transmission Loss

3.2. Absorption Coefficient

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Comission. A New Industrial Strategy for Europe; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Al-Malack, M.H. Migration of Lead from Unplasticized Polyvinyl Chloride Pipes. J. Hazard. Mater. 2001, 82, 263–274. [Google Scholar] [CrossRef]

- Health Care without Harm. The Polyvinyl Chloride Debate: Why PVC Remains a Problematic Material; Health Care without Harm: Washington, DC, USA, 2021. [Google Scholar]

- World Health Organization. Environmental Noise Guidelines for the European Region; WHO: Geneva, Switzerland, 2018. [Google Scholar]

- European Commission. Noise Impacts on Health; European Comission: Brussels, Belgium, 2015. [Google Scholar]

- Cheng, L.; Yao, Y.; Tang, X. On the Flame-Retardant Properties of Soft PVC-Base Composite Insulation. J. Zhejiang Technol. Univ. 2011, 28, 160–165. [Google Scholar]

- Yang, T.; Fu, Y. Sound Insulation of Honeycomb Weave Fabric Reinforced Polyvinylchloride Composite. J. Text. Res. 2011, 32, 65–70. [Google Scholar]

- Liu, H. Study on Performance Impact of Filler to PVC Flexible Insulation Composite Material; Zhejiang University of Technology: Hangzhou, China, 2012. [Google Scholar]

- Huang, L.; Tan, L.; Xia, B. Noise Test and Control for Commercial Air Conditioner’s Compressors. Noise Vib. Control 2015, 1, 191–194. [Google Scholar]

- Xue, H.; Lai, X.; Zhang, S. Research on Deadening Felt of Inverter Compressor. Electr. Appl. 2014, 8, 76–78. [Google Scholar]

- Pulngern, T.; Eakintumas, W.; Rosarpitak, V.; Sombatsompop, N. Compressive Load, Thermal and Acoustic Properties of Wood/Polyvinyl Chloride Composite Log-Wall Panels. J. Reinf. Plast. Compos. 2017, 36, 1183–1193. [Google Scholar] [CrossRef]

- Mun, D.-H.; Song, G.-G.; Lee, C.-S.; Park, H.-G. Reduction of Floor Impact Noise and Impact Force for PVC Floor Covering and Floor Mat. Trans. Korean Soc. Noise Vib. Eng. 2014, 27, 501–508. [Google Scholar] [CrossRef]

- Hussein, H.H.; Eedan, O.A.; Ahmed, M.K. Mechanical, Thermal and Acoustical Properties of Concrete with Fine Polyvinyl Chloride (PVC). Iraqi J. Civ. Eng. 2016, 12, 81–91. [Google Scholar]

- Xu, X.; Quan, J. Brief Analysis on Application of PVC Foam Materials in Building Material Industry. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2019; Volume 944, pp. 729–735. [Google Scholar] [CrossRef]

- Konstantinov, A.; Verkhovsky, A.; Lyabakova, E. Sound Insulation of PVC Windows at Negative Outdoor Temperatures. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 896. [Google Scholar]

- Fang, Z.; Jiang, M.; Zhang, Y. Experimental Research on PVC Sound Insulation Improving the Front Noise of Refrigerator. Home Appl. Technol. 2014, 2–4. [Google Scholar]

- Agyeman-Prempeh, N.O.W.O. Noise Abatement in Machine Shops Through the Use of Recycled Coconut Fibre and Polyvinyl Chloride Sheets As Noise Absorbing Materials. Master’s Thesis, University of Ghana, Accra, Ghan, 2017. [Google Scholar]

- Kuan, L.J. Analysis of Noise Barrier for Apartment. Bachelor’s Thesis, Tunku Abdul Rahman University College, Lumpur, Malaysia, 2017. [Google Scholar]

- Roschke, P.N.; Esch, S.T. Construction of Full-Scale Noise Barrier with Recycled Plastic. Transp. Res. Rec. 1999, 1656, 94–101. [Google Scholar] [CrossRef]

- Saageghvaziri, M.; Macbain, K. Sound Barrier Applications of Recycled Plastics. Transp. Res. Rec. 1998, 1626, 85–92. [Google Scholar] [CrossRef]

- Benkreira, H.; Khan, A.; Horoshenkov, K.V. Sustainable Acoustic and Thermal Insulation Materials from Elastomeric Waste Residues. Chem. Eng. Sci. 2011, 66, 4157–4171. [Google Scholar] [CrossRef]

- May, D.N.; Osman, N.M. Highway Noise Barriers: New Shapes. J. Sound Vib. 1980, 71, 73–101. [Google Scholar] [CrossRef]

- Murata, K.; Nagakura, K.; Tanaka, S.I. Noise Reduction Effect of Noise Barrier for Shinkansen Based on Y-Shaped Structure. Q. Rep. RTRI 2006, 47, 162–168. [Google Scholar] [CrossRef]

- Galińska, B.; Kopania, J. Hałas Drogowy a Skuteczność Ekranów z Oktagonalnymi Reduktorami Dźwięku. Autobusy Tech. Eksploat. Syst. Transp. 2016, 6, 168–171. [Google Scholar]

- Fujiwara, K.; Hothersall, D.C.; Kim, C. Noise Barriers with Reactive Surfaces. Appl. Acoust. 1996, 53, 255–272. [Google Scholar] [CrossRef]

- Watts, G.R. Acoustic Performance of Parallel Traffic Noise Barriers. Appl. Acoust. 1996, 47, 95–119. [Google Scholar] [CrossRef]

- Jolibois, A.; Defrance, J.; Jean, P.; Duhamel, D.; Sparrow, V.W. In Situ Measurement of the Acoustic Performance of a Full Scale Tramway Low Height Noise Barrier Prototype. Appl. Acoust. 2015, 94, 57–68. [Google Scholar] [CrossRef] [Green Version]

- Castiñeira-Ibañez, S.; Rubio, C.; Sánchez-Pérez, J.V. Environmental Noise Control during Its Transmission Phase to Protect Buildings. Design Model for Acoustic Barriers Based on Arrays of Isolated Scatterers. Build. Environ. 2015, 93, 179–185. [Google Scholar] [CrossRef]

- Heckl, M. Untersuchungen an Orthotropen Platten. Acoustics 1960, 10, 109–115. [Google Scholar]

- Cremer, L.; Heckl, M. Structure-Borne Sound; Springer: Berlin/Heidelberg, Germany, 1988; ISBN 978-3-662-10123-0. [Google Scholar]

- Bies, D.A.; Hansen, C.H. Engineering Noise Control; Unwin Hyman Ltd.: London, UK, 1988. [Google Scholar]

- Alexander, N.J.H. Measurement of Sound Absorption and Transmission of Corrugated Steel Plates. Proc. Inst. Acoust. 1988, 10, 39–50. [Google Scholar]

- Rowell, M.A.; Oldham, D.J. The Directivity of Orthotropic Factory Cladding Panels. Proc. Inst. Acoust. 1988, 10, 39–51. [Google Scholar]

- Cordonnier-Cloarec, P. Contribution to the Study of Sound Transmission and Radiation of Corrugated Steel Structures. J. Sound Vib. 1992, 157, 515–530. [Google Scholar] [CrossRef]

- Hansen, C.H. Sound Transmission Loss of Corrugated Panels. Noise Control Eng. J. 1993, 40, 187–197. [Google Scholar] [CrossRef]

- Davy, J.L. Predicting the Sound Transmission Loss of Cavity Walls. In Proceedings of the Interior Noise Climates: National Conference of the Australian Acoustical Society, Perth, Australia, 19–20 April 1990. [Google Scholar]

- Mohammadi, H.; Ziaei-Rad, S.; Dayyani, I. An Equivalent Model for Trapezoidal Corrugated Cores Based on Homogenization Method. Compos. Struct. 2015, 131, 160–170. [Google Scholar] [CrossRef]

- Bartolozzi, G.; Pierini, M.; Orrenius, U.; Baldanzini, N. An Equivalent Material Formulation for Sinusoidal Corrugated Cores of Structural Sandwich Panels. Compos. Struct. 2013, 100, 173–185. [Google Scholar] [CrossRef]

- Mang Herbert, A.; Vallabhan, C.G.; Smith Jimmy, H. Finite Element Analysis of Doubly Corrugated Shells. J. Struct. Div. 1976, 102, 2033–2051. [Google Scholar] [CrossRef]

- Aoki, Y.; Maysenhölder, W. Experimental and Numerical Assessment of the Equivalent-Orthotropic-Thin-Plate Model for Bending of Corrugated Panels. Int. J. Solids Struct. 2017, 108, 11–23. [Google Scholar] [CrossRef]

- Piscoya, R.; Ochmann, M. Calculation of the Transmission Loss of Thin Plates in a Kundt’s Tube. In Proceedings of the Euronoise 2012, Prague, Czech Republic, 10–13 June 2012; p. 6. [Google Scholar]

- Piscoya, R.; Burgschweiger, R.; Ochmann, M. Numerical Simulation of the Transmission Loss of Plates. J. Acoust. Soc. Am. 2012, 131, 3271. [Google Scholar] [CrossRef]

- Piscoya, R.; Ochmann, M. Transmission Loss of Corrugated Plates. In Proceedings of the Forum Acusticum 2011, Aalborg, Denmark, 27 June–1 July 2011; p. 5. [Google Scholar]

- Nabeel Alshabatat Design of Corrugated Plates for Optimal Fundamental Frequency. Adv. Acoust. Vib. 2016, 2016, 4290247. [CrossRef] [Green Version]

- Zhang, Y.; Thompson, D.; Squicciarini, G.; Ryue, J.; Xiao, X.; Wen, Z. Sound Transmission Loss Properties of Truss Core Extruded Panels. Appl. Acoust. 2018, 131, 134–153. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.-M.; Xu, Y. A Modified Transfer Matrix Method for Prediction of Transmission Loss of Multilayer Acoustic Materials. J. Sound Vib. 2009, 326, 290–301. [Google Scholar] [CrossRef]

- Lee, C.-M.; Wang, Y.S. A Prediction Method of the Acoustical Properties of Multilayered Noise Control Materials in Standing Wave-Duct Systems. J. Sound Vib. 2006, 298, 350–365. [Google Scholar] [CrossRef]

- Santoni, A.; Davy, J.L.; Fausti, P.; Bonfiglio, P. A review of the Different Approaches to Predict the Sound Transmission Loss Building Partions. Build. Acoust. 2020, 27, 253–279. [Google Scholar] [CrossRef]

- Lin, H.-J.; Wang, C.-N.; Kuo, Y.-M. Sound Transmission Loss across Specially Orthotropic Laminates. Appl. Acoust. 2007, 68, 1177–1191. [Google Scholar] [CrossRef]

- Mechel, F.P. The Acoustic Sealing of Holes and Slits in Walls. J. Sound Vib. 1986, 111, 297–336. [Google Scholar] [CrossRef]

- Oldham, D.J.; Zhao, X. Measurement of the Sound Transmission Loss of Circular and Slit-Shaped Apertures in Rigid Walls of Finite Thickness by Intensimetry. J. Sound Vib. 1993, 161, 119–135. [Google Scholar] [CrossRef]

- Nieradka, P.; Dobrucki, A. Insertion Loss of Enclosures with Lined Slits. In Proceedings of the Euronoise 2018, Crete, Greece, 27–31 May 2018. [Google Scholar]

- Asakura, T.; Sakamoto, S. Improvement of Sound Insulation of Doors or Windows by Absorption Treatment inside the Peripheral Gaps. Acoust. Sci. Tech. 2013, 34, 241–252. [Google Scholar] [CrossRef] [Green Version]

| Panel | Panel Thickness mm | Commercial Mark | Young’s Modulus GPa | Poisson’s Ratio | Cross-Sectional Panel Height mm |

|---|---|---|---|---|---|

| h | E | ν | Z | ||

| GW270 | 3.5 | light | 2.4 | 0.4 | 0.150 |

| GW300 | 5.5 | light | 2.4 | 0.4 | 0.115 |

| GW580 | 7.0 | Z-type | 2.4 | 0.4 | 0.240 |

| GW700 | 9.0 | Z-type Strengthened * | 2.4 | 0.4 | 0.250 |

| GW610 | 9.0 | Ω-type | 2.4 | 0.4 | 0.230 |

| GW448 | 12.0 | Z type | 2.4 | 0.4 | 0.254 |

| Panel Type | Surface Weight kg/m2 | Bending Stiffness kg × m2/s2 | Effective Bending Stiffness kg × m2/s2 | Critical Frequencies Hz | First Resonance Frequency Hz | ||

|---|---|---|---|---|---|---|---|

| m | Bx | By | Beff | fc1 | fc2 | f1,1 | |

| GW270 | 7.2 | 44,599 | 13.7 | 780.5 | 238 | 13,594 | 136 |

| GW300 | 14.3 | 35,282 | 65.8 | 1523.8 | 377 | 8728 | 86 |

| GW580 | 23.6 | 224,863 | 142.4 | 5659.6 | 192 | 7621 | 168 |

| GW700 | 29.4 | 255,173 | 282.9 | 8496.1 | 201 | 6036 | 161 |

| GW610 | 22.6 | 219,878 | 266.8 | 7658.5 | 190 | 5450 | 170 |

| GW448 | 30.7 | 529,198 | 692.2 | 19,139.6 | 143 | 3943 | 227 |

| Frequency Hz | GW270 | GW300 | ||

|---|---|---|---|---|

| Calculated | Experimental | Calculated | Experimental | |

| dB | dB | dB | dB | |

| 50 | 4.0 | 6.2 | 6.0 | 7.5 |

| 63 | 6.0 | 9.9 | 8.0 | 11.7 |

| 80 | 8.0 | 14.8 | 10.0 | 18.2 |

| 100 | 10.7 | 17.9 | 12.0 | 22.4 |

| 125 | 16.1 | 12.5 | 14.0 | 13.2 |

| 160 | 15.8 | 13.4 | 15.2 | 17.9 |

| 200 | 16.0 | 9.2 | 21.1 | 11.5 |

| 250 | 16.4 | 14.6 | 20.8 | 15.7 |

| 315 | 17.1 | 18.2 | 20.9 | 19.5 |

| 400 | 18.0 | 16.3 | 21.4 | 18.1 |

| 500 | 19.0 | 16.6 | 22.1 | 18.0 |

| 630 | 20.1 | 15.4 | 23.0 | 17.1 |

| 800 | 21.4 | 15.9 | 24.0 | 17.6 |

| 1000 | 22.6 | 19.4 | 25.1 | 21.4 |

| 1250 | 23.9 | 20.9 | 26.3 | 22.9 |

| 1600 | 25.3 | 22.7 | 27.6 | 25.8 |

| 2000 | 26.7 | 24.7 | 28.9 | 26.5 |

| 2500 | 28.1 | 25.4 | 30.2 | 27.3 |

| 3150 | 29.6 | 26.2 | 31.7 | 28.0 |

| 4000 | 31.2 | 28.4 | 33.2 | 30.8 |

| 5000 | 32.7 | 29.0 | 35.0 | 31.8 |

| 6300 | 34.2 | 31.6 | 37.0 | 34.6 |

| 8000 | 35.0 | 33.7 | 39.0 | 37.0 |

| 10,000 | 37.0 | 36.0 | 41.0 | 41.0 |

| Frequency Hz | GW580 | GW700 | ||

|---|---|---|---|---|

| Calculated | Experimental | Calculated | Experimental | |

| dB | dB | dB | dB | |

| 50 | 11.0 | 5.4 | 11.0 | 5.4 |

| 63 | 15.0 | 13.2 | 15.0 | 13.2 |

| 80 | 19.1 | 18.7 | 20.0 | 18.7 |

| 100 | 20.4 | 20.5 | 21.4 | 20.5 |

| 125 | 20.0 | 12.7 | 21.2 | 12.7 |

| 160 | 20.2 | 15.5 | 21.3 | 15.5 |

| 200 | 20.6 | 10.7 | 21.7 | 10.7 |

| 250 | 21.3 | 14.4 | 22.3 | 14.4 |

| 315 | 22.2 | 20.0 | 23.1 | 20.0 |

| 400 | 23.2 | 16.7 | 24.2 | 16.7 |

| 500 | 24.3 | 16.8 | 25.2 | 16.8 |

| 630 | 25.5 | 16.9 | 26.4 | 16.9 |

| 800 | 26.8 | 18.5 | 27.7 | 18.5 |

| 1000 | 28.0 | 20.8 | 28.9 | 20.8 |

| 1250 | 29.4 | 22.2 | 30.2 | 22.2 |

| 1600 | 30.9 | 24.9 | 31.8 | 24.9 |

| 2000 | 32.3 | 25.2 | 33.1 | 25.2 |

| 2500 | 33.7 | 25.4 | 34.6 | 25.4 |

| 3150 | 35.2 | 26.7 | 36.0 | 26.7 |

| 4000 | 37.0 | 29.1 | 38.0 | 29.1 |

| 5000 | 39.0 | 30.4 | 40.0 | 30.4 |

| 6300 | 41.0 | 33.7 | 42.0 | 33.7 |

| 8000 | 43.0 | 35.1 | 44.0 | 35.1 |

| 10,000 | 45.0 | 37.1 | 46.0 | 37.1 |

| Frequency Hz | GW610 | GW458 | ||

|---|---|---|---|---|

| Calculated | Experimental | Calculated | Experimental | |

| dB | dB | dB | dB | |

| 50 | 11.0 | 6.6 | 11.0 | 6.6 |

| 63 | 15.0 | 12.1 | 15.0 | 12.1 |

| 80 | 18.6 | 17.9 | 18.8 | 17.9 |

| 100 | 20.1 | 18.3 | 19.9 | 18.3 |

| 125 | 21.2 | 13.3 | 20.1 | 13.3 |

| 160 | 21.3 | 17.0 | 20.7 | 17.0 |

| 200 | 21.7 | 11.9 | 21.4 | 11.9 |

| 250 | 22.3 | 15.5 | 22.3 | 15.5 |

| 315 | 23.1 | 19.4 | 23.3 | 19.4 |

| 400 | 24.2 | 16.9 | 24.5 | 16.9 |

| 500 | 25.2 | 16.7 | 25.7 | 16.7 |

| 630 | 26.4 | 16.6 | 27.0 | 16.6 |

| 800 | 27.7 | 16.2 | 28.3 | 16.2 |

| 1000 | 28.9 | 20.8 | 29.7 | 20.8 |

| 1250 | 30.2 | 22.1 | 31.0 | 22.1 |

| 1600 | 31.8 | 24.2 | 32.6 | 24.2 |

| 2000 | 33.1 | 25.1 | 34.1 | 25.1 |

| 2500 | 34.6 | 25.2 | 35.0 | 25.2 |

| 3150 | 35.0 | 26.6 | 36.0 | 26.6 |

| 4000 | 36.0 | 29.2 | 37.0 | 29.2 |

| 5000 | 37.0 | 30.4 | 38.0 | 30.4 |

| 6300 | 38.0 | 33.8 | 39.0 | 33.8 |

| 8000 | 39.0 | 36.0 | 41.0 | 36.0 |

| 10,000 | 41.2 | 38.4 | 43.0 | 38.4 |

| Frequency Hz | GW300 | GW270 | GW580 | GW700 | GW610 | GW610 (Reversed) | GW458 |

|---|---|---|---|---|---|---|---|

| 50 | 0.056 | −0.052 | 0.224 | 0.000 | 0.258 | 0.013 | 0.007 |

| 63 | −0.007 | −0.056 | 0.139 | −0.201 | 0.145 | −0.127 | 0.096 |

| 80 | 0.237 | 0.188 | 0.267 | 0.168 | 0.298 | 0.109 | −0.047 |

| 100 | 0.296 | 0.277 | 0.305 | 0.213 | 0.224 | 0.261 | 0.187 |

| 125 | 0.295 | 0.287 | 0.457 | 0.342 | 0.393 | 0.364 | 0.240 |

| 160 | 0.317 | 0.182 | 0.191 | 0.089 | 0.222 | 0.206 | 0.221 |

| 200 | 0.253 | 0.185 | 0.171 | 0.190 | 0.315 | 0.242 | 0.148 |

| 250 | 0.164 | 0.140 | 0.150 | 0.152 | 0.159 | 0.221 | 0.181 |

| 315 | 0.248 | 0.137 | 0.131 | 0.233 | 0.111 | 0.130 | 0.124 |

| 400 | 0.205 | 0.079 | 0.122 | 0.115 | 0.066 | 0.059 | 0.167 |

| 500 | 0.224 | 0.070 | 0.075 | 0.090 | 0.049 | 0.060 | 0.018 |

| 630 | 0.192 | 0.094 | 0.104 | 0.098 | 0.071 | 0.072 | −0.033 |

| 800 | 0.079 | 0.103 | 0.123 | 0.125 | 0.077 | 0.066 | 0.060 |

| 1000 | 0.036 | 0.106 | 0.090 | 0.152 | 0.098 | 0.098 | 0.004 |

| 1250 | 0.066 | 0.087 | 0.105 | 0.120 | 0.100 | 0.088 | −0.093 |

| 1600 | 0.080 | 0.034 | 0.109 | 0.070 | 0.079 | 0.059 | 0.145 |

| 2000 | 0.099 | 0.039 | 0.078 | 0.101 | 0.081 | 0.061 | 0.093 |

| 2500 | 0.086 | 0.015 | 0.055 | 0.137 | 0.078 | 0.049 | −0.048 |

| 3150 | 0.064 | −0.001 | 0.019 | 0.122 | 0.044 | 0.008 | −0.086 |

| 4000 | 0.024 | −0.038 | −0.006 | 0.162 | 0.021 | −0.017 | −0.280 |

| 5000 | −0.009 | −0.080 | −0.079 | 0.105 | 0.025 | −0.058 | −0.388 |

| 6300 | 0.038 | −0.141 | −0.103 | 0.121 | −0.034 | −0.105 | −0.827 |

| 8000 | −0.009 | −0.161 | −0.118 | 0.089 | −0.066 | −0.096 | −1.308 |

| 10,000 | −0.097 | −0.242 | −0.218 | −0.094 | −0.133 | −0.166 | −1.106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopania, J.M.; Zakrzewicz, W.; Kubiak, P.; Mrowicki, A.; Głogowski, M.; Gralewski, J.; Bogusławski, G.; Wójciak, K.; Gaj, P. The Properties of Materials and Structures of Fluted PVC Panels for the Transmission of Airborne Sound. Appl. Sci. 2022, 12, 5732. https://doi.org/10.3390/app12115732

Kopania JM, Zakrzewicz W, Kubiak P, Mrowicki A, Głogowski M, Gralewski J, Bogusławski G, Wójciak K, Gaj P. The Properties of Materials and Structures of Fluted PVC Panels for the Transmission of Airborne Sound. Applied Sciences. 2022; 12(11):5732. https://doi.org/10.3390/app12115732

Chicago/Turabian StyleKopania, Joanna Maria, Wojciech Zakrzewicz, Przemysław Kubiak, Adam Mrowicki, Michał Głogowski, Jacek Gralewski, Grzegorz Bogusławski, Kamil Wójciak, and Patryk Gaj. 2022. "The Properties of Materials and Structures of Fluted PVC Panels for the Transmission of Airborne Sound" Applied Sciences 12, no. 11: 5732. https://doi.org/10.3390/app12115732

APA StyleKopania, J. M., Zakrzewicz, W., Kubiak, P., Mrowicki, A., Głogowski, M., Gralewski, J., Bogusławski, G., Wójciak, K., & Gaj, P. (2022). The Properties of Materials and Structures of Fluted PVC Panels for the Transmission of Airborne Sound. Applied Sciences, 12(11), 5732. https://doi.org/10.3390/app12115732