Seismic Performance of Corroded Reinforced Concrete Columns Strengthened with Basalt Fiber Sheets

Abstract

:1. Introduction

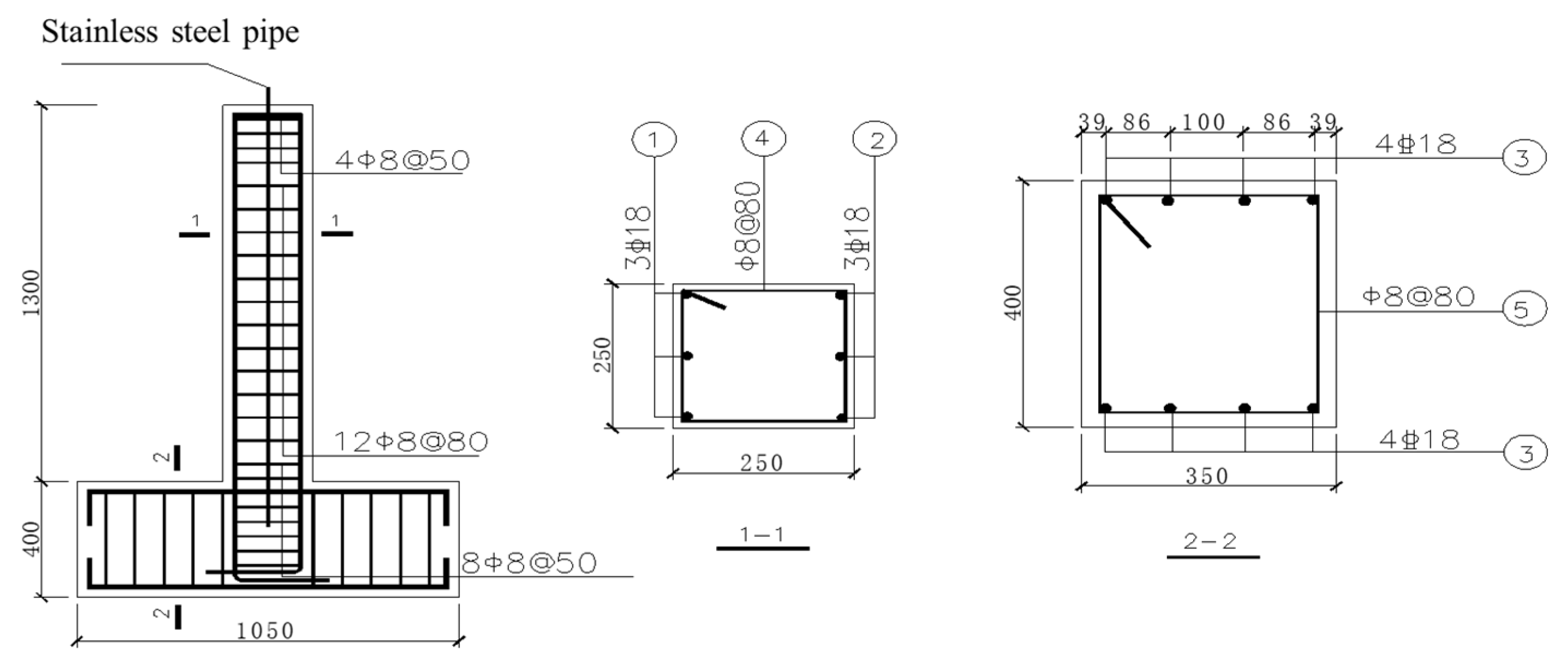

2. Specimen Design and Fabrication

2.1. Specimen Design

2.2. Specimen Corrosion Scheme and Control

- (1)

- At first, the corrosion test tank were built. After that, specimens were placed into the tank and the water was injected. Then the salt was added to make a 5% NaCl solution. The corrosion rate refers to the mass loss rate. In order to improve the speed of reinforcement corrosion, the high concentrations of NaCl solution were adopted. If water leakage was found, it would be remedied in time.

- (2)

- The specimens were immersed in the tank for seven days to let the chloride ion enter the concrete and then started energizing. The positive pole of the constant voltage and current source was connected with the hook welded on the specimen. The negative electrode was connected with the stainless-steel tube through a wire, while the stainless-steel tube was put into NaCl solution to act as the cathode. The accelerated corrosion test of the specimen is shown in Figure 2.

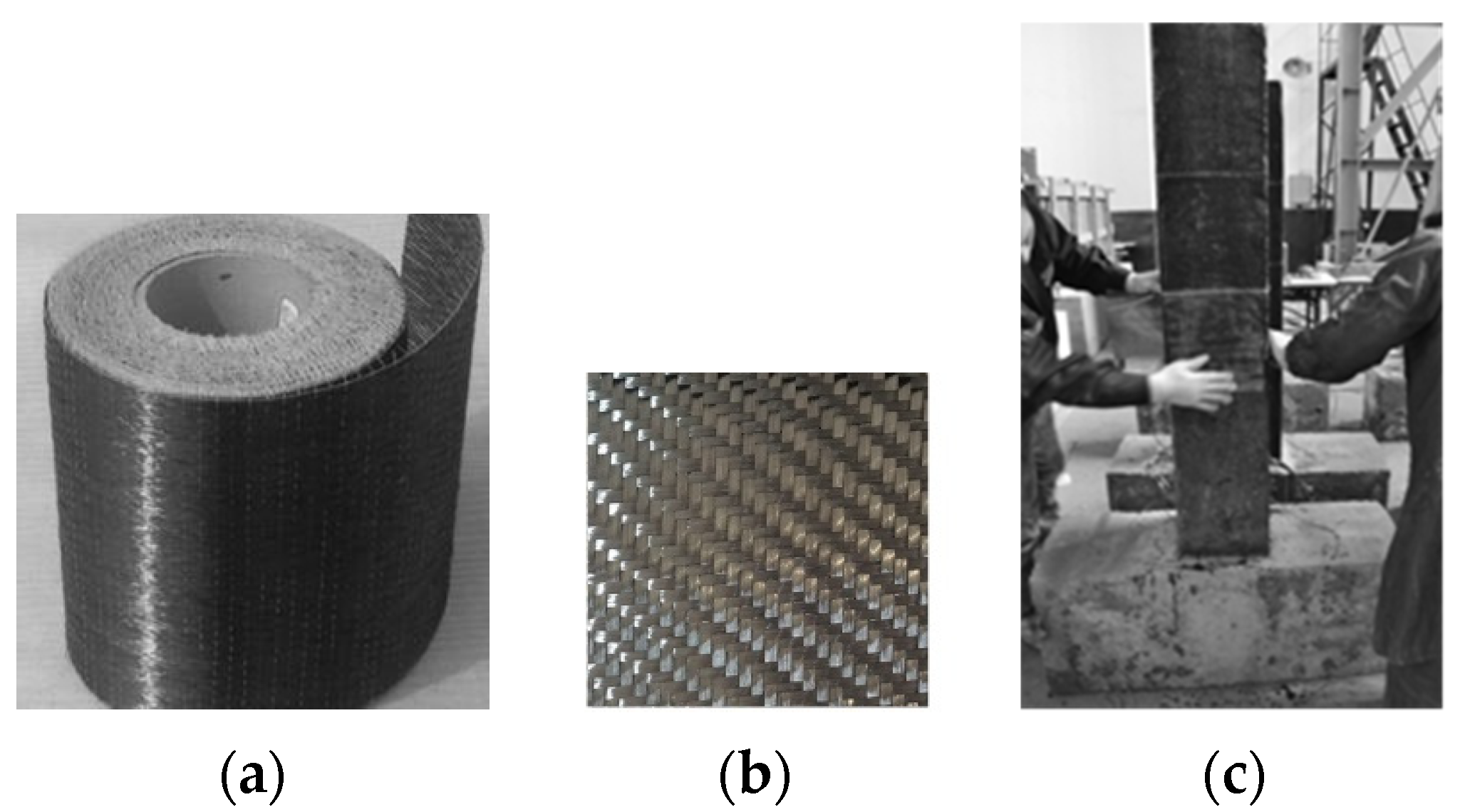

2.3. Reinforcement Construction of Reinforced Concrete Column

2.4. Material Properties

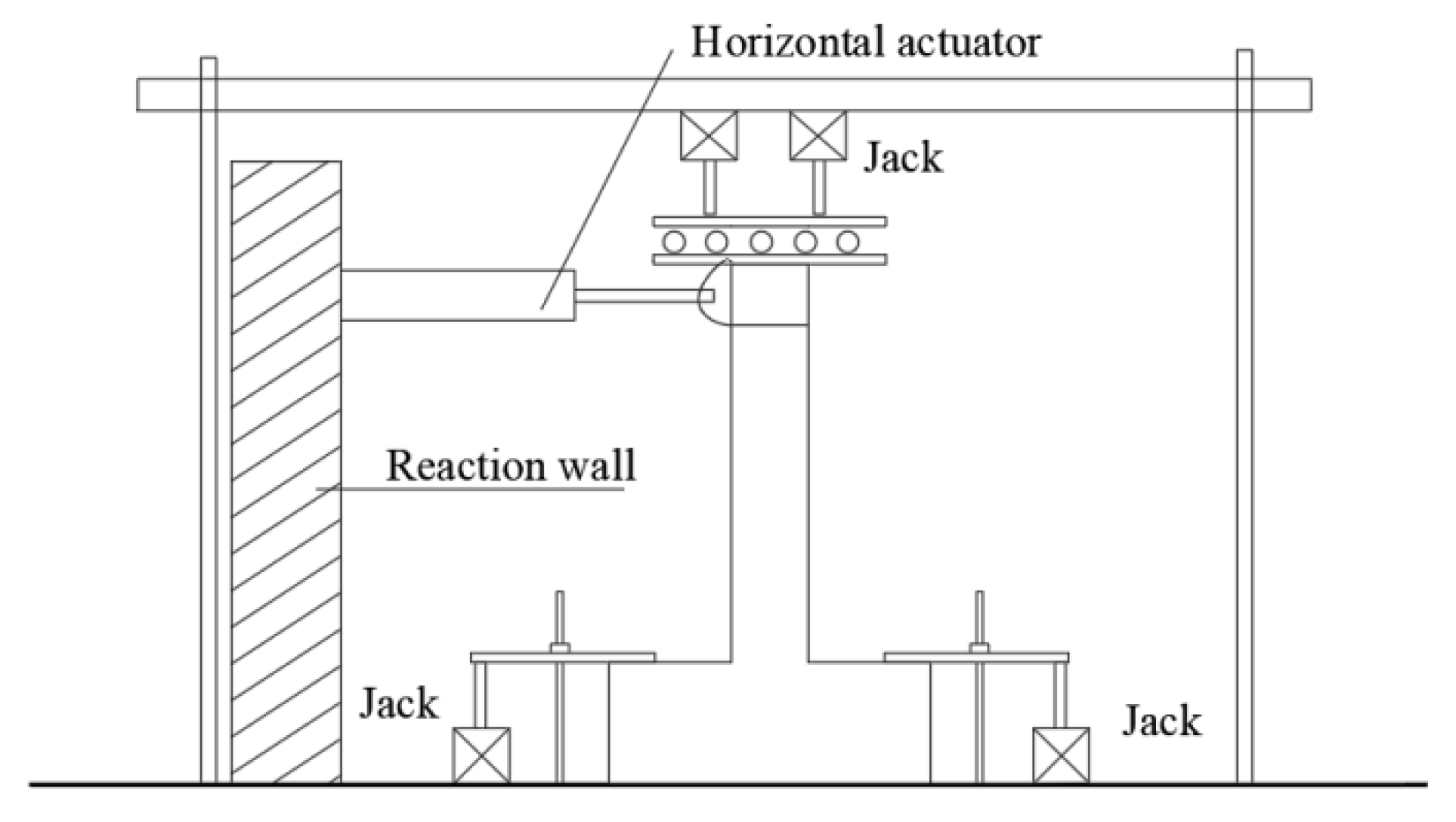

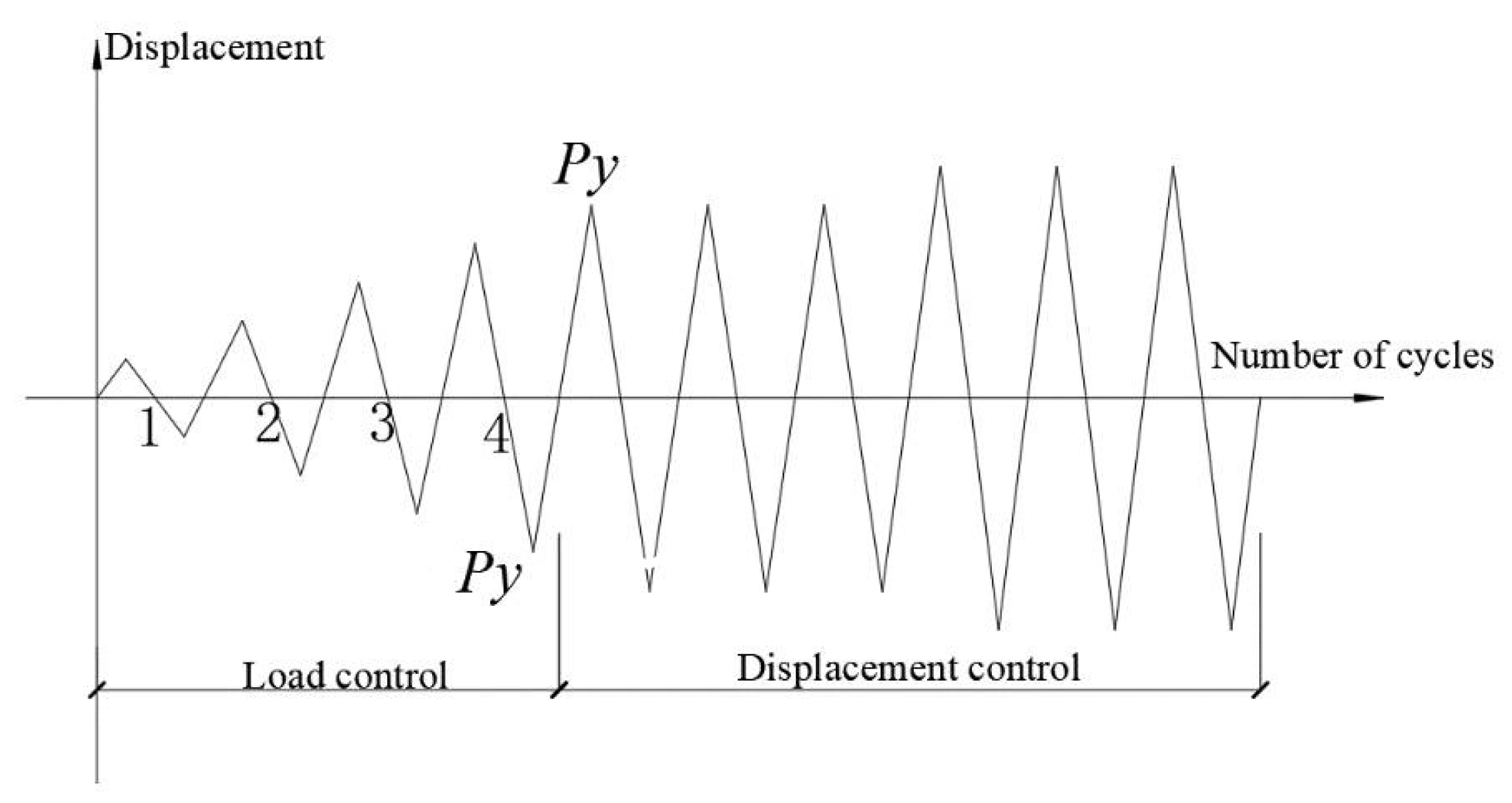

2.5. Test Setup and Loading Method

3. Test Results and Analysis

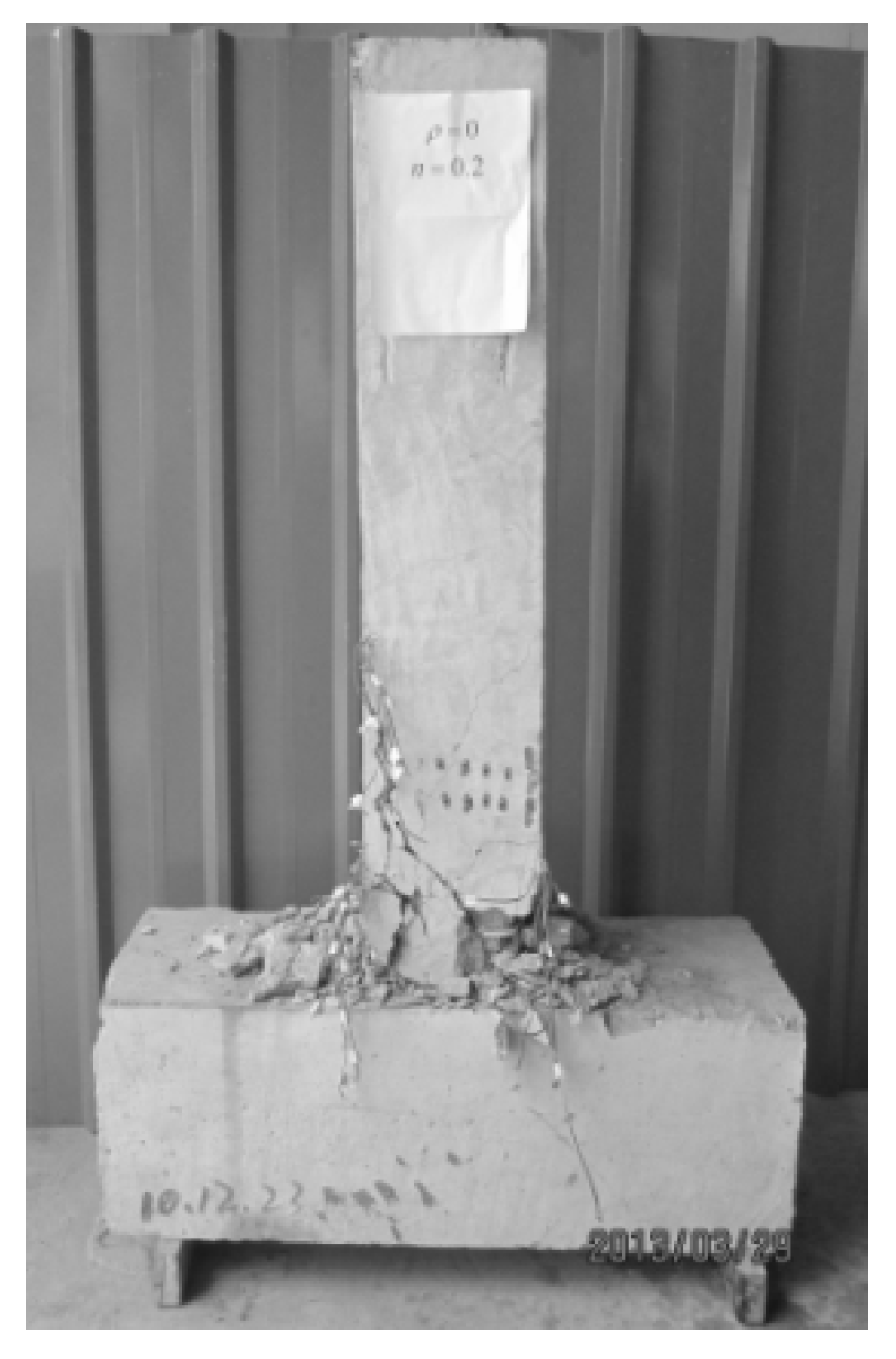

3.1. Failure Mode

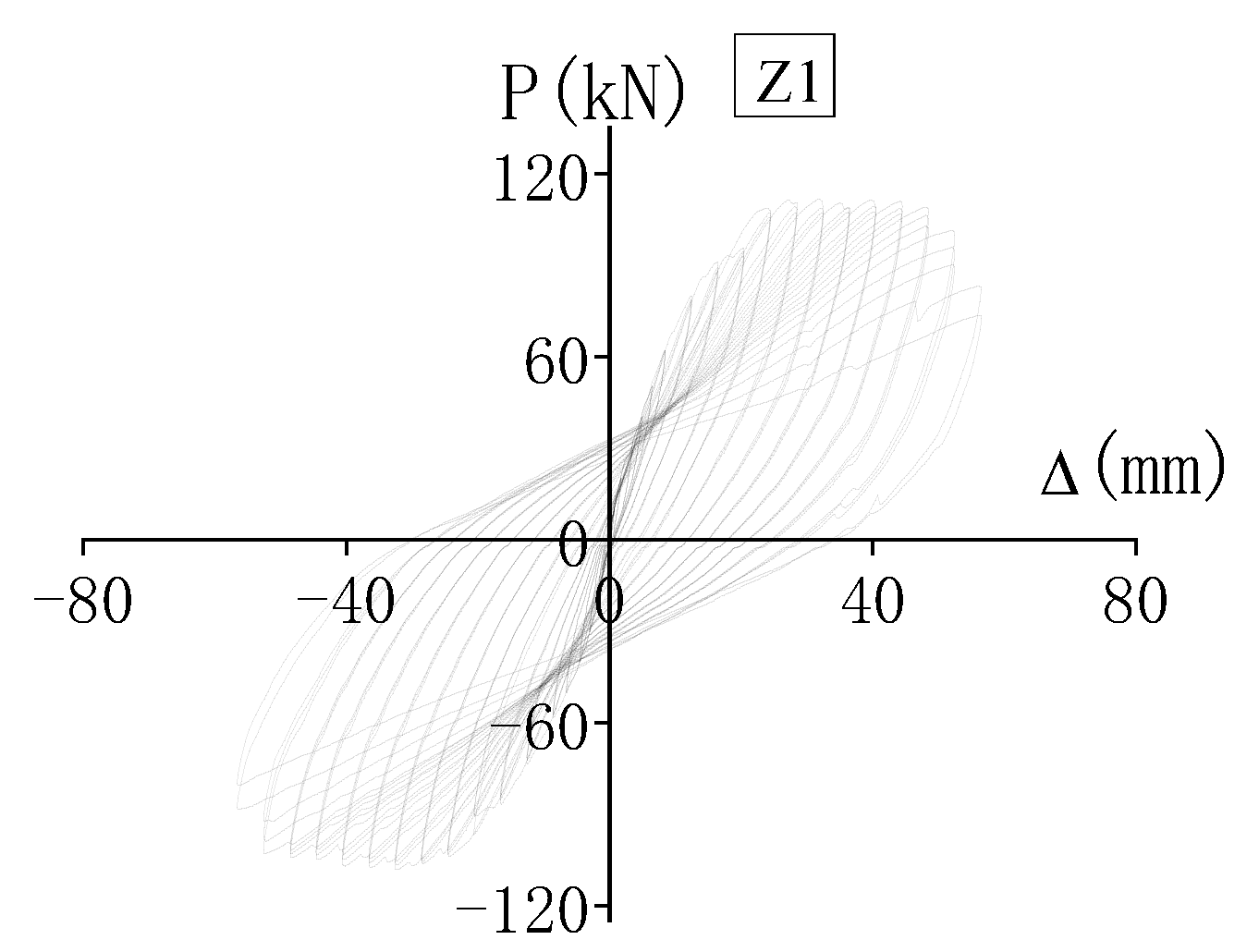

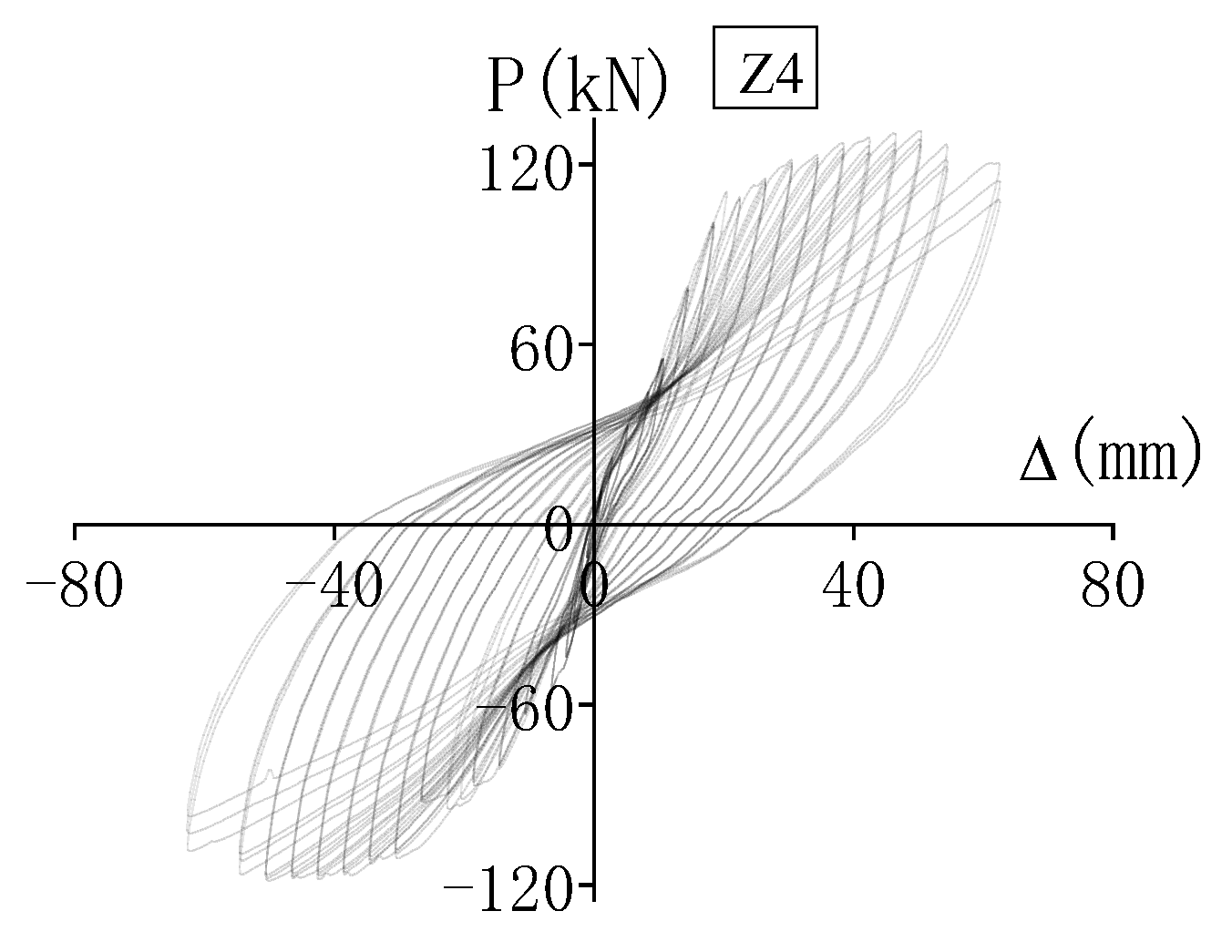

3.2. Hysteretic Performance

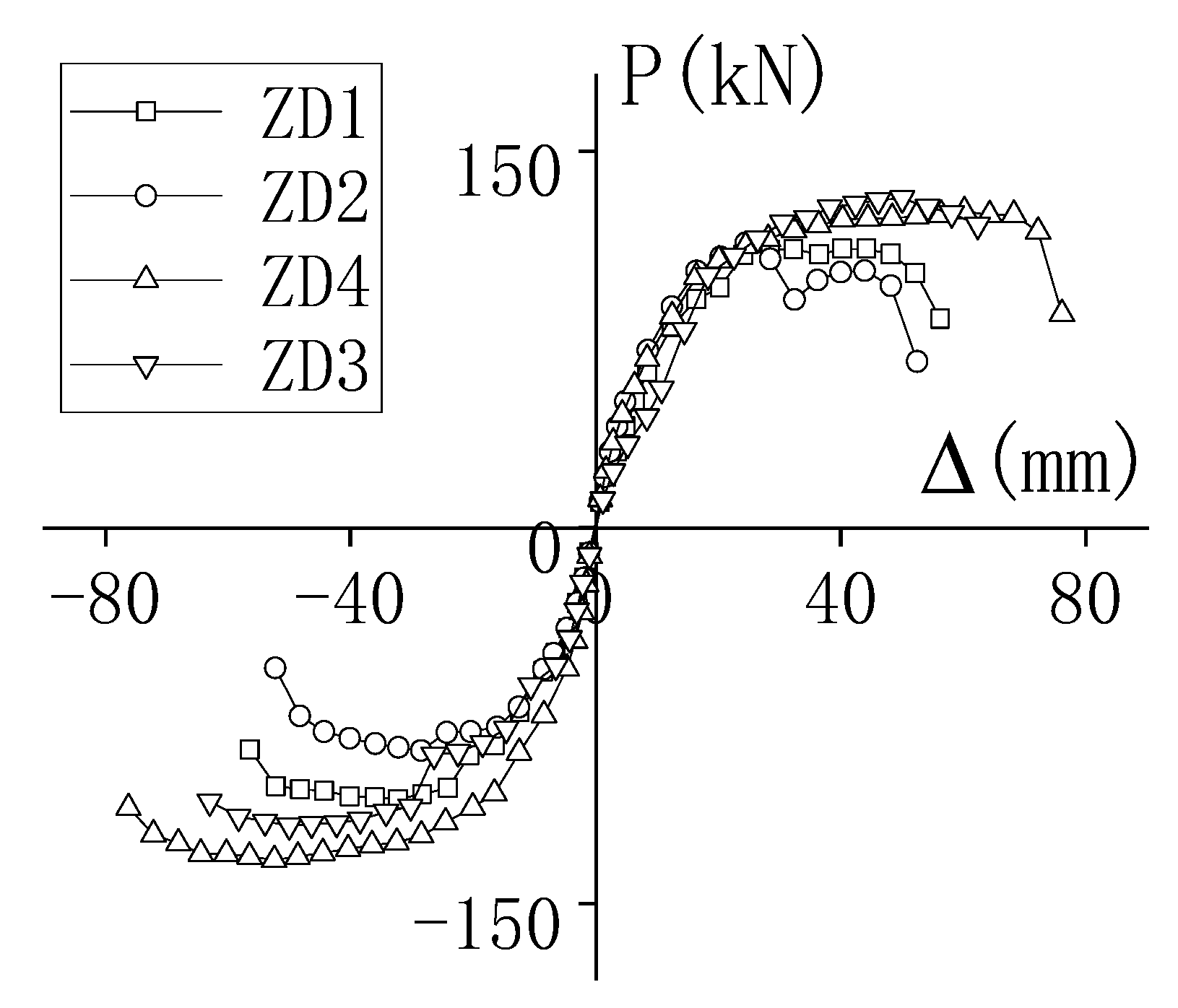

3.3. Backbone Curve

3.4. Ductility and Bearing Capacity

4. Conclusions

- (1)

- The basalt fiber sheet bulged under horizontal repeated loads, indicating the crush of concrete. However, the concrete was still well wrapped in the basalt fiber sheet, which plays a good role in restraining the concrete.

- (2)

- The hysteresis curve of the intact specimen is much fuller than the corroded specimens and the hysteresis loop area is obviously larger, indicating that the energy-dissipation capacity and ductility of specimens is reduced after corrosion. The hysteretic curve of the specimen strengthened with basalt fiber sheet is much fuller than that of the corroded specimen with a larger hysteretic loop area, indicating that the bearing capacity, energy-dissipation capacity and ductility is greatly improved when reinforced with basalt fiber sheet.

- (3)

- The bearing capacity and ductility of the corroded specimens under repeated horizontal loads were significantly weakened compared with the intact specimens, while the bearing capacity and ductility of the corroded and reinforced specimen all exceeded those of the intact specimen.

- (4)

- The restraint effect of basalt fiber sheet on the specimen increases with the reinforcement layers. The more reinforced layers of basalt fiber sheet, the more obvious the ductility of the reinforced specimens is improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choe, G.; Shinohara, Y.; Kim, G.; Lee, S.; Lee, E.; Nam, J. Concrete corrosion cracking and transverse bar strain behavior in a reinforced concrete column under simulated marine conditions. Appl. Sci. 2020, 10, 1794. [Google Scholar] [CrossRef] [Green Version]

- Ou, Y.C.; Nguyen, N.D. Influences of location of reinforcement corrosion on seismic performance of corroded reinforced concrete beams. Eng. Struct. 2016, 126, 210–223. [Google Scholar] [CrossRef]

- Zheng, A.H.; Li, S.; Zhang, D.F.; Yan, Y.H. Shear strengthening of RC beams with corrosion-damaged stirrups using FRP grid-reinforced ECC matrix composites. Compos. Struct. 2021, 272, 114229. [Google Scholar] [CrossRef]

- Firouzi, A.; Abdolhosseini, M.; Ayazian, R. Service life prediction of corrosion-affected reinforced concrete columns based on time-dependent reliability analysis. Eng. Fail. Anal. 2020, 117, 104944. [Google Scholar] [CrossRef]

- Shi, Q.X.; Niu, D.T.; Yan, G.Y. Experimental research on hysteretic characteristics of corroded RC members with fiexural and compressive axial loads under repeated horizontal loading. Earthq. Eng. Eng. Vib. 2000, 20, 44–50. [Google Scholar]

- Yan, G.Y.; Sun, B.N.; Wang, Z.J.; Niu, D.T. Experimental research on seismic behavior of the corroded RC members with bending and compression loads. J. Build. Struct. 2003, 33, 16–18. [Google Scholar]

- Niu, D.T.; Chen, X.X.; Wang, X.M. Experimental study on seismic performance of corroded reinforced concrete members with flexure and compression. J. Build. Struct. 2004, 34, 36–38. [Google Scholar]

- Chen, X.X.; Niu, D.T.; Wang, X.M. The force-restoring model of corroded reinforced concrete members with flexure and compression. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2005, 37, 155–159. [Google Scholar]

- Gong, J.X.; Zhong, W.Q.; Zhao, G.F. Experimental study on low-cycle behavior of corroded reinforced concrete member under eccentric compression. J. Build. Struct. 2004, 25, 92–104. [Google Scholar]

- Gong, J.X.; Li, J.B.; Zhao, G.F. Restoring force model of corroded reinforced concrete elements. China Civil. Eng. J. 2005, 8, 38–101. [Google Scholar]

- Jiang, L.J.; Yuan, Y.S. Experimental study on stiffness deterioration of corroded reinforced concrete column for axial load and moment under cyclic loading. J. Concr. 2011, 5, 3–5. [Google Scholar]

- Jiang, L.J.; Yuan, Y.S. Restoring force model of corroded reinforced concrete column for axial load and moment. J. Concr. 2011, 6, 29–32. [Google Scholar]

- Li, J.B. Study on Seismic Strengthening of Corroded Reinforced Concrete Columns. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2009. (In Chinese). [Google Scholar]

- Li, J.B.; Gong, J.X. Influences of rebar corrosion on seismic behavior of circular RC columns. China J. Highw. Transp. 2008, 21, 55–60. [Google Scholar]

- Li, J.B.; Gong, J.X. Experimental research on ductile behavior of corroded reinforced concrete column confined with CFRP. J. Dalian Univ. Technol. 2010, 50, 220–227. [Google Scholar]

- Li, J.B.; Gong, J.X.; Wang, L.H. Experimental study on seismic behavior of corroded reinforced concrete columns strengthened with concrete jacket and CFRP. China Civil. Eng. J. 2009, 42, 17–26. [Google Scholar]

- Gong, J.X.; Zhang, Y.Q.; Li, J.B. Research on seismic behavior of corroded and reinforced concrete specimens. Constr. Technol. 2011, 40, 74–80. [Google Scholar]

- Gong, J.X.; Li, J.B.; Cheng, L. Seismic behavior of strengthened corrosion-damaged circular reinforced concrete columns. China J. Highw. Transp. 2010, 23, 41–48. [Google Scholar]

- GB 50010-2015; Chinese Standard, Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010. (In Chinese)

- Shen, D.J.; Yang, Q.; Huang, C.B.; Cui, Z.H.; Zhang, J.Y. Tests on seismic performance of corroded reinforced concrete shear walls repaired with basalt fiber-reinforced polymers. Constr. Build. Mater. 2019, 209, 508–521. [Google Scholar] [CrossRef]

- Jiang, S.F.; Zeng, X.X.; Shen, S.; Xu, X.C. Experimental studies on the seismic behavior of earthquake-damaged circular bridge columns repaired by using combination of near-surface-mounted BFRP bars with external BFRP sheets jacketing. Eng. Struct. 2016, 106, 317–331. [Google Scholar] [CrossRef]

- Ma, G.; Chen, X.H.S.; Yan, L.B.; Hwang, H.J. Effect of pre-damage on compressive properties of circular RC columns repaired with BFRP composites: Testing and modeling. Compos. Struct. 2020, 247, 112483. [Google Scholar] [CrossRef]

- Liu, X.F.; Li, Y. Experimental study of seismic behavior of partially corrosion-damaged reinforced concrete columns strengthened with FRP composites with large deformability. Constr. Build. Mater. 2018, 191, 1071–1081. [Google Scholar] [CrossRef]

| Specimens | Designed Corrosion Rate | Axial Compression Ratio | Reinforcement Form |

|---|---|---|---|

| Z1 | 0 | 0.2 | not reinforced with FRP |

| Z2 | 8% | 0.2 | not reinforced with FRP |

| Z3 | 8% | 0.2 | jacketed with FRP (one layer) |

| Z4 | 8% | 0.2 | jacketed with FRP (two layers) |

| Specimens | Actual Corrosion Rate | Nominal Yield Strength (N/mm2) | Nominal Ultimate Strength (N/mm2) |

|---|---|---|---|

| Z1 | 0 | 440 | 640 |

| Z2 | 8.4% | 399 | 587 |

| Z3 | 9.1% | 376 | 547 |

| Z4 | 7.6% | 415 | 592 |

| Number | Test Items | Test Results |

|---|---|---|

| 1 | Tensile strength (MPa) | 2303 |

| 2 | Elastic modulus (MPa) | 1.05 × 105 |

| 3 | Elongation (%) | 2.18 |

| Number | Test Items | Test Results | Test Results | ||

|---|---|---|---|---|---|

| Class A | Class B | ||||

| 1 | Colloidal properties | Tensile strength (MPa) | ≥40 | ≥30 | 45.79 |

| Elastic modulus (MPa) | ≥2.5 × 103 | ≥1.5 × 103 | 2.6 × 103 | ||

| Elongation (%) | ≥1.5 | 3.47 | |||

| 2 | Bonding properties | Normal bonding strength with concrete (MPa) | ≥2.5 (C30 Concrete failure) | 5.87 | |

| Specimens | Pu (kN) | Δy (mm) | Δu (mm) | u | 0.85Pu (kN) |

|---|---|---|---|---|---|

| Z1 | 109.58 | 14.43 | 54.27 | 3.76 | 93.14 |

| Z2 | 98.5 | 12.51 | 46.22 | 3.69 | 83.73 |

| Z3 | 114.04 | 14.52 | 57.84 | 3.98 | 96.93 |

| Z4 | 124.9 | 15.09 | 60.21 | 3.99 | 106.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Shen, D. Seismic Performance of Corroded Reinforced Concrete Columns Strengthened with Basalt Fiber Sheets. Appl. Sci. 2022, 12, 5611. https://doi.org/10.3390/app12115611

Yuan J, Shen D. Seismic Performance of Corroded Reinforced Concrete Columns Strengthened with Basalt Fiber Sheets. Applied Sciences. 2022; 12(11):5611. https://doi.org/10.3390/app12115611

Chicago/Turabian StyleYuan, Jiaojiao, and Dejian Shen. 2022. "Seismic Performance of Corroded Reinforced Concrete Columns Strengthened with Basalt Fiber Sheets" Applied Sciences 12, no. 11: 5611. https://doi.org/10.3390/app12115611

APA StyleYuan, J., & Shen, D. (2022). Seismic Performance of Corroded Reinforced Concrete Columns Strengthened with Basalt Fiber Sheets. Applied Sciences, 12(11), 5611. https://doi.org/10.3390/app12115611