Qualitative and Quantitative Analysis of the Causes of Occupational Accidents Related to the Use of Construction Scaffoldings

Abstract

:1. Introduction

1.1. Identification and Analysis of Accident Factors

- Technical (T), related to, among others, defects and damage to tools and devices used during works;

- Organizational (O), related to, among others, the improper organization of the work process and workstations;

- Human (L), related to the incorrect behavior of employees, their psychophysical state, etc.

1.2. Causes of Accidents

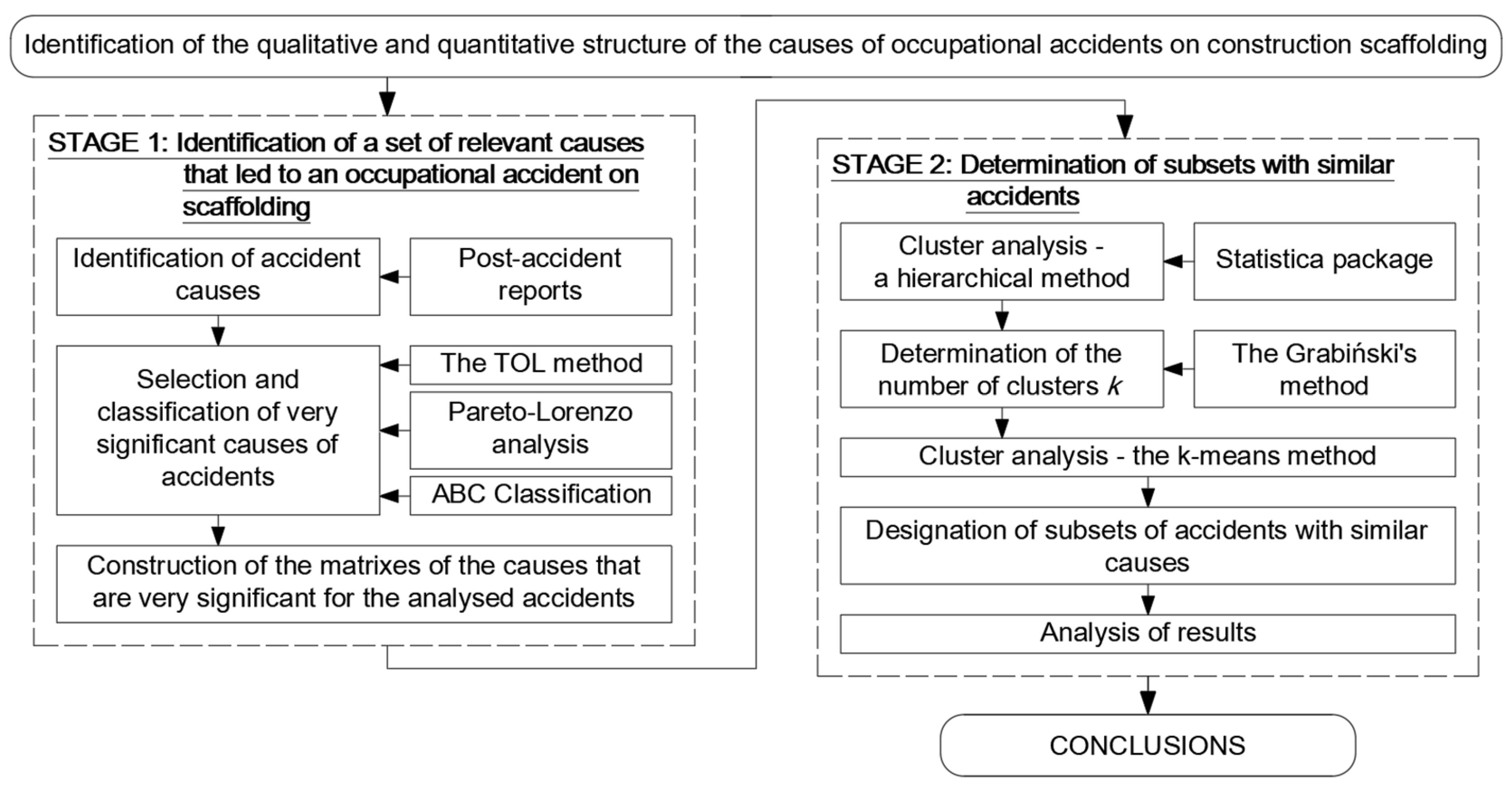

2. Research Methodology

- The identification of a set of significant causes that lead to accidents on building scaffoldings;

- The development of subsets of similar accidents, and the identification of their causes.

2.1. The Identification of a Set of Significant Causes That Lead to Accidents on Building Scaffoldings

- The set of very significant causes, which is marked as A, includes 80% of all the causes that can be attributed to a specific group of causes;

- The set of significant causes, which is marked as B, includes the causes that constitute 15% of all the causes that can be attributed to a specific group of causes;

- The set of insignificant causes, which is marked as C, includes 5% of all the causes identified in the set.

- —a set of analyzed accidents;

- —the n-th technical cause of accident (), ();

- —the n-th organizational cause of accident

- —the n-th human cause of accident

2.2. The Development of the Subsets of Similar Accidents, and the Identification of Their Causes

- —the analyzed objects, i.e., occupational accidents and , where a ≠ b, and ;

- —the values of individual parameters that describe the analyzed accidents and , where ; ; ; and .

- —the distance between the bonds for subsequent stages: ;

- —the average value of the distance between the bonds;

- —standard deviation ;

- —the constant, ranging from 2.75 to 3.50.

3. Results

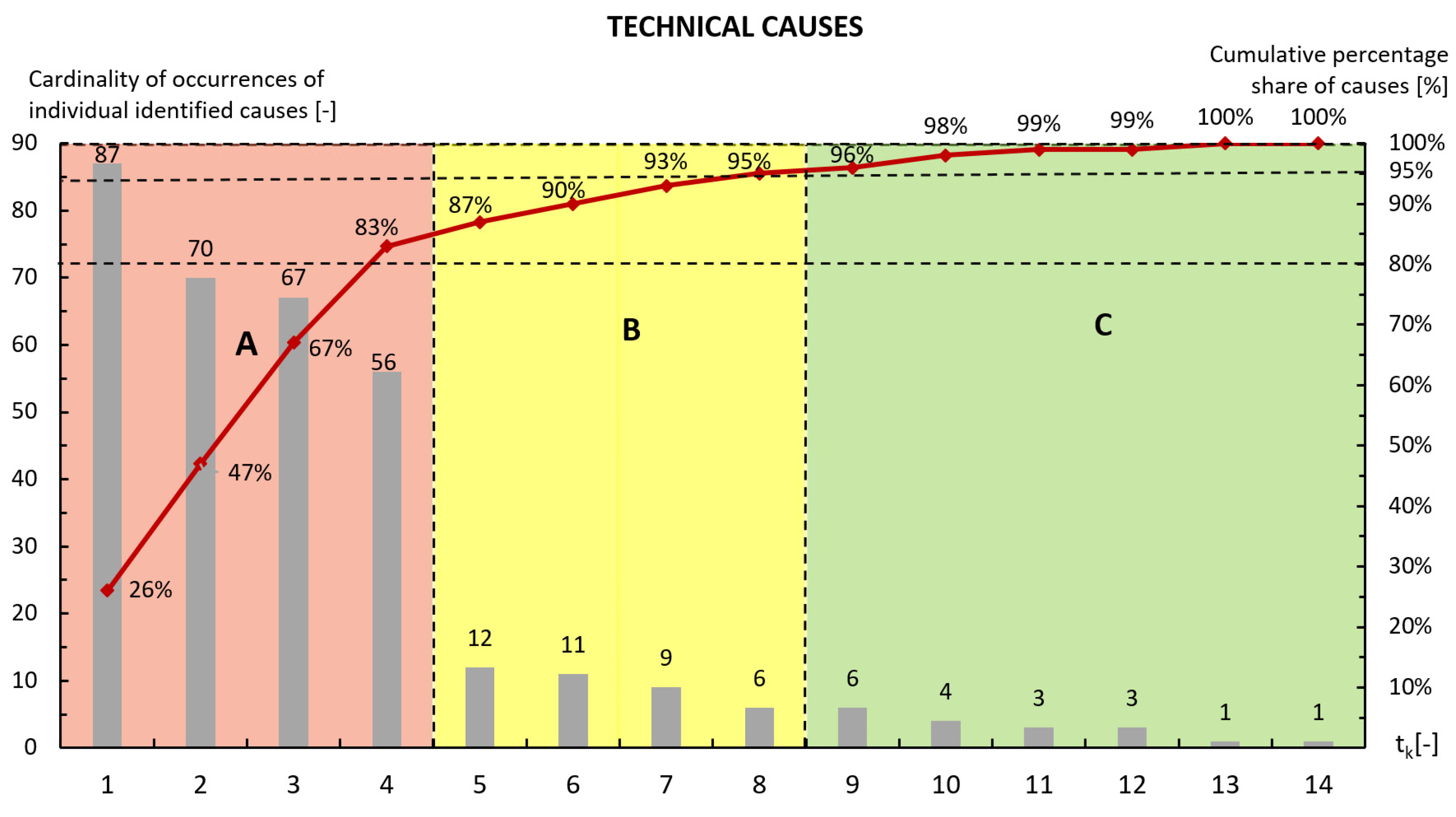

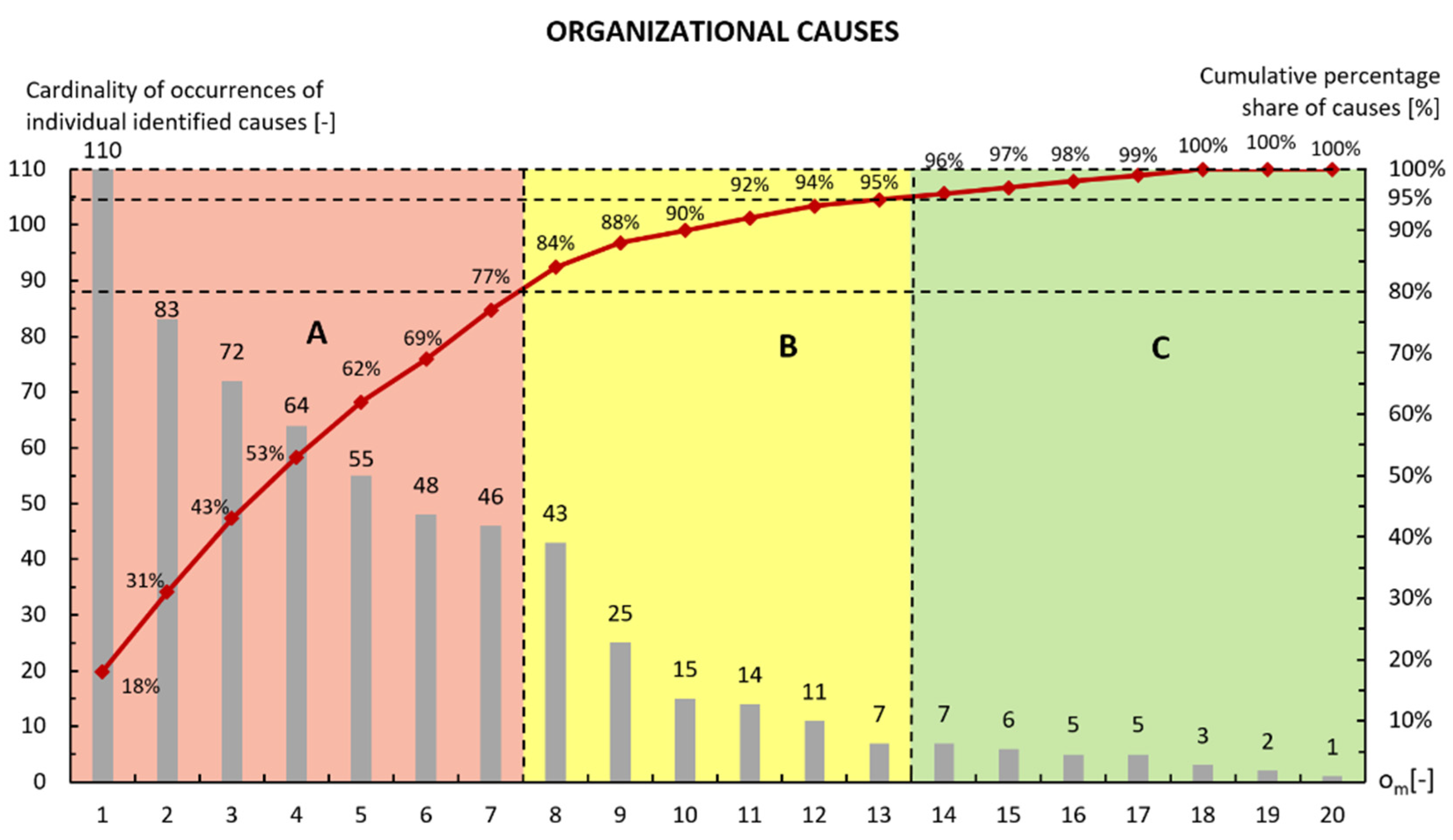

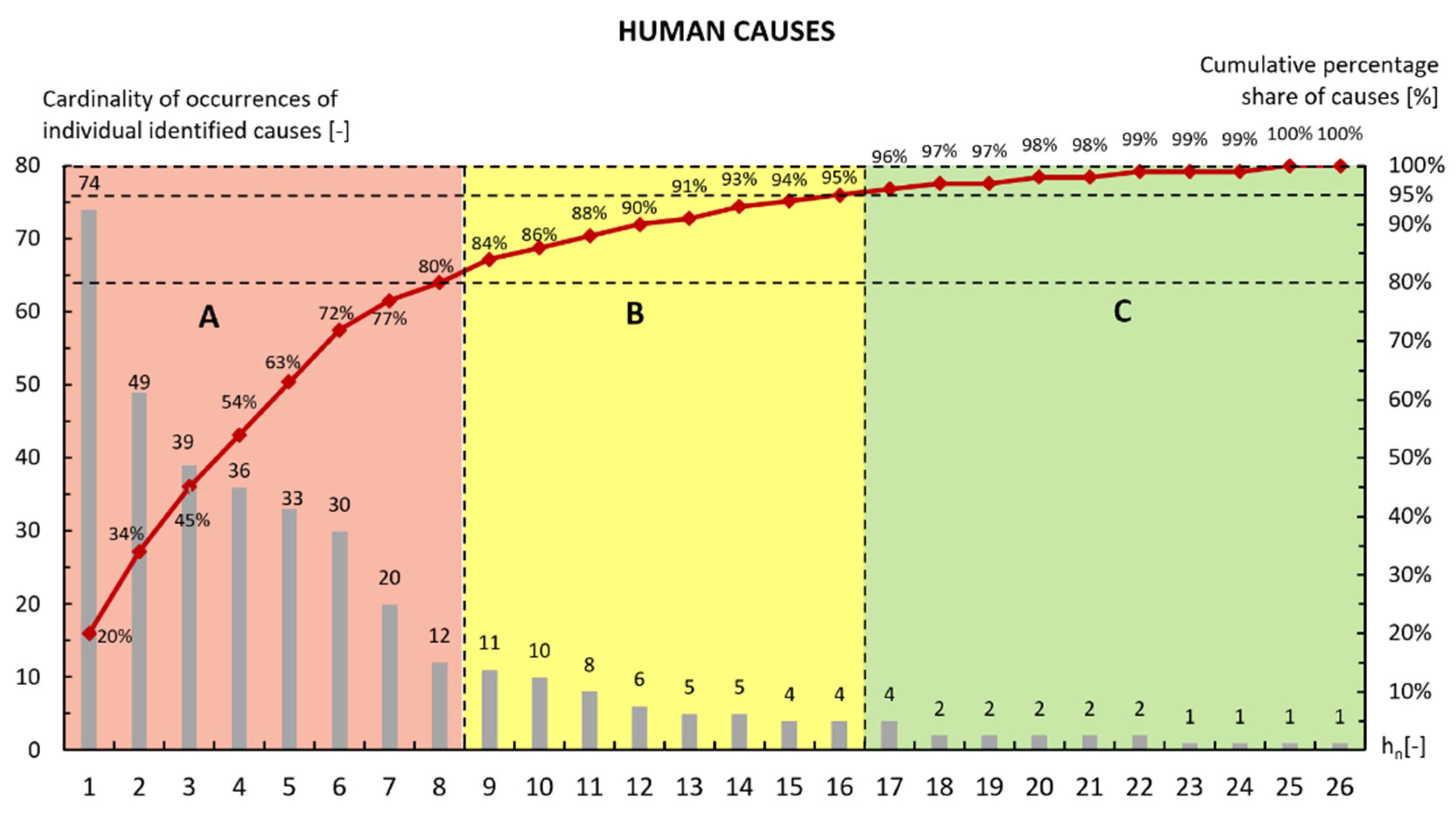

3.1. The Identification of a Set of Significant Causes That Lead to Accidents on Building Scaffoldings

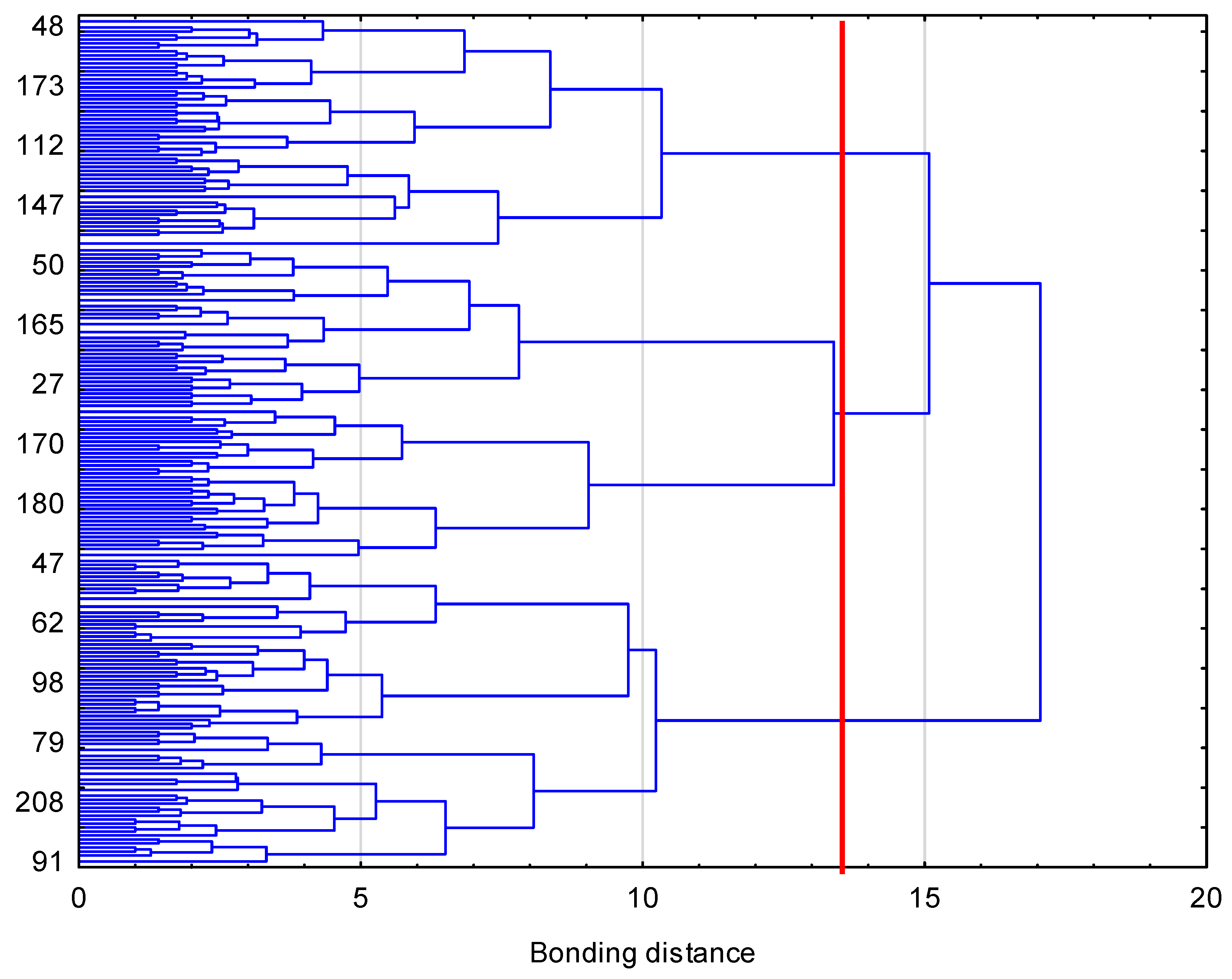

3.2. The Development of the Subsets of Similar Accidents, and the Identification of Their Causes

- Cluster —112 accident events ;

- Cluster —66 accident events ;

- Cluster —35 accident events .

4. Discussion

4.1. The Identification of a Set of Significant Causes That Lead to Accidents on Building Scaffoldings

- Very significant technical causes were: —lack of or inadequate protective devices; —lack of or inadequate measures of collective protection; —improper spatial structure of scaffoldings; —improper stability of scaffoldings. These causes constituted 28.6% of all the identified technical causes and occurred in 83% of all the accidents.

- Very significant organizational causes were: —a lack of supervision; —admission of scaffoldings to operation without the required inspection and supervision; —lack of or inadequate training in the area of occupational health and safety; —acceptance of deviations from the rules and regulations of occupational health and safety; —inadequate professional training of an employee; —lack of instructions on how to use scaffoldings safely; —admission of an employee to work without medical examination or with medical contraindications;—inadequate passages and access points. These causes constituted 40% of all the organizational causes and occurred in 84% all the accidents.

- Very significant human causes were: —failure to use personal protective equipment by an employee; —disregarding danger; —being surprised by an unexpected event; —consumption of alcohol, drugs or psychotropic substances; —insufficient concentration; —going to, driving through or staying in places that are forbidden; —performing work that is not included in the scope of an employee’s duties; —ignorance of hazards. These causes accounted for 30.76% of all the identified human causes and occurred in 80% of all the accidents.

4.2. The Development of the Subsets of Similar Accidents, and the Identification of Their Causes

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Labour Organization. Safety and Health at Work: A Vision for Sustainable Prevention; International Labour Organization: Frankfurt, Germany, 2014. [Google Scholar]

- Hoła, B.; Nowobilski, T.; Szer, I.; Szer, J. Identification of factors affecting the accident rate in the construction industry. Procedia Eng. 2017, 208, 35–42. [Google Scholar] [CrossRef]

- Hoła, B.; Nowobilski, T.; Rudy, J.; Czarnocki, K. An analysis of the influence of selected factors on the accident rate in the construction industry. Tech. Trans. 2018, 6, 95–102. [Google Scholar] [CrossRef]

- Williams, O.S.; Hamid, R.A.; Misnan, M.S. Accident Causal Factors on the Building Construction Sites: A Review. Int. J. Built Environ. Sustain. 2018, 5, 248. [Google Scholar] [CrossRef]

- Goh, K.C.; Goh, H.H.; Omar, M.F.; Toh, T.C.; Zin, A.A.M. Accidents Preventive Practice for High-Rise Construction. MATEC Web Conf. 2016, 47, 4004. [Google Scholar] [CrossRef] [Green Version]

- Toole, T.M. Construction Site Safety Roles. J. Constr. Eng. Manag. 2002, 128, 203–210. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D. Why operatives engage in unsafe work behavior: Investigating factors on construction sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Stępień, T. Identification of factors determining accident rate in construction industry. Czas. Tech. 2014, 111, 265–281. [Google Scholar]

- Hoła, A.; Sawicki, M.; Szóstak, M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Appl. Sci. 2018, 8, 48. [Google Scholar] [CrossRef] [Green Version]

- Cañamares, M.S.; Escribano, B.M.V.; García, M.N.G.; Barriuso, Á.R.; Sáiz, Á.R. Occupational risk-prevention diagnosis: A study of construction SMEs in Spain. Saf. Sci. 2017, 92, 104–115. [Google Scholar] [CrossRef]

- Drozd, W. Badania Cech Terenu Budowy i ich Wpływu na Bezpieczeństwo Prowadzenia Robót Budowlanych Przy Obiektach Nieliniowych; Monografie Politechniki Krakowskiej, Seria Inżynieria Lądowa: Cracow, Poland, 2017. [Google Scholar]

- Szóstak, M. Analysis of occupational accidents in the construction industry with regards to selected time parameters. Open Eng. 2019, 9, 312–320. [Google Scholar] [CrossRef] [Green Version]

- Dąbrowski, A. Propozycje poprawy bezpieczeństwa pracy w małych firmach budowlanych. Occup. Safety. Sci. Pract. 2016, 507, 9–13. [Google Scholar] [CrossRef]

- Musonda, I.; Pretorius, J.-H.; Haupt, T. Investigating the Role of the External Environment to Influence Clients’ Health and Safety (H&S) Performance in the Construction Industry. In Proceedings of the 19th International CIB World Building Congress, Brisbane, Australia, 5–9 May2013. [Google Scholar]

- Pietrzak, L. Analiza Wypadków Przy Pracy Dla Potrzeb Prewencji; Państwowa Inspekcja Pracy: Warszawa, Poland, 2007. [Google Scholar]

- Hansen, A. Kompleksowa Ocena Poziomu Bezpieczeństwa i Higieny Pracy; Instytut Wydawniczy Związków Zawodowych: Warszawa, Poland, 1988. [Google Scholar]

- Hansen, A. Zarys Wypadkoznawstwa; Państwowa Inspekcja Pracy: Warszawa, Poland, 1992. [Google Scholar]

- Halperin, K.M.; McCann, M. An evaluation of scaffold safety at construction sites. J. Saf. Res. 2004, 35, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-H.; Chen, C.-Y. Statistical analysis of fatal occupational falls in the Taiwan construction industry from 1996–2007. In Proceedings of the 40th International Conference on Computers & Indutrial Engineering, Awaji, Japan, 25–28 July 2010; pp. 1–4. [Google Scholar]

- Lin, Y.-H.; Chen, C.-Y.; Wang, T.-W. Fatal occupational falls in the Taiwan construction industry. J. Chin. Inst. Ind. Eng. 2011, 28, 586–596. [Google Scholar] [CrossRef]

- Państwowa Inspekcja Pracy. Sprawozdanie z Działalności Państwowej Inspekcji Pracy w 2018 Roku; Państwowa Inspekcja Pracy: Warszawa, Poland, 2019. [Google Scholar]

- Państwowa Inspekcja Pracy. Sprawozdanie z Działalności Państwowej Inspekcji Pracy w 2019 Roku; Państwowa Inspekcja Pracy: Warszawa, Poland, 2020. [Google Scholar]

- Liy, C.; Ibrahim, S.; Affandi, R.; Rosli, N.; Nawi, M. Causes of fall hazards in construction site management. Int. Rev. Manag. Mark. 2016, 6, 257–263. [Google Scholar]

- Whitaker, S.M.; Graves, R.J.; James, M.; McCann, P. Safety with access scaffolds: Development of a prototype decision aid based on accident analysis. J. Saf. Res. 2003, 34, 249–261. [Google Scholar] [CrossRef]

- Suraji, A.; Duff, A.; Peckitt, S. Development of casual model of construction accident causation. J. Constr. Eng. Manag. 2001, 12, 337–344. [Google Scholar] [CrossRef]

- Chi, S.; Han, S. Analyses of systems theory for construction accident prevention with specific reference to OSHA accident reports. Int. J. Proj. Manag. 2013, 31, 1027–1041. [Google Scholar] [CrossRef] [Green Version]

- Evanoff, B.; Dale, A.M.; Zeringue, A.; Fuchs, M.; Gaal, J.; Lipscomb, H.J.; Kaskutas, V. Results of a fall prevention educational intervention for residential construction. Saf. Sci. 2016, 89, 301–307. [Google Scholar] [CrossRef] [Green Version]

- Wong, L.; Wang, Y.; Law, T.; Lo, C.T. Association of Root Causes in Fatal Fall-from-Height Construction Accidents in Hong Kong. J. Constr. Eng. Manag. 2016, 142, 04016018. [Google Scholar] [CrossRef]

- Gibb, A.; Hide, S.; Haslam, R.; Hastings, S.; Suraji, A.; Duff, A.R.; Abdelhamid, T.S.; Everett, J.G. Identifying Root Causes of Construction Projects. J. Constr. Eng. Manag. 2001, 127, 348–349. [Google Scholar] [CrossRef] [Green Version]

- Gibb, A.G.F.; Haslam, R.; Gyi, D.E.; Hide, S.; Duff, R. What causes accidents? Proc. ICE Civ. Eng. 2006, 159, 46–50. [Google Scholar] [CrossRef]

- Błazik-Borowa, E.; Szer, J. The analysis of the stages of scaffolding “life” with regard to the decrease in the hazard at building works. Arch. Civ. Mech. Eng. 2015, 15, 516–524. [Google Scholar] [CrossRef]

- Błazik-Borowa, E.; Gontarz, J. The influence of the dimension and the configuration of the geometric imperfections on the static strength of a typical façade scaffolding. Arch. Civ. Mech. Eng. 2016, 16, 269–281. [Google Scholar] [CrossRef]

- Chu, C.-W.; Liang, G.-S.; Liao, C.-T. Controlling inventory by combining ABC analysis and fuzzy classification. Comput. Ind. Eng. 2008, 55, 841–851. [Google Scholar] [CrossRef]

- Dhoka, D.; Choudary, D.Y.L. ABC Classification for Inventory Optimization. IOSR J. Bus. Manag. 2013, 15, 38–41. [Google Scholar] [CrossRef]

- Stanisz, A. An Easy Course of Statistics with the Use of STATISTICA PL Using Examples from Medicine, Volume 3: Linear and Nonlinear Models; Cracow: Statsoft, Poland, 2007. [Google Scholar]

- Wierzchoń, S.; Kłopotek, M. Cluster Analysis Algorithms; WNT Publisher: Warsaw, Poland, 2015. [Google Scholar]

- Leśniak, A.; Juszczyk, M.; Piskorz, G. Delays factors of a completion construction project aggregation with the use of cluster analysis. Mater. Bud. 2018, 10, 62–65. [Google Scholar]

- Hoła, B.; Nowobilski, T. Classification of Economic Regions with Regards to Selected Factors Characterizing the Construction Industry. Sustainability 2018, 10, 1637. [Google Scholar] [CrossRef] [Green Version]

- Hoła, B.; Nowobilski, T. Classification of Polish voivodeships with regards to the selected indicators that characterize the construction industry. Sci. Rev. Eng. Environ. Sci. 2018, 27, 310–318. [Google Scholar]

- Ward, J.H. Hierarchical Grouping to Optimize an Objective Function. J. Am. Stat. Assoc. 1963, 58, 236. [Google Scholar] [CrossRef]

- Grabiński, T. Metody Taksonometrii; Akademia Ekonomiczna w Krakowie: Kraków, Poland, 1992. [Google Scholar]

- Mojena, R. Hierarchical grouping methods and stopping rulet: An evaluation. Comput. J. 1977, 20, 359–363. [Google Scholar] [CrossRef] [Green Version]

| Notation | Definition |

|---|---|

| TOL | Methodology of accident case classification |

| T | Technical causes |

| O | Organizational causes |

| L | Human causes |

| A set of analyzed accidents | |

| ABC | Classification of causes in terms of materiality |

| A | The set of very significant causes |

| B | The set of significant causes |

| C | The set of insignificant causes |

| Cardinality of Occurrence | Share [%] | Cumulative Share [%] | Validity Class of Cause | ||

|---|---|---|---|---|---|

| Lack of or inadequate protective devices | 87 | 26% | 26% | A | |

| Lack of or inadequate measures of collective protection | 70 | 21% | 47% | A | |

| Improper spatial structure of scaffoldings | 67 | 20% | 67% | A | |

| Improper stability of scaffoldings | 56 | 17% | 83% | A | |

| Design defects of scaffoldings that are a source of hazards | 12 | 4% | 87% | B | |

| Use of substitute materials | 11 | 3% | 90% | B | |

| Lack of or incorrect signaling of hazards | 9 | 3% | 93% | B | |

| Insufficient strength of scaffolding components | 6 | 2% | 95% | B | |

| Failure to meet required technical parameters | 6 | 2% | 96% | C | |

| Hidden material defects | 4 | 1% | 98% | C | |

| Excessive use of scaffoldings | 3 | 1% | 99% | C | |

| Inadequate maintenance of scaffoldings | 3 | 1% | 99% | C | |

| Excessive use of scaffoldings | 1 | 0% | 100% | C | |

| Improper repairs and renovations of scaffoldings | 1 | 0% | 100% | C | |

| Cardinality of Occurrence | Share [%] | Cumulative Share [%] | Validity Class of Cause | ||

|---|---|---|---|---|---|

| Lack of supervision | 110 | 18% | 18% | A | |

| Admission of scaffoldings to operation without the required inspection and supervision | 83 | 13% | 31% | A | |

| Lack of or inadequate training in the area of occupational health and safety | 72 | 12% | 43% | A | |

| Acceptance of deviations from the rules and regulations of occupational health and safety | 64 | 10% | 53% | A | |

| Inadequate professional training of an employee | 55 | 9% | 62% | A | |

| Lack of instructions on how to use scaffoldings safely | 48 | 8% | 69% | A | |

| Admission of an employee to work without medical examination or with medical contraindications | 46 | 7% | 77% | A | |

| Inadequate passages and access points | 43 | 7% | 84% | B | |

| Lack of personal protective equipment | 25 | 4% | 88% | B | |

| Acceptance of the use of improper technology by supervisors | 15 | 2% | 90% | B | |

| Incorrect job sharing or task scheduling | 14 | 2% | 92% | B | |

| Improper placement and storage of work tools | 11 | 2% | 94% | B | |

| Incorrect location of equipment at a workstation | 7 | 1% | 95% | B | |

| Improper selection of personal protective equipment | 7 | 1% | 96% | C | |

| Incorrect coordination of collective work | 6 | 1% | 97% | C | |

| Incorrect commands of superiors | 5 | 1% | 98% | C | |

| Not removing unnecessary tools, substances or energy, e.g., waste | 5 | 1% | 99% | C | |

| Performing work when short-staffed | 3 | 0% | 100% | C | |

| Performing work on command that is not included in the scope of an employee’s duties | 2 | 0% | 100% | C | |

| Performing work despite having the wrong tools and materials | 1 | 0% | 100% | C | |

| Cardinality of Occurrence | Share [%] | Cumulative Share [%] | Validity Class of Cause | ||

|---|---|---|---|---|---|

| Failure to use personal protective equipment by an employee | 74 | 20% | 20% | A | |

| Disregarding danger | 49 | 13% | 34% | A | |

| Being surprised by an unexpected event | 39 | 11% | 45% | A | |

| Consumption of alcohol, drugs or psychotropic substances | 36 | 10% | 54% | A | |

| Insufficient concentration | 33 | 9% | 63% | A | |

| Going to, driving through or staying in places that are forbidden | 30 | 8% | 72% | A | |

| Performing work that is not included in the scope of an employee’s duties | 20 | 5% | 77% | A | |

| Ignorance of hazards | 12 | 3% | 80% | A | |

| Ignorance of regulations and rules of occupational health and safety | 11 | 3% | 84% | B | |

| Using equipment that is not appropriate for the work | 10 | 3% | 86% | B | |

| Improper securing of a device (e.g., brake not applied when parked) | 8 | 2% | 88% | B | |

| Sudden illness, physical deterioration, fatigue | 6 | 2% | 90% | B | |

| Improper grasping or holding of materials or tools | 5 | 1% | 91% | B | |

| Carrying out activities without removing the hazard (e.g., machine shutdown, power off) | 5 | 1% | 93% | B | |

| Failure to use collective protection measures | 4 | 1% | 94% | B | |

| Disregarding superiors’ commands | 4 | 1% | 95% | B | |

| Improper pace of work | 4 | 1% | 96% | C | |

| Using a device while people are in the danger zone | 2 | 1% | 97% | C | |

| Using a device contrary to its intended purpose | 2 | 1% | 97% | C | |

| Lack of using safety devices by employees | 2 | 1% | 98% | C | |

| Entering an endangered area without making sure that there is no danger | 2 | 1% | 98% | C | |

| Lack of experience | 2 | 1% | 99% | C | |

| Performing work by hand instead of using devices | 1 | 0% | 99% | C | |

| Defective installation, fastening, suspension of devices by an employee | 1 | 0% | 99% | C | |

| Improper handling of the limbs in the danger zone | 1 | 0% | 100% | C | |

| Fatigue | 1 | 0% | 100% | C | |

| Causes | Cluster | |||

|---|---|---|---|---|

| 0.40 | 0.24 | 0.74 | ||

| 0.26 | 0.59 | 0.06 | ||

| 0.30 | 0.47 | 0.20 | ||

| 0.26 | 0.29 | 0.23 | ||

| 0.20 | 0.27 | 0.09 | ||

| 0.53 | 0.56 | 0.40 | ||

| 0.22 | 0.76 | 0.23 | ||

| 0.10 | 0.74 | 0.34 | ||

| 0.14 | 0.29 | 0.83 | ||

| 0.17 | 0.38 | 0.31 | ||

| 0.21 | 0.29 | 0.17 | ||

| 0.07 | 0.47 | 0.20 | ||

| 0.13 | 0.21 | 0.43 | ||

| 0.27 | 0.48 | 0.40 | ||

| 0.30 | 0.29 | 0.60 | ||

| 0.10 | 0.20 | 0.71 | ||

| 0.17 | 0.15 | 0.29 | ||

| 0.24 | 0.11 | 0.06 | ||

| 0.21 | 0.11 | 0.06 | ||

| 0.07 | 0.09 | 0.46 | ||

| 0.13 | 0.03 | 0.11 | ||

| 0.23 | 0.33 | 0.60 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoła, B.; Nowobilski, T.; Woźniak, Z.; Białko, M. Qualitative and Quantitative Analysis of the Causes of Occupational Accidents Related to the Use of Construction Scaffoldings. Appl. Sci. 2022, 12, 5514. https://doi.org/10.3390/app12115514

Hoła B, Nowobilski T, Woźniak Z, Białko M. Qualitative and Quantitative Analysis of the Causes of Occupational Accidents Related to the Use of Construction Scaffoldings. Applied Sciences. 2022; 12(11):5514. https://doi.org/10.3390/app12115514

Chicago/Turabian StyleHoła, Bożena, Tomasz Nowobilski, Zuzanna Woźniak, and Marta Białko. 2022. "Qualitative and Quantitative Analysis of the Causes of Occupational Accidents Related to the Use of Construction Scaffoldings" Applied Sciences 12, no. 11: 5514. https://doi.org/10.3390/app12115514

APA StyleHoła, B., Nowobilski, T., Woźniak, Z., & Białko, M. (2022). Qualitative and Quantitative Analysis of the Causes of Occupational Accidents Related to the Use of Construction Scaffoldings. Applied Sciences, 12(11), 5514. https://doi.org/10.3390/app12115514