Evaluation of Indirect-Heated Microwave Thermal Desorption Treatment on Engineering Properties of Lubricant-Contaminated Soil

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

| Parameters | Unit | Results | References | ||

|---|---|---|---|---|---|

| Initial Soil | Contaminated Soil | Treated Soil | |||

| USCS Classification | - | † SM | SM | SM | ASTM D-2487 [29] |

| Natural Water Content | % | 7.1 | 5.5 | 0.2 | ASTM D-698 [30] |

| # Liquid Limit | % | * N.P. | 29.3 | N.P. | ASTM D-4318 [31] |

| # Plastic Limit | N.P. | N.P. | N.P. | ASTM D-4318 [31] | |

| # Plastic Index | - | N.P. | N.P. | N.P. | ASTM D-4318 [31] |

| Specific Gravity | - | 2.6 | 2.6 | 2.6 | ASTM D-792 [32] |

| Coefficient of Permeability | cm/s | 2.1 × 10−4 | 5.6 × 10−5 | 7.1 × 10−4 | ASTM D-2434 [33] |

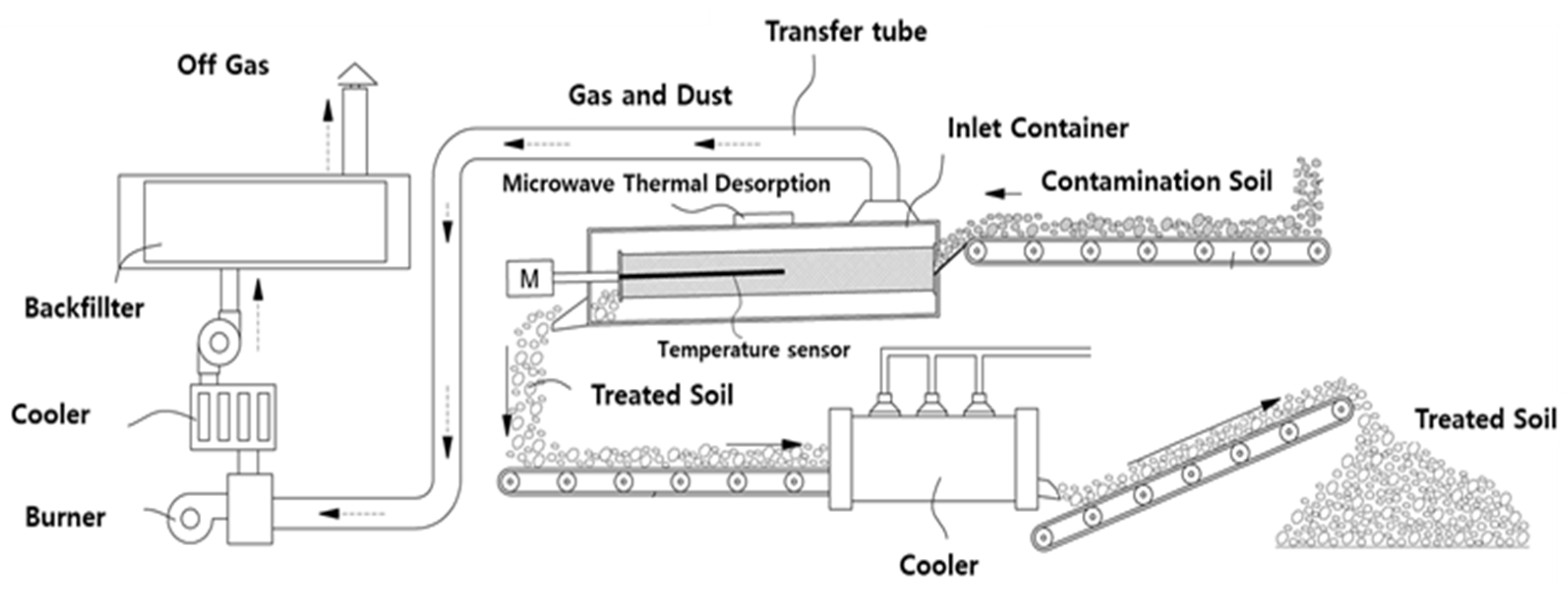

2.2. Experimental Methods

2.3. Laboratory Tests

2.3.1. Environmental Properties

2.3.2. Geotechnical Properties

3. Results and Discussion

3.1. Analysis of Environmental Properties

3.2. Analysis of Geotechnical Properties

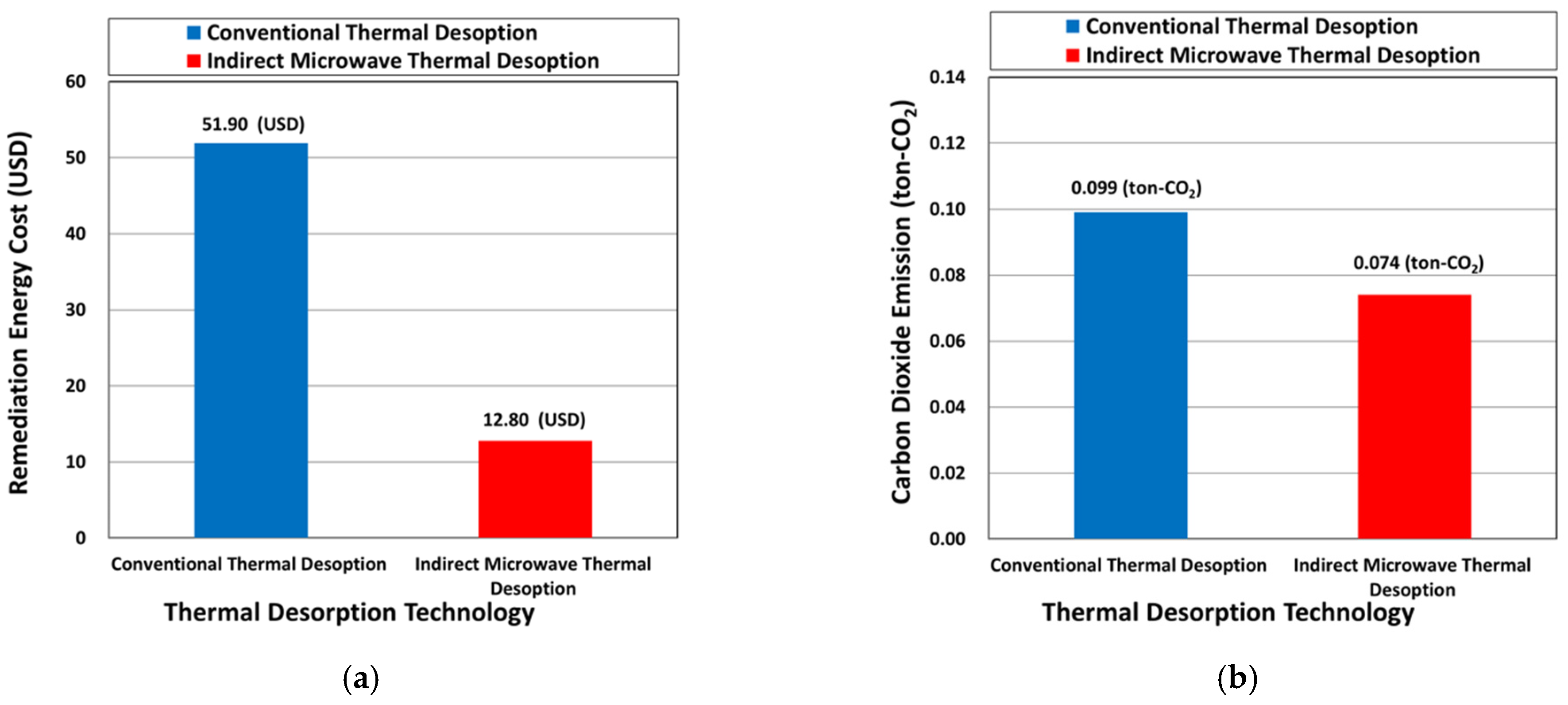

3.3. Analysis of CO2 Emission and Energy Cost

4. Conclusions

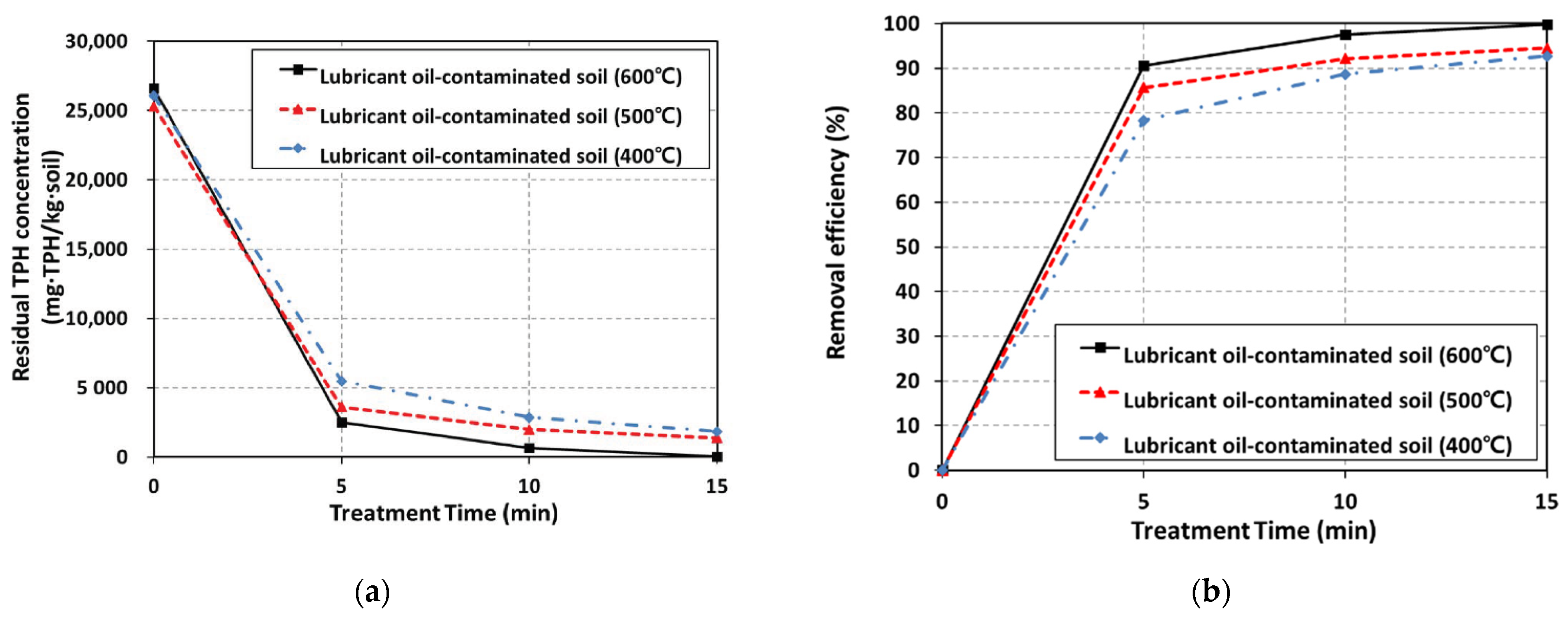

- The indirect-heated microwave thermal desorption equipment was preheated for 3 h with the electric power of 32, 24 and 16 kW to reach the target temperatures of 600, 500 and 400 °C, and the contaminated soil was put into the soil container for the desorption of the oil and organic pollutants from the soil. With treatment times of 5, 10 and 15 min as the main processes, environmental TPH concentrations were reduced to 2512, 652 and 38.2 mg/kg, respectively, indicating removal efficiencies of 90.56, 97.55 and 99.86% accordingly. Based on these environmental test results, it was found that the developed indirect-heated microwave thermal desorption method in this study has an excellent effect on removing semi-volatile organic pollutants.

- The analyses of the geotechnical properties are as follows: (1) The proportion of coarse-grained soils retained in sieve No. 200 (0.075 mm) was increased compared to the initial as well as contaminated soils due to the desorption of the oil and organic matters absorbed in the soil particles and even fine-grained soil particles in the form of dust and mist. It was found that the liquid limit and permeability coefficient were almost recovered to levels of the initial state due to the desorption of the oil occupying the pores between soil particles. (2) The internal friction angle, maximum dry density and permeability coefficient of the soil were reduced by oil contamination and were finally restored to the almost initial level of soil after treatment. (3) The cohesion of the soil was increased by oil contamination due to the lubrication effect of viscous oil and decreased after treatment.

- Due to the fossil-fuel-free heating mechanism designed for the remediation of lubricant-oil-contaminated soil at 600 °C in this study, newly developed indirect-heated microwave thermal desorption technology reduces energy costs and CO2 emissions by 75% and 25%, respectively, compared with conventional thermal desorption methods using fossil fuels.

- It is finally found that soil treated by an indirect-heated microwave thermal desorption technology is expected to be reusable for geotechnical construction purposes such as road and railway fill materials.

5. Patents

- United States Patent

- Title of Invention: Thermal desorption system for oil-contaminated soil and gravel, using microwave indirect irradiation method and including microwave leakage prevention device and preheating device using waste heat, and thermal desorption method for oil-contaminated soil and gravel, using same.

- Applicant: Korea Railroad Research Institute (KR)

- Inventors: Tae Hoon Koh, (KR); Dong Geun Lee, (KR); Han Ju Yoo, (KR)

- Patent No.: US 10,518,303 B2

- Publication Number: WO/2018/151451

- Publication Date: 23.08.2018

- International Application No.: PCT/KR2018/001538

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Data of Chromatogram (Peak Results)

| Index | Sample | Time [min] | Quantity [ng] | Height [μV] | Area [μV·min] | Area [%] |

|---|---|---|---|---|---|---|

| 1 | 400C0m | 17.53 | 3708.41 | 26,044.1 | 73,744.6 | 100.0 |

| 2 | 400C5m | 17.53 | 2767.28 | 18,626.2 | 54,639.0 | 100.0 |

| 3 | 400C10m | 17.53 | 2929.44 | 18,231.5 | 57,486.2 | 100.0 |

| 4 | 400C15m | 17.53 | 3179.31 | 4072.1 | 47,627.2 | 100.0 |

| 5 | 500C0m | 17.53 | 4212.39 | 24,706.3 | 67,440.4 | 100.0 |

| 6 | 500C5m | 17.53 | 3633.51 | 23,288.4 | 72,491.5 | 100.0 |

| 7 | 500C10m | 17.53 | 1979.15 | 3823.0 | 40,664.2 | 100.0 |

| 8 | 500C15m | 17.53 | 2788.72 | 4826.8 | 46,055.9 | 100.0 |

| 9 | 600C0m | 17.53 | 2657.43 | 15,132.7 | 47,699.0 | 100.0 |

| 10 | 600C5m | 17.53 | 3087.28 | 6243.6 | 63,353.0 | 100.0 |

| 11 | 600C10m | 17.53 | 3284.47 | 15,847.5 | 52,130.9 | 100.0 |

| 12 | 600C15m | 17.53 | 382.92 | 11,304.4 | 20,178.3 | 100.0 |

Appendix A.2. TPH Results

- : Area count for hydrocarbon range of interest (ng);

- : Volume of total extract (mL);

- : Dilution Factor;

- : Dry weight of sample (g);

- : Volume of sample extracted (μL).

| Index | Sample | TPH (mg/kg) | |||||

|---|---|---|---|---|---|---|---|

| 1 | 400C0m | 3708.41 | 2 | 70 | 9.96 | 2 | 26,063 |

| 2 | 400C5m | 2767.28 | 2 | 20 | 10.08 | 2 | 5490 |

| 3 | 400C10m | 2929.44 | 2 | 10 | 10.22 | 2 | 2866 |

| 4 | 400C15m | 3179.31 | 2 | 5 | 8.61 | 2 | 1846 |

| 5 | 500C0m | 4212.39 | 2 | 60 | 9.98 | 2 | 25,325 |

| 6 | 500C5m | 3633.51 | 2 | 10 | 10.02 | 2 | 3626 |

| 7 | 500C10m | 1979.15 | 2 | 10 | 9.92 | 2 | 1995 |

| 8 | 500C15m | 2788.72 | 2 | 5 | 10.08 | 2 | 1383 |

| 9 | 600C0m | 2657.43 | 2 | 100 | 9.99 | 2 | 26,600 |

| 10 | 600C5m | 3087.28 | 2 | 8 | 9.83 | 2 | 2512 |

| 11 | 600C10m | 3284.47 | 2 | 2 | 10.07 | 2 | 652 |

| 12 | 600C15m | 382.92 | 2 | 1 | 10.02 | 2 | 38.2 |

Appendix A.3. Calculation of Remediation Energy Cost and Carbon Dioxide Emissionv

| Conventional Thermal Desorption | This Study | |

|---|---|---|

| Remediation Energy Cost |

|

|

| Carbon Dioxide Emission |

| |

References

- Lee, J.K.; Park, D.; Kim, B.-U.; Dong, J.-I.; Lee, S. Remediation of petroleum-contaminated soils by fluidized thermal desorption. Waste Manag. 1998, 18, 503–507. [Google Scholar] [CrossRef]

- Mansurov, Z.; Ongarbaev, E.; Tuleutaev, B. Contamination of soil by crude oil and drilling muds. Use of wastes by production of road construction materials. Chem. Technol. Fuels Oils 2001, 37, 441–443. [Google Scholar] [CrossRef]

- Karer, J.; Wawra, A.; Zehetner, F.; Dunst, G.; Wagner, M.; Pavel, P.-B.; Puschenreiter, M.; Friesl-Hanl, W.; Soja, G. Effects of biochars and compost mixtures and inorganic additives on immobilisation of heavy metals in contaminated soils. Water Air Soil Pollut. 2015, 226, 342. [Google Scholar] [CrossRef]

- Kim, J.; Hong, J.; Kim, J.; Kim, H. Cases of design and application of treatment of oil-contaminated soil. Korean Soc. Geotech. Eng. 2009, 25, 8–17. [Google Scholar]

- Kostecki, P.T. Petroleum Contaminated Soils: Remediation Techniques, Environmental Fate, and Risk Assessment; CRC Press: Boca Raton, FL, USA, 1989; Volume 2. [Google Scholar]

- Ayen, R.J.; Swanstrom, C.P. Process & Operation Review; Thermal desorption. In Hazardous Waste Site Soil Remediation: Theory and Application of Innovative Technologies; Winson, D.J., Clarke, A.N., Eds.; Marcel Dekker: New York, NY, USA, 1994; pp. 265–301. [Google Scholar]

- Ministry of Korean Environment. Soil and Groundwater Remediation Technology; Jinhan M&B: Seoul, Korea, 2014; pp. 135–157. [Google Scholar]

- Da Rocha, U.N.; van Elsas, J.D.; van Overbeek, L.S. Real-time PCR detection of Holophagae (Acidobacteria) and Verrucomicrobia subdivision 1 groups in bulk and leek (Allium porrum) rhizosphere soils. J. Microbiol. Methods 2010, 83, 141–148. [Google Scholar] [CrossRef]

- Ouriache, H.; Arrar, J.; Namane, A.; Bentahar, F. Treatment of petroleum hydrocarbons contaminated soil by Fenton like oxidation. Chemosphere 2019, 232, 377–386. [Google Scholar] [CrossRef]

- Cho, K.; Myung, E.; Kim, H.; Park, C.; Choi, N.; Park, C. Effect of soil washing solutions on simultaneous removal of heavy metals and arsenic from contaminated soil. Int. J. Environ. Res. Public Health 2020, 17, 3133. [Google Scholar] [CrossRef]

- Fanning, D.S.; Keramidas, V.Z.; El-Desoky, M.A. Minerals in Soil Environments; SSSA Book Series; Dixon, J.B., Weed, S.B., Eds.; SSSA: Madison, WI, USA, 1989; Volume 1, pp. 551–634. [Google Scholar]

- Pape, A.; Switzer, C.; McCosh, N.; Knapp, C.W. Impacts of thermal and smoldering remediation on plant growth and soil ecology. Geoderma 2015, 243–244, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Dixon, J.B. Kaolin and serpentine group minerals. In Minerals in Soil Environments; SSSA Book Series; Dixon, J.B., Weed, S.B., Eds.; SSSA: Madison, WI, USA, 1989; Volume 1, pp. 467–525. [Google Scholar]

- Kawala, Z.; Atamańczuk, T. Microwave-enhanced thermal decontamination of soil. Environ. Sci. Technol. 1998, 32, 2602–2607. [Google Scholar] [CrossRef]

- Chien, Y.-C. Field study of in situ remediation of petroleum hydrocarbon contaminated soil on site using microwave energy. J. Hazard. Mater. 2012, 199, 457–461. [Google Scholar] [CrossRef]

- Jones, D.A.; Lelyveld, T.; Mavrofidis, S.; Kingman, S.; Miles, N. Microwave heating applications in environmental engineering—A review. Resour. Conserv. Recycl. 2002, 34, 75–90. [Google Scholar] [CrossRef]

- Jeong, S.; Choi, H. Removal of semi-volatile soil organic contaminants with microwave and additives. J. Soil Groundw. Environ. 2013, 18, 67–77. [Google Scholar] [CrossRef] [Green Version]

- Haapea, P.; Tuhkanen, T. Integrated treatment of PAH contaminated soil by soil washing, ozonation and biological treatment. J. Hazard. Mater. 2006, 136, 244–250. [Google Scholar] [CrossRef]

- Abramovitch, R.A.; Bangzhou, H.; Abramovitch, D.A.; Jiangao, S. In situ decomposition of PAHs in soil and desorption of organic solvents using microwave energy. Chemosphere 1999, 39, 81–87. [Google Scholar] [CrossRef]

- Gan, Q. A case study of microwave processing of metal hydroxide sediment sludge from printed circuit board manufacturing wash water. Waste Manag. 2000, 20, 695–701. [Google Scholar] [CrossRef]

- Campanella, L.; Grossi, R.; Martini, E.; Visco, G. Degradation of pollutants by microwaves. Curr. Top. Anal. Chem. 2004, 4, 35–46. [Google Scholar]

- Liu, X.; Quan, X.; Bo, L.; Chen, S.; Zhao, Y. Simultaneous pentachlorophenol decomposition and granular activated carbon regeneration assisted by microwave irradiation. Carbon 2004, 42, 415–422. [Google Scholar] [CrossRef]

- Boateng, A.A. Rotary Kilns: Transport Phenomena and Transport Processes, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Venkateswaran, V.; Brimacombe, J. Mathematical model of the SL/RN direct reduction process. Metall. Trans. B 1977, 8, 387–398. [Google Scholar] [CrossRef]

- Tscheng, S.; Watkinson, A. Convective heat transfer in a rotary kiln. Can. J. Chem. Eng. 1979, 57, 433–443. [Google Scholar] [CrossRef] [Green Version]

- Gorog, J.; Adams, T.; Brimacombe, J. Heat transfer from flames in a rotary kiln. Metall. Trans. B 1983, 14, 411–424. [Google Scholar] [CrossRef]

- Boateng, A.A. Boundary layer modeling of granular flow in the transverse plane of a partially filled rotating cylinder. Int. J. Multiph. Flow 1998, 24, 499–521. [Google Scholar] [CrossRef]

- ASTM D-6913; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2009; No. 19428–2959.

- ASTM D-2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2011; No. 19428–2959.

- ASTM D-698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2007; No. 19428–2959.

- ASTM D-4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017; No. 19428–2959.

- ASTM D-792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020; No. 19428–2959.

- ASTM D-2434; Standard Test Methods for Measurement of Hydraulic Conductivity of Coarse-Grained Soils. ASTM International: West Conshohocken, PA, USA, 2022; No. 19428–2959.

- Dawei, L.; Yaobin, Z.; Xie, Q.; Yazhi, Z. Microwave thermal remediation of crude oil contaminated soil enhanced by carbon fiber. J. Environ. Sci. 2009, 21, 1290–1295. [Google Scholar]

- Lin, L.; Yuan, S.; Chen, J.; Wang, L.; Wan, J.; Lu, X. Treatment of chloramphenicol-contaminated soil by microwave radiation. Chemosphere 2010, 78, 66–71. [Google Scholar] [CrossRef]

- Falciglia, P.P.; Vagliasindi, F.G.A. Remediation of hydrocarbon-contaminated soils by ex-situ microwave treatment: Technical, energy and economic considerations. Environ. Technol. 2014, 35, 2280–2288. [Google Scholar] [CrossRef]

- ASTM D-1945; Standard Test Method for Analysis of Natural Gas by Gas Chromatography. ASTM International: West Conshohocken, PA, USA, 2020; No. 19428–2959.

- ASTM D-3080; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2012; No. 19428–2959.

- Yazdi, A.; Sharifi Teshnizi, E. Effects of contamination with gasoline on engineering properties of fine-grained silty soils with an emphasis on the duration of exposure. SN Appl. Sci. 2021, 3, 1–24. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons: New York, NY, USA, 2005; Volume 3. [Google Scholar]

- Sharifi Teshnizi, E.; Reisi Dehkordi, M.; Moaiede Kia, A. Environmental Effects of Hydrocarbon Pollution on Soil and Water; Supreme National Defense University: Tehran, Iran, 2020; p. 402. [Google Scholar]

- Elsaigh, W.A.H.; Oluremi, J.R. Assessment of Geotechnical Properties of Oil Contaminated Subgrade Soil: Review. Soil Sediment Contam. Int. J. 2021, 1–25. [Google Scholar] [CrossRef]

| Chemical Substance | CAS No. | EC No. | Content (%) |

|---|---|---|---|

| Distillates (petroleum), hydrotreated heavy paraffinic | 64742-54-7 | 265-157-1 | 85~95 |

| Phosphorodithioic acid mixed O,O-bis(1,3-dimethylbutyl and iso-Pr) esters zinc salts | 84605-29-8 | 283-392-8 | 0~2 |

| Dodecylphenol, branched | 121158-58-5 | 310-154-3 | 0~2 |

| Arcrylic copolymer | - | - | 0~1 |

| Microwave Heating | This Study | Dawei et al. [34] | Lin et al. [35] | Y. C. Chien [15] | Falciglia et al. [36] |

|---|---|---|---|---|---|

| Heating modes | Indirect | Direct | Direct | Direct | Direct |

| Types of Microwave absorber | Slag | Carbon fiber | Activated carbon | None | None |

| Microwave exposure | Exposure to absorber | Exposure to mixture of soil and absorber | Exposure to mixture of soil and absorber | Exposure to soil | Exposure to soil |

| Applications | Ex situ | Ex situ | Ex situ | In situ | Ex situ |

| Driving Part | |

|---|---|

| Operation Type | Rotary, Batch |

| Treatment Heat Source | Microwave and Microwave Absorber |

| Rotatory Inner Container | ∅ 0.6 m × L 1.6 m |

| Outer Container Size | W 1.5 m × L 2.4 m × H 2.4 m |

| Rotation Speed | Max. 12.5 rpm |

| Operation Angle | 0°~3° |

| Capacity | 50 kg/batch |

| Heating Part | |

| Microwave Output Power | 1 kW |

| Frequency | 2.45 GHz |

| Peak Anode Voltage | 4.0 kV |

| Average Anode Current | 340 mA |

| Filament Voltage | 3.3 V |

| Filament Current | 10 A |

| Capacity of Air Cooling | 800 L/min |

| Treatment Temperature (°C) | Treatment Time (min) | Residual TPH Concentration (mg/kg) | Removal Efficiency (%) |

|---|---|---|---|

| 400 | 0 | ∇ 26,063 | - |

| 5 | 5490 | 78.3 | |

| 10 | 2866 | 88.7 | |

| 15 | 1846 | 92.7 | |

| 500 | 0 | 25,325 | - |

| 5 | 3626 | 85.7 | |

| 10 | 1995 | 92.1 | |

| 15 | 1383 | 94.5 | |

| 600 | 0 | 26,600 | - |

| 5 | 2512 | 90.6 | |

| 10 | 652 | 97.6 | |

| 15 | 38.2 | 99.9 |

| Descriptions | Conditions |

|---|---|

| GC Instrument/Detector | Varian, 450-C/300-MS |

| Column | Agilent CP-Sil 8CB; Ultra-2 (Cross-linked 5% phenyl methyl silicon) |

| Temperature | Injection 300 °C Detector FID 320 °C 12 °C/min rate to 310 °C for 18.33 min hold |

| Carrier gas/flow rate | Helium (2.0 mL/min) |

| Injection volume | 2 μL |

| Split ratio | 10:1 |

| Ultrasonic extractor model | Bandelin, Sonoplus UW3100 |

| Type of filters | ADVANTEC, Quantitative Filter Paper 5B 110 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Koh, T.; Park, D. Evaluation of Indirect-Heated Microwave Thermal Desorption Treatment on Engineering Properties of Lubricant-Contaminated Soil. Appl. Sci. 2022, 12, 5254. https://doi.org/10.3390/app12105254

Lee D, Koh T, Park D. Evaluation of Indirect-Heated Microwave Thermal Desorption Treatment on Engineering Properties of Lubricant-Contaminated Soil. Applied Sciences. 2022; 12(10):5254. https://doi.org/10.3390/app12105254

Chicago/Turabian StyleLee, Donggeun, Taehoon Koh, and Duhee Park. 2022. "Evaluation of Indirect-Heated Microwave Thermal Desorption Treatment on Engineering Properties of Lubricant-Contaminated Soil" Applied Sciences 12, no. 10: 5254. https://doi.org/10.3390/app12105254

APA StyleLee, D., Koh, T., & Park, D. (2022). Evaluation of Indirect-Heated Microwave Thermal Desorption Treatment on Engineering Properties of Lubricant-Contaminated Soil. Applied Sciences, 12(10), 5254. https://doi.org/10.3390/app12105254