Study on Dynamic Characterization and Vibration Reduction of Scrubber Structures Using Fluid Structure Interaction Analysis

Abstract

:1. Introduction

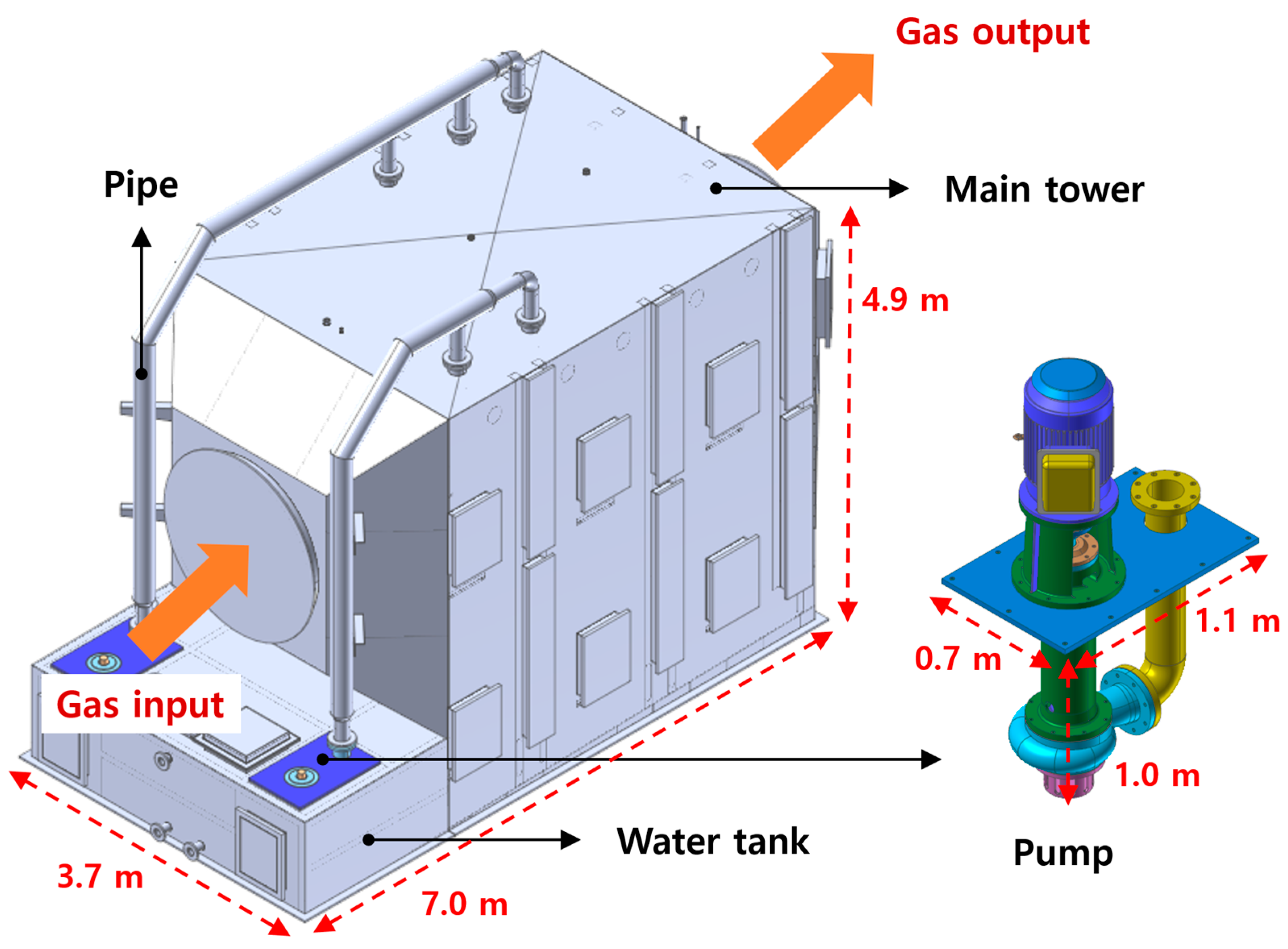

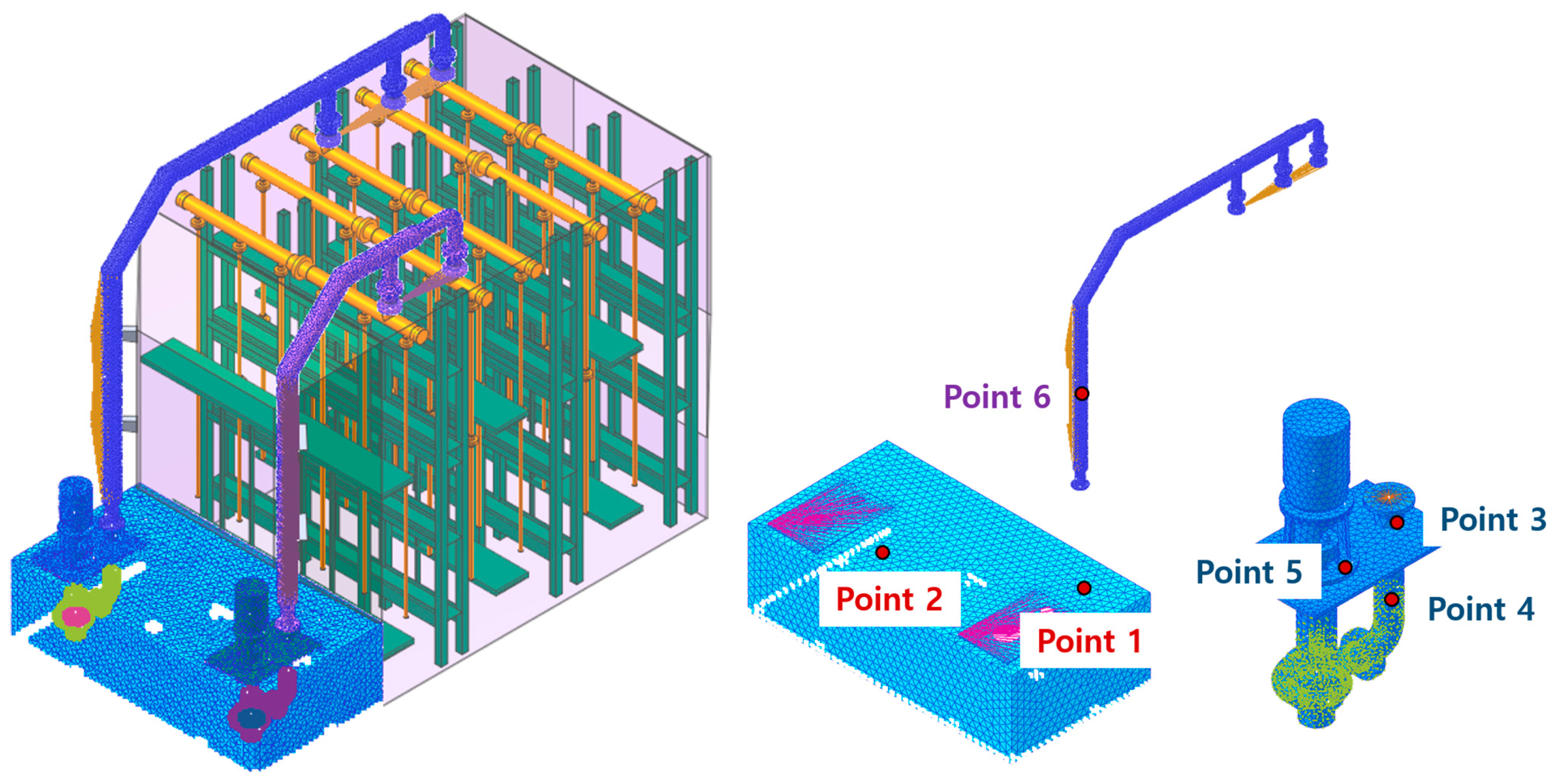

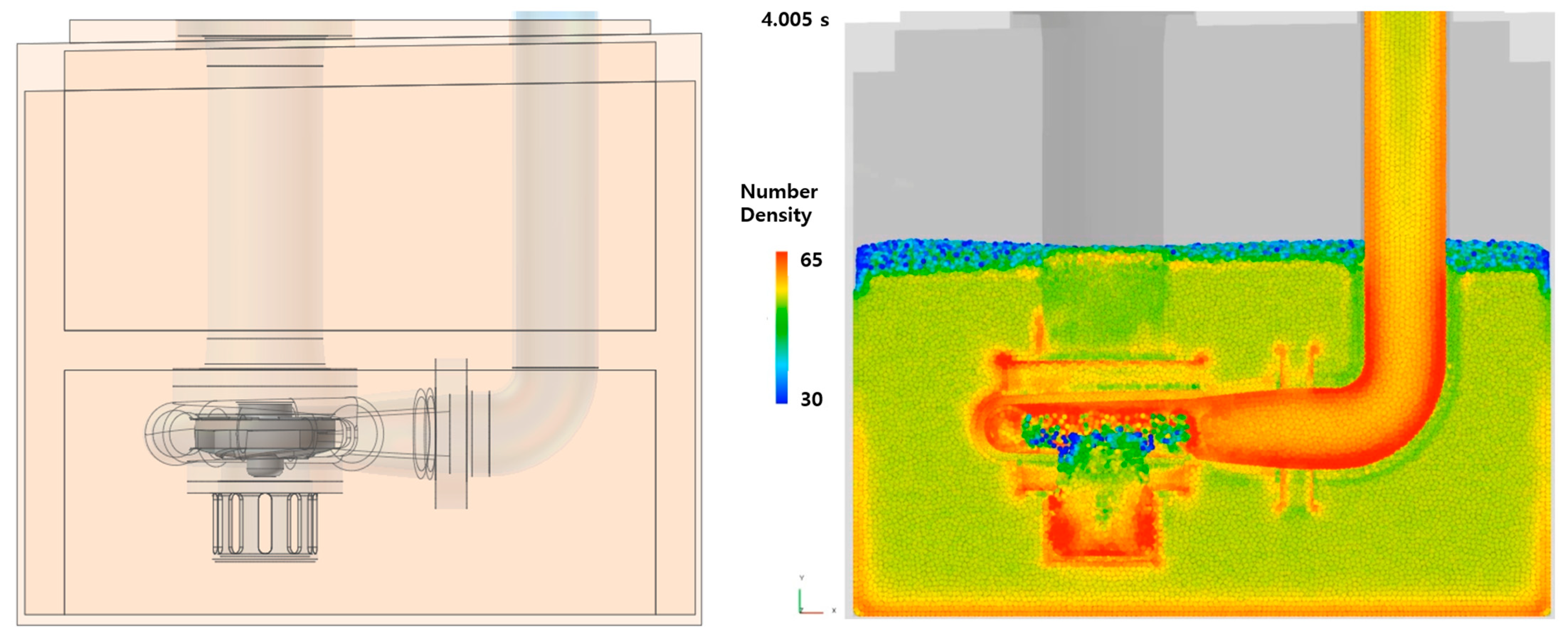

2. Dynamic Model of the System

2.1. Analysis Modeling

2.2. Calculation of the Force Transmission Rate

3. Selection of Design Factors for Vibration Reduction

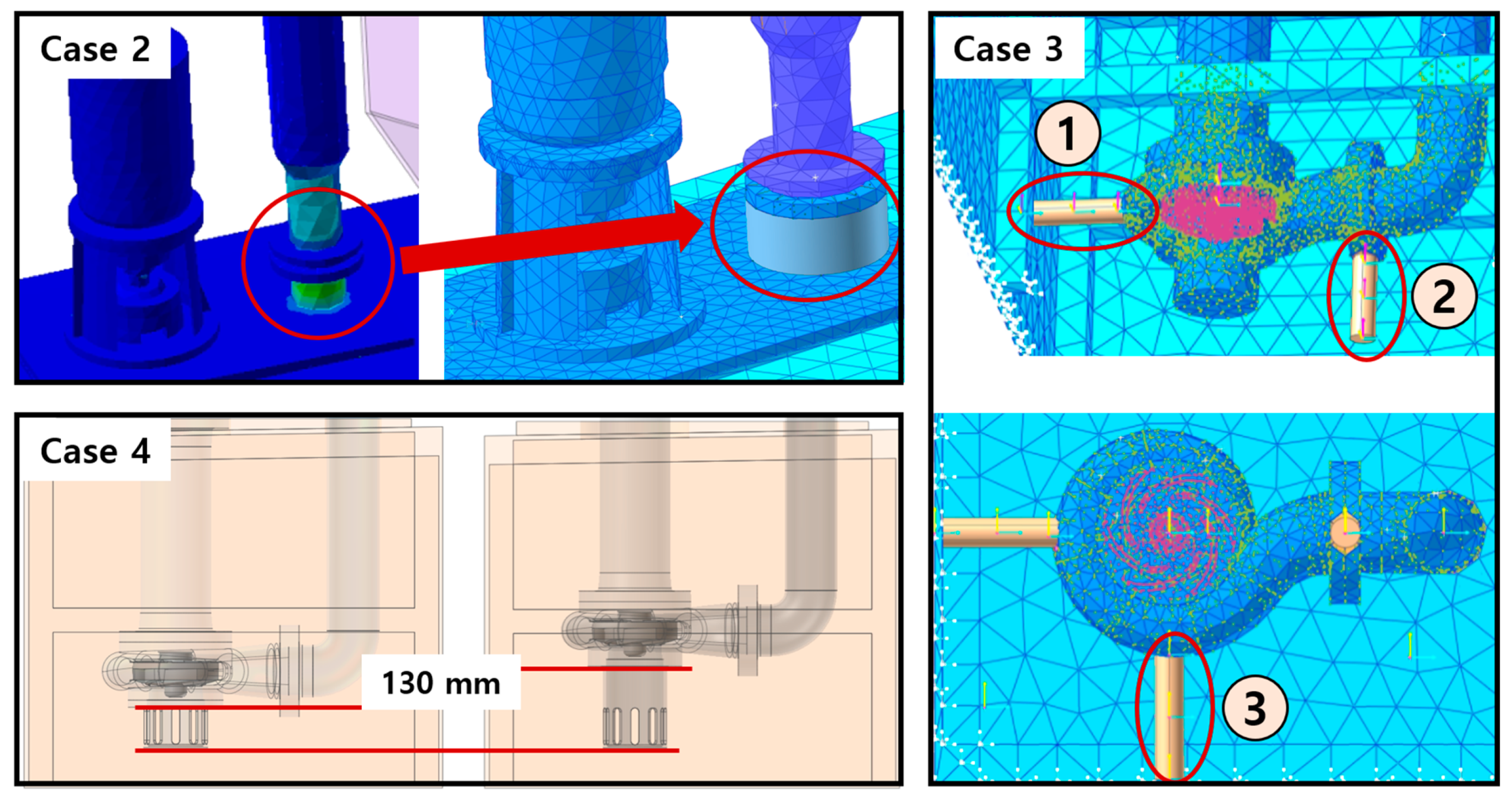

3.1. Configuring an Analysis Case

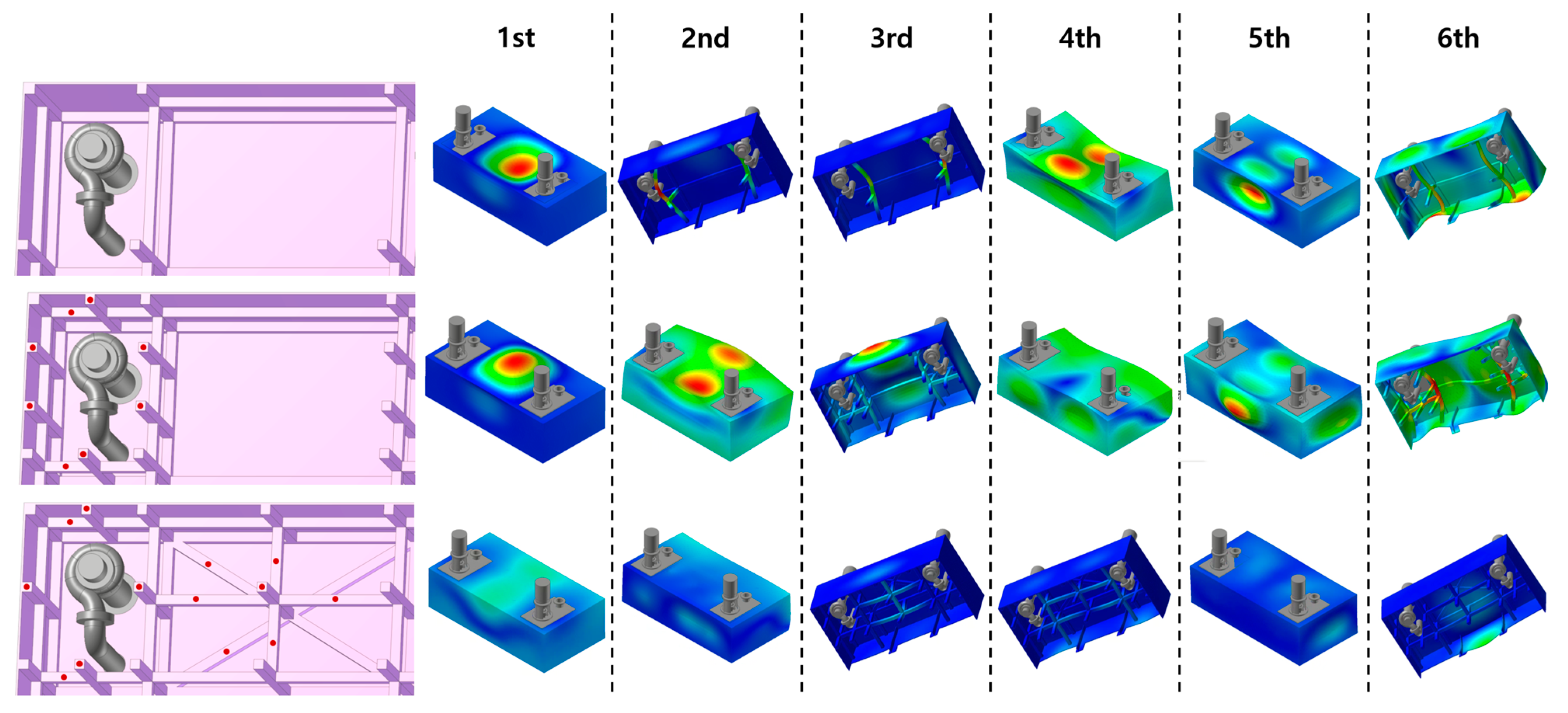

3.2. Modal Analysis

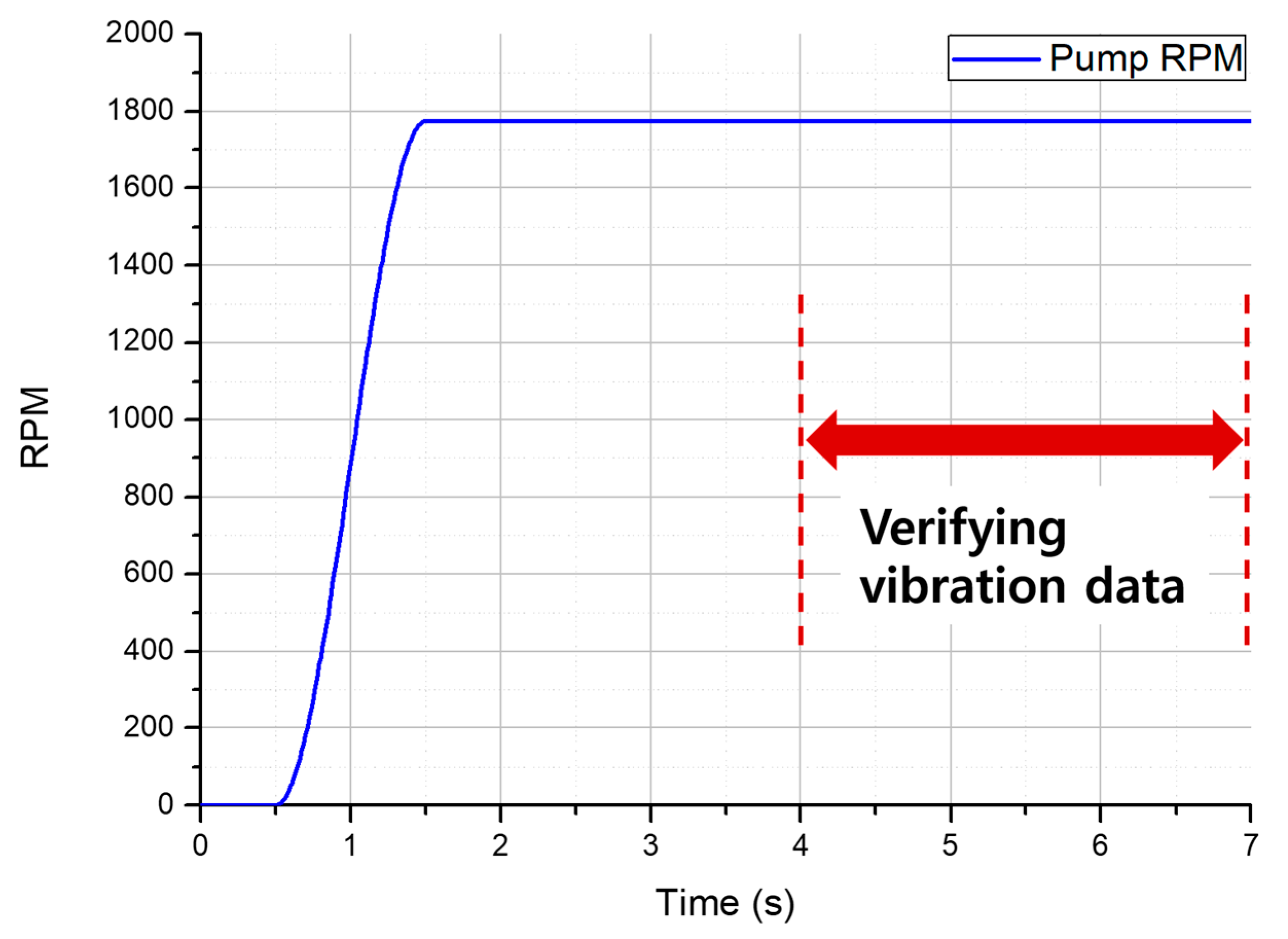

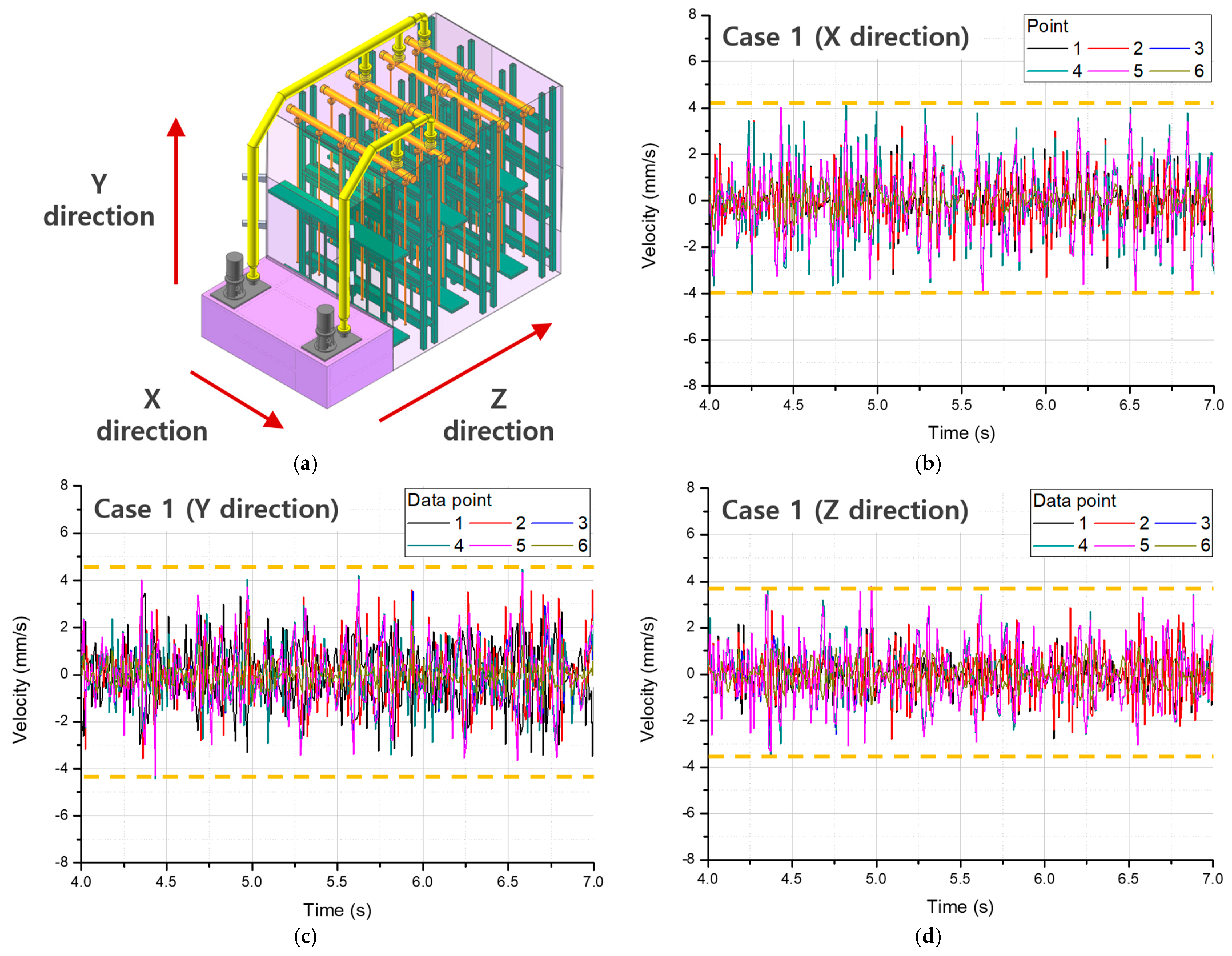

4. Analysis of Vibration Data

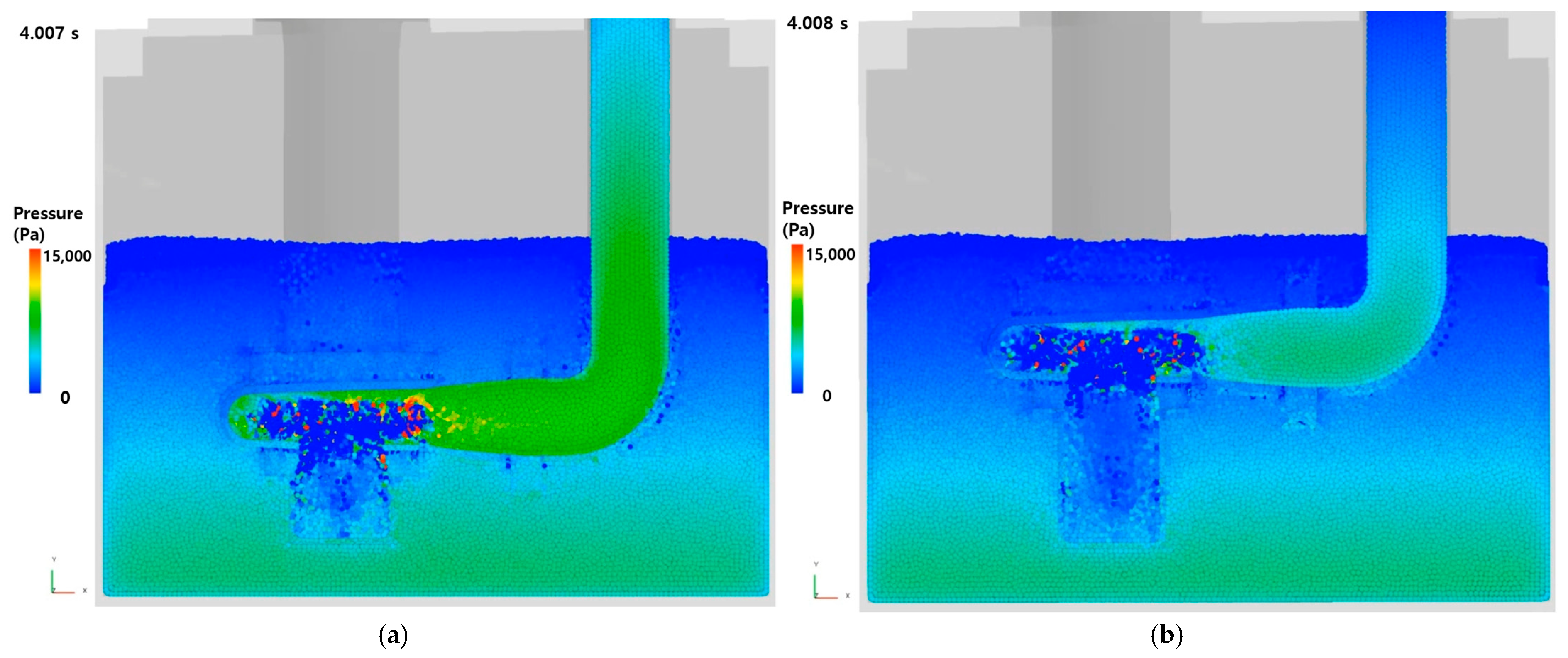

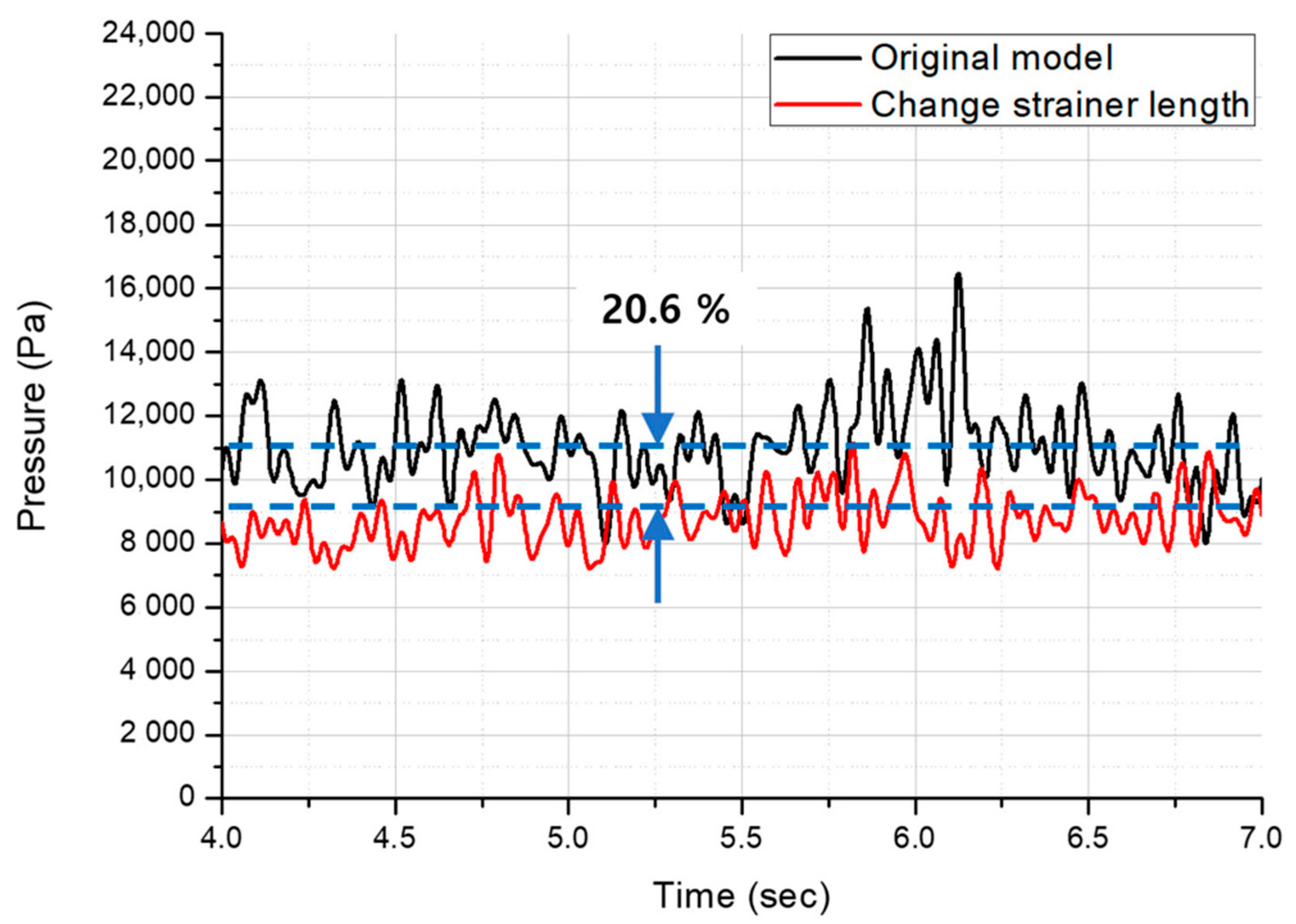

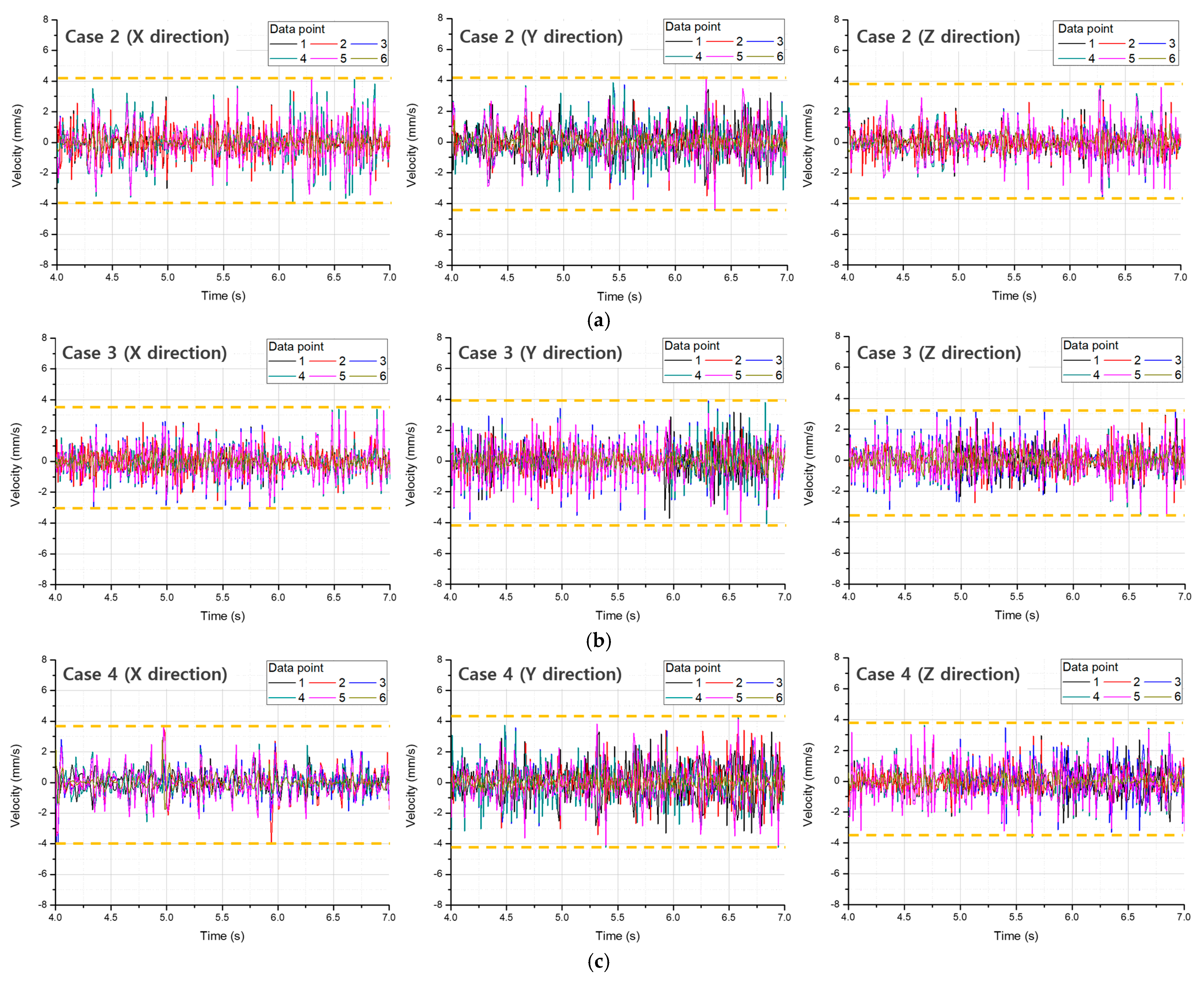

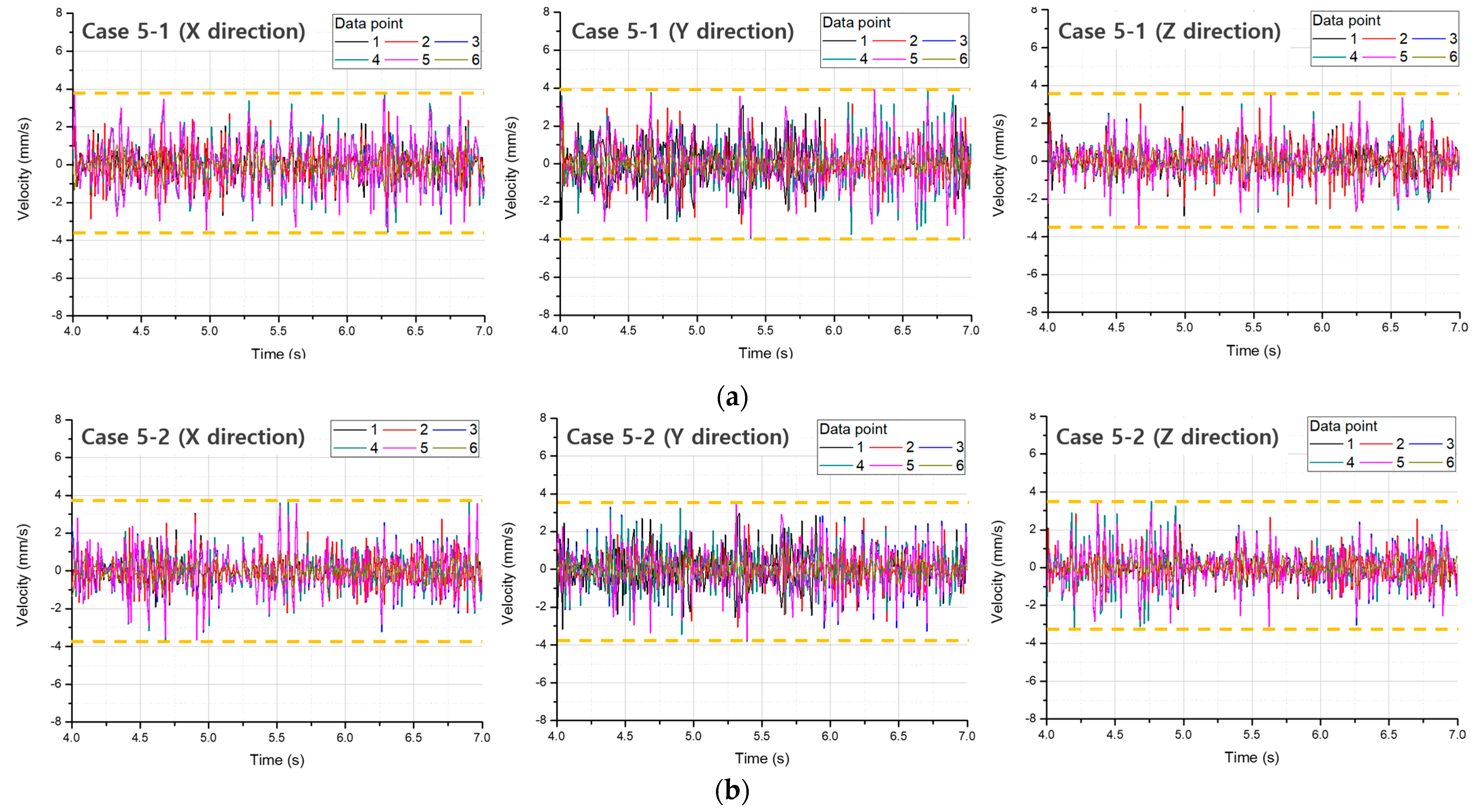

4.1. Comparison of Data According to Design Factors

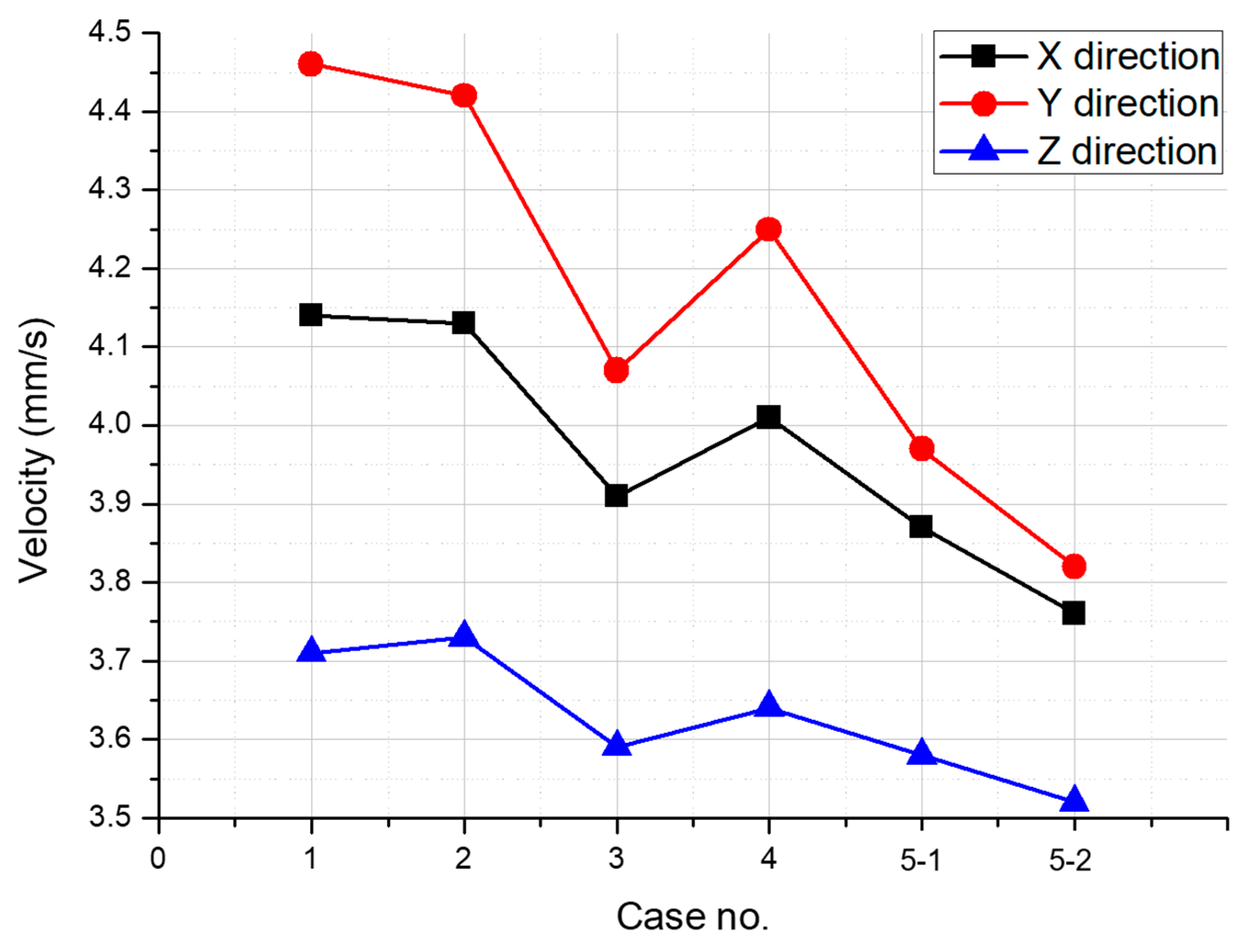

4.2. Efficeint Vibration Design

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chouichi, A.; Blue, J.; Yugma, C.; Pasqualini, F. Chamber-to-Chamber Discrepancy Detection in Semiconductor Manufacturing. Trans. Semicond. Manuf. 2020, 33, 86–95. [Google Scholar] [CrossRef]

- Haq, A.A.U.; Djurdjanovic, D. Dynamics-inspired feature extraction in semiconductor manufacturing processes. J. Ind. Inf. Integr. 2019, 13, 22–31. [Google Scholar]

- Tonke, D.; Grunow, M. Maintenance, shutdown and production scheduling in semiconductor robotic cells. Int. J. Prod. Res. 2018, 56, 3306–3325. [Google Scholar] [CrossRef]

- Arba’in, A.N.; Belaidan, S.L.M. Fault Detection and Prediction in the Semiconductor Manufacturing Process. Int. J. Manag. 2020, 11, 2023–2028. [Google Scholar]

- Hu, S.; Gao, Y.; Hu, F.; Liu, C.; Li, J. Experimental study of the dust-removal performance of a wet scrubber. Int. J. Coal Sci. Technol. 2021, 8, 228–239. [Google Scholar] [CrossRef]

- Shaisundaram, V.S.; Chandrasekaran, M.; Raj, S.M.; Muraliraha, R.; Vinodkumar, T. Control of carbon dioxide emission in automobile vehichles using CO2 scrubber. Int. J. Ambient. Energy 2019, 40, 699–703. [Google Scholar] [CrossRef]

- Lu, Z.; Rath, A.; Amini, S.H.; Noble, A.; Shahab, S. A computational fluid dynamics investigation of a novel flooded-bed dust scrubber with vibrating mesh. Int. J. Min. Sci. Technol. 2022, in press. [Google Scholar] [CrossRef]

- Dinora, M.M. Effect of Ultrasonic Vibration on the Mass Transfer Coefficient in a Sieve Plate Scrubber. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2010. [Google Scholar]

- Kim, N.Y.; Hong, M.S. Diagnosis and Reduction of Robot Arm Vibration for 12-Inch Wafer Spin Scrubber. Key Eng. Mater. 2004, 270–273, 884–889. [Google Scholar] [CrossRef]

- Benra, F.K.; Dohmen, H.J.; Schuster, S.; Wan, B. A Comparison of One-Way and Two-Way Coupling Methods for Numerical Analysis of Fluid-Structure Interactions. J. Appl. Math. 2011, 2011, 853560. [Google Scholar] [CrossRef]

- Dhande, D.Y.; Pande, D.W. A two-way FSI analysis of multiphase flow in hydrodynamic journal bearing with cavitation. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3399–3412. [Google Scholar] [CrossRef]

- Gummer, A.; Sauer, B. Modeling planar slider-crank mechanisms with clearance joints in RecurDyn. Multibody Syst. Dyn. 2014, 31, 127–145. [Google Scholar] [CrossRef]

- Cheng, K.; Liu, Y.; Xu, X.; Xie, H. Virtual Prototyping of Belt Conveyor Based on RecurDyn. Appl. Mech. Mater. 2009, 16–19, 776–780. [Google Scholar]

- Hattori, M. An attempt to apply mathematical foundation of Moving Particle Simulation to the MPS software “Particleworks”. Proc. Symp. Educ. Appl. Inf. Technol. 2015, 9, 59–62. [Google Scholar]

- Ojala, S.; Oy, W.F. Designing and analysing the cooling of a medium speed engine piston using MPS method. In Proceedings of the International CAE Conference and Exhibition, Vicenza, Italy, 8–9 October 2018. [Google Scholar]

- Mobley, A.V.; Carroll, M.P.; Canann, S.A. An Object Oriented Approach to Geometry Defeaturing for Finite Element Meshing. IMR 1998, 547–563. [Google Scholar]

- Mounir, H.; Nizar, A.; Abdelmajid, B. CAD model simplification using a removing details and merging faces technique for a FEM simulation. J. Mech. Sci. Technol. 2012, 26, 3539–3548. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. The Hertzian contact surface. J. Mater. Sci. 1999, 34, 129–137. [Google Scholar] [CrossRef]

| Target | Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| Water Tank | 7850 | 200 | 0.285 |

| Pump | 1940 | 17.2 | 0.32 |

| Pipe | 1750 | 5.8 | 0.32 |

| Target | Coefficient |

|---|---|

| Stiffness (N/mm) | 50,000–100,000 |

| Damping (kg/s) | 5–10 |

| Target | Surface Tension (N/m) | ||

|---|---|---|---|

| Water | 1000 | 0.072 |

| Stiffness (N/m) | Damping Ratio |

|---|---|

| 0.25 |

| Data | Numerical | Analysis | Error Rate |

|---|---|---|---|

| Reaction Force (N) | 827.5 | 815.1 | 1.5% |

| Case No. | Contents |

|---|---|

| 1 | Original model |

| 2 | Pump top reinforcement |

| 3 | Structural reinforcement of impeller part |

| 4 | Change in the strainer length |

| 5 | Water tank structure reinforcement |

| Mode Response | Original Model | Reinforcement of the Impeller Part | Internal Overall Reinforcement |

|---|---|---|---|

| 1st | 98.47 | 101.26 | 138.42 |

| 2nd | 118.54 | 140.11 | 141.29 |

| 3rd | 122.18 | 149.72 | 144.73 |

| 4th | 137.51 | 152.93 | 157.25 |

| 5th | 151.04 | 163.56 | 169.75 |

| 6th | 151.81 | 173.19 | 172.55 |

| Case No. | Contents | Max. Vibration Velocity (mm/s) | Vibration Reduction Rate Based on Max. Value (%) | ||

|---|---|---|---|---|---|

| X Direction | Y Direction | Z Direction | |||

| 1 | Original model | 4.14 | 4.46 | 3.71 | Default value |

| 2 | Pump top reinforcement | 4.13 | 4.42 | 3.73 | 0.9 |

| 3 | Structural reinforcement of the impeller part | 4.91 | 4.07 | 3.59 | 9 |

| 4 | Change strainer length | 4.01 | 4.25 | 3.64 | 4.6 |

| 5-1 | Water tank structure reinforcement (1) | 3.87 | 3.97 | 3.58 | 11 |

| 5-2 | Water tank structure reinforcement (2) | 3.76 | 3.82 | 3.52 | 14.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cha, W.-Y. Study on Dynamic Characterization and Vibration Reduction of Scrubber Structures Using Fluid Structure Interaction Analysis. Appl. Sci. 2022, 12, 5207. https://doi.org/10.3390/app12105207

Cha W-Y. Study on Dynamic Characterization and Vibration Reduction of Scrubber Structures Using Fluid Structure Interaction Analysis. Applied Sciences. 2022; 12(10):5207. https://doi.org/10.3390/app12105207

Chicago/Turabian StyleCha, Woon-Yong. 2022. "Study on Dynamic Characterization and Vibration Reduction of Scrubber Structures Using Fluid Structure Interaction Analysis" Applied Sciences 12, no. 10: 5207. https://doi.org/10.3390/app12105207

APA StyleCha, W.-Y. (2022). Study on Dynamic Characterization and Vibration Reduction of Scrubber Structures Using Fluid Structure Interaction Analysis. Applied Sciences, 12(10), 5207. https://doi.org/10.3390/app12105207