The Process of Natural and Styrene–Butadiene Rubbers Biodegradation by Lactobacillus plantarum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biological Materials

2.2. Culture Condition

2.3. Statistics

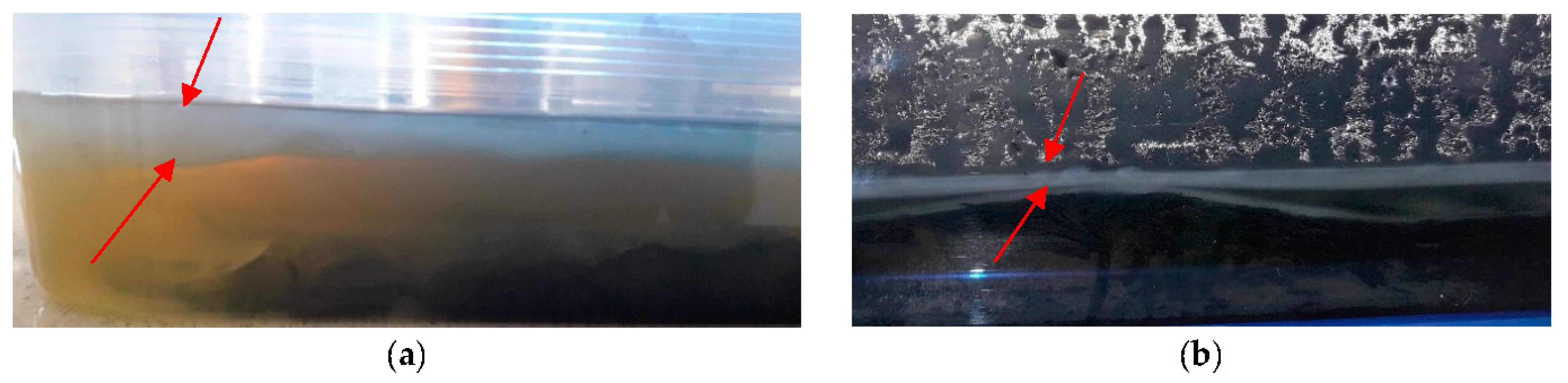

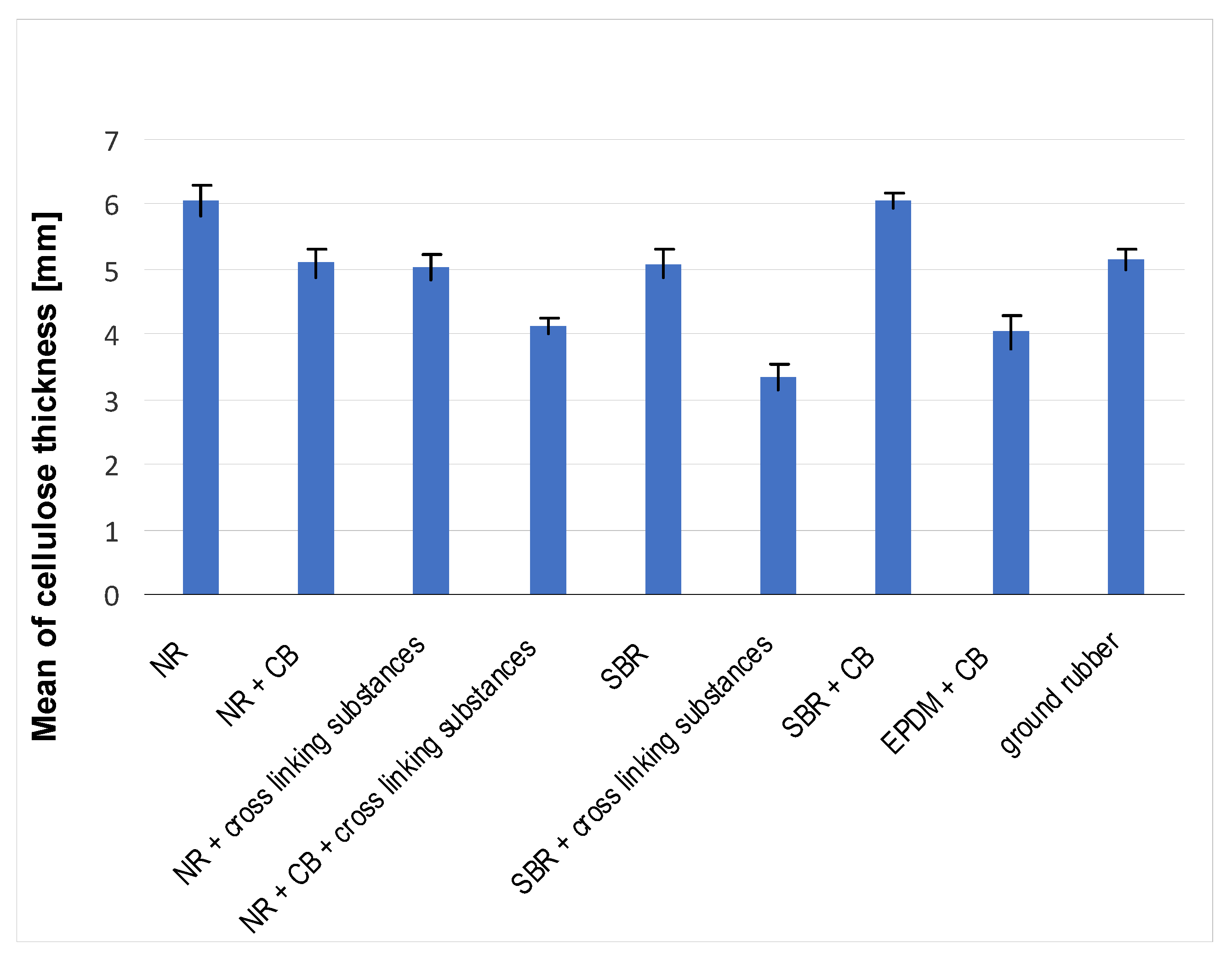

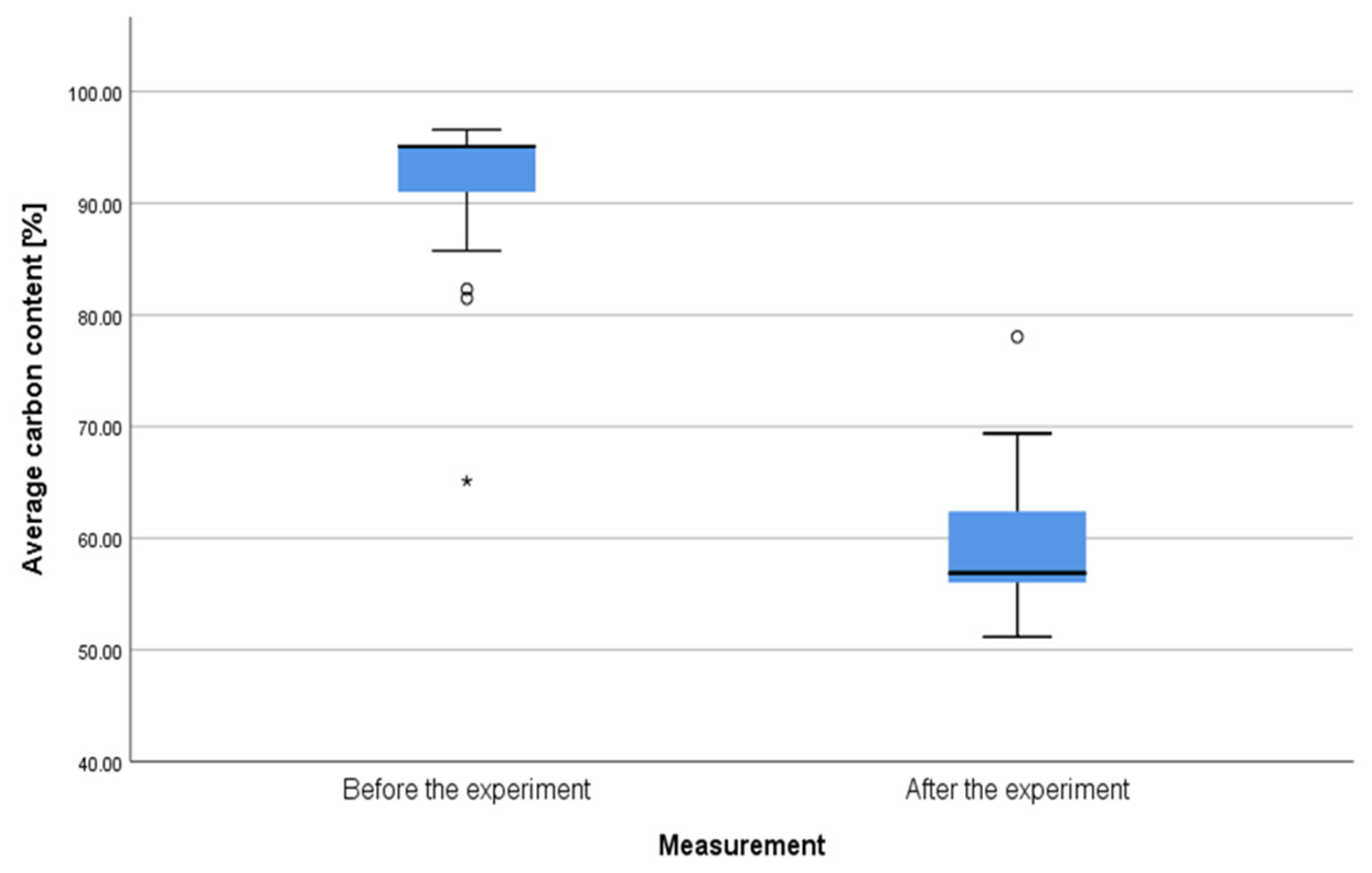

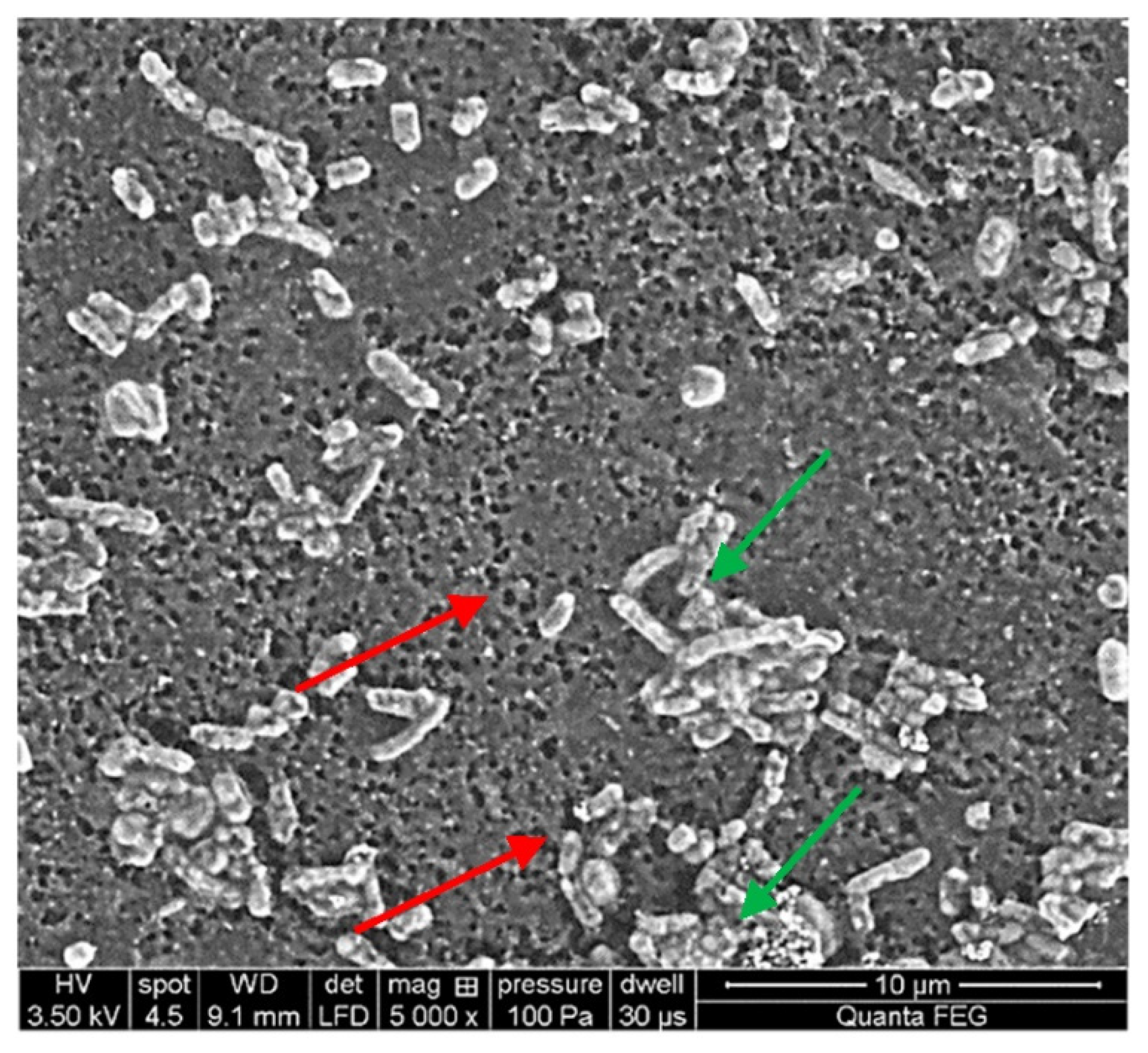

3. Results and Discussion

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schiessler, N.; Thorpe, E.; Jones, W.; Philips, L. LIFE and Waste Recycling—Innovative Waste Management Options in Europe; European Commission DG Environment, Office for Official Publications of the European Communities: Luxemburg, 2007; pp. 1–56. [Google Scholar]

- Dave, G.; Wik, A. Occurrence and effects of tire wear particles in the environment—A critical review and an initial risk assessment. Environ. Pollut. 2009, 157, 1–11. [Google Scholar]

- Sobiecka, E.; Kołaciński, Z.; Rincón, J.M.; Szymański, Ł.; Olejnik, T.P. Coloured sintered glass-ceramics from hospital incineration fly ash. Mater. Lett. 2019, 252, 34–37. [Google Scholar] [CrossRef]

- Abraham, E.; Cherian, B.M.; Elbi, P.A.; Pothen, L.A.; Thomas, S. Recent advances in the recycling of rubber waste. In Recent Developments in Polymer Recycling; Fainleib, A., Grigoryeva, O., Eds.; Transworld Research Network: Trivandrum, India, 2011; pp. 47–100. [Google Scholar]

- Act on duties of entrepreneurs concerning some wastes management, and product fee and deposit fee. J. Pol. Laws 2007, 90.

- Act on amending the act on recycling of end-of-life vehicles. J. Pol. Law 2015, 933.

- Speaker’s Notice of the Parliament of the Republic of Poland regarding the publication of an uniform text of the Act on the recycling of end-of-life vehicles. J. Pol. Law 2016, 803.

- The Act of Waste. J. Pol. Law 2013, 21.

- Re Depaolini, A.; Bianchi, G.; Fornai, D.; Cardelli, A.; Badalassi, M.; Cardelli, C.; Davoli, E. Physical and chemical characterization of representative samples of recycled rubber from end-of-life tires. Chemosphere 2017, 184, 1320–1326. [Google Scholar] [CrossRef] [PubMed]

- Abramek, K.; Uzdowski, M. Możliwości recyklingu elementów gumowych z pojazdów wycofanych z eksploatacji. Autobusy 2011, 10, 37–40. [Google Scholar]

- Foysal, M.J.; Fotedar, R.; Siddik, M.A.B.; Tay, A. Lactobacillus acidophilus and L. plantarum improve health status, modulate gut microbiota and innate immune response of marron (Cherax cainii). Sci. Rep. 2020, 10, 5916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seddik, H.A.; Bendali, F.; Gancel, F.; Fliss, I.; Spano, G.; Drider, D. Lactobacillus plantarum and Its Probiotic and Food Potentialities. Probiotics Antimicrob. Proteins 2017, 9, 111–122. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, J.Y.; Yoon, S.; You, S.; Kim, S.H. Multifunctional properties of Lactobacillus plantarum strains WiKim83 and WiKim87 as a starter culture for fermented food. Food Sci. Nutr. 2019, 7, 2505–2516. [Google Scholar]

- Lee, K.; Lim, S.; Go, N.; Kim, J.; Mun, J.; Kim, T.-H. Dopamine-grafted heparin as an additive to the commercialized carboxymethyl cellulose/styrene-butadiene rubber binder for practical use of SiOx/graphite composite anode. Sci. Rep. 2018, 8, 113–122. [Google Scholar] [CrossRef]

- Lodz University of Technology. The Strain of Lactic Bacteria Lactobacillus Plantarum LOCK 1145 and a Method of Producing Bacterial Cellulose by Culturing a Strain Lactobacillus Plantarum LOCK 1145. Polish Patent No. 238266, 7 May 2021.

- Ebinuma, A.V.; Gama, F.; Seckler, M. Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Appl. Microbiol. Biotechnol. 2014, 99, 1181–1190. [Google Scholar]

- Hosseinia, S.M.; Kashani, M.R. Catalytic and networking effects of carbon black on the kinetics and conversion of sulfur vulcanization in styrene butadiene rubber. Soft Matter 2018, 14, 9194–9208. [Google Scholar] [CrossRef] [PubMed]

- Medeiros, A.M.S.; Bourgeat-Lami, E.; McKenna, T. Styrene-Butadiene Rubber by Miniemulsion Polymerization Using In Situ Generated Surfactant. Polymers 2020, 12, 1476. [Google Scholar] [CrossRef]

- Commercial Standard BN-72/6031-03; Rubber Mixtures Composition and Methodology of Analysis. Zjednoczenie Przemysłu Gumowego “Stomil”: Warsaw, Poland, 1972.

| Abbreviation | Name of the Substance |

|---|---|

| SBR | vulcanizate of styrene–butadiene rubber |

| SBR + cls | sulfuric vulcanizate of styrene–butadiene rubber with an addition of cross-linking substance |

| SBR + CB | sulfuric vulcanizate of styrene–butadiene rubber with the addition of carbon black |

| SBR + CB + cls | sulfuric vulcanizate of styrene–butadiene rubber with the addition of carbon black with an addition of cross-linking substances |

| NR | sulfuric vulcanizate of natural rubber |

| NR + CB | sulfuric vulcanizate of natural rubber with an addition of carbon black |

| NR + cls | sulfuric vulcanizate of natural rubber with an addition of cross-linking substances |

| NR + CB + cls | sulfuric vulcanizate of natural rubber with an addition of carbon black and cross-linking substances |

| EPDM | sulfuric vulcanizate of ethylene–propylene–diene monomer rubber |

| EPDM + CB | sulfuric vulcanizate of ethylene–propylene–diene monomer rubber filled with carbon black |

| EPDM + CB + cls | sulfuric vulcanite of ethylene–propylene–diene rubber filled with carbon black, with an addition of cross-linking substances |

| EPDM Keltan | sulfuric vulcanizate of ethylene–propylene–diene rubber, KELTAN type |

| Ground rubber from transmissions tape | ---- |

| Average Carbon Content (%) | M | Me | SD | Sk. | Kurt. | Min. | Max. |

|---|---|---|---|---|---|---|---|

| Before the experiment | 91.49 | 95.08 | 7.51 | −2.55 | 7.21 | 65.12 | 96.58 |

| After the experiment | 59.71 | 56.88 | 6.68 | 1.20 | 1.32 | 51.17 | 78.03 |

| Before the Experiment (n = 21) | After the Experiment (n = 21) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mrank | Mdn | IQR | Mrank | Mdn | IQR | Z | p | η2 | |

| Average carbon content (%) | 31.81 | 95.08 | 5.23 | 11.19 | 56.88 | 8.01 | −5.51 | <0.001 | 0.74 |

| pH | Variables | M | Me | SD | Min. | Max. |

|---|---|---|---|---|---|---|

| 5.6 | Rubber mass before (g) | 4.37 | 4.32 | 0.22 | 4.19 | 4.61 |

| Rubber mass after (g) | 4.19 | 4.18 | 0.19 | 4.01 | 4.38 | |

| Average mass loss (g) | 0.18 | 0.18 | 0.05 | 0.14 | 0.23 | |

| Average mass loss (%) | 4.17 | 4.29 | 0.88 | 3.24 | 4.99 | |

| 5.7 | Rubber mass before (g) | 4.75 | 4.85 | 0.22 | 4.50 | 4.90 |

| Rubber mass after (g) | 4.51 | 4.62 | 0.20 | 4.28 | 4.64 | |

| Average mass loss (g) | 0.24 | 0.23 | 0.02 | 0.22 | 0.26 | |

| Average mass loss (%) | 4.98 | 4.89 | 0.30 | 4.74 | 5.31 | |

| 5.8 | Rubber mass before (g) | 4.18 | 4.12 | 0.15 | 4.06 | 4.35 |

| Rubber mass after (g) | 4.00 | 3.98 | 0.16 | 3.86 | 4.17 | |

| Average mass loss (g) | 0.17 | 0.18 | 0.03 | 0.14 | 0.20 | |

| Average mass loss (%) | 4.32 | 4.14 | 0.57 | 3.86 | 4.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olejnik, T.P.; Pietras, M.; Sielski, J.; Śliżewska, K.; Sobiecka, E. The Process of Natural and Styrene–Butadiene Rubbers Biodegradation by Lactobacillus plantarum. Appl. Sci. 2022, 12, 5148. https://doi.org/10.3390/app12105148

Olejnik TP, Pietras M, Sielski J, Śliżewska K, Sobiecka E. The Process of Natural and Styrene–Butadiene Rubbers Biodegradation by Lactobacillus plantarum. Applied Sciences. 2022; 12(10):5148. https://doi.org/10.3390/app12105148

Chicago/Turabian StyleOlejnik, Tomasz P., Marta Pietras, Jan Sielski, Katarzyna Śliżewska, and Elżbieta Sobiecka. 2022. "The Process of Natural and Styrene–Butadiene Rubbers Biodegradation by Lactobacillus plantarum" Applied Sciences 12, no. 10: 5148. https://doi.org/10.3390/app12105148

APA StyleOlejnik, T. P., Pietras, M., Sielski, J., Śliżewska, K., & Sobiecka, E. (2022). The Process of Natural and Styrene–Butadiene Rubbers Biodegradation by Lactobacillus plantarum. Applied Sciences, 12(10), 5148. https://doi.org/10.3390/app12105148