Abstract

With the attitude adjustment of shield machine, the jack thrust angle will change and may lead to great damage to segmental lining structures. In this paper, a three-dimensional refined finite element method is proposed to study the action mechanism and influence of jack thrust angle change on the mechanical characteristics of shield tunnel, considering additional constrained boundaries formed by various construction loads. Firstly, the finite element method is established and verified. Then, a series of analyses is carried out to investigate the mechanical performance of a certain tunnel lining with eleven rings under conditions of different jack thrust angles. An in-depth discussion is conducted on the obtained displacement, deformation, and stress distribution. A quantitative standard is finally gained for controlling the jack thrust angle. The results show that the maximum segment displacement occurs at the lower part of the arch waist of the second ring out of the shield tail, which has little relationship with the attitude adjustment. With the increase of the jack thrust angle, the maximum offset between the rings increases linearly, which is not conducive to the safety of the lining structures. The development direction of the tunnel displacement is opposite to that of the jack thrust deflection. The displacement of the tunnel is most affected by the jack thrust deflection when the shield machine is upward, which is also the most unfavorable situation for the segmental linings. The results in this paper provide novel insights into the effect of jack thrust on shield tunnel.

1. Introduction

During the shield tunneling construction, different thrust has to be assigned to distinct hydro-cylinders to control the attitude of shield machine, so that its axis can be the same as that of the designed tunnel [1]. Under such conditions, the resultant jack force generally provides eccentric load for the segmental lining structures, which may lead to local damage to the segments [2]. Therefore, it is very critical to maintain good control of the jack thrust and its angle. Moreover, the segmental lining structures are under complex action of various types of loads in the construction stage, e.g., water and soil pressure, grouting pressure, reaction force of shield tail brush, and jack thrust. However, the aforementioned loads were commonly studied as separate factors in the past studies. To obtain more reliable guidance for practical engineering, it is essential to investigate the influence of the jack thrust on shield tunnel with consideration of the additional constrained boundaries formed by other construction loads.

Based on the reports published by Lorenzo [3], there is increasing evidence implying that the jack thrust forces are transient load cases with respect to the reasonable design of the reinforced concrete segments, which means that the jack thrust forces and angle have a great influence on the safety of the whole segmental linings. Looking at this problem, a great number of efforts have been made to reveal the impact of the jack thrust on the mechanical properties of the segments. Lee et al. [4] established a fluid-structure interaction numerical model to examine the stability of the shield machine and the nearby segments by considering jack thrust at different levels. Qiao et al. [5] simplified the segmental lining structures as the continuous circular beam to analyze the control methods of the tunneling parameters by governing the appropriate jack thrust forces under different soil stratum. From their conclusions, the deviation of the horizontal axis for the constructed shield tunnel greatly grows with the increasing jack thrust. Additionally, Zhou et al. [6] conducted exploration of the causes of damage to the tunnel segments in the construction stage and found that the uneven jack thrust caused a great proportion of adverse effects. Similar results were gained during the study on the splitting and crushing behavior of the lining structures under TBM hydraulic jack thrust [7]. Generally, great concentrated jack thrust forces are imposed on the linings by the shield machine, resulting in high compressive stresses under the thrust shoes during the lining construction process [8]. These high compressive stresses may further develop into crush damage and lead to unexpected leakage failure of the segments. Although it is obvious that the jack thrust has fundamental importance in controlling the mechanical properties of the segmental lining structures, there is still a great challenge to determine the reasonable governing parameters, especially for tunnels constructed in special environments [9]. To obtain the appropriate values of the jack thrust, Peng et al. [10] fully analyzed the force-arranged characteristics of the key segment with action of jack thrust force experimentally, theoretically, and numerically, during which various influence factors were considered, including the arrangement and distance of the jack as well as the loading of thrust force. Considering the fact that the conventional reinforced concrete segments are vulnerable under jack thrust force, Avanaki [11] studied the mechanical characteristics of hybrid steel fiber reinforced composite segments subjected to thrust. It was found that fiber-reinforced concrete segments may be a good choice for tunnels whose construction is in need of frequent adjustment of jack thrust [12,13]. Another method to accurately control the jack thrust is to introduce the intellectualized technology, with which the real-time updating can be realized by the prediction from the analysis of the relationship between the historical data of the thrust and geological condition [14]. The aforesaid publications make great contributions to a better understanding of the effect of jack thrust, and some qualitative conclusions are available for certain conditions [15]. However, further investigation is still necessary to get more detailed knowledge of the mechanical influence of the jack thrust on the segmental linings.

Distinct methods have been adopted in analyzing the impact of jack thrust, among which the most popular one may be the numerical approach [16,17,18,19]. Although some researchers also conducted experiments on the safety analysis of the segmental linings subjected to jack thrust [20], the numerical method shows more attraction due to its significant advantages in a parametric study [21]. It should be noted that most of the existing research applied simplified models and structures, which may cause limitations to the calculation results. In this paper, a refined three-dimensional model considering the bolts and other construction loads is proposed to study the effect of jack thrust angle change on mechanical characteristics of shield tunnel segmental linings. Discussions are carried out on the displacement, deformation, and stress of the tunnel segments and the connecting bolts. According to the obtained results, final recommendations will be provided to control the jack thrust angle.

2. Project Overview

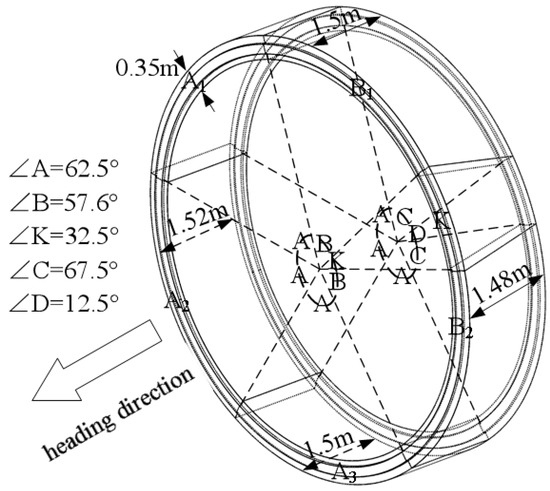

The total length of a shield tunnel project is 16.75 km, while the buried depth of the tunnel slab bottom is 8.3~30 m. The project is a marine alluvial plain with a simple fill on the surface. Soft soil is widely distributed along the tunnel, while sandy clay, silt, and silty sand are occasionally found. The ground elevation is 2.5~4 m, and the design water level is 2 m. The shield tunnel adopts a general pipe ring design. The outer diameter of the tunnel is 6.6 m, whereas the segment thickness is 0.35 m, and the wedge-shaped amount of the universal pipe ring is 0.04 m. Each segmental ring can be divided into six segments, including three standard segments, two temporary connection segments, and one K segment, as shown in Figure 1. The segment joints are connected by two M30 bending bolts, and the rings are connected by sixteen M30 bending bolts at 22.5° equal spacing. The specific joint structure is shown in Figure 2.

Figure 1.

Segmental lining ring.

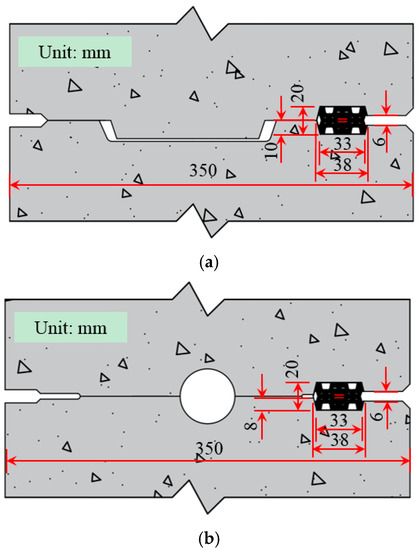

Figure 2.

Circumferential and longitudinal joint. (a) Circumferential joint. (b) Longitudinal joint.

3. Numerical Modelling

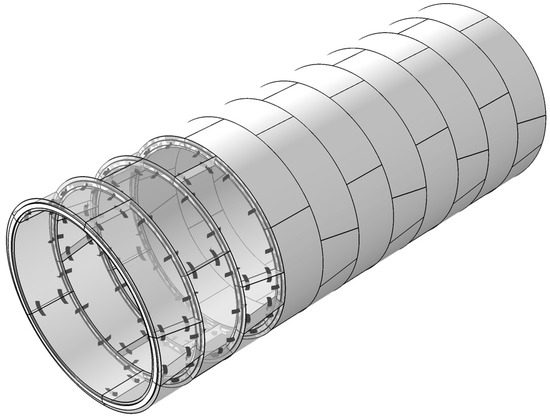

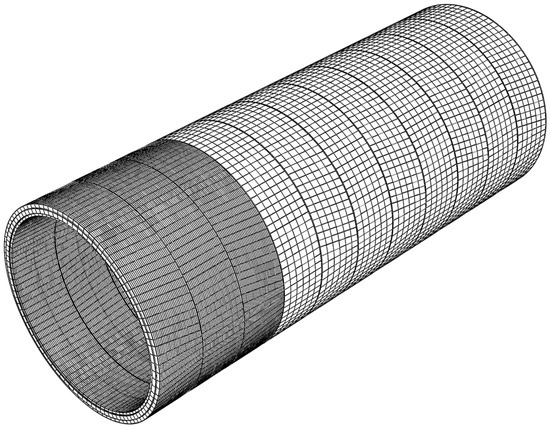

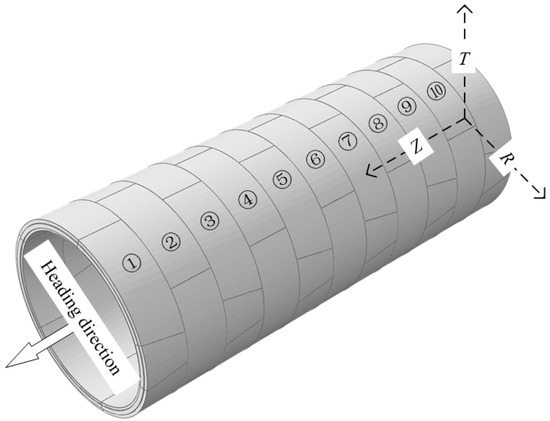

3.1. D Finite Element Model

The structure-load model is established to study the mechanical properties of the shield tunnel under the action of the jack thrust angle. The joint of the shield segment is divided into ring joint and segment joint. Joint is the weak link of shield tunnel, where local damage of segment is easy to occur, and then cause leakage. ABAQUS finite element software is used to establish the standard segment, temporary connection segment, and K segment, considering the circumferential groove. All the segments are assembled together with the bolts to form eleven rings in total, as shown in Figure 3. In this model, the weakness of the joint, the distribution of construction loads along the tunnel axis, and the longitudinal difference of the tunnel are considered. The segment part is simulated by the C3D8 element, while the bolt is simulated using B31 element. The mesh division is shown in Figure 4. The joint is composed of joints and connecting bolts. The interaction between segments is simulated by setting a surface-to-surface contact relationship, and the contact attribute is defined as a hard attribute. The connecting bolts connect the segment components to each other through the embedded constraint relationship.

Figure 3.

Tunnel model.

Figure 4.

Mesh of numerical model.

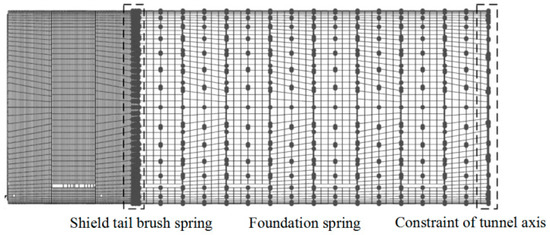

The axial direction constraint of the tunnel is set from the current position of the jack, and the ground springs are arranged outside the tunnel to simulate the soil constraint. Additionally, springs are arranged outside the third ring segment from the jack shoes to simulate the constraint effect of the shield machine tail, as shown in Figure 5.

Figure 5.

Boundary conditions.

3.2. Material Properties

The strength grade of segment concrete is C60, and the damage to plastic constitutive relation of CDP concrete is adopted. The elastic modulus is 3.45 × 104 MPa. Poisson’s ratio is 0.2. Density is 2420 kg/m3. Shear expansion angle is 38°. Eccentricity is 0.1. The ratio of biaxial ultimate compressive strength to uniaxial ultimate compressive strength is 1.16, and the flow potential offset value is 0.67. The cohesion coefficient is 0.001, while the damage factor can be seen in Table 1.

Table 1.

Compressive and tensile properties of C50 concrete.

M30 bending bolt with a strength grade of 8.8 is used as the joint bolt, and the ideal elastic-plastic constitutive relation is set. The elastic modulus is 210 GPa, while Poisson’s ratio is 0.167, and the yield stress is 660 MPa.

3.3. Water and Soil Pressure

The loading state of the shield tunnel in the stratum is simulated by applying water and soil pressure and foundation spring. The foundation spring is a nonlinear spring under uniaxial compression in the radius direction of the tunnel. The calculation method of spring stiffness is as follows:

In the above formula, KR is the foundation spring stiffness, k is the foundation bed coefficient, n is the number of grids represented by the foundation spring, Si is the unit area divided by the outer segment surface, R+ denotes tunnel radius direction is positive, while R− means tunnel radius direction is reversed, and the coordinate system is shown in Figure 6. The foundation spring stiffness in the Z direction and T direction is taken as 1/3 of R positive spring stiffness in the radius direction of the tunnel.

Figure 6.

Tunnel coordinates.

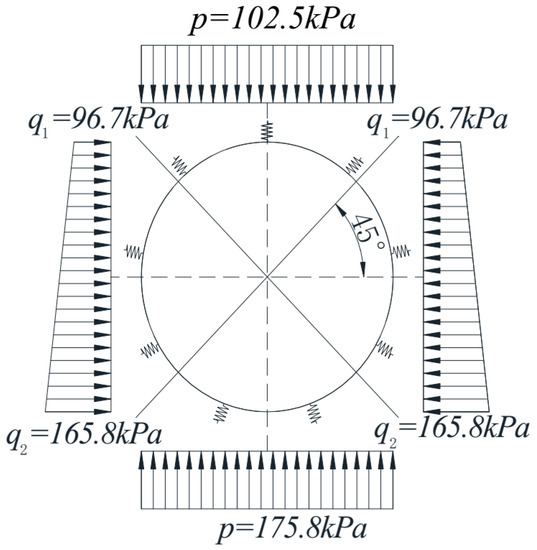

The typical stratum section of the shield tunnel is selected to calculate the water and soil pressure. The specific soil layer parameters are shown in Table 2. The buried depth of the tunnel is set at 9.9 m. The water and soil pressure are calculated by the soil and water integrated overburden earth pressure, and the distribution model is shown in Figure 7.

Table 2.

Soil parameter.

Figure 7.

Water and soil pressure.

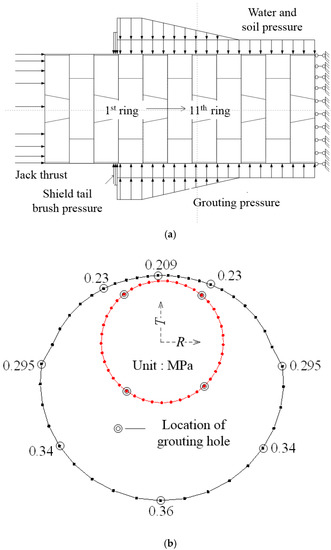

3.4. Grouting Pressure

The shield tail synchronous grouting method is adopted in shield tunneling. The circular distribution mode of grouting pressure is selected as a fan-shaped filling diffusion model, and Bingham fluid is selected as grouting slurry. The annular distribution formula of grouting pressure is as follows:

In the above formula, P is the grouting pressure, Pi is the grouting hole pressure, which is generally 0.1 MPa~0.2 MPa higher than the water pressure at the grouting hole position. A is the slurry weight parameter, α is the diffusion angle, αi is the grouting hole angle, B is the slurry shear force, which is related to the fluid property, generally taken as 0.84 kPa, ρ is the slurry fluid density, g is the gravity acceleration, R is the outer tunnel diameter. The fourth ring after synchronous grouting pipe ring attenuates to 0 linearly, as shown in Figure 8.

Figure 8.

Grouting pressure distribution. (a) Longitudinal distribution pattern of grouting pressure. (b) Circumferential distribution pattern of grouting pressure.

3.5. Tail Reaction

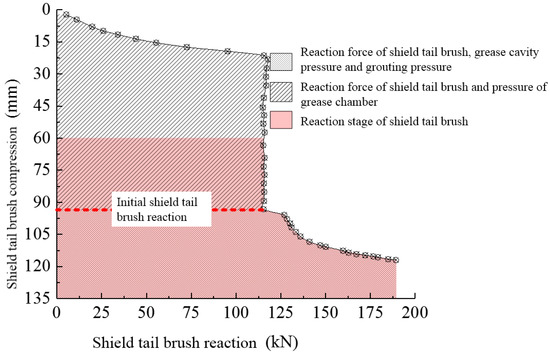

Generally, there is a gap of 0.8~1% in the outer diameter of the pipe ring between the shield tail and the segment. Under this condition, the extrusion force between the shield tail brush and the segment is minimal. However, under the joint influence of the posture adjustment and synchronous grouting at the shield tail, the shield tail gap is unevenly distributed along the circumferential direction. The grouting slurry is easy to be immersed into the shield tail brush. The stiffness of the shield tail brush increases obviously, and the reaction force tends to be non-uniform distribution. Under the coupling effect of the tail grease cavity pressure, the shield tail brush reaction force, the grouting pressure, and the segment which is about to come out of the shield tail can be easily damaged.

The nonlinear spring has the characteristics of automatic adjustment, distribution, and rebalancing load mode according to the deformation of the shield tunnel. The real stress state of the shield tail segment in shield tunneling is simulated by using a nonlinear shield tail spring and initial position shield tail brush reaction force. The curve of the relationship between the reaction force of the shield tail brush and the compression amount is shown in Figure 9.

Figure 9.

Reaction of shield tail.

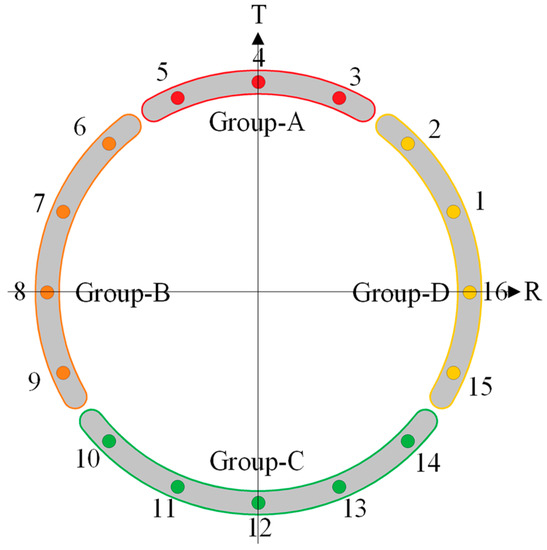

3.6. Jack Thrust

The total thrust of the jack includes six parts: Friction between shield machine periphery and soil mass, earth pressure at tunnel excavation face, friction resistance between the inner segment of shield tail and shield shell, traction resistance of rear trolley, penetration resistance generated in front of cutting ring edge during shield tunneling, and variable direction resistance of tunnel turning correction. Through the calculation of the selected typical section, the total thrust of the jack is about 14,000 kN. The jack thrust distribution is shown in Table 3, while the layout of the jack thrust is shown in Figure 10.

Table 3.

Table of the jack thrust distribution.

Figure 10.

Layout of Jack Thrust.

3.7. Verification

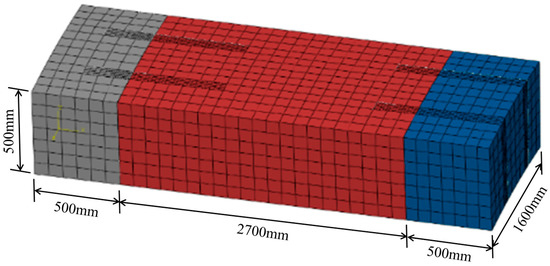

To verify the reliability and accuracy of the established finite element, a smaller model with totally identical modeling criteria was set up according to the experiments conducted by He et al. [22]. The validated experiments include three segments and four bolts, which can properly reflect the overall characteristics of the proposed numerical method in this paper.

The length, width, and depth of the segments on the sides are 350, 1600, and 500 mm, while those of the middle segment are 2700, 1600, and 500 mm, respectively, as shown in Figure 11. Besides, the material properties of the segments and bolts are the same as those described in Section 3.2. The two circumferential joints are subjected to shear force during the experiments, which is simulated in the verified model. More detailed information about the verified experiments can be directly found in [22].

Figure 11.

Verified numerical model.

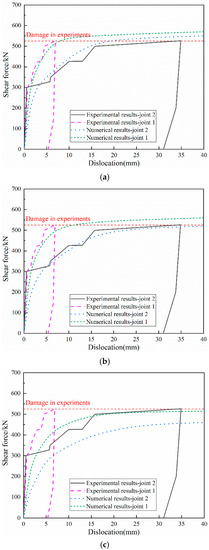

Additionally, a convergence study is also carried out by comparing calculation results obtained from numerical models with different mesh criteria, i.e., large mesh, medium mesh, and small mesh. Figure 12 illustrates the results of the numerical analysis against those of the experiments. It can be seen that the overall behavior of the results from the two different approaches shows good agreement, no matter which mesh size is utilized. However, the numerical results with large mesh size (nearly 40 cm) are not accurate enough, whereas those with medium mesh size (nearly 20 cm) and small mesh size (nearly 5 cm) both exhibit satisfactory reliability compared with the corresponding experimental results. The aforementioned verification study provides confidence for the reliability and accuracy of the proposed numerical method so that it can be used to further investigate the effect of the jack thrust on the mechanical characteristics of the segmental lining structures. Besides, the mesh of the first three segmental rings adopts a small size, while the other ones uses a medium size. In this way, both the accuracy and computational efficiency can be considered during the numerical analysis.

Figure 12.

Comparison between numerical and experimental results. (a) Small mesh size. (b) Medium mesh size. (c) Large mesh size.

4. Analysis of Calculation Results

4.1. Segment Staggering

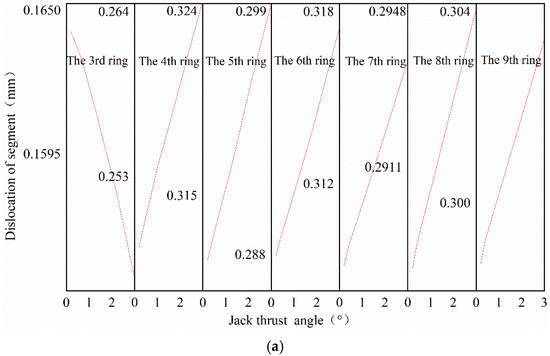

It can be seen from Figure 13a that the first ring and the second ring are only affected by the longitudinal Jack thrust force in the Z direction of the tunnel axis combined with the numerical simulation calculation structure. They are all less than 10−1 mm. That is, no comparative analysis is conducted.

Figure 13.

Maximum Dislocation. (a) Upward direction of shield machine. (b) Downward direction of shield machine. (c) Left direction of shield machine.

Under the action of jack thrust angle, the statistical results of the maximum segment staggering position of the 3rd~9th rings are shown in Table 4.

Table 4.

Statistical table for the location of maximum segment dislocation.

According to the statistical results, the maximum staggering number of segments in two adjacent rings occurs at the joints of A2–A3 and A1–A2 segments, respectively. The adjacent faces are lower than the arch waist of the K segment, and the vertical section of the tunnel is symmetrically distributed.

When the shield machine is upward, the amount of segment staggering in the third ring decreases linearly with the increase of the jack thrust angle, while the segment staggering amount of the fourth to ninth rings increases linearly with the increase of the jack thrust angle. Under the condition of the jack thrust angle of 3°, the segment staggering amount of the fifth ring in the third to ninth rings is the largest, which is 0.324. When the shield machine is downward, the staggering amount of segments in rings 3~9 decreases with the increase of jack thrust angle. When the jack thrust angle is 3°, the segment staggering amount of the fifth ring is the largest, which is 0.31. When the shield machine runs on the left, the segment staggering amount of odd number ring (K segment is on the left side of shield tunneling prevention) decreases linearly with the increase of jack thrust deflection angle, while that of eighth number ring (K segment is on the right side of shield machine tunneling prevention) increases linearly with the increase of jack thrust deflection angle. When the jack thrust deflection angle is 0.2°, the segment staggering amount of the fifth ring is the largest, which is 0.31 mm.

According to the statistical results of the maximum displacement of segments and the variation law with the jack thrust angle, it can be seen that the amount of segment staggering is jointly controlled by the RT plane transverse load and the Z-axis longitudinal load. The location of the maximum segment staggering amount in each ring is the maximum position of the tunnel transverse shear force, which is consistent with the actual situation. The adjustment of the shield machine attitude has no effect on the position of the maximum segment stagger but only changes the development law of segment staggering amount with jack’s thrust deflection angle. No matter how the shield machine posture is adjusted, the segment staggering amount of the second ring, which is detached from the shield tail, is the largest.

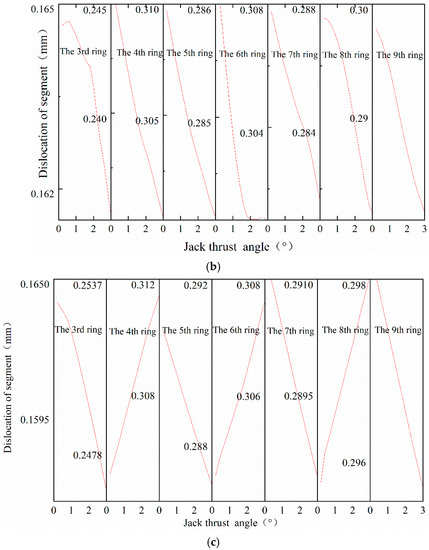

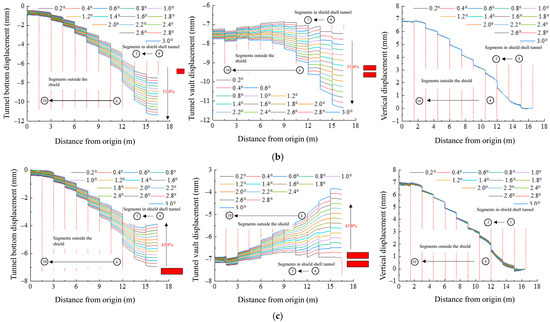

4.2. Displacement and Dislocation between Rings

In the process of shield machine attitude adjustment, when the shield machine is pitching, the jack thrust produces vertical component force due to the existence of a deflection angle, which only affects the vertical displacement of the tunnel. In the same way, when the shield machine yaws, the horizontal component force of jack thrust is produced due to the existence of a deflection angle, and the horizontal displacement of the entering tunnel will be affected. Consequently, the vertical displacement and deformation of the shield machine are analyzed, whereas the horizontal displacement and deformation of the left row of the shield machine are neglected.

It can be seen from Figure 14a that when the shield machine goes up, the displacement of the tunnel vault and arch bottom develops vertically and downward (the opposite direction of the Z-axis) is consistent with the stress direction. The influence degree of the jack thrust angle decreases with the increase of the distance from the shield machine and finally tends to be stable. The vertical displacement of the tunnel increases by 51.4%, and the rising slope is 1.82 mm/°. The vertical deformation increases with the increase of the distance from the shield machine and finally approaches 6.83 mm, and it is not affected by the jack thrust angle. From Figure 14b, when the shield machine goes down, the displacement of the tunnel vault and arch bottom vertically upward (Z-axis downward) is consistent with the stress direction. The variation law of the influence degree of the jack thrust angle with the distance from the shield machine is the same as that of the upward direction of the shield machine. The results show that the displacement of the arch crown and arch bottom decreases with the increase of the jack thrust deflection angle, and the vertical displacement of the tunnel on jack’s action surface decreases by 43.9%, and the decline slope is 1.08 mm/°. The vertical deformation increases with the increase of the distance from the shield machine and finally approaches 7.03 mm, which is not affected by the jack thrust deflection angle. From Figure 14c, the displacement of the left and right sides of the tunnel moves horizontally to the right (in the opposite direction of the R-axis), which is consistent with the stress direction. The influence of the jack thrust angle decreases with the distance from the shield machine and finally tends to be stable. The displacement of the left and right sides of the tunnel increases with the increase of the thrust deflection angle of the jack. The horizontal displacement of the working surface of the jack increases by 1750.3%, and the rising slope is 1.31 mm/°.

Figure 14.

Tunnel displacement and transverse deformation. (a) Upward direction of shield machine. (b) Downward direction of shield machine. (c) Left direction of shield machine.

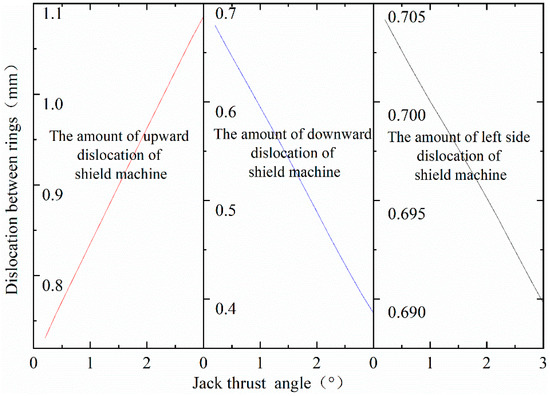

By comparing the amount of staggered platform between the four positions of the tunnel vault, arch bottom, and both sides of the arch waist, it is finally determined that the maximum amount of staggered abutment is found between the arch bottom ring and the arch bottom ring. Compared with the adjacent pipe rings, the amount of staggering between the third and fourth rings is the largest. It can be seen from Figure 15 that when the shield machine goes up, the maximum amount of staggering between rings increases linearly with the increase of jack thrust deflection angle, and the rising slope is 0.127 mm/°. When the shield machine goes down and left, the maximum amount of staggering between rings decreases linearly with the increase of Jack thrust deflection angle, and the decline rate is −0.105 mm/° and −0.005 mm/°.

Figure 15.

Maximum dislocation of circumferential joint.

According to the above analysis of tunnel displacement and staggered platform amount between rings, it can be seen that the adjustment of the shield machine attitude does not influence the lateral deformation of the tunnel. The tunnel displacement is sensitive to the jack thrust deflection angle, and the tunnel displacement direction is opposite to the shield machine posture adjustment direction, which is consistent with the jack thrust RT plane component direction and has a linear change. When the shield goes down, with the increase of jack thrust deflection angle, the tunnel displacement direction is more sensitive to the jack thrust deflection angle. After the deformation of the tunnel, the axis of the tunnel is gradually parallel to the Z-axis, and the stress of the structure tends to be reasonable. The angle between the tunnel axis and the Z-axis will increase with the increase of jack thrust when the shield machine goes up and left. The structure will have excessive regional deformation and easy segment damage.

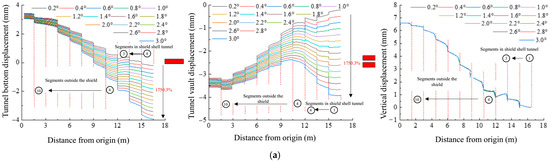

4.3. Stress of Segment and Bolt

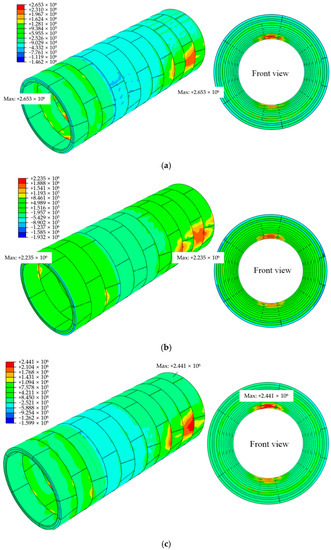

It can be seen from Figure 16 that the maximum principal stress is distributed at the joints between rings 1st–2nd and 2nd–3rd, the outside of the arch waist segments of the rings 8, 9, and 10, and the inside of the segments at the top and bottom of the arch. Due to the influence of the jack thrust deflection angle, the vertical shear stress of the joints between the rings increases gradually. The maximum principal stress of the grooves at the bottom of the arch of the second and third rings in the 1st–2nd and 2nd–3rd rings is the largest, which is the thinness of the structure. When the shield machine goes down, the maximum principal stress is distributed on the outer side of the segment at the eighth, ninth, and tenth ring, which are the central positions of the segment at the bottom of the arch. Besides, the joint between the 1st–2nd and 2nd–3rd rings is only at the spandrel position, which is smaller than that in the upward direction of the shield machine. This further verifies that the shield machine in Section 4.2 is under relatively reasonable stress. On the left side of the shield machine, the maximum principal stress is distributed on the outer side of the arch waist segment of the eighth, ninth, and tenth rings, the outer groove of the arch waist position of the joint between the 1st–2nd and 2nd–3rd rings and the inner groove at the arch bottom. Similarly, due to the influence of the jack pushing angle, the horizontal shear force of the joint between the rings increases gradually, which leads to the maximum principal stress on the right side of the arch waist of the 1st–2nd and 2nd–3rd ring joints. It is larger than the maximum principal stress of the left spandrel.

Figure 16.

Maximum stress of segmental lining structures. (a) Upward direction of shield machine. (b) Downward direction of shield machine. (c) Left direction of shield machine.

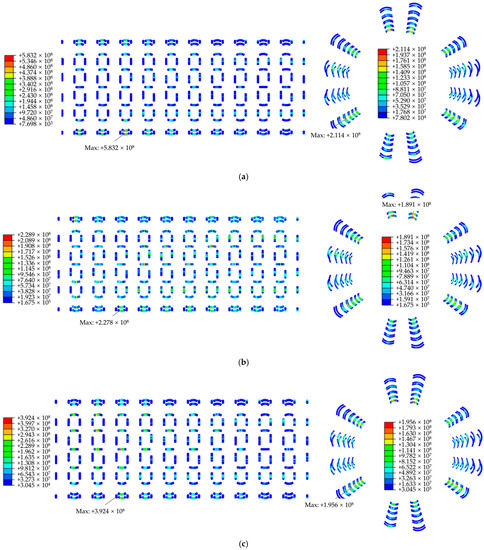

According to the comparison between the left and right pictures in Figure 17, no matter how the shield machine posture is adjusted, the bolt stress between the rings is higher than that between segments. The maximum stress of the bolts between the rings is distributed at the arch bottom of the joint between the third and fourth rings, which is also the most significant position of the amount of staggering between rings. The actual maximum stress of bolts between segments is distributed near the lower position of arch waist, which is consistent with the maximum segment staggering. The measurement positions correspond to each other.

Figure 17.

Stress of Bolts. (a) Upward direction of shield machine. (b) Downward direction of shield machine. (c) Left direction of shield machine.

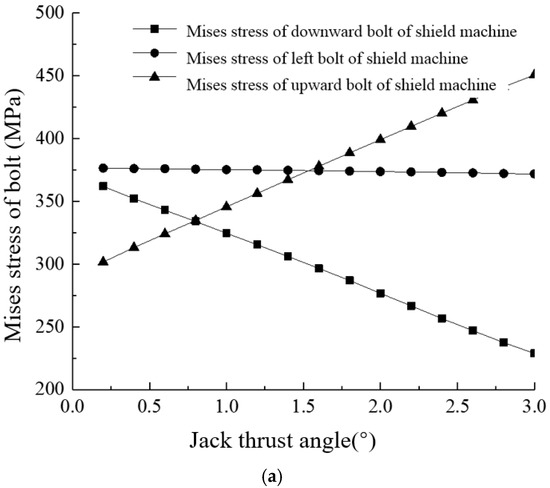

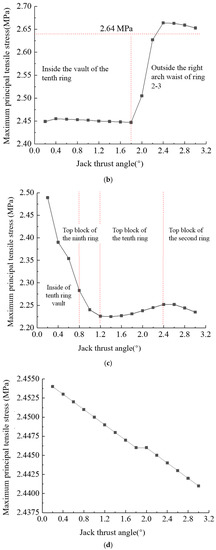

It can be seen from Figure 18a that the maximum von Mises stress of all bolts in the tunnel increases linearly with the increase of the jack thrust angle when the shield machine goes up, and the increase slope is 53.28 MPa/°. When the shield machine goes down and left, the maximum von Mises stress of bolts decreases linearly with the increase of jack thrust angle, and the descending ramps are −47.83 MPa/° and −1.6 MPa/°, respectively. From Figure 18b–d, when the shield machine goes up and down, the position where the maximum principal stress of the segment appears is continuously changing and finally stays at the 2nd–3rd ring. When the shield machine runs on the left, the maximum principal stress of the segment appears on the inner side of the 1tenth ring vault. When the shield machine goes up, the jack thrust deflection angle is within 2.2° and does not exceed the ultimate material strength. When the shield machine goes up, the arch waist position on the right side of the joint between the second and third rings is on the right side. When the shield machine goes down, the maximum principal stress of the segment decreases rapidly within 1.2° of jack thrust deflection angle, and it is basically stable at 2.23 MPa after exceeding 1.2°, which is less than the ultimate strength of the material. When the shield machine goes left, the maximum principal stress of the segment decreases linearly with the increase of jack thrust angle.

Figure 18.

Stress of tunnel and bolt. (a) Stress of bolt. (b) Stress of tunnel in upward direction. (c) Stress of tunnel in downward direction. (d) Stress of tunnel in left direction.

Based on the above analysis, the bolt stress of the inter ring joint is higher than that of the segment joint, and the position of the maximum bolt stress is the same as that of the maximum staggering amount. When the shield machine goes up, the jack thrust deflection angle on the structural stress and the tunnel structure under the conventional external loads (water and soil pressure, grouting pressure, shield tail brush reaction force) are superimposed as the most unfavorable combination for the structure.

5. Conclusions

This paper focuses on the mechanical influence of jack thrust angle on the tunnel structure caused by the shield machine posture adjustment. Through the analysis of the calculation results, the quantitative change rules of tunnel joint deformation, displacement, and stress with jack thrust angle are obtained. The control range of the deflection angle is given, which has particular guiding significance for practical engineering. The specific conclusions are as follows:

- (1)

- No matter how the shield machine attitude is adjusted, the maximum amount of segment staggering occurs at the lower side of the arch waist, and the second ring segment out of the shield tail has the most substantial amount.

- (2)

- When the shield machine goes up, down, and left, the maximum amount of staggering between rings occurs at the joint position of the 3rd–4th ring at the bottom of the arch. When the shield machine goes up, the joint between the rings increases linearly by 0.127 mm/° with the increase of the jack thrust deflection angle.

- (3)

- The development direction of tunnel displacement is opposite to that of jack’s thrust angle, and the lateral deformation of the tunnel is not affected by the posture adjustment of the shield machine.

- (4)

- When the shield machine goes down, the structural stress tends to be reasonable. When the shield machine goes up, the structure has been damaged, which is an unfavorable combination of tunnel load, and the deflection angle should be controlled within 2.2°. When the shield machine goes left, it only affects the variation of deformation and stress with the deviation angle of jack thrust force.

Author Contributions

Formal analysis, Y.J.; methodology, W.Z.; software, L.H.; visualization, Y.J.; writing—original draft, L.H.; writing—review & editing, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (Grant No. 51978460) and the Scientific Research Project Investment Plan of Beijing Capital Highway Development Group Co., Ltd. (Grant No. 2021-4).

Acknowledgments

This research was funded by the National Natural Science Foundation of China (Grant No. 51978460) and the Scientific Research Project Investment Plan of Beijing Capital Highway Development Group Co., Ltd. (Grant No. 2021-4), which are gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shi, C.H.; Wang, Z.X.; Gong, C.J.; Liu, J.W.; Peng, Z.; Cao, C.Y. Prediction of the additional structural response of segmental tunnel linings induced by asymmetric jack thrusts. Tunn. Undergr. Space Technol. 2022, 124, 104471. [Google Scholar] [CrossRef]

- Shen, X.; Yuan, D.J.; Jin, D.L. Influence of shield attitude change on shield–soil interaction. Appl. Sci. 2019, 9, 1812. [Google Scholar] [CrossRef] [Green Version]

- Lorenzo, S.G. Design guidelines for concrete segmental linings in transverse interaction with the TBM. Tunn. Undergr. Space Technol. 2022, 122, 104388. [Google Scholar] [CrossRef]

- Lee, H.S.; Na, Y.M.; Jang, H.S.; Suk, I.H.; Kang, S.H.; Kim, H.T.; Park, J.K. A Study on the Stability of Shield TBM Thrust Jack in the Behavior of Operating Fluid According to Thrust Force. J. Korean Soc. Manuf. Process. Eng. 2019, 18, 38–45. [Google Scholar] [CrossRef]

- Qiao, S.; Xu, P.; Liu, R.; Wang, G. Study on the Horizontal Axis Deviation of a Small Radius TBM Tunnel Based on Winkler Foundation Model. Appl. Sci. 2020, 10, 784. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.H.; Wu, D.; Zhou, S.H.; Cui, Y.X. Analysis on damage cause of shield tunnel segments during construction. Adv. Mat. Res. 2012, 594, 1308–1313. [Google Scholar] [CrossRef]

- Medeghini, F.; Trabucchi, I.; Conforti, A.; Tiberti, G.; Plizzari, G.A. Local splitting and crushing behavior under TBM hydraulic jacks. Galle. Grand. Opere. Sotte. 2018, 127, 37–44. [Google Scholar]

- Conforti, A.; Tiberti, G.; Plizzari, G.A. Splitting and crushing failure in FRC elements subjected to a high concentrated load. Compos. Part B Eng. 2016, 105, 82–92. [Google Scholar] [CrossRef]

- Zhe, G.; Li, S.C.; Zhao, S.S.; Zhang, J.Y. Nonlinear dynamic analysis and application of thrust force for slurry balance shield. Rock Soil Mech. 2018, 39, 469–476. [Google Scholar]

- Peng, Z.Y.; Liu, W.N.; Ding, D.Y.; Yang, X.R.; Yan, M.; Lu, W.D. Arrangement of thrust force about partitioned key segment. J. Cent. Sou. Univ. Sci. Technol. 2014, 45, 4018–4025. [Google Scholar]

- Jamshidi Avanaki, M. Effects of hybrid steel fiber reinforced composites on structural performance of segmental linings subjected to TBM jacks. Struct. Concr. 2019, 20, 1909–1925. [Google Scholar] [CrossRef]

- Yao, Y.; Bakhshi, M.; Nasri, V.; Mobasher, B. Interaction diagrams for design of hybrid fiber-reinforced tunnel segments. Mater. Struct. 2018, 51, 35. [Google Scholar] [CrossRef]

- Neu, G.E.; Edler, P.; Freitag, S.; Gudžulić, V.; Meschke, G. Reliability based optimization of steel-fibre segmental tunnel linings subjected to thrust jack loadings. Eng. Struct. 2022, 254, 113752. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, J.; He, Z.; Zhang, H. Design of intellectualized controller of shield machine. J. Tongji Univ. Nat. Sci. 2008, 36, 76–80. [Google Scholar]

- Cho, S.H.; Kim, J.; Won, J.; Kim, M.K. Effects of jack force and construction steps on the change of lining stresses in a TBM tunnel. KSCE J. Civ. Eng. 2017, 21, 1135–1146. [Google Scholar] [CrossRef]

- Chaipanna, P.; Jongpradist, P. 3D-FEM analysis of shield tunnel construction with ground-spring model. Geomate J. 2017, 12, 58–62. [Google Scholar] [CrossRef]

- Deng, K.S.; Li, Y.Y.; Yin, Z.R. Thrust distribution characteristics of thrust systems of shield machines based on spatial force ellipse model in mixed ground. J. Mech. Sci. Technol. 2016, 30, 279–286. [Google Scholar] [CrossRef]

- Chaipanna, P.; Jongpradist, P. 3D response analysis of a shield tunnel segmental lining during construction and a parametric study using the ground-spring model. Tunn. Undergr. Space Technol. 2019, 90, 369–382. [Google Scholar] [CrossRef]

- Dastjerdy, B.; Hasanpour, R.; Samimi Namin, F.; Chakeri, H. 3D computational study of tunnel segment behaviour under loading by TBM thrust jacks. Geomech. Geoengin. 2021, 16, 182–197. [Google Scholar] [CrossRef]

- Jamshidi, A.M.; Abedi, M.; Hoseini, A. Experimental and numerical-based design of hybrid steel fibre-reinforced concrete tunnels. Mag. Concr. Res. 2020, 72, 720–733. [Google Scholar] [CrossRef]

- Trabucchi, I.; Tiberti, G.; Plizzari, G.A. A parametric numerical study on the behavior of large precast tunnel segments during TBM thrust phase. Eng. Struct. 2021, 241, 112253. [Google Scholar] [CrossRef]

- He, Y.; Yang, Z.H.; Liu, X.; Ding, W.Q. Theoretical solution for failure mechanism of circumferential joint of shield tunnel segment connected using diagonal bolts. Tunn. Constr. 2021, 41, 933. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).