The 3D Deburring Processing Trajectory Recognition Method and Its Application Base on Random Sample Consensus

Abstract

:1. Introduction

- Planning the trajectories of various workpieces offline is a costly, time-consuming, and labor-intensive process that cannot meet the manufacturing industry’s demand for rapid production of customized goods.

- Molding processes (such as plastic injection molding and metal casting molding) are affected by their environments. If large dimensional deviations occur during processing, workpieces may fail to maintain their fixed dimensions, and predetermined processing trajectories will not be applicable to all workpieces.

2. Online 3D Trajectory Generation for Deburring Processing

2.1. Matching the Mathematical Model

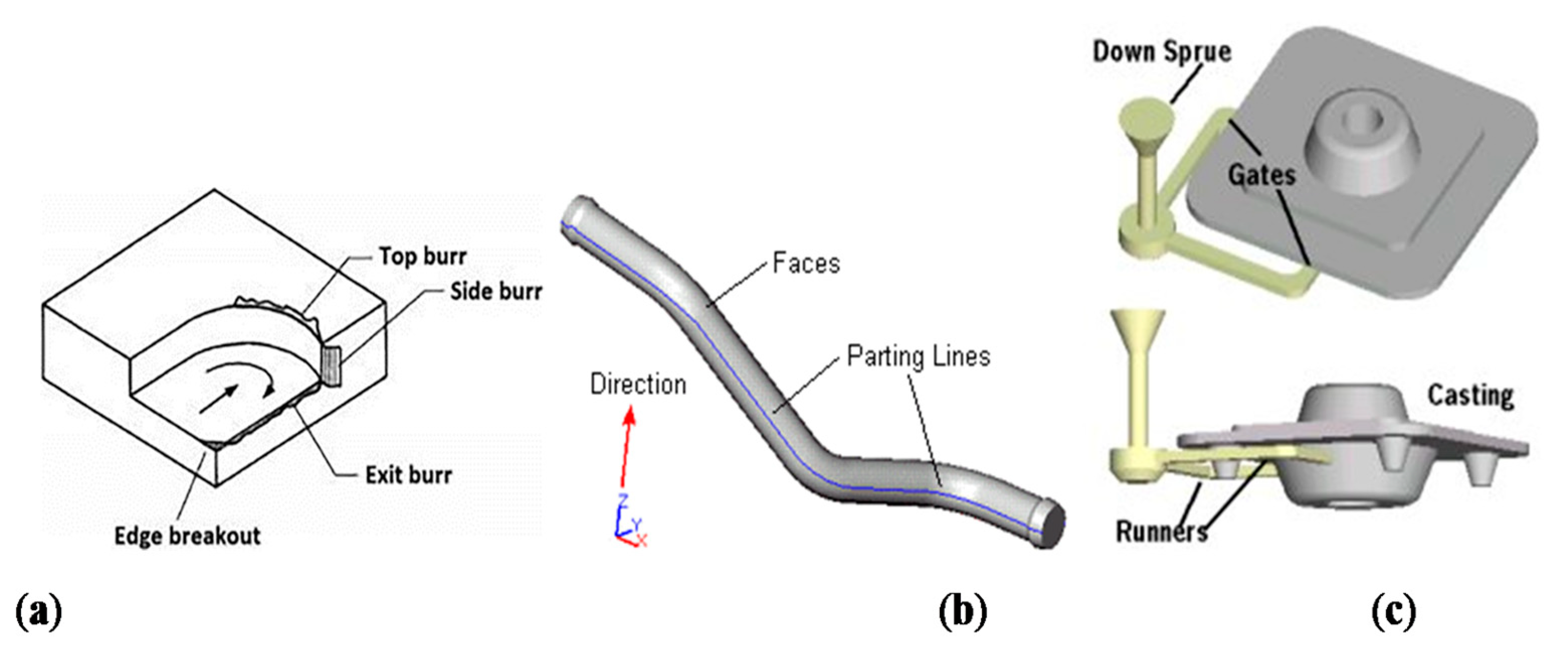

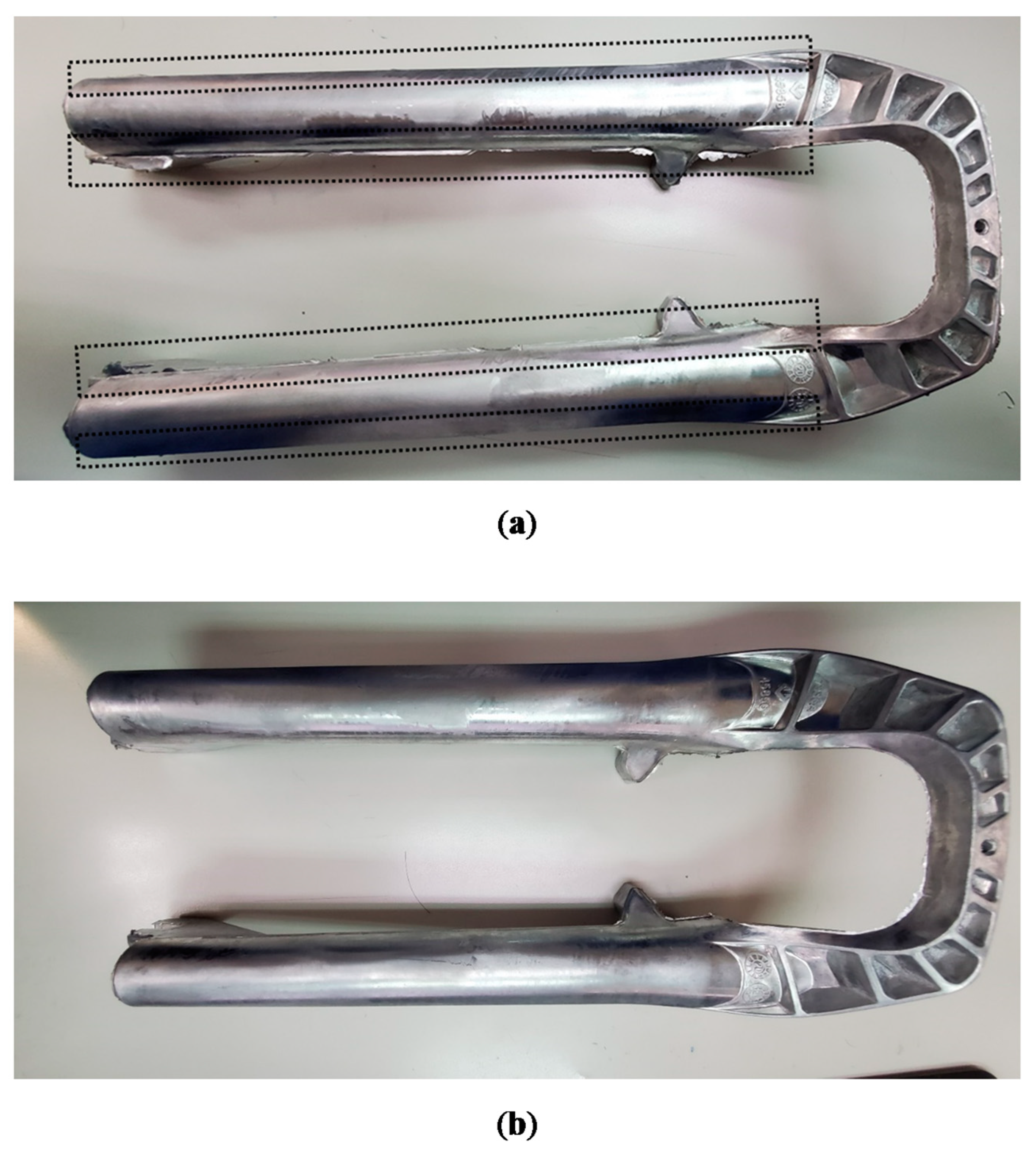

- The CAD model and target workpiece processing are analyzed to determine the deburring region. In workpieces that have undergone cutting, the deburring regions tend to be the processed edges. In those that have undergone casting, the deburring regions tend to include the gates, risers, and parting lines (Figure 2).

- The cross-sectional images of the deburring regions of the target workpieces along the cutting direction (e.g., the direction of the processed edge or parting lines) are obtained. To remove burrs on gates or risers, bow-shaped loops are used to plan surface-seeking trajectories. The contours are divided into n segments according to the cross-sectional contour curve characteristics, and the mathematical models for the different curves are determined accordingly. Because the characteristics of distinct cross-sectional boundary contour curves vary, their mathematical models vary. These models may include polynomial boundary curve equations, circular boundary curve equations, elliptic boundary curve equations, parabolic boundary curve equations, and square–ellipse boundary curve equations.

- The curve fitting errors are calculated and analyzed to determine whether they meet specific values (e.g., a coefficient of determination > 0.99).

- For polynomial boundary curve equations, error analyses and model assessments can be performed using the coefficient of determination. Assuming that a dataset includes n observed values (i.e., ) and that the corresponding model-predicted values are , respectively, the residual is defined as , and the mean observed value is defined as .

- The sum of squares of the observed and mean values are calculated using .

- The residual sum of squares of the predicted and observed values obtained using the curve fitting model is calculated using .

- For polynomial boundary curve equations, the coefficient of determination is .

- Curve fitting residual plot analyses are performed to verify the accuracy of the residual distribution (Figure 3) according to the following criteria: (1) the residual value must be close to 0; (2) the residual points must be randomly and uniformly distributed between −1 and 1; (3) the residual point distribution must have no consistent pattern; and (4) the residuals must not contain any predictable information.

- The error analysis constraints, residual plot criteria, and minimum order equations comprise the curve-fitting model of the boundary equations.

2.2. Fit the Equations of Boundary Contour Curves (S130, S140) in Linear Contour Scanning

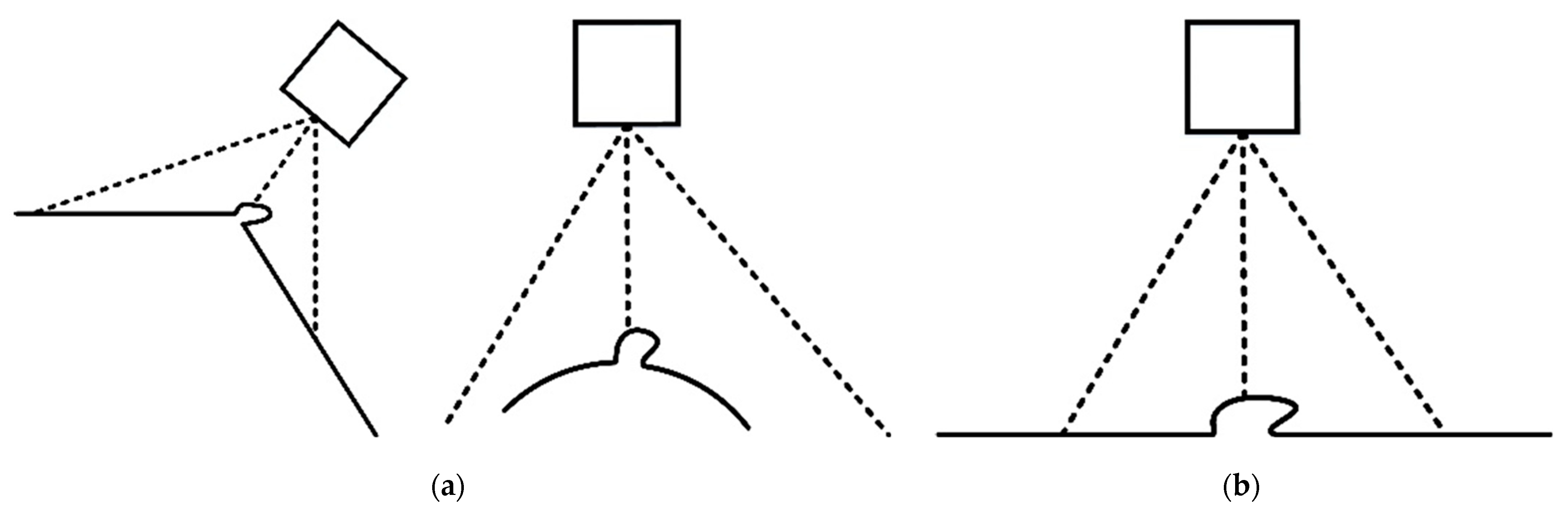

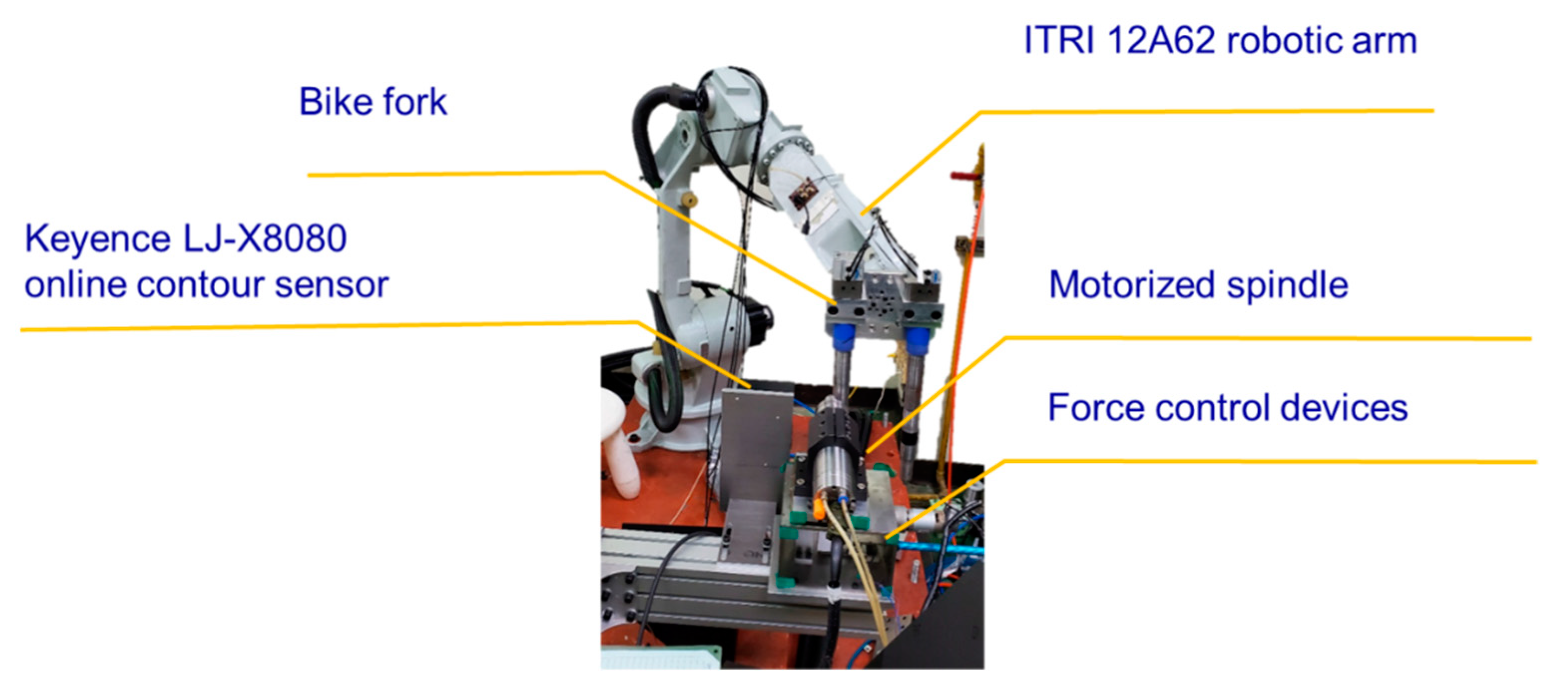

- After the mathematical models for the boundary contour curves of the target workpieces are determined, the workpiece contour cross-sectional information is obtained using linear contour scanning sensors. When the sensors move and scan the workpiece contours, they obtain as much information regarding the contours near burrs as possible by setting the burrs as the center of the scans (Figure 4).

- The contour information obtained using the linear contour scanning sensors is processed, and the random sample consensus (RANSAC) method [22] is used to perform the fitting. This prevents burr information from influencing the curve fitting results.

- Letting , , , , and , the mathematical models for the boundary curves are selected (similar to Step 3).

- A total of n samples are randomly selected, and the models are fit to obtain the curve equation .

- Letting and , the data points are substituted into the curve equations to calculate the errors (), where and are the number of interior points and exterior points, respectively.

- is compared with the allowable error (): if , ; otherwise, .

- If , then and .

- When , if and , the RANSAC procedure is performed with as the number of iterations. If not, the number of iterations is updated to , where P is the expected probability of RANSAC obtaining the correct model, and r , which is based on the numbers of interior and exterior points.

- Curve fitting is performed on the curve models obtained using the CAD cross-sectional contour characteristics. Using a fourth-order polynomial boundary curve equation as an example, the procedure is as follows:

- The fourth-order polynomial model is expanded to .

- If the contour curves are the curves of two different models, the contour points obtained from linear contour scanning are divided into head and tail sections for fitting; if the contour curves are the curves of a single model, the head and tail contour points obtained from linear contour scanning are substituted into the equations for fitting. The contour point dataset is

- The error sum of squares of the contour data points for the fourth-order polynomial is calculated using where and are unknown variables.

- Curve fitting searches for a set of coefficients ( and ) that minimize errors; therefore, a first-order equation with a derivative of zero is used to determine the locations of the extrema, producing five linear equations. The simultaneous linear equations are solved to obtain the coefficients for the boundary contour curve equations (i.e., and ).

- ▪

- Perform a partial derivation of E with respect to () to solve for the position of the extreme value and obtain the first equation, which is expressed as follows:

- ▪

- Perform a partial derivation of E with respect to ) to solve for the position of the extreme value and obtain the second equation, which is expressed as follows:

- ▪

- Perform a partial derivation of E with respect to ) to solve for the position of the extreme value and obtain the third equation, which is expressed as follows:

- ▪

- Perform a partial derivation of E with respect to () to solve for the position of the extreme value and obtain and the fourth equation, which is expressed as follows:

- ▪

- Perform a partial derivation of E with respect to () to solve for the position of the extreme value and obtain the fifth equation, which is expressed as follows:

- ▪

- Solve the linear simultaneous equations, and obtain the coefficients of the contour boundary curve equations ().

2.3. Detect Burrs and Generate Deburring Trajectories

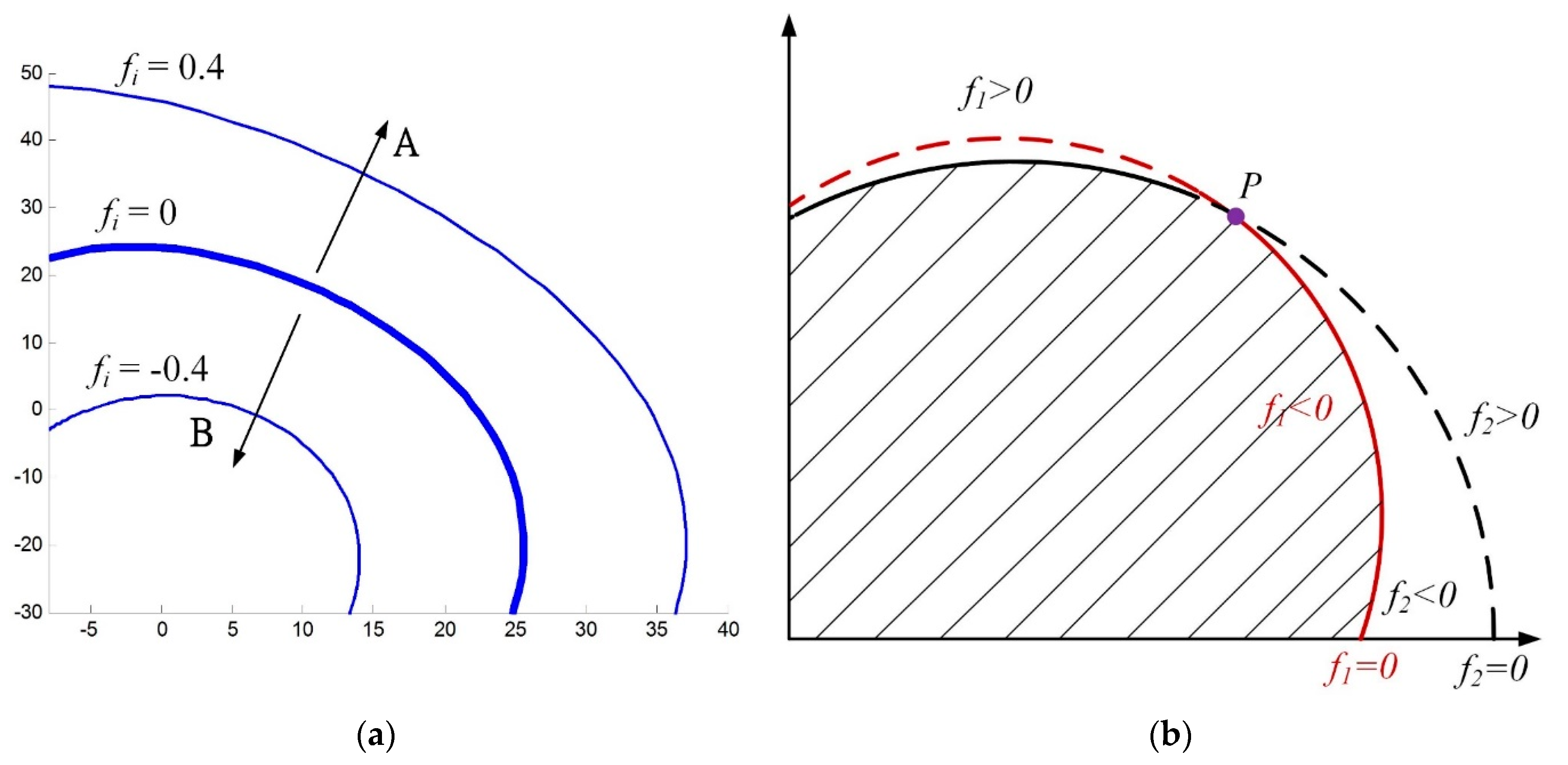

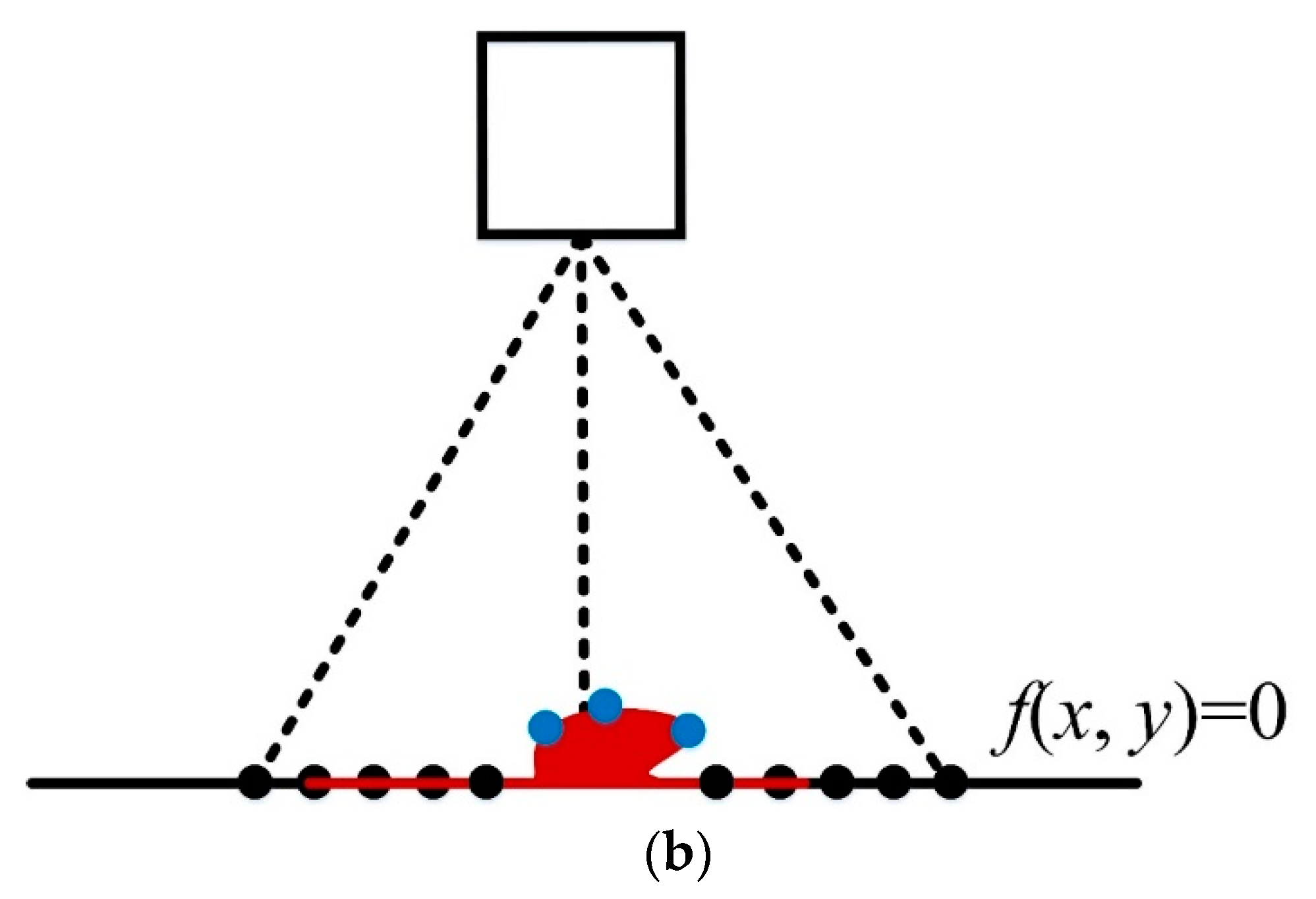

- The equation obtained through curve fitting is defined as the boundary contour curve equation , and the space is divided into two intervals (i.e., workpiece region A [the region on the same side as the sensor] and environmental region B [the region on the same side as the sensor]). Intervals A and B correspond to the positive and negative signs of equation function value ; therefore, to obtain the positive and negative signs of the functions corresponding to the equations in the two areas, the sensor coordinates are substituted to derive , which represents the positive and negative signs of the function values corresponding to the inadmissible interval. If the equation function value corresponding to the environmental area is <0, then , and all the equation function values corresponding to the workpiece intervals are ≤0 (Figure 5a). If the cross-sectional boundary contour curves are composed of different line segments, the intersection area where is the inner side of the workpiece cross-sectional contour (Figure 5b).

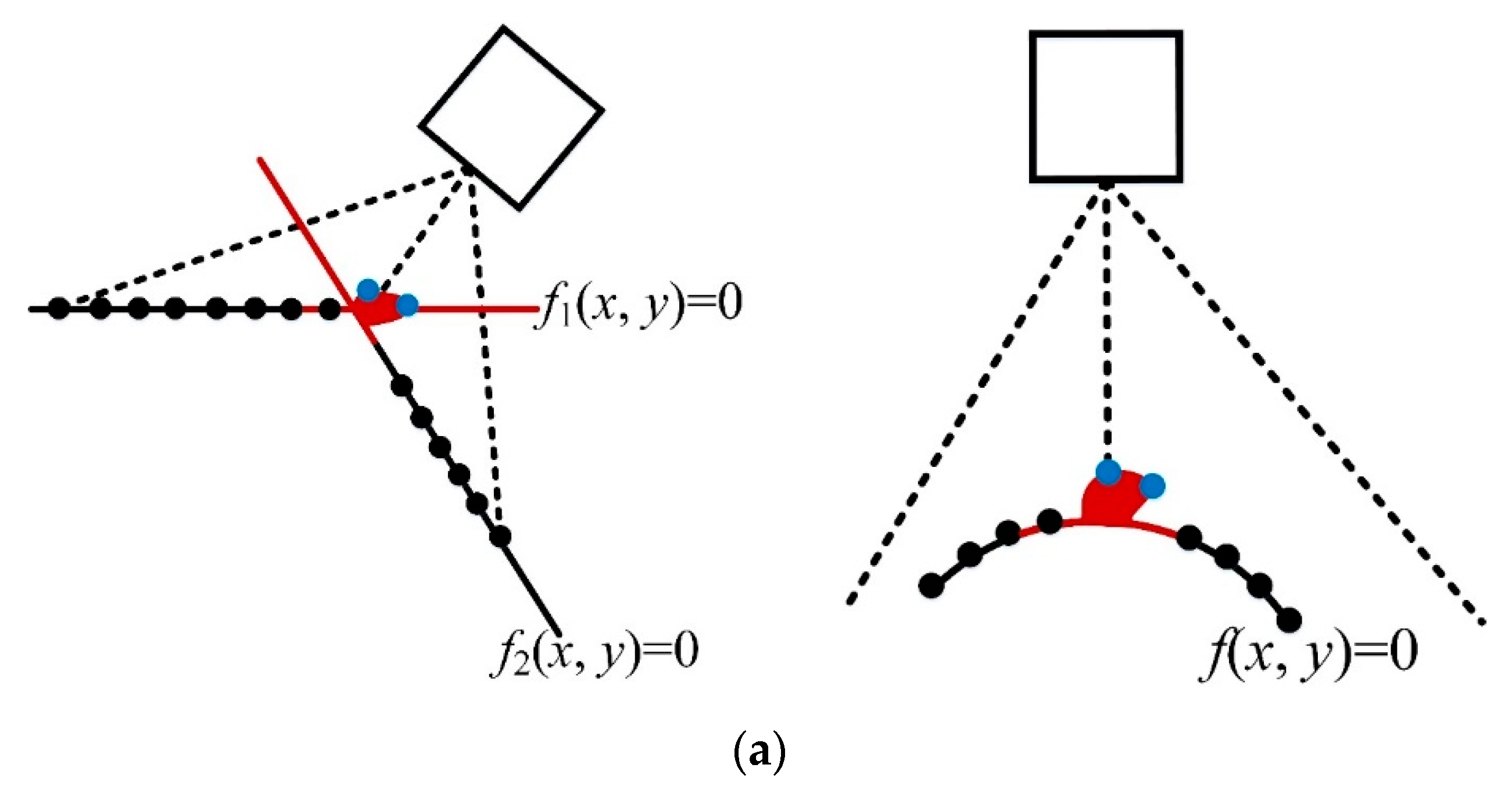

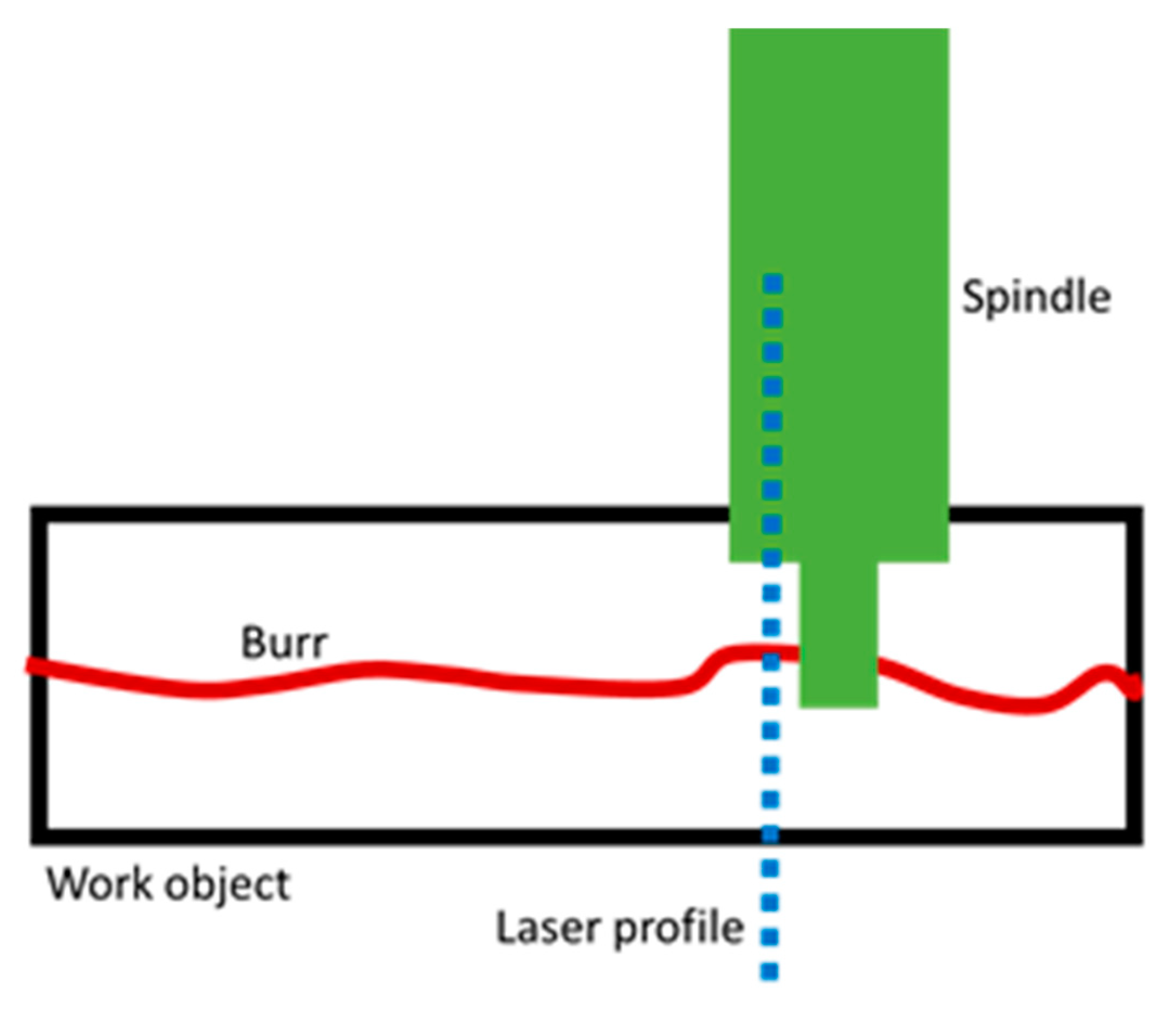

- The contour point information obtained from linear contour scanning is substituted into the equations. ε is the allowable boundary contour error, and its value is determined by sensor precision and the residual plot error values (Figure 6). If the value of any function , burrs are located at .

- Deburring trajectories are generated according to the contour data and burr detection results through the following procedure: (1) The bottom of the cutter is aligned with the contour curve, with the cutter’s U axis and curve normal vector facing in the same direction, to generate the deburring processing points and cutter direction. (2) The cutter axis is placed parallel to the direction of the contour, the center of the cutter is shifted in the direction of according to the cutter radius, and the direction of the contour is shifted by a specified amount (Figure 7).

- The robotic arm is moved forward to the deburring processing points to remove the burrs, and burr analyses and trajectory generation are performed for the next boundary contour. Once all the deburring regions have been scanned and processed, the deburring of the target workpiece is considered complete.

3. Verifying the Automatic Deburring System

4. Conclusions

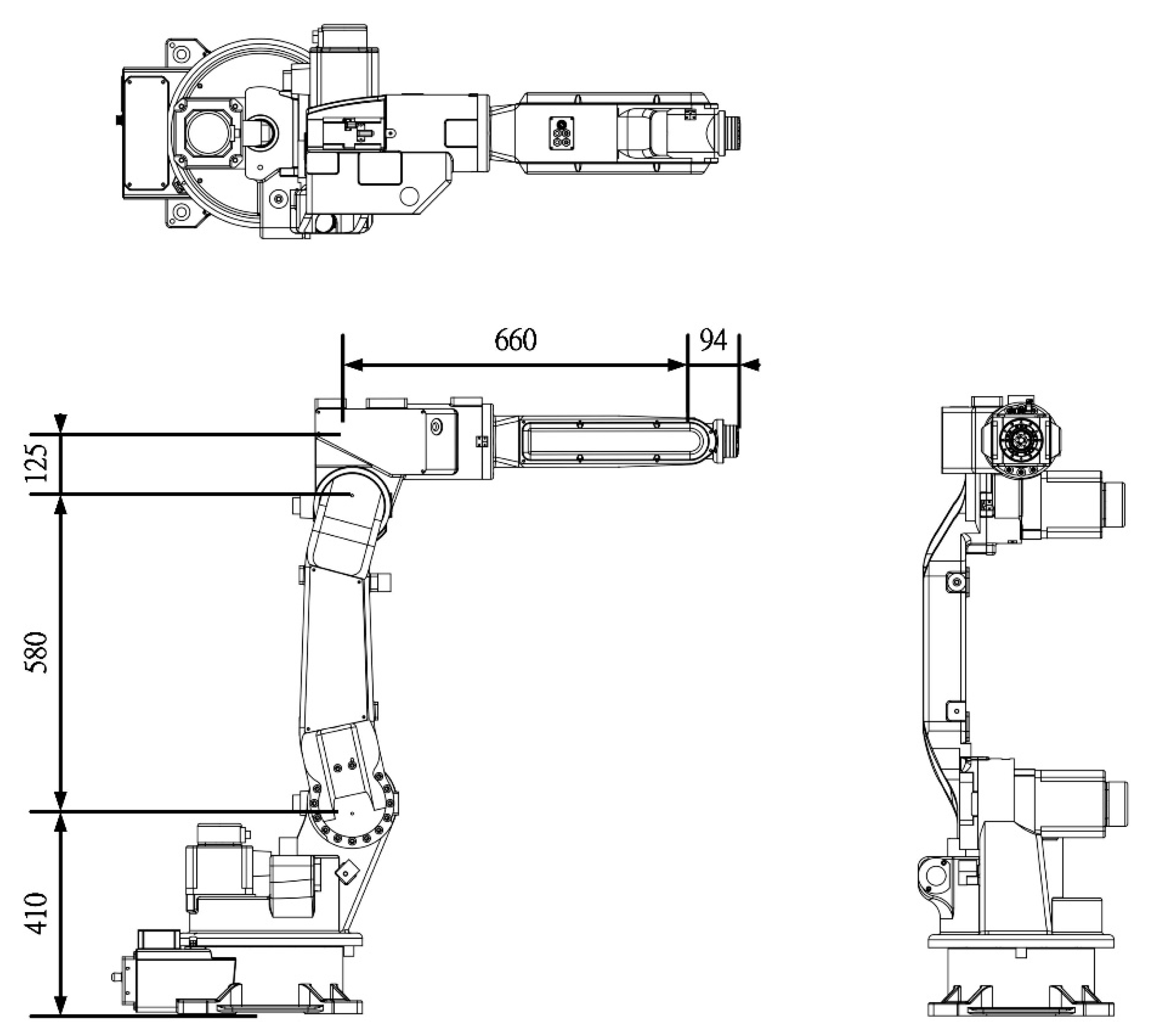

- Regarding the automated equipment and systems integration technology required by the robotic industry, this study developed a model and automated technology for deburring using robotic arms, which may facilitate the integration between midstream and downstream supply chains, create complementary and clustering effects, and enhance the commercialized automated systems and relevant systems integration technology used by domestic firms.

- This study’s technological contributions will help the domestic robotics industry further improve and develop new applications for robotic arms and will facilitate the development of complete solutions to the industrial robotic arm and machine tool integration.

- The online deburring trajectory generation technology presented herein solves the problems encountered by domestic firms when using automated robotic arms (e.g., requiring a series of calibrations and compensations, generating trajectories only after using force control devices and offline programming software that can cost as much as NT$4.3 million, and facing costs and inefficiencies that may create an inability to satisfy industry demand).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| dataset | |

| corresponding model-predicted values; corresponding model-predicted values | |

| residual | |

| mean observed value | |

| The sum of squares of the observed and mean values | |

| The residual sum of squares of the predicted and observed values | |

| the coefficient of determination | |

| the number of iterations | |

| P | the expected probability of RANSAC |

| set of coefficients |

References

- International Federation of Robotics. World Robotics Report 2019; International Federation of Robotics: Frankfurt, Germany, 2019. [Google Scholar]

- International Monetary Fund. World Economic Outlook; International Monetary Fund: Washington, DC, USA, 2019. [Google Scholar]

- Wu, J.H.; Zhang, D.Q.; Jiang, C.; Han, X.; Li, Q. On reliability analysis method through rotational sparse grid nodes. Mech. Syst. Signal. Process 2021, 147, 107106. [Google Scholar] [CrossRef]

- Zhao, Q.Q.; Guo, J.K.; Zhao, D.T.; Yu, D.W.; Hong, J. Time-dependent system kinematic reliability analysis for robotic manipulators. J. Mech. Des. 2021, 143, 041704. [Google Scholar] [CrossRef]

- Wu, J.H.; Zhang, D.Q.; Liu, J.; Jia, X.Y.; Han, X. A computational framework of kinematic accuracy reliability analysis for industrial robots. Appl. Math. Model. 2020, 82, 189–216. [Google Scholar] [CrossRef]

- Zhao, Q.Q.; Guo, J.K.; Hong, J. System kinematic reliability analysis for robotic manipulators under rectangular and spherical tolerant boundaries. J. Mech. Robot. 2021, 13, 011004. [Google Scholar] [CrossRef]

- Gu, Y. Deburring Device including Visual Sensor and Force Sensor. U.S. Patent 9724801, 8 August 2017. [Google Scholar]

- Kuss, A.; Drust, M.; Verl, A. Detection of workpiece shape deviations for tool path adaptation in robotic deburring systems, 49th CIRP. Procedia CIRP 2016, 57, 545–550. [Google Scholar] [CrossRef]

- Leo, P.F.; Selvaraj, T. Vision assisted robotic deburring of edge burrs in cast parts. Procedia Eng. 2014, 97, 1906–1914. [Google Scholar]

- Song, H.C.; Kim, B.S.; Song, J.B. Tool path generation based on matching between teaching points and CAD model for robotic deburring. In Proceedings of the 2012 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Kaohsiung, Taiwan, 11–14 July 2012; pp. 890–895. [Google Scholar]

- Kosler, H.; Pavlovčič, U.; Jezeršek, M.; Možina, J. Adaptive robotic deburring of die-cast parts with position and orientation measurements using a 3D laser-triangulation sensor. J. Mechan. Eng. 2016, 62, 207–212. [Google Scholar] [CrossRef] [Green Version]

- Lee, Z.C.; Bai, X.; Lin, C.S.; Wang, B.Y. A Kind of Robotic Deburring’s System and Burr Removing Method with Vision-Based Detection. CN106041948B, 13 June 2016. [Google Scholar]

- Brogardh, T. System for Controlling the Position and Orientation of an Object in Dependence on Received Forces and Torques from a User. U.S. Patent 20090259412A1, 23 February 2006. [Google Scholar]

- Hori, A.; Mori, K.; Fujita, T.; Sato, G.; Imagi, A.; Negishi, H. Processing Control Device, Machine Tool, and Processing Control Method. TWI667095B, 27 April 2017. [Google Scholar]

- Zhang, K.; Chen, Y.X.; Zheng, J. A Kind of Automatic Identifying Method of Weld Joint Tracking Deviation and Cross-seam Type. CN108672988A, 19 October 2018. [Google Scholar]

- Lovoi, P.A. Adaptive Tracking Vision and Guidance System. U.S. Patent 4907169A, 30 September 1987. [Google Scholar]

- Neumann, K.E. Deburring Method. U.S. Patent 6155757A, 11 July 1996. [Google Scholar]

- Gu, Y.; Satou, T. Deburring Apparatus. U.S. Patent 10478935B2, 8 December 2016. [Google Scholar]

- Diaz Posada, J.R.; Kumar, S.; Kuss, A.; Schneider, U.; Drust, M.; Dietz, T.; Verl, A. Automatic programming and control for robotic deburring. In Proceedings of the ISR 2016: 47th International Symposium on Robotics, Munich, Germany, 5 September 2016. [Google Scholar]

- Khalaj, O.; Jamshidi, M.; Saebnoori, E.; Masek, B.; Stadler, C.; Svoboda, J. Hybrid machine learning techniques and computational mechanics: Estimating the dynamic behavior of oxide precipitation hardened steel. IEEE Access 2021, 9, 156930–156946. [Google Scholar] [CrossRef]

- Jamshidi, M.; Lalbakhsh, A.; Alibeigi, N.; Soheyli, M.; Oryani, B.; Rabbani, N. Socialization of industrial robots: An innovative solution to improve productivity. In Proceedings of the 2018 IEEE 9th Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), Vancouver, BC, Canada, 17 January 2019. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Comm. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Li, J.; Chen, M.; Jin, X.; Chen, Y.; Dai, Z.; Ou, Z.; Tang, Q. Calibration of a multiple axes 3-D laser scanning system consisting of robot, portable laser scanner and turntable. Optik 2011, 122, 324–329. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ting, C.-C.; Huang, C.-K.; Chiou, S.-J.; Li, K.-Y. The 3D Deburring Processing Trajectory Recognition Method and Its Application Base on Random Sample Consensus. Appl. Sci. 2022, 12, 4852. https://doi.org/10.3390/app12104852

Ting C-C, Huang C-K, Chiou S-J, Li K-Y. The 3D Deburring Processing Trajectory Recognition Method and Its Application Base on Random Sample Consensus. Applied Sciences. 2022; 12(10):4852. https://doi.org/10.3390/app12104852

Chicago/Turabian StyleTing, Chun-Chien, Cheng-Kai Huang, Shean-Juinn Chiou, and Kun-Ying Li. 2022. "The 3D Deburring Processing Trajectory Recognition Method and Its Application Base on Random Sample Consensus" Applied Sciences 12, no. 10: 4852. https://doi.org/10.3390/app12104852

APA StyleTing, C.-C., Huang, C.-K., Chiou, S.-J., & Li, K.-Y. (2022). The 3D Deburring Processing Trajectory Recognition Method and Its Application Base on Random Sample Consensus. Applied Sciences, 12(10), 4852. https://doi.org/10.3390/app12104852