Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process

Abstract

:1. Introduction

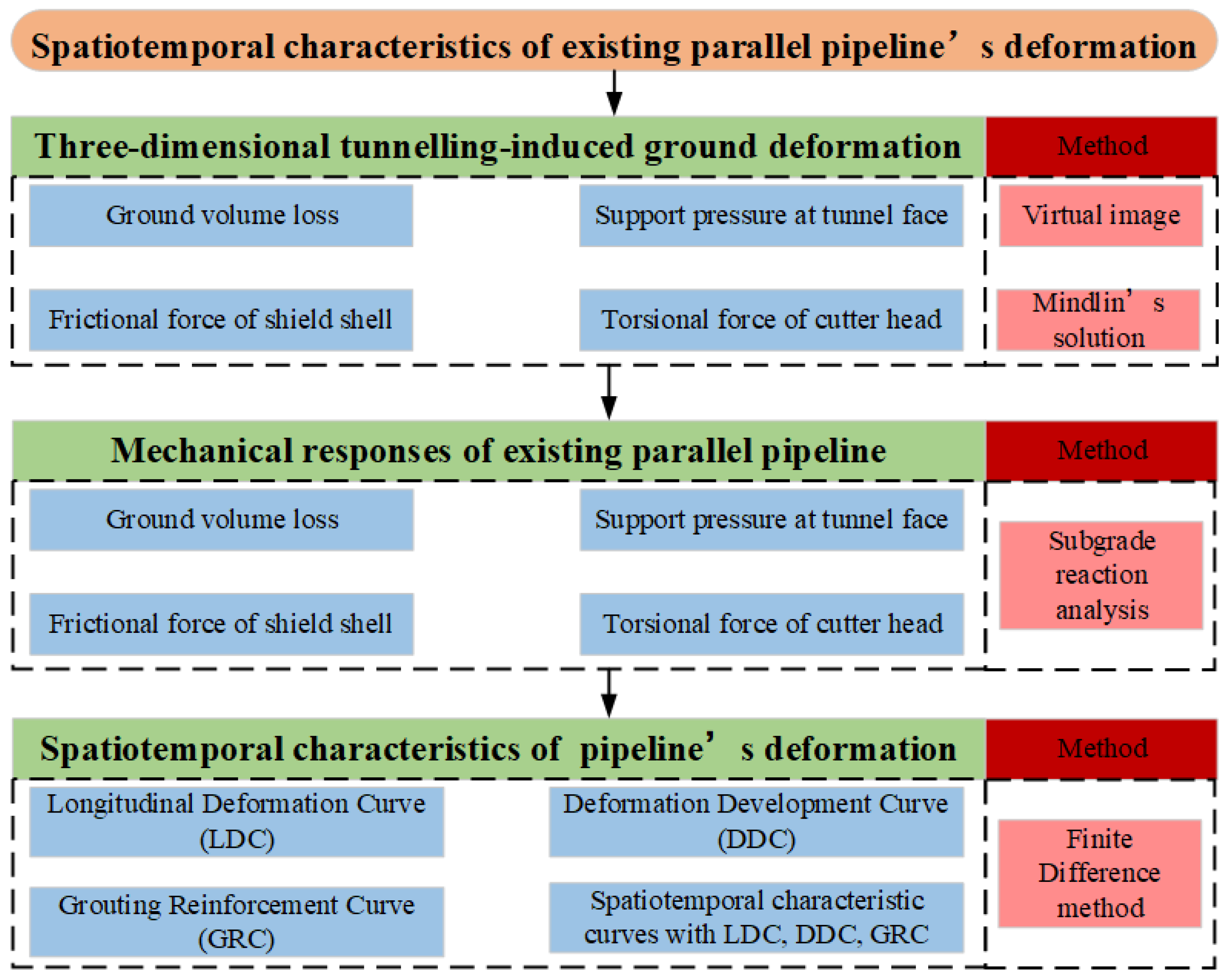

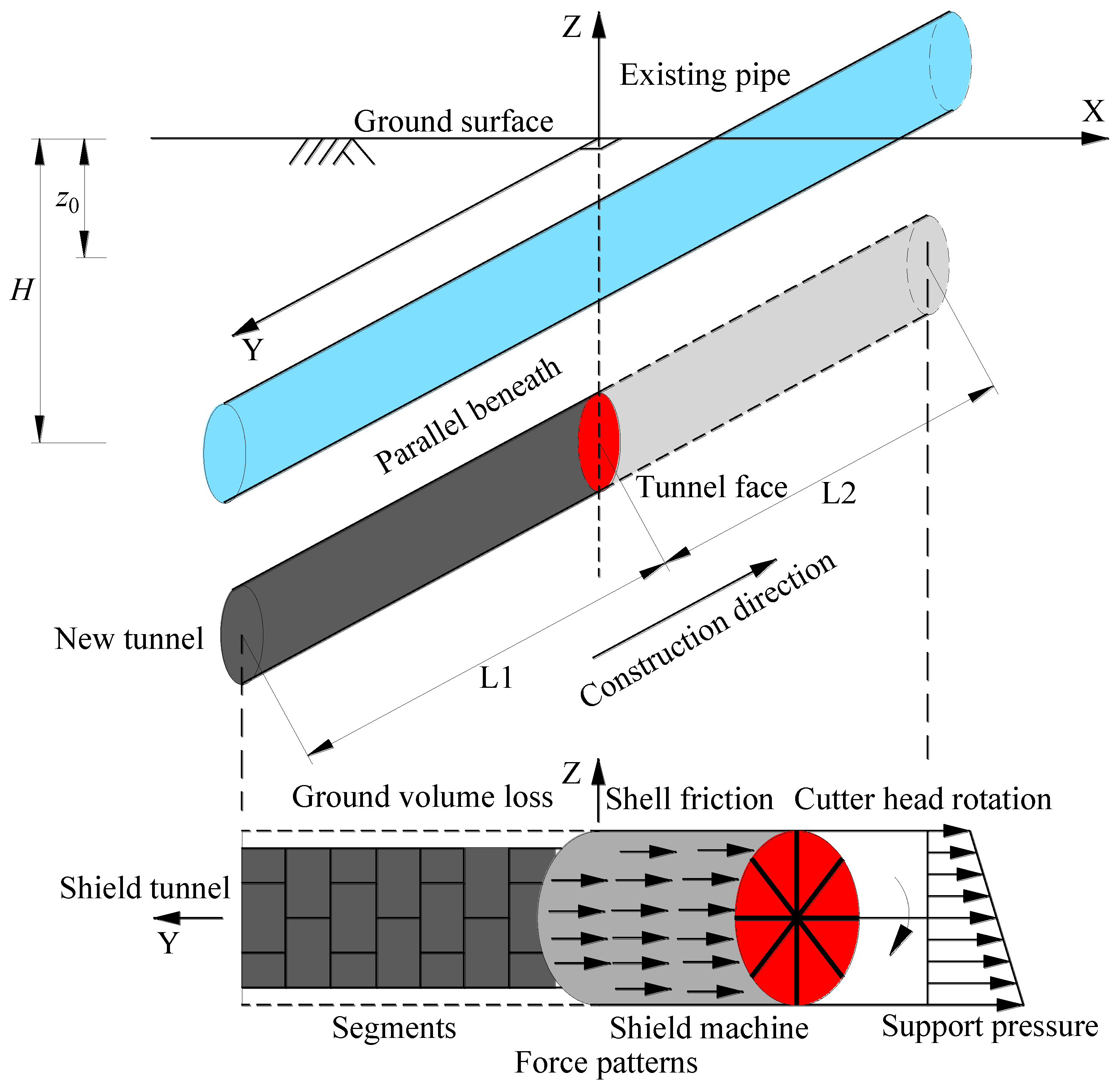

2. Tunnel-Soil-Pipeline Interaction

2.1. Free-Field Movements Induced by Ground Volume Loss

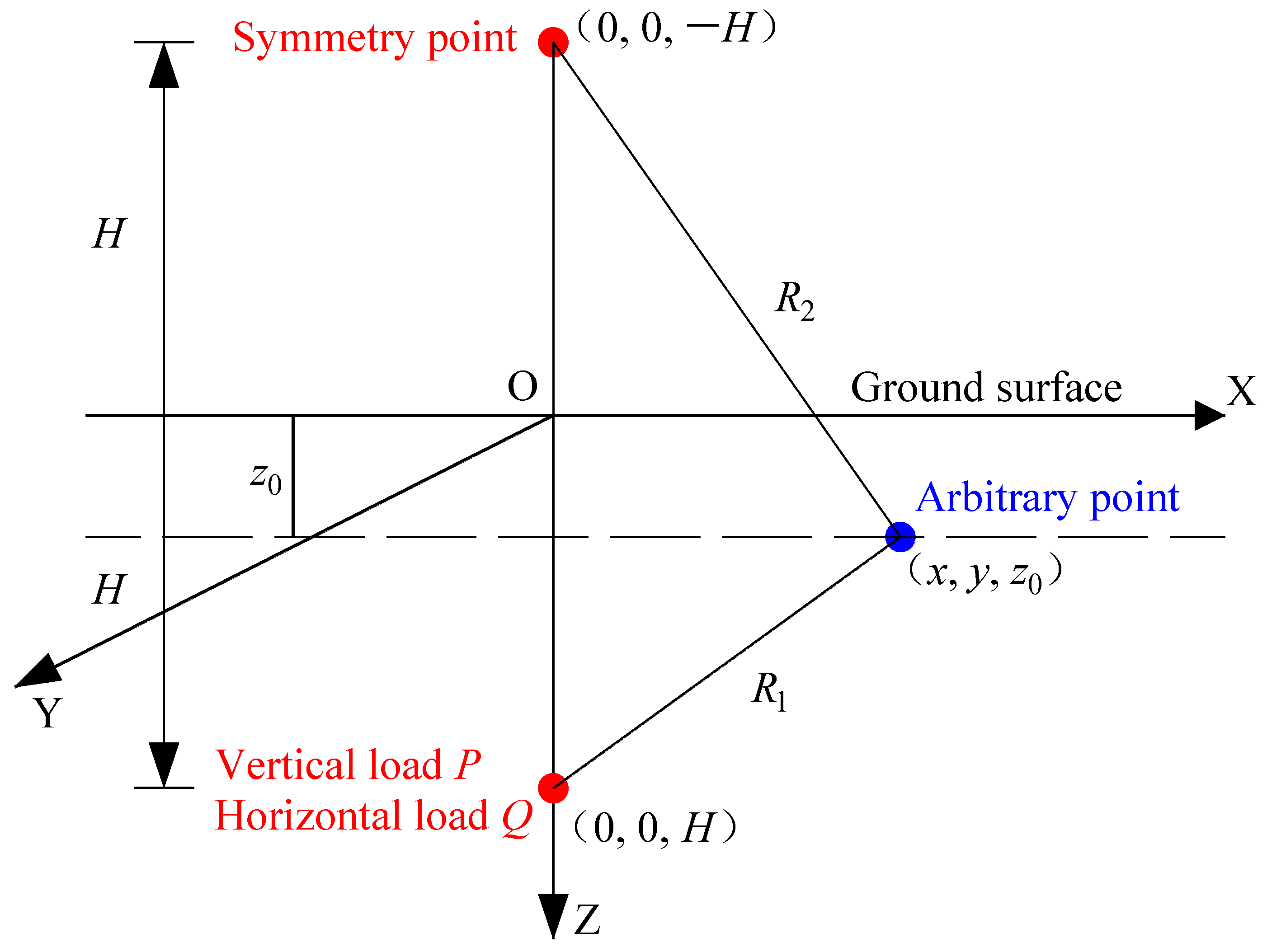

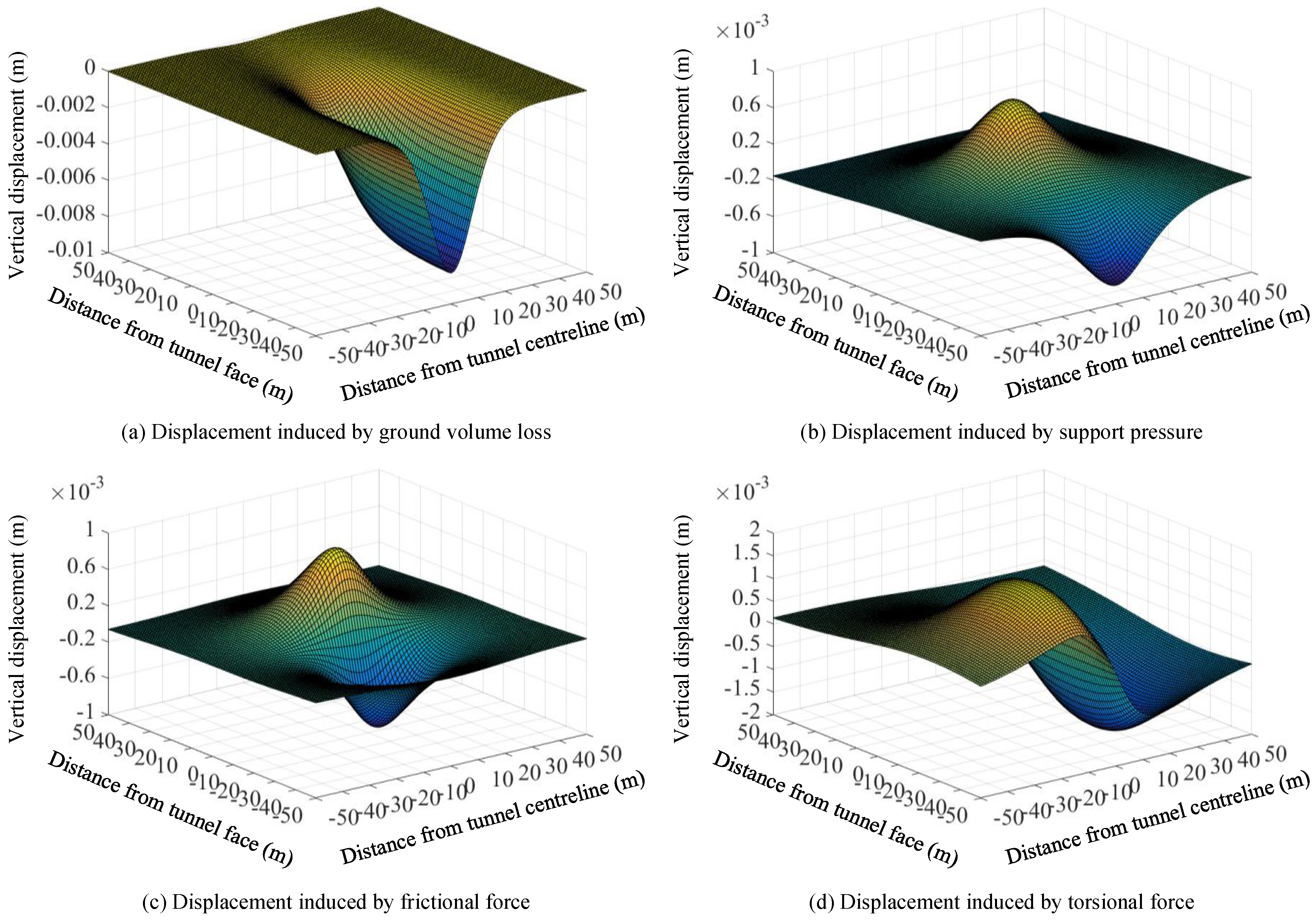

2.2. Free-Field Movements Induced by Different Force Patterns

2.2.1. Support Pressure at Tunnel Face

2.2.2. Frictional Force of Shield Shell

2.2.3. Torsional Force of Cutter Head

2.3. Tunnel-Soil-Pipeline Interaction Based on Subgrade Reaction Analysis

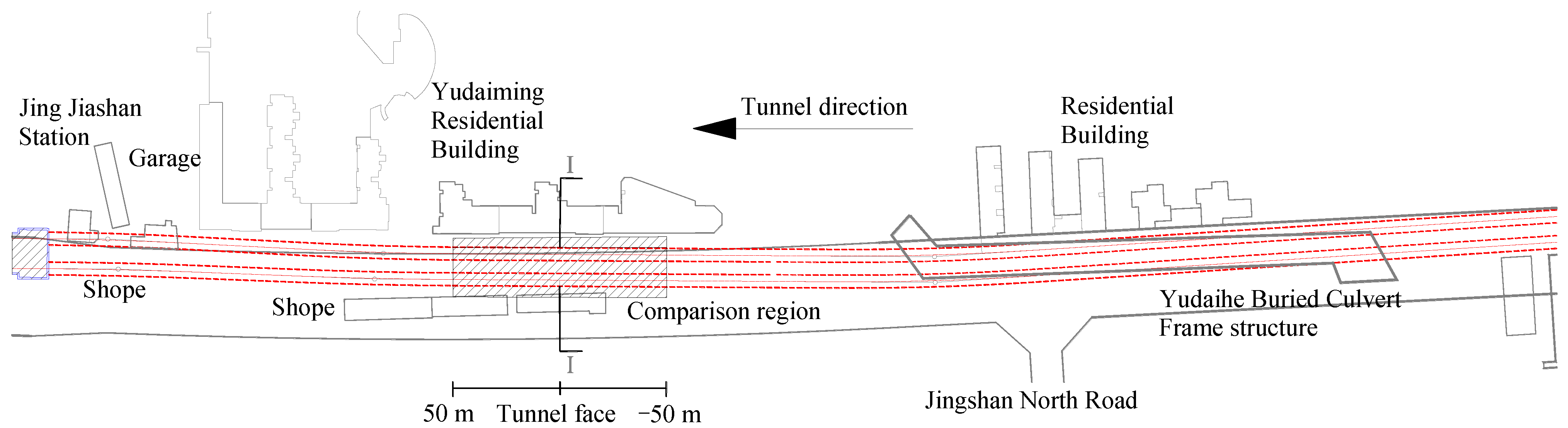

3. Application of Proposed Method on Nanchang Subway Line 3

3.1. Project Overview and Monitored Data

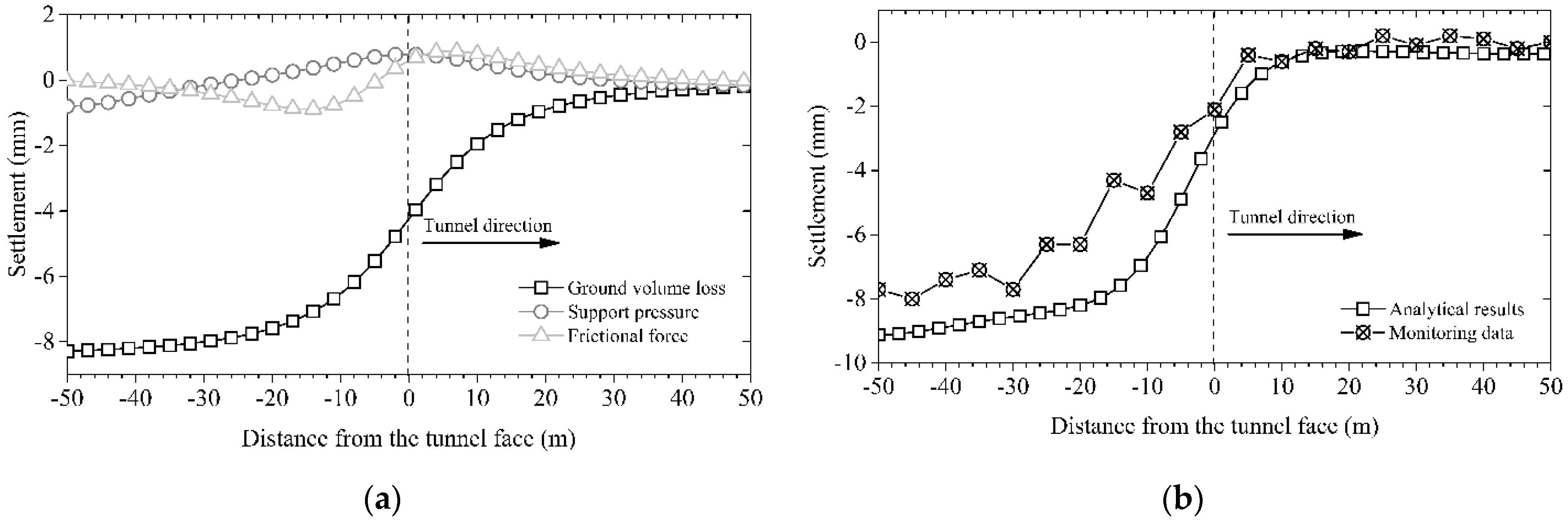

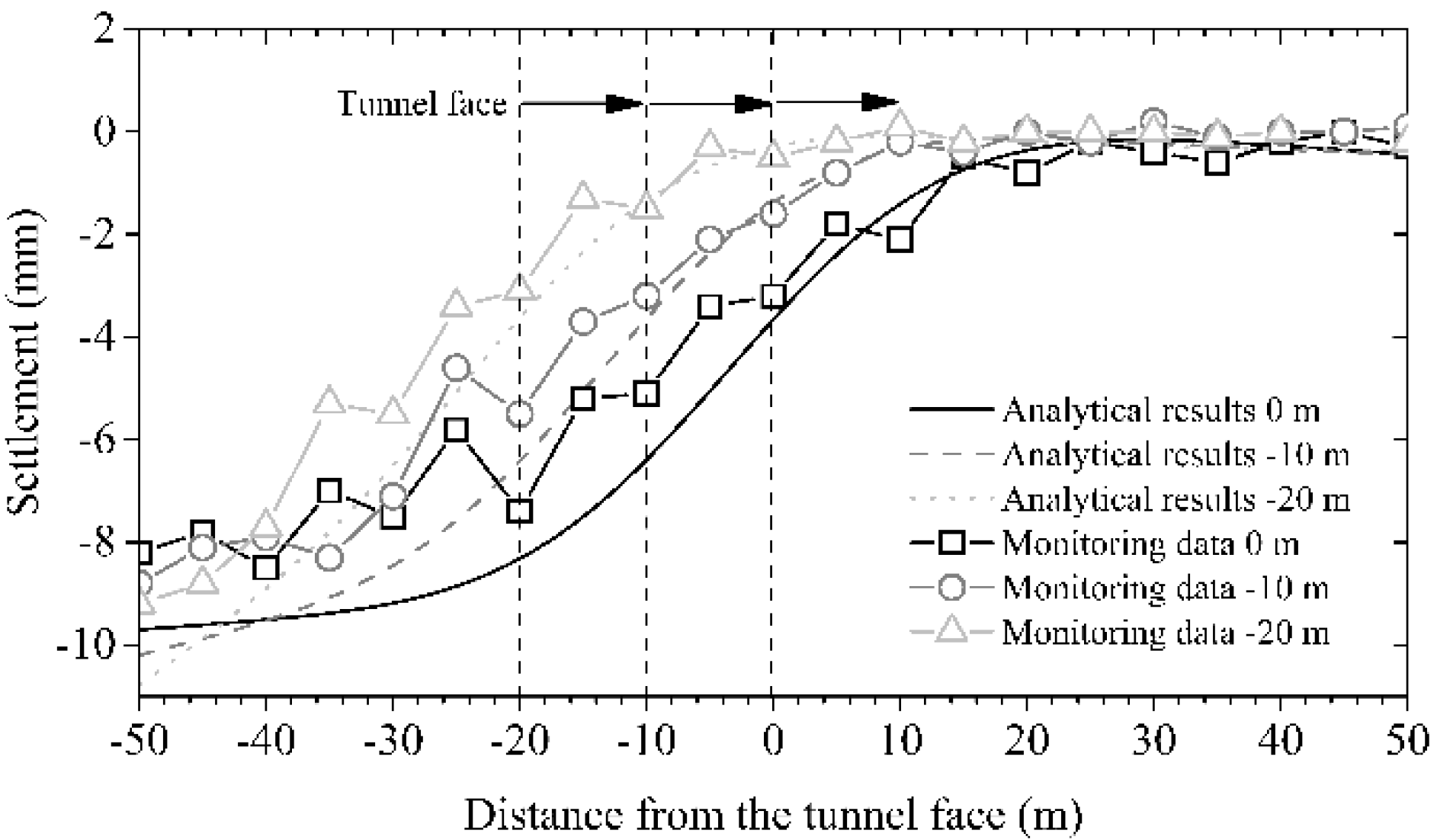

3.2. Calculated Deformation of Ground Surface and Pipeline

3.3. Comparison between Analytical and Monitoring Results

4. Parametric Analysis

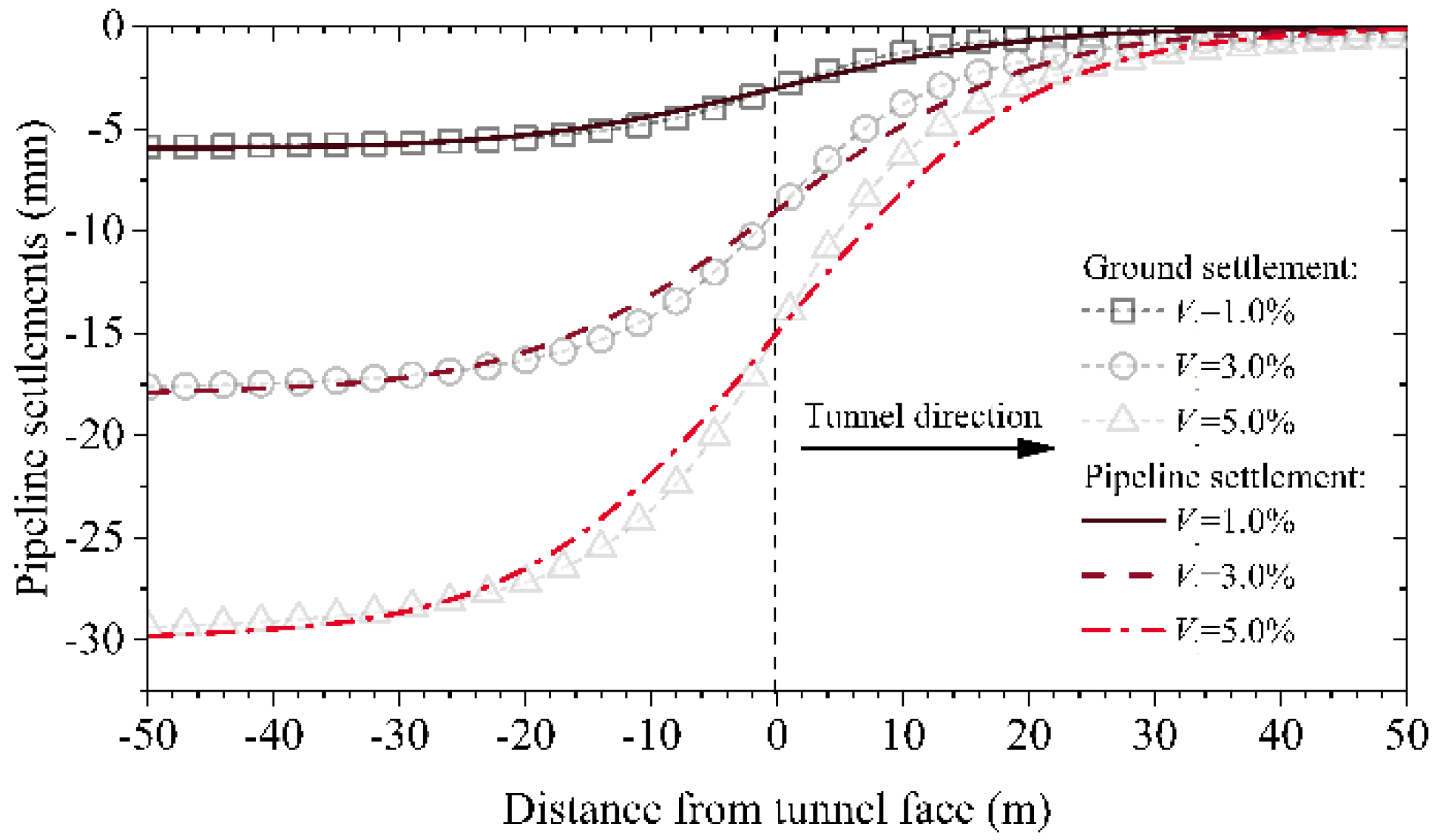

4.1. Ground Volume Loss

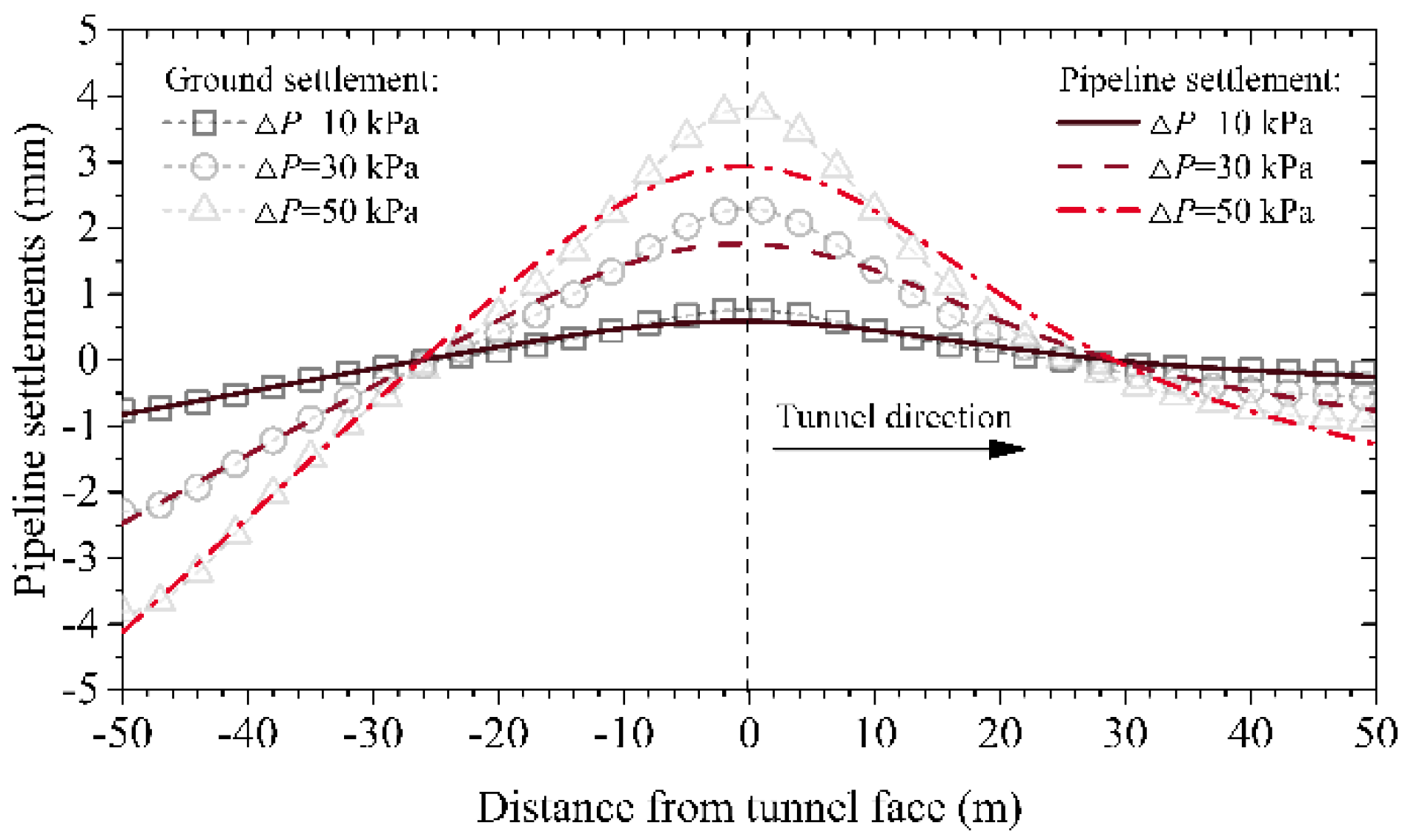

4.2. Support Pressure

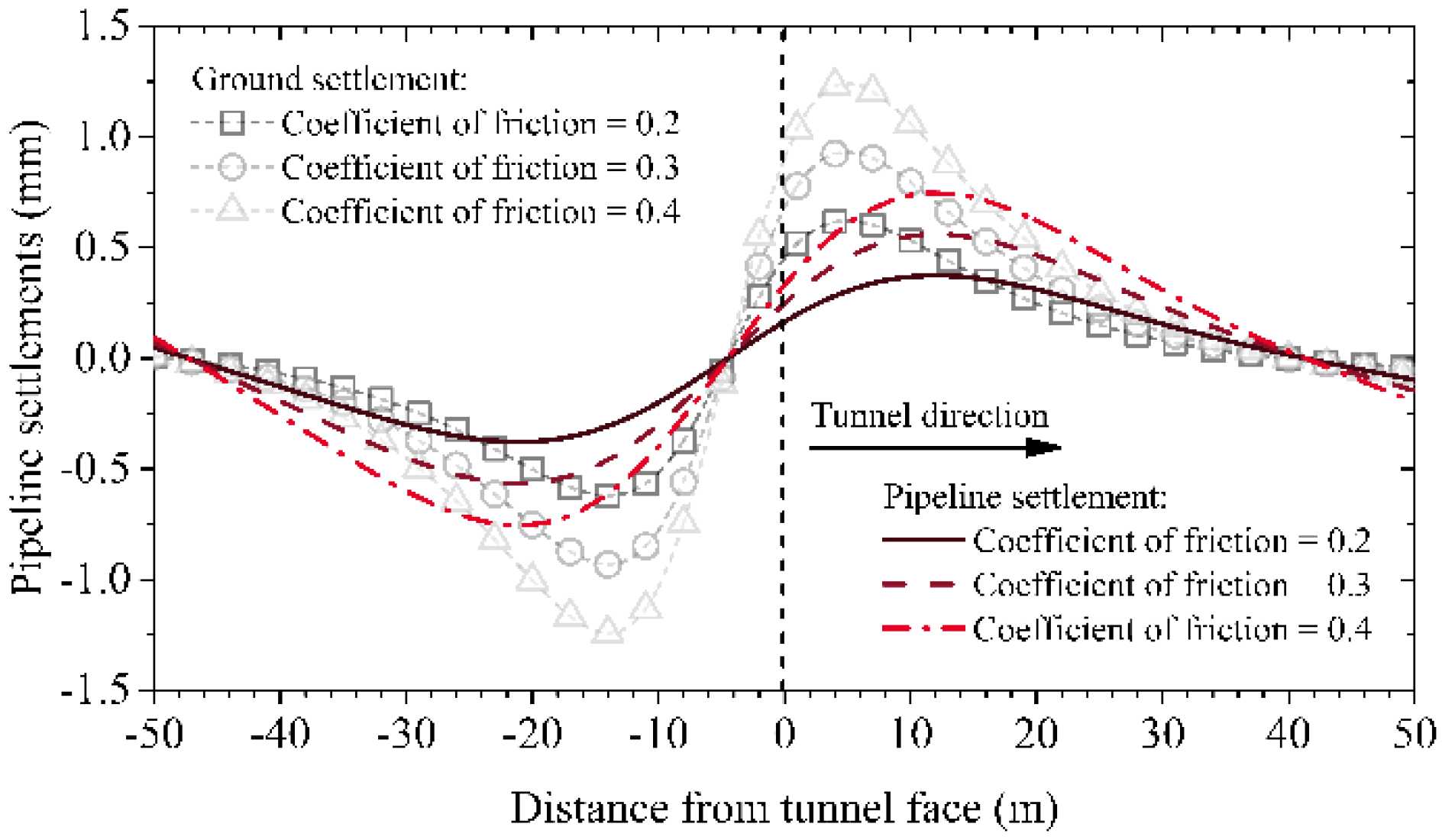

4.3. Frictional Force

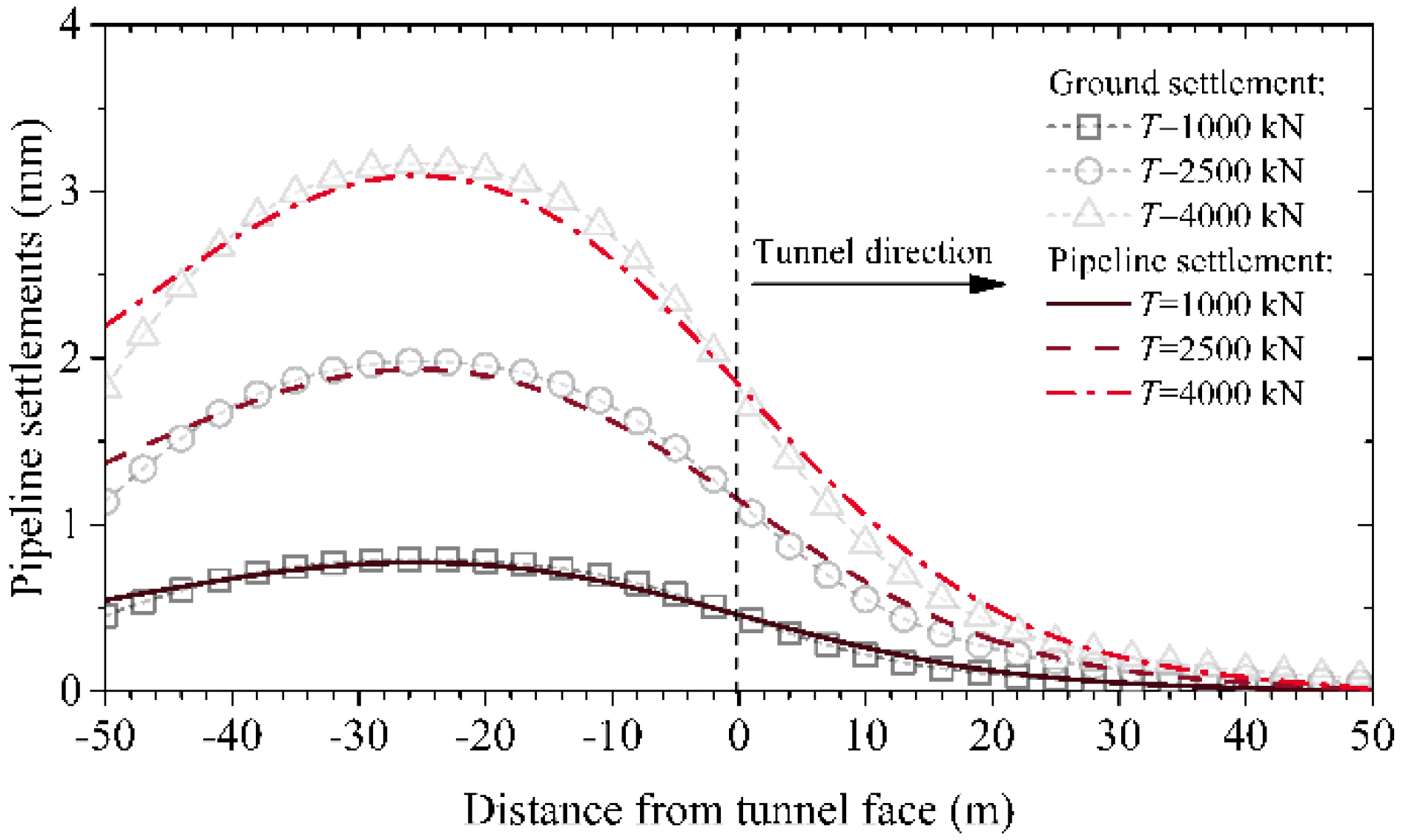

4.4. Torsional Force

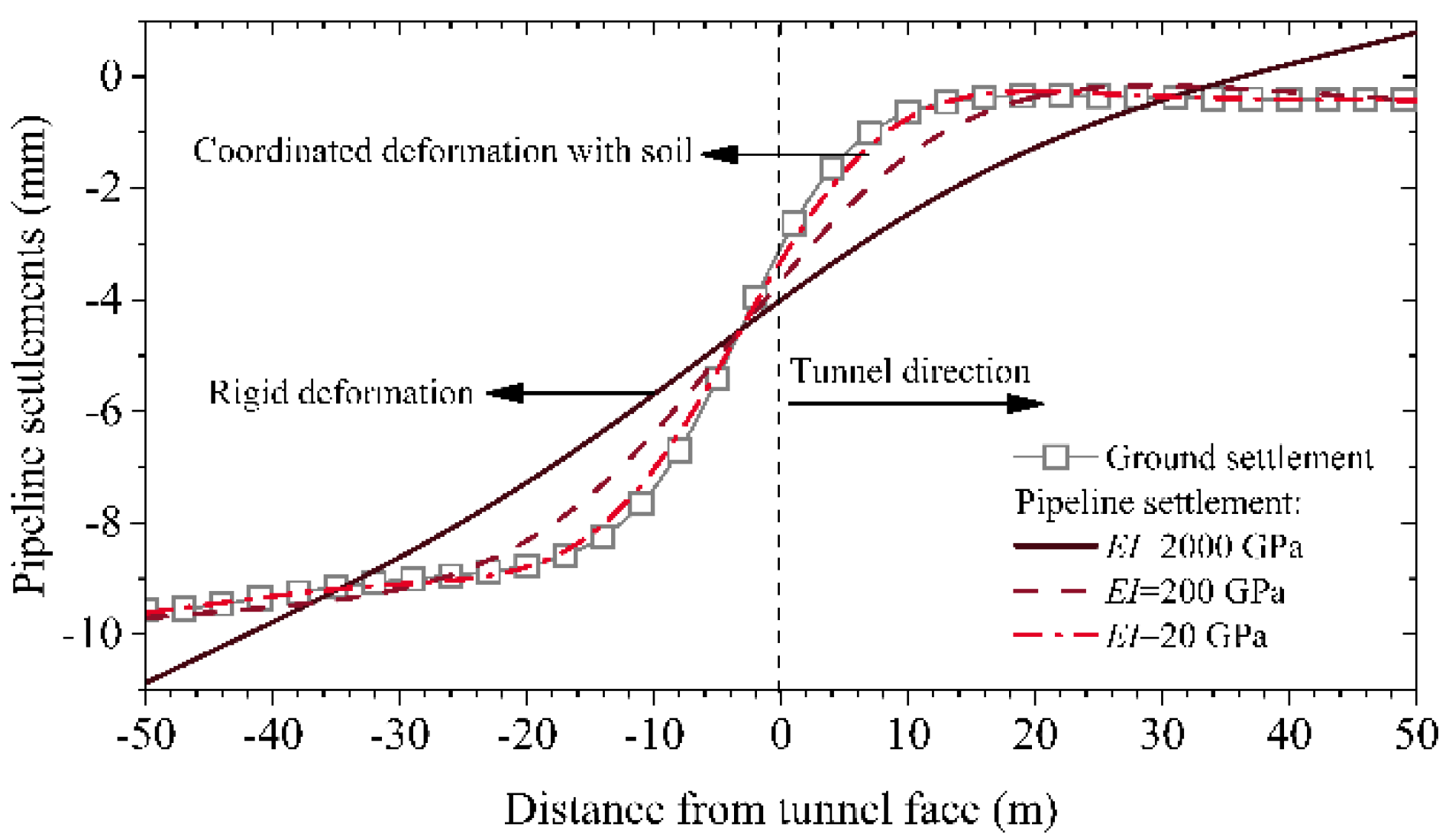

4.5. Equivalent Bending Stiffness of Pipeline

5. Spatiotemporal Characteristics of Existing Pipeline’s Deformation

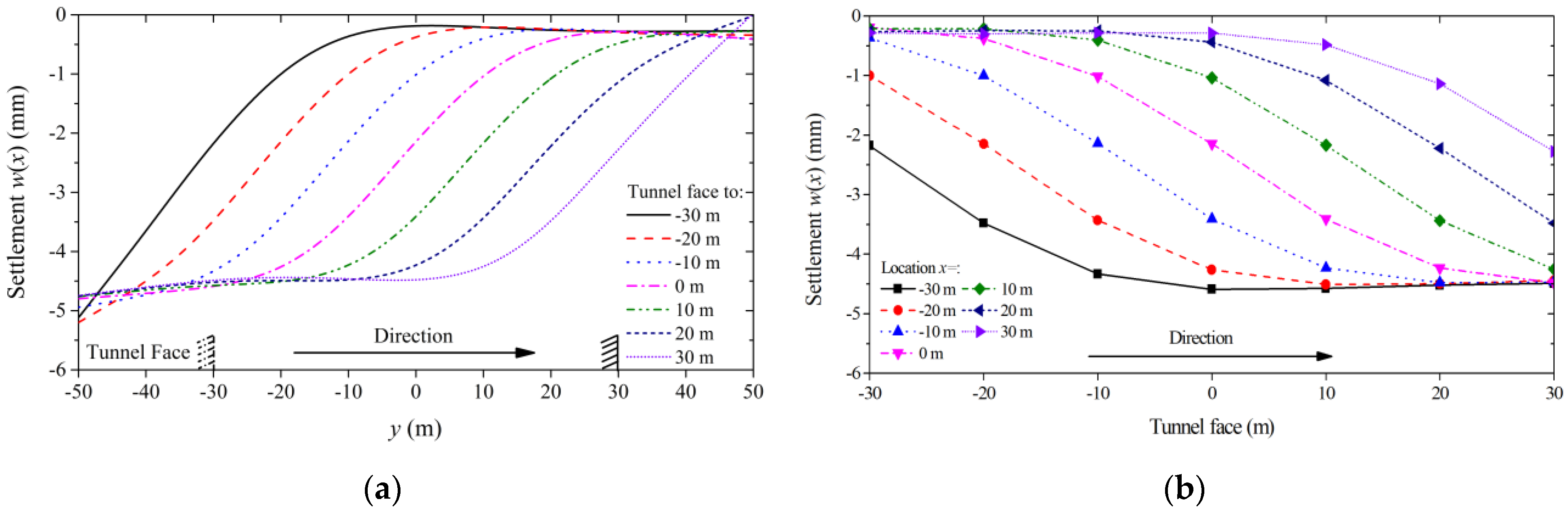

5.1. Three-Dimensional Deformation with Tunnel Construction and Grouting Processes

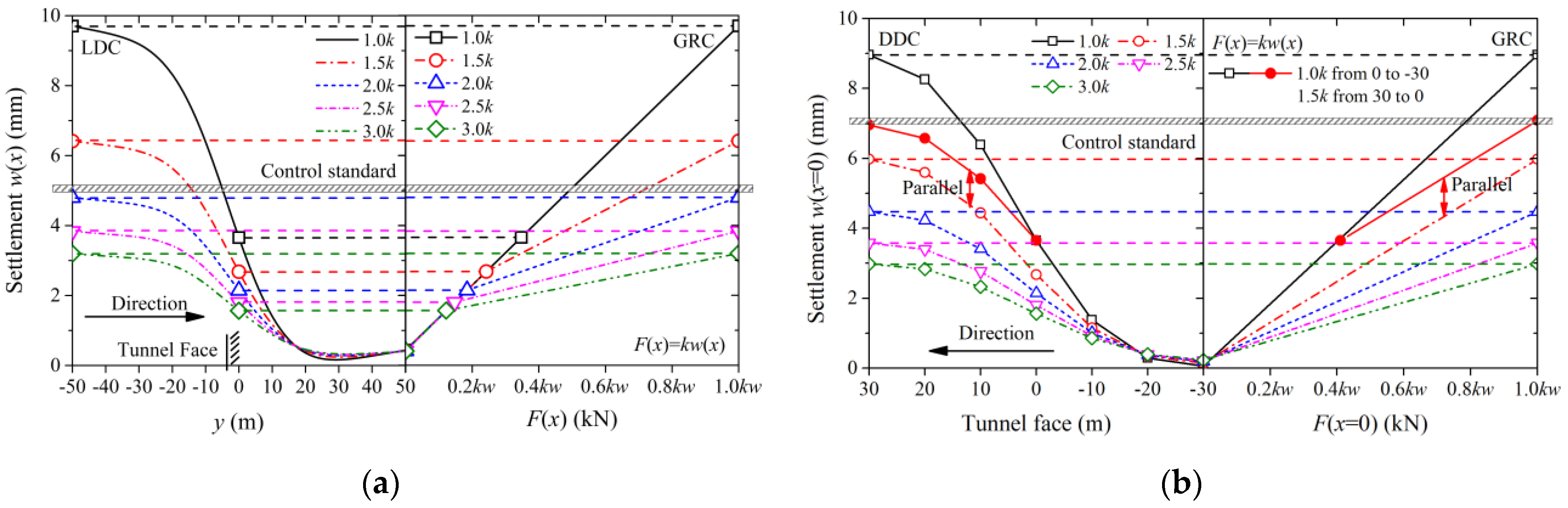

5.2. Spatiotemporal Characteristic Curves Combined with LDC, DDC, and GRC

6. Conclusions

- Compared with the final deformation in previous research, our analyses focus on the pipeline’s deformation during the tunnel construction and grouting reinforcement. The importance of deformation control during tunnel construction is emphasised.

- The influences of different force patterns on the spatiotemporal deformation during the construction phase is considered in more detail. The force patterns consist of the ground volume loss, support pressure at tunnel face, frictional force on shield shell, and torsional force of cutter head.

- The spatiotemporal deformation of the existing pipeline is studied considering the shield tunnel advance. The calculated results agree well with the monitoring data of the existing pipeline in Subway Line 3 of Nanchang. Our proposed method provides a feasible estimation of the pipeline’s deformation with the tunnel advance.

- The pipeline’s deformation increases with the increased ground volume loss, support pressure, frictional force, and torsional force. Although most of the deformation is induced by the ground volume loss, the effects of other force patterns on the deformation should not be ignored.

- We provide the longitudinal deformation curve (LDC), deformation development curve (DDC), and grouting reinforcement curve (GRC) to represent the spatiotemporal characteristics of the existing pipeline’s deformation. The deformation at any point and any moment during the tunnel advance can be roughly extrapolated from the monitored data of any two points.

- The curves combined with LDC, DDC, and GRC are provided to represent the spatiotemporal characteristics. It can be applied to suggest an appropriate construction and grouting scheme during the shield tunnel construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Standing, J.R.; Selman, R. 29 The response to tunnelling of existing tunnels at Waterloo and Westminster. In Building Response to Tunnelling: Case Studies from Construction of the Jubilee Line Extension; Thomas Telford Publishing: London, UK, 2001; pp. 509–546. [Google Scholar]

- Mohamad, H.; Bennett, P.; Soga, K.; Mair, R.; Bowers, K. Behaviour of an old masonry tunnel due to tunnelling-induced ground deformation. Géotechnique 2010, 60, 927–938. [Google Scholar] [CrossRef]

- Li, X.G.; Yuan, D.J. Response of a double-decked metro tunnel to shield driving of twin closely under-crossing tunnels. Tunn. Undergr. Space Technol. 2012, 28, 18–30. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, D.; Li, Q.; Wong, L.N.Y. Effects of twin tunnels construction beneath existing shield-driven twin tunnels. Tunn. Undergr. Space Technol. 2015, 45, 128–137. [Google Scholar] [CrossRef]

- Fang, Q.; Du, J.-M.; Li, J.-Y.; Zhang, D.-L.; Cao, L.-Q. Settlement characteristics of large-diameter shield excavation below existing subway in close vicinity. J. Cent. South Univ. 2021, 28, 882–897. [Google Scholar] [CrossRef]

- Marshall, A.M. Tunnelling in sand and Its Effect on Pipelines and Piles. Ph.D. Thesis, University of Cambridge, London, UK, 2009. [Google Scholar]

- Ng, C.W.W.; Boonyarak, T.; Masin, D. Three-dimensional centrifuge and numerical modeling of the interaction between perpendicularly crossing tunnels. Can. Geotech. J. 2013, 50, 935–946. [Google Scholar] [CrossRef]

- Franza, A. Tunnelling and Its Effects on Piles and Piled Structures. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2017. [Google Scholar]

- Do, N.A.; Dias, D.; Oreste, P.; Djeran-Maigre, I. Three-dimensional numerical simulation of a mechanised twin tunnels in soft ground. Tunn. Undergr. Space Technol. 2014, 42, 40–51. [Google Scholar] [CrossRef]

- Avgerinos, V.; Potts, D.M.; Standing, J.R. Numerical investigation of the effects of tunnelling on existing tunnels. Géotechnique 2017, 67, 808–822. [Google Scholar] [CrossRef]

- Sun, S.; Rong, C.; Wang, H.; Cui, L.; Shi, X. The ground settlement and the existing pipeline response induced by the nonsynchronous construction of a twin-tunnel. Adv. Civ. Eng. 2021, 2021, 8815304. [Google Scholar] [CrossRef]

- Vorster, T.E.B.; Klar, A.; Soga, K.; Mair, R.J. Estimating the effects of tunnelling on existing pipelines. J. Geotech. Geoenviron. Eng. 2005, 131, 1399–1410. [Google Scholar] [CrossRef]

- Klar, A.; Marshall, A. Linear elastic tunnel pipeline interaction: The existence and consequence of volume loss equality. Géotechnique 2015, 65, 788–792. [Google Scholar] [CrossRef]

- Marshall, A.M.; Klar, A.; Mair, R. Tunneling beneath buried pipes: View of soil strain and its effect on pipeline behavior. J. Geotech. Geoenviron. Eng. 2010, 136, 1664–1672. [Google Scholar] [CrossRef]

- Lin, C.; Huang, M.; Nadim, F.; Liu, Z.; Yu, J. Analytical solutions for tunnelling-induced response of two overlying pipelines. Tunn. Undergr. Space Technol. 2021, 108, 103678. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, X.; Yu, J.; Leung, C.; Tan, J.Q.W. Estimating the effects of tunnelling on existing jointed pipelines based on Winkler model. Tunn. Undergr. Space Technol. 2019, 86, 89–99. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Q.; Zhang, D.L. Mechanical responses of existing tunnel due to new tunnelling below without clearance. Tunn. Undergr. Space Technol. 2018, 80, 44–52. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Q.; Zhang, D.; Wang, Z. Behaviour of existing tunnel due to new tunnel construction below. Comput. Geotech. 2019, 110, 71–81. [Google Scholar] [CrossRef]

- Zhang, D.-M.; Huang, Z.-K.; Li, Z.-L.; Zong, X. Analytical solution for the response of an existing tunnel to a new tunnel excavation underneath. Comput. Geotech. 2019, 108, 197–211. [Google Scholar] [CrossRef]

- Lin, C.; Huang, M.; Nadim, F.; Liu, Z. Tunnelling-induced response of buried pipelines and their effects on ground deformations. Tunn. Undergr. Space Technol. 2020, 96, 103193. [Google Scholar] [CrossRef]

- Franza, A.; Viggiani, G.M.B. Role of shear deformability on the response of tunnels and pipelines to single and twin tunnelling. J. Geotech. Geoenviron. Eng. 2021, 147, 04021145. [Google Scholar] [CrossRef]

- Peck, R.B. Deep excavations and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, State of the Art Report, Mexico City, Mexico, 25–29 August 1969; pp. 225–290. [Google Scholar]

- Mindlin, R.D. Force at a point in the interior of a semi-infinite solid. Physics 1936, 5, 195–202. [Google Scholar] [CrossRef]

- Sagaseta, C. Analysis of undrained soil deformation due to ground loss. Geotechnique 1987, 37, 301–320. [Google Scholar] [CrossRef]

- Verruijt, A. A complex variable solution for a deforming circular tunnel in an elastic half-plane. Int. J. Numer. Anal. Methods Geomech. 1999, 21, 77–89. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Huang, M.S.; Zhang, M.X. Theoretical prediction of ground movements induced by tunnelling in multi-layered soils. Tunn. Undergr. Space Technol. 2011, 26, 345–355. [Google Scholar] [CrossRef]

- Wang, F.; Lu, H.; Gou, B.; Han, X.; Zhang, Q.; Qin, Y. Modeling of shield-ground interaction using an adaptive relevance vector machine. Appl. Math. Model. 2016, 40, 5171–5182. [Google Scholar] [CrossRef]

- Wang, H.N.; Zeng, G.S.; Jiang, M.J. Analytical stress and displacement around non-circular tunnels in semi-infinite ground. Appl. Math. Model. 2018, 63, 303–328. [Google Scholar] [CrossRef]

- Kong, F.; Lu, D.; Du, X.; Shen, C. Elastic analytical solution of shallow tunnel owing to twin tunnelling based on a unified displacement function. Appl. Math. Model. 2019, 68, 422–442. [Google Scholar] [CrossRef]

- Zou, J.F.; Wang, F.; Wei, A. A semi-analytical solution for shallow tunnels with radius-iterative-approach in semi-infinite space. Appl. Math. Model. 2019, 73, 285–302. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, G.; Yu, F.; Du, J. Analytical algorithm for longitudinal deformation profile of a deep tunnel. J. Rock. Mech. Geotech. Eng. 2021, 13, 845–854. [Google Scholar] [CrossRef]

- Li, S.H.; Zhang, M.J.; Li, P.F. Analytical solutions to ground settlement induced by ground loss and construction loadings during curved shield tunneling. J. Zhejiang Univ.-Sci. A (Appl. Phys. Eng.) 2021, 22, 296–313. [Google Scholar] [CrossRef]

- Li, P.F.; Wei, Y.J.; Zhang, M.J.; Huang, Q.F.; Wang, F. Influence of non-associated flow rule on passive face instability for shallow shield tunnels. Tunn. Undergr. Space Technol. 2022, 119, 104202. [Google Scholar] [CrossRef]

- Jin, D.L.; Shen, X.; Yuan, D.J. Theoretical analysis of three-dimensional ground displacements induced by shield tunnelling. Appl. Math. Model. 2020, 79, 85–105. [Google Scholar] [CrossRef]

- Loganathan, N.; Poulos, H.G. Analytical prediction for tunnelling-induced ground movements in clays. J. Geotech. Geoenviron. Eng. 1998, 124, 846–856. [Google Scholar] [CrossRef]

- Rowe, R.K.; Lo, K.Y.; Kack, G.J. A method of estimating surface settlement above tunnels constructed in. Can. Geotech. J. 1983, 20, 11–22. [Google Scholar] [CrossRef]

- Han, Y.W.; Liang, J.H.; Yuan, X.H. Deformation model of backfill grouting and ground movement analysis of shield tunnel. Chin. J. Geotech. Eng. 2007, 26, 3646–3652. (In Chinese) [Google Scholar]

- Lee, K.; Rowe, R.K.; Lo, K. Subsidence owing to tunnelling. 1. Estimating the gap parameter. Can. Geotech. J. 1992, 29, 929–940. [Google Scholar] [CrossRef]

- Winkler, E. Die Lehre von der Elastizitat and Feistigkeit; H. Dominicus: Prague, Czech Republic, 1867. [Google Scholar]

- Pasternak, P.L. On a New Method of Analysis of an Elastic Foundation by Means of Two Foundation Constants; Gosudatstvennoe Lzdatelgtro Liberaturi po Stroiterlstvui Arkhitekture: Moscow, Russia, 1954. (In Russian) [Google Scholar]

- Biot, M.A. Bending of an infinite beam on an elastic foundation. Zeitschrift fiir Angewandte Maihematik und Mechanik 1922, 2, 165–184. [Google Scholar] [CrossRef]

- Vesic, A.S. Bending of beams resting on isotropic elastic solid. J. Soil Mech. Found. Eng. ASCE 1961, 87, 35–53. [Google Scholar] [CrossRef]

- Attewell, P.B.; Yeates, J.; Selby, A.R. Soil Movement Induced by Tunnelling and Their Effects on Pipelines and Structures; Blackie and Son Ltd.: London, UK, 1986. [Google Scholar]

- Klar, A.; Vorster, T.E.B.; Soga, K.; Mair, R.J. Soil-pipe interaction due to tunnelling: Comparison between Winkler and elastic continuum solutions. Géotechnique 2005, 55, 461–466. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, C.R.; Huang, M.S. Soil–pipe interaction due to tunnelling: Assessment of Winkler modulus for underground pipelines. Comput. Geotech. 2013, 50, 17–28. [Google Scholar] [CrossRef]

- Tanahashi, H. Formulas for an infinitely long bernoulli-euler beam on the Pasternak model. J. Jpn. Geotech. Soc. Soils Found 2004, 44, 109–118. [Google Scholar] [CrossRef] [Green Version]

- Xu, L. Study on the Longitudinal Settlement of Shield Tunnel in Soft Soil; Tongji University: Shanghai, China, 2005. (In Chinese) [Google Scholar]

- Liu, X. Mechanical Behaviours of Existing Tunnels Due to New Tunnel Construction Below. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2020. [Google Scholar]

| zg (m) | zp (m) | H (m) | R (m) | Vl (%) | S (m) | μ | Es (MPa) | EI (GPam3) | ΔP (kPa) | T (kNm) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 4.0 | 15.6 | 3.0 | 1.5 | 9.0 | 0.3 | 20.0 | 200.0 | 10.0 | 2500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Jiang, A.; Fang, Q.; Wan, Y.; Li, J.; Guo, X. Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process. Appl. Sci. 2022, 12, 500. https://doi.org/10.3390/app12010500

Liu X, Jiang A, Fang Q, Wan Y, Li J, Guo X. Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process. Applied Sciences. 2022; 12(1):500. https://doi.org/10.3390/app12010500

Chicago/Turabian StyleLiu, Xiang, Annan Jiang, Qian Fang, Yousheng Wan, Jianye Li, and Xinping Guo. 2022. "Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process" Applied Sciences 12, no. 1: 500. https://doi.org/10.3390/app12010500

APA StyleLiu, X., Jiang, A., Fang, Q., Wan, Y., Li, J., & Guo, X. (2022). Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process. Applied Sciences, 12(1), 500. https://doi.org/10.3390/app12010500