Large-Scale Truss Topology and Sizing Optimization by an Improved Genetic Algorithm with Multipoint Approximation

Abstract

:1. Introduction

2. Problem Formulation

2.1. Optimization Model of a Large-Scale Truss

2.2. Further Explanations for the Model

3. Optimization Scheme

3.1. Flowchart for the Optimization Scheme

3.2. The First-Level Approximation Problems by BMA

3.3. The Label–Clip–Slice Strategy and GA to Address Mixed Variables

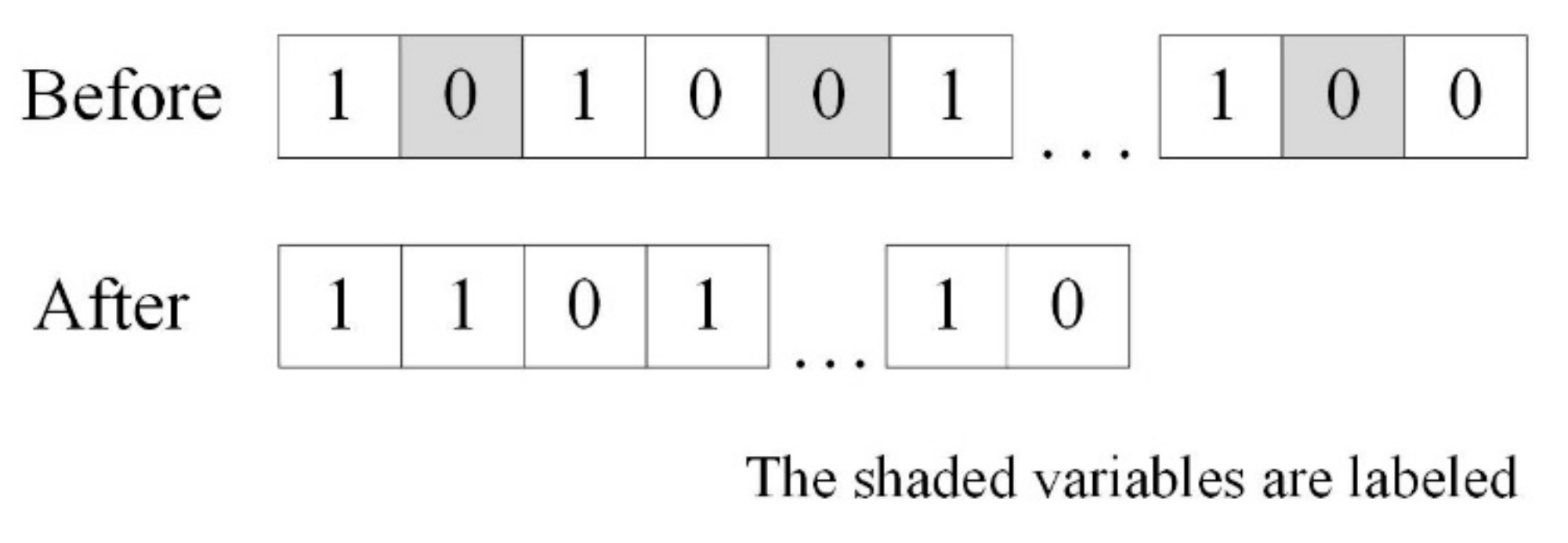

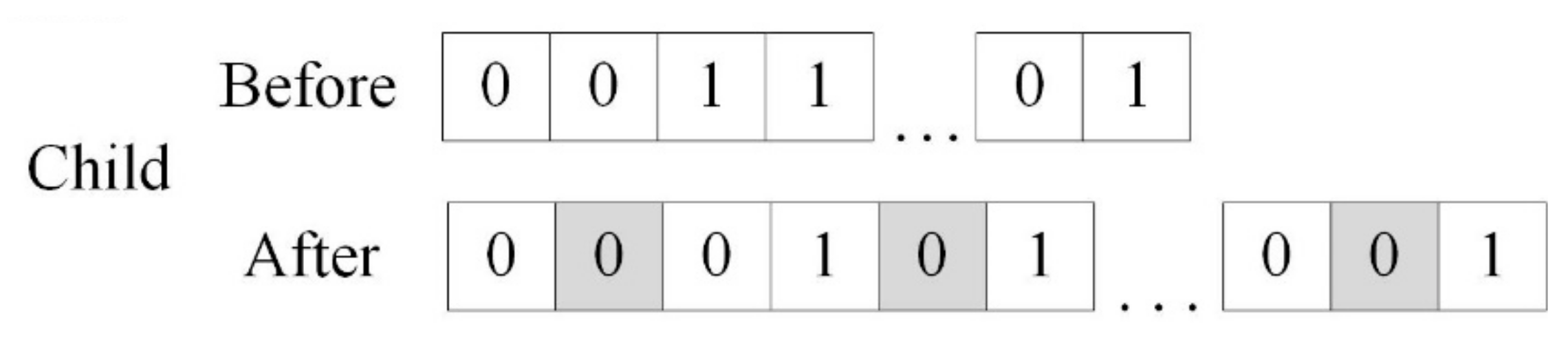

3.3.1. Labeling of the Topology Variables

3.3.2. Clipping of the Chromosome of the Last Best Individual

3.3.3. Generating of the Initial Population

- (a)

- The optimized individual that is obtained in previous iterations;

- (b)

- Individuals that randomly mutated from the optimized topology vector ;

- (c)

- Individuals that are calculated according to the optimized size vector .

3.3.4. Splicing of the Individuals in the Current Population

3.3.5. Fitness Calculation and Sizing Optimization

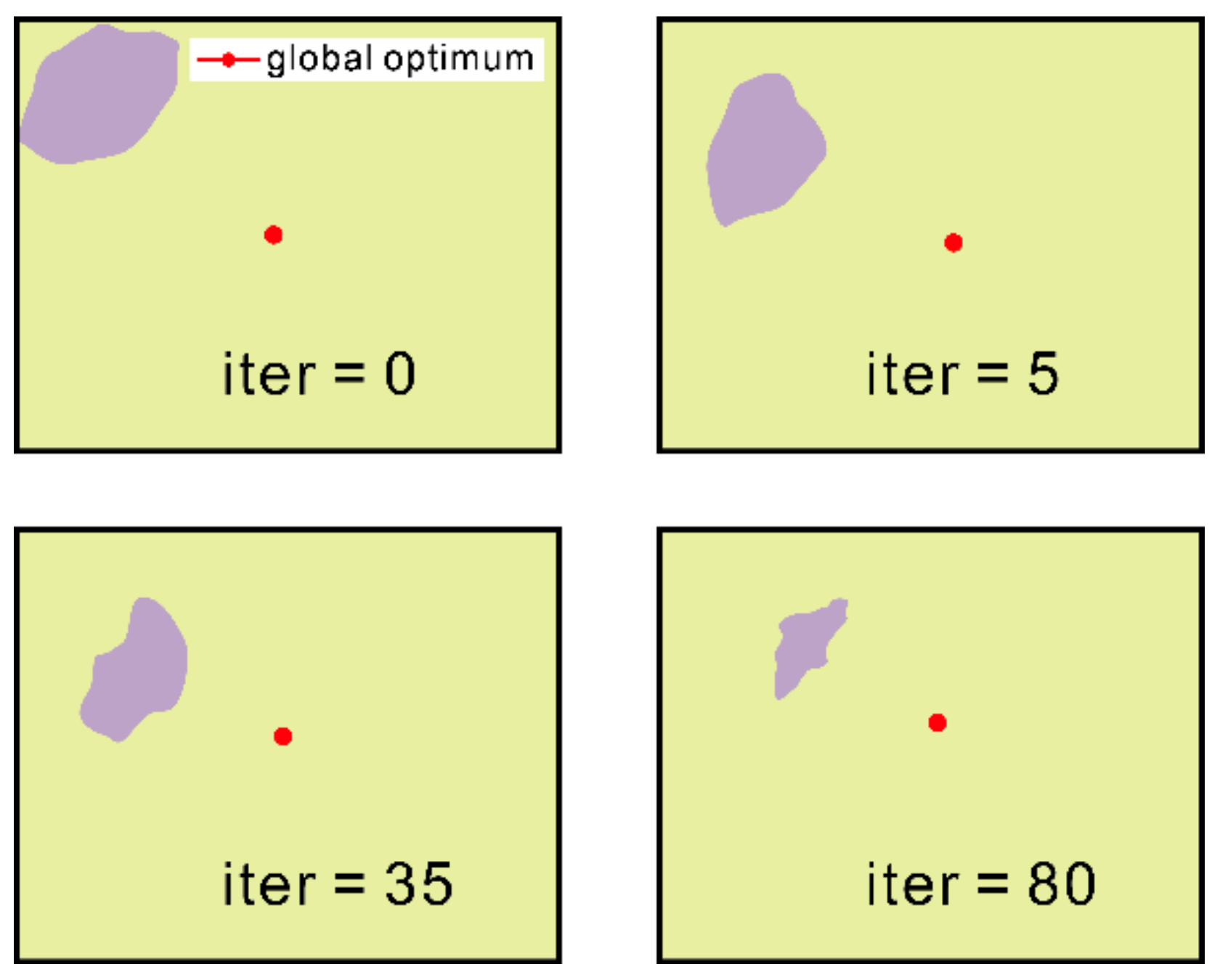

3.4. Analysis and Discussion

4. Numerical Examples

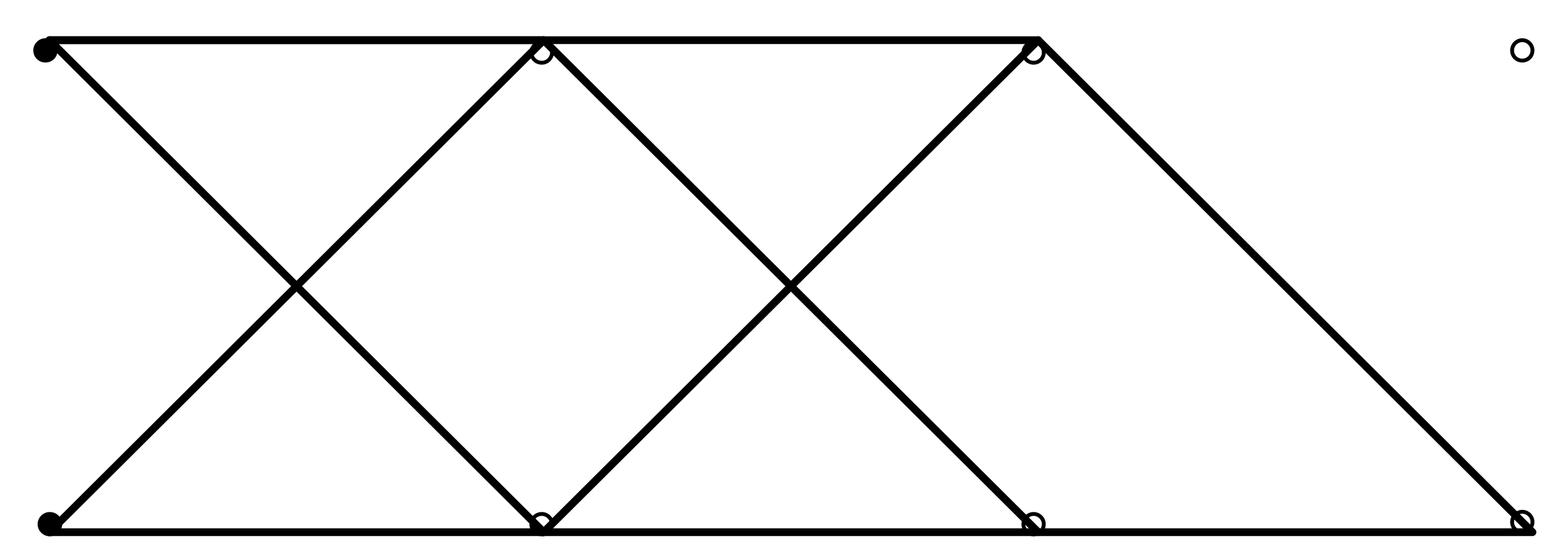

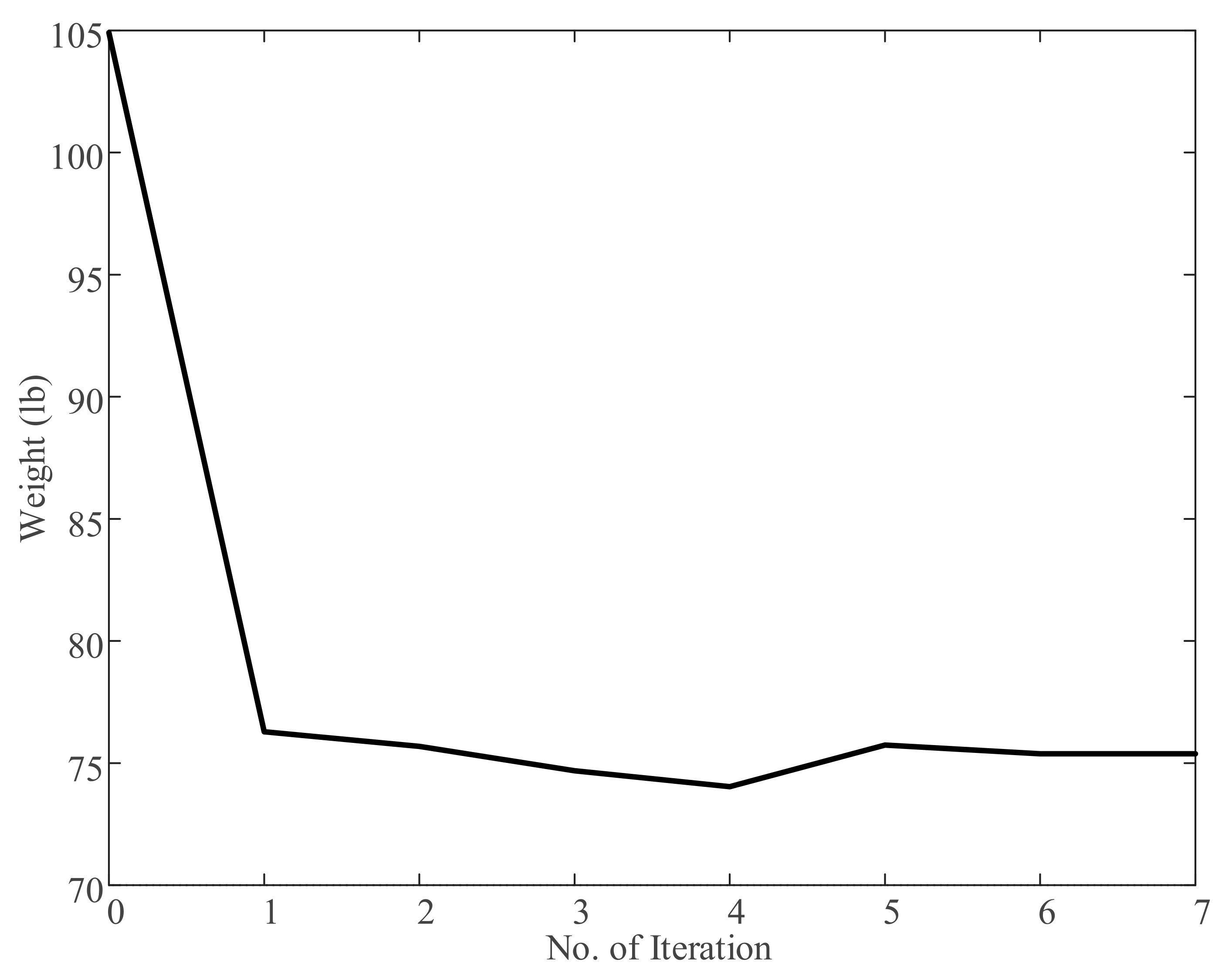

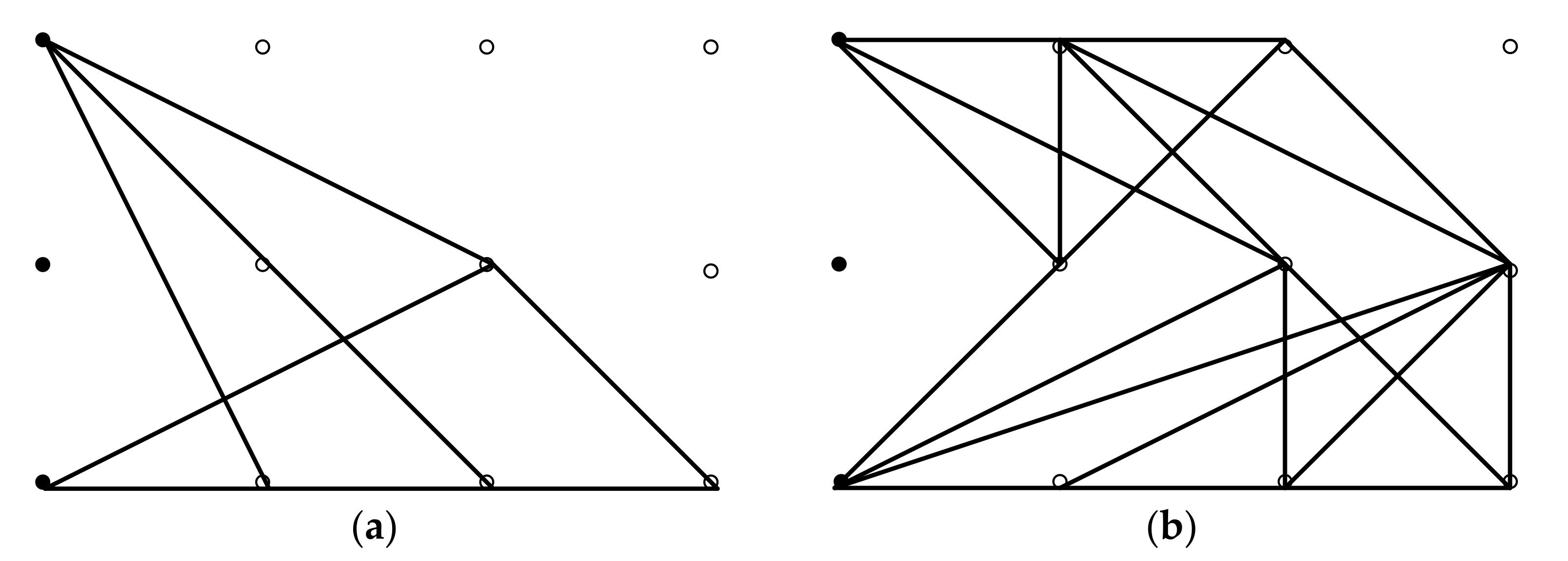

4.1. Example 1: 15-Bar Planar Truss

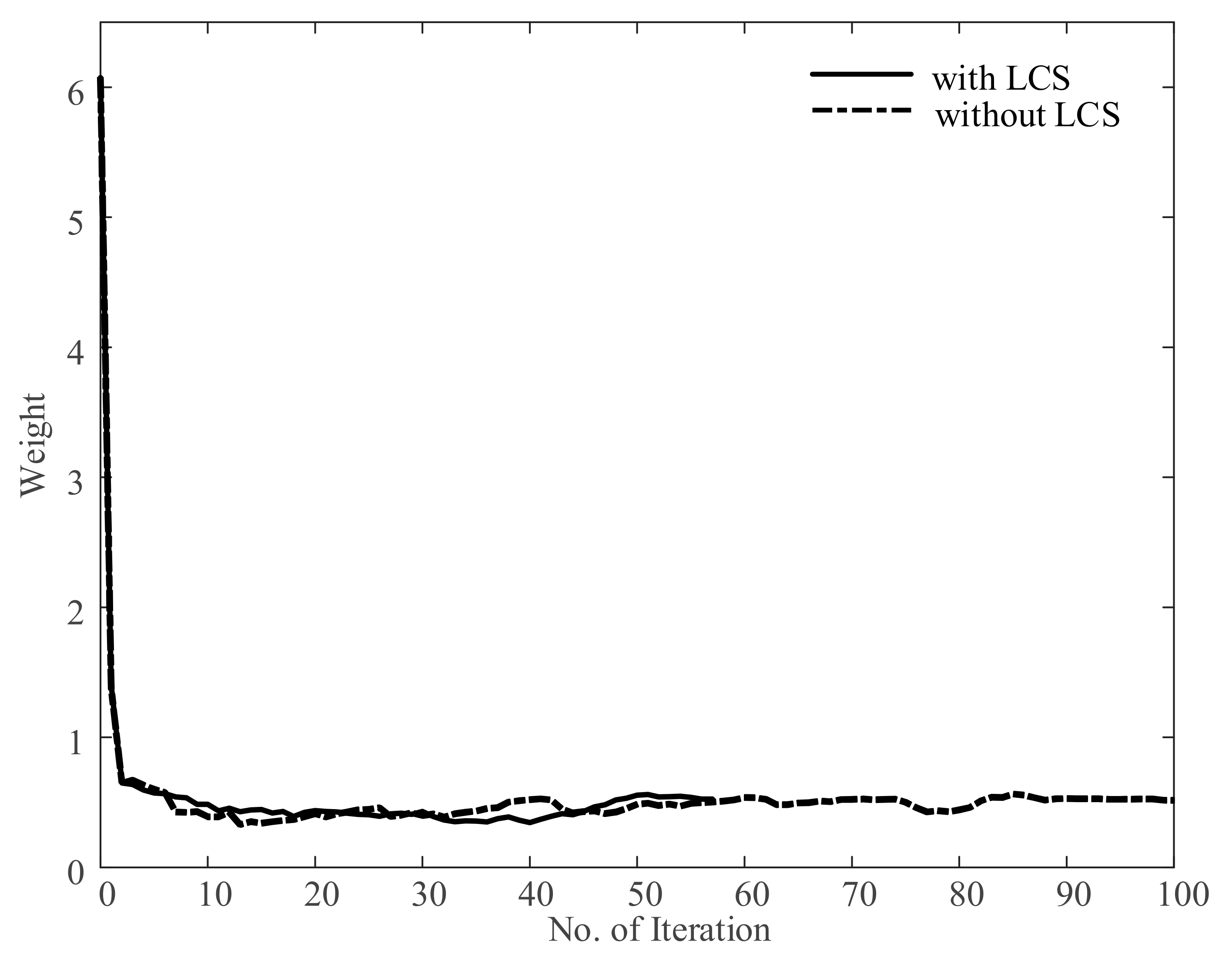

4.2. Example 2: A Cantilever Truss

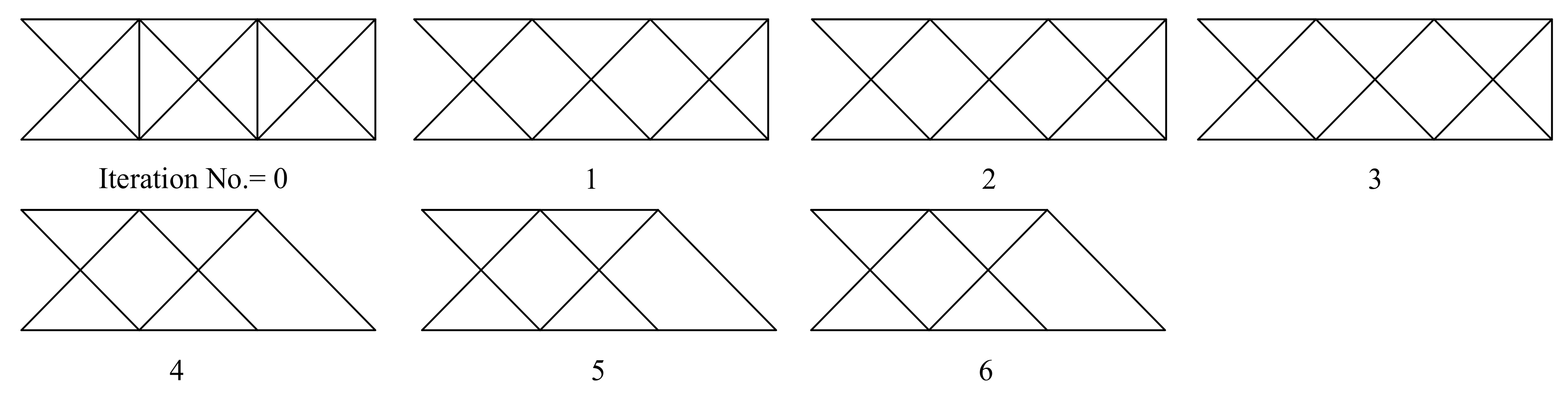

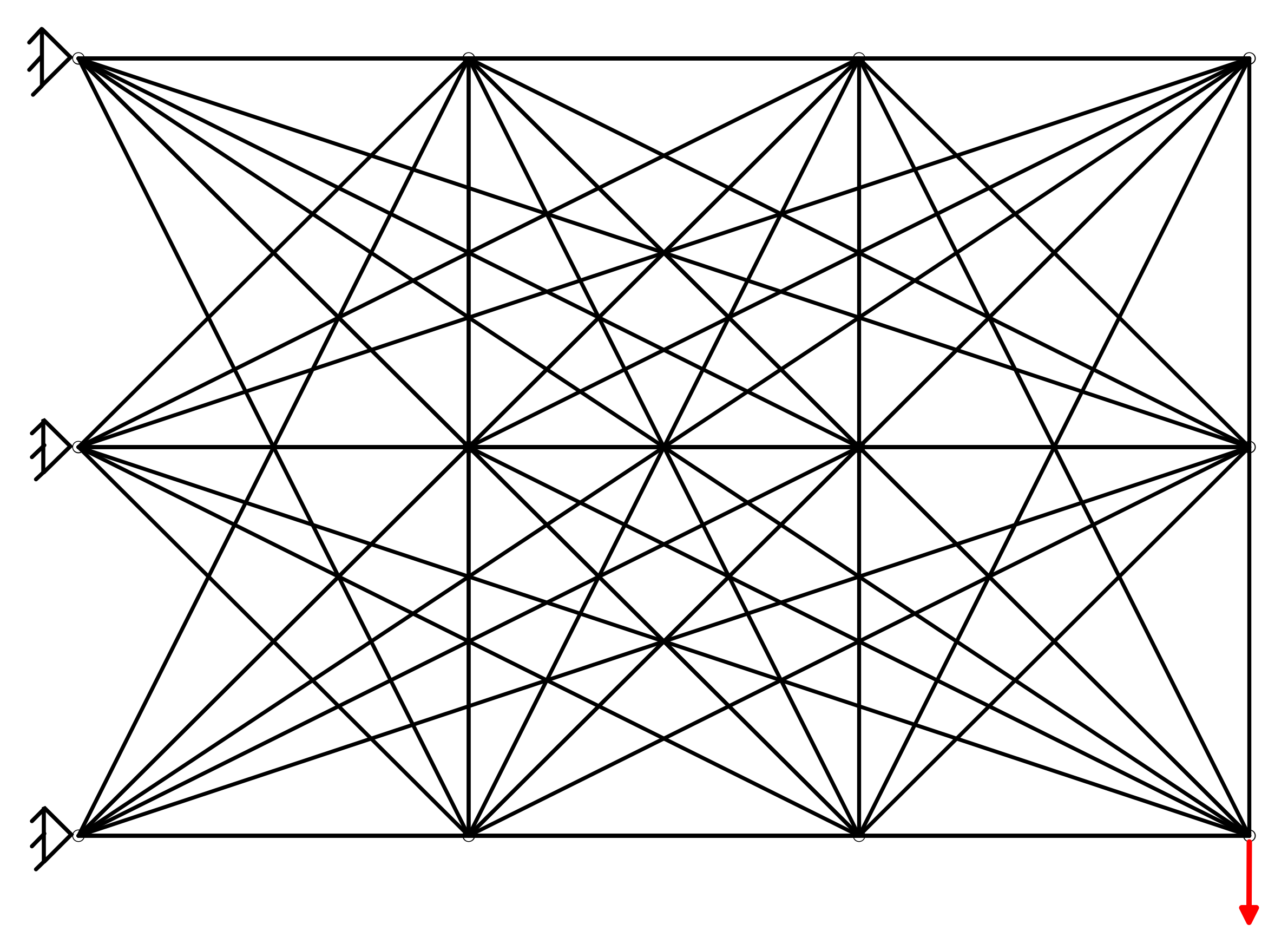

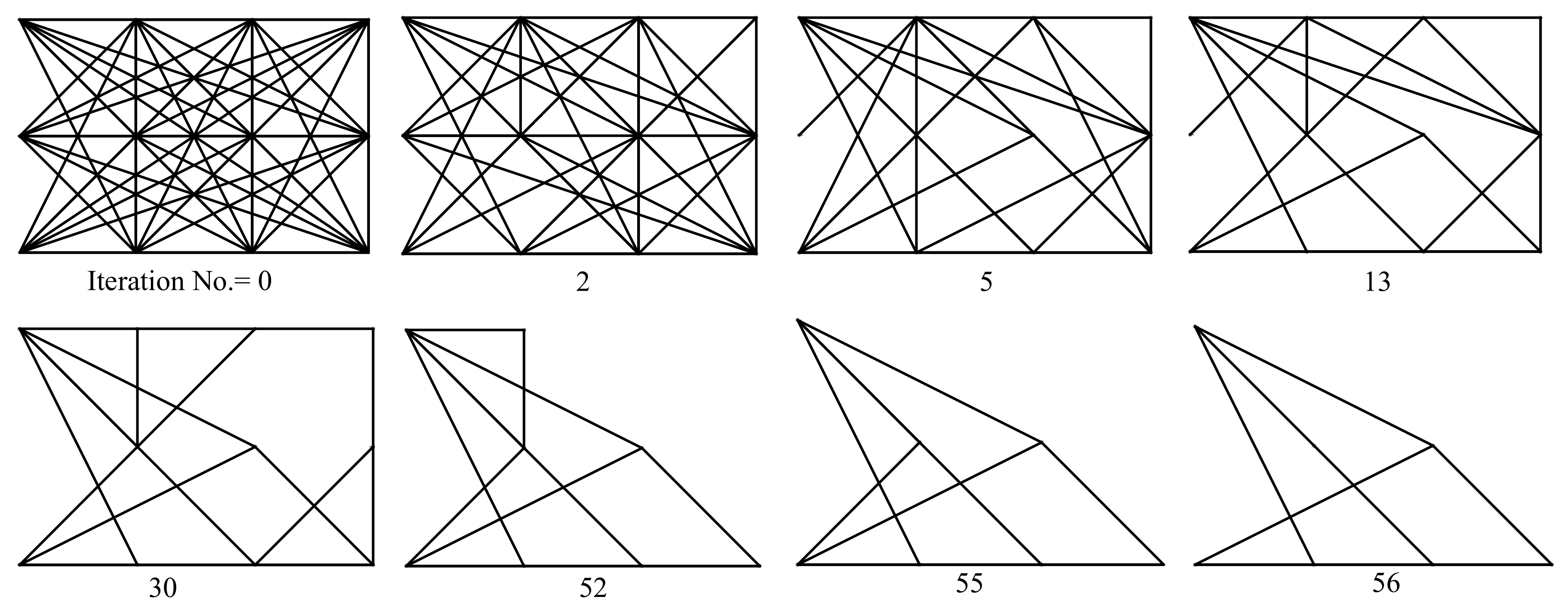

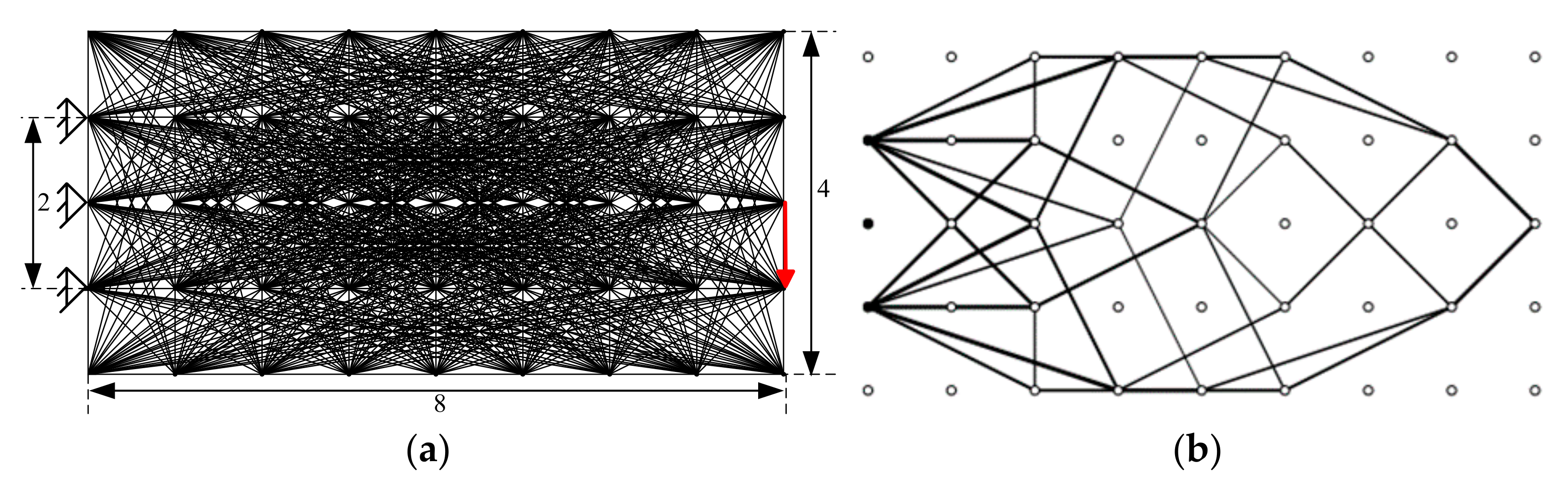

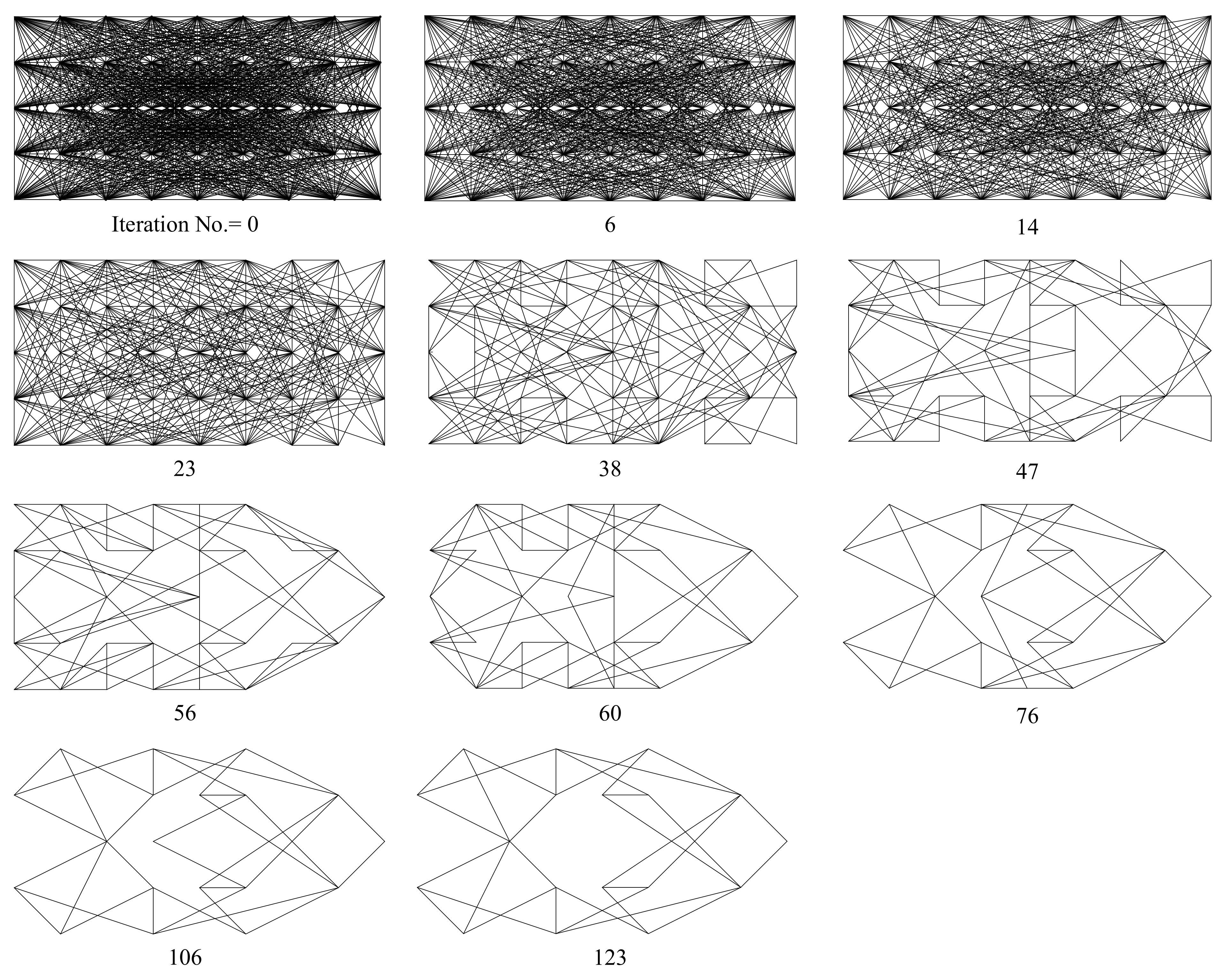

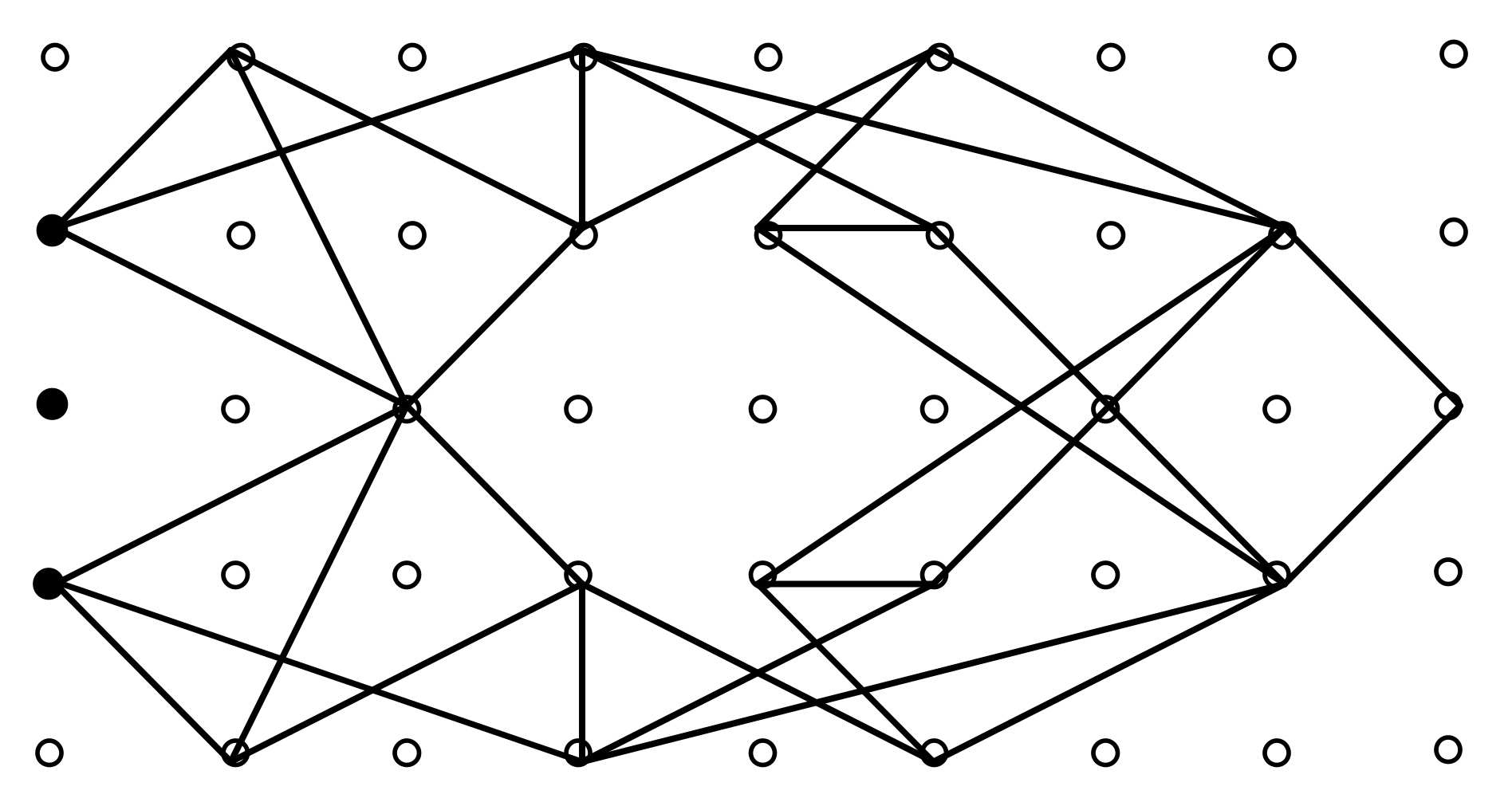

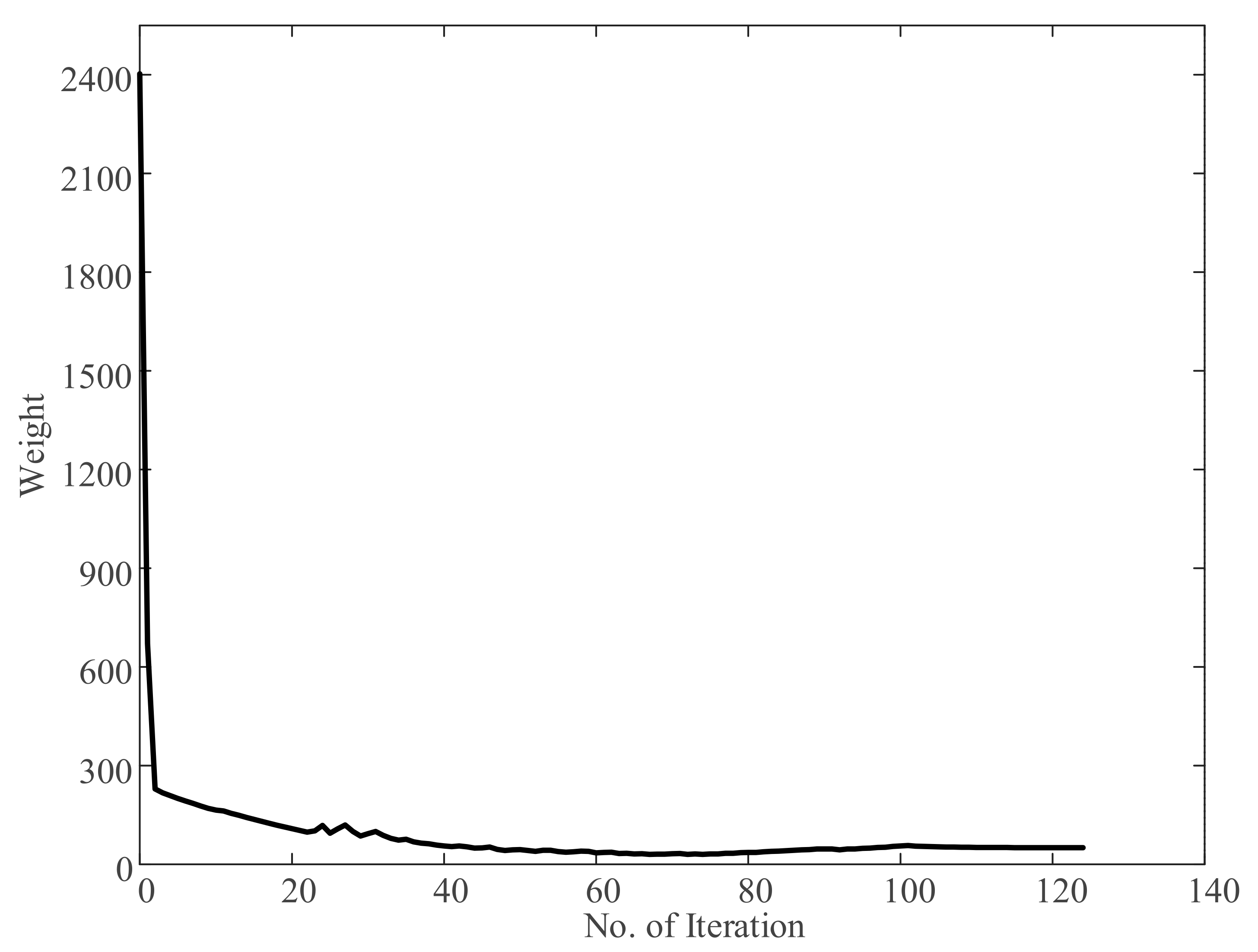

4.3. Example 3: A Michell Truss

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, G.; Gao, B.; Xu, M.; Feng, B. Active Suspension Method and Active Vibration Control of a Hoop Truss Structure. AIAA J. 2018, 56, 1689–1695. [Google Scholar] [CrossRef]

- Tian, D.; Jin, L.; Liu, R.; Liu, Z.; Fan, X. Research on the Topological Characteristics of Truss Structure for Large Space Modular Deployable Truss Antenna. In Proceedings of the 2020 IEEE 3rd International Conference on Electronics Technology (ICET), Chengdu, China, 8–12 May 2020. [Google Scholar]

- Zuo, W.; Saitou, K. Multi-material topology optimization using ordered SIMP interpolation. Struct. Multidiscip. Optim. 2017, 5, 477–491. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.M.; Guo, D.M. A level set method for structural topology optimization. Comput. Meth. Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Deng, S.G.; Krishnan, S. Stress Constrained Thermo-Elastic Topology Optimization with Varying Temperature Fields via Augmented Topological Sensitivity Based Level-Set. Struct. Multi-Discip. Optim. 2017, 56, 1–19. [Google Scholar] [CrossRef]

- Xie, Y.M.; Steven, G.P. A simple evolutionary procedure for structural optimization. Comput. Struct. 1993, 49, 885–896. [Google Scholar] [CrossRef]

- Yang, X.Y.; Xie, Y.M.; Steven, G.P.; Querin, O.M. Bidirectional Evolutionary Method for Stiffness Optimization. AIAA J. 1999, 37, 1483–14889. [Google Scholar] [CrossRef]

- Ajit, P.; David, B.; Ian, A.; Ricky, W.; Richard, H. Hierarchical remeshing strategies with mesh mapping for topology optimization. Int. J. Numer. Methods Eng. 2017, 111, 676–700. [Google Scholar]

- Fu, Y.-F.; Rolfe, B.; Chiu, L.N.; Wang, Y.; Huang, X.; Ghabraie, K. SEMDOT: Smooth-edged material distribution for optimizing topology algorithm. Adv. Eng. Softw. 2020, 150, 102921. [Google Scholar] [CrossRef]

- Huang, X. On smooth or 0/1 designs of the fixed-mesh element-based topology optimization. Adv. Eng. Softw. 2021, 151, 102942. [Google Scholar] [CrossRef]

- Dorn, W. Automatic design of optimal structures. J. De Mec. 1964, 3, 25–52. [Google Scholar]

- Erbatur, F.; Al-Hussainy, M.M. Optimum design of frames. Comput. Struct. 1992, 45, 887–891. [Google Scholar] [CrossRef]

- Tabak, E.I.; Wright, P.M. Optimality criteria method for building frames. J. Struct. Div. ASCE 1981, 107, 1327–1342. [Google Scholar] [CrossRef]

- Saka, M.P. Optimum design of pin-jointed steel structures with practical applications. J. Struct. Eng. ASCE 1990, 116, 2599–2620. [Google Scholar] [CrossRef]

- Hajela, P.; Lee, E. Genetic algorithms in truss topological optimization. Int. J. Solids Struct. 1995, 32, 3341–3357. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Yang, X.-S.; Alavi, A.H. Cuckoo search algorithm: A metaheuristic approach to solve structural optimization problems. Eng. Comput. 2013, 29, 17–35. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Hasançebi, O.; Kazemzadeh Azad, S. Adaptive dimensional search: A new metaheuristic algorithm for discrete truss sizing optimization. Comput. Struct. 2015, 154, 1–16. [Google Scholar] [CrossRef]

- Eusuff, M.; Lansey, K.; Pasha, F. Shuffled frog-leaping algorithm: A memetic meta-heuristic for discrete optimization. Eng. Optim. 2006, 38, 129–154. [Google Scholar] [CrossRef]

- Sokó, T. Topology optimization of large-scale trusses using ground structure approach with selective subsets of active bars. In Proceedings of the 19th International Conference on Computer Methods in Mechanics, Warsaw, Poland, 9–12 May 2011. [Google Scholar]

- Degertekin, S.O.; Minooei, M.; Santoro, L.; Trentadue, B.; Lamberti, L. Large-Scale Truss-Sizing Optimization with Enhanced Hybrid HS Algorithm. Appl. Sci. 2021, 11, 3270. [Google Scholar] [CrossRef]

- Azad, S.K.; Aminbakhsh, S. High-dimensional optimization of large-scale steel truss structures using guided stochastic search. Structures 2021, 33, 1439–1456. [Google Scholar] [CrossRef]

- Kaveh, A. Optimum Design of Large-Scale Truss Towers Using Cascade Optimization; Springer International Publishing: Cham, Switzerland, 2017; pp. 281–295. [Google Scholar]

- Dong, Y.; Huang, H. Truss topology optimization by using multipoint approximation and GA. Chin. J. Comput. Mech. 2004, 21, 746–751. [Google Scholar]

- Chen, S.Y.; Shui, X.F.; Huang, H. Improved genetic algorithm with two-level approximation using shape sensitivities for truss layout optimization. Struct. Multidiscip. Optim. 2016, 55, 1–18. [Google Scholar] [CrossRef]

- Huang, H.; An, H.; Ma, H.; Chen, S. An Engineering Method for Complex Structural Optimization Involving Both Size and Topology Design Variables. Int. J. Numer. Methods Eng. 2019, 117, 291–315. [Google Scholar] [CrossRef]

- Huang, H.; Ke, W.; Xia, R.W. Numerical accuracy of the multi-point approximation and its application in structural synthesis. In Proceedings of the 7th AIAA/USAF/NASA/ISSMO Symposium on Multidisciplinary Analysis and Optimization, St. Louis, MO, USA, 2–4 September 1998; Available online: https://arc.aiaa.org/doi/pdfplus/10.2514/6.1998-4962 (accessed on 22 August 2012).

- Huang, H.; Wang, Y.; Lian, H. Comparisons of several multi-point approximation methods used in structural topology optimization. In Proceedings of the Chinese Conference on Computational Mechanics, Beijing, China, 5–6 December 2003; Volume 1. [Google Scholar]

- Tang, W.; Tong, L.; Gu, Y. Improved genetic algorithm for design optimization of truss structures with sizing, shape and topology variables. Int. J. Numer. Methods Eng. 2005, 62, 1737–1762. [Google Scholar] [CrossRef]

- Miguel, L.F.F.; Lopez, R.H.; Miguel, L.F.F. Multimodal size, shape, and topology optimisation of truss structures using the Firefly algorithm. Adv. Eng. Softw. 2013, 56, 23–37. [Google Scholar] [CrossRef]

- Achtziger, W.; Stolpe, M. Global optimization of truss topology with discrete bar areas—Part II: Implementation and numerical results. Comput. Optim. Appl. 2009, 44, 315–341. [Google Scholar] [CrossRef]

- Achtziger, W.; Stolpe, M. Global optimization of truss topology with discrete bar areas—Part I: Theory of relaxed problems. Comput. Optim. Appl. 2008, 40, 247–280. [Google Scholar] [CrossRef]

| Design Domain | Cross-Sectional Type | Topology Variables | Size Variables |

|---|---|---|---|

| Truss | BAR | αi (i = 1, 2, 3, 4, 5, 6, 7) | xi (i = 1, 2, 3, 4, 5, 6, 7) |

| Design Variables | Data from [29] | Data from [30] | Present |

|---|---|---|---|

| A1 | 1.081 | 0.954 | 1.60 |

| A2 | 0.539 | 0.539 | 1.59 |

| A3 | 0 | 0.141 | 0 |

| A4 | 1.081 | 0.954 | 2.39 |

| A5 | 0.954 | 0.539 | 0.80 |

| A6 | 0.440 | 0.287 | 0.79 |

| A7 | 0 | 0.141 | 0 |

| A8 | 0.141 | 0 | 0 |

| A9 | 0 | 3.813 | 0 |

| A10 | 0.270 | 0.440 | 1.13 |

| A11 | 0.270 | 0.440 | 0.20 |

| A12 | 0.539 | 0.220 | 0.20 |

| A13 | 0.141 | 0.220 | 1.13 |

| A14 | 0.440 | 0.347 | 1.13 |

| A15 | 0 | 0.141 | 0 |

| Iteration number | 7 | ||

| Labeled variables | 5 | ||

| Critical constraint | −0.00088 | −0.0649 | 0.000 |

| Weight (lb.) | 77.84 | 74.33 | 75.376 |

| Percentage difference (%) | 5.57 | 0.23 | — |

| Structural analysis | 8000 | 8000 | 15 |

| Percentage difference (%) | 0.19 | 0.19 | — |

| With LCS | Without LCS (No Convergence) | |

|---|---|---|

| Iteration number | 56 | 100 |

| Labeled variables | 51 | / |

| Critical constraint | 0.000 | 5.492 × 10−2 |

| Weight | 0.525 | 0.517 |

| Structural analysis | 66 | 117 |

| NO. | Area LCS/No LCS | No. | Area LCS/No LCS | No. | Area LCS/No LCS | |||

|---|---|---|---|---|---|---|---|---|

| 1 | 0.1830 | 0.4293 | 15 | 0 | 0.1 | 43 | 0 | 1.0140 |

| 2 | 0 | 0.1 | 16–18 | 0 | 0 | 44–47 | 0 | 0 |

| 3 | 0.4113 | 0.2727 | 19 | 0.1 | 0 | 48 | 0.1 | 1.3853 |

| 4 | 0.5575 | 0.3942 | 20–26 | 0 | 0 | 49 | 1.4154 | 0.1386 |

| 5 | 0.4056 | 0.1349 | 27–28 | 0 | 0.1 | 50–51 | 0 | 0 |

| 6 | 0 | 0.1 | 29–35 | 0 | 0 | 52 | 0 | 0.1 |

| 7 | 0 | 0 | 36 | 0 | 0.1 | 53 | 0 | 0 |

| 8 | 0 | 0.1 | 37 | 0 | 0.4385 | 54 | 1.6756 | 0 |

| 9–11 | 0 | 0 | 38 | 0 | 0.1 | 55–56 | 0 | 0.1 |

| 12 | 0 | 0.1470 | 39 | 0 | 0 | 57–61 | 0 | 0 |

| 13 | 0 | 0 | 40 | 0.4103 | 0 | 62 | 0 | 0.1026 |

| 14 | 0.1826 | 0.1860 | 41–42 | 0 | 0 | 63 | 0 | 0.1414 |

| Literature | Present | |

|---|---|---|

| Iteration number | 124 | |

| Labeled variables | / | 314 |

| Critical constraint | 0.000 | 0.000 |

| Weight | / | 50.522 |

| Structural analysis | 10,783 | 139 |

| Percentage difference (%) | 1.29 | - |

| No. | Area | No. | Area | No. | Area | No. | Area |

|---|---|---|---|---|---|---|---|

| 1–12 | 0 | 56 | 0.9887 | 96 | 0.6406 | 171 | 0.1 |

| 13 | 0.2199 | 57–60 | 0 | 97–128 | 0 | 172–238 | 0 |

| 14–19 | 0 | 61 | 0.3213 | 129 | 1.4555 | 239 | 2.847 |

| 20 | 0.9186 | 62–63 | 0 | 130 | 0 | 240–317 | 0 |

| 21–35 | 0 | 64 | 0.3215 | 131 | 0.5037 | 318 | 0.1578 |

| 36 | 0.4054 | 65 | 0.7449 | 132 | 0 | 319–331 | 0 |

| 37–43 | 0 | 66–88 | 0 | 133 | 0.957 | ||

| 44 | 0.1221 | 89 | 0.6388 | 134–169 | 0 | ||

| 45–55 | 0 | 90–95 | 0 | 170 | 0.1438 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, T.; Chen, S.; Huang, H.; Han, C.; Dai, Z.; Yang, Z. Large-Scale Truss Topology and Sizing Optimization by an Improved Genetic Algorithm with Multipoint Approximation. Appl. Sci. 2022, 12, 407. https://doi.org/10.3390/app12010407

Dong T, Chen S, Huang H, Han C, Dai Z, Yang Z. Large-Scale Truss Topology and Sizing Optimization by an Improved Genetic Algorithm with Multipoint Approximation. Applied Sciences. 2022; 12(1):407. https://doi.org/10.3390/app12010407

Chicago/Turabian StyleDong, Tianshan, Shenyan Chen, Hai Huang, Chao Han, Ziqi Dai, and Zihan Yang. 2022. "Large-Scale Truss Topology and Sizing Optimization by an Improved Genetic Algorithm with Multipoint Approximation" Applied Sciences 12, no. 1: 407. https://doi.org/10.3390/app12010407

APA StyleDong, T., Chen, S., Huang, H., Han, C., Dai, Z., & Yang, Z. (2022). Large-Scale Truss Topology and Sizing Optimization by an Improved Genetic Algorithm with Multipoint Approximation. Applied Sciences, 12(1), 407. https://doi.org/10.3390/app12010407