1. Introduction

Geotextiles have been utilized as filters in numerous geotechnical and environmental protection applications, such as drainage trenches and sludge dewatering [

1,

2,

3]. To assure effective filtration performance, the filter design involves retention capability and the anti-clogging function of geotextiles. The percent open area (POA) and pore-opening size are commonly used as pore structure parameters defining filter design criteria of woven geotextiles [

4,

5,

6]. In addition, the POA is usually dependent on the pore-opening size O

95 [

5,

7]. Conventional standards suggest that apparent opening size (AOS or O

95) and filtration opening size (FOS or O

98) are characteristic pores for geotextile filter design [

8,

9,

10,

11]. O

95 (or O

98) describes that pore diameter for which 95% (or 98%) of the remaining pore diameters are smaller, obtained in sieving tests, in bubble point tests, or tests using image analysis [

12]. The specific filtration opening size O

95 ignores that pore-opening sizes vary at a wide range in practice. As manufactured products, woven slit-film geotextiles show different frequency distributions for various pore sizes. Consequently, uncertainties still exist regarding the prediction about the influence of different characteristic pore sizes on the filtration performance of woven geotextiles.

A series of tests carried out by Gendrin suggested that the numbers of soil particles passing through two types of geotextiles were quite different despite the same filtration opening size [

13]. Compared with a specific pore-opening size value, the pore-size distribution (PSD) curve indicated various sizes of pore diameters, including O

98, O

50, O

10, etc., [

14]. Considering various characteristic pore-opening sizes, Palmeira et al. indicated smaller pore-opening sizes (O

50, O

30, and O

10) of nonwoven geotextiles were less sensitive to tensile strain than larger characteristic pore-opening sizes (O

95 and O

98) [

12]. Aydilek et al. determined two characteristic pore-opening sizes, O

95 and O

50, derived from the pore-size distribution of unstrained woven geotextiles [

6]. There are limited studies carried out in predicting various characteristic pore sizes of woven slit-film geotextiles.

In the practice of filtration, geotextiles are typically subjected to tensile strains [

15]. Therefore, many laboratory tests have been conducted to investigate the filtration behaviors of woven and nonwoven geotextiles under various tensile loads [

12,

16,

17]. Wu et al. and Tang et al. suggested that O

95 and O

98 increased linearly with notable tensile strain for woven slit-film geotextiles [

18,

19]. However, problems exist with the currently available methods for determining characteristic pore sizes at every 3% or 5% tensile strain. The woven geotextile tubes suggested an insignificant tensile strain of less than 5%, and the tensile deformation increases slowly with time [

20,

21]. The low tensile deformation of geotextiles has gained greater importance in engineering practice and laboratory experiments.

Characteristic pore-opening sizes of woven geotextiles are generally determined by the direct method of image analysis [

5] and indirect methods, including dry sieving test [

8], wet sieving test [

10], and hydrodynamic sieving test [

22]. The image analysis is a rapid, accurate, and less user-dependent method in determining POA and pore-opening size for woven slit-film geotextiles subjected to tensile strain even for low tensile deformation [

5,

18,

23].

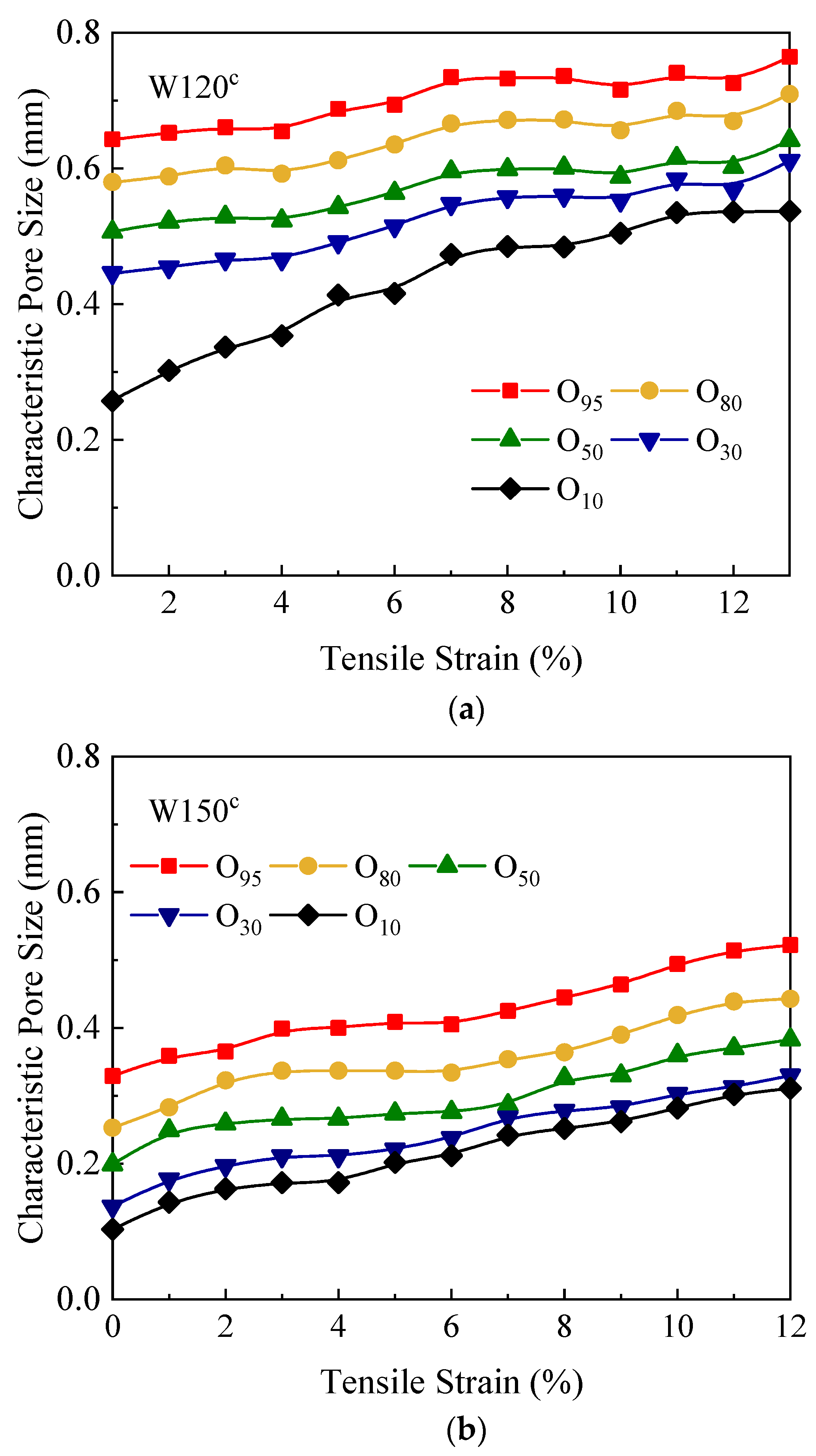

The laboratory tests in this paper adopt five woven geotextiles from three manufacturers to assure the effective prediction about pore-opening sizes with uniaxial tensile strain. The image analysis method is used to determine the POA and pore size. The large pore size (i.e., O95), medium pore size (i.e., O50), and small pore size (i.e., O10) obtained composite the pore size-frequency distribution of woven geotextiles. The variations of different characteristic pore sizes, O95, O80, O50, O30, and O10 under each 1% tensile strain, are recorded as uniaxial tensile strain increases. Three representative specific pore diameters O95s, O50s, and O10s are monitored with uniaxial tensile strain. Five comparable pore sizes with each specific pore size (i.e., pore sizes ranging from O93s to O97s with O95s) are monitored when uniaxial tensile strain increases. Using MATLAB code, the colorful pore size distribution diagrams demonstrate the variation in specific pore sizes of the specimen in a visual way. The pore-opening sizes are observed to agree well with the bell-shaped Gaussian distribution. The results exhibit an accurate prediction of the variations in pore diameters with uniaxial tensile strain for all tested woven geotextiles.

4. Monitoring of Variation in Specific Pore Sizes

4.1. Monitoring of Specific Characteristic Pore Sizes

Figure 6 shows that fifteen specific unstrained pore diameters are selected and their variation behaviors are monitored with uniaxial tensile strain for geotextile W120

c. In order to specify the deformation of large pore sizes, medium pore sizes, and small pore sizes, the variations in three specific characteristic pore diameters O

95s, O

50s, and O

10s are recorded under each uniaxial tensile strain of 1%. Five comparable pore sizes with each specific pore size (i.e., pore sizes ranging from O

93s to O

97s with O

95s) are monitored as uniaxial tensile strain increases.

The large specific unstrained pore sizes (‘L’ Size) are represented by five selected unstrained pore sizes O

93s, O

94s, O

95s, O

96s, and O

97s, as shown in

Figure 6. These specific unstrained pore-opening sizes ranging from 0.618 mm to 0.647 mm are monitored with uniaxial tensile strain. As tensile strain increases to 6%, the selected pore size O

95s increases by 5.24%. Then O

95s increases by 15.84% with uniaxial tensile strain ranging from 6% to 14%. The results suggest a good consistency with the variation of characteristic pore size O

95s and the variation of the other specific large pore size O

93s, O

94s, O

96s, and O

97s, respectively, for geotextile W120

c.

The grey shaded area illustrates a possible range for monitored medium specific pore sizes (‘M’ Size) ranging from O30s to O70s as tensile strain increases to 14%. The possible lower bound of ‘M’ Size varies from 0.434 mm to 0.575 mm and the upper bound varies from 0.543 mm to 0.685 mm. Five representative unstrained pore diameters O48s, O49s, O50s, O51s, and O52s have a narrow range from 0.486 mm to 0.500 mm. The monitored characteristic pore size O50s increases by 6.67% with tensile strain increasing to 6%. Then O50s increases by 18.94% with uniaxial tensile strain ranging from 6% to 14%. There is a similar gentle variation trend between large pore size and medium pore size under the low tensile deformation. The results suggest a good consistency with the variation of medium characteristic pore size O50s and the variation of other four specific pore sizes O48s, O49s, O51s, and O52s for geotextile W120c.

Figure 6 shows a relatively wide range of small specific unstrained pore sizes (‘S’ Size) O

8s, O

9s, O

10s, O

11s, and O

12s ranging from 0.173 mm to 0.270 mm. The monitored pore size O

10s increases by 179.00% with a steady growth rate during the whole tensioning, has a good consistency with the variations of specific pore sizes O

8s and O

12s. The specific pore sizes O

9s and O

11s have a slower growth rate. A slight deviation exists among the variations of five small specific pore sizes, particularly in the late period of uniaxial tensile strain.

The pore diameters for both ‘L’ Size and ‘M’ Size appear to show minimal changes in the strain ranges of 3–7%, 3–7%, 4–8%, 3–6%, and 4–8% for geotextile W120a, W120b, W120c, W150c, and W250c, respectively. The reason is that geotextile pore diameters are likely to be deformed by the displacement of woven strips considering the complexity of their interface forces during the early and medium tensioning stage. Therefore, the initially large and medium specific pore sizes may have a gentle variation behavior followed by a moderate growth rate, whereas a previously smaller pore may become the new medium one with tensile strain. The growth rate of medium specific pore size is higher than that of large specific pore size. The small specific pore sizes have a steady large growth rate under the uniaxial tensile strain. However, the large specific pore sizes ranging from O93s to O97s are observed to be always larger than medium specific pore sizes ranging from O48s to O52s of geotextile W120c. Part of specific small pore sizes get closer to the medium pore sizes under the late period of tensile strain, but unlikely exceed the medium pore sizes during tensioning. Therefore, the medium pore sizes are likely to have a larger distribution frequency with the uniaxial tensile strain. The variation behaviors of geotextile W120c indicate less difference compared to the other four tested woven geotextiles.

4.2. Monitoring of Distribution of Pore Sizes

Figure 7 demonstrates a random distribution of various pore sizes within the illuminated region of unstrained geotextile W120

c. The specific large pore sizes ranging from O

80s to O

100s are marked with red squares. The yellow circles and blue diamonds mark the specific medium pore sizes ranging from O

40s to O

60s and the specific small pore sizes ranging from O

0s to O

20s. For the selected region of geotextile W120

c, the large pore sizes are identified to be mainly located on the outer sides, the small pore sizes are located inside the district and the medium pore sizes are located randomly in the selected region.

The MATLAB code contributes to monitoring pore locations and displaying the visual distributions of various pore-opening sizes.

Figure 8 provides the visual distribution of pore sizes along the warp direction and weft direction for the selected region of geotextile W120

c shown in

Figure 7. Colored dots along the weft direction and the warp direction indicate the arrangement of pores. Ten columns and twenty rows of dots are arranged in sequence in the weft direction and the warp direction, respectively. Each colored dot area demonstrates the corresponding pore-opening size. Therefore, the larger dot area illustrates a larger pore-opening size of geotextile W120

c. Different pore-opening sizes are demonstrated by dots with contrasting colors. The dark red colored dot indicates the largest pore size of geotextile W120

c, while the smallest pore size is described with the dark blue colored dot. The transition of contrasting colors indicates the various pore sizes ranging from 0 to 0.8 mm.

To verify the deformation of various pore sizes with detailed distribution,

Figure 8 monitors all pore sizes within the selected region of geotextile W120

c under the tensile strain of 0, 3%, 6%, and 9%, respectively.

Figure 8a shows the visual distribution of unstrained pore sizes of geotextile W120

c. The contrasting colors and various dot areas indicate a wide range of unstrained pore size distribution. The red dots on the outer sides suggest the distribution of large pore sizes. The blue dots inside the selected region describe the small pore size distribution. The yellow dots demonstrate the medium pore sizes, which are randomly distributed in the selected region of the specimen. Three typical colored dots are selected to monitor the pore size deformation in a visual way with uniaxial tensile strain. The blue dot in the third column and the seventeenth row (C3R17) indicates a small specific unstrained pore diameter of 0.088 mm, as shown in

Figure 8a. The red dot in C10R8 illustrates a large specific unstrained pore size of 0.66 mm and the yellow dot in C5R13 shows a medium specific unstrained pore size of 0.39 mm.

The dark blue dot in C3R17 shown in

Figure 8a transforms to a light blue dot, as shown in

Figure 8b. The pore diameter in C3R17 increases to 0.27 mm as the uniaxial tensile strain increases to 3%. Then it becomes 0.39 mm with tensile strain increasing to 6%, as shown in

Figure 8c.

Figure 8d suggests the specific pore diameter is 0.46 mm as tensile strain increases to 9%.

Figure 8b–d illustrate that the yellow dot in C5R13 has pore diameters of 0.39 mm, 0.39 mm, and 0.45 mm under the tensile strain of 3%, 6%, and 9%, respectively. Both the unstrained small pore size in C3R17 and the unstrained medium pore size in C5R13 become medium pore sizes under the tensile strain of 9%.

Figure 8b–d indicate the red dot area in C10R8 increases with a slower growth rate, has pore sizes of 0.68 mm, 0.69 mm, and 0.73 mm under the tensile strain of 3%, 6%, and 9%, respectively. The red dot area maintains a large value until the tensile strain reaches 9%.

For the selected region of geotextile W120c, pore sizes on the outer sides appear to be larger than pore sizes located on the inner area of a specimen with uniaxial tensile strain. The small pore sizes inside the selected region have a significant increase in dot areas and an obvious transition between dot colors as uniaxial tensile strain increases. The large pore sizes and medium pore sizes indicate a relatively insignificant transition between dot colors and a slower increase in dot areas. The results exhibit a good consistency with pore size distribution variation of geotextile W120c and the pore size distribution variation of tested geotextiles W120a, W120b, W150c, and W250c.

5. Variation in Pore Size Distribution

The design pore size distribution encloses a scope of guided pore sizes for retention and permeability under tensioning. In order to identify the effect of different pore sizes on the pore size variation with uniaxial tensile strain, the pore size distribution frequency and pore size distribution scale are supposed to be specified. Therefore, the experimental pore sizes of geotextile W120

c are analyzed.

Figure 9 illustrates the distributions of unstrained pore sizes and pore sizes under the uniaxial tensile strain of 9%. The

x-axis indicates the values of pore-opening sizes. The left

y-axis illustrates the frequency distribution of pore sizes and the right

y-axis shows the cumulative frequency of pore-opening sizes. The

x values ranging from 0 to 1 mm are divided into 20 groups on average. The number of pore sizes in each group is counted to calculate the frequency distribution of geotextile W120

c.

As shown in

Figure 9, the light orange histogram and light orange curve show that unstrained pore-opening sizes have a Gaussian distribution which is a symmetrical bell-shaped curve. The dark orange curve demonstrates the cumulative frequency of unstrained pore-opening sizes. The characteristic pore-opening sizes O

950, O

500, and O

100, obtained by using image analysis, describe the pore diameters for which 95%, 50%, and 10% of the remaining pore diameters are smaller for unstrained W120

c. The characteristic pore size O

500 has the approximately largest distribution proportion among all pore-opening sizes of unstrained geotextile W120

c.

The dark green curve describes the cumulative frequency of pore-opening sizes which are subjected to the uniaxial tensile strain of 9%. The characteristic pore-opening sizes O

959%, O

509%, and O

109%, demonstrate the pore diameters for which 95%, 50%, and 10% of the remaining pore diameters are smaller for geotextile W120

c under the tensile strain of 9%.

Figure 9 illustrates the pore size-frequency distribution under the uniaxial tensile strain of 9% by the light green histogram and light green curve. The pore-opening sizes subjected to the tensile strain of 9%, exhibit a bell-shaped Gaussian distribution curve which is similar to the unstrained Gaussian distribution curve. For geotextile W120

c, the characteristic pore size O

509% has the largest distribution proportion among all pore sizes subjected to the uniaxial tensile strain of 9%. There is a good consistency with pore-opening size Gaussian distribution of woven geotextile W120

c and pore size distributions of the other tested geotextiles.

The bell-shaped Gaussian distribution curves of unstrained pore-opening sizes and strained pore-opening sizes of woven geotextiles can be expressed by the Equation (1):

where

y is the frequency of various pore-opening sizes;

y0 is the frequency distribution of pore sizes ranging from 0 to 0.1 mm;

x is the pore-opening size;

xc is the expected pore size value of the maximum frequency distribution;

A is the amplitude of the frequency distribution and

w is the variance of Gaussian distribution curves.

Table 2 suggests that uniaxial tensile strains can influence the Gaussian distribution curve parameters of geotextile W120

c.

xc is almost the same as the value of medium pore size of woven geotextiles, which has a larger value in the late period of tensile strain. However, the value of

xc has a slight fluctuation under the low tensile deformation. Meanwhile, the largest distribution frequency

y of

xc suggests that the medium pore size has the largest distribution proportion among all pore sizes. The distribution frequency of medium pore size increases as uniaxial tensile strain increases.

y0 is approximately equal to 0 under various tensile strains. The increasing

A value with uniaxial tensile strain indicates a larger maximum frequency of pore size Gaussian distribution.

w increases under the tensile strain ranging from 0 to 6% and then decreases under the tensile strain ranging from 6% to 12%. It indicates an increasing distribution scale of pore sizes under low tensile deformation followed by a decreasing distribution scale of pore sizes in the late period of tensile strain. The values of

R2 are approximately equal to 1, which indicates a good consistency with theoretical values and experimental results of woven geotextiles. In applications of geotextile filters, certain manufactured pore size distributions should be selected according to the guided Gaussian distribution curve parameters in expected tensile strain levels.