Experimental Investigation on the Behavior of Gravelly Sand Reinforced with Geogrid under Cyclic Loading

Abstract

:1. Introduction

2. Experiment

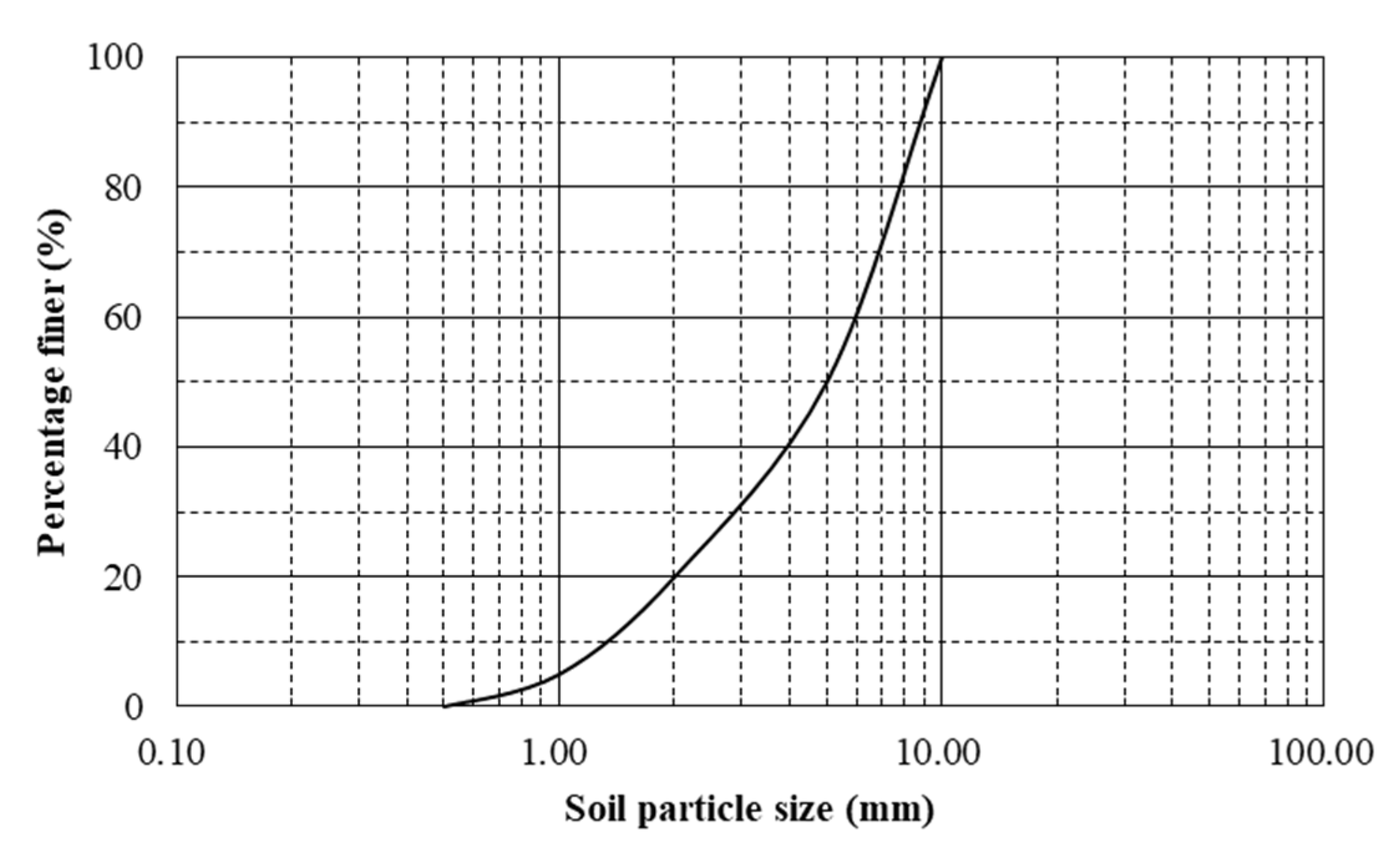

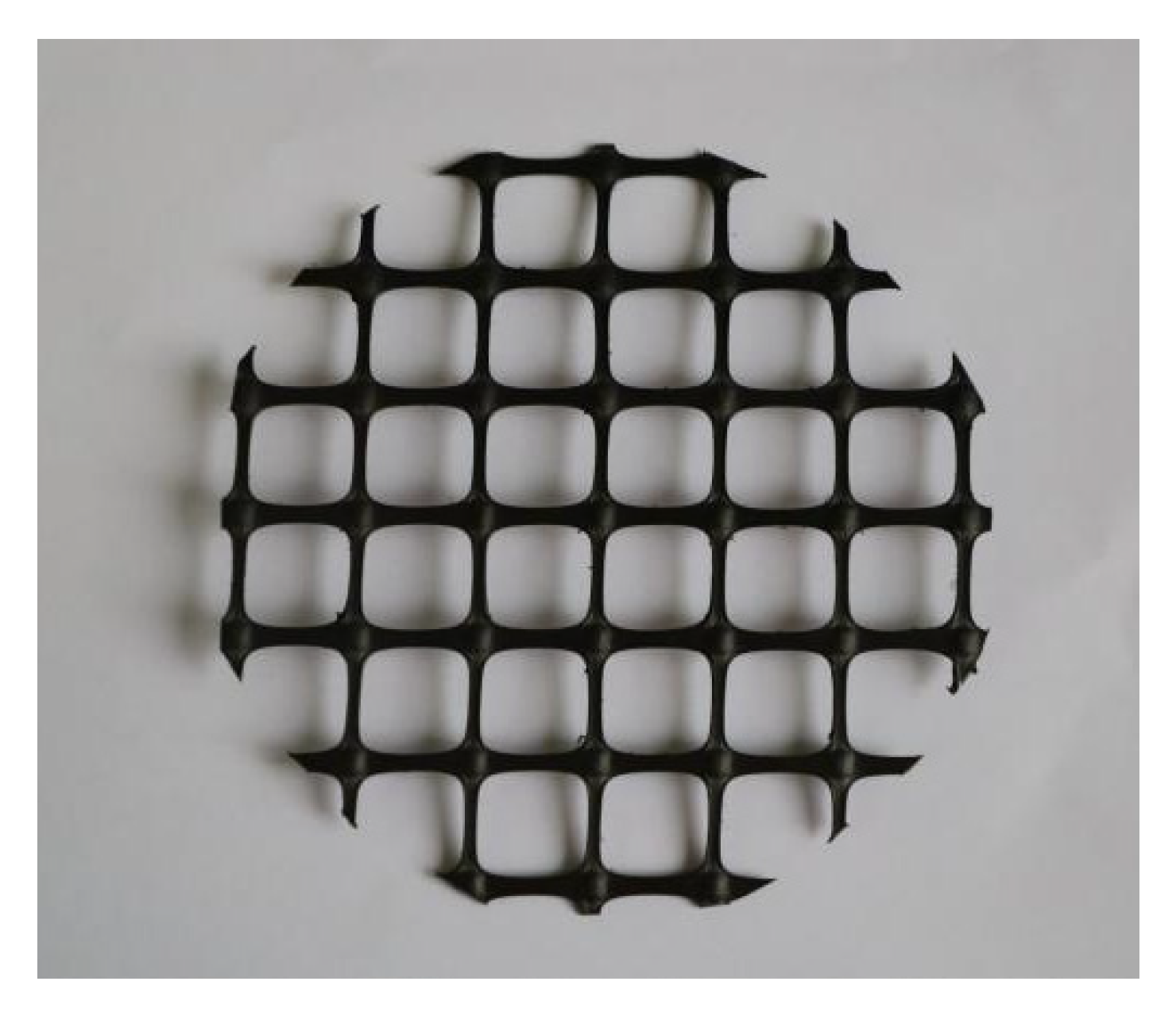

2.1. Materials Used in the Tests

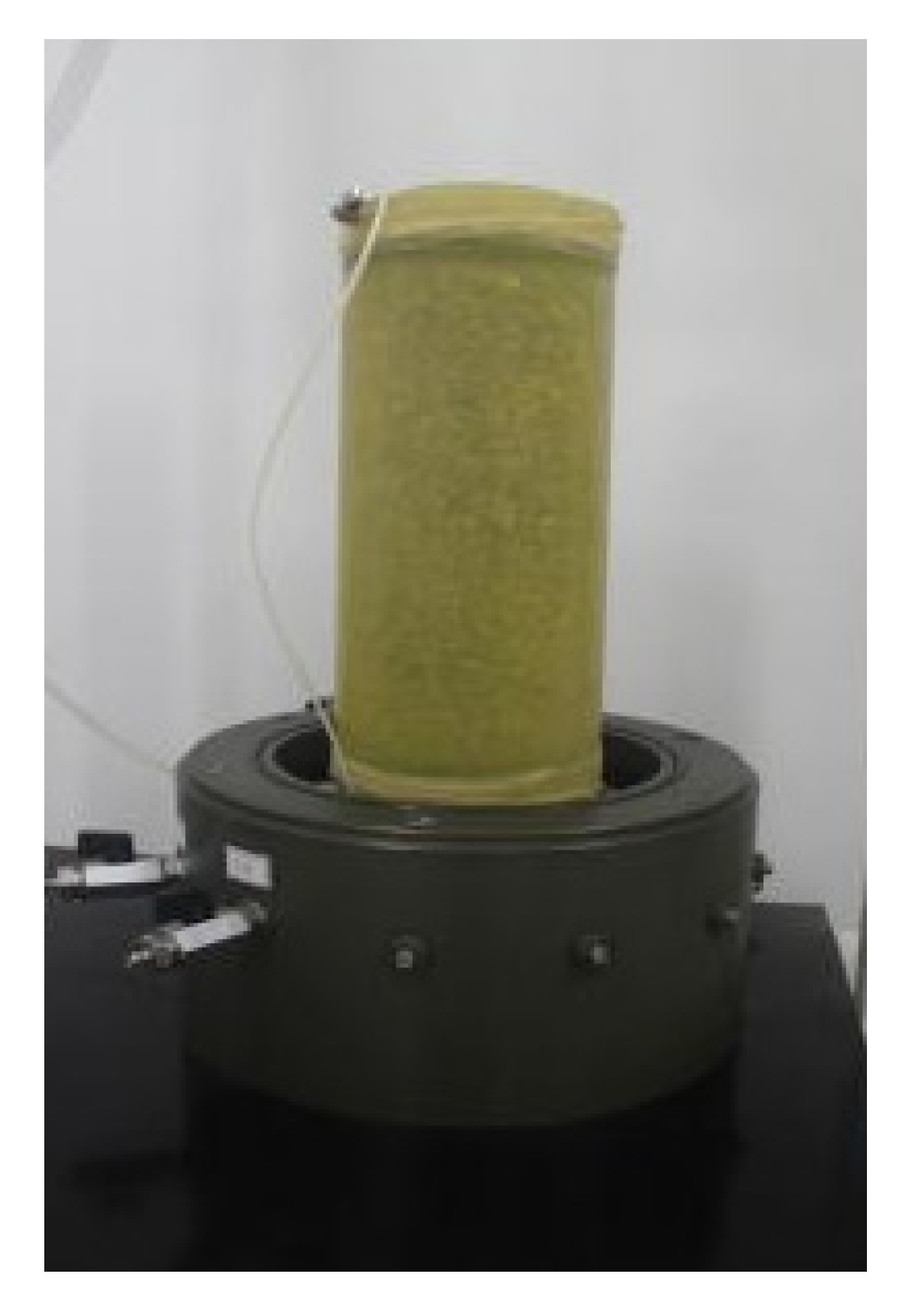

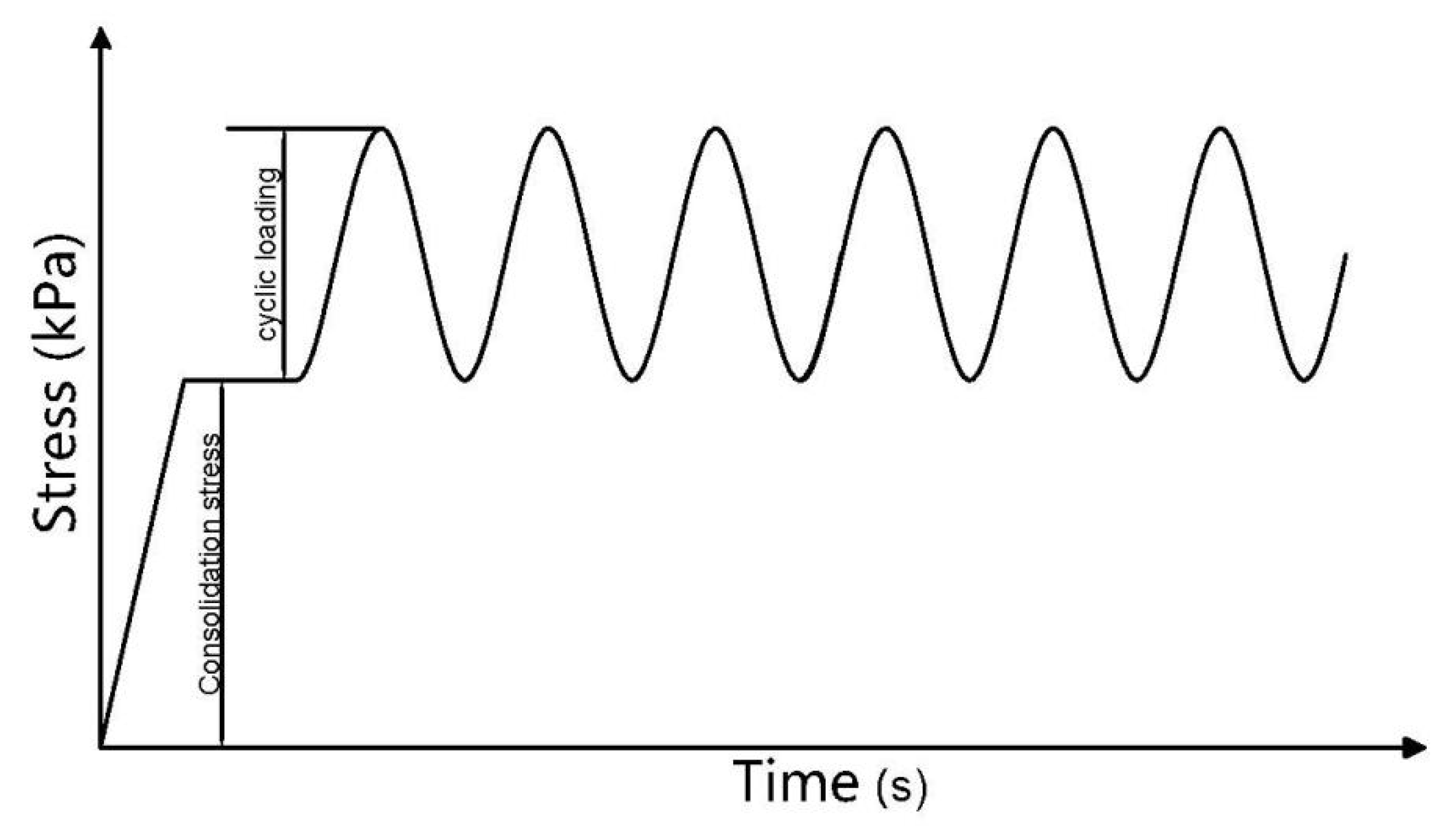

2.2. Experiment Setup

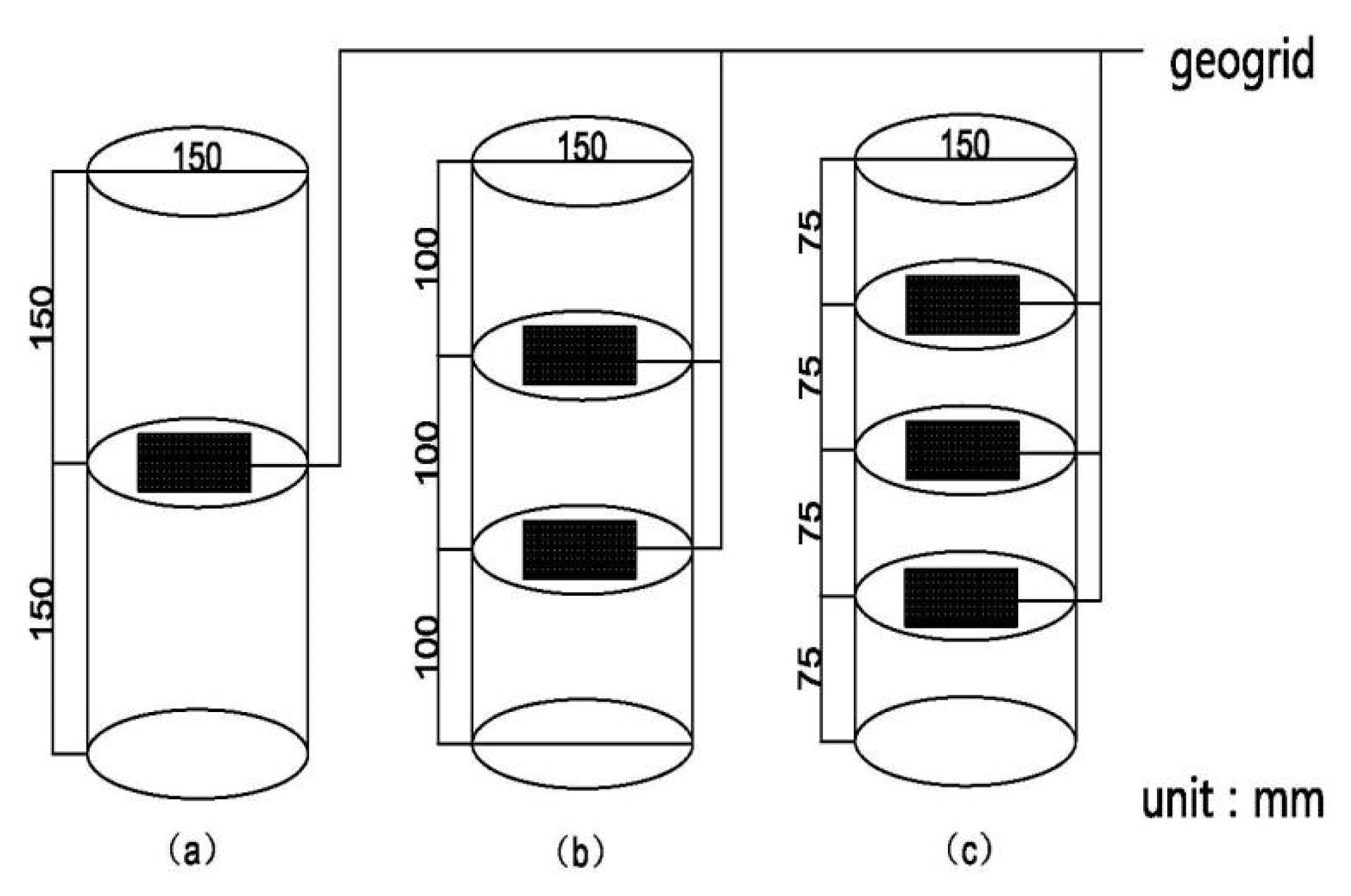

2.3. Experiment Scheme

3. Experiment Results and Analysis of Dynamic Characteristics

3.1. Analysis of Influence of Reinforced Layer on Dynamic Characteristics of Gravel Soil

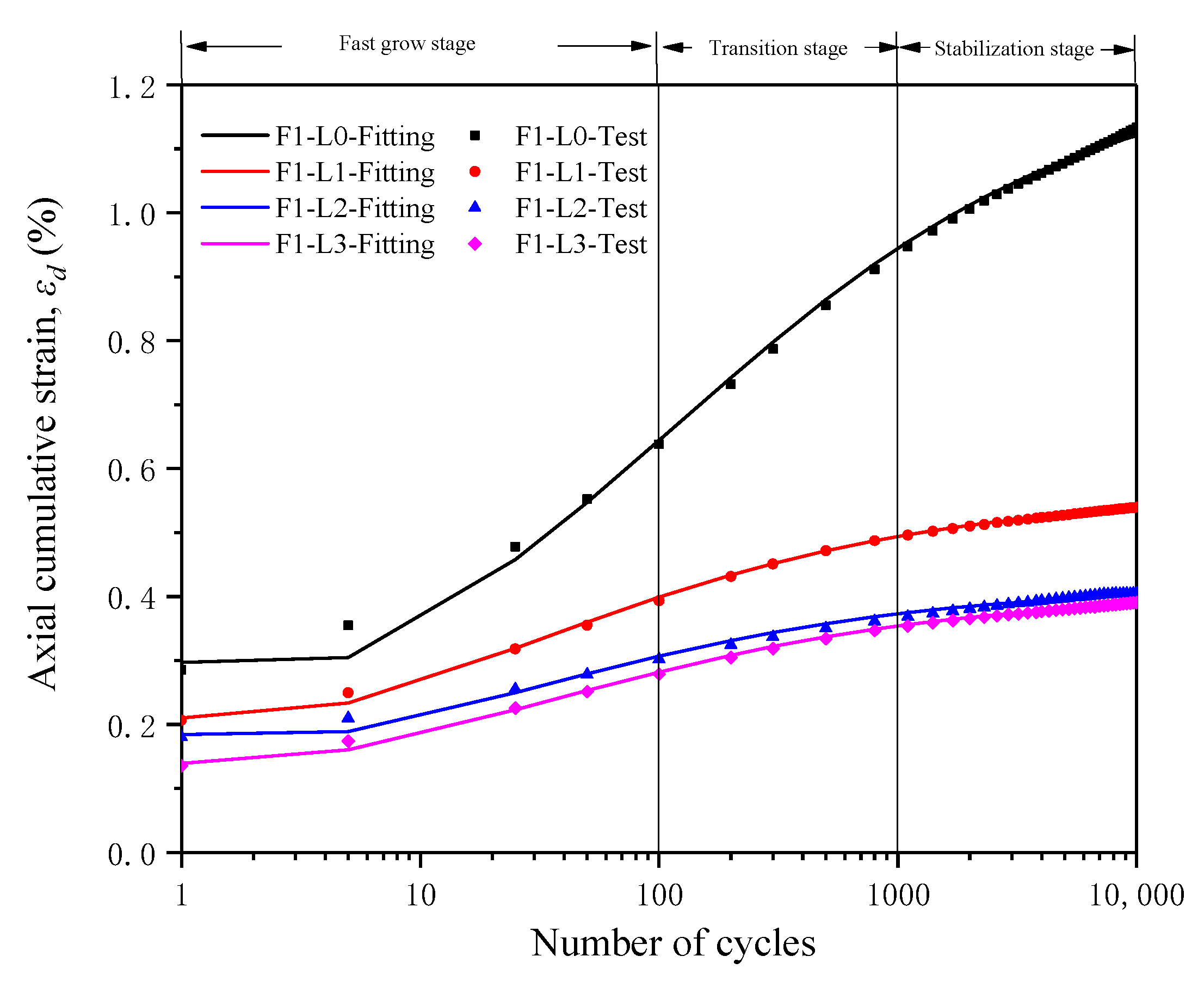

3.1.1. Effect of Number of Reinforced Layers on Axial Cumulative Strain

3.1.2. Effect of the Number of Reinforced Layers on Resilient Modulus

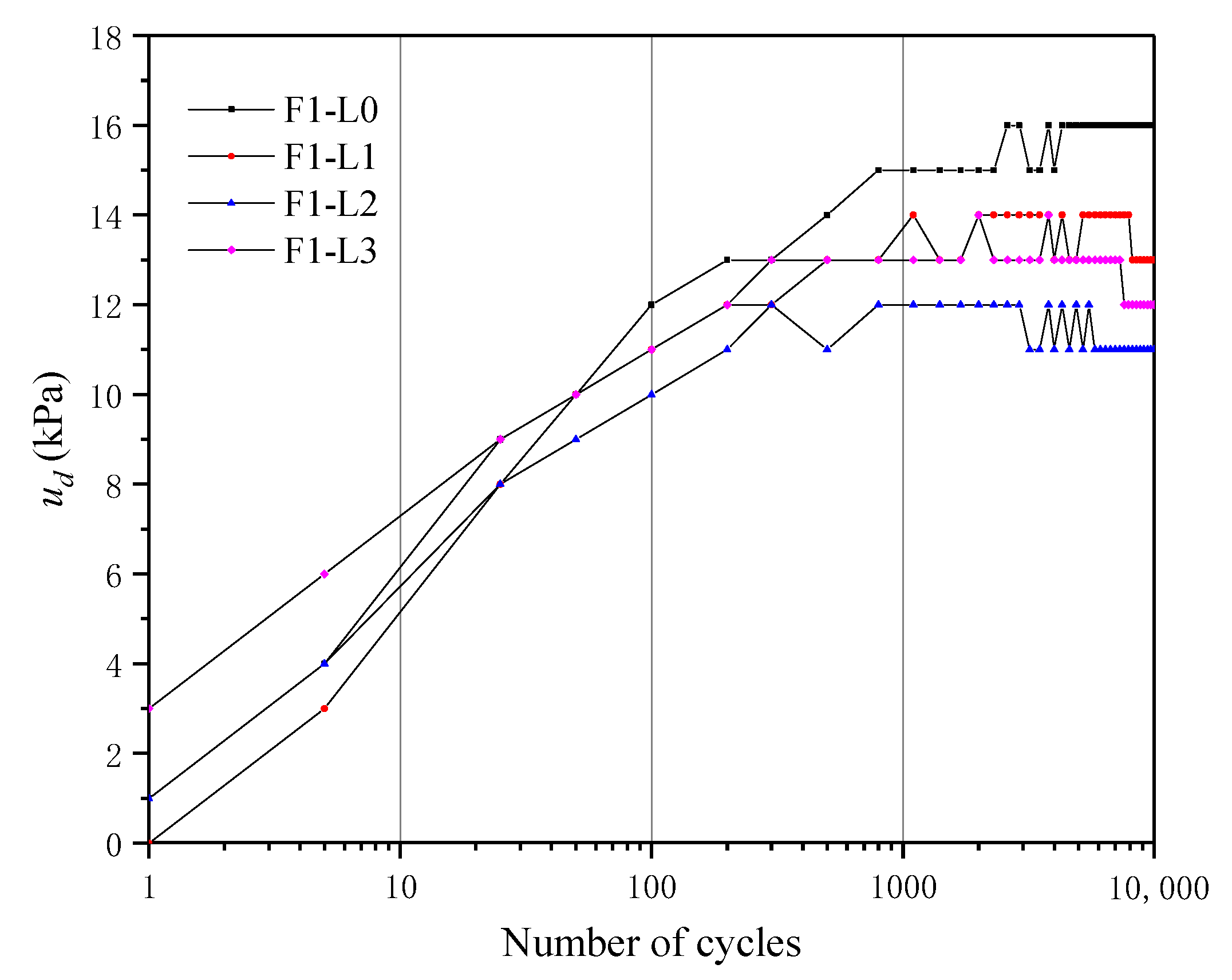

3.1.3. Effect of Number of Reinforcement Layers on Excess Pore Water Pressure

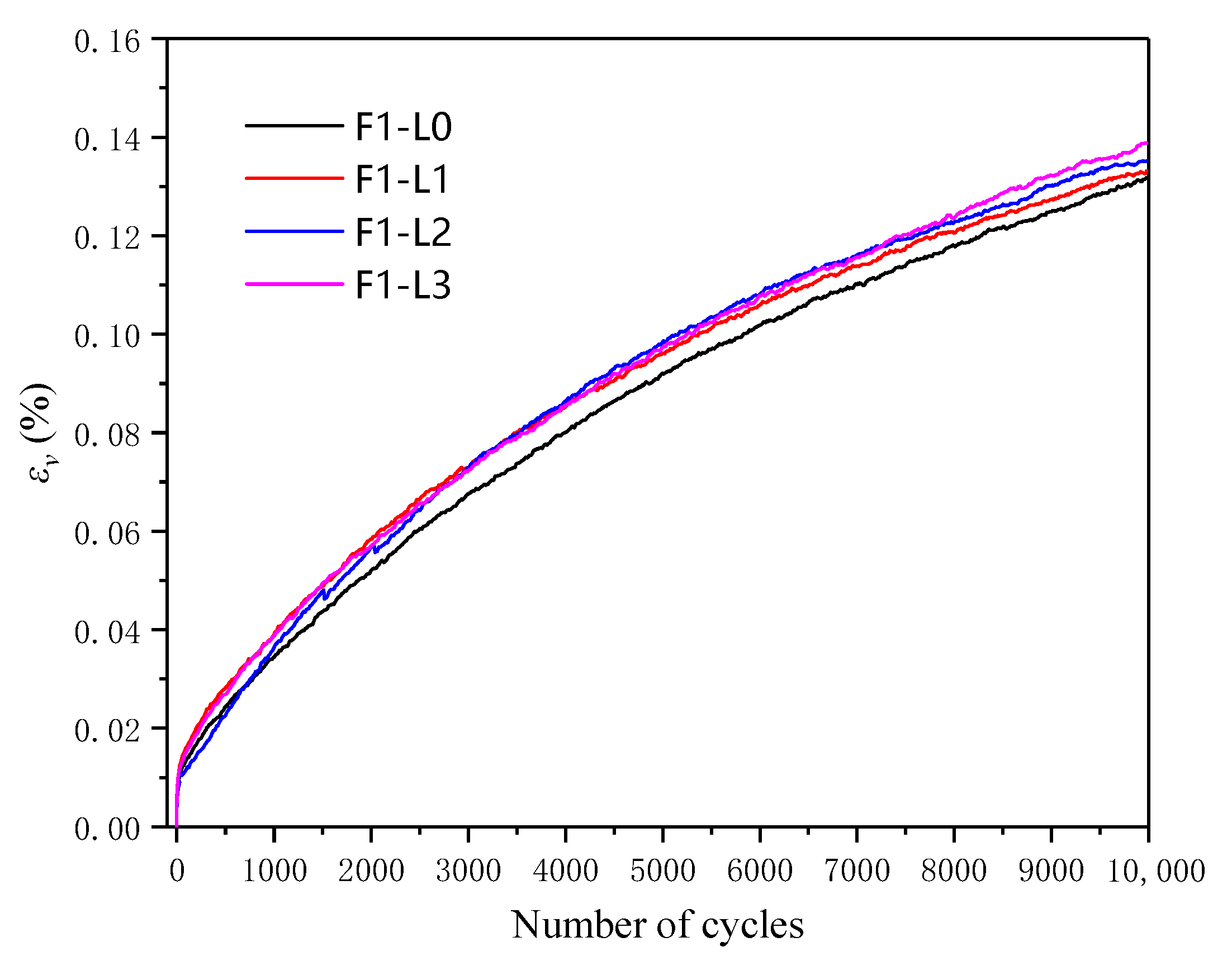

3.1.4. Effect of Number of Reinforced Layers on Volumetric Strain

3.1.5. Reinforcing Effect Coefficients of Different Reinforcing Schemes

3.2. Influence of Loading Frequency on Reinforced Gravelly Soil

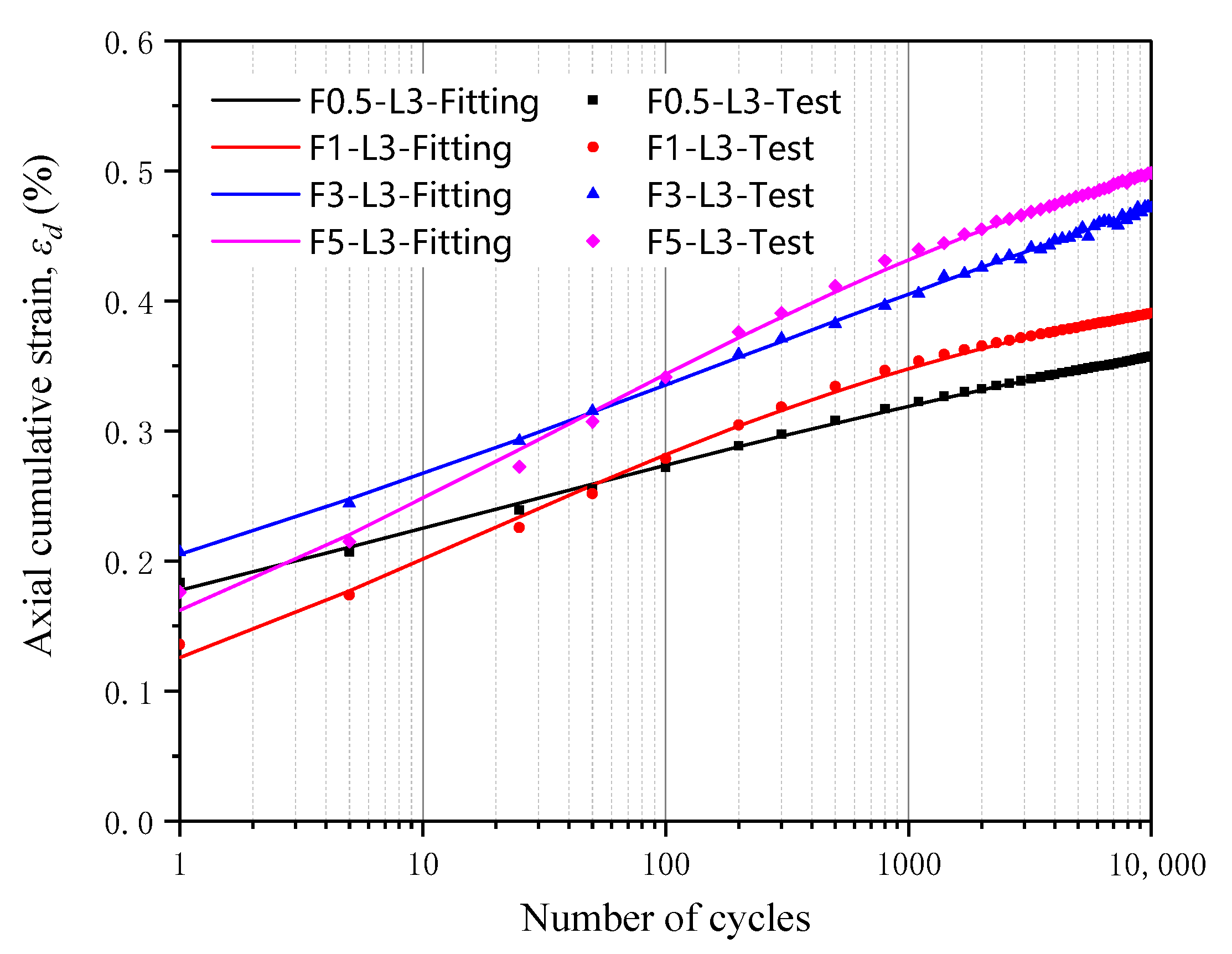

3.2.1. Effect of Loading Frequency on Cumulative Axial Strain

3.2.2. Effect of Loading Frequency on Resilient Modulus

3.2.3. Effect of Frequency on Excess Pore Water Pressure

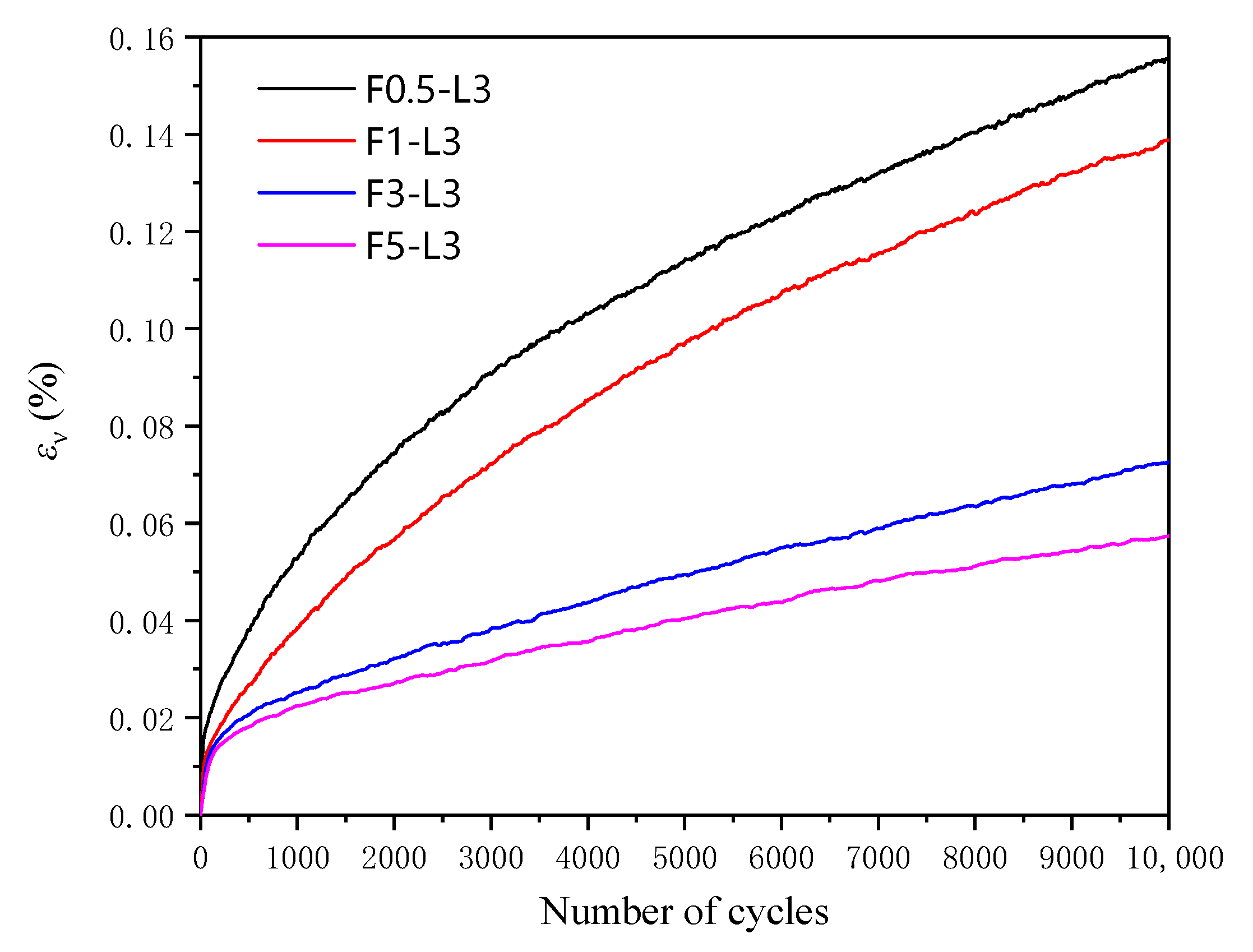

3.2.4. Effect of Frequency on Accumulative Volumetric Strain

3.3. Discussion

4. Conclusions

- (1)

- The inclusion of geogrid could reduce the cumulative axial strain of the samples under cyclic loading. The cumulative axial strain increases with loading frequency. The cumulative axial strain of the samples tends to stabilize after about 2000 loading cycles. After that the cumulative axial strain increases with loading cycles at nearly logarithm scale.

- (2)

- The resilient moduli of the samples increase with loading cycles. For the sample with fewer reinforcement layers, the increment rate decreases faster than those with more layers of reinforcement. With the same number of reinforcement layers, the higher the loading frequency, the lower the resilient modulus.

- (3)

- The inclusion of geogrid may reduce the excess pore water pressure developed in the samples: the more layers of reinforcement, the less the excess pore water pressure. For reinforced samples, the higher the loading frequency, the greater the excess pore water pressure.

- (4)

- Under the same loading frequency, the addition of geogrid can slightly aggravate the rubber mold embedding effect of sand samples. For samples with the same number of reinforcement layers, the lower the loading frequency, the more significant the rubber mold embedding effect of the sand samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, L. Experimental Study on Dynamic Behavior of Unbound Granular Materials with Different Fines Contents under Different-Frequency Cyclic Loadings. Master’s Thesis, Zhejiang University, Hangzhou, China, 2017. (In Chinese). [Google Scholar]

- Yu, X.J.; Ren, Z.; Gao, L. Experimental Study on Dynamic Characteristics and Associated Influencing Factors of Saturated Sand. In Transportation Research Congress 2016: Innovations in Transportation Research Infrastructure; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 530–536. [Google Scholar]

- Han, Z.; Cheng, X.; Ma, Q. An experimental study on dynamic response for MICP strengthening liquefiable sands. Earthq. Eng. Eng. Vib. 2016, 15, 673–679. [Google Scholar] [CrossRef]

- Ghayoomi, M.; Suprunenko, G.; Mirshekari, M. Cyclic triaxial test to measure strain-dependent shear modulus of unsaturated sand. Int. J. Geomech. 2017, 17, 04017043. [Google Scholar] [CrossRef] [Green Version]

- Nie, Z.; Chi, S.; Gong, S. Numerical modeling of cyclic triaxial experiments for granular soil. Int. J. Geomech. 2017, 17, 04016147. [Google Scholar] [CrossRef]

- Jafarian, Y.; Javdanian, H.; Haddad, A. Dynamic properties of calcareous and siliceous sands under isotropic and anisotropic stress conditions. Soils Found. 2018, 58, 172–184. [Google Scholar] [CrossRef]

- Shivaprakash, B.G.; Dinesh, S.V. Effect of plastic fines on initial shear modulus of sand-clay mixtures. KSCE J. Civ. Eng. 2018, 22, 73–82. [Google Scholar] [CrossRef]

- Wang, Y.; Kong, L.; Wang, Y.; Wang, M.Y.; Wang, M. Liquefaction response of loose gassy marine sand sediments under cyclic loading. Bull. Eng. Geol. Environ. 2018, 77, 963–976. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Vafaei, A.; Soleimani Kutanaei, S. Static and cyclic triaxial behavior of cemented sand with nanosilica. J. Mater. Civ. Eng. 2018, 30, 04018269. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, J.; Huang, S. Experimental Study on the Effects of Initial Shear Stress and Vibration Frequency on Dynamic Strength of Saturated Sands. Adv. Mater. Sci. Eng. 2019, 2019, 3758527. [Google Scholar] [CrossRef] [Green Version]

- Mashiri, M.; Vinod, J.S.; Sheikh, M.N.; Carraro, J.A.H. Shear modulus of sand-tyre chip mixtures. Environ. Geotech. 2018, 5, 336–344. [Google Scholar] [CrossRef] [Green Version]

- Javdanian, H.; Jafarian, Y. Dynamic shear stiffness and damping ratio of marine calcareous and siliceous sands. Geo-Mar. Lett. 2018, 38, 315–322. [Google Scholar] [CrossRef]

- LeBoeuf, D. Behaviour of a loose silty sand under static and cyclic loading conditions. E3S Web Conf. EDP Sci. 2019, 92, 08001. [Google Scholar] [CrossRef]

- Madhusudhan, B.R.; Boominathan, A.; Banerjee, S. Factors Affecting Strength and Stiffness of Dry Sand-Rubber Tire Shred Mixtures. Geotech. Geol. Eng. 2019, 37, 2763–2780. [Google Scholar] [CrossRef]

- Xiao, P.; Liu, H.; Stuedlein, A.W.; Evans, T.M.; Xiao, Y. Effect of relative density and biocementation on cyclic response of calcareous sand. Can. Geotech. J. 2019, 56, 1849–1862. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.; Sachan, A. Dynamic characteristics of natural kutch sandy soils. Soil Dyn. Earthq. Eng. 2019, 125, 105717. [Google Scholar] [CrossRef]

- Kang, X.; Wang, F. Dynamic-Triaxial Tests of Dynamic Shear Modulus and Damping Ratio for sandy silt in Beijing area. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Beijing, China, 2019; Volume 490, p. 062090. [Google Scholar]

- Li, J.S.; Zhang, Y.Z. Undrained monotonic and dynamic triaxial properties of the aeolian sand. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Beijing, China, 2019; Volume 242, p. 062010. [Google Scholar]

- Ling, X.Z.; Zhang, F.; Li, Q.L.; An, L.S.; Wang, J.H. Dynamic shear modulus and damping ratio of frozen compacted sand subjected to freeze-thaw cycle under multi-stage cyclic loading. Soil Dyn. Earthq. Eng. 2015, 76, 111–121. [Google Scholar] [CrossRef]

- Chattaraj, R.; Sengupta, A. Liquefaction potential and strain dependent dynamic properties of Kasai River sand. Soil Dyn. Earthq. Eng. 2016, 90, 467–475. [Google Scholar] [CrossRef]

- Sharma, P.; Maheshwari, B.K. Effect of Saturation on Dynamic Properties of Solani Sand. In Soil Dynamics and Earthquake Geotechnical Engineering; Springer: Singapore, 2019; pp. 51–55. [Google Scholar]

- Jin, J.X.; Cui, H.Z.; Liang, L.; Li, S.W.; Zhang, P.Y. Variation of pore water pressure in tailing sand under dynamic loading. Shock. Vib. 2018, 2018, 1921057.1–1921057.13. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Li, Q.; Liu, E.; Liu, X.; Zhang, G.; Song, B. Dynamic properties of frozen silty soils with different coarse-grained contents subjected to cyclic triaxial loading. Cold Reg. Sci. Technol. 2019, 157, 64–85. [Google Scholar] [CrossRef]

- Liu, F.Y.; Zhu, C.; Yuan, G.H.; Wang, J.; Gao, Z.Y.; Ni, J.F. Behaviour evaluation of a gravelly soil—Geogrid interface under normal cyclic loading. Geosynth. Int. 2021, 28, 508–520. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, S.; Han, H. Experimental investigations on the residual strain behavior of a rockfill material subjected to dynamic loading. J. Mater. Civ. Eng. 2017, 29, 04016278. [Google Scholar] [CrossRef]

- Zhang, X.D.; Ren, K. Experimental Study on Dynamic Elastic Modulus and Critical Dynamic Stress of Cinder-Improved Soil Subgrade. J. Highw. Transp. Res. Dev. (Engl. Ed.) 2018, 12, 25–32. [Google Scholar] [CrossRef]

- Bian, X.; Jiang, J.; Jin, W.; Sun, D.; Li, W.; Li, X. Cyclic and postcyclic triaxial testing of ballast and subballast. J. Mater. Civ. Eng. 2016, 28, 04016032. [Google Scholar] [CrossRef]

- Hussain, J.; Wilson, D.J.; Henning, T.F.; Alabaster, D. Comparing results between the repeated load triaxial test and accelerated pavement test on unbound aggregate. J. Mater. Civ. Eng. 2014, 26, 476–483. [Google Scholar] [CrossRef]

- Yan, F.X.; Huang, X.Z. Dynamic and static mechanical properties of loess subgrade in Shanxi. In Advances in Soil Dynamics and Foundation Engineering; American Society of Civil Engineers: Shanghai, China, 2014; pp. 39–44. [Google Scholar]

- Cai, Y.; Gu, C.; Wang, J.; Juang, C.H.; Xu, C.; Hu, X. One-way cyclic triaxial behavior of saturated clay: Comparison between constant and variable confining pressure. J. Geotech. Geoenviron. Eng. 2013, 139, 797–809. [Google Scholar] [CrossRef]

- Leng, W.; Xiao, Y.; Nie, R.; Zhou, W.; Liu, W. Investigating Strength and Deformation Characteristics of Heavy-Haul Railway Embankment Materials Using Large-Scale Undrained Cyclic Triaxial Tests. Int. J. Geomech. 2017, 17, 04017074. [Google Scholar] [CrossRef]

- Sun, Q.D.; Indraratna, B.; Nimbalkar, S. Effect of cyclic loading frequency on the permanent deformation and degradation of railway ballast. Géotechnique 2014, 64, 746–751. [Google Scholar] [CrossRef] [Green Version]

- Indraratna, B.; Thakur, P.K.; Vinod, J.S. Experimental and numerical study of railway ballast behavior under cyclic loading. Int. J. Geomech. 2010, 10, 136–144. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Kutanaei, S.S.; Ghadakpour, M. Shear behavior of fiber-reinforced sand composite. Arab. J. Geosci. 2019, 12, 157. [Google Scholar] [CrossRef]

- Goodarzi, S.; Shahnazari, H. Strength enhancement of geotextile-reinforced carbonate sand. Geotext. Geomembr. 2019, 47, 128–139. [Google Scholar] [CrossRef]

- Ghorbani, A.; Salimzadehshooiili, M. Dynamic Characterization of Sand Stabilized with Cement and RHA and Reinforced with Polypropylene Fiber. J. Mater. Civ. Eng. 2019, 31, 04019095. [Google Scholar] [CrossRef]

- Byun, Y.H.; Tutumluer, E.; Feng, B.; Kim, J.H.; Wayne, M.H. Horizontal stiffness evaluation of geogrid-stabilized aggregate using shear wave transducers. Geotext. Geomembr. 2019, 47, 177–186. [Google Scholar] [CrossRef]

- Han, B.; Ling, J.; Shu, X.; Song, W.; Boudreau, R.L.; Hu, W.; Huang, B. Quantifying the effects of geogrid reinforcement in unbound granular base. Geotext. Geomembr. 2019, 47, 369–376. [Google Scholar] [CrossRef]

- Amini, P.F.; Noorzad, R. Energy-based evaluation of liquefaction of fiber-reinforced sand using cyclic triaxial testing. Soil Dyn. Earthq. Eng. 2018, 104, 45–53. [Google Scholar] [CrossRef]

- Moayed, R.Z.; Alibolandi, M. Effect of geotextile reinforcement on cyclic undrained behavior of sand. Soil Dyn. Earthq. Eng. 2018, 104, 395–402. [Google Scholar] [CrossRef]

- Shi, W.; Lu, T.; Zhang, L.; Pan, Y. Dynamic Characteristics Study of Geosynthetic-Reinforced Soil under Cyclic Loading. Geo-China 2016, 2016, 210–216. [Google Scholar]

- Nair, A.M.; Latha, G.M. Large diameter triaxial tests on geosynthetic-reinforced granular subbases. J. Mater. Civ. Eng. 2015, 27, 04014148. [Google Scholar] [CrossRef]

- Nair, A.M.; Latha, G.M. Cyclic loading behaviour of reinforced soil-aggregate bases. Proc. Inst. Civ. Eng. Ground Improv. 2014, 167, 88–98. [Google Scholar] [CrossRef]

- Sadeghi, M.M.; Beigi, F.H. Dynamic behavior of reinforced clayey sand under cyclic loading. Geotext. Geomembr. 2014, 42, 564–572. [Google Scholar] [CrossRef]

- Ossa, A.; Romo, M.P. Dynamic characterization of EPS geofoam. Geotext. Geomembr. 2011, 29, 40–50. [Google Scholar] [CrossRef]

- Leng, J.; Gabr, M.A. Characteristics of geogrid-reinforced aggregate under cyclic load. Transp. Res. Rec. 2002, 1786, 29–35. [Google Scholar] [CrossRef]

- Latha, G.M.; Nandhi Varman, A.M. Static and cyclic load response of reinforced sand through large triaxial tests. Jpn. Geotech. Soc. Spec. Publ. 2016, 2, 2342–2346. [Google Scholar]

- Naeini, S.A.; Gholampoor, N. Cyclic behaviour of dry silty sand reinforced with a geotextile. Geotext. Geomembr. 2014, 42, 611–619. [Google Scholar] [CrossRef]

- Qiu, C.; Zhang, M. Discrete element modeling of dynamic triaxial test on reinforced saturated sand. Electron. J. Geotech. Eng. 2014, 19, 10661–10672. [Google Scholar]

- Zhang, R.B. Research of The Influencing Factors of Gravel Soil Shear Wave Velocity. Master’s Thesis, Institute of Engineering Mechanics China Seismological Administration, Haerbin, China, 2015. (In Chinese). [Google Scholar]

- Wang, J.; Liu, D.P.; Yang, X.H. Experimental study on dynamic constitutive relationship of gravel soil under traffic loading. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2017, 36, 49–53. (In Chinese) [Google Scholar]

- Nanjing Hydraulic Research Institute. Specification of Soil Testing, SL237-1999; China Water Power Press: Beijing, China, 1999; pp. 456–462. (In Chinese) [Google Scholar]

- Li, C.; He, C.R.; Wang, C.; Zhao, H.F. Study of scale effect of large-scale triaxialest of coarse-grained meterials. Rock Soil Mech. 2008, 29, 563–566. (In Chinese) [Google Scholar]

- Huang, B.; Ding, H.; Chen, Y.M. Simulation of high-speed train load by dynamic triaxial tests. Chin. J. Geotech. Eng. 2011, 33, 195–202. (In Chinese) [Google Scholar]

- Zhang, X. Experimental Study on Static and Dynamic Characteristics of B-Group Medium Sand for CRH Subgrade by Triaxial Tests. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2015. (In Chinese). [Google Scholar]

- Cen, C.L.; Zang, H.M. Some problems in triaxial test on saturated sands. Chin. J. Geotech. Eng. 2000, 22, 659–663. (In Chinese) [Google Scholar]

| The mesh size (mm) | 20.0 × 20.0 |

| Rib width on X-machine direction (mm) | 2.0 |

| Rib width on machine direction (mm) | 3.0 |

| Rib thickness on X-machine direction (mm) | 1.0 |

| Rib thickness on machine direction (mm) | 1.5 |

| Node size (mm) | 4.0 × 3.0 |

| Yield strength (X-machine direction) (kN/m) | 15.4 |

| Yield strength (Machine direction) (kN/m) | 18.6 |

| Test Series | Frequency (Hz) | Number of Reinforcement Layers |

|---|---|---|

| F0.5-L3 | 0.5 | 3 |

| F1-L0 | 1.0 | 0 |

| F1-L1 | 1.0 | 1 |

| F1-L2 | 1.0 | 2 |

| F1-L3 | 1.0 | 3 |

| F3-L3 | 3.0 | 3 |

| F5-L3 | 5.0 | 3 |

| Number of Reinforcement Layers | Fitting Parameters | R2 | ||

|---|---|---|---|---|

| a | b | c | ||

| 0 | −5.379 | 0.814 | 7.930 | 0.998 |

| 1 | −4.713 | 1.786 | 7.685 | 0.999 |

| 2 | −6.266 | 2.394 | 9.291 | 0.996 |

| 3 | −6.748 | 2.469 | 11.460 | 0.999 |

| Number of Reinforcement Layers | ηεd | ηEd | ηud | ηvd |

|---|---|---|---|---|

| 0 | 0.000 | 0.000 | 0.000 | 0.000 |

| 1 | −0.524 | 0.088 | −0.188 | 0.010 |

| 2 | −0.643 | 0.141 | −0.313 | 0.026 |

| 3 | −0.655 | 0.164 | −0.250 | 0.053 |

| Frequency (Hz) | Fitting Parameters | R2 | ||

|---|---|---|---|---|

| a | b | c | ||

| 0.5 | −6.326 | 2.764 | 8.887 | 0.994 |

| 1.0 | −6.747 | 2.469 | 11.46 | 0.999 |

| 3.0 | −6.397 | 2.091 | 8.972 | 0.983 |

| 5.0 | −6.887 | 1.933 | 10.470 | 0.997 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.-Q.; Chang, Z.-C.; Xue, J.-F.; Lin, Z.-N.; Tang, Y. Experimental Investigation on the Behavior of Gravelly Sand Reinforced with Geogrid under Cyclic Loading. Appl. Sci. 2021, 11, 12152. https://doi.org/10.3390/app112412152

Wang J-Q, Chang Z-C, Xue J-F, Lin Z-N, Tang Y. Experimental Investigation on the Behavior of Gravelly Sand Reinforced with Geogrid under Cyclic Loading. Applied Sciences. 2021; 11(24):12152. https://doi.org/10.3390/app112412152

Chicago/Turabian StyleWang, Jia-Quan, Zhen-Chao Chang, Jian-Feng Xue, Zhi-Nan Lin, and Yi Tang. 2021. "Experimental Investigation on the Behavior of Gravelly Sand Reinforced with Geogrid under Cyclic Loading" Applied Sciences 11, no. 24: 12152. https://doi.org/10.3390/app112412152

APA StyleWang, J.-Q., Chang, Z.-C., Xue, J.-F., Lin, Z.-N., & Tang, Y. (2021). Experimental Investigation on the Behavior of Gravelly Sand Reinforced with Geogrid under Cyclic Loading. Applied Sciences, 11(24), 12152. https://doi.org/10.3390/app112412152