Effect of Fibre Reinforcement on Creep in Early Age Concrete

Abstract

:1. Introduction

2. Materials and Methods

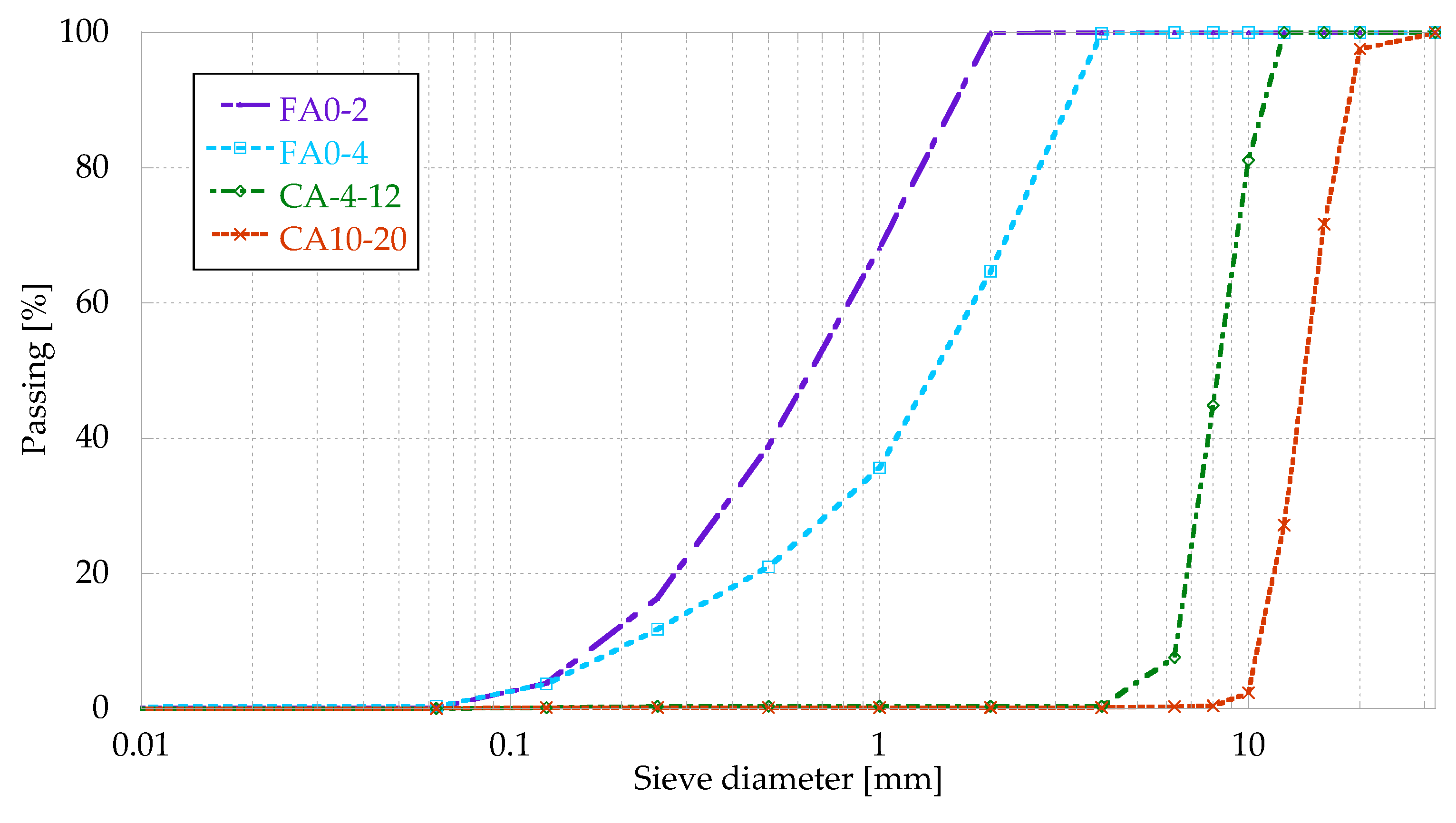

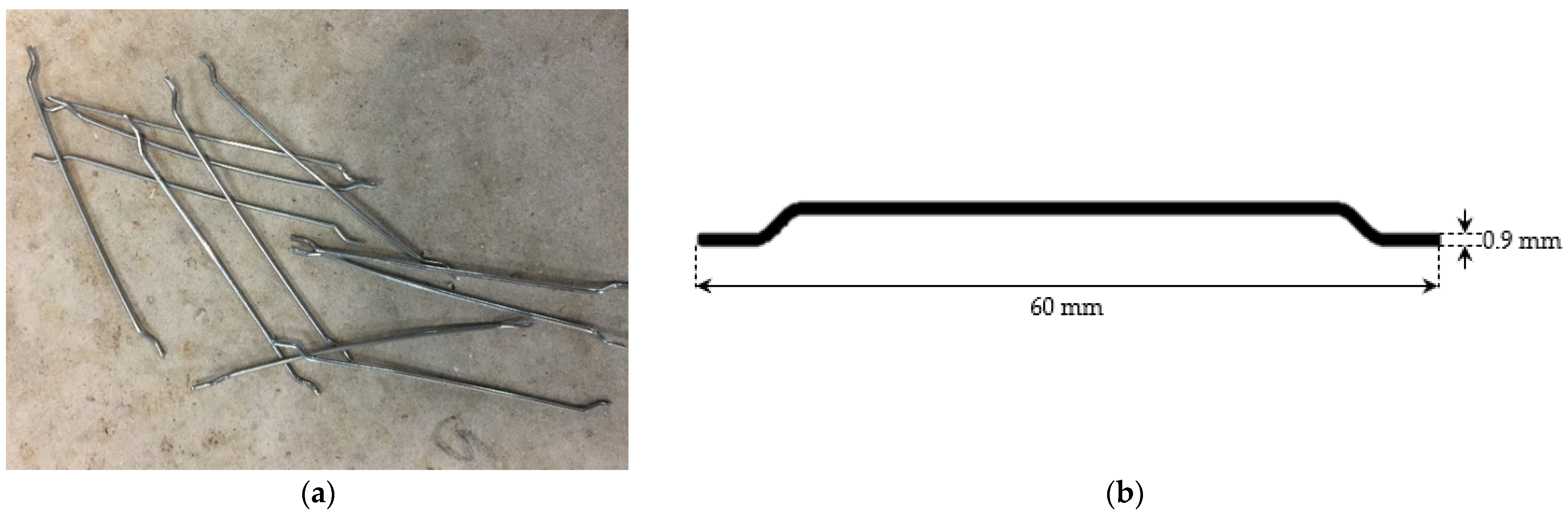

2.1. Materials

2.2. Methods

2.2.1. Compressive Strength

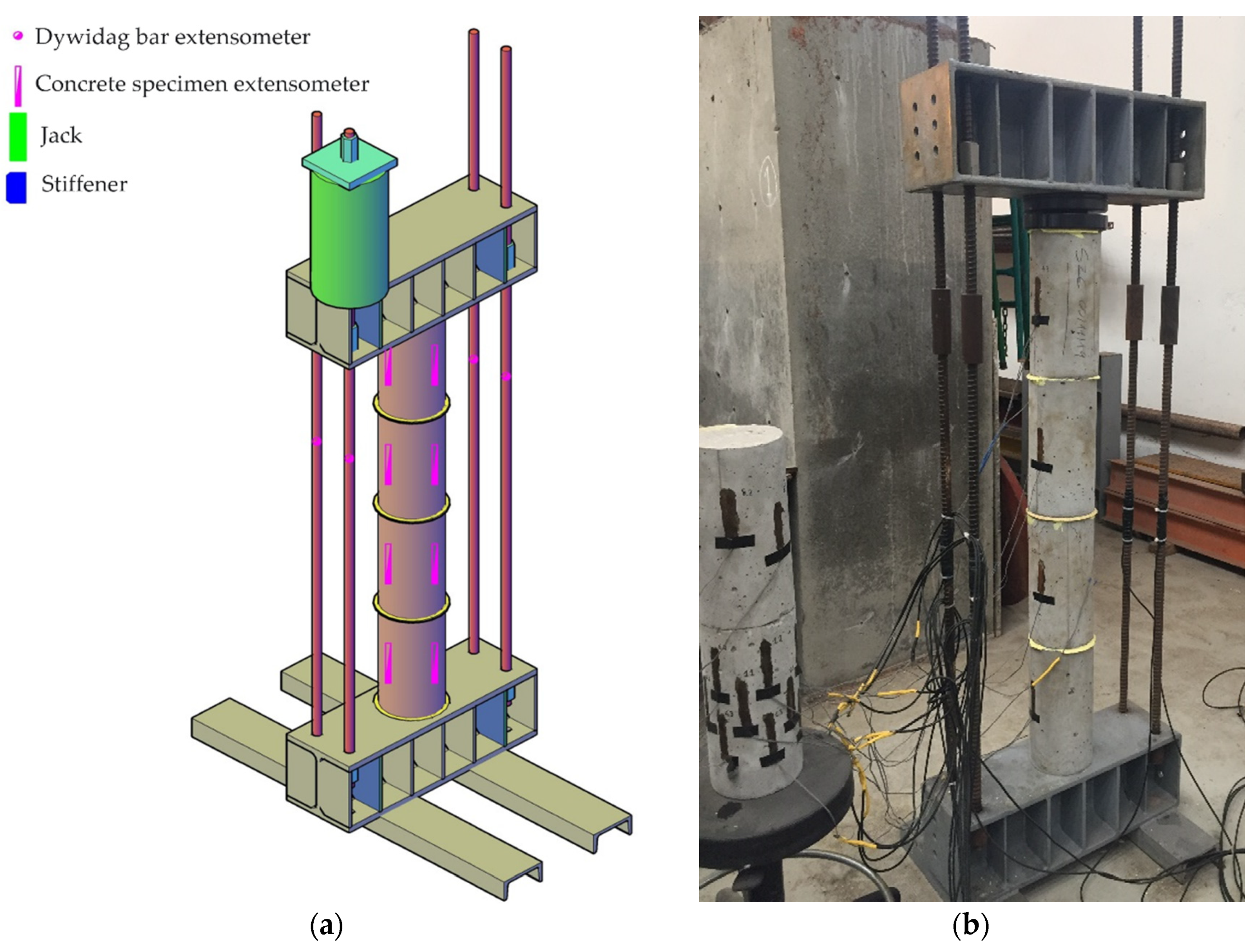

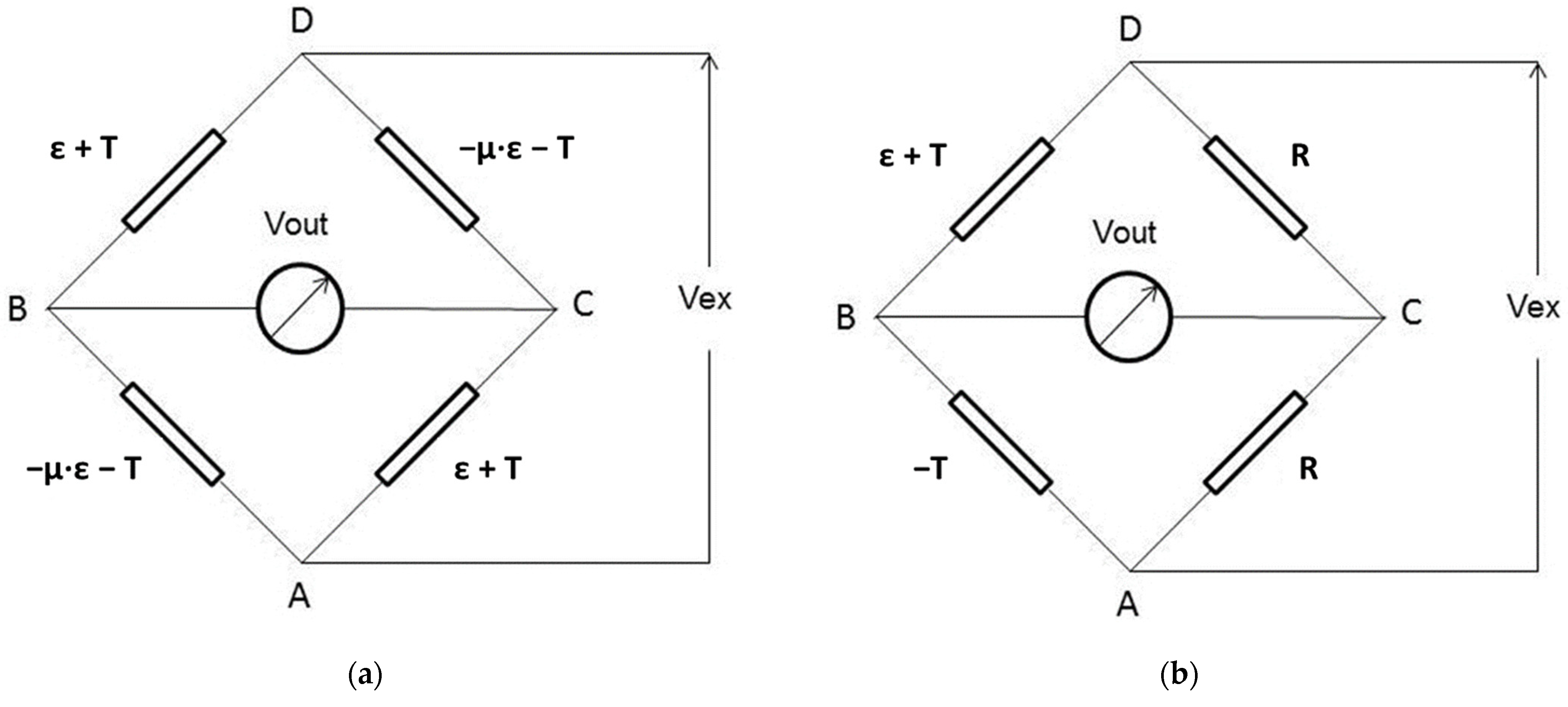

2.2.2. Creep Test

2.2.3. Modulus of Elasticity

2.2.4. Delayed Elastic Strain

2.2.5. Microscopic Analysis

3. Results and Discussion

3.1. Compressive Strength

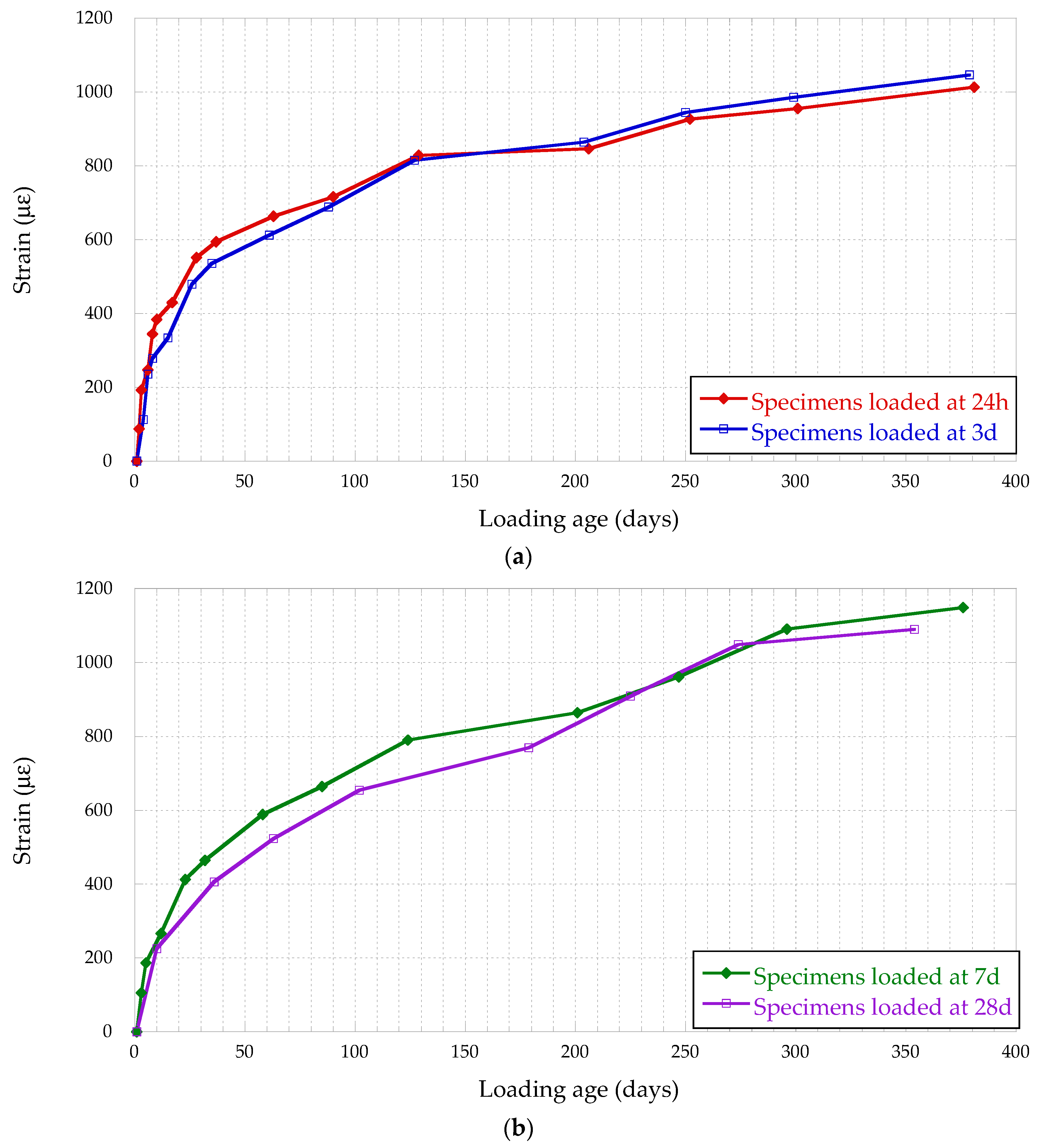

3.2. Creep Test

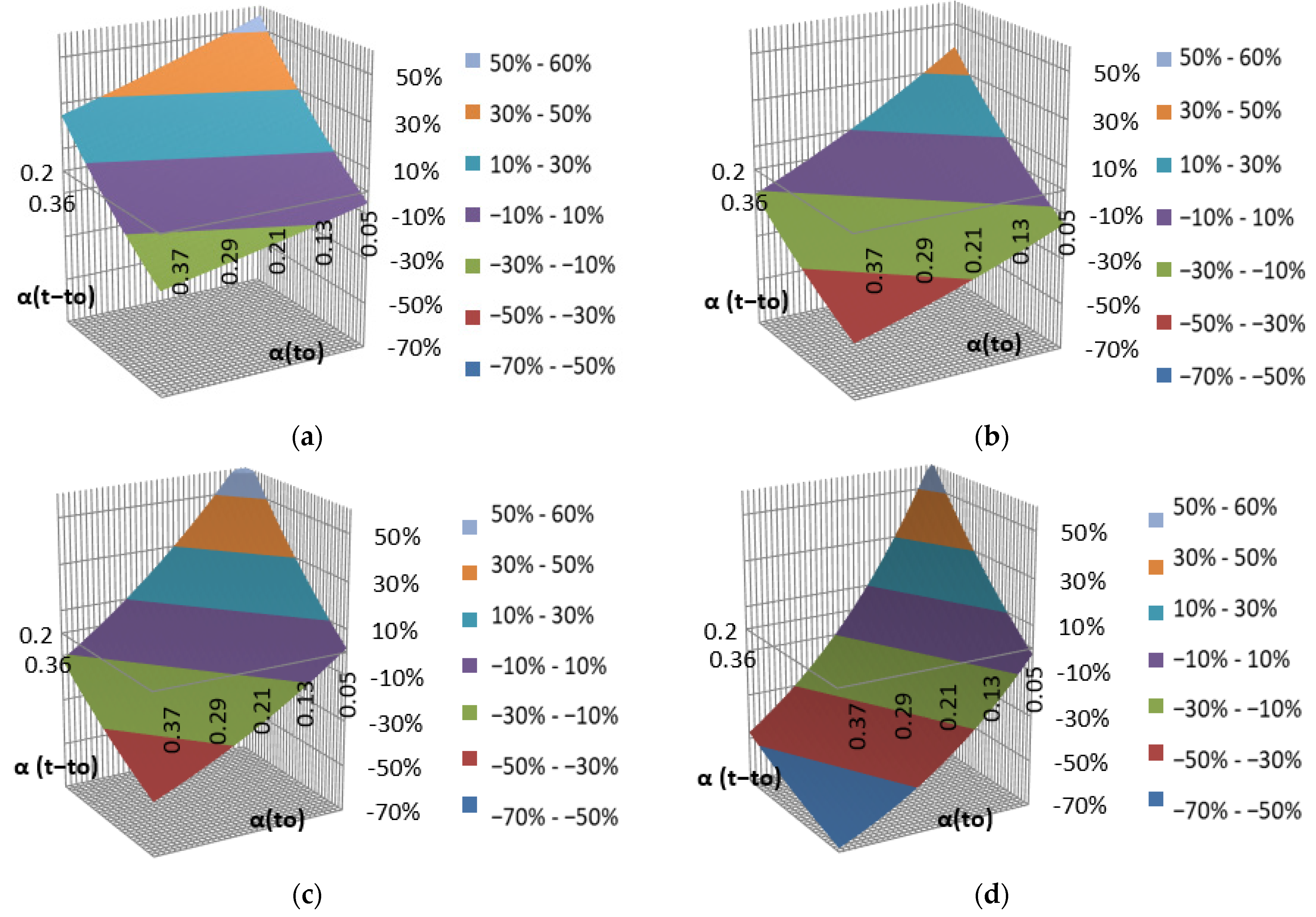

3.2.1. Proposed Creep Formulation

- -

- σ(to) is stress on specimens during creep test.

- -

- Ec,to is the initial modulus of elasticity in specimens.

- -

- Ec,28 is the modulus of elasticity of the specimens at 28 days.

- -

- φHR is the coefficient of influence of relative humidity [22].

- -

- -

- α(t0) is the coefficient associated with the loading age proposed by the authors;

- -

- α(t − t0) is the coefficient associated with the evolution of creep with time proposed by the authors.

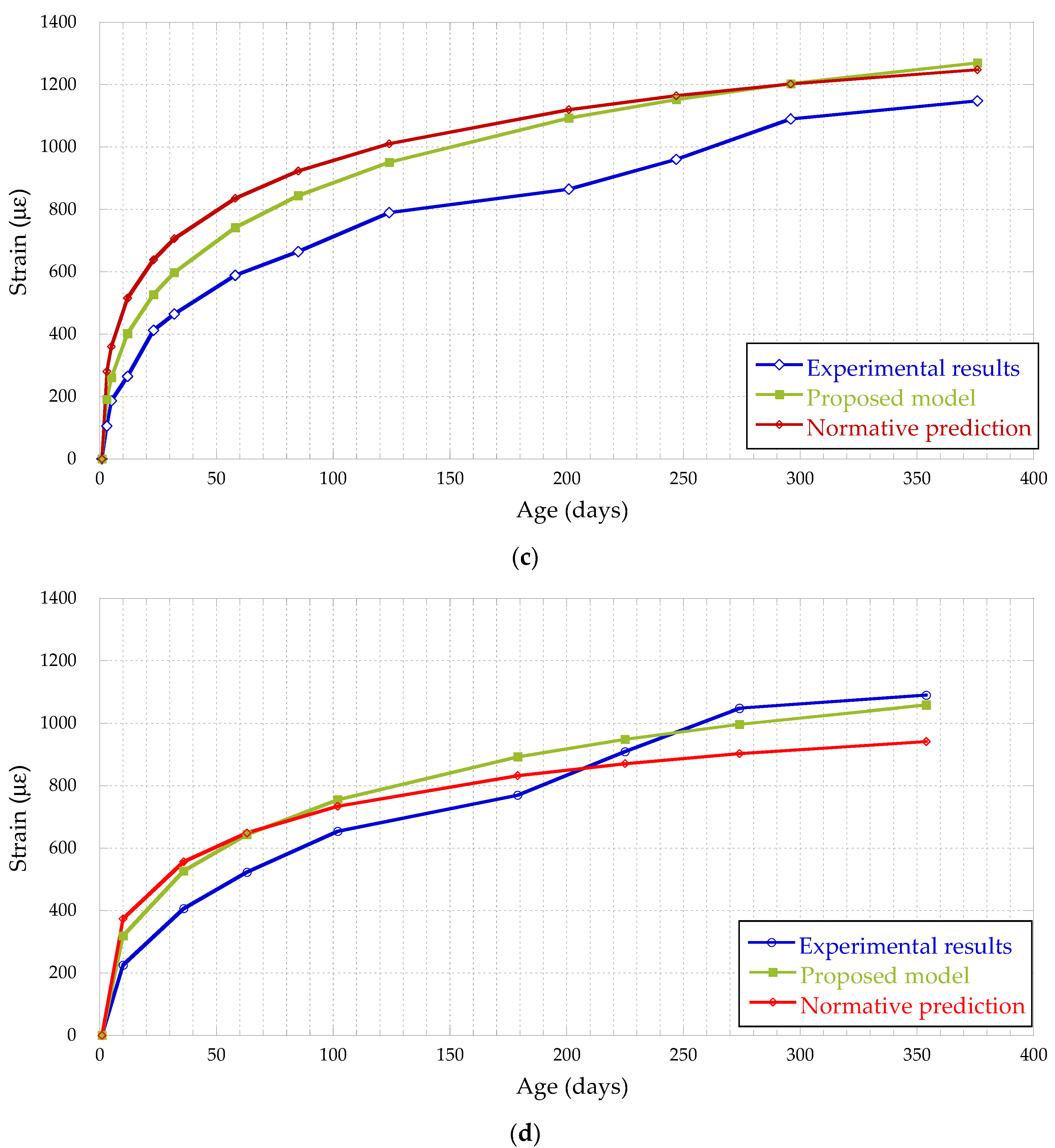

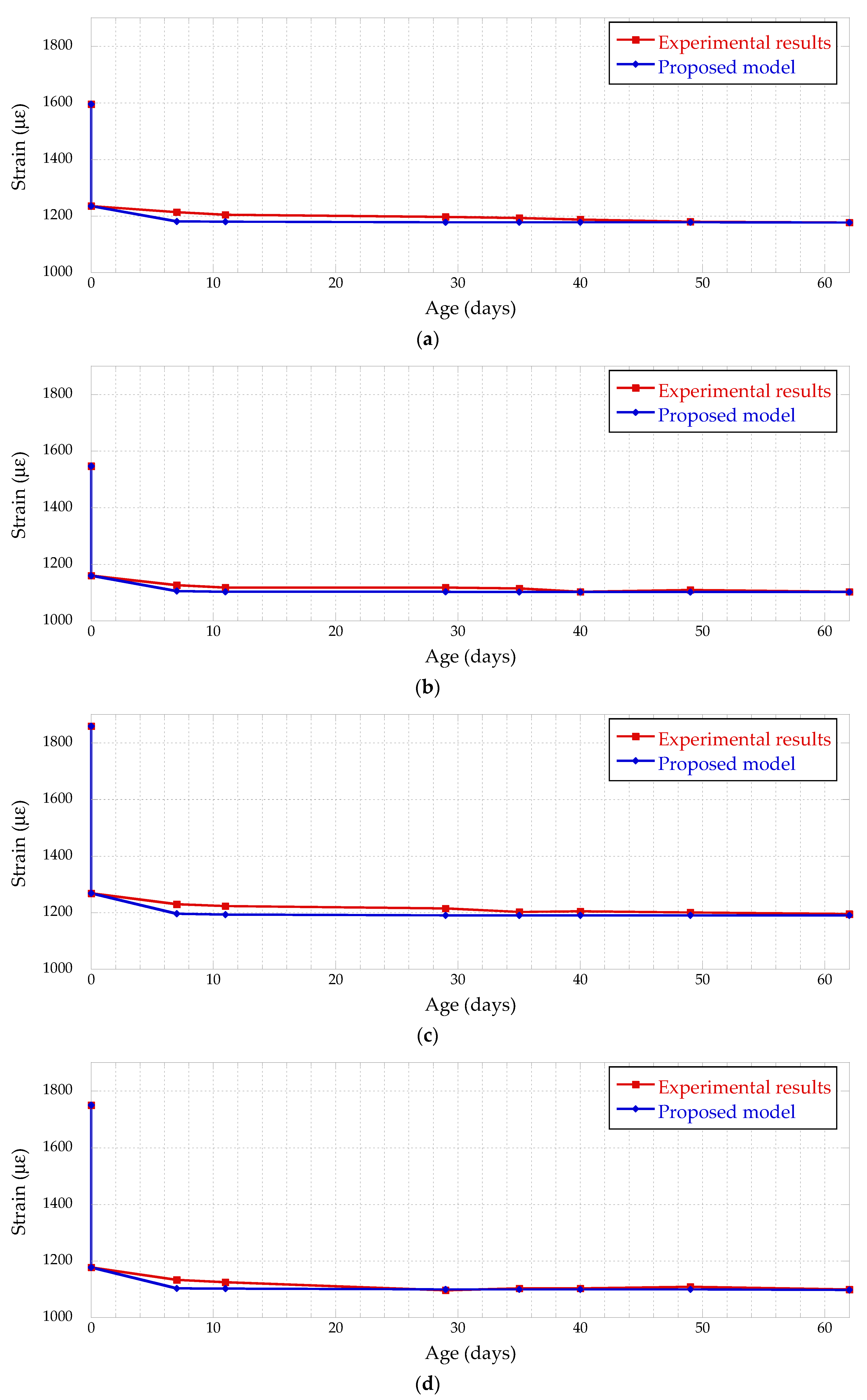

3.2.2. Verification of Creep Formulation

3.3. Modulus of Elasticity

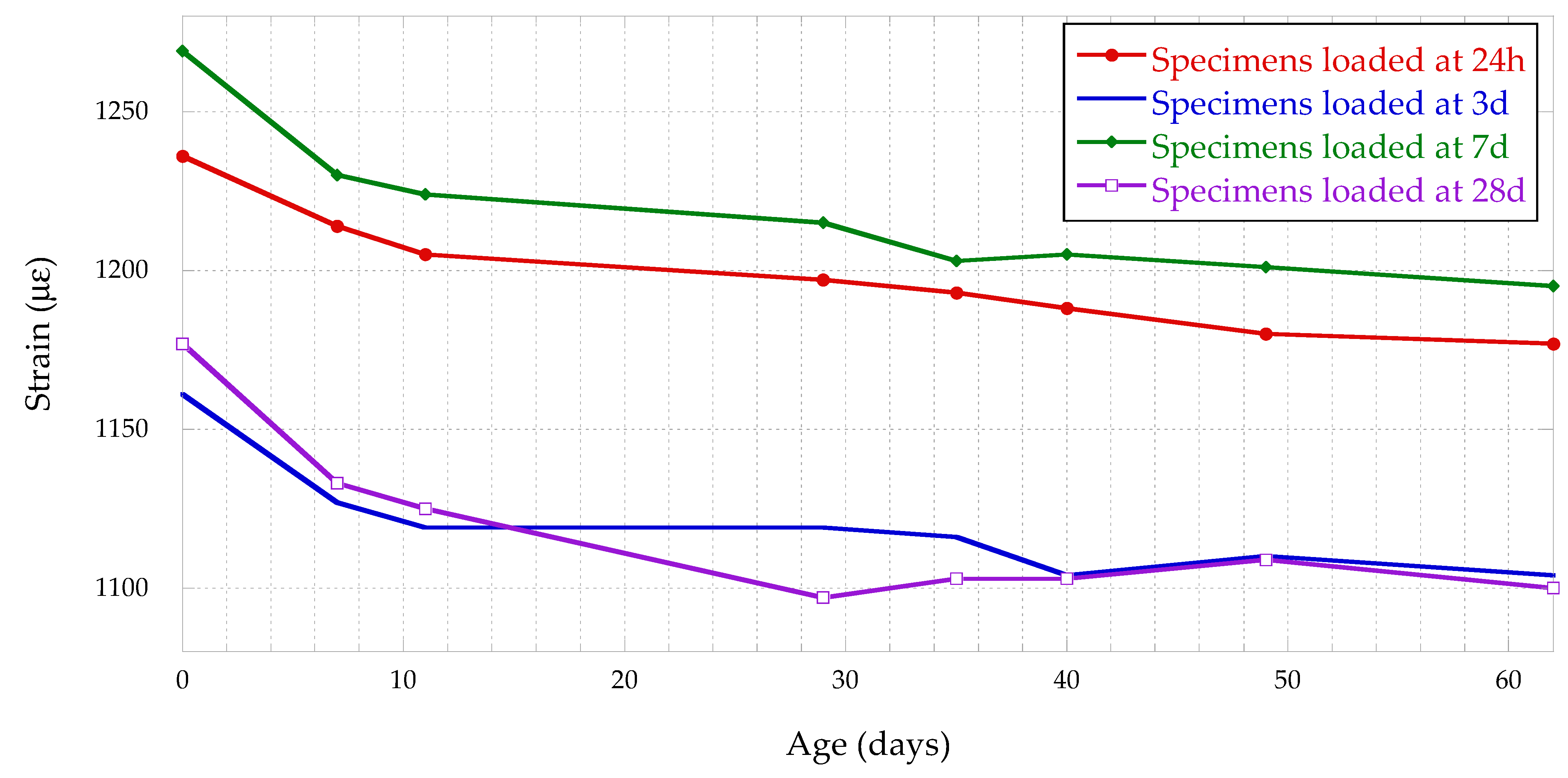

3.4. Delayed Elastic Strain

- -

- ɛe,i is the instantaneous elastic strain.

- -

- ɛe,d is the delayed elastic strain.

- -

- td is the unloading age.

- -

- Ec,td is the modulus of elasticity of the specimens at unloading age.

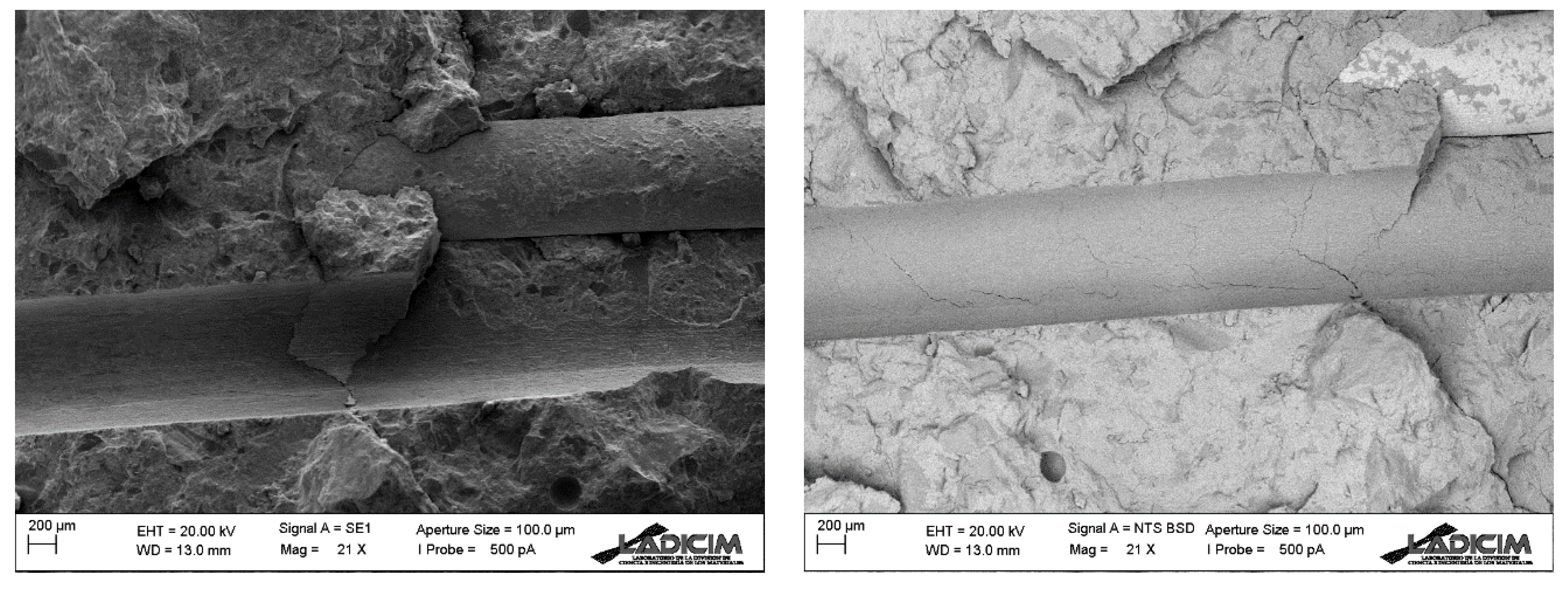

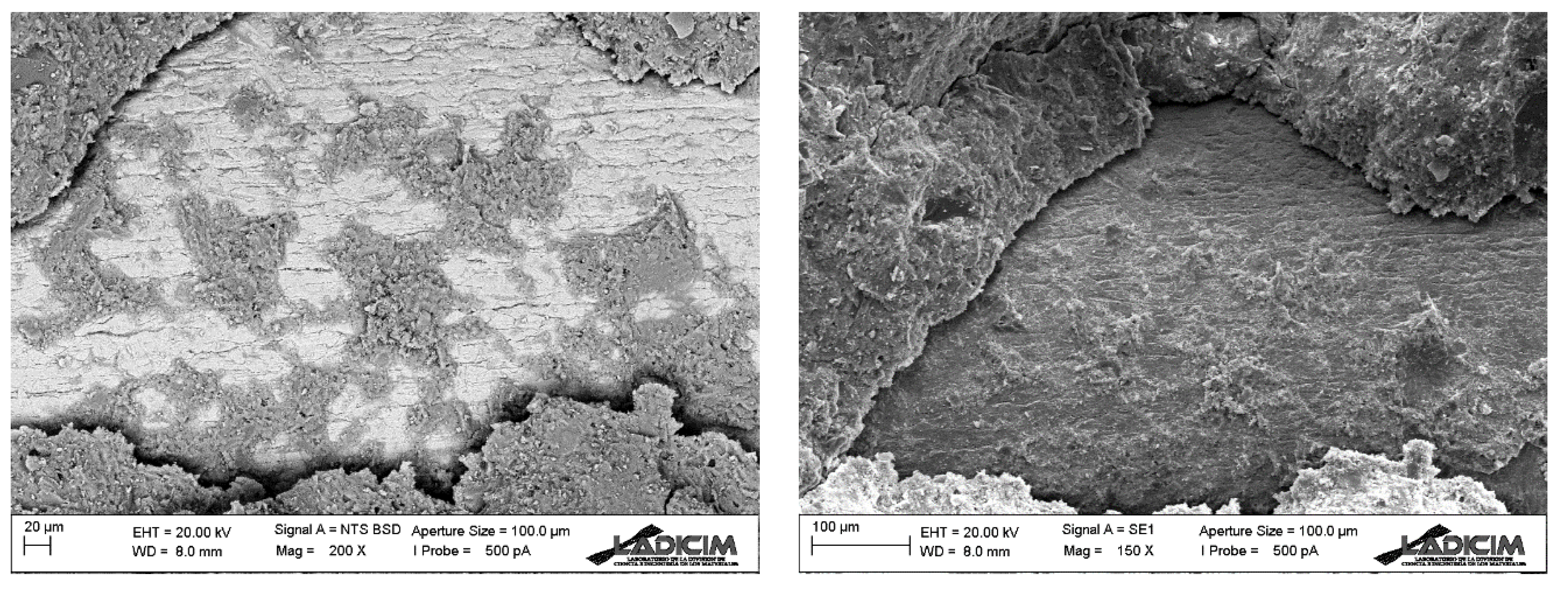

3.5. Microscopic Analysis

4. Conclusions

- -

- From the analysis of the creep strain undergone by the FRC specimens analysed during the test, two stages can be distinguished: (a) in a first stage, the creep deformation of the specimens loaded at an earlier age shows a greater strain; (b) in the second stage, the creep strain is equalized for the different loading ages.

- -

- The strain undergone by FRC specimens loaded at an earlier age, 24 h after their manufacture, shows a much lower level than predicted by the formulation proposed by the EHE-08 standard. In the case of the specimens loaded at the ages of three, seven and twenty-eight days, the strain is also less than that foreseen in the EHE-08 standard, although the difference is not so high.

- -

- The authors propose an adjustment of the creep coefficients proposed in the EHE-08 equation associated with the loading age β(t0) and the evolution of the creep in time βc(t − t0).

- -

- From a comparative analysis of the stress/strain curves of the FRC specimens during their loading and unloading, it can be concluded that the FRC loaded at an earlier age stiffens after a creep episode.

- -

- Once the results of the creep test of FRC loaded at different ages was analysed, it could be concluded that FRC had better creep behaviour than conventional concrete.

- -

- Analysing the evolution of the delayed elastic deformation of the FRC specimens after the end of the creep test, it is concluded that, the FRC loaded at an earlier age, undergoes less deformation.

- -

- The authors propose a formulation for the analysis of the delayed elastic deformation of FRC after a creep episode.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tosic, N.; Aidarov, S.; De la Fuente, A. Systematic Review on the Creep of Fiber-Reinforced Concrete. Materials 2020, 13, 5098. [Google Scholar] [CrossRef] [PubMed]

- Ríos, J.D.; Cifuentes, H.; Blasón, S.; López-Aenlle, M.; Martínez-De La Concha, A. Flexural fatigue behaviour of a heated ultra-high-performance fibre-reinforced concrete. Constr. Build. Mater. 2021, 276, 122209. [Google Scholar] [CrossRef]

- Atea, R.S. A Case Study On Concrete Column Strength Improvement with Different steel fibers and polypropylene fibers. J. Mater. Res. Technol. 2019, 8, 6106–6114. [Google Scholar] [CrossRef]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Rahimian Koloor, S.S.; Petrů, M.; Radwan, N. Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Banjara, N.K.; Ramanjaneyulu, K. Experimental and numerical study on behaviour of HSFRC overlay strip strengthened flexural deficient RC beams. Eng. Struct. 2019, 198, 109561. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Thomas, C.; Borinaga-Treviño, R.; Lombillo, I. Influence of recycled carbon powder waste addition on the physical and mechanical properties of cement pastes. Mater. Struct. 2016, 49, 5147–5159. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Gonzalez, L.; Thomas, C.; Rico, J.; Polanco, J.; Carrascal, I.; Setién, J. Effect of Steel Fibre Reinforcement on Flexural Fatigue Behaviour of Notched Structural Concrete. Materials 2021, 14, 5854. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.X.; Ran, Z.H. Calculation of Creep Effect of Extradosed Cable-stayed bridge based on Midas Civil. Mater. Sci. Eng. 2018, 423, 012113. [Google Scholar] [CrossRef]

- Bazant, Z.; Asce, H.; Yu, Q.; Li, G.-H. Excessive Long-Time Deflections of Prestressed Box Girders. I: Record-Span Bridge in Palau and Other Paradigms. J. Struct. Eng. 2012, 138, 676–686. [Google Scholar] [CrossRef] [Green Version]

- Mangat, P.S.; Azari, M.M. Compression creep behaviour of steel fibre reinforced cement composites. Mater. Struct. 1986, 19, 361–370. [Google Scholar] [CrossRef]

- Nakov, D.; Mark, P. Experimental and Analytical Analysis of Creep of Steel Fibre Reinforced Concrete. Period. Polytech. Civ. Eng. 2017, 62. [Google Scholar] [CrossRef] [Green Version]

- Błyszko, J. Comparative Analysis of Creep in Standard and Fibre Reinforced Concretes under different Load Conditions. Procedia Eng. 2017, 193, 478–485. [Google Scholar] [CrossRef]

- Zhang, J. Modeling of the influence of fibers on creep of fiber reinforced cementitious composite. Compos. Sci. Technol. 2003, 63, 1877–1884. [Google Scholar] [CrossRef]

- Zhao, Q.; Yu, J.; Geng, G.; Jiang, J.; Liu, X. Effect of fiber types on creep behavior of concrete. Constr. Build. Mater. 2016, 105, 416–422. [Google Scholar] [CrossRef]

- Madureira, E.L.; Fontes, B.V. Temperature influence on creep of reinforced concrete. Revista IBRACON de Estruturas e Materiais 2020, 13. [Google Scholar] [CrossRef]

- Jin, S.-S.; Cha, S.-L.; Jung, H.-J. Improvement of concrete creep prediction with probabilistic forecasting method under model uncertainty. Constr. Build. Mater. 2018, 184, 617–633. [Google Scholar] [CrossRef]

- Reddy, D.H.; Ramaswamy, A. Experimental and numerical modeling of creep in different types of concrete. Heliyon 2018, 4, e00698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, R.; Ye, H.; Liu, Y.; Zhao, H.; Correia, J.A.F.O.; Xin, H. Numerical simulation of concrete creep behaviour using integral creep algorithm with alternating stresses. Structures 2021, 29, 1979–1987. [Google Scholar] [CrossRef]

- Havlásek, P.; Šmilauer, V.; Dohnalová, L.; Sovják, R. Shrinkage-induced deformations and creep of structural concrete: 1-year measurements and numerical prediction. Cem. Concr. Res. 2021, 144, 106402. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications Chemistry; AASHTO: Washington, DC, USA, 2012. [Google Scholar]

- A.C. Institute. Creep and Shrinkage. Guide for Modeling and Calculating Shrinkage and Creep in Hardened Concrete. ACI Committee 209. 2008. Available online: http://www.civil.northwestern.edu/people/bazant/PDFs/Papers/R21.pdf (accessed on 1 December 2021).

- Ministerio de Fomento, Gobierno de España. EHE-08. Instrucción de Homigón Estructural; Ministerio de Fomento: Madrid, Spain, 2008; pp. 175–177. [Google Scholar]

- GEN, E.N. 933-1:2012; Tests for Geometrical Properties of Aggregates-Part 1: Determination of Particle Size Distribution-Sieving Method. Spanish Association for Standardisation, UNE: Madrid, Spain, 2012.

- CEN, EN 197-1; Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Spanish Association for Standardisation, UNE: Madrid, Spain, 2011.

- CEN, EN 80103:2013; Test Methods of Cements. Physical Analysis. Actual Density Determination. Spanish Association for Standardisation, UNE: Madrid, Spain, 2013.

- CEN, EN 83507; Concrete with Fibres. Testing in Compression. Spanish Association for Standardisation, UNE: Madrid, Spain, 2004.

- William, F.R.; James, W.D. Experimental Stress Analysis; McGraw-Hill Book Company: New York, NY, USA, 1978. [Google Scholar]

- Delsaute, B.; Torrenti, J.-M.; Staquet, S. Modeling basic creep of concrete since setting time. Cem. Concr. Compos. 2017, 83, 239–250. [Google Scholar] [CrossRef]

- Altoubat, S. Early Age Stresses and Creep-Shrinkage Interaction of Restrained Concrete. Ph.D. Thesis, University of Illinois Urbana-Champaign, Champaign, IL, USA, 2000. [Google Scholar]

- Landsberger, G.A.; Gomez, J. Evaluación de las Deformaciones por Fluencia del Hormigón Autocompactante; JSSN 008-8919, Nº927; Cemento Hormigón: Valencia, Spain, 2008; pp. 42–52. [Google Scholar]

| Fraction of Aggregate | Absorption [wt.%] | Density [kg/m3] | Sand Equivalent |

|---|---|---|---|

| FA0-2 | 0.49 | 2690 | >75 |

| FA0-4 | 0.49 | 2690 | >80 |

| CA4-12 | 0.54 | 2700 | - |

| CA10-20 | 0.54 | 2680 | - |

| Fe2O3 | CaO | SiO2 | Al2O3 | MgO | TiO2 | SO3 | K2O | Others | |

|---|---|---|---|---|---|---|---|---|---|

| Compound [wt.%] | 3.38 | 66.60 | 17.81 | 4.79 | 1.30 | 0.20 | 4.49 | 0.78 | <0.5 |

| Material | Mix [kg/m3] |

|---|---|

| FA0-2 | 480 |

| FA0-4 | 480 |

| CA4-12 | 480 |

| CA10-20 | 480 |

| Cement | 390 |

| Water | 165 |

| Additive Master Ease 5025 | 3.9 (1% wt. cement) |

| Fibres | 35 |

| w/c | 0.45 |

| Specimen Code | Group | Loading Age [d] | Test Load [kN] | Test Stress [MPa] |

|---|---|---|---|---|

| CF-1 | 1 | 1 | 265 | 15 |

| CF-2 | 1 | 1 | 265 | 15 |

| CF-3 | 2 | 3 | 265 | 15 |

| CF-4 | 2 | 3 | 265 | 15 |

| CF-5 | 3 | 7 | 353 | 20 |

| CF-6 | 3 | 7 | 353 | 20 |

| CF-7 | 4 | 28 | 353 | 20 |

| CF-8 | 4 | 28 | 353 | 20 |

| Loading Age (d) | Eo (GPa) | Er (GPa) |

|---|---|---|

| 1 | 21.913 | 41.712 |

| 3 | 33.500 | 38.842 |

| 7 | 33.667 | 33.904 |

| 28 | 36.100 | 34.918 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, L.; Gaute, Á.; Rico, J.; Thomas, C. Effect of Fibre Reinforcement on Creep in Early Age Concrete. Appl. Sci. 2022, 12, 257. https://doi.org/10.3390/app12010257

González L, Gaute Á, Rico J, Thomas C. Effect of Fibre Reinforcement on Creep in Early Age Concrete. Applied Sciences. 2022; 12(1):257. https://doi.org/10.3390/app12010257

Chicago/Turabian StyleGonzález, Laura, Álvaro Gaute, Jokin Rico, and Carlos Thomas. 2022. "Effect of Fibre Reinforcement on Creep in Early Age Concrete" Applied Sciences 12, no. 1: 257. https://doi.org/10.3390/app12010257

APA StyleGonzález, L., Gaute, Á., Rico, J., & Thomas, C. (2022). Effect of Fibre Reinforcement on Creep in Early Age Concrete. Applied Sciences, 12(1), 257. https://doi.org/10.3390/app12010257