Effect of Purple-Colored Wheat Bran Addition on Quality and Antioxidant Property of Bread and Optimization of Bread-Making Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analysis of the Physicochemical Properties of Flour–Bran Blends

2.3. Solvent Retention Capacity Analysis of the Flour–Bran Blends

2.4. Determination of the Dough Mixing Property of the Flour–Bran Blends

2.5. Preparation of Bread Made of Flour–Bran Blends at Different Bran Ratios

2.6. Measurement of Total Phenolic and Anthocyanin Contents of Bread Made with Flour–Bran Blends

2.7. Measurement of the Antioxidant Activity of Bread Made with Flour–Bran Blends

2.8. Experimental Design for Optimizing the Processing Conditions of Bread Made of Flour–Bran Blends at 30% Bran

2.9. Measurement of Bread Quality

2.10. Statistical Analysis

3. Results and Discussion

3.1. Moisture and Ash Contents of the Flour–Bran Blends

3.2. Quality of Flour–Bran Blends Using SRC

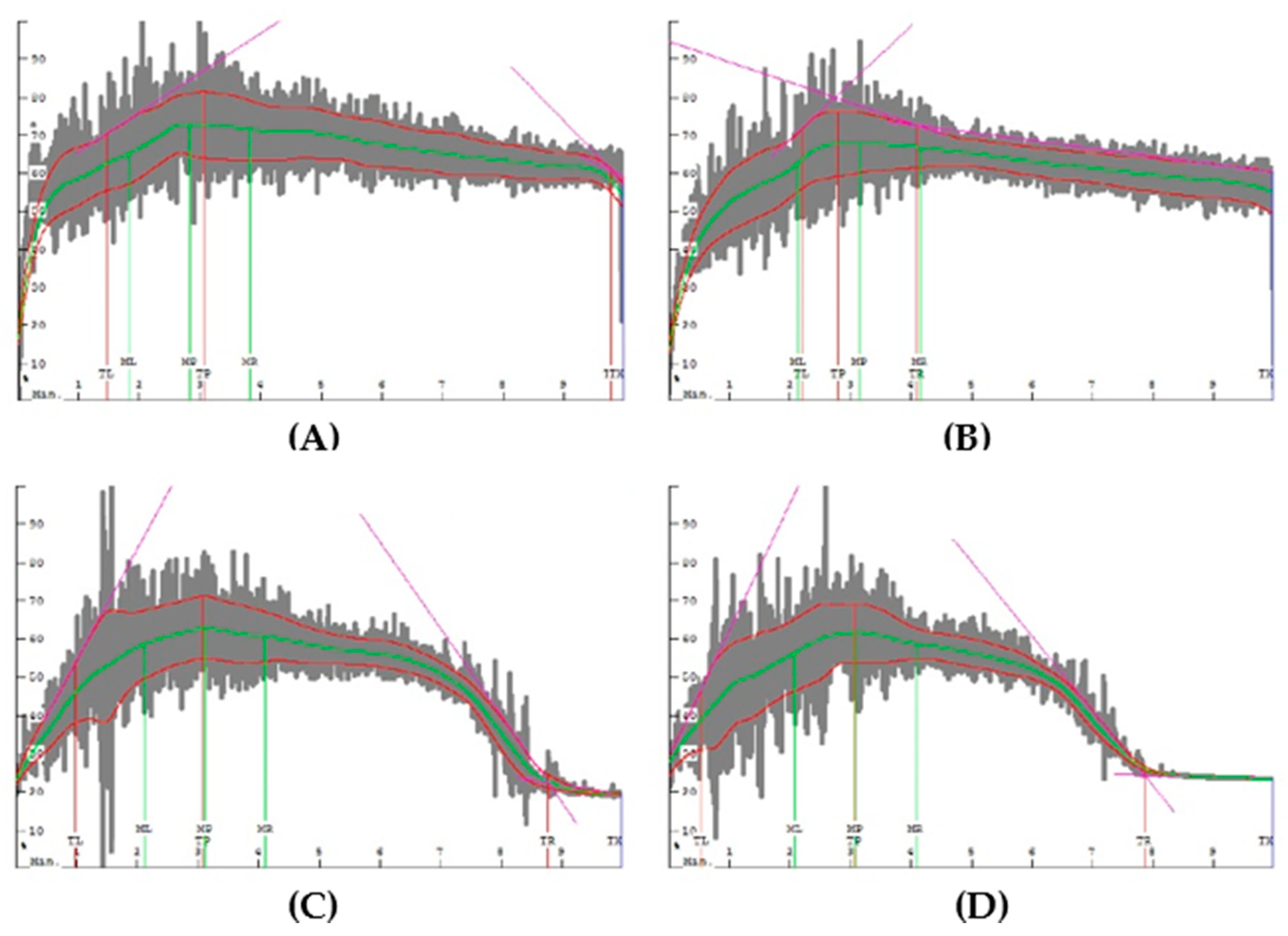

3.3. Dough Property of Flour–Bran Blends Using Mixograph

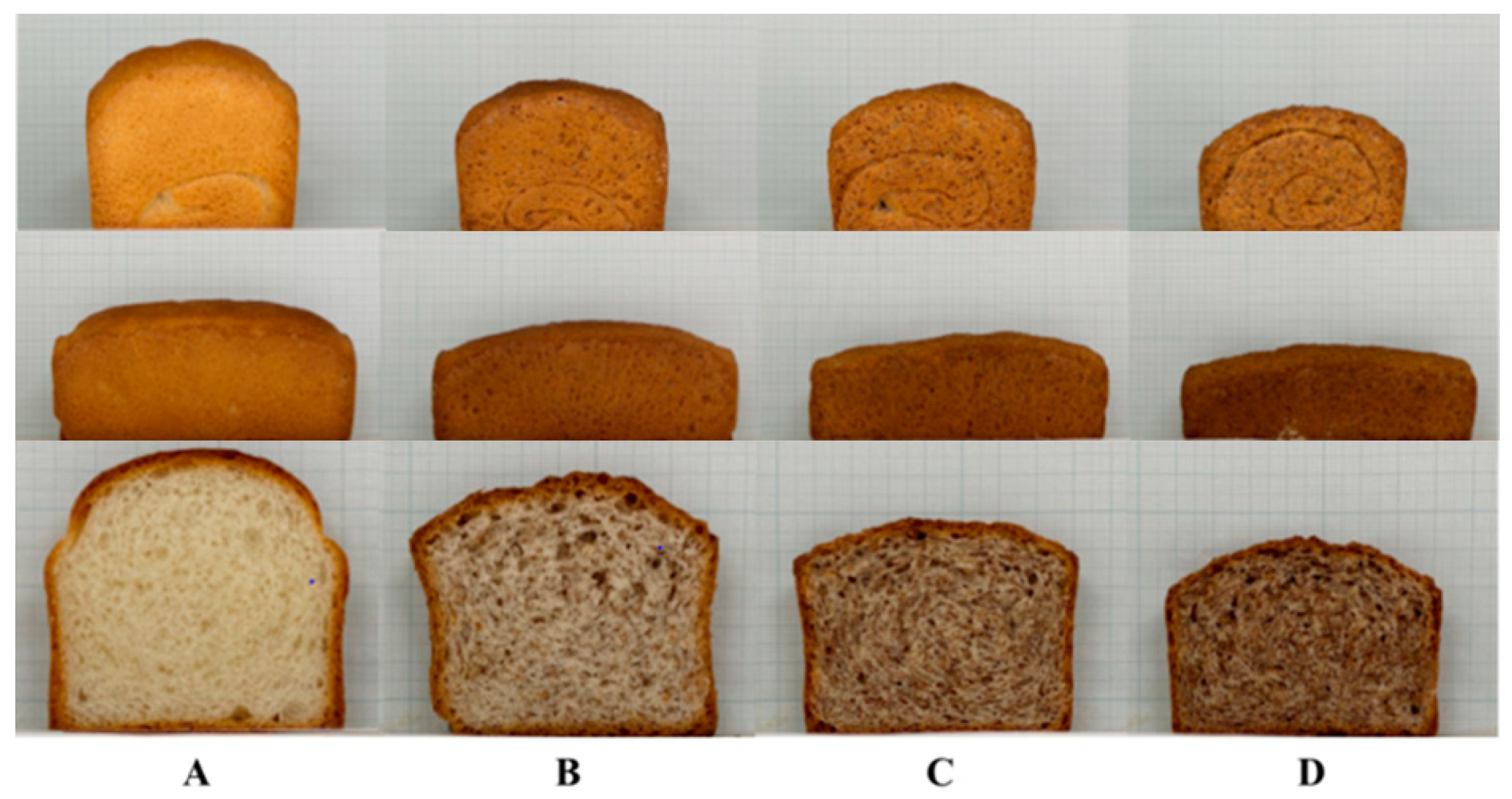

3.4. Quality of Bread Prepared with Flour–Bran Blends at Different Blending Ratios

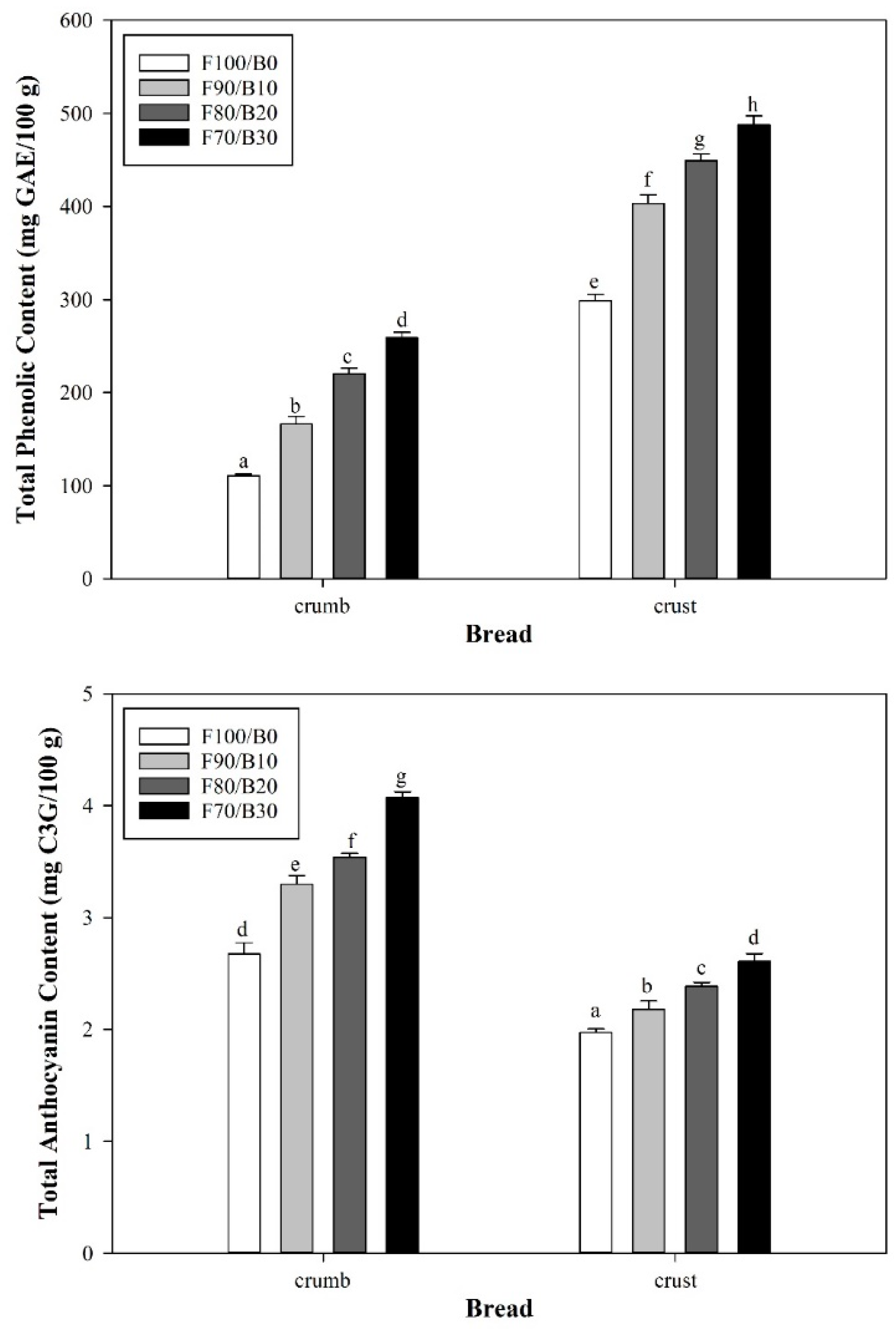

3.5. Total Phenolic and Anthocyanin Contents of the Bread Prepared with the Flour–Bran Blends

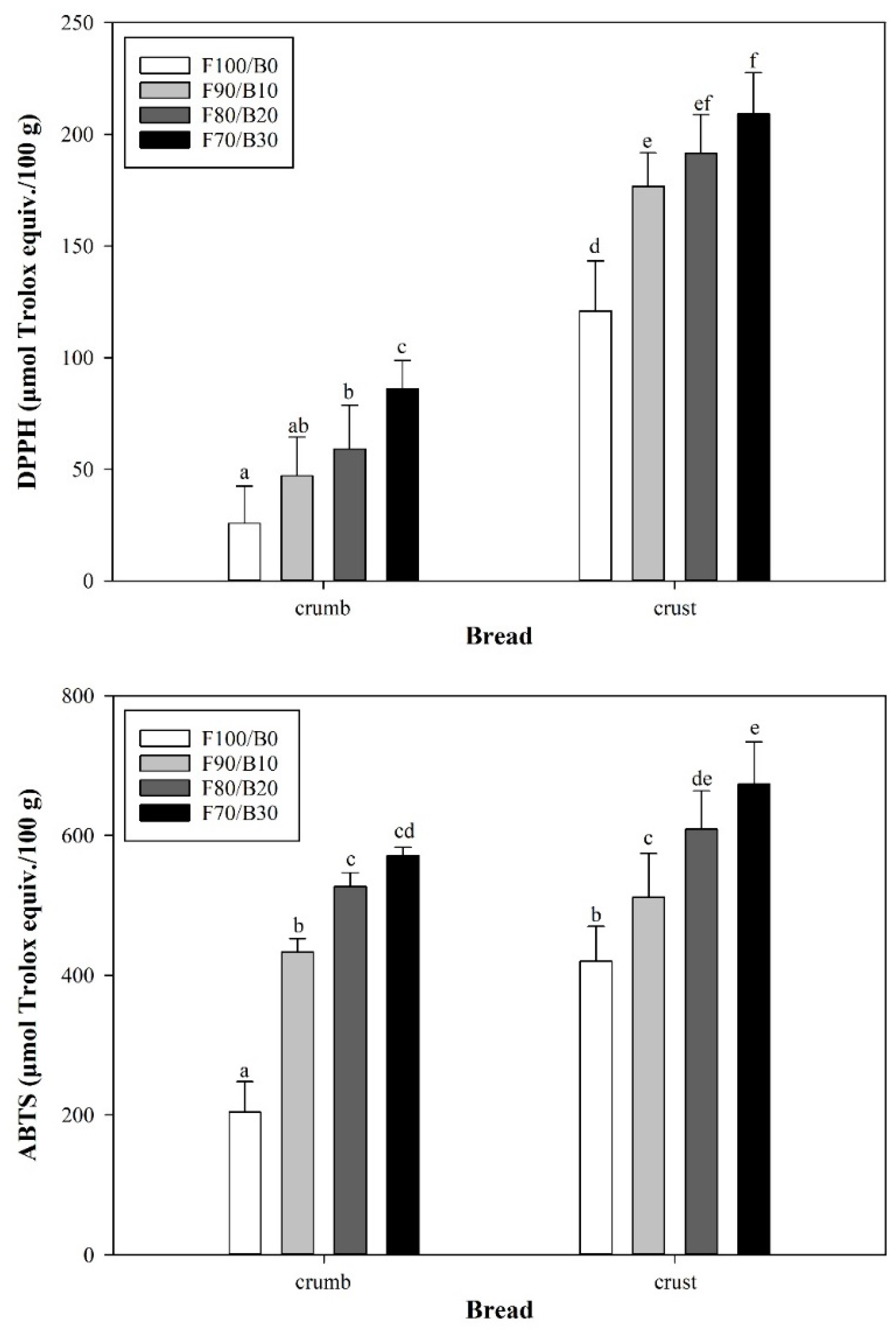

3.6. Antioxidant Activity of Bread Prepared with Flour–Bran Blends

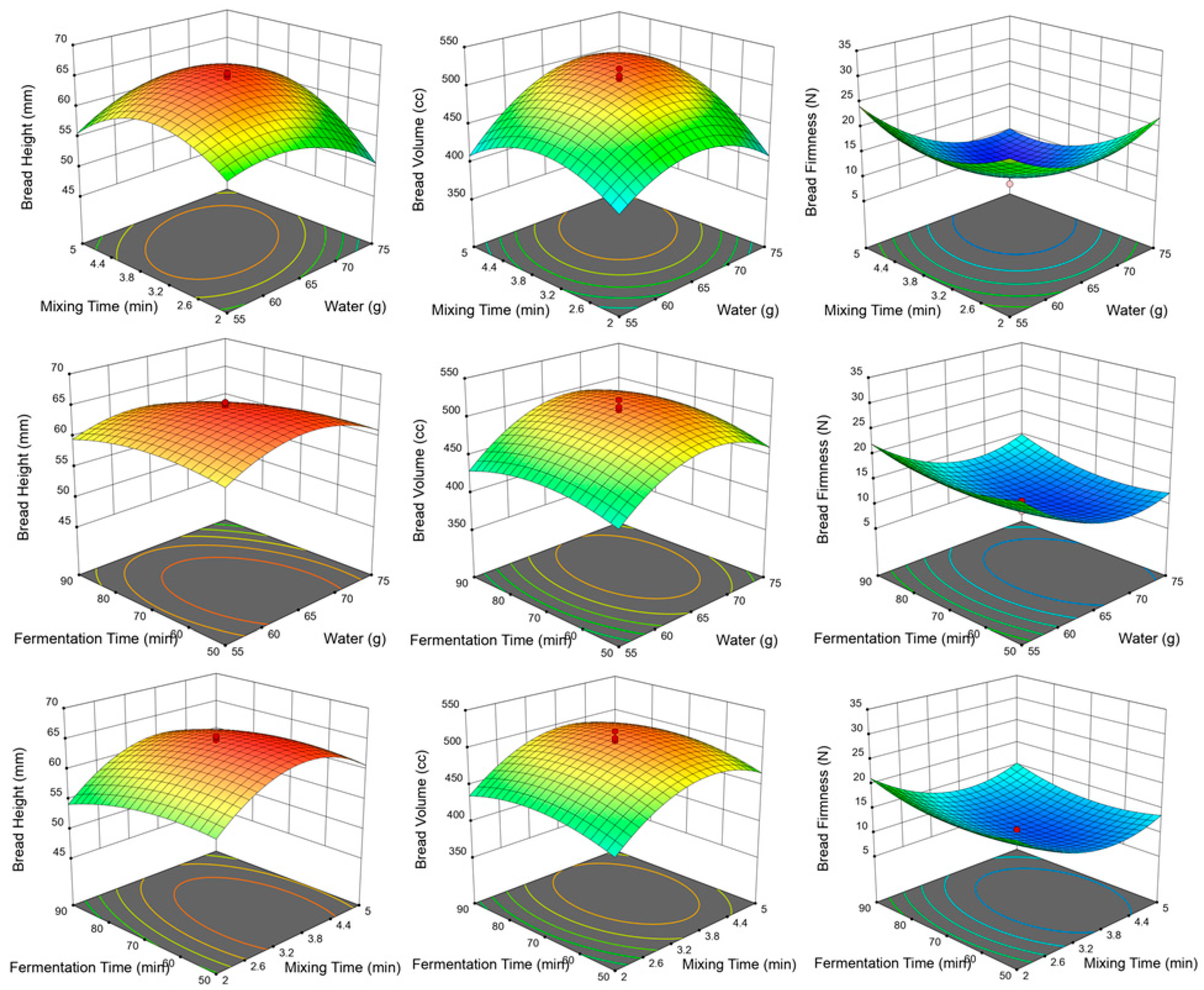

3.7. Optimization of Processing Conditions for Bread Prepared with Flour–Bran Blends at 30% Bran

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flour Yield Classification: Korea Flour Mills Industrial Association. Available online: http://www.kofmia.org/data/stat_idx03.jsp (accessed on 3 August 2018).

- Processed Food Segmentation Market Status: Food Information Statistics System. Available online: https://www.atfis.or.kr/article/M001010000/view.do?articleId=3086&page=&searchKey=&searchString=&searchCategory= (accessed on 23 October 2020).

- Shin, Y.J.; Jegal, J.M.; Lee, M.H. Quality and antioxidant properties of white bread with gynura procumbens powder. Culin. Sci. Hosp. Res. 2019, 25, 1–11. [Google Scholar]

- Vetrimani, R.; Rao, P.H. Studies on stabilization of wheat bran. J. Food Sci. Technol. 1990, 27, 332–335. [Google Scholar]

- Onipe, O.O.; Jideani, A.I.O.; Beswa, D. Composition and functionality of wheat bran and its application in some cereal food products. Int. J. Food Sci. Technol. 2015, 50, 2509–2518. [Google Scholar] [CrossRef]

- Hwang, J.K.; Kim, C.T.; Cho, S.J.; Kim, C.J. Effects of various thermal treatments on physicochemical properties of wheat bran. Korean J. Food Sci. 1995, 27, 394–403. [Google Scholar]

- Gȯmez, M.; Jiménez, S.; Ruíz, E.; Oliette, B. Effect of extruded wheat bran on dough rheology and bread quality. LWT Food Sci. Technol. 2011, 44, 2231–2237. [Google Scholar] [CrossRef]

- Sudha, M.L.; Vetrimani, R.; Leelavathi, K.E. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Leelavathi, K.E.; Rao, P.H. Development of high fiber biscuits using wheat bran. J. Food Sci. Technol. 1993, 30, 187–190. [Google Scholar]

- Agrifood Department Briefing. Available online: https://www.gov.kr/portal/ntnadmNews/1476047 (accessed on 23 October 2020).

- Rural Development Administration Briefing. Available online: https://www.gov.kr/portal/gvrnPolicy/view/156154662?PolicyType=G00301&srchTxt=%EB%B0%B1%EA%B0%95%20%EB%B0%80%EA%B0%80%EB%A3%A8 (accessed on 23 October 2020).

- Yu, L.; Beta, T. Identification and antioxidant properties of phenolic compounds during production of bread from purple wheat grains. Molecules 2015, 20, 15525–15549. [Google Scholar] [CrossRef] [PubMed]

- Hřivna, L.; Zigmundová, V.; Burešová, I.; Maco, R.; Vyhnánek, T.; Trojan, V. Rheological properties of dough and baking quality of products using coloured wheat. Plant Soil Environ. 2018, 64, 203–208. [Google Scholar]

- Li, L.; Wang, Z.; Li, L.M.; Zheng, X.L.; Ma, S.; Wang, X.X. Effects of fermented wheat bran on flour, dough, and steamed bread characteristics. J. Chem. 2018, 1597308, 1–7. [Google Scholar] [CrossRef]

- Messia, M.C.; Reale, A.; Maiuro, L.; Candigliota, T.; Sorrentino, E.; Marconi, E. Effects of pre-fermented wheat bran on dough and bread characteristics. J. Cereal Sci. 2016, 69, 138–144. [Google Scholar] [CrossRef]

- Rezaei, S.; Najafi, M.A.; Haddadi, T. Effect of fermentation process, wheat bran size and replacement level on some characteristics of wheat bran, dough, and high-fiber Tafton bread. J. Cereal Sci. 2019, 85, 56–61. [Google Scholar] [CrossRef]

- AACC. Method 08-01.01, 10-10.03, 44-15.02, 54-40.02, 56-11.02. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Kweon, M.; Slade, L.; Levine, H. Solvent retention capacity (SRC) testing of wheat flour: Principles and value in predicting flour functionality in different wheat-based food processes, as well as in wheat breeding—A review. Cereal Chem. 2011, 88, 537–552. [Google Scholar] [CrossRef]

- Avarzed, E.; Wang, X.; Moon, Y.; Kim, K.H.; Kweon, M. Quality characteristics and antioxidant activities of cookies formulated with the blend of Korean domestic wheat flour and purple wheat bran. Korean J. Food Cook Sci. 2020, 36, 152–162. [Google Scholar] [CrossRef]

- Kweon, M.; Martin, R.; Souza, E. Effect of tempering conditions on milling performance and flour functionality. Cereal Chem. 2009, 86, 12–17. [Google Scholar] [CrossRef]

- Katina, K. High-Fiber Baking; Woodhead Publishing: Cambridge, UK, 2003; pp. 487–499. [Google Scholar]

- Navrotskyi, S.; Guo, G.; Baenziger, S.; Xu, L.; Rose, D.J. Impact of wheat bran physical properties and chemical composition on whole grain flour mixing and baking properties. J. Cereal Sci. 2019, 89, 102790. [Google Scholar] [CrossRef]

- Joo, O.S.; Jung, Y.M. Effects of attrition milling in wheat flour on starch damaged of dough and bread baking properties. Korean J. Food Preserv. 2001, 8, 434–441. [Google Scholar]

- Farrand, E.A. The Influence of particles size and starch damaged on the characteristies of bread flours. Bak. Dig. 1972, 46, 22–26. [Google Scholar]

- Tester, R.F. Properties of damaged starch granules. Composition and swelling properties of maize, rice, pea and potato starch fractions in water at various temp. Food Hydrocoll. 1997, 11, 293–301. [Google Scholar] [CrossRef]

- Miller, B.S.; Trimbo, H.B.; Powell, K.R. Effect of flour granulation and starch damage on the cake making quality of soft wheat flour. Cereal Sci. Today 1967, 12, 245–252. [Google Scholar]

- Zeleznak, K.J.; Hoseney, K.C. The role of water in the retrogradation of wheat starch gels and bread crumb. Cereal Chem. 1986, 63, 407–411. [Google Scholar]

- Kim, Y.S.; Ha, T.Y.; Lee, S.H.; Lee, H.Y. Properties of dietary fiber extract from rice bran and application in bread-making. Korean J. Food Sci. Technol. 1997, 29, 502–508. [Google Scholar]

- Li, W.; Brennan, M.; Serventi, L.; Brennan, C. Effect of wheat bran on dough rheology and final quality of Chinese steamed bread. Cereal Chem. 2017, 94, 581–587. [Google Scholar] [CrossRef]

- Schmiele, M.; Jackel, L.Z.; Patricio, S.M.C.; Steel, C.J.; Chang, Y.K. Rheological properties of wheat flour and quality characteristics of pan bread as modified by partial additions of wheat bran or whole grain wheat flour. Int. J. Food Sci. Technol. 2012, 47, 2141–2150. [Google Scholar] [CrossRef]

- Sangnak, A.; Noomhorm, A. Chemical, physical and baking properties of dietary fiber prepared from rice straw. Food Res. Int. 2004, 37, 66–74. [Google Scholar] [CrossRef]

- Sangnak, A.; Noomhorm, A. Effect of dietary fiber from sugarcane bagasse and sucrose ester on dough and bread properties. LWT Food Sci. Technol. 2004, 37, 697–704. [Google Scholar] [CrossRef]

- Wang, J.; Rosell, C.M.; Barber, C. Effect of addition of different fibers on wheat dough performance and bread quality. Food Chem. 2002, 79, 221–226. [Google Scholar] [CrossRef]

- Lee, Y.T. Quality characteristics of high-fiber breads added with domestic wheat bran. J. Korean Soc. Agric. Chem. Biotechnol. 2003, 46, 323–328. [Google Scholar]

- Boita, E.R.F.; Oro, T.; Bressiani, J.; Santetti, G.S.; Bertolin, T.E.; Gutkoski, L.C. Rheological properties of wheat flour dough and pan bread with wheat bran. J. Cereal Sci. 2016, 71, 177–182. [Google Scholar] [CrossRef]

- Jung, D.S.; Lee, E.Z.; Eun, J.B. Quality properties of bread made of wheat flour and black rice flour. Korean J. Food Sci. Technol. 2002, 34, 232–237. [Google Scholar]

- Pomeranz, Y.; Shogren, M.D.; Finney, K.F.; Bechtel, D.B. Fiber in breadmaking—Effects on functional properties. Cereal Chem. 1977, 54, 25–41. [Google Scholar]

- Wang, W.M.; Klopfenstein, C.F. Effect of twin-screw extrusion on the nutritional quality of wheat, barley, and oats. Cereal Chem. 1993, 70, 712–715. [Google Scholar]

- Perez-Jimenez, J.; Diaz-Rubio, M.E.; Mesias, M.; Morales, F.J.; Saura-Calixto, F. Evidence for the formation of maillardized insoluble dietary fiber in bread: A specific kind of dietary fiber in thermally processed food. Food Res. Int. 2014, 55, 391–396. [Google Scholar] [CrossRef]

- Borrelli, R.C.; Mennella, C.; Barba, F.; Russo, M.; Russo, G.L.; Krome, K.; Erbersdobler, H.F.; Faist, V.; Fogliano, V. Characterization of colored compounds by enzymatic extraction of bakery products. Food Chem. Toxicol. 2003, 41, 1367–1374. [Google Scholar] [CrossRef]

- Li, W.; Pickard, M.D.; Beta, T. Effect of thermal processing on antioxidant properties of purple wheat bran. Food Chem. 2007, 104, 1080–1086. [Google Scholar] [CrossRef]

- Abdel-Aal, E.S.M.; Hucl, P. Composition and stability of anthocyanins in blue-grained wheat. J. Agric. Food Chem. 2003, 51, 2174–2180. [Google Scholar] [CrossRef]

- Kim, S.J.; Baek, S.Y.; Kim, D.H.; Kim, M.R. Physicochemical properties and antioxidant activities of morning bread added with Enteromorpha prolifera. J. Korean Soc. Food Sci. Nutr. 2019, 48, 1244–1252. [Google Scholar] [CrossRef]

- Duval, B.; Shetty, K. The stimulation of phenolics and antioxidant activity in pea (Pisum sativum) elicited by genetically transformed anise root extract. J. Food Biochem. 2001, 25, 361–377. [Google Scholar] [CrossRef]

- Sui, X.; Yap, P.Y.; Zhou, W. Anthocyanins during baking: Their degradation kinetics and impacts on color and antioxidant capacity of bread. Food Bioprocess Technol. 2015, 8, 983–994. [Google Scholar] [CrossRef]

- Manzocco, L.; Calligaris, S.; Mastrocola, D.; Nicoli, M.C.; Lerici, R.C. Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci. Technol. 2001, 11, 340–346. [Google Scholar] [CrossRef]

- Lingnert, H. Antioxidative Maillard reaction products III. Application in cookies. J. Food Process Preserv. 1980, 4, 219–243. [Google Scholar] [CrossRef]

- Summa, C.T.; Wenzl, M.; Brohee, M.; De La Calle, B.; Anklam, E. Investigation of the correlation of the acrylamide content and the antioxidant activity of model cookies. J. Agric. Food Chem. 2006, 54, 853–859. [Google Scholar] [CrossRef] [PubMed]

- Soares, C.M.D.; Alves, R.C.; Oliveira, M.B.P.P. Acrylamide in coffee. In Processing and Impact on Active Components in Food; Elsevier: Amsterdam, The Netherlands, 2015; pp. 575–582. [Google Scholar]

- Jo, Y.; Chun, A.; Sim, E.Y.; Park, H.Y.; Kwak, J.E.; Kim, M.J.; Lee, C.K. Effect of kneading and fermentation conditions on the quality of gluten-free rice bread. Korean J. Food Sci. Technol. 2020, 52, 510–515. [Google Scholar]

- Kim, J.K.; Kim, Y.H.; Oh, J.C.; Yu, H.H. Optimization of White Pan Bread Preparation via Addition of Purple Barley Flour and Olive Oil by Response Surface Methodology. J. Korean Soc. Food Sci. Nutr. 2012, 41, 1813–1822. [Google Scholar] [CrossRef][Green Version]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and functional ingredients in whole wheat bread: A review of their effects on dough properties and bread quality. Trends Food Sci. Technol. 2018, 81, 10–24. [Google Scholar] [CrossRef]

| Standard Order | Run Order | Water (g) | Mixing Time (min) | Fermentation Time (min) |

|---|---|---|---|---|

| 1 | 4 | 55 | 2.00 | 50 |

| 2 | 8 | 75 | 2.00 | 50 |

| 3 | 15 | 55 | 5.00 | 50 |

| 4 | 16 | 75 | 5.00 | 50 |

| 5 | 3 | 55 | 2.00 | 90 |

| 6 | 5 | 75 | 2.00 | 90 |

| 7 | 14 | 55 | 5.00 | 90 |

| 8 | 7 | 75 | 5.00 | 90 |

| 9 | 13 | 50 | 3.50 | 70 |

| 10 | 6 | 80 | 3.50 | 70 |

| 11 | 17 | 65 | 1.25 | 70 |

| 12 | 11 | 65 | 5.75 | 70 |

| 13 | 12 | 65 | 3.50 | 40 |

| 14 | 10 | 65 | 3.50 | 100 |

| 15 | 2 | 65 | 3.50 | 70 |

| 16 | 1 | 65 | 3.50 | 70 |

| 17 | 9 | 65 | 3.50 | 70 |

| Moisture | Ash | SRC (%) | ||

|---|---|---|---|---|

| (%) | (%) | Water | Sodium Carbonate | |

| F100/B0 | 12.1 ± 0.0 a (1) | 0.48 ± 0.00 a | 65.2 ± 0.6 a | 88.4 ± 0.0 a |

| F90/B10 | 12.4 ± 0.1 b | 0.81 ± 0.00 b | 70.5 ± 0.3 b | 92.1 ± 0.4 b |

| F80/B20 | 12.7 ± 0.0 c | 1.14 ± 0.01 c | 76.3 ± 0.6 c | 97.8 ± 0.5 c |

| F70/B30 | 12.9 ± 0.0 d | 1.46 ± 0.01 d | 81.7 ± 0.3 d | 102.5 ± 0.1 d |

| Flour–Bran Blend | Bread Ht (mm) | Color | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| F100/B0 | 77.2 | 74.1 ± 0.5 d (1) | 1.1 ± 0.0 a | 14.9 ± 0.4 b |

| F90/B10 | 65.4 | 63.4 ± 0.6 c | 3.8 ± 0.6 b | 13.4 ± 0.9 a |

| F80/B20 | 60.7 | 55.1 ± 0.7 b | 5.2 ± 0.4 c | 12.1 ± 0.7 a |

| F70/B30 | 53.7 | 50.8 ± 0.2 a | 6.9 ± 0.3 d | 13.3 ± 0.5 a |

| Std Order | Moisture Content (%) | Crumb Color | Height (mm) | Volume (mL) | Firmness (N) | ||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | |||||

| 1 | 39.3 | 54.1 | 6.2 | 13.0 | 55.1 | 394 | 27.7 |

| 2 | 44.8 | 47.1 | 6.1 | 11.6 | 54.7 | 413 | 18.7 |

| 3 | 39.6 | 56.1 | 6.3 | 13.3 | 56.3 | 412 | 30.0 |

| 4 | 45.1 | 50.5 | 5.8 | 11.9 | 60.5 | 474 | 12.6 |

| 5 | 39.6 | 53.1 | 6.2 | 12.6 | 55.1 | 399 | 24.1 |

| 6 | 45.7 | 47.4 | 6.4 | 12.3 | 45.4 | 395 | 27.3 |

| 7 | 39.6 | 53.4 | 6.6 | 13.5 | 52.0 | 381 | 30.0 |

| 8 | 45.4 | 48.9 | 5.8 | 11.8 | 57.7 | 497 | 11.4 |

| 9 | 37.6 | 56.6 | 6.3 | 13.5 | 58.0 | 381 | 27.9 |

| 10 | 46.0 | 48.5 | 6.1 | 12.2 | 52.6 | 421 | 17.5 |

| 11 | 42.7 | 48.9 | 6.2 | 12.2 | 49.4 | 378 | 27.6 |

| 12 | 42.2 | 50.9 | 6.5 | 13.0 | 54.0 | 436 | 16.7 |

| 13 | 42.4 | 56.7 | 5.7 | 12.4 | 60.5 | 426 | 16.7 |

| 14 | 42.7 | 51.5 | 6.2 | 12.7 | 59.6 | 477 | 16.7 |

| 15 | 42.6 | 51.5 | 5.9 | 12.1 | 65.3 | 523 | 10.7 |

| 16 | 42.5 | 52.7 | 5.8 | 12.1 | 64.9 | 510 | 10.5 |

| 17 | 42.7 | 51.3 | 5.9 | 11.9 | 65.5 | 513 | 8.6 |

| Response | Factor (1) | p-Value | Model |

|---|---|---|---|

| Bread height | Water | 0.3747 | Quadratic |

| MT | 0.0360 | ||

| FT | 0.0844 | ||

| Bread volume | Water | 0.0281 | Quadratic |

| MT | 0.0287 | ||

| FT | 0.5639 | ||

| Bread firmness | Water | 0.0030 | Quadratic |

| MT | 0.0148 | ||

| FT | 0.3919 |

| Response | Source | DF | Sum of Squares | Mean Square | F Value | R2 |

|---|---|---|---|---|---|---|

| Bread height | Model | 9 | 450.93 | 50.10 | 8.00 ** | 0.911 |

| Residual | 7 | 43.82 | 6.26 | |||

| Total | 16 | 494.75 | ||||

| Bread volume | Model | 9 | 36,822.12 | 4091.35 | 6.17 * | 0.888 |

| Residual | 7 | 4642.61 | 663.23 | |||

| Total | 16 | 41,464.73 | ||||

| Bread firmness | Model | 9 | 758.65 | 84.29 | 8.03 ** | 0.912 |

| Residual | 7 | 73.52 | 10.50 | |||

| Total | 16 | 832.17 |

| Optimum Condition | ||

|---|---|---|

| Water (g) | 68.1 | 68.1 |

| Mixing time (min) | 4.0 | 4.0 |

| Fermentation time (min) | 67.3 | 67.3 |

| Response | Predicted value | Experimental value |

| Bread height (mm) | 64.6 | 64.7 ± 1.5 |

| Bread volume (mL) | 513.2 | 530.5 ± 9.0 |

| Bread firmness (N) | 8.8 | 8.2 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, Y.; Moon, Y.; Kweon, M. Effect of Purple-Colored Wheat Bran Addition on Quality and Antioxidant Property of Bread and Optimization of Bread-Making Conditions. Appl. Sci. 2021, 11, 4034. https://doi.org/10.3390/app11094034

Seo Y, Moon Y, Kweon M. Effect of Purple-Colored Wheat Bran Addition on Quality and Antioxidant Property of Bread and Optimization of Bread-Making Conditions. Applied Sciences. 2021; 11(9):4034. https://doi.org/10.3390/app11094034

Chicago/Turabian StyleSeo, Yeri, Yujin Moon, and Meera Kweon. 2021. "Effect of Purple-Colored Wheat Bran Addition on Quality and Antioxidant Property of Bread and Optimization of Bread-Making Conditions" Applied Sciences 11, no. 9: 4034. https://doi.org/10.3390/app11094034

APA StyleSeo, Y., Moon, Y., & Kweon, M. (2021). Effect of Purple-Colored Wheat Bran Addition on Quality and Antioxidant Property of Bread and Optimization of Bread-Making Conditions. Applied Sciences, 11(9), 4034. https://doi.org/10.3390/app11094034