Numerical Modelling of Flow-Debris Interaction during Extreme Hydrodynamic Events with DualSPHysics-CHRONO

Abstract

1. Introduction

2. Methodology

2.1. DualSPHysics

2.2. CHRONO Engine and Coupling with DualSPHyics

2.3. Modelled Experiments

2.4. Numerical Setup

2.5. Properties of the Materials

2.6. Model Performance Assessment

3. Results

3.1. Dam Break Hydrodynamics

3.2. Sensitivity of the Container Dynamics to the Material Characteristics Parameters

3.3. Container Kinematics

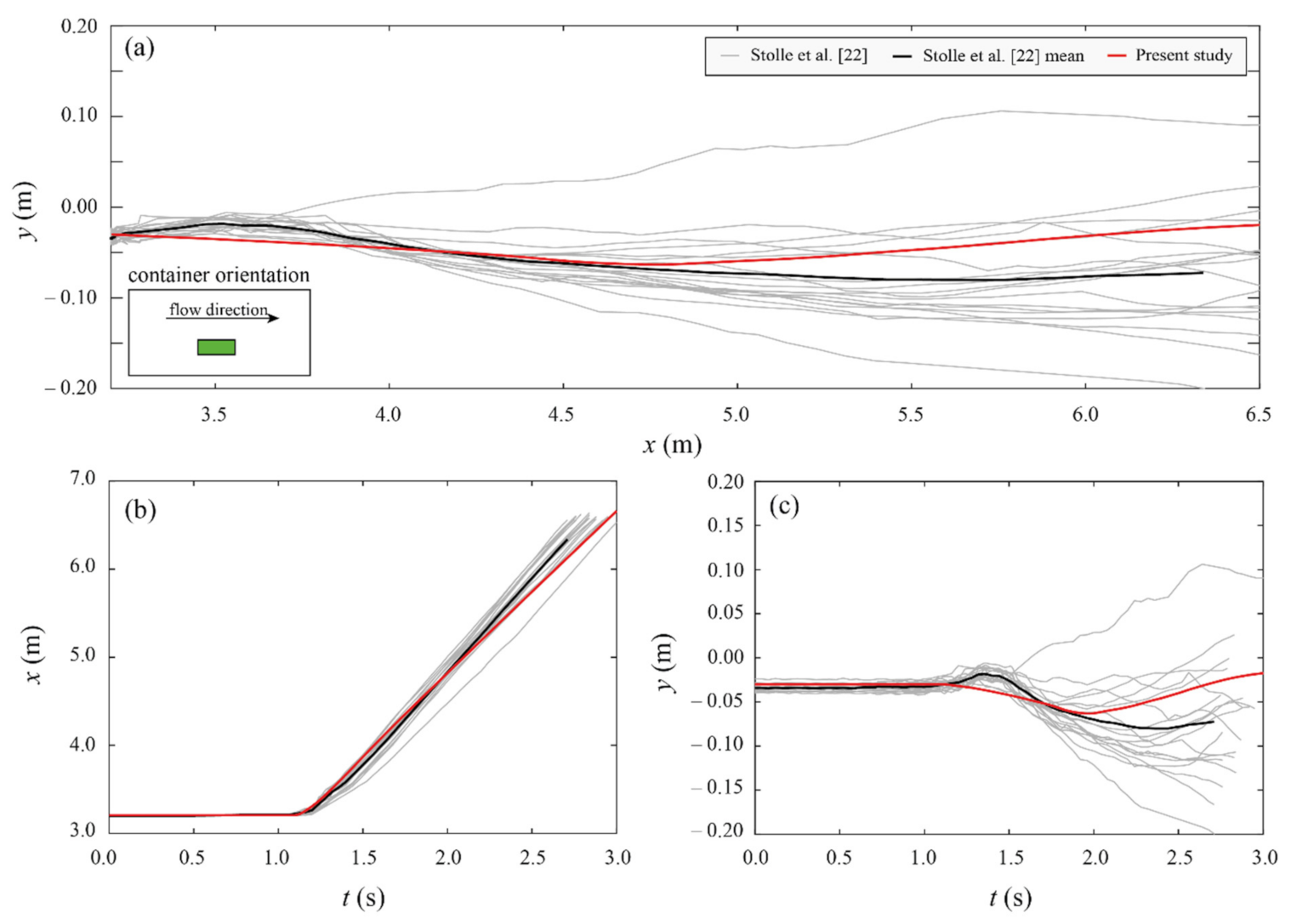

3.3.1. Trajectories

3.3.2. Velocity

3.3.3. Qualitative Description of the Interaction between Container and Flow

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mori, N.; Takahashi, T.; Yasuda, T.; Yanagisawa, H. Survey of 2011 Tohoku earthquake tsunami inundation and run-up. Geophys. Res. Lett. 2011, 38, L00G14. [Google Scholar] [CrossRef]

- Sassa, S.; Takagawa, T. Liquefied gravity flow-induced tsunami: First evidence and comparison from the 2018 Indonesia Sulawesi earthquake and tsunami disasters. Landslides 2019, 16, 195–200. [Google Scholar] [CrossRef]

- Bellotti, G.; Briganti, R.; Beltrami, G.M. The combined role of bay and shelf modes in tsunami amplification along the coast. J. Geophys. Res. Oceans 2012, 117, C08027. [Google Scholar] [CrossRef]

- De Girolamo, P.; Di Risio, M.; Romano, A.; Molfetta, M.G. Landslide Tsunami: Physical Modeling for the Implementation of Tsunami Early Warning Systems in the Mediterranean Sea. Procedia Eng. 2014, 70, 429–438. [Google Scholar] [CrossRef]

- Romano, A.; Di Risio, M.; Bellotti, G.; Molfetta, M.G.; Damiani, L.; De Girolamo, P. Tsunamis generated by landslides at the coast of conical islands: Experimental benchmark dataset for mathematical model validation. Landslides 2016, 13, 1379–1393. [Google Scholar] [CrossRef]

- Romano, A.; Lara, J.L.; Barajas, G.; Di Paolo, B.; Bellotti, G.; Di Risio, M.; Losada, I.J.; De Girolamo, P. Tsunamis Generated by Submerged Landslides: Numerical Analysis of the Near-Field Wave Characteristics. J. Geophys. Res. Oceans 2020, 125, e2020JC016157. [Google Scholar] [CrossRef]

- Ruffini, G.; Heller, V.; Briganti, R. Numerical characterisation and efficient prediction of landslide-tsunami propagation over a wide range of idealised bathymetries. Coast. Eng. 2021, 103854, in press. [Google Scholar] [CrossRef]

- Naito, C.; Cercone, C.; Riggs, H.R.; Cox, D. Procedure for Site Assessment of the Potential for Tsunami Debris Impact. J. Waterw. Port Coast. Ocean Eng. 2014, 140, 223–232. [Google Scholar] [CrossRef]

- FEMA. P646 Guidelines for Design of Structure for Vertical Evacuation from Tsunamis; Federal Emergency Management Agency: Redwood City, CA, USA, 2012. [Google Scholar]

- Haehnel, R.B.; Daly, S.F. Maximum impact force of woody debris on flood plain structures. J. Hydraul. Eng. 2004, 130, 112–120. [Google Scholar] [CrossRef]

- American Society for Civil Engineers (ASCE). Minimum Design Loads and Associated Criteria for Buildings and Other Structures; ASCE/SEI 7-16; American Society for Civil Engineers (ASCE): Reston, VA, USA, 2016. [Google Scholar]

- Imamura, F.; Goto, K.; Ohkubo, S. A numerical model for the transport of a boulder by tsunami. J. Geophys. Res. Space Phys. 2008, 113, C01008. [Google Scholar] [CrossRef]

- Rueben, M.; Cox, D.; Holman, R.; Shin, S.; Stanley, J. Optical Measurements of Tsunami Inundation and Debris Movement in a Large-Scale Wave Basin. J. Waterw. Port Coast. Ocean Eng. 2015, 141, 04014029. [Google Scholar] [CrossRef]

- Goseberg, N.; Stolle, J.; Nistor, I.; Shibayama, T. Experimental analysis of debris motion due the obstruction from fixed obstacles in tsunami-like flow conditions. Coast. Eng. 2016, 118, 35–49. [Google Scholar] [CrossRef]

- Nistor, I.; Goseberg, N.; Stolle, J.; Mikami, T.; Shibayama, T.; Nakamura, R.; Matsuba, S. Experimental Investigations of Debris Dynamics over a Horizontal Plane. J. Waterw. Port Coast. Ocean Eng. 2017, 143, 04016022. [Google Scholar] [CrossRef]

- Nouri, Y.; Nistor, I.; Palermo, D.; Cornett, A. Experimental Investigation of Tsunami Impact on Free Standing Structures. Coast. Eng. J. 2010, 52, 43–70. [Google Scholar] [CrossRef]

- Riggs, H.R.; Cox, D.T.; Naito, C.J.; Kobayashi, M.H.; Piran Aghl, P.; Ko, H.S.; Khowitar, E. Experimental and analytical study of water-driven debris impact forces on structures. J. Offshore Mech. Arct. Eng. 2014, 136, 041603. [Google Scholar] [CrossRef]

- Ikeno, M.; Takabatake, D.; Kihara, N.; Kaida, H.; Miyagawa, Y.; Shibayama, A. Improvement of collision force formula for woody debris by airborne and hydraulic experiments. Coast. Eng. J. 2016, 58, 1640022. [Google Scholar] [CrossRef]

- Shafiei, S.; Melville, B.W.; Shamseldin, A.Y.; Beskhyroun, S.; Adams, K.N. Measurements of tsunami-borne debris impact on structures using an embedded accelerometer. J. Hydraul. Res. 2016, 54, 435–449. [Google Scholar] [CrossRef]

- Derschum, C.; Nistor, I.; Stolle, J.; Goseberg, N. Debris impact under extreme hydrodynamic conditions part 1: Hydrodynamics and impact geometry. Coast. Eng. 2018, 141, 24–35. [Google Scholar] [CrossRef]

- Stolle, J.; Derschum, C.; Goseberg, N.; Nistor, I.; Petriu, E. Debris impact under extreme hydrodynamic conditions part 2: Impact force responses for non-rigid debris collisions. Coast. Eng. 2018, 141, 107–118. [Google Scholar] [CrossRef]

- Stolle, J.; Goseberg, N.; Nistor, I.; Petriu, E. Probabilistic Investigation and Risk Assessment of Debris Transport in Extreme Hydrodynamic Conditions. J. Waterw. Port Coast. Ocean Eng. 2018, 144, 04017039. [Google Scholar] [CrossRef]

- Goseberg, N.; Nistor, I.; Mikami, T.; Shibayama, T.; Stolle, J. Nonintrusive Spatiotemporal Smart Debris Tracking in Turbulent Flows with Application to Debris-Laden Tsunami Inundation. J. Hydraul. Eng. 2016, 142, 04016058. [Google Scholar] [CrossRef]

- Nistor, I.; Goseberg, N.; Stolle, J. Tsunami-Driven Debris Motion and Loads: A Critical Review. Front. Built Environ. 2017, 3, 2. [Google Scholar] [CrossRef]

- Wu, T.R.; Chu, C.R.; Huang, C.J.; Wang, C.Y.; Chien, S.Y.; Chen, M.Z. A two-way coupled simulation of moving solids in free-surface flows. Comput. Fluids 2014, 100, 347–355. [Google Scholar] [CrossRef]

- De Finis, S.; Romano, A.; Bellotti, G. Numerical and laboratory analysis of post-overtopping wave impacts on a storm wall for a dike-promenade structure. Coast. Eng. 2020, 155, 103598. [Google Scholar] [CrossRef]

- Chen, F.; Heller, V.; Briganti, R. Numerical modelling of tsunamis generated by iceberg calving validated with large-scale laboratory experiments. Adv. Water Resour. 2020, 142, 103647. [Google Scholar] [CrossRef]

- Koshizuka, S.; Oka, Y. Moving-Particle Semi-Implicit Method for Fragmentation of Incompressible Fluid. Nucl. Sci. Eng. 1996, 123, 421–434. [Google Scholar] [CrossRef]

- Gomez-Gesteira, M.; Rogers, B.D.; Crespo, A.J.C.; Dalrymple, R.A.; Narayanaswamy, M.; Dominguez, J.M. SPHysics–development of a free-surface fluid solver Part 1: Theory and formulations. Comput. Geosci. 2012, 48, 289–299. [Google Scholar] [CrossRef]

- Koshizuka, S.; Nobe, A.; Oka, Y. Numerical analysis of breaking waves using the moving particle semi-implicit method. Int. J. Numer. Methods Fluids 1998, 26, 751–769. [Google Scholar] [CrossRef]

- Amicarelli, A.; Albano, R.; Mirauda, D.; Agate, G.; Sole, A.; Guandalini, R. A Smoothed Particle Hydrodynamics model for 3D solid body transport in free surface flows. Comput. Fluids 2015, 116, 205–228. [Google Scholar] [CrossRef]

- Tan, H.; Ruffini, G.; Heller, V.; Chen, S. A Numerical Landslide-Tsunami Hazard Assessment Technique Applied on Hypothetical Scenarios at Es Vedrà, Offshore Ibiza. J. Mar. Sci. Eng. 2018, 6, 111. [Google Scholar] [CrossRef]

- Heller, V.; Bruggemann, M.; Spinneken, J.; Rogers, B.D. Composite modelling of subaerial landslide–tsunamis in different water body geometries and novel insight into slide and wave kinematics. Coast. Eng. 2016, 109, 20–41. [Google Scholar] [CrossRef]

- Rogers, B.D.; Dalrymple, R.A.; Stansby, P.K.; Smith, J.M. SPH modeling of floating bodies in the surf zone. In Coastal Engineering 2008: (In 5 Volumes); World Scientific Publishing Co Pte Lt: Singapore, 2009; pp. 204–215. [Google Scholar]

- Canelas, R.; Ferreira, R.M.; Crespo, A.; Domínguez, J.M. A generalized SPH-DEM discretization for the modelling of complex multiphasic free surface flows. In Proceedings of the 8th International SPHERIC Workshop, Trondheim, Norway, 4–6 June 2013; pp. 74–79. [Google Scholar]

- Canelas, R.B.; Domínguez, J.M.; Crespo, A.J.; Gómez-Gesteira, M.; Ferreira, R.M. A smooth particle hydrodynamics discretization for the modelling of free surface flows and rigid body dynamics. Int. J. Numer. Methods Fluids 2015, 78, 581–593. [Google Scholar] [CrossRef]

- Goseberg, N.; Heunecke, M.; Stolle, J.; Nistor, I. Numerical modelling of shipping container transport over horizontal bottom. In Proceedings of the International Short Course and Conference on Applied Coastal Research, Santander, Spain, 3–6 October 2017. [Google Scholar]

- Crespo, A.J.C.; Domínguez, J.M.; Rogers, B.D.; Gómez-Gesteira, M.; Longshaw, S.; Canelas, R.; Vacondio, R.; Barreiro, A.; García-Feal, O. DualSPHysics: Open-source parallel CFD solver based on Smoothed Particle Hydrodynamics (SPH). Comput. Phys. Commun. 2015, 187, 204–216. [Google Scholar] [CrossRef]

- Domínguez, J.M.; Fourtakas, G.; Altomare, C.; Canelas, R.B.; Tafuni, A.; García-Feal, O.; Martínez-Estévez, I.; Mokos, A.; Vacondio, R.; Crespo, A.J.C.; et al. DualSPHysics: From fluid dynamics to Multiphysics problems. Comput. Part Mech. 2021, 1–29. [Google Scholar] [CrossRef]

- Tasora, A.; Anitescu, M. A matrix-free cone complementarity approach for solving large-scale, nonsmooth, rigid body dynamics. Comput. Methods Appl. Mech. Eng. 2011, 200, 439–453. [Google Scholar] [CrossRef]

- Anitescu, M.; Tasora, A. An iterative approach for cone complementarity problems for nonsmooth dynamics. Comput. Optim. Appl. 2010, 47, 207–235. [Google Scholar] [CrossRef]

- Tagliafierro, B.; Mancini, S.; Ropero-Giralda, P.; Domínguez, J.M.; Crespo, A.J.C.; Viccione, G. Performance Assessment of a Planing Hull Using the Smoothed Particle Hydrodynamics Method. J. Mar. Sci. Eng. 2021, 9, 244. [Google Scholar] [CrossRef]

- Violeau, D.; Rogers, B.D. Smoothed particle hydrodynamics (SPH) for free-surface flows: Past, present and future. J. Hydraul. Res. 2016, 54, 1–26. [Google Scholar] [CrossRef]

- Monaghan, J.J. Smoothed particle hydrodynamics. Annu. Rev. Astron. Astrophys. 1992, 30, 543–574. [Google Scholar] [CrossRef]

- Gotoh, H.; Shao, S.; Memita, T. SPH-LES model for numerical investigation of wave interaction with partially immersed breakwater. Coast. Eng. J. 2001, 46, 39–63. [Google Scholar] [CrossRef]

- Liu, G.R.; Liu, M.B. Smoothed Particle Hydrodynamics: A Meshfree Particle Method; World Scientific Publishing Co Pte Lt: Singapore, 2003. [Google Scholar]

- Crespo, A.J.C.; Gómez-Gesteira, M.; Dalrymple, R.A. Boundary conditions generated by dynamic particles in SPH methods. Comput. Mater. Contin. 2007, 5, 173–184. [Google Scholar]

- Gomez-Gesteira, M.; Rogers, B.D.; Dalrymple, R.A.; Crespo, A.J. State-of-the-art of classical SPH for free-surface flows. J. Hydraul. Res. 2010, 48, 6–27. [Google Scholar] [CrossRef]

- Stolle, J.; Ghodoosipour, B.; Derschum, C.; Nistor, I.; Petriu, E.; Goseberg, N. Swing gate generated dam-break waves. J. Hydraul. Res. 2019, 57, 675–687. [Google Scholar] [CrossRef]

- Wendland, H. Piecewise polynomial, positive definite and compactly supported radial functions of minimal degree. Adv. Comput. Math. 1995, 4, 389–396. [Google Scholar] [CrossRef]

- Fourtakas, G.; Vacondio, R.; Domínguez, J.M.; Rogers, B.D. Improved density diffusion term for long duration wave propagation. In Proceedings of the International SPHERIC Workshop, Harbin, China, 13–16 January 2020. [Google Scholar]

- Tan, H.; Xu, Q.; Chen, S. Subaerial rigid landslide-tsunamis: Insights from a block DEM-SPH model. Eng. Anal. Bound. Elem. 2018, 95, 297–314. [Google Scholar] [CrossRef]

- Vacondio, R.; Mignosa, P.; Pagani, S. 3D SPH numerical simulation of the wave generated by the Vajont rockslide. Adv. Water Resour. 2013, 59, 146–156. [Google Scholar] [CrossRef]

- Harper, C.A. Modern Plastics Handbook; McGraw Hill Professional: New York, NY, USA, 2000. [Google Scholar]

- Michael, L.B. SPI Plastics Engineering Handbook of the Society of the Plastics Industry; Springer: New York, NY, USA, 1991. [Google Scholar]

- Stolle, J.; Nistor, I.; Goseberg, N. Optical Tracking of Floating Shipping Containers in a High-Velocity Flow. Coast. Eng. J. 2016, 58, 1650005. [Google Scholar] [CrossRef]

- Stolle, J.; Nistor, I.; Goseberg, N.; Petriu, E. Multiple Debris Impact Loads in Extreme Hydrodynamic Conditions. J. Waterw. Port Coast. Ocean Eng. 2020, 146, 04019038. [Google Scholar] [CrossRef]

- Chanson, H. Tsunami Surges on Dry Coastal Plains: Application of Dam Break Wave Equations. Coast. Eng. J. 2006, 48, 355–370. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| dp (m) | 0.01 |

| Total number of particles | 28.9 × 106 |

| Smoothing kernel | Wendland, 1995 [50] |

| 1.73 | |

| Dissipative term | Artificial viscosity [44] |

| 0.04 | |

| 9 | |

| Density diffusion term | Fourtakas et al. 2020 [51] (only between fluid particles) |

| Property | Container (HMWPE) | Flume Floor (Concrete + Sand Paint) |

|---|---|---|

| (Gpa) | 0.8 | 30 |

| (-) | 0.4 | 0.2 |

| (-) | 0.6–0.75 | 0.6–0.75 |

| (-) | 0.125–0.2 | 0.3–0.5 |

| 0.122 | 0.024 |

| 0.190 | 0.044 |

| Container Orientation | ||

|---|---|---|

| OR1 | 0.135 | 0.016 |

| OR2 | 0.133 | 0.024 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruffini, G.; Briganti, R.; De Girolamo, P.; Stolle, J.; Ghiassi, B.; Castellino, M. Numerical Modelling of Flow-Debris Interaction during Extreme Hydrodynamic Events with DualSPHysics-CHRONO. Appl. Sci. 2021, 11, 3618. https://doi.org/10.3390/app11083618

Ruffini G, Briganti R, De Girolamo P, Stolle J, Ghiassi B, Castellino M. Numerical Modelling of Flow-Debris Interaction during Extreme Hydrodynamic Events with DualSPHysics-CHRONO. Applied Sciences. 2021; 11(8):3618. https://doi.org/10.3390/app11083618

Chicago/Turabian StyleRuffini, Gioele, Riccardo Briganti, Paolo De Girolamo, Jacob Stolle, Bahman Ghiassi, and Myrta Castellino. 2021. "Numerical Modelling of Flow-Debris Interaction during Extreme Hydrodynamic Events with DualSPHysics-CHRONO" Applied Sciences 11, no. 8: 3618. https://doi.org/10.3390/app11083618

APA StyleRuffini, G., Briganti, R., De Girolamo, P., Stolle, J., Ghiassi, B., & Castellino, M. (2021). Numerical Modelling of Flow-Debris Interaction during Extreme Hydrodynamic Events with DualSPHysics-CHRONO. Applied Sciences, 11(8), 3618. https://doi.org/10.3390/app11083618