Quasi-Passive Resistive Exosuit for Space Activities: Proof of Concept

Abstract

1. Introduction

2. Materials and Methods

2.1. Wearable Device Requirements and Technology Overview

2.1.1. Exoskeleton Structure and Actuation Strategy

2.1.2. Sensing Strategy

2.1.3. Control Architecture

2.2. Proof of Concept

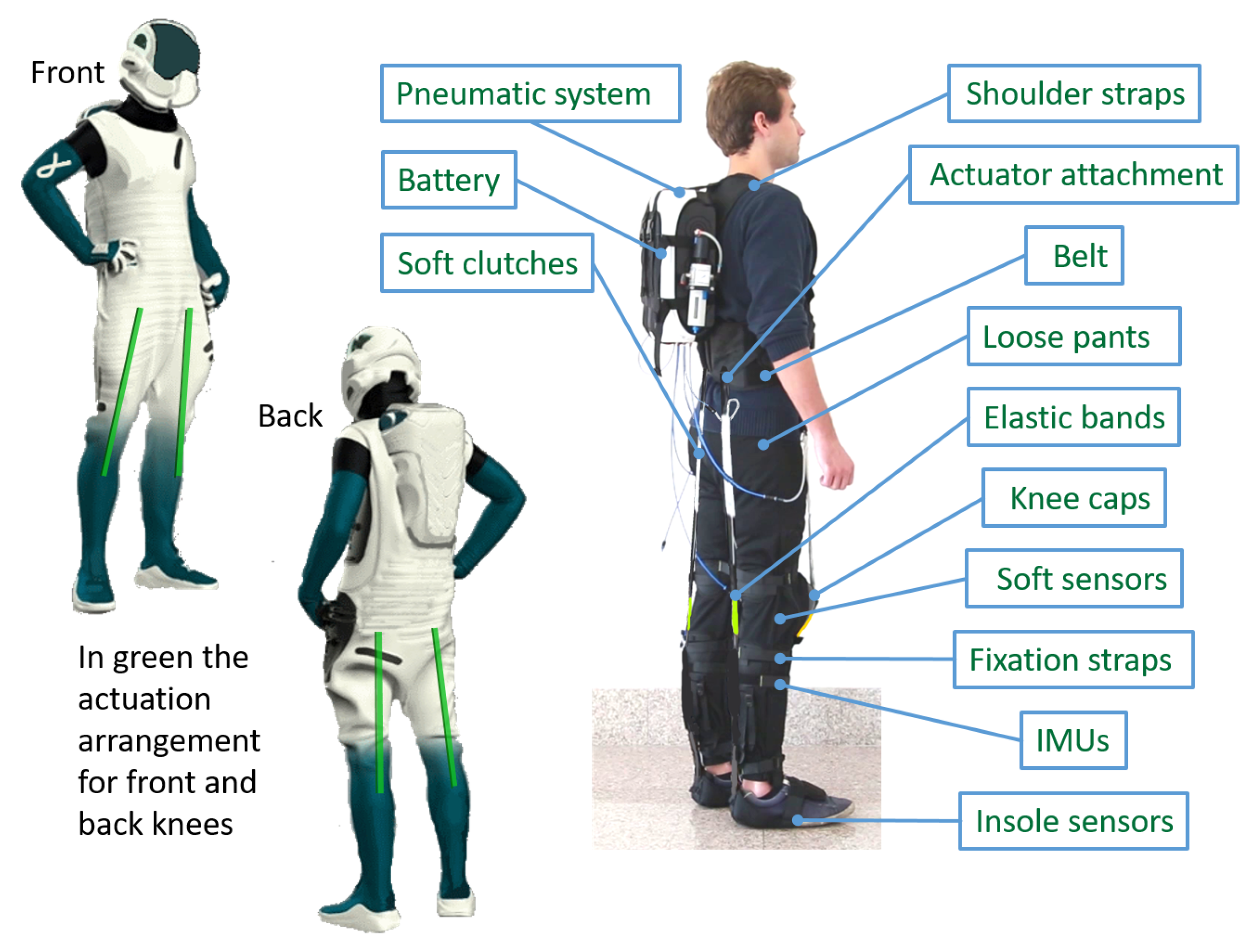

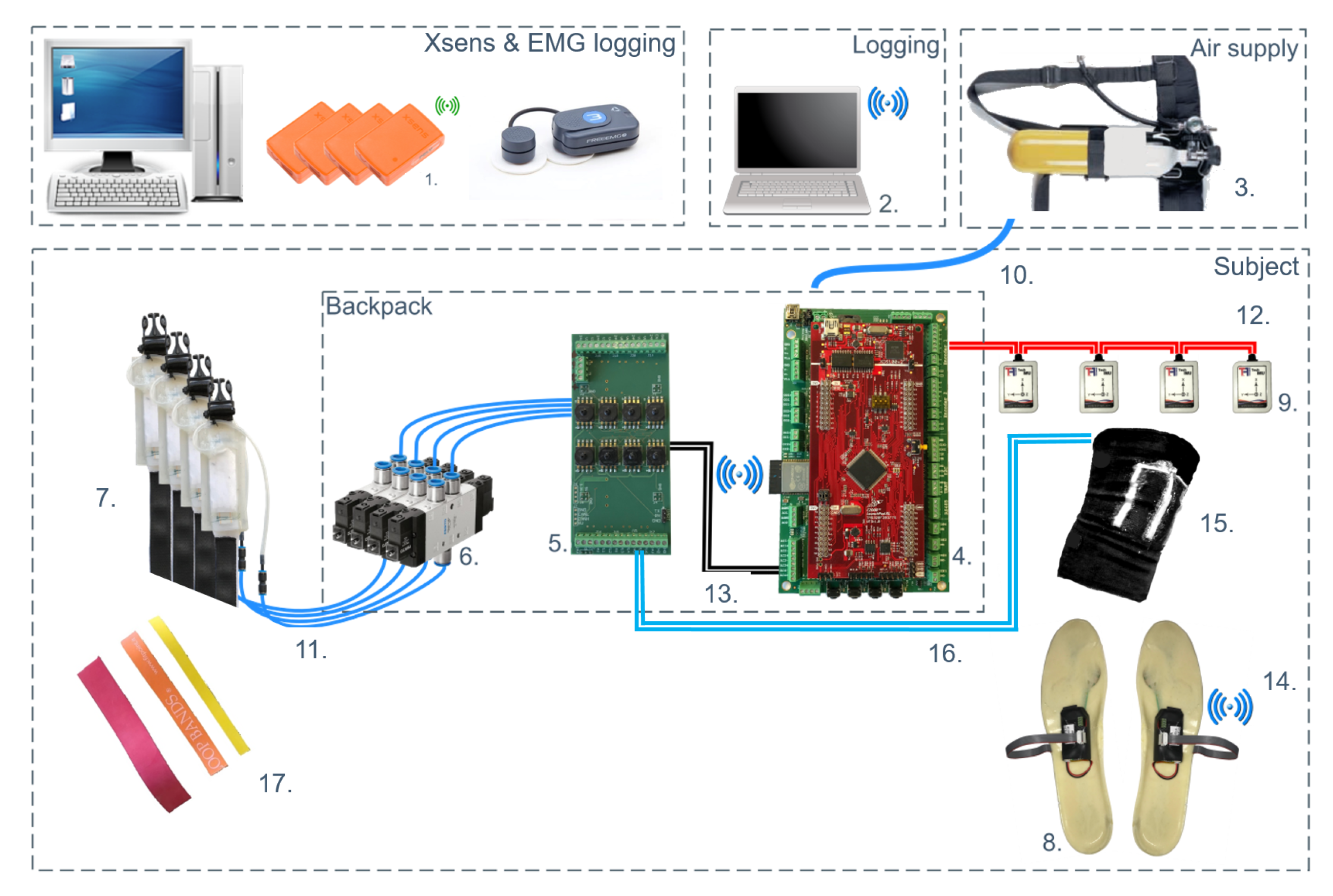

2.2.1. Exosuit Platform and Actuation Unit

- Quasi-Passive Actuation (QPA): is composed of a soft clutch (or textile based clutch [88] and Elastic bands (EB). The soft clutch (SC) creates controlled storage and release of energy. The EB stores the user generated mechanical energy.

- Body Attachment: Body attachment is required to transmit the forces from the actuators to the wearer’s body. The body attachments consist of shoulder straps, fixation straps, belt, and actuation attachments.

- Wearable Sensors: Sensors are used as an input for the motion segmentation. Insole sensors and two versions of knee angle displacement measuring sensors (details are reported in Section 2.2.3) are employed.

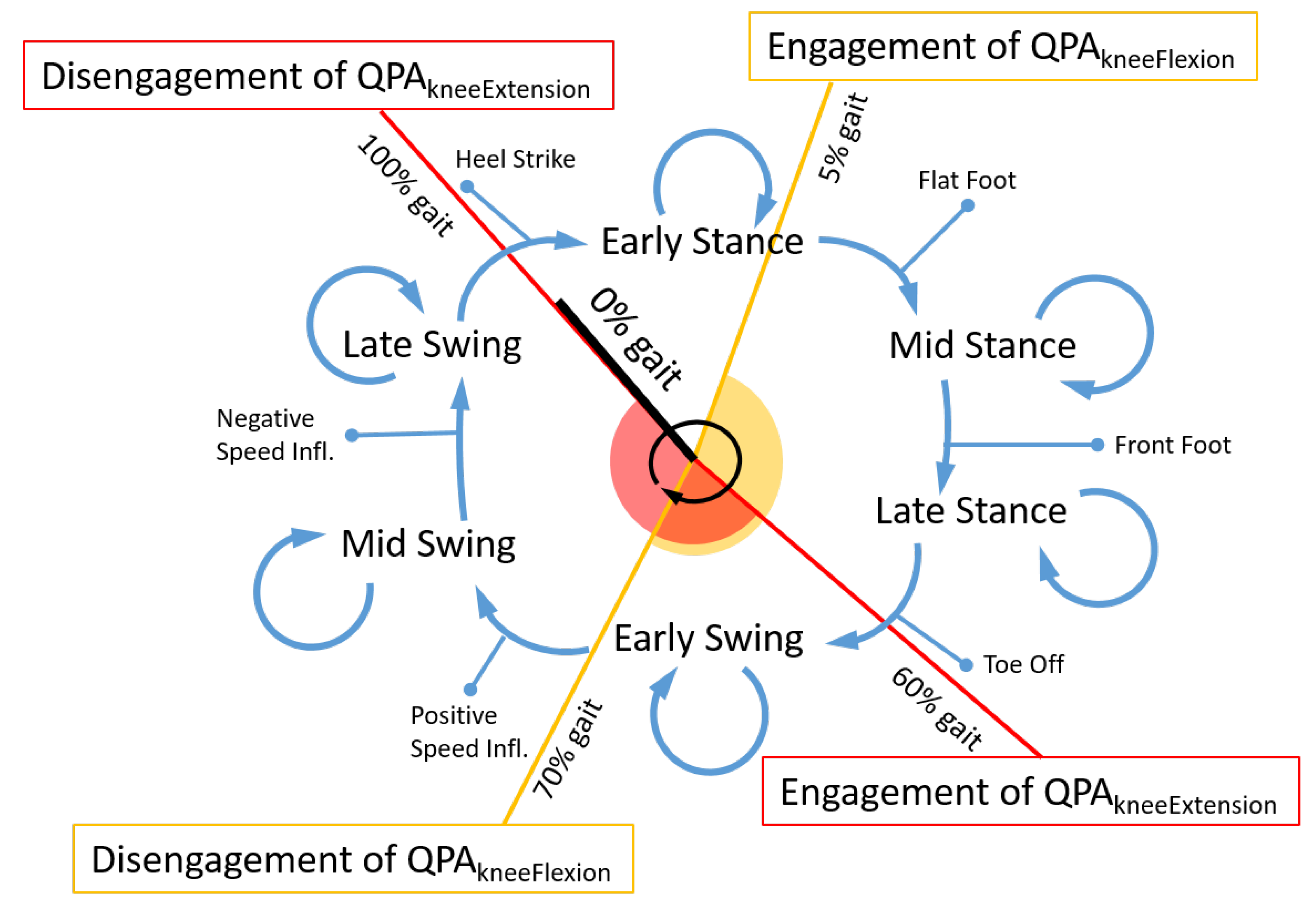

2.2.2. Control Strategy

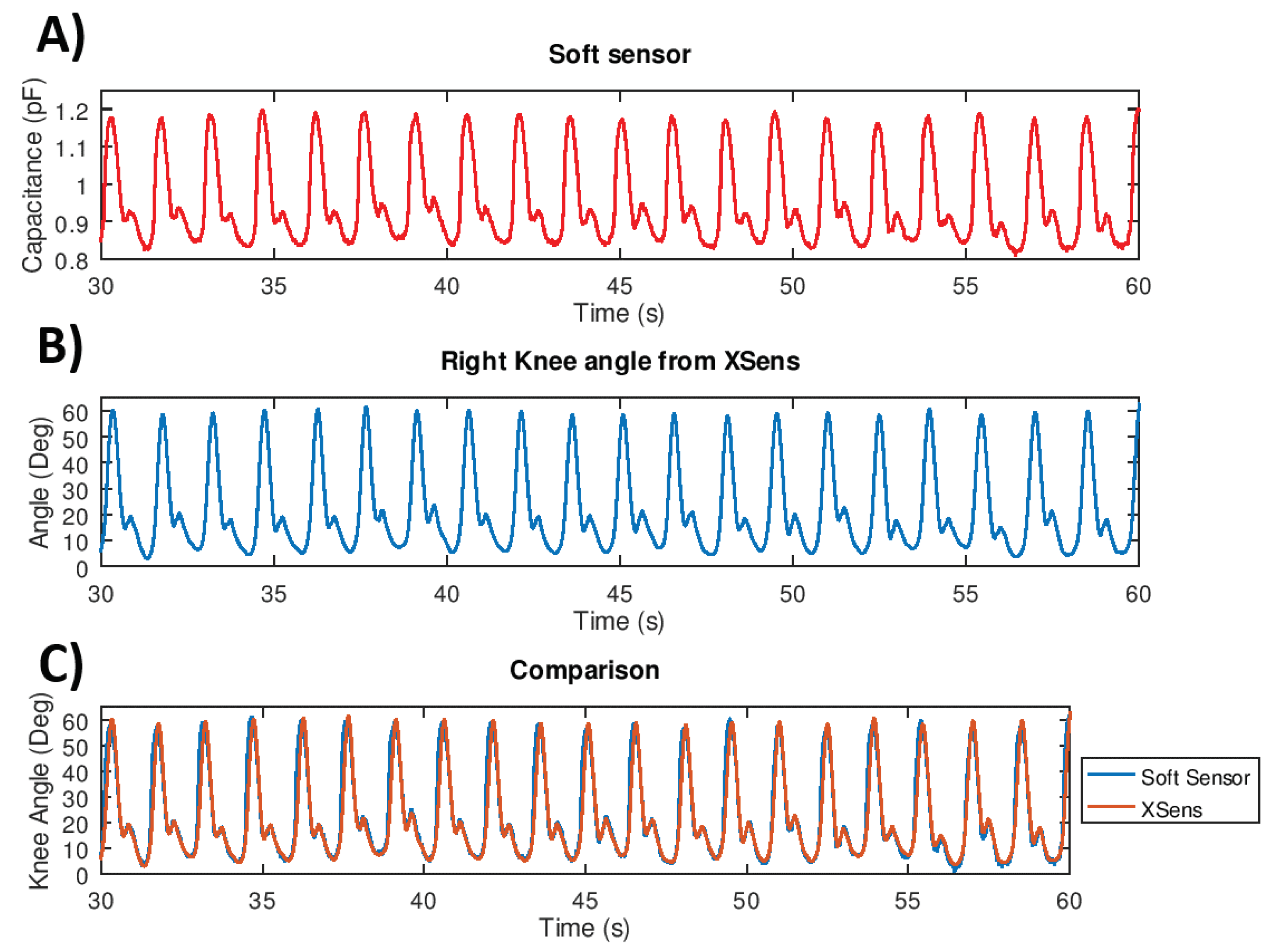

2.2.3. Soft Sensors Technology

3. Experimental Evaluation

3.1. Subsystems Validation

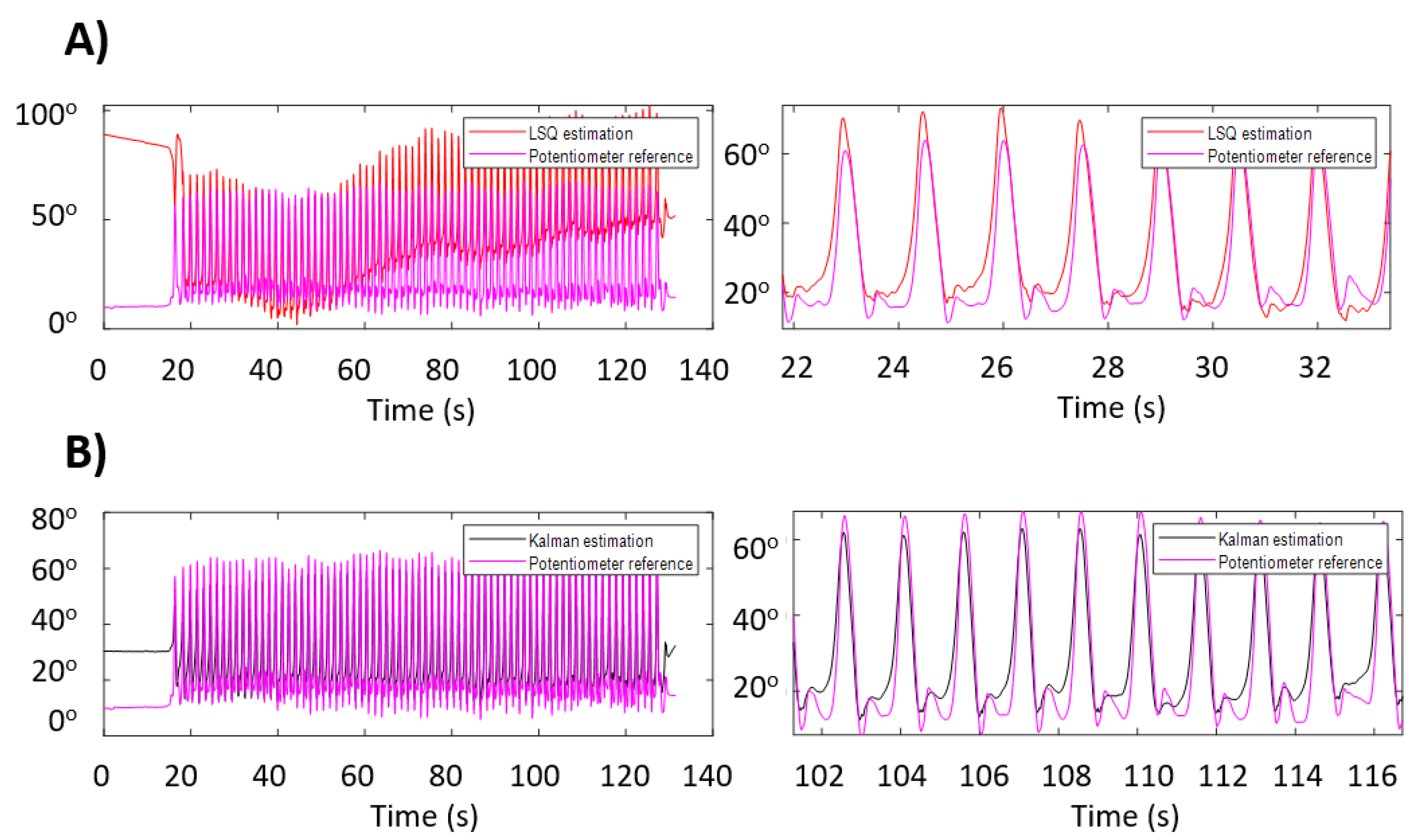

3.1.1. Lab Validation of the Soft Sensor Technology

3.1.2. Lab Validation of IMUs Sensor Technology

3.2. Overall Assessment

3.2.1. Experimental Protocol

3.2.2. EMG Data Analysis

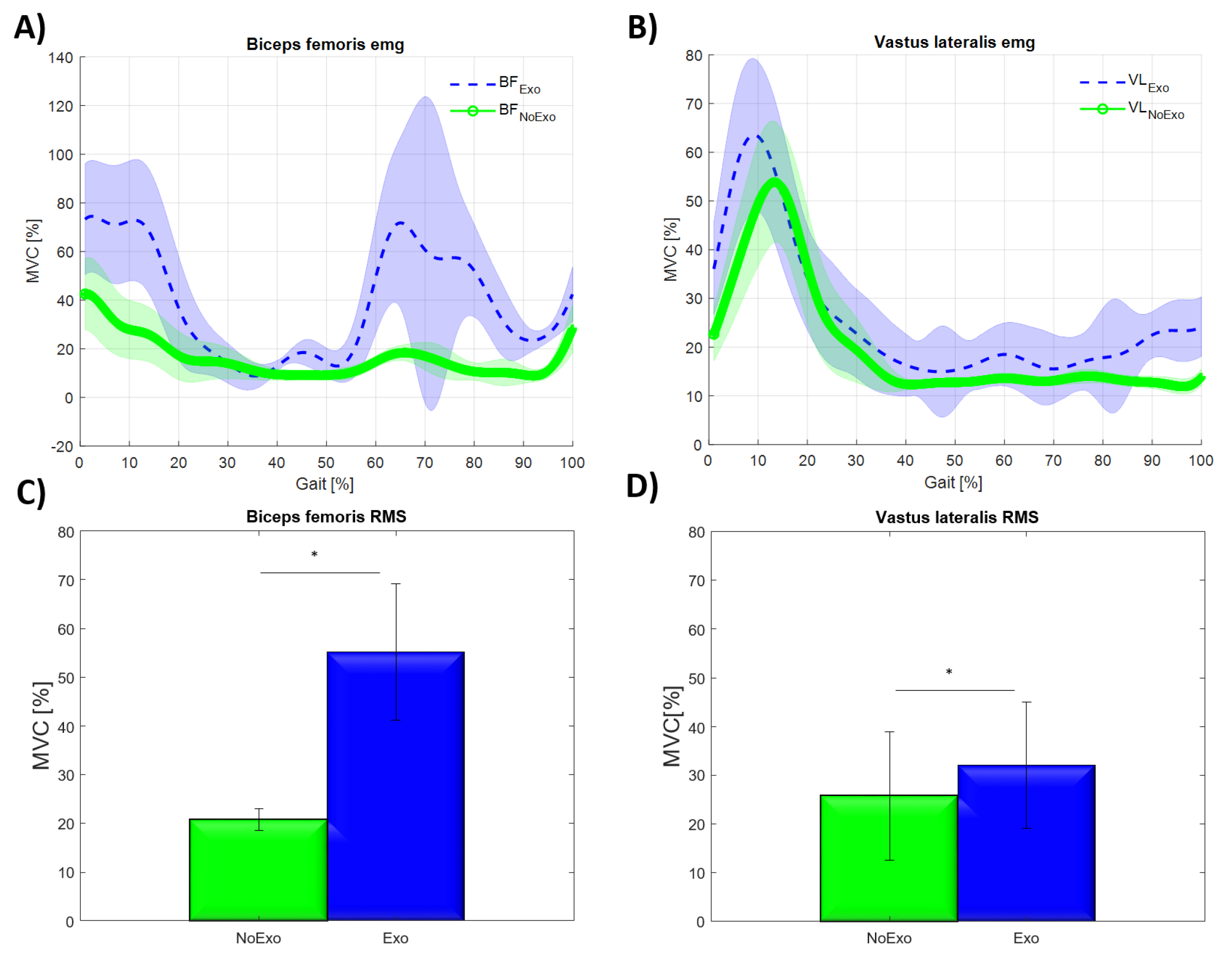

3.2.3. Kinematic Assessment Results

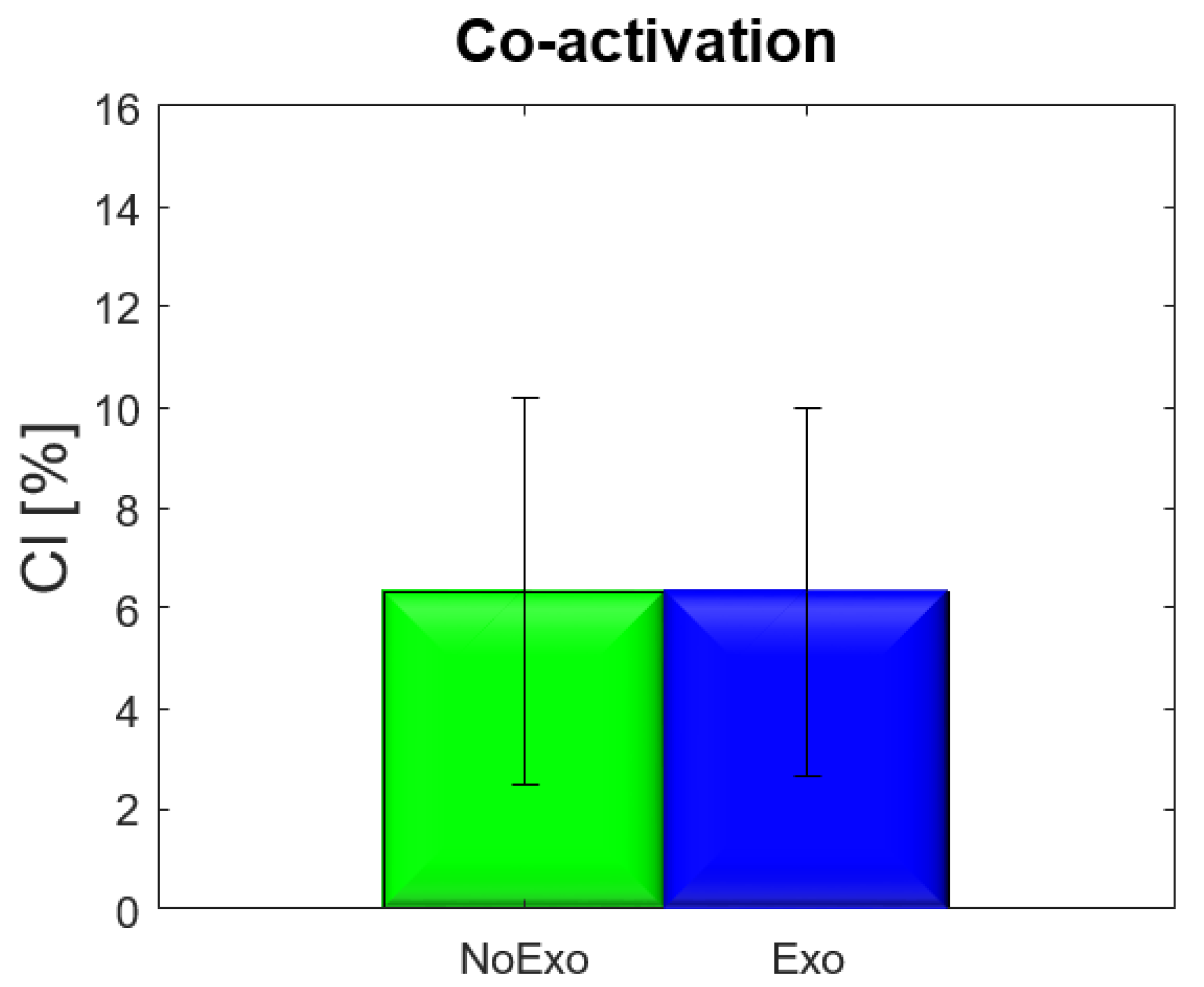

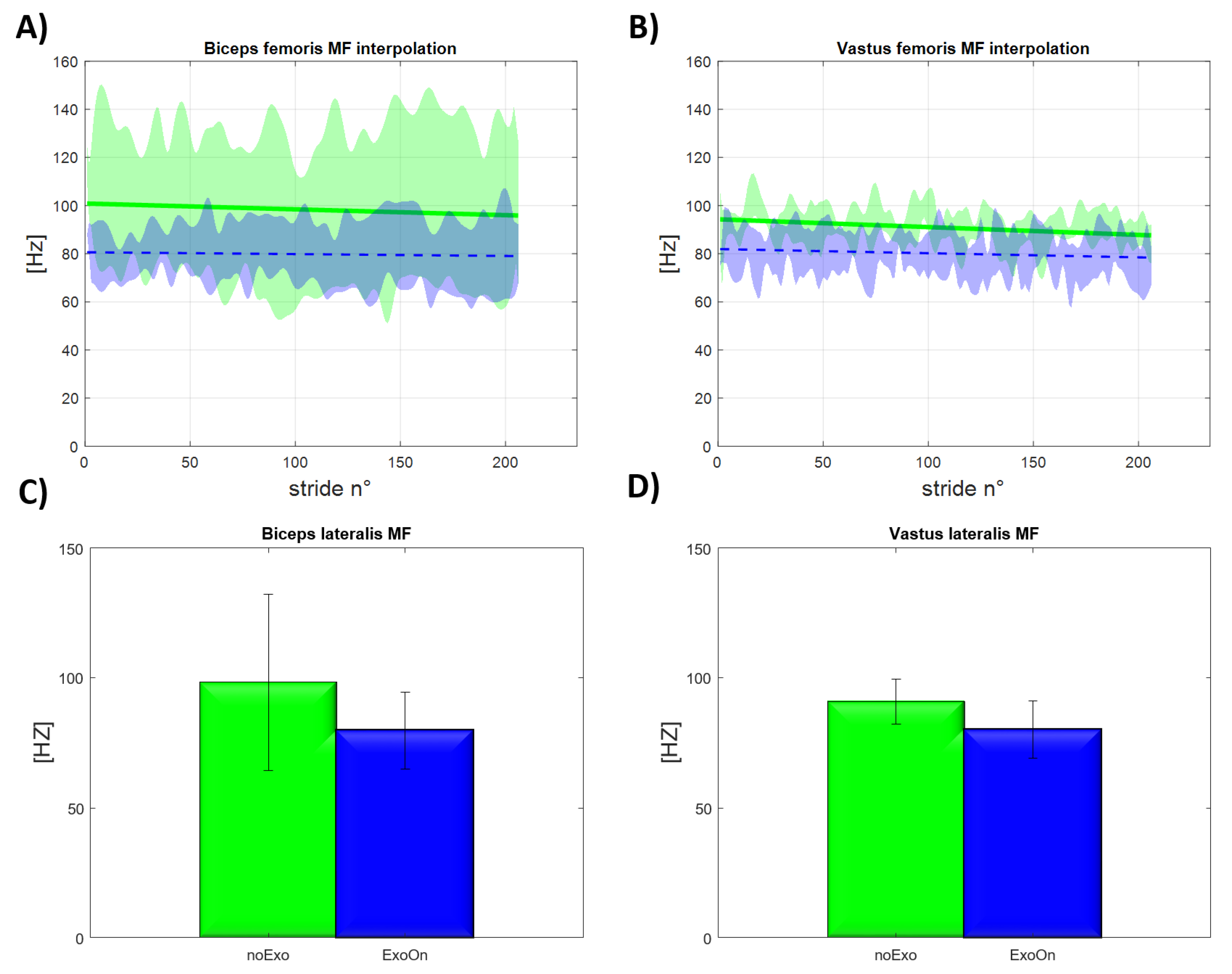

3.2.4. EMG Assessment Results

4. Discussion & Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| EMG | elettromiografia |

| COLBERT | Combined Operational Load Bearing External Resistance Treadmills |

| ISS | International Space Station |

| iRED | interim Resistive Exercise Device |

| ARED | Advanced Resistive Exercise Device |

| CEVIS | cycle egometer |

| METS | metabolic equivalent of task |

| QPA | Quasi-passive Actuation |

| HRI | Human-Robot Interaction |

| EB | Elastic Band |

| SC | Soft Clutch |

| HS | heel strike |

| FlF | flat foot |

| FrF | front foot |

| TO | toe off |

| PSI | positive speed inflection |

| NSI | negative speed inflection |

| HS | heel pressure signal |

| OS | outside insole pressure signal |

| IS | inside insole pressure signal |

| TS | toe pressure signal |

| KAD | knee angular displacement |

| IMU | inertial measurement unit |

| LSQ | Least Square method |

| EKF | extended kalman filter |

| RMSE | root mean square error |

| MVC | maximal voluntary contraction |

| BF | biceps femoris |

| VL | vastus lateralis |

| MF | mean frequency |

| TMCf | time varying multi muscle co-activation function |

| CI | co-activation index |

| RoM | range of motion |

| PKF | Peak Knee Flexion |

References

- Smith, M., Jr.; Rambaut, P.; Vogel, J.; Whittle, M. Bone mineral measurement: Experiment M078. In Biomedical Results from Skylab (NASA SP-377); National Aeronautics and Space Administration: Washington, DC, USA, 1977; pp. 183–190. [Google Scholar]

- Lang, T.; LeBlanc, A.; Evans, H.; Lu, Y.; Genant, H.; Yu, A. Cortical and trabecular bone mineral loss from the spine and hip in long-duration spaceflight. J. Bone Miner. Res. 2004, 19, 1006–1012. [Google Scholar] [CrossRef]

- Smith, S.M.; Wastney, M.E.; O’Brien, K.O.; Morukov, B.V.; Larina, I.M.; Abrams, S.A.; Davis-Street, J.E.; Oganov, V.; Shackelford, L.C. Bone markers, calcium metabolism, and calcium kinetics during extended-duration space flight on the Mir space station. J. Bone Miner. Res. 2005, 20, 208–218. [Google Scholar] [CrossRef]

- Sibonga, J.D.; Cavanagh, P.R.; Lang, T.F.; LeBlanc, A.D.; Schneider, V.S.; Shackelford, L.C.; Smith, S.M.; Vico, L. Adaptation of the skeletal system during long-duration spaceflight. Clin. Rev. Bone Miner. Metab. 2007, 5, 249–261. [Google Scholar] [CrossRef]

- LeBlanc, A.D.; Spector, E.R.; Evans, H.J.; Sibonga, J.D. Skeletal responses to space flight and the bed rest analog: A review. J. Musculoskelet. Neuronal Interact. 2007, 7, 33. [Google Scholar]

- Fitts, R.H.; Riley, D.R.; Widrick, J.J. Functional and structural adaptations of skeletal muscle to microgravity. J. Exp. Biol. 2001, 204, 3201–3208. [Google Scholar] [PubMed]

- Fitts, R.H.; Riley, D.R.; Widrick, J.J. Physiology of a microgravity environment invited review: Microgravity and skeletal muscle. J. Appl. Physiol. 2000, 89, 823–839. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.M.; Heer, M.A.; Shackelford, L.C.; Sibonga, J.D.; Ploutz-Snyder, L.; Zwart, S.R. Benefits for bone from resistance exercise and nutrition in long-duration spaceflight: Evidence from biochemistry and densitometry. J. Bone Miner. Res. 2012, 27, 1896–1906. [Google Scholar] [CrossRef] [PubMed]

- Cavanagh, P.R.; Licata, A.A.; Rice, A.J. Exercise and pharmacological countermeasures for bone loss during longduration space flight. Gravit. Space Res. 2007, 18, 39–58. [Google Scholar]

- Carpinelli, R.N. Exercise countermeasure to weightlessness during manned spaceflight. Med. Sport. 2014, 18, 42–44. [Google Scholar] [CrossRef]

- Schneider, S.M.; Amonette, W.E.; Blazine, K.; Bentley, J.; Lee, S.; Loehr, J.A.; Moore, J.A.; Rapley, M.; Mulder, E.R.; Smith, S.M. Training with the International Space Station interim resistive exercise device. Med. Sci. Sport. Exerc. 2003, 35, 1935–1945. [Google Scholar] [CrossRef] [PubMed]

- Loehr, J.A.; Lee, S.M.; English, K.L.; Sibonga, J.; Smith, S.M.; Spiering, B.A.; Hagan, R.D. Musculoskeletal adaptations to training with the advanced resistive exercise device. Med. Sci. Sport. Exerc. 2011, 43, 146–156. [Google Scholar] [CrossRef] [PubMed]

- Trappe, S.; Costill, D.; Gallagher, P.; Creer, A.; Peters, J.R.; Evans, H.; Riley, D.A.; Fitts, R.H. Exercise in space: Human skeletal muscle after 6 months aboard the International Space Station. J. Appl. Physiol. 2009. [Google Scholar] [CrossRef] [PubMed]

- Ainsworth, B.E.; Haskell, W.L.; Whitt, M.C.; Irwin, M.L.; Swartz, A.M.; Strath, S.J.; O Brien, W.L.; Bassett, D.R.; Schmitz, K.H.; Emplaincourt, P.O.; et al. Compendium of physical activities: An update of activity codes and MET intensities. Med. Sci. Sport. Exerc. 2000, 32, S498–S504. [Google Scholar] [CrossRef] [PubMed]

- Rea, R.; Beck, C.; Rovekamp, R.; Neuhaus, P.; Diftler, M. X1: A robotic exoskeleton for in-space countermeasures and dynamometry. In Proceedings of the AIAA Space 2013 Conference and Exposition, San Diego, CA, USA, 12 September 2013; p. 5510. [Google Scholar]

- Jezernik, S.; Colombo, G.; Keller, T.; Frueh, H.; Morari, M. Robotic orthosis lokomat: A rehabilitation and research tool. Neuromodul. Technol. Neural Interface 2003, 6, 108–115. [Google Scholar] [CrossRef]

- Veneman, J.F.; Kruidhof, R.; Hekman, E.E.; Ekkelenkamp, R.; Van Asseldonk, E.H.; Van Der Kooij, H. Design and evaluation of the LOPES exoskeleton robot for interactive gait rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 379–386. [Google Scholar] [CrossRef]

- Farris, R.J.; Quintero, H.A.; Goldfarb, M. Preliminary evaluation of a powered lower limb orthosis to aid walking in paraplegic individuals. IEEE Trans. Neural Syst. Rehabil. Eng. 2011, 19, 652–659. [Google Scholar] [CrossRef]

- Murray, S.A.; Ha, K.H.; Goldfarb, M. An assistive controller for a lower-limb exoskeleton for rehabilitation after stroke, and preliminary assessment thereof. In Proceedings of the 2014 36th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Chicago, IL, USA, 26–30 August 2014; pp. 4083–4086. [Google Scholar]

- Awad, L.N.; Bae, J.; O’donnell, K.; De Rossi, S.M.; Hendron, K.; Sloot, L.H.; Kudzia, P.; Allen, S.; Holt, K.G.; Ellis, T.D.; et al. A soft robotic exosuit improves walking in patients after stroke. Sci. Transl. Med. 2017, 9, eaai9084. [Google Scholar] [CrossRef]

- Jin, S.; Iwamoto, N.; Hashimoto, K.; Yamamoto, M. Experimental evaluation of energy efficiency for a soft wearable robotic suit. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 1192–1201. [Google Scholar] [CrossRef]

- Schmidt, K.; Duarte, J.E.; Grimmer, M.; Sancho-Puchades, A.; Wei, H.; Easthope, C.S.; Riener, R. The Myosuit: Bi-articular anti-gravity exosuit that reduces hip extensor activity in sitting transfers. Front. Neurorobot. 2017, 11, 57. [Google Scholar] [CrossRef]

- Di Natali, C.; Poliero, T.; Sposito, M.; Graf, E.; Bauer, C.; Pauli, C.; Bottenberg, E.; De Eyto, A.; O’Sullivan, L.; Hidalgo, A.F.; et al. Design and Evaluation of a Soft Assistive Lower Limb Exoskeleton. Robotica 2019, 37, 2014–2034. [Google Scholar] [CrossRef]

- Di Natali, C.; Sadeghi, A.; Mondini, A.; Bottenberg, E.; Hartigan, B.; De Eyto, A.; O’Sullivan, L.; Rocon, E.; Stadler, K.; Mazzolai, B.; et al. Pneumatic Quasi-Passive Actuation For Soft Assistive Lower Limbs Exoskeleton. Front. Neurorobot. 2020, 14, 31. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, A.; Mondini, A.; Totaro, M.; Mazzolai, B.; Beccai, L. A Wearable Sensory Textile-Based Clutch with High Blocking Force. Adv. Eng. Mater. 2019, 21, 1900886. [Google Scholar] [CrossRef]

- Graf, E.S.; Bauer, C.M.; Power, V.; de Eyto, A.; Bottenberg, E.; Poliero, T.; Sposito, M.; Scherly, D.; Henke, R.; Pauli, C.; et al. Basic functionality of a prototype wearable assistive soft exoskeleton for people with gait impairments: A case study. In Proceedings of the 11th PErvasive Technologies Related to Assistive Environments Conference, Corfu, Greece, 26–29 June 2018; pp. 202–207. [Google Scholar]

- Sposito, M.; Poliero, T.; Di Natali, C.; Ortiz, J.; Pauli, C.; Graf, E.; De Eyto, A.; Bottenberg, E.; Caldwell, D. Evaluation of XoSoft Beta-1 lower limb exoskeleton on a post stroke patient. In Proceedings of the Sixth National Congress of Bioengineering, Milan, Italy, 25–27 June 2018. [Google Scholar]

- Shore, L.; Power, V.; Hartigan, B.; Schülein, S.; Graf, E.; de Eyto, A.; O’Sullivan, L. Exoscore: A design tool to evaluate factors associated with technology acceptance of soft lower limb exosuits by older adults. Hum. Factors 2020, 62, 391–410. [Google Scholar] [CrossRef]

- Graf, E.; Bauer, C.; Schülein, S.; de Eyto, A.; Power, V.; Bottenberg, E.; Weyermann, B.; O’Sullivan, L.; Wirz, M. Assessing usability of a prototype soft exoskeleton by involving people with gait impairments. In Proceedings of the WCPT World Confederation for Physical Therapy Congress, Geneva, Switzerland, 10–13 May 2019; ZHAW Zürcher Hochschule für Angewandte Wissenschaften: Winterthur, Switzerland, 2019. [Google Scholar]

- Tanimoto, M.; Ishii, N. Effects of low-intensity resistance exercise with slow movement and tonic force generation on muscular function in young men. J. Appl. Physiol. 2006, 100, 1150–1157. [Google Scholar] [CrossRef]

- Westcott, W.L.; Winett, R.A.; Anderson, E.S.; Wojcik, J.R. Effects of regular and slow speed resistance training on muscle strength. J. Sport. Med. Phys. Fit. 2001, 41, 154. [Google Scholar]

- Hansen, D.; Dendale, P.; Jonkers, R.; Beelen, M.; Manders, R.; Corluy, L.; Mullens, A.; Berger, J.; Meeusen, R.; Van Loon, L. Continuous low-to moderate-intensity exercise training is as effective as moderate-to high-intensity exercise training at lowering blood HbA 1c in obese type 2 diabetes patients. Diabetologia 2009, 52, 1789–1797. [Google Scholar] [CrossRef]

- Evans, C.H., Jr.; Ball, J.R. Behavioral health and performance. In Safe Passage: Astronaut Care for Exploration Missions; National Academies Press (US): Washington, DC, USA, 2001. [Google Scholar]

- Wolf, S.; Grioli, G.; Eiberger, O.; Friedl, W.; Grebenstein, M.; Höppner, H.; Burdet, E.; Caldwell, D.G.; Carloni, R.; Catalano, M.G.; et al. Variable stiffness actuators: Review on design and components. IEEE/ASME Trans. Mechatron. 2016, 21, 2418–2430. [Google Scholar] [CrossRef]

- Van Ham, R.; Sugar, T.G.; Vanderborght, B.; Hollander, K.W.; Lefeber, D. Compliant actuator designs. IEEE Robot. Autom. Mag. 2009, 3, 81–94. [Google Scholar]

- Manti, M.; Cacucciolo, V.; Cianchetti, M. Stiffening in soft robotics: A review of the state of the art. IEEE Robot. Autom. Mag. 2016, 23, 93–106. [Google Scholar] [CrossRef]

- Caldwell, D.G.; Tsagarakis, N.G.; Kousidou, S.; Costa, N.; Sarakoglou, I. “SOFT” exoskeletons for upper and lower body rehabilitation—Design, control and testing. Int. J. Hum. Robot. 2007, 4, 549–573. [Google Scholar] [CrossRef]

- Kesner, S.B.; Jentoft, L.; Hammond, F.L.; Howe, R.D.; Popovic, M. Design considerations for an active soft orthotic system for shoulder rehabilitation. In Proceedings of the 2011 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 8130–8134. [Google Scholar]

- Asbeck, A.T.; De Rossi, S.M.; Galiana, I.; Ding, Y.; Walsh, C.J. Stronger, smarter, softer: Next-generation wearable robots. IEEE Robot. Autom. Mag. 2014, 21, 22–33. [Google Scholar] [CrossRef]

- Taghavi, M.; Helps, T.; Huang, B.; Rossiter, J. 3D-printed ready-to-use variable-stiffness structures. IEEE Robot. Autom. Lett. 2018, 3, 2402–2407. [Google Scholar] [CrossRef]

- Alkan, M.S.; Gurocak, H.; Gonenc, B. Linear magnetorheological brake with serpentine flux path as a high force and low off-state friction actuator for haptics. J. Intell. Mater. Syst. Struct. 2013, 24, 1699–1713. [Google Scholar] [CrossRef]

- Nikitczuk, J.; Weinberg, B.; Canavan, P.K.; Mavroidis, C. Active knee rehabilitation orthotic device with variable damping characteristics implemented via an electrorheological fluid. IEEE/ASME Trans. Mechatronics 2010, 15, 952–960. [Google Scholar] [CrossRef]

- Diller, S.; Majidi, C.; Collins, S.H. A lightweight, low-power electroadhesive clutch and spring for exoskeleton actuation. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 682–689. [Google Scholar]

- Ramachandran, V.; Shintake, J.; Floreano, D. All-Fabric Wearable Electroadhesive Clutch. Adv. Mater. Technol. 2019, 4, 1800313. [Google Scholar] [CrossRef]

- Zubrycki, I.; Granosik, G. Novel haptic device using jamming principle for providing kinaesthetic feedback in glove-based control interface. J. Intell. Robot. Syst. 2017, 85, 413–429. [Google Scholar] [CrossRef]

- Walsh, C.J.; Endo, K.; Herr, H. A quasi-passive leg exoskeleton for load-carrying augmentation. Int. J. Hum. Robot. 2007, 4, 487–506. [Google Scholar] [CrossRef]

- Van Dijk, W.; Van der Kooij, H.; Hekman, E. A passive exoskeleton with artificial tendons: Design and experimental evaluation. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; pp. 1–6. [Google Scholar]

- Sasaki, D.; Noritsugu, T.; Takaiwa, M. Development of pneumatic lower limb power assist wear driven with wearable air supply system. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 4440–4445. [Google Scholar]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal robotic gripper based on the jamming of granular material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Jiang, A.; Xynogalas, G.; Dasgupta, P.; Althoefer, K.; Nanayakkara, T. Design of a variable stiffness flexible manipulator with composite granular jamming and membrane coupling. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 2922–2927. [Google Scholar]

- Follmer, S.; Leithinger, D.; Olwal, A.; Cheng, N.; Ishii, H. Jamming user interfaces: Programmable particle stiffness and sensing for malleable and shape-changing devices. In Proceedings of the 25th Annual ACM Symposium on User Interface Software and Technology, Cambridge, MA, USA, 7–10 October 2012; pp. 519–528. [Google Scholar]

- Stanley, A.A.; Gwilliam, J.C.; Okamura, A.M. Haptic jamming: A deformable geometry, variable stiffness tactile display using pneumatics and particle jamming. In Proceedings of the World Haptics Conference (WHC), Daejeon, Korea, 14–17 April 2013; pp. 25–30. [Google Scholar]

- Li, M.; Ranzani, T.; Sareh, S.; Seneviratne, L.D.; Dasgupta, P.; Wurdemann, H.A.; Althoefer, K. Multi-fingered haptic palpation utilizing granular jamming stiffness feedback actuators. Smart Mater. Struct. 2014, 23, 095007. [Google Scholar] [CrossRef]

- Sadeghi, A.; Mondini, A.; Mazzolai, B. Preliminary Experimental Study on Variable Stiffness Structures Based on Textile Jamming for Wearable Robotics. In Proceedings of the International Symposium on Wearable Robotics, Pisa, Italy, 16–20 October 2018; Springer: Berlin Germany, 2018; pp. 49–52. [Google Scholar]

- Mengüç, Y.; Park, Y.L.; Pei, H.; Vogt, D.; Aubin, P.M.; Winchell, E.; Fluke, L.; Stirling, L.; Wood, R.J.; Walsh, C.J. Wearable soft sensing suit for human gait measurement. Int. J. Robot. Res. 2014, 33, 1748–1764. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef]

- Yogeswaran, N.; Dang, W.; Navaraj, W.T.; Shakthivel, D.; Khan, S.; Polat, E.O.; Gupta, S.; Heidari, H.; Kaboli, M.; Lorenzelli, L.; et al. New materials and advances in making electronic skin for interactive robots. Adv. Robot. 2015, 29, 1359–1373. [Google Scholar] [CrossRef]

- Yang, T.; Xie, D.; Li, Z.; Zhu, H. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R Rep. 2017, 115, 1–37. [Google Scholar] [CrossRef]

- Tiwana, M.I.; Redmond, S.J.; Lovell, N.H. A review of tactile sensing technologies with applications in biomedical engineering. Sens. Actuators A Phys. 2012, 179, 17–31. [Google Scholar] [CrossRef]

- Stassi, S.; Cauda, V.; Canavese, G.; Pirri, C.F. Flexible tactile sensing based on piezoresistive composites: A review. Sensors 2014, 14, 5296–5332. [Google Scholar] [CrossRef]

- Salim, A.; Lim, S. Review of recent inkjet-printed capacitive tactile sensors. Sensors 2017, 17, 2593. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Totaro, M.; Beccai, L. Toward perceptive soft robots: Progress and challenges. Adv. Sci. 2018, 5, 1800541. [Google Scholar] [CrossRef]

- Ivančo, J.; Halahovets, Y.; Végsö, K.; Klačková, I.; Kotlár, M.; Vojtko, A.; Micuśík, M.; Jergel, M.; Majková, E. Cyclopean gauge factor of the strain-resistance transduction of indium oxide films. IOP Conf. Ser. Mater. Sci. Eng. 2016, 108, 012043. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Cui, Y.L.; Mi, W.T.; Yang, Y.; Xie, D.; Ren, T.L. Scalable fabrication of high-performance and flexible graphene strain sensors. Nanoscale 2014, 6, 699–705. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296. [Google Scholar] [CrossRef]

- Viry, L.; Levi, A.; Totaro, M.; Mondini, A.; Mattoli, V.; Mazzolai, B.; Beccai, L. Flexible three-axial force sensor for soft and highly sensitive artificial touch. Adv. Mater. 2014, 26, 2659–2664. [Google Scholar] [CrossRef]

- Atalay, A.; Sanchez, V.; Atalay, O.; Vogt, D.M.; Haufe, F.; Wood, R.J.; Walsh, C.J. Batch fabrication of customizable silicone-textile composite capacitive strain sensors for human motion tracking. Adv. Mater. Technol. 2017, 2, 1700136. [Google Scholar] [CrossRef]

- White, E.L.; Yuen, M.C.; Case, J.C.; Kramer, R.K. Low-Cost, Facile, and Scalable Manufacturing of Capacitive Sensors for Soft Systems. Adv. Mater. Technol. 2017, 2, 1700072. [Google Scholar] [CrossRef]

- Zhao, H.; O’Brien, K.; Li, S.; Shepherd, R.F. Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides. Sci. Robot. 2016, 1, eaai7529. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Park, S.; Park, B.; Kim, Y.; Park, S.K.; Nam, S.; Kyung, K.U. Polymer-waveguide-based flexible tactile sensor array for dynamic response. Adv. Mater. 2014, 26, 4474–4480. [Google Scholar] [CrossRef] [PubMed]

- Lazarus, N.; Bedair, S.S. Bubble inductors: Pneumatic tuning of a stretchable inductor. AIP Adv. 2018, 8, 056601. [Google Scholar] [CrossRef]

- Felt, W.; Chin, K.Y.; Remy, C.D. Smart braid feedback for the closed-loop control of soft robotic systems. Soft Robot. 2017, 4, 261–273. [Google Scholar] [CrossRef]

- Wang, H.; Kow, J.; Raske, N.; De Boer, G.; Ghajari, M.; Hewson, R.; Alazmani, A.; Culmer, P. Robust and high-performance soft inductive tactile sensors based on the Eddy-current effect. Sens. Actuators A Phys. 2018, 271, 44–52. [Google Scholar] [CrossRef]

- Wang, H.; Totaro, M.; Beccai, L. Development of Fully Shielded Soft Inductive Tactile Sensors. In Proceedings of the 2019 26th IEEE International Conference on Electronics, Circuits and Systems (ICECS), Genoa, Italy, 27–29 November 2019; pp. 246–249. [Google Scholar]

- Rocon, E.; Pons, J.L. Exoskeletons in Rehabilitation Robotics: Tremor Suppression; Springer: Berlin, Germany, 2011; Volume 69. [Google Scholar]

- Naruse, K.; Kawai, S.; Yokoi, H.; Kakazu, Y. Development of wearable exoskeleton power assist system for lower back support. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003)(Cat. No. 03CH37453), Las Vegas, NV, USA, 27–31 October 2003; IEEE: Piscataway, NJ, USA, 2003; Volume 4, pp. 3630–3635. [Google Scholar]

- Chen, B.; Lanotte, F.; Grazi, L.; Vitiello, N.; Crea, S. Classification of lifting techniques for application of a robotic hip exoskeleton. Sensors 2019, 19, 963. [Google Scholar] [CrossRef]

- Cevzar, M.; Petrič, T.; Jamšek, M.; Babič, J. Real-time control of quasi-active hip exoskeleton based on gaussian mixture model approach. In Wearable Robotics: Challenges and Trends, Proceedings of the International Symposium on Wearable Robotics, Pisa, Italy, 16–20 October 2018; Springer: Berlin, Germany, 2018; pp. 244–248. [Google Scholar]

- Poliero, T.; Toxiri, S.; Anastasi, S.; Monica, L.; Ortiz, D.G.C.J. Assessment of an On-board Classifier for Activity Recognition on an Active Back-Support Exoskeleton. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 559–564. [Google Scholar]

- Singh, R.M.; Chatterji, S.; Kumar, A. Trends and challenges in EMG based control scheme of exoskeleton robots-a review. Int. J. Sci. Eng. Res. 2012, 3, 933–940. [Google Scholar]

- Gopura, R.; Bandara, D.; Gunasekara, J.; Jayawardane, T. Recent trends in EMG-Based control methods for assistive robots. Electrodiagnosis New Front. Clin. Res. 2013, 237–268. [Google Scholar]

- Bi, L.; Guan, C.; Aberham. A review on EMG-based motor intention prediction of continuous human upper limb motion for human-robot collaboration. Biomed. Signal Process. Control. 2019, 51, 113–127. [Google Scholar] [CrossRef]

- Chen, J.; Damiano, D.L.; Lerner, Z.F.; Bulea, T.C. Validating Model-Based Prediction of Biological Knee Moment during Walking with an Exoskeleton in Crouch Gait: Potential Application for Exoskeleton Control. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 778–783. [Google Scholar]

- Proietti, T.; Crocher, V.; Roby-Brami, A.; Jarrasse, N. Upper-limb robotic exoskeletons for neurorehabilitation: A review on control strategies. IEEE Rev. Biomed. Eng. 2016, 9, 4–14. [Google Scholar] [CrossRef] [PubMed]

- Yan, T.; Cempini, M.; Oddo, C.M.; Vitiello, N. Review of assistive strategies in powered lower-limb orthoses and exoskeletons. Robot. Auton. Syst. 2015, 64, 120–136. [Google Scholar] [CrossRef]

- XoSoft. European Project. 2016–2019. Available online: https://www.xosoft.eu/ (accessed on 15 April 2021).

- Sadeghi, A.; Mondini, A.; Mazzolai, B. A Vacuum Powered Soft Textile-Based Clutch. Actuators 2019, 8, 47. [Google Scholar] [CrossRef]

- Endo, K.; Paluska, D.; Herr, H. A quasi-passive model of human leg function in level-ground walking. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006; pp. 4935–4939. [Google Scholar]

- De Rossi, S.M.; Crea, S.; Donati, M.; Reberšek, P.; Novak, D.; Vitiello, N.; Lenzi, T.; Podobnik, J.; Munih, M.; Carrozza, M.C. Gait segmentation using bipedal foot pressure patterns. Poceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; pp. 361–366. [Google Scholar]

- Totaro, M.; Poliero, T.; Mondini, A.; Lucarotti, C.; Cairoli, G.; Ortiz, J.; Beccai, L. Soft Smart Garments for Lower Limb Joint Position Analysis. Sensors 2017, 17, 2314. [Google Scholar] [CrossRef]

- Picerno, P.; Cereatti, A.; Cappozzo, A. Joint kinematics estimate using wearable inertial and magnetic sensing modules. Gait Posture 2008, 28, 588–595. [Google Scholar] [CrossRef]

- Kok, M.; Hol, J.D.; Schön, T.B. Using inertial sensors for position and orientation estimation. arXiv 2017, arXiv:1704.06053. [Google Scholar]

- Hidalgo, A.F.; Lora-Millán, J.S.; Rocon, E. IMU-Based Knee Angle Estimation using an Extended Kalman Filter. In Proceedings of the 2019 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, 23–27 July 2019; pp. 570–573. [Google Scholar]

- Seel, T.; Raisch, J.; Schauer, T. IMU-based joint angle measurement for gait analysis. Sensors 2014, 14, 6891–6909. [Google Scholar] [CrossRef]

- Roetenberg, D. Inertial and Magnetic Sensing of Human Motion. Ph.D. Thesis, Universiteit Twente, Enschede, The Netherlands, 2006. [Google Scholar]

- Hermens, H.J.; Freriks, B.; Disselhorst-Klug, C.; Rau, G. Development of recommendations for SEMG sensors and sensor placement procedures. J. Electromyogr. Kinesiol. 2000, 10, 361–374. [Google Scholar] [CrossRef]

- Barbero, M.; Merletti, R.; Rainoldi, A. Atlas of Muscle Innervation Zones: Understanding Surface Electromyography and Its Applications; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Stegeman, D.; Hermens, H. Standards for surface electromyography: The European project Surface EMG for non-invasive assessment of muscles (SENIAM). Enschede Roessingh Res. Dev. 2007, 108–112. [Google Scholar]

- Ranavolo, A.; Mari, S.; Conte, C.; Serrao, M.; Silvetti, A.; Iavicoli, S.; Draicchio, F. A new muscle co-activation index for biomechanical load evaluation in work activities. Ergonomics 2015, 58, 966–979. [Google Scholar] [CrossRef] [PubMed]

- Ament, W.; Bonga, G.J.; Hof, A.L.; Verkerke, G.J. EMG median power frequency in an exhausting exercise. J. Electromyogr. Kinesiol. 1993, 3, 214–220. [Google Scholar] [CrossRef]

- Dimitrov, G.V.; Arabadzhiev, T.I.; Mileva, K.N.; Bowtell, J.L.; Crichton, N.; Dimitrova, N.A. Muscle fatigue during dynamic contractions assessed by new spectral indices. Med. Sci. Sport. Exerc. 2006, 38, 1971–1979. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi, A.; Zahediasl, S. Normality tests for statistical analysis: A guide for non-statisticians. Int. J. Endocrinol. Metab. 2012, 10, 486. [Google Scholar] [CrossRef]

- Faul, F.; Erdfelder, E.; Lang, A.; Buchner, A. A flexible statistical power analysis program for the social, behavioral and biomedical sciences. Behav. Res. Methods 2007, 39, 175–191. [Google Scholar] [CrossRef]

- Grood, E.S.; Suntay, W.J. A joint coordinate system for the clinical description of three-dimensional motions: Application to the knee. J. Biomech. Eng. 1983, 105, 136–144. [Google Scholar] [CrossRef]

- Perry, J. Normal gait. In AAOS Atlas of Orthoses and Assistive Devices; Hsu, J.D., Michael, J.W., Fisk, J.R., Eds.; Mosby Elsevier: Philadelphia, PE, USA, 2008; pp. 61–82. [Google Scholar]

- Brinkmann, J.R.; Perry, J. Rate and range of knee motion during ambulation in healthy and arthritic subjects. Phys. Ther. 1985, 65, 1055–1060. [Google Scholar] [CrossRef] [PubMed]

- Serrao, M.; Chini, G.; Casali, C.; Conte, C.; Rinaldi, M.; Ranavolo, A.; Marcotulli, C.; Leonardi, L.; Fragiotta, G.; Bini, F.; et al. Progression of gait ataxia in patients with degenerative cerebellar disorders: A 4-year follow-up study. Cerebellum 2017, 16, 629–637. [Google Scholar] [CrossRef] [PubMed]

- Cifrek, M.; Medved, V.; Tonković, S.; Ostojić, S. Surface EMG based muscle fatigue evaluation in biomechanics. Clin. Biomech. 2009, 24, 327–340. [Google Scholar] [CrossRef] [PubMed]

| Index | NoExo | Exo | Difference |

|---|---|---|---|

| RoM | |||

| PKF | |||

| CI | 6.3% | 6.3% | 0.0 |

| RMS of VL | 20.8% MVC | 55.2% MVC | 34.4% MVC |

| RMS of BF | 25.8% MVC | 32.1% MVC | 7.3% MVC |

| MF of VL | 98.4% | 79.8% | −18.6% |

| MF of BF | 90.9% | 80.1% | −10.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Natali, C.; Chini, G.; Totaro, M.; Lora-Millán, J.S.; Rocon, E.; Beccai, L.; Caldwell, D.G.; Visentin, G.; Ortiz, J. Quasi-Passive Resistive Exosuit for Space Activities: Proof of Concept. Appl. Sci. 2021, 11, 3576. https://doi.org/10.3390/app11083576

Di Natali C, Chini G, Totaro M, Lora-Millán JS, Rocon E, Beccai L, Caldwell DG, Visentin G, Ortiz J. Quasi-Passive Resistive Exosuit for Space Activities: Proof of Concept. Applied Sciences. 2021; 11(8):3576. https://doi.org/10.3390/app11083576

Chicago/Turabian StyleDi Natali, Christian, Giorgia Chini, Massimo Totaro, Julio S. Lora-Millán, Eduardo Rocon, Lucia Beccai, Darwin G. Caldwell, Gianfranco Visentin, and Jesús Ortiz. 2021. "Quasi-Passive Resistive Exosuit for Space Activities: Proof of Concept" Applied Sciences 11, no. 8: 3576. https://doi.org/10.3390/app11083576

APA StyleDi Natali, C., Chini, G., Totaro, M., Lora-Millán, J. S., Rocon, E., Beccai, L., Caldwell, D. G., Visentin, G., & Ortiz, J. (2021). Quasi-Passive Resistive Exosuit for Space Activities: Proof of Concept. Applied Sciences, 11(8), 3576. https://doi.org/10.3390/app11083576