Effects of Tube Radius and Surface Tension on Capillary Rise Dynamics of Water/Butanol Mixtures

Abstract

1. Introduction

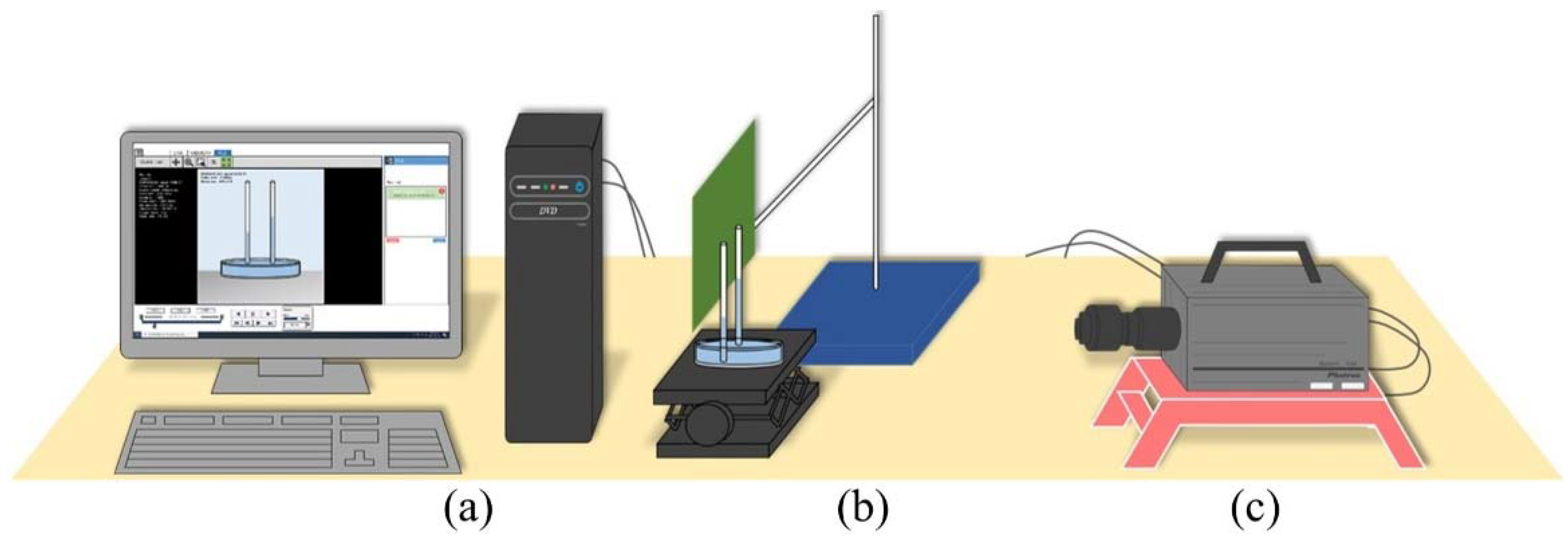

2. Materials and Methods

2.1. Materials

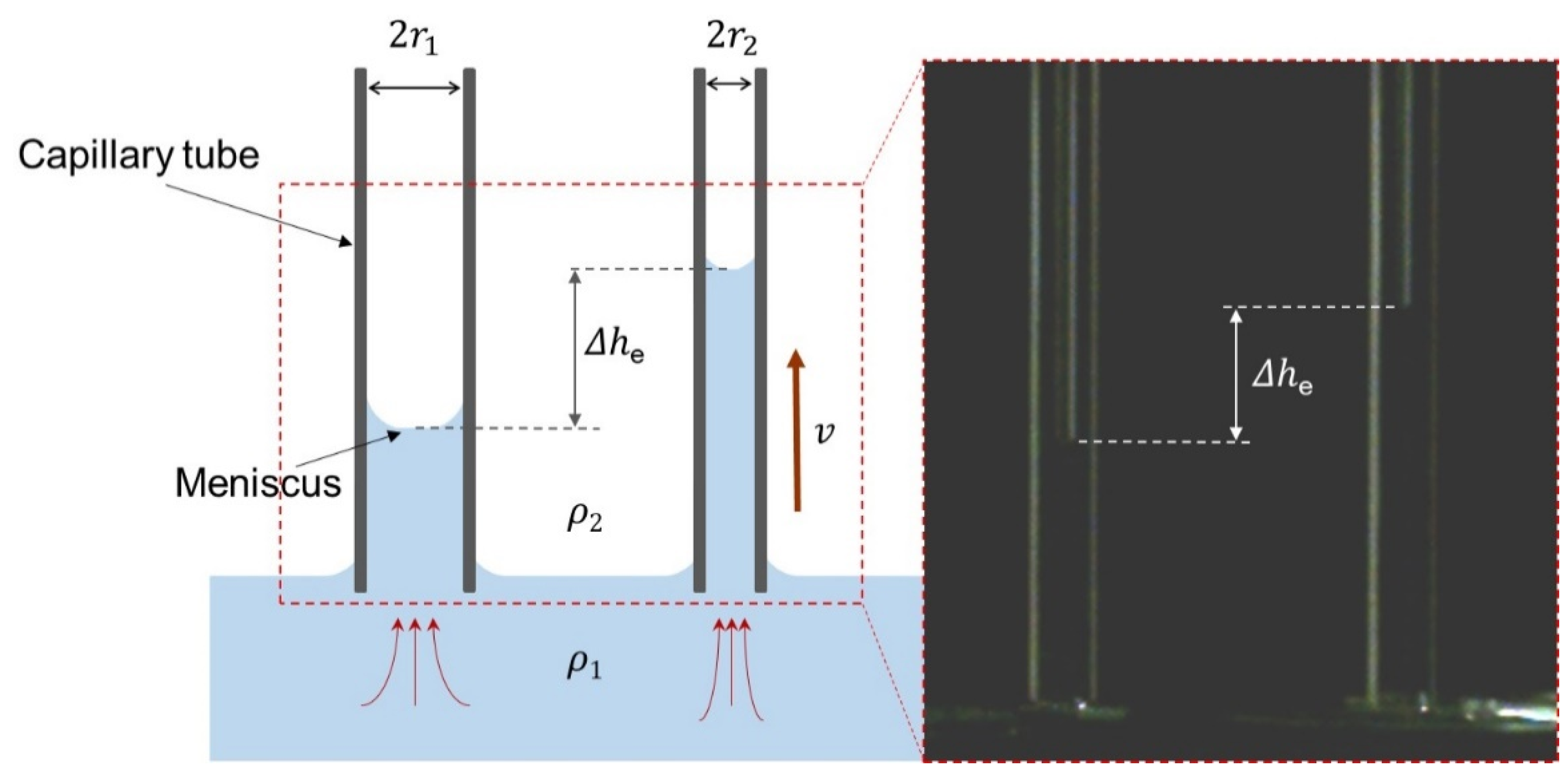

2.2. Methods

3. Results and Discussion

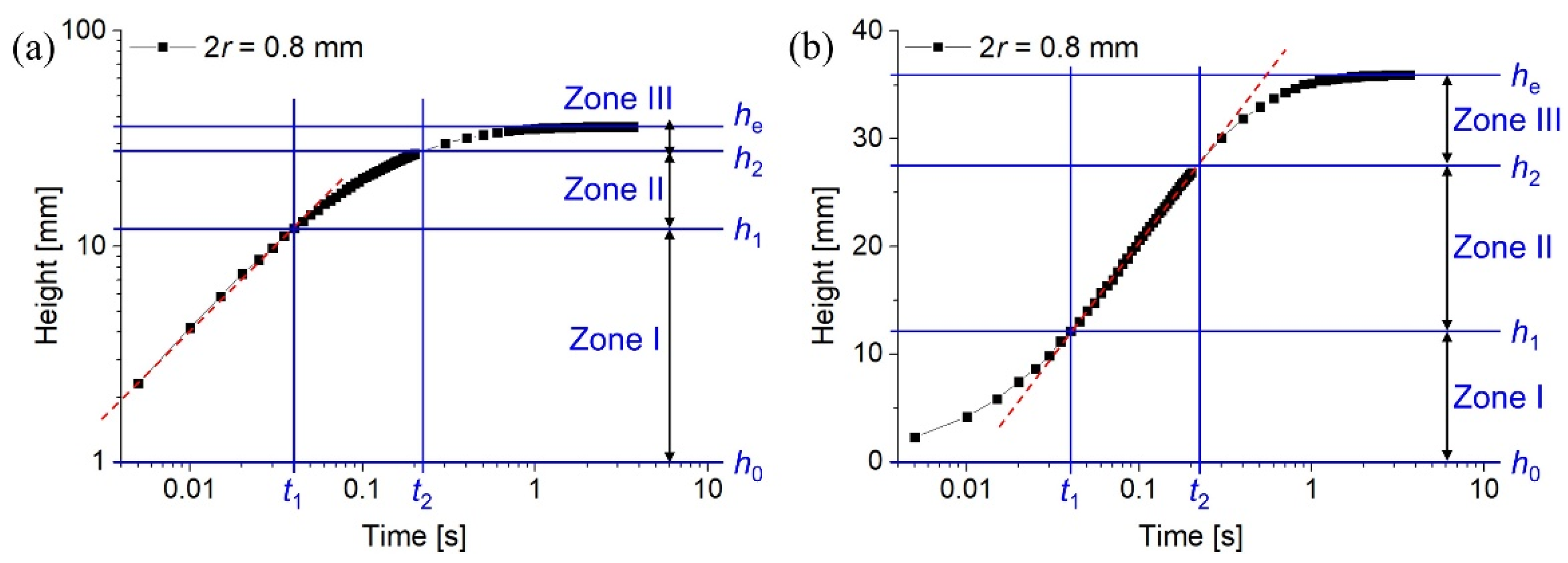

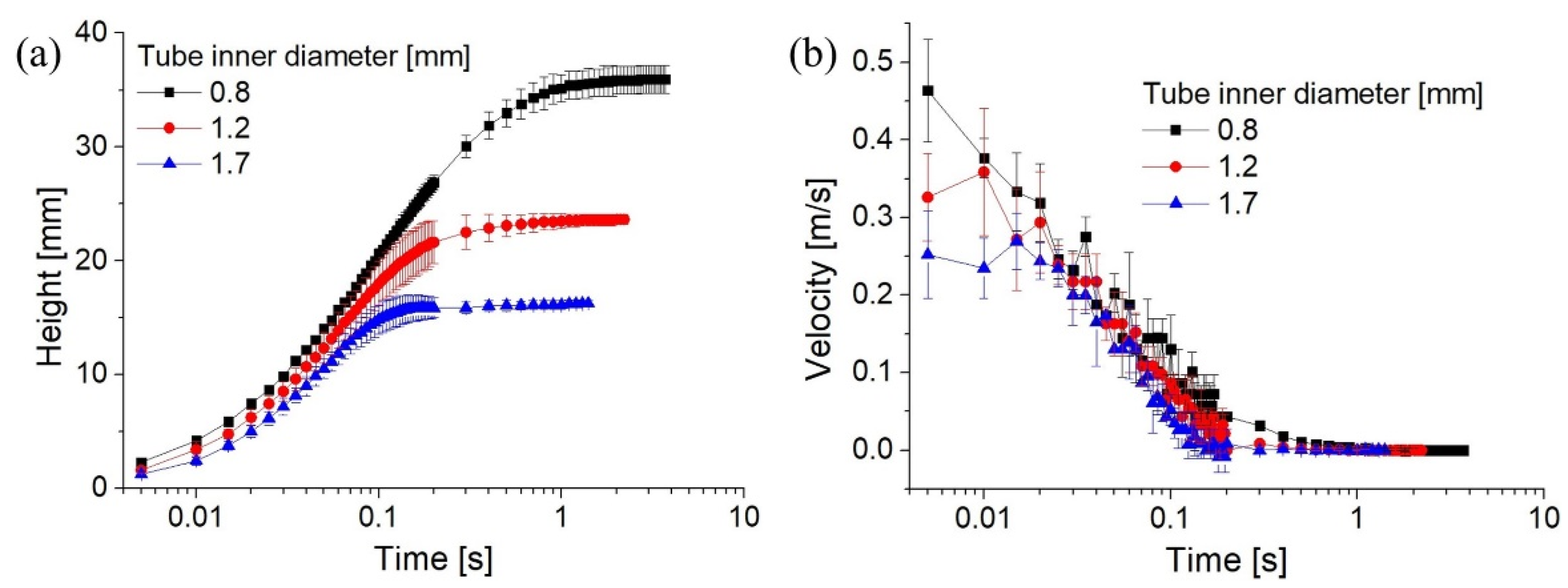

3.1. Effect of Tube Inner Radius on Capillary Dynamics

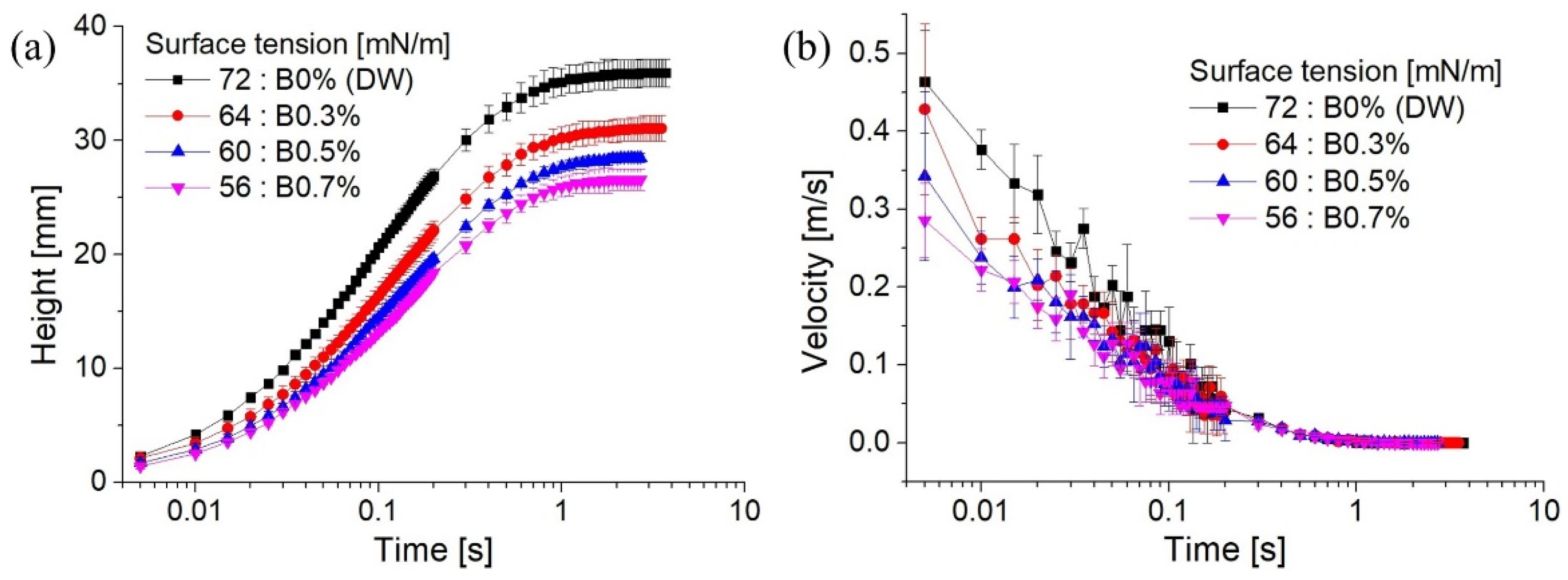

3.2. Effect of Surface Tension of the Fluids on Capillary Rise Dynamics

4. Conclusions

- (1)

- The height of rise and the velocity of rise are dependent on the capillary tube radii. The larger the radius, the lower is the equilibrium height and the velocity of rise. The meniscus oscillation was observed only at the test case of r = 0.85.

- (2)

- The capillary rise process is divided into three characteristic stages: the inertial (Stage I), inertial + viscous (Stage II), and viscous (Stage III) flow region. The capillary rise was predominantly influenced by the pure inertia and hybrid region (inertia + viscous).

- (3)

- The capillary rise height decreased with an increase in the concentration of n-butanol and with a decrease in the surface tension of n-butanol/water mixtures. With respect to the velocity of rise, the higher the surface tension of the mixtures, the higher the velocity.

- (4)

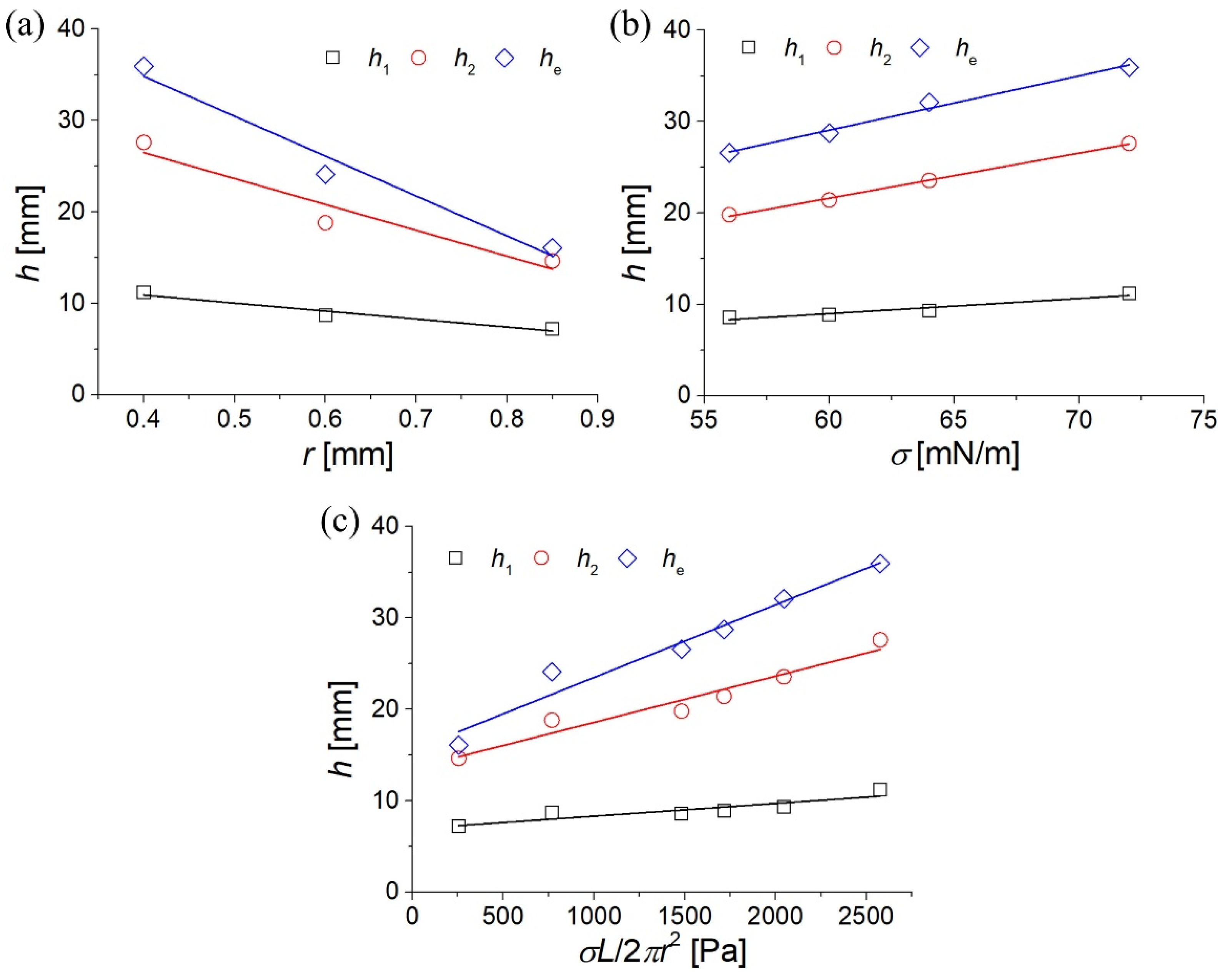

- There were some correlations between the characteristic heights (h1, h2, and he) and the capillary tube radius and liquid surface tension. Characteristic heights showed a linear decrease in the capillary tube radius and a linear decrease in the liquid surface tension. Consequentially, each characteristic height exhibited a linear function of the consolidated quantity of σL/2πr2.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| B | n-butanol |

| DW | Distilled water |

| g | Standard gravity [m/s2] |

| h | Capillary rise height [mm] |

| h1 | Height at the transition time between the purely inertial and the visco-inertial stage [mm] |

| h2 | Height at the transition time between the visco-inertial and the purely viscous stage [mm] |

| he | Equilibrium capillary rise height [mm] |

| L | Capillary tube length [mm] |

| PC | Capillary pressure [Pa] |

| PG | Pressure in gas [Pa] |

| PL | Pressure in liquid [Pa] |

| r | Capillary tube radius [mm] |

| t1 | Transition time between the purely inertial and the visco-inertial stage [s] |

| t2 | Transition time between the visco-inertial and the purely viscous stage [s] |

| θe | Equilibrium contact angle [°] |

| μ | Viscosity of liquid [mPa·s] |

| ρ | Density of liquid [kg/m3] |

| σ | Surface tension of liquid [mN/m] |

References

- Esfandyari, H.; Hoseini, A.H.; Shadizadeh, S.R.; Davarpanah, A. Simultaneous evaluation of capillary pressure and wettability alteration based on the USBM and imbibition tests on carbonate minerals. J. Pet. Sci. Eng. 2021, 200, 108285. [Google Scholar] [CrossRef]

- Davarpanah, A. Parametric study of polymer-nanoparticles-assisted injectivity performance for axisymmetric two-phase flow in EOR processes. Nanomaterials 2020, 10, 1818. [Google Scholar] [CrossRef] [PubMed]

- Pan, F.; Zhang, Z.; Zhang, X.; Davarpanah, A. Impact of anionic and cationic surfactants interfacial tension on the oil recovery enhancement. Powder Technol. 2020, 373, 93–98. [Google Scholar] [CrossRef]

- Esfandyari, H.; Shadizadeh, S.R.; Esmaeilzadeh, F.; Davarpanah, A. Implications of anionic and natural surfactants to measure wettability alteration in EOR processes. Fuel 2020, 278, 118392. [Google Scholar] [CrossRef]

- Das, P.K.; Mallik, A.K.; Ganguly, R.; Santra, A.K. Synthesis and characterization of TiO2-water nanofluids with different surfactants. Int. Commun. Heat Mass Transf. 2016, 75, 341–348. [Google Scholar] [CrossRef]

- Fumoto, K.; Sasa, M.; Okabe, T.; Savino, R.; Inamura, T.; Shirota, M. Research on heat transfer performance of the open-loop micro pulsating heat pipe with self-rewetting fluids. Microgravity Sci. Technol. 2019, 31, 261–268. [Google Scholar] [CrossRef]

- Gan, J.S.; Hung, Y.M. Thermal analysis of Al2O3/water nanofluid-filled micro heat pipes. RSC Adv. 2015, 5, 26716–26725. [Google Scholar] [CrossRef]

- Savino, R.; di Francescantonio, N.; Fortezza, R.; Abe, Y. Heat pipes with binary mixtures and inverse Marangoni effects for microgravity applications. Acta Astron. 2017, 61, 16–26. [Google Scholar] [CrossRef]

- Berthier, J.; Brakke, K.A.; Furlani, E.P.; Karampelas, I.H.; Poher, V.; Gosselin, D.; Cubizolles, M.; Pouteau, P. Whole blood spontaneous capillary flow in narrow V-groove microchannels. Sens. Actuator B Chem. 2015, 206, 258–267. [Google Scholar] [CrossRef]

- Li, J.; Zou, Y.; Cheng, L. Experimental study on capillary pumping performance of porous wicks for loop heat pipe. Exp. Therm. Fluid Sci. 2010, 34, 1403–1408. [Google Scholar] [CrossRef]

- Huang, S.; Wan, Z.; Zhang, X.; Yang, X.; Tang, Y. Evaluation of capillary performance of a stainless steel fiber-powder composite wick for stainless steel heat pipe. Appl. Therm. Eng. 2019, 148, 1224–1232. [Google Scholar] [CrossRef]

- Li, X.; Yao, D.; Zuo, K.; Xia, Y.; Zeng, Y.P. Effects of pore structures on the capillary and thermal performance of porous silicon nitride as novel loop heat pipe wicks. Int. J. Heat Mass Transf. 2021, 169, 120985. [Google Scholar] [CrossRef]

- Cao, H.; Amador, C.; Jia, X.; Ding, Y. Capillary dynamics of water/ethanol mixtures. Ind. Eng. Chem. Res. 2015, 54, 12196–12203. [Google Scholar] [CrossRef]

- O’Loughlin, M.; Wilk, K.; Priest, C.; Ralston, J.; Popescu, M.N. Capillary rise dynamics of aqueous glycerol solutions in glass capillaries: A critical examination of the Washburn equation. J. Colloid Interface Sci. 2013, 411, 257–264. [Google Scholar] [CrossRef] [PubMed]

- Extrand, C.W.; Moon, S.I. Experimental measurement of forces and energies associated with capillary rise in a vertical tube. J. Colloid Interface Sci. 2013, 407, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Quéré, D. Inertial capillarity. Europhys. Lett. 1997, 39, 533–538. [Google Scholar] [CrossRef]

- Hamraoui, A.; Thuresson, K.; Nylander, T.; Yaminsky, A. Can a dynamic contact angle be understood in terms of a friction coefficient? J. Colloid Interface Sci. 2000, 226, 199–204. [Google Scholar] [CrossRef]

- Stange, M.; Dreyer, M.E.; Rath, H.J. Capillary driven flow in circular cylindrical tubes. Phys. Fluids 2018, 30, 082103. [Google Scholar] [CrossRef]

- Fries, N.; Dreyer, M. The transition from inertial to viscous flow in capillary rise. J. Colloid Interface Sci. 2008, 327, 125–128. [Google Scholar] [CrossRef]

- Zhong, X.; Sun, B.; Liao, S. Analytic solutions of the rise dynamics of liquid in a vertical cylindrical capillary. Eur. J. Mech. B Fluids 2019, 78, 1–10. [Google Scholar] [CrossRef]

- Walls, P.L.L.; Dequire, G.; Bird, J.C. Capillary displacement of viscous liquids. Langmuir 2016, 32, 3186–3190. [Google Scholar] [CrossRef]

- Kondou, C.; Higashi, Y. Surface tension measurement for a new low-GWP refrigerant HFO-1123 by a differential capillary rise method. Trans. Jpn. Soc. Refriger. Air Condit. Eng. 2018, 35, 403–408. [Google Scholar]

- Shardt, O.; Waghmare, P.R.; Derksen, J.J.; Mitra, S.K. Inertial rise in short capillary tubes. RSC Adv. 2014, 4, 14781–14785. [Google Scholar] [CrossRef]

- Gittens, G.J. Variation of surface tension of water with temperature. J. Colloid Interface Sci. 1969, 30, 406–412. [Google Scholar] [CrossRef]

- Vargaftik, N.B.; Volkov, B.N.; Voljak, L.D. International tables of the surface tension of water. J. Phys. Chem. Ref. Data 1983, 12, 817–820. [Google Scholar] [CrossRef]

- Hamraoui, A.; Nylander, T. Analytical approach for the Lucas-Washburn equation. J. Colloid Interface Sci. 2002, 250, 415–421. [Google Scholar] [CrossRef] [PubMed]

- Marston, J.; Toyofuku, G.; Li, C.; Truscott, T.; Uddin, J. Drainage, rebound and oscillation of a meniscus in a tube. Phys. Fluids 2018, 30, 082103. [Google Scholar] [CrossRef]

- Maggi, F.; Alonso-Marroquin, F. Temperature dependence of capillary dynamics: A multiphase and multicomponent adiabatic approach. Phys. Rev. E 2013, 88, 053013. [Google Scholar] [CrossRef] [PubMed]

- Zhmud, B.V.; Tiberg, F.; Hallstensson, K. Dynamics of capillary rise. J. Colloid Interface Sci. 2000, 228, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Masoodi, R.; Languri, E.; Ostadhossein, A. Dynamics of liquid rise in a vertical capillary tube. J. Colloid Interface Sci. 2013, 389, 268–272. [Google Scholar] [CrossRef] [PubMed]

- Fries, N.; Dreyer, M. An analytic solution of capillary rise restrained by gravity. J. Colloid Interface Sci. 2008, 320, 259–263. [Google Scholar] [CrossRef]

- Bosanquet, C.H. LV. On the flow of liquids into capillary tubes. Philos. Mag. Ser. 1923, 45, 525–531. [Google Scholar] [CrossRef]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Siebold, A.; Nardin, M.; Schultz, J.; Walliser, A.; Oppliger, M. Effect of dynamic contact angle on capillary rise phenomena. Colloid Surf. A-Physicochem. Eng. Asp. 2000, 161, 81–87. [Google Scholar] [CrossRef]

- Dreyer, M.; Delgado, A.; Rath, H.J. Capillary rise of liquid between parallel plates under microgravity. J. Colloid Interface Sci. 1994, 163, 158–168. [Google Scholar] [CrossRef]

- Wijnhorst, R.; de Goede, T.C.; Bonn, D.; Shchidzadeh, N. Surfactant effects on the dynamics of capillary rise and finger formation in square capillaries. Langmuir 2020, 36, 13784–13792. [Google Scholar] [CrossRef] [PubMed]

- Hassanizadeh, S.M.; Gray, W.G. Thermodynamic basis of capillary pressure in porous media. Water Resour. Res. 1993, 29, 3389–3405. [Google Scholar] [CrossRef]

- Zuo, J.Y.; Guo, X.; Liu, Y.; Pan, S.; Canas, J.; Mullins, O.C. Impact of capillary pressure and nanopore confinement on phase behaviors of shale gas and oil. Energy Fuels 2018, 32, 4705–4714. [Google Scholar] [CrossRef]

- Delannoy, J.; Lafon, S.; Koga, Y.; Reyssat, É.; Quéré, D. The dual role of viscosity in capillary rise. Soft Matter 2019, 15, 2757–2761. [Google Scholar] [CrossRef] [PubMed]

- Sun, B. Monotonic rising and oscillating of capillary-driven flow in circular cylindrical tubes. API Adv. 2021, 11, 025227. [Google Scholar] [CrossRef]

- Arashiro, E.Y.; Demarquette, N.R. Use of the pendant drop method to measure interfacial tension between molten polymers. Mater. Res. 1999, 2, 23–32. [Google Scholar] [CrossRef]

- Stauffer, C.E. The measurement of surface tension by the pendant drop technique. J. Phys. Chem. 1965, 69, 1933–1938. [Google Scholar] [CrossRef]

- Cheng, K.K.; Park, C. Surface tension of dilute alcohol-aqueous binary fluids: N-Butanol/water, n-Pentanol/water, and n-Hexanol/water solutions. Heat Mass Transf. 2017, 53, 2255–2263. [Google Scholar] [CrossRef]

- Habrdová, K.; Hovorka, Š.; Bartovská, L. Concentration dependence of surface tension for very dilute aqueous solutions of organic nonelectrolytes. J. Chem. Eng. Data 2004, 49, 1003–1007. [Google Scholar] [CrossRef]

- Xue, H.T.; Fang, Z.N.; Tang, Y.; Huang, J.P.; Zhou, L.W. Contact angle determined by spontaneous dynamic capillary rise with hydrostatic effects: Experiment and theory. Chem. Phys. Lett. 2006, 432, 326–330. [Google Scholar] [CrossRef]

| r (mm) | Stage I (mm) | Stage II (mm) | Stage III (mm) | h1 (mm) | h2 (mm) | he (mm) |

|---|---|---|---|---|---|---|

| 0.4 | 11.2 (31.2%) | 16.4 (45.7%) | 8.3 (23.1%) | 11.2 | 27.6 | 35.9 |

| 0.6 | 8.7 (36.1%) | 10.1 (41.9%) | 5.3 (22%) | 8.7 | 18.8 | 24.1 |

| 0.8 | 7.2 (44.7%) | 7.4 (46%) | 1.5 (9.3%) | 7.2 | 14.6 | 16.1 |

| Mixture (Butanol wt.%) | Stage I (mm) | Stage I (mm) | Stage I (mm) | h1 (mm) | h2 (mm) | he (mm) | σ (mN/m) |

|---|---|---|---|---|---|---|---|

| B0% (DW) | 11.2 (31.2%) | 16.4 (45.7%) | 8.3 (23.1%) | 11.2 | 27.6 | 35.9 | 72 |

| B0.3% | 9.3 (29%) | 14.3 (44.5%) | 8.5 (26.5%) | 9.3 | 23.6 | 32.1 | 64 |

| B0.5% | 8.9 (31%) | 12.5 (43.6%) | 7.3 (25.4%) | 8.9 | 21.4 | 28.7 | 60 |

| B0.7% | 8.6 (32.3%) | 11.2 (42.1%) | 6.8 (25.6%) | 8.6 | 19.8 | 26.6 | 56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.; Jeong, S.; Seo, J.; Lee, S.; Park, S.; Choi, J.; Jeong, H.; Sung, Y. Effects of Tube Radius and Surface Tension on Capillary Rise Dynamics of Water/Butanol Mixtures. Appl. Sci. 2021, 11, 3533. https://doi.org/10.3390/app11083533

Baek S, Jeong S, Seo J, Lee S, Park S, Choi J, Jeong H, Sung Y. Effects of Tube Radius and Surface Tension on Capillary Rise Dynamics of Water/Butanol Mixtures. Applied Sciences. 2021; 11(8):3533. https://doi.org/10.3390/app11083533

Chicago/Turabian StyleBaek, Seungyeop, Sungjin Jeong, Jaedeok Seo, Sanggon Lee, Seunghwan Park, Jaeyoun Choi, Hyomin Jeong, and Yonmo Sung. 2021. "Effects of Tube Radius and Surface Tension on Capillary Rise Dynamics of Water/Butanol Mixtures" Applied Sciences 11, no. 8: 3533. https://doi.org/10.3390/app11083533

APA StyleBaek, S., Jeong, S., Seo, J., Lee, S., Park, S., Choi, J., Jeong, H., & Sung, Y. (2021). Effects of Tube Radius and Surface Tension on Capillary Rise Dynamics of Water/Butanol Mixtures. Applied Sciences, 11(8), 3533. https://doi.org/10.3390/app11083533