Abstract

Investigating the irradiation effects on borosilicate glass is of great significance for understanding the long-term evolutions of this substance in radioactive environments. In the present study, the hardness and modulus of conventional and ion-irradiated borosilicate glass were investigated through nanoindentation measurements. The obtained results show that the maximum decrease of the mean hardness after He and Ar ion irradiation was 8.4% and 17.0%, respectively, when the fluence reached 1.1 × 1015. It was found that the hardness reduction had a significant ionic correlation. Meanwhile, it was observed that the mean modulus increased by less than 5.0%, while there was no meaningful ionic correlation. The variation in hardness and modulus were primarily the consequence of nuclear energy deposition. The hardness recovery was observed under Ar-irradiated and He-irradiated Ar pre-damaged samples. It was concluded that the hardness recovery mainly originates from electronic energy deposition induced by ion irradiation.

1. Introduction

With the rapid development of science and technology, borosilicate glass has been widely applied in irradiated environments, including aircrafts, radioactive medicine and the disposal of high-radiation waste [1,2,3,4]. Considering the nature of these applications, having a stable mechanical property is of significant importance to ensure long-term performance in nuclear technological applications. However, investigations have revealed that the radiation originated from the decay of radionuclides affects the mechanical characteristics of most conventional materials, including borosilicate glass. Therefore, investigating the irradiation-induced evolutions of the mechanical characteristics of borosilicate glass is an essential issue.

Reviewing the literature indicates that many researchers have studied the mechanical property evolutions of ion- and electron-irradiated borosilicate glass. In order to reveal the underlying mechanisms of this issue, experiments have been carried out to study the microstructure and macrostructure changes of glass after the irradiation [5,6,7,8,9]. The obtained results showed that variations in the mechanical characteristics mainly depended on the ion species [5,10,11,12]. Peuget et al. showed that the hardness of an equivalent non-radioactive glass decreased by 30% after Kr ion irradiation, while He ion irradiation did not affect it [5]. Accordingly, it was concluded that nuclear energy deposition is the principal factor, and that the electronic energy deposition has a negligible effect on the hardness reduction after irradiation. However, further investigations demonstrated that the induced hardness by the electronic energy deposition significantly decreased in the electron-irradiated borosilicate glass [10]. This issue may be attributed to the structural variations originating from sodium migration that is induced by electron energy deposition. Karakurt et al. carried out experiments and showed that the hardness of irradiated borosilicate glass by He and Au ions decreased by 22% and 38%, respectively [11]. Accordingly, it was inferred that both electronic and nuclear energy deposition affect the mechanical characteristics of the glass. Moreover, Mir et al. showed that, when BS3 and SON68 glasses were exposed to He ion irradiation, the corresponding hardness initially decreased by 18% and 14%, respectively, and then remained constant. Meanwhile, such a reduction for Au ion irradiation was 35%. It was inferred that the hardness reduction mainly originated from the nuclear energy loss for the electronic energy loss less than 4 keV/nm [12]. These results indicate that ionic irradiation affects the mechanical property of borosilicate glass. However, the correlation between ionic irradiation and the mechanical characteristics of glass has not been expressed yet. This is especially more pronounced for the effects of electronic and nuclear processes [12]. In order to resolve these shortcomings, it is of significant importance to carry out a systematic study to clarify the detailed mechanism.

In this regard, this study is intended to investigate borosilicate glass subjected to the external irradiation of 0.5 MeV He and 2 MeV Ar. Furthermore, the evolutions of hardness and the Young modulus before and after irradiation are analyzed through the nano-indentation measurement method. The main objective of the present study is to establish a correlation between evolutions of mechanical characteristics and ionic irradiation.

2. Materials and Methods

2.1. Compositions of Materials

In the present study, conventional borosilicate glass is considered as the research object. Table 1 shows the chemical composition of the specimen. The glass sample was prepared from the Quartz and Special Glasses Institute of China Building Materials Academy. The dimension of the sample was 10 mm × 10 mm × 1 mm, and it was polished and ultrasonically cleaned before the experiment.

Table 1.

Chemical composition (mol%) of the studied borosilicate glass.

2.2. Irradiation Conditions

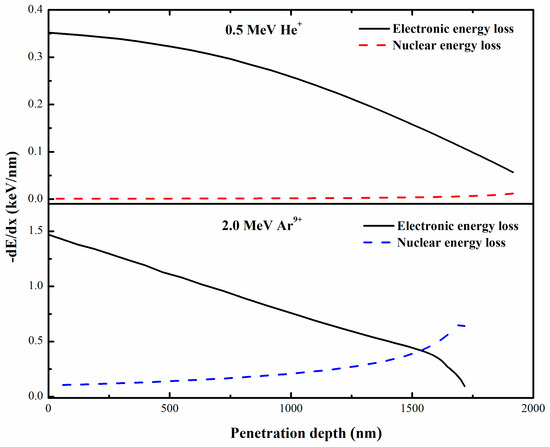

Room-temperature irradiations with 0.5 MeV He+ and 2 MeV Ar9+ ions were performed by a 320 kV electron cyclotron resonance (ECR) ion source. All experiments were carried out in a heavy-ion accelerator research facility, Lanzhou (HIRFL). During the experiment, beam currents for He and Ar ion irradiations were set to 15.0 μA and 6.0 μA, respectively. It is worth noting that different scenarios were followed in experiments. First, part of the samples were irradiated by He ions with different fluences. In the second scenario, the other part of the samples were irradiated by Ar ions. Finally, the samples pre-irradiated with 1.1 × 1013, 1.7 × 1014, 1.1 × 1015 and 1.7 × 1016 Ar cm−2 were irradiated with 3.3 × 1016 He cm−2. In this regard, Figure 1 illustrates the stopping power against the projectile ranges. It should be indicated that the SRIM2010 code was used in the present study to calculate the total displacements of the collision events in the irradiated samples with 0.5 MeV He+ and 2 MeV Ar9+ ions. Table 2 presents details of irradiation and stopping power of ions.

Figure 1.

Distribution of stopping power against the glass depth exposed to 0.5 MeV He and 2 MeV Ar ion irradiation, respectively.

Table 2.

Statistics of ion irradiation in the studied borosilicate glass.

2.3. Characterization Method

In the experiments, the mechanical characteristics of the specimen were calculated from load-displacement curves, which were obtained from a nanoindenter device (MTS G200, Milpitas, CA, USA). Moreover, a Berkovich diamond indenter was applied to perform nanoindentation tests in high-load continuous stiffness measurement (CSM) mode at room temperature, where small sinusoidal contributions were added to the applied load. It should be indicated that the default depth in all experiments was 3.5 μm and more than five indentations were carried out on each specimen.

3. Results

3.1. Hardness

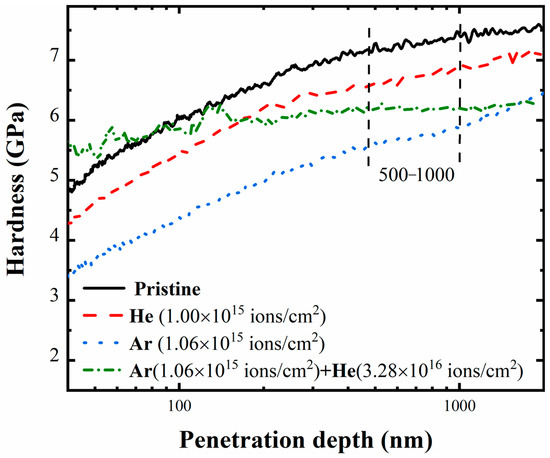

Figure 2 illustrates the distribution of hardness for irradiated borosilicate glass exposed at the ion fluence of 1.0 × 1015 ions/cm2. It was observed that the hardness sharply increased along the depth in the surface influence zone area. This phenomenon may be attributed to the blunt tip of the indenter and surface effects [13,14,15]. Then, the hardness gradually increased along the glass depth. Compared with published reports in this area [5,15,16], hardness of the Ar pre-irradiated samples subjected to the He ion had a plateau-like region, while there was not a similar trend for the hardness of He- and Ar-irradiated specimens made of borosilicate glass.

Figure 2.

Distribution of hardness against the penetration depth for He and Ar ion–irradiated borosilicate glass.

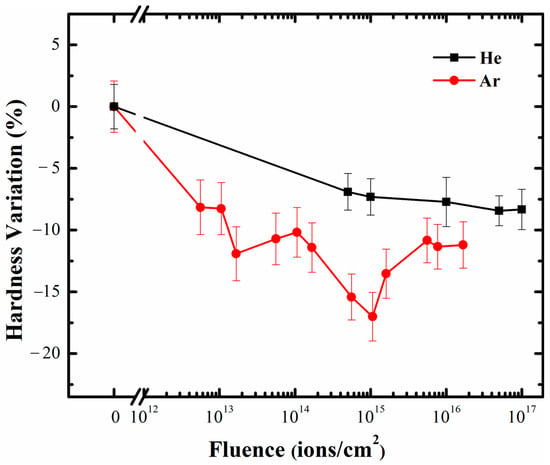

Figure 2 indicates that the hardness of the irradiated glasses is remarkably less than that of the pristine one. This was especially more pronounced for the Ar-ion-irradiated glass. Since the plastic interaction zone is approximately twice the depth of plastic penetration [5,13,14], the measured values with penetration depths varying from 500 nm to 1000 nm were considered to describe the corresponding mean hardness values of the specimens. Figure 3 reveals that, as the irradiation fluence increased, the corresponding mean hardness of He-ion-irradiated glass reduced. For the ion fluence of 1 × 1015 ions/cm2 (i.e., Enucl. = 1.8 × 1020 keV/cm3), the hardness saturated. This is consistent with the published reports for the ion-irradiated borosilicate glass [8,11,12,13,15,17]. The obtained results demonstrated that the maximum hardness reduction was approximately 8.4%. For Ar- ion-irradiated borosilicate glass, the mean hardness decreased first, and when the fluence reached 1.06 × 1015 ions/cm2, it increased. The maximum reduction was about 17.0%. Moreover, when the ion fluence was set to 7.7 × 1015 ions/cm2 (i.e., Enucl. = 7.6 × 1022 keV/cm3), the mean hardness increased first and then saturated. It should be indicated that the hardness of the Ar-ion-irradiated samples had a significant recovery of approximately 6.2%, while there was no similar trend in the He-ion-irradiated samples. This is also consistent with published reports.

Figure 3.

The hardness variation of borosilicate glasses versus the He and Ar ion fluence.

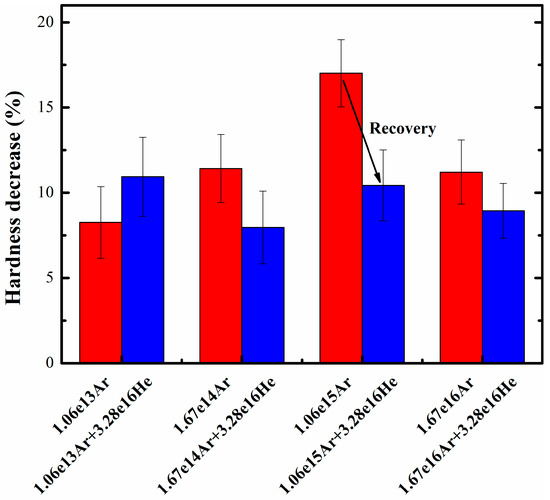

It was observed that Ar ions imposed high and intermediate damage levels (i.e., 17.0% and 11.5%, respectively), while He ions imposed a low damage level (i.e., 8.4%). Moreover, Figure 4 indicates that He ions induced different degrees of the recovery effect in the hardness of the Ar pre-irradiated specimens. More specifically, both the maximum and intermediate damage levels recovered to the saturation damage level of He ion irradiation.

Figure 4.

Variations of hardness against the He irradiation in Ar pre-irradiated samples.

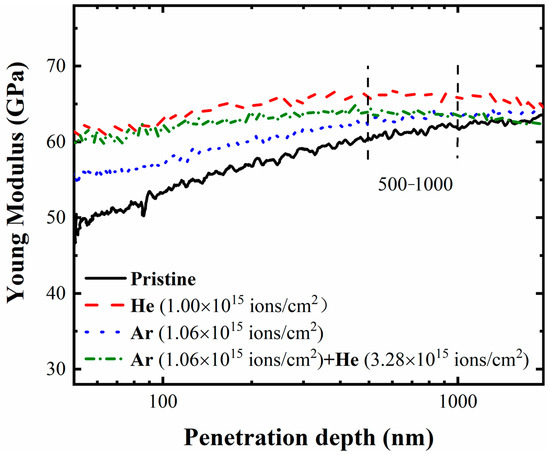

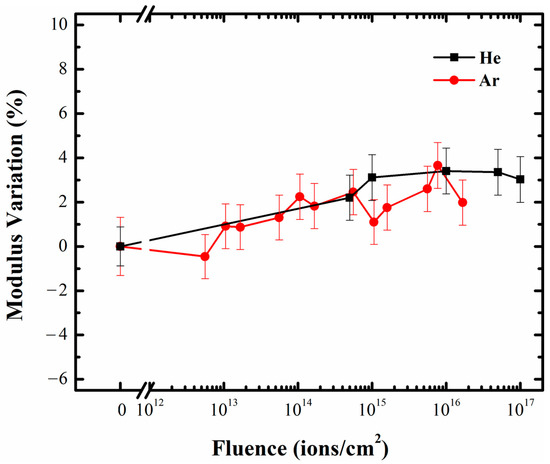

3.2. Young Modulus

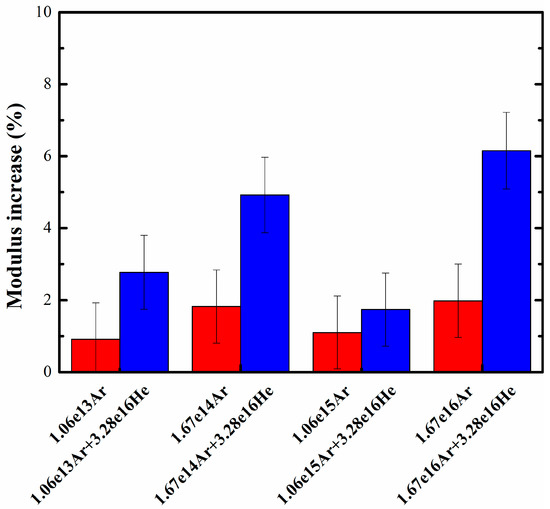

Figure 5 illustrates the distribution of the Young modulus for irradiated borosilicate glass exposed at the ion fluence of 1.0 × 1015 ions/cm. Investigations have demonstrated that the elastic affected region is significantly larger than that of the plastic region [15]. Accordingly, a plateau region did not appear in the modulus distributions of the irradiated specimens. Consequently, the measured values corresponding to the penetration depths of 500 nm to 1000 nm were applied to analyze the modulus of the ion-irradiated specimens. In this regard, Figure 6 shows that as the He and Ar ion irradiation fluences increased, the corresponding mean Young modulus of the irradiated borosilicate glass increased slightly. The maximum increase of modulus was less than 5%. Unlike hardness distributions, Figure 6 indicates that there was no obvious ionic correlation between the modulus variation and tendency. Meanwhile, Figure 7 shows that the modulus of the Ar pre-irradiated glass increased as the intensity of the He ion irradiation increased. It was observed that the upper and lower bounds of the increment were about 6.2% and 1.8%, respectively. The maximum hardness recovery and the minimum modulus increase were for the same sample.

Figure 5.

Distribution of Young modulus against the penetration depth for He– and Ar–ion–irradiated borosilicate glass.

Figure 6.

Distribution of modulus against He and Ar ion fluence in borosilicate glass.

Figure 7.

Variations of modulus against the He irradiation in Ar pre-irradiated specimen.

4. Discussion

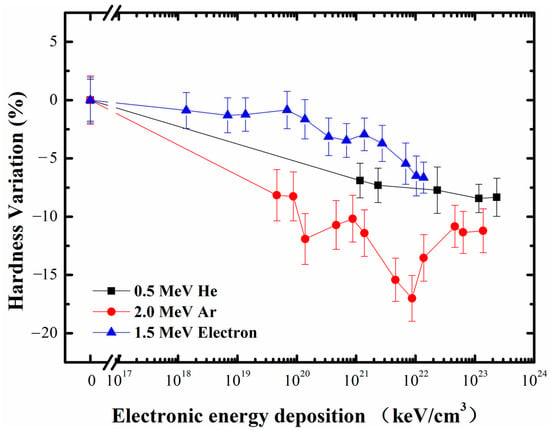

4.1. Energy Deposition

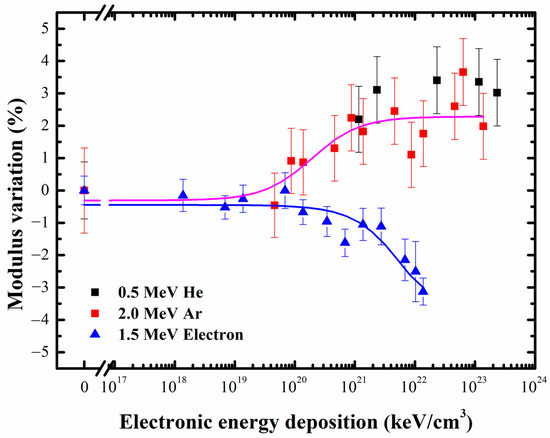

In order to understand the influence of energy deposition on the hardness and modulus, evolutions of the mechanical properties induced by the irradiation of He and Ar ions were compared with the electron irradiation data [15]. Figure 8 and Figure 9 illustrate variations of the mean hardness and modulus against the electronic energy deposition. It was found that variations of the mean hardness induced by electron irradiation had a different trend with the ion irradiation scenario. Although the maximum reductions in the electron and He ion irradiation for the deposited electronic energy of 1022 keV/cm3 were the same, there was an obvious reduction in the hardness induced in the ion irradiation scheme at a lower electronic energy deposition. The maximum hardness reduction in the Ar-ion-irradiated specimen was much greater than that of the electron-irradiated specimen. It was thus inferred that compared to the electron-irradiated scheme, Ar ions induce larger damage at the same electronic energy deposition. Moreover, the Young modulus decreased after electron irradiation, while it increased after ion irradiation. These discrepancies may be attributed to the influence of nuclear energy deposition of He and Ar ions on the hardness reduction and increase of the Young modulus.

Figure 8.

Distributions of hardness against electronic energy deposition in borosilicate glass.

Figure 9.

Distribution of modulus against electronic energy deposition in borosilicate glass (the magenta curve is the fitting curve of the modulus variation caused by Ar and He ion irradiation).

4.2. Correlation between the Ionic Irradiation and Hardness and Young Modulus

The discrepancies in the hardness decreases induced by the irradiation of He and Ar ions demonstrate that an ionic correlation can be established for the hardness reduction by ion irradiation. The obtained results revealed that such a correlation depends on the nuclear energy loss and the self-restoration induced by electronic energy deposition. It was found that, in the ion irradiation scenario, the hardness reduction originated from the displacement damages caused by the nuclear energy deposition [5,11,12,17]. In this regard, Table 2 shows that the nuclear energy loss for Ar ion irradiation is about 80 times larger than that of the He ion irradiation, resulting in a significant damage level. Moreover, the numbers of the total displacements for irradiations of 0.5 MeV He ions and 2.0 MeV Ar ions were 164 and 5960, respectively. It was thus inferred that, at the same deposited nuclear energy, displacement levels caused by ballistic effects with Ar ion irradiation are significantly more than those caused by He ion irradiation. Meanwhile, as the mass and energy of the ion increased, the displacement damage intensified. This is because, in a highly dense displacement cascade, the atomic bonds would be severely disrupted, thereby decreasing the effective displacement energy of atoms [18].

The obtained results showed that, as the irradiation fluence of He and Ar ions increased, the corresponding mean Young modulus increased slightly and uniformly. In other words, within an acceptable margin of error, there is no meaningful correlation in the modulus increase between the He and Ar ion irradiation. It was thus concluded that the variations of Young modulus can be determined by mean ring size, density, the transformation of [BO4] to [BO3] ions and network depolymerization in the glass structure [15,19,20]. It is worth noting that the last three factors also affect the hardness. Therefore, the mean ring size may be the main affecting factor for variations of the modulus in nonionic environments. The Raman spectra results showed that the reduction of the mean ring size induced by the heavier ion irradiation was greater than that of the lighter ion irradiation [11,21].

4.3. Hardness Recovery

The hardness variation in the He-ion-irradiated specimen saturated for a nuclear energy deposition of 1.8 × 1020 keVnucl.cm−3. It should be indicated that this finding is in good agreement with ion irradiation-induced hardness reduction [4,5,7,8,13,14,15]. Moreover, an obvious recovery was observed in the hardness variations of Ar-ion-irradiated specimens. Figure 8 illustrates that when the electronic energy deposition in electron irradiated glass exceeded 1 × 1022 keVelec./cm3, the corresponding hardness decreased significantly. Lv et al. showed that Au ion irradiation slightly affects the hardness variations. Moreover, it was found that the variations of the start point are similar to that of the electron irradiated glass [16]. Consequently, the hardness recovery may be attributed to the effects of electronic energy deposition. Accordingly, it was inferred that for the hardness recovery of ion-irradiated borosilicate glass, the deposited electronic energy threshold is 1 × 1022 keVelec./cm3. Since the hardness evolution induced by electronic energy deposition changes as a function of the chemical compositions, such a threshold depends on the chemical composition of the specimen. Reported results for different glass compositions showed that the mechanical characteristics of the specimen change differently with ionizing radiations [5,13,15,22,23].

For electronic energy deposition, the displacement damage caused by ion irradiation has the self-restoration phenomenon [13,24]. In this regard, Mir et al. observed the hardness recovery in the He ion irradiated with gold pre-damaged glasses [21]. Moreover, it was found that the nuclear energy deposition leads to displacement damage in the glass after ion irradiation. However, considering the effect of electronic energy deposition, the microdamage in the glass can be recovered partially. Moreover, for single ion-implanted borosilicate glass, the electronic energy loss for the Ar ion was greater than that of He ion. As a result, the corresponding self-restoration effect is more obvious while depositing the same level of electronic energy.

Figure 6 presents different degrees of He ion-induced recovery in the hardness of the Ar pre-irradiated glass (I~IV samples). It was observed that both the maximum and intermediate damage levels recovered to the saturation damage level of the He ion irradiation, while there was no such a recovery effect in the hardness of sample I. Accordingly, it was inferred that there is a damage threshold for the hardness recovery of ion-irradiated borosilicate glass. When the damage level exceeds the threshold, the effect of hardness recovery caused by electronic energy deposition is more pronounced. Mir et al. observed the recovery phenomenon induced by He-ion-irradiated and Au pre-irradiated amorphous silica when the pre-existing damage level exceeded the threshold. It was found that, when the pre-existing damage level is lower than this threshold, the superposition effect appears in the damage [25]. This is the main reason for the hardness saturation after He ion irradiation and the absence of recovery. One explanation that supports the recovery effect induced by ion irradiation in borosilicate glass is the low-temperature non-melting thermal spike originating from the electron energy loss. In this regard, an alpha-induced thermal spike has been proposed to improve the nanoligament connectivity and hardness of nanoporous silica [26]. However, the thermal peak scheme has not yet been applied to borosilicate glass. Consequently, the mechanism of the hardness recovery and the damage threshold of recovery induced by ion-irradiated borosilicate glass has not been clarified yet.

5. Conclusions

The main objective of the present article was to investigate the influence of different ions on the radiation-induced mechanical characteristics of borosilicate glass. To this end, two ions, including 0.5 MeV He+ and 2 MeV Ar9+, were separately exposed into borosilicate glass samples. The nanoindentation results indicate that, at the studied conditions, the mean hardness significantly decreases, while the mean Young modulus slightly increases after exposure to the irradiation of He and Ar ions. Compared to the data of electron-irradiated samples, the obtained results indicate that the hardness reduction and the modulus increment of the specimen may be attributed to the nuclear energy deposition. Meanwhile, the significant discrepancy of hardness variations induced by He and Ar ion irradiation mainly originated from the nuclear energy loss and ballistic effects. On the other hand, it was found that there was not a meaningful correlation between the irradiation intensity and the modulus variation, and the mean ring-size variation was the main factor for this phenomenon. It was found that there exists a deposited electronic energy threshold (approximately 1 × 1022 keVelec./cm3) for the hardness recovery of ion-irradiated borosilicate glass. He ions induce different degrees of recovery in the hardness of the Ar pre-irradiated glass. Moreover, it was found that there exists a damage threshold for the hardness recovery of ion-irradiated borosilicate glass. Thus, when the damage level exceeds the threshold, the corresponding hardness recovery in the electronic energy deposition is more pronounced.

Author Contributions

Investigation, Z.S. and L.W.; methodology, P.L. and B.Z.; resources, Z.W.; supervision, Y.J. and L.Z.; validation, L.C. and T.W.; writing—original draft, Y.G.; writing—review and editing, Y.G. and L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Nature Science Foundation of China, grant numbers U1867207, 11505084 and 11675068, and the Fundamental Research Funds for Central University of China, grant number lzujbky-2016-37.

Data Availability Statement

The data used to support the findings of this study are included within the article.

Acknowledgments

This work was supported by the National Nature Science Foundation of China (NSFC, Nos. U1867207, 11505084 and 11675068); and the Fundamental Research Funds for Central University of China (No. lzujbky-2016-37). The ECR-group in Institute of Modern Physics, Lanzhou, is acknowledged for providing technical supports. The authors are also grateful to the Public Center for Characterization and Test, Suzhou Institute of Nano-tech and Nano-bionics, Chinese Academy of Sciences.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Al-Hadeethi, Y.; Tijani, S.A. The use of lead-free transparent 50BaO-(50-x)borosilicate-xBi(2)O(3) glass system as radiation shields in nuclear medicine. J. Alloys Compd. 2019, 803, 625–630. [Google Scholar] [CrossRef]

- Sun, Y.P.; Xia, X.B.; Qiao, Y.B.; Zhao, Z.Q.; Ma, H.J.; Liu, X.Y.; Qian, Z.H. Properties of phosphate glass waste forms containing fluorides from a molten salt reactor. Nucl. Sci. Tech. 2016, 27, 63. [Google Scholar] [CrossRef]

- Weber, W.J.; Ewing, R.C.; Angell, C.A.; Arnold, G.W.; Cormack, A.N.; Delaye, J.M.; Griscom, D.L.; Hobbs, L.W.; Navrotsky, A.; Price, D.L.; et al. Radiation effects in glasses used for immobilization of high-level waste and plutonium disposition. J. Mater. Res. 1997, 12, 1948–1978. [Google Scholar] [CrossRef]

- Du, X.; Wang, T.-T.; Duan, B.H.; Zhang, X.-Y.; Liu, F.-F.; Lan, C.-L.; Wang, G.-F.; Chen, L.; Peng, H.-B.; Wang, T.-S.; et al. Techniques, Effects of energy deposition on mechanical properties of sodium borosilicate glass irradiated by three heavy ions: P, Kr, and Xe. Nucl. Sci. Tech. 2019, 30, 1–9. [Google Scholar] [CrossRef]

- Peuget, S.; Noel, P.Y.; Loubet, J.L.; Pavan, S.; Nivet, P.; Chenet, A. Effects of deposited nuclear and electronic energy on the hardness of R7T7-type containment glass. Nucl. Instrum. Methods B 2006, 246, 379–386. [Google Scholar] [CrossRef]

- Deschanels, X.; Peuget, S.; Cachia, J.N.; Charpentier, T. Plutonium solubility and self-irradiation effects in borosilicate glass. Prog. Nucl. Energy 2007, 49, 623–634. [Google Scholar] [CrossRef]

- Peuget, S.; Cachia, N.J.; Jégou, C.; Deschanels, X.; Roudil, D.; Broudic, V.; Delaye, J.M.; Bart, J.-M. Irradiation stability of R7T7-type borosilicate glass. J. Nucl. Mater. 2006, 354, 1–13. [Google Scholar] [CrossRef]

- Peuget, S.; Delaye, J.M.; Jégou, C. Specific outcomes of the research on the radiation stability of the French nuclear glass towards alpha decay accumulation. J. Nucl. Mater. 2014, 444, 76–91. [Google Scholar] [CrossRef]

- Duan, B.H.; Chen, L.; Lv, P.; Du, X.; Zhang, L.M.; Wang, T.S. In situ TEM study on electron irradiation effects in SiO2–Na2O–B2O3 glasses. Int. J. Appl. Glass Sci. 2019, 10, 220–227. [Google Scholar] [CrossRef]

- Lv, P.; Chen, L.; Duan, B.H.; Zhang, D.F.; Wang, T.S. Composition dependence of mechanical property changes in electron irradiated borosilicate glasses. Nucl. Instrum. Methods B 2017, 405, 61–66. [Google Scholar] [CrossRef]

- Karakurt, G.; Abdelouas, A.; Guin, J.P.; Nivard, M.; Sauvage, T.; Paris, M.; Bardeau, J.F. Understanding of the mechanical and structural changes induced by alpha particles and heavy ions in the French simulated nuclear waste glass. J. Nucl. Mater. 2016, 475, 243–254. [Google Scholar] [CrossRef]

- Mir, A.H.; Monnet, I.; Toulemonde, M.; Bouffard, S.; Jegou, C.; Peuget, S. Mono and sequential ion irradiation induced damage formation and damage recovery in oxide glasses: Stopping power dependence of the mechanical properties. J. Nucl. Mater. 2016, 469, 244–250. [Google Scholar] [CrossRef]

- Yang, K.J.; Wang, T.S.; Zhang, G.F.; Peng, H.B.; Chen, L.; Zhang, L.M.; Li, C.X.; Tian, F.; Yuan, W. Study of irradiation damage in borosilicate glass induced by He ions and electrons. Nucl. Instrum. Methods B 2013, 307, 541–544. [Google Scholar] [CrossRef]

- Zhang, G.F.; Wang, T.S.; Yang, K.J.; Chen, L.; Zhang, L.M.; Peng, H.B.; Yuan, W.; Tian, F. Raman spectra and nano-indentation of Ar-irradiated borosilicate glass. Nucl. Instrum. Methods B 2013, 316, 218–221. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, W.; Nan, S.; Du, X.; Zhang, D.F.; Lv, P.; Wang, T.S. Study of modifications in the mechanical properties of sodium aluminoborosilicate glass induced by heavy ions and electrons. Nucl. Instrum. Methods B 2016, 370, 42–48. [Google Scholar] [CrossRef]

- Lv, P.; Chen, L.; Zhang, B.T.; Yuan, W.; Duan, B.H.; Guan, Y.D.; Zhao, Y.; Zhang, X.Y.; Zhang, L.M.; Wang, T.S. Composition-dependent mechanical property changes in Au-ion-irradiated borosilicate glasses. J. Nucl. Mater. 2019, 520, 218–225. [Google Scholar] [CrossRef]

- Wang, T.S.; Zhang, D.F.; Chen, L.; Lv, P.; Du, X.; Yuan, W.; Yang, D. Irradiation-induced modifications in the mechanical properties of borosilicate glass. Acta Phys. Sin. 2017, 66, 026101. [Google Scholar]

- Kucheyev, S.O.; Williams, J.S.; Jagadish, C.; Zou, J.; Li, G.; Titov, A.I. Effect of ion species on the accumulation of ion-beam damage in GaN. Phys. Rev. B 2001, 64, 035202. [Google Scholar] [CrossRef]

- Rao, K.J. Structural Chemistry of Glasses; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Kieu, L.H.; Kilymis, D.; Delaye, J.M.; Peuget, S. Discussion on the Structural Origins of the Fracture Toughness and Hardness Changes in Rapidly Quenched Borosilicate Glasses: A Molecular Dynamics Study. Procedia Mater. Sci. 2014, 7, 262–271. [Google Scholar] [CrossRef]

- Mir, A.H.; Peuget, S.; Toulemonde, M.; Bulot, P.; Jegou, C.; Miro, S.; Bouffard, S. Defect recovery and damage reduction in borosilicate glasses under double ion beam irradiation. Europhys. Lett. 2015, 112, 36002. [Google Scholar] [CrossRef]

- Gedeon, O.; Lukes, J.; Jurek, K. Reduced Young modulus and hardness of electron irradiated binary potassium-silicate glass. Nucl. Instrum. Methods B 2012, 275, 7–10. [Google Scholar] [CrossRef]

- Mir, A.H.; Boizot, B.; Charpentier, T.; Gennisson, M.; Odorico, M.; Podor, R.; Jégou, C.; Bouffard, S.; Peuget, S. Surface and bulk electron irradiation effects in simple and complex glasses. J. Non-Cryst. Solids 2016, 453, 141–149. [Google Scholar] [CrossRef]

- Abbas, A.; Serruys, Y.; Ghaleb, D.; Delaye, J.M.; Boizot, B.; Reynard, B.; Calas, G. Evolution of nuclear glass structure under a-irradiation. Nucl. Instrum. Methods B 2000, 166, 445–450. [Google Scholar] [CrossRef]

- Mir, A.H.; Toulemonde, M.; Jegou, C.; Miro, S.; Serruys, Y.; Bouffard, S.; Peuget, S. Understanding and simulating the material behavior during multi-particle irradiations. Sci. Rep. 2016, 6, 30191. [Google Scholar] [CrossRef]

- Sauli, F.; Sharma, A. Micropattern gaseous detectors. Annu. Rev. Nucl. Part. Sci. 1999, 49, 341–388. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).