1. Introduction

Manufacturing internally threaded mechanical parts, particularly parts with numerous threads, requires high machining precision. Fabrication of threads using high-precision molds is usually the final step in the manufacturing process. Therefore, manufacturers require a reliable method of maintaining high quality in machining internal threads, especially in mass-produced mechanical components with internal threads. Tapping accuracy largely depends on whether the movement of the feed of the tapping axis is well synchronized with the rotation of the spindle during the tapping cycle. The observed index of the tapping axis feed to spindle rotation is the synchronization error. Therefore, to obtain a high-precision internal thread by rigid tapping, the goal is to minimize synchronization error.

For servo parameter commissioning, Lee et al. [

1] proposed an iterative measurement and contour performance simulation. Servo parameters were adjusted to reduce contour error, and the Kreuz–Gitter–Meβsystem (KGM) method was used to verify the contour’s accuracy. Yeh et al. [

2] proposed “learning automata,” an automatic parameter adjustment method for improving parameter convergence and improving efficiency in adjusting control parameters. To optimize the synchronous motion between the spindle and the tap-ping axis, Yeh et al. [

3] proposed several linear and nonlinear control design techniques for improving control performance and synchronization, including (1) Cross-coupling control, (2) Nonlinear friction compensation, and (3) Interference observation. Servo gain was optimized by the command control method. The authors achieved synchronization accuracy within 10 ums at a spindle speed of 6000 rpm by applying these techniques. Lu et al. [

4] used a fuzzy adaptive proportional–integral–derivative (PID) controller to control Computer Numerical Control (CNC) machine tools used in rigid tapping. The proposed control method can be performed without establishing a controlled object, and the online PID controllable parameters are automatically adjusted by the fuzzy inference method. In another study, Ishizaki et al. [

5] proposed a cross-coupled controller for accurately synchronizing the motion of a servo system driven by dual motors. The proposed cross-coupled controller compensates for differential positioning errors between dual servo drives by modifying reference positions and speed commands. Biris et al. [

6] performed experiments to compare the effectiveness of eliminating positioning and contour errors. The authors also proposed an adjustment method based on a mathematical model and evaluated its performance in reducing positioning and contour errors in CNC machine tools. Chen et al. [

7] proposed an iterative learning control (ILC) algorithm for reducing synchronization error in rigid tapping.

In recent years, additive manufacturing (AM) technology has been proposed to be suitable for manufacturing critical components. Additive manufacturing is completely different from traditional subtractive processing. In contrast, additive manufacturing uses polymer, metal, or ceramic material spray stacking to construct a 3D shapes method that can quickly and flexibly produce a small number of diverse products, significantly reducing the time from the design stage to mass production of the products and considerably improving the utilization rate of materials [

8,

9,

10,

11,

12]. At present, additive manufacturing can be used to produce energy, aerospace, or biomedical parts, providing high-strength and lightweight products. The machine tools manufacturer MAZAK’s hybrid multi-objective machine tool type can perform laser additive manufacturing and 5-axis machining processes on machine tools, demonstrating the possibilities and characteristics of future advanced techniques [

13].

The learning control modifies the

z-axis and the spindle commands to optimize synchronicity between

z-axis output responses and the spindle. Their experiments revealed that 10 runs of the ILC algorithm reduced synchronization error from 0.26 mm to 2.6 × 10

−13. That is, the use of ILC learning control can substantially reduce synchronization error. Chen et al. [

14] proposed intelligent computer-aided process planning (i-CAPP). When the machining process’s complexity increases, i-CAPP’s Integration intelligence function works together with the domain expert’s procedure. Ma et al. [

15] accord the coupling between the radial and axial vibrations and the dynamic cutting forces modeled along the tapping path. The radial and axial chatter stability is separately predicted in the frequency domain for the tapping process’s stability.

In the past, when the machining process was executed in the factory, the teeth or the tapping tools occasionally broke when the tapping speed was different. Usually, it was necessary to wait for the equipment manufacturer to inspect the equipment to obtain the best parameters. The current study developed a novel method of adjusting rigid tapping electrical control parameters and explored the effects of the adjusted parameters on thread quality obtained by tapping in internally threaded parts. The proposed method combines uniform design (UD) [

16,

17,

18,

19], regression analysis [

20,

21,

22,

23], fractional-order particle swarm optimizer (FPSO) [

24,

25,

26,

27,

28], and the Taguchi method [

29,

30,

31,

32,

33,

34,

35,

36] to analyze the effects of rigid tapping parameters on thread quality and to determine the key parameters and the optimal parameter values. Application of the proposed method in an actual factory process verified its effectiveness for improving thread tapping quality. Through the method provided in this article, the processing industry can get the minimum error parameter combination at different tapping speeds through experiments to avoid breaking the tool when rigid tapping is performed at the end of the processing process and causing damage to the workpiece.

This paper is organized as follows. The problem considered in this study is briefly described in

Section 2.

Section 3 briefly discusses relevant methods, including UD, regression analysis, FPSO, and the Taguchi method.

Section 4 presents and discusses the experimental and simulation results. Finally,

Section 5 concludes the study.

2. Problem Description

Machining internal threads is an essential process in mechanical parts manufacturing in various industries. For example, numerous internally threaded holes are required to manufacture printed circuit boards (PCBs) in the computer, communications, and consumer-electronics (3C) electronics industry and manufacture mobile phone cases in the mold industry. Holes are typically threaded in a late stage of the manufacturing process. Poorly threaded holes can severely diminish the manufactured part’s quality and performance; therefore, manufacturers require a fast and reliable method for tapping internally threaded holes.

Tapping can be classified as floating or rigid. Each method uses a different tool clamping device, so each method has different synchronization requirements for the spindle and the tapping axis. Floating tapping was developed to solve the problem of synchronization between the spindle and the tapping axis. In floating tapping, the tap-ping tool is clamped in an elastic chuck. The advantage of floating tapping is that tapping can be achieved without complex control theory. The disadvantage, however, is that an excessively high tapping speed causes severe vibration resulting in imprecise tapping and/or disordered or broken teeth. In rigid tapping, a tap collet is typically used to clamp the tapping tool, which provides more precise teeth and enables a more efficient tapping speed than floating tapping. Rigid tapping is also much faster than floating tap-ping. However, synchronization between the spindle and the tapping axis must be exact. Even a slight difference can cause a breakage of the tool. Therefore, accurate synchronization of the spindle and tapping axis is essential. Most research in rigid tap-ping control has focused on minimizing the synchronization error between the tapping axis movement and the spindle to obtain internal threads with high quality and accuracy.

To obtain the required screw pitch specifications in a rigid tapping process, the tapping axis and the spindle must be adjusted to meet the required combination of spindle speed and feed rate of the tapping axis. The relationships can be formulated as in Equation (1)

where

P is the thread pitch (unit: mm),

F is the feed rate of the tapping axis (unit: mm/min), and

S is the spindle speed (RPM).

In a rigid tapping procedure, the spindle speed and tapping axis feed rate must maintain a certain proportional relationship according to the required pitch specifications. Because pitch P depends on the scale of spindle speed and feed rate of the feed axis, if spindle speed and feed rate of feed axis do not match, it causes synchronization error which is too large and pitch P, not precision. Therefore, the controller has a command-type compensation architecture, and the controller simultaneously commands the spindle and the tapping axis and compensates for positioning errors.

Additionally, the FANUC 31iMA controller used in this experiment is that the control method in which the tapping axis follows the spindle identifies synchronization errors between the spindle and the tapping axis.

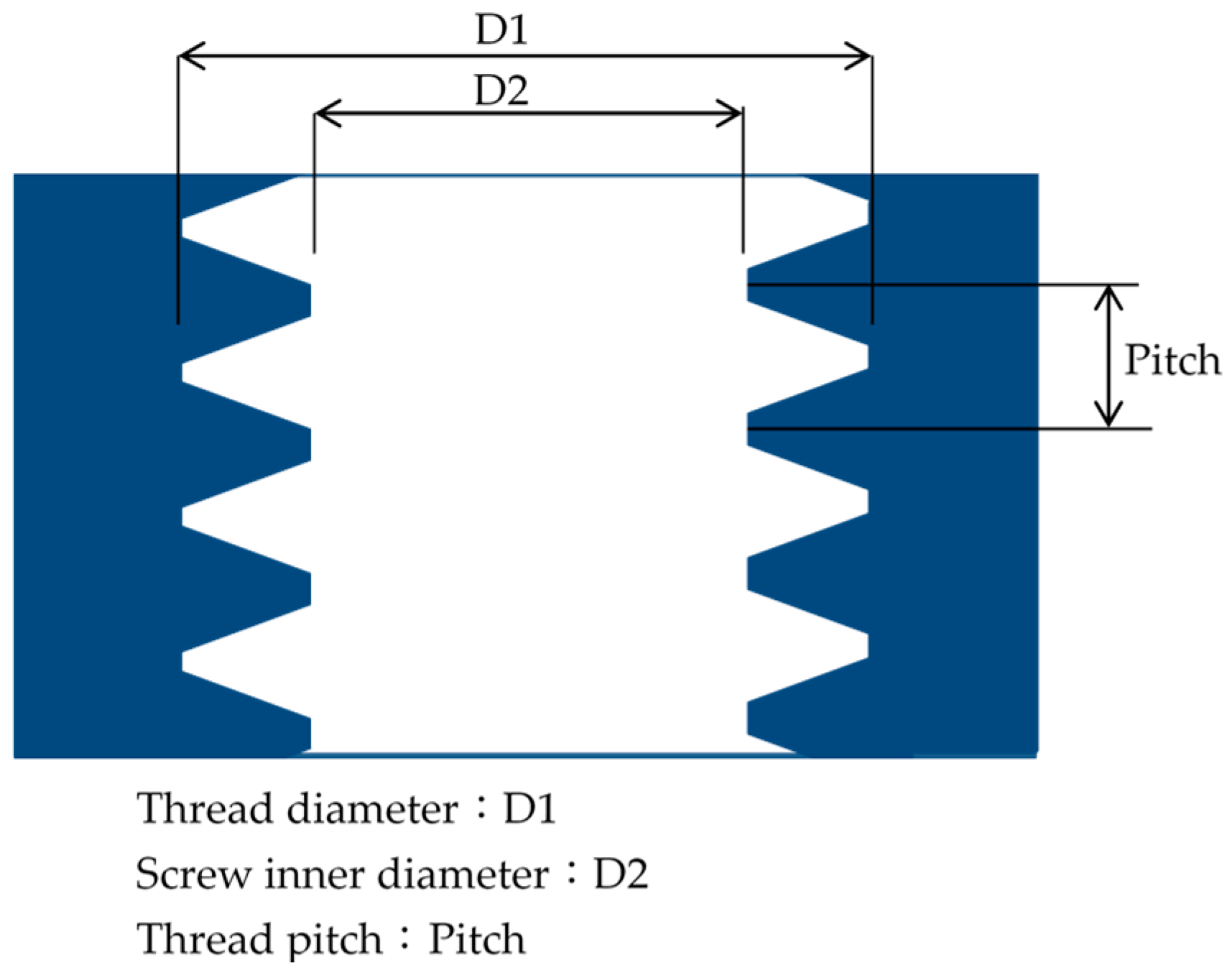

Figure 1 shows that synchronization error is an essential indicator in rigid tapping because it affects internal threads’ shape and precision.

4. Experimental Planning and Methods

Drilling and tapping processes are used in the manufacturing processes for diverse products ranging from cylinder engines in the automobile industry to mobile phone molds in the consumer electronics industry. Since the manufacture of these products often requires numerous drilling and tapping procedures, determining the parameter combination that provides the best tapping accuracy is needed to achieve high product quality in the post-process. This study’s objective was to find the parameter combination that minimizes rigid tapping synchronization error without increasing manufacturing time.

Figure 2 shows that the experiments were performed in an NDV series machine tool (Yeong-Chin machinery industries Co. Ltd., Taichung, Taiwan) with a FANUC 31iMA controller. The material used for the through-hole processing experiments was polymethyl methacrylate (PMMA) due to its high plasticity, high hardness, and low brittleness. The PMMA was considered an excellent experimental material because it enabled observation of broken or irregular cutters’ effects. Therefore, even a significant synchronization error would be unlikely to damage the tapping tool in the tapping axis. The phenomena of stripped thread or thread damage can still be observed in PMMA. An M6 × 1 tapping tool was used in the experiments. The cutting conditions were as follows. Spindle speed, tapping axis feed rate, and tapping depth were set to 3000 RPM, 3000 mm/min, and 50 mm, respectively. The experiment was performed five times at these settings.

Figure 3 shows the processing path.

The experimental input was the factor that affected synchronization error, and the output was synchronization error. Input factors were factors that affected synchronization error, including feedforward speed coefficient (

x1, unit: 0.01%), rigid tapping speed loop proportional gain (

x2, unit: As), motor excitation delay time (

x3, unit: microsecond), rigid tapping speed loop integral gain (

x4, unit: microsecond)), feed position coefficient (

x5, unit: 0.01%) and tapping axis position gain (

x6, unit: 0.01s-1) [

54,

55,

56,

57]. These parameters were set on the FANUC controller system.

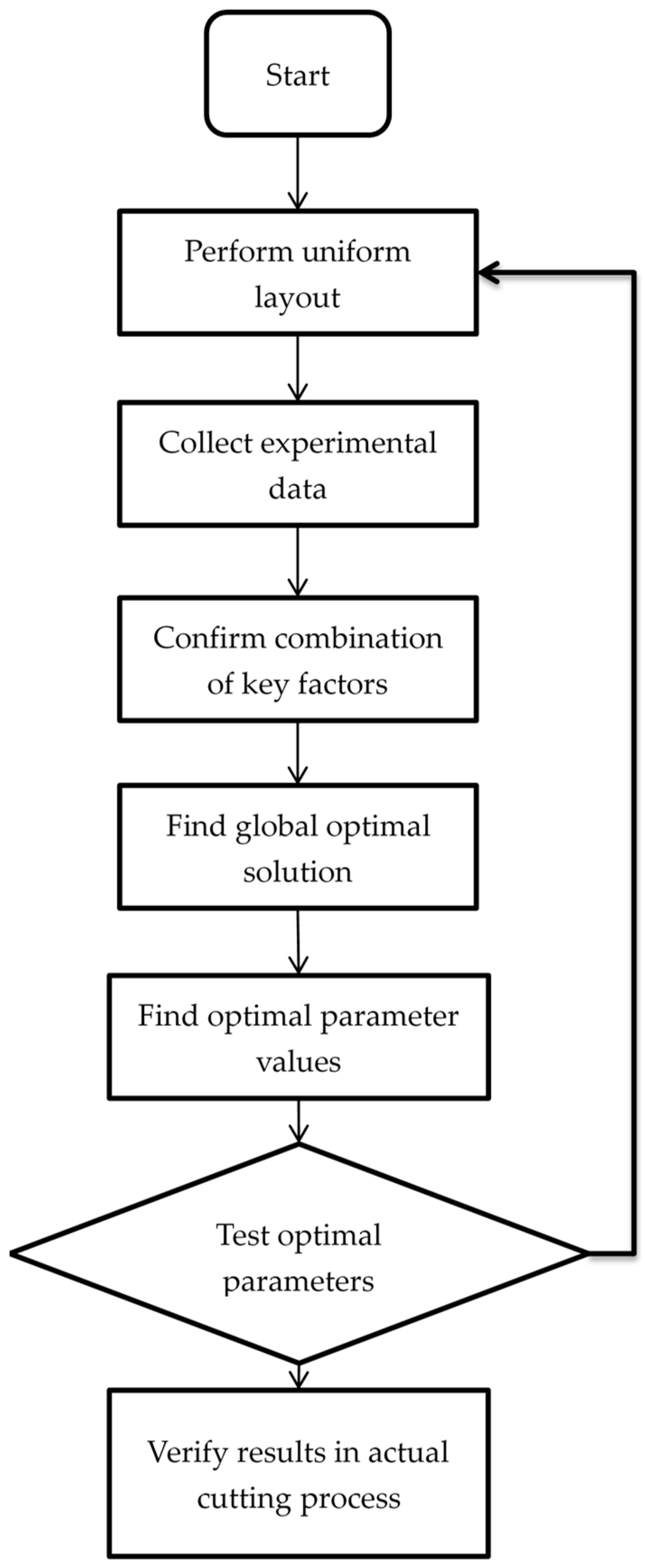

Figure 4 shows the experimental procedure. The uniform distribution characteristic of UD made each experimental combination meaningful, which substantially reduced the required number of experiments.

Table 3 shows the

U *

28 (288) uniform layout selected for this study’s experiments. First, input factors were entered in the

U *

28 uniform layout. Synchronization error was the quality characteristic, and the response value was obtained by the-smaller-the-better characteristic.

Table 4 is the table for selecting column numbers according to the experiment number.

Table 4 shows that columns 1–7 were used to construct the

U *

28 (286) uniform layout, and

Table 5 shows the resulting layout.

Table 6 shows the 28 levels for each factor. A CCD electronic image microscope was used to observe the results (thread pitch and workpiece shape) of the tapping experiments performed using the factor combinations in

Table 5 and

Table 6.

Table 7 displays the experimental results.

The rigid tapping command for the FANUC 31iMA controller used in the experiments was as follows:

M29 S__;

G84 X__Y__Z__R__F__K__;

where

M29 is the rigid tapping command,

S is the spindle speed, G84 is the right-hand thread tapping by M3 spindle rotation,

X, Y are the hole positions in the X- and Y-axes,

Z is the tapping depth from the R-plane to Z-depth,

R is the R plane position,

F is the tapping axis feed rate, and

K is the number of cycles.

The rigid tapping program was as follows:

G91 G94

N1

N2 M29 S3000

G84 Z-50.000 R-20.000 F3000.000 K5

G80

G04 X1.N999 G04 X1.

M99

Table 8 presents the results obtained by the

U *

28(28

6) uniform layout. Based on the regression analysis results and the experimental results in

Table 8, the following regression equation was obtained:

According to Equation (9), the key factors in synchronization error in rigid tapping are x2 (rigid tapping speed loop proportional gain), x3 (motor excitation delay time), x4 (rigid tapping speed loop integral gain), x5 (position feed coefficient) and x6 (tapping axis position gain). Next, FPSO was used to find the global best combination of values for factors x2, x3, x4, x5, and x6 and to find the global best output value. According to the FPSO results, the global best combination was (x2, x3, x4, x5, x6) = (50, 360, 260, 9400, 9400), and the global best output value was 39.9329.

Next, the Taguchi method was used to verify the global best combination obtained by UD and FPSO.

Table 9 is the

L’

16(4

5) orthogonal array selected for this number of factors. Here, the levels of the

L’

16(4

5) orthogonal array were based on the global best combination obtained by UD and FPSO.

Table 10 shows the values for

x2,

x3,

x4,

x5, and

x6, and

Table 11 shows the factor combinations of

L’

16(4

5). The values in

Table 11 were used to obtain the results shown in

Table 12.

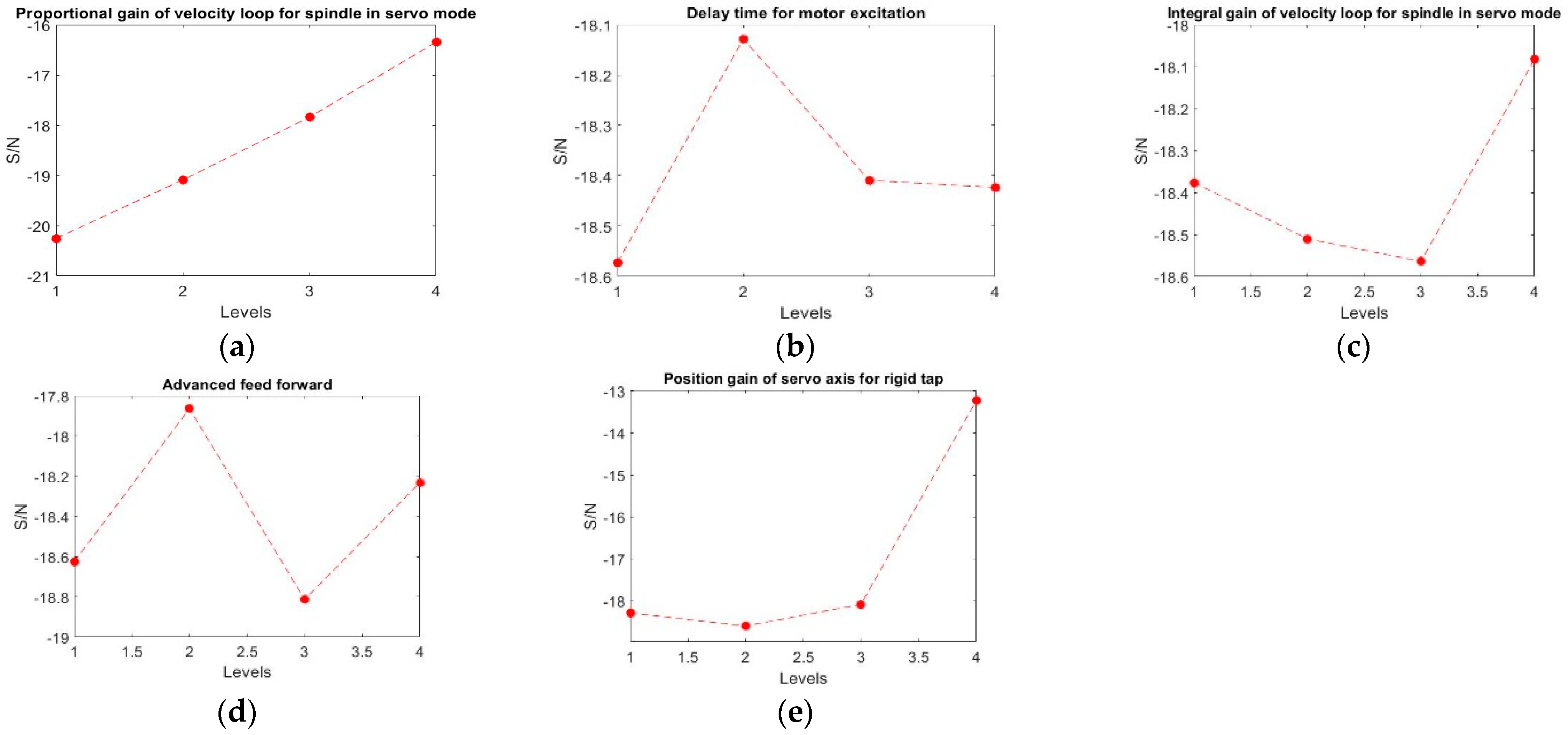

Table 13 and

Figure 5 are the response table and figure, respectively, which show that the best combination of values for

x2,

x3,

x4,

x5, and

x6 was 55, 355, 260, 7900, and 9900, respectively.

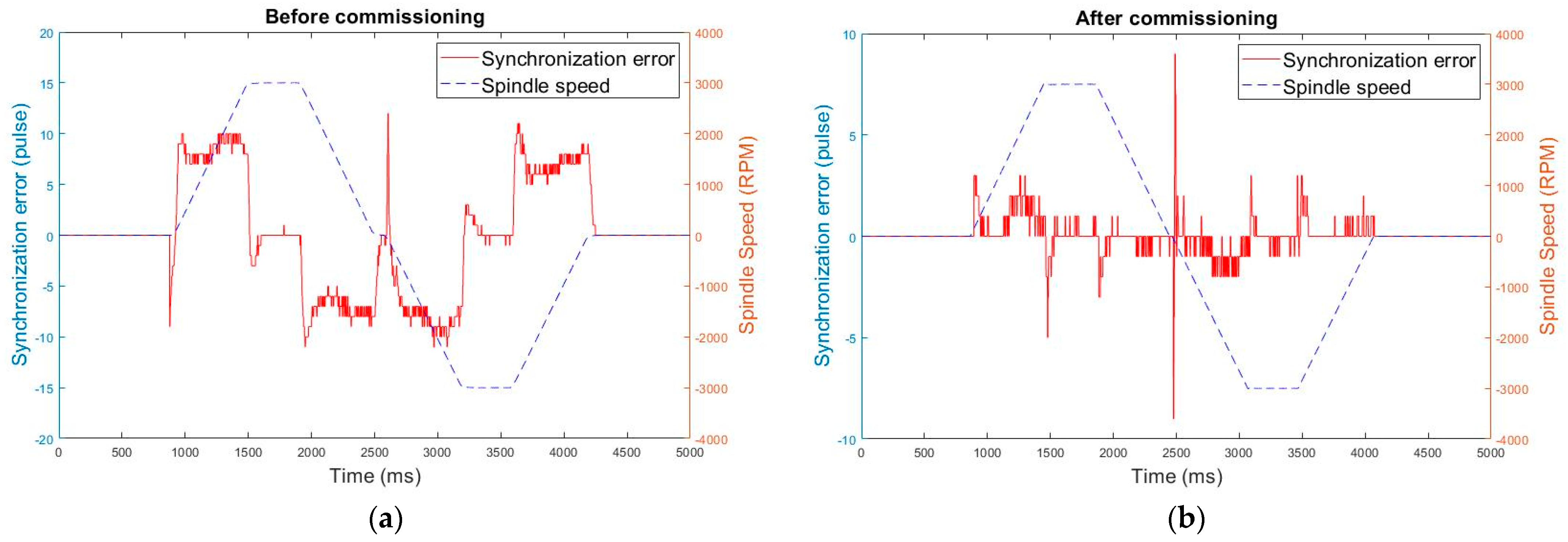

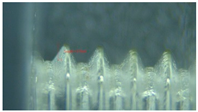

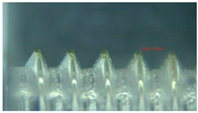

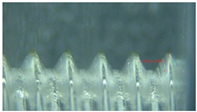

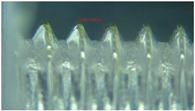

Figure 6 displays the rigid tapping errors obtained under the optimal parameter combination. Synchronization error was 23 pulses before adjustment and 18 pulses after adjustment. For verification, the simulation results and actual processing results were compared before and after optimization. The optimal combination was then used in an actual thread cutting process. After the process was performed five times, the bolt was cut in half with a face milling cutter, and the workpiece was placed under a CCD electronic image microscope to observe its shape and measure the pitch and appearance of the thread. The outer diameter (D1) and inner diameter (D2) of the thread were measured, and the difference between D1 and D2 was obtained.

Table 14 shows that a significant difference between D1 and D2 indicated that the screw teeth were well-shaped and that the potential for tooth collapse was minimal.

Conversely, a slight difference indicated poorly-shaped screw teeth and a high potential for tooth collapse. Screw thread pitch was also measured to determine whether disordered teeth had caused an excessive error during the same period.

Table 14 shows that the proposed method obtained superior tapping results compared to the results obtained without optimizing rigid tapping electrical control parameters.

5. Conclusions

The proposed hybrid method for optimizing synchronization in rigid tapping was verified in an actual thread cutting process. Errors in synchronization of the spindle and the tapping axis were captured, and parameter values were adjusted for optimal synchronization.

Rigid tapping is easily performed when the CNC machine tool used for spiral tap-ping is operated at the expected speed and feed rate. However, high synchronization of motion is required to achieve a high-quality tap and avoid damage to the tapping tool and the workpiece. Therefore, the UD method proposed in this study integrated regression analysis, FPSO, and the Taguchi method to optimize rigid tapping parameters and obtained excellent tapping results.

For parameters x2, x3, x4, x5, x6, the optimal combination of values was 55, 355, 260, 7900, and 9900, respectively. This combination reduced synchronization error from 23 pulses under the original parameters to 18 pulses, which was a 22% improvement in accuracy. The optimized combination also reduced processing time from 20,880 ms to 20,033 ms.

The method proposed in this study improves machining accuracy by determining the critical factors in rigid tapping synchronization error and the optimal values for the key factors. Additionally, the proposed method reduces the potential for damage to the workpiece during a tapping procedure and reduces the time required for parameter commissioning. The four main findings of the experiments were as follows:

The proportional gain and integral gain of the spindle can be adjusted to increase its rigidity during rigid tapping.

Adjusting the position gain of the tapping axis and the feedforward coefficient can substantially decrease synchronization errors.

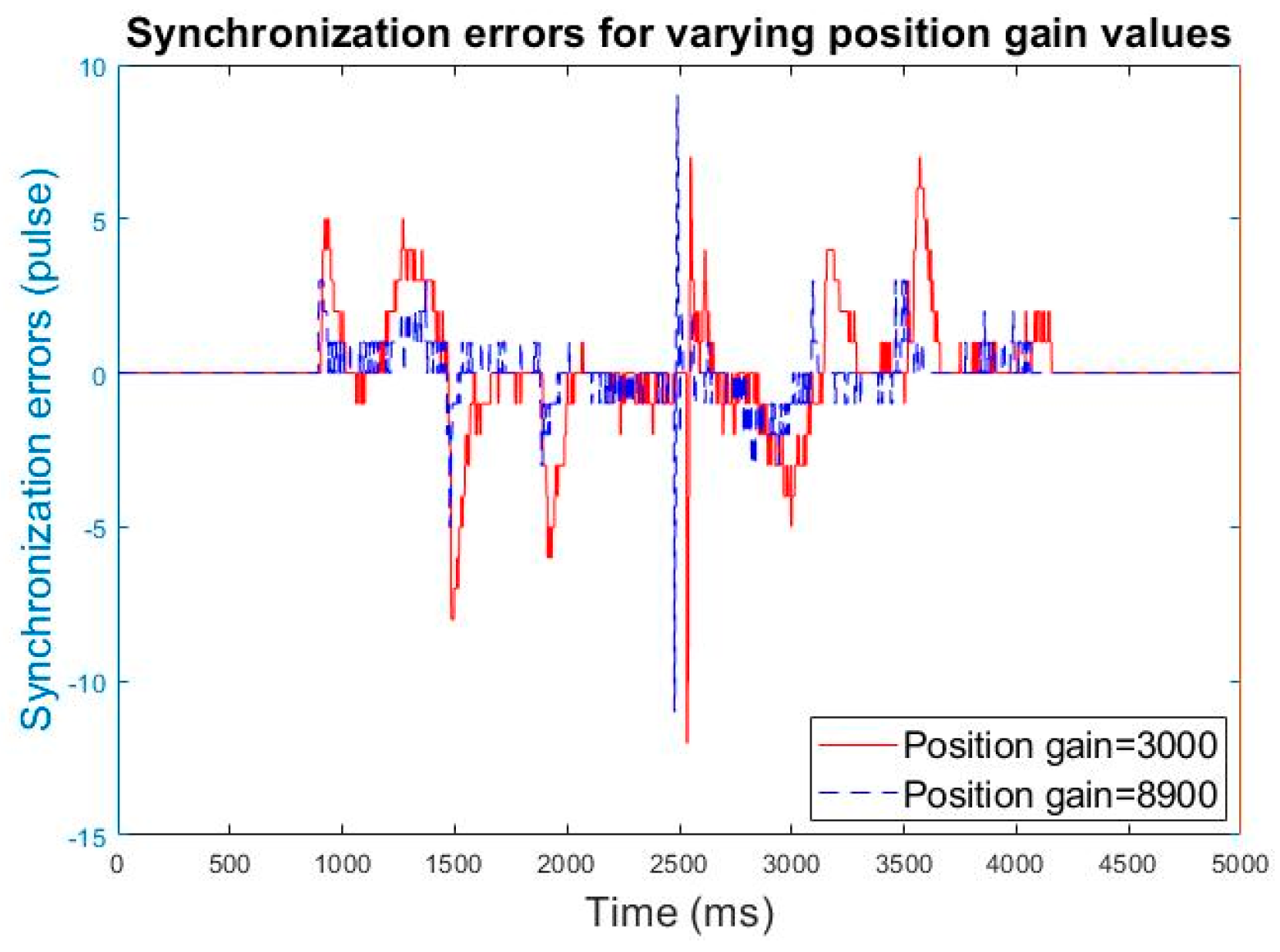

Figure 7 and

Figure 8 show how to position gain affects synchronization error and torque command. When position gain is significant, synchronization error is small, but current increases. Notably, the present value during air cut commissioning should not exceed 70–80%, and a reserve margin should be set to avoid overheating or overloading the motor during actual cutting. Air cut commissioning means dry run commissioning.

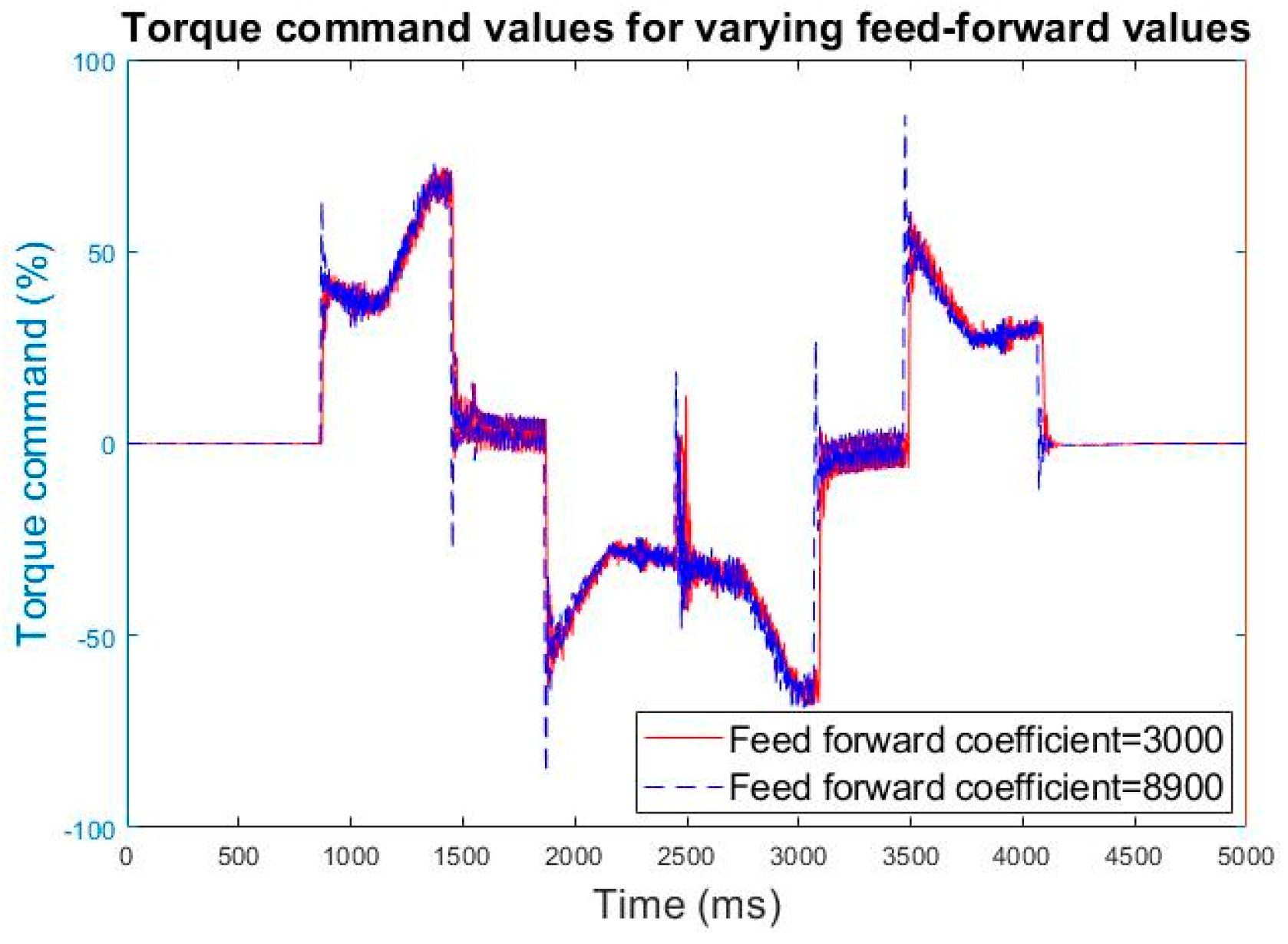

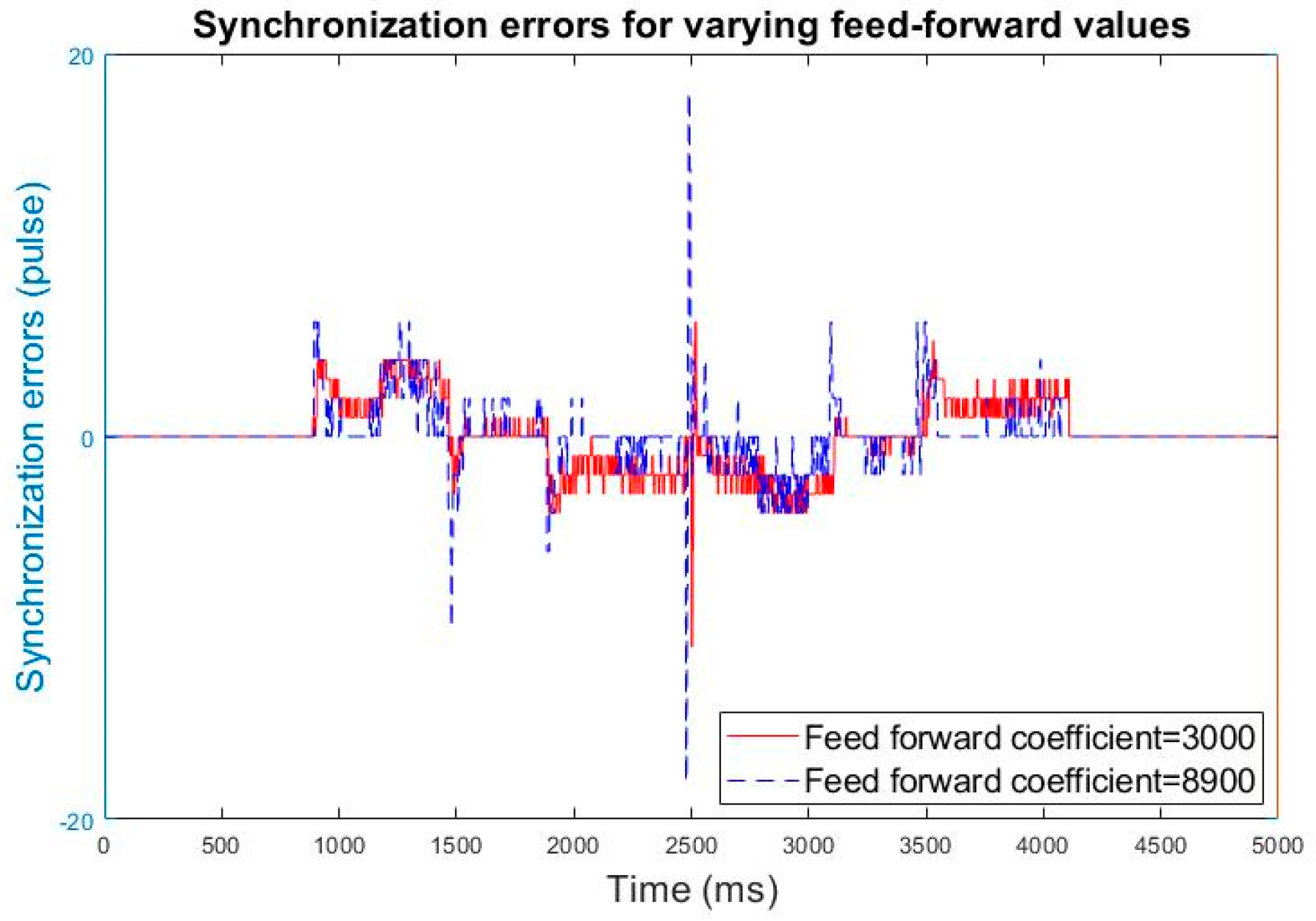

Figure 9 and

Figure 10 compare the effects of different feedforward coefficients on torque command.

Adjusting the time required for motor excitation and stabilization can reduce errors at the start of rigid tapping.

Reducing the z-axis following error, the synchronization error of rigid tapping can get better performance. After a synchronization error, reducing the z-axis following error and commissioning proportional gain, integral gain, and position gain can improve rigid tapping precision.