An Empirical Evaluation of Prediction by Partial Matching in Assembly Assistance Systems

Abstract

1. Introduction

2. Related Work

3. Prediction-Based Assembly Support System

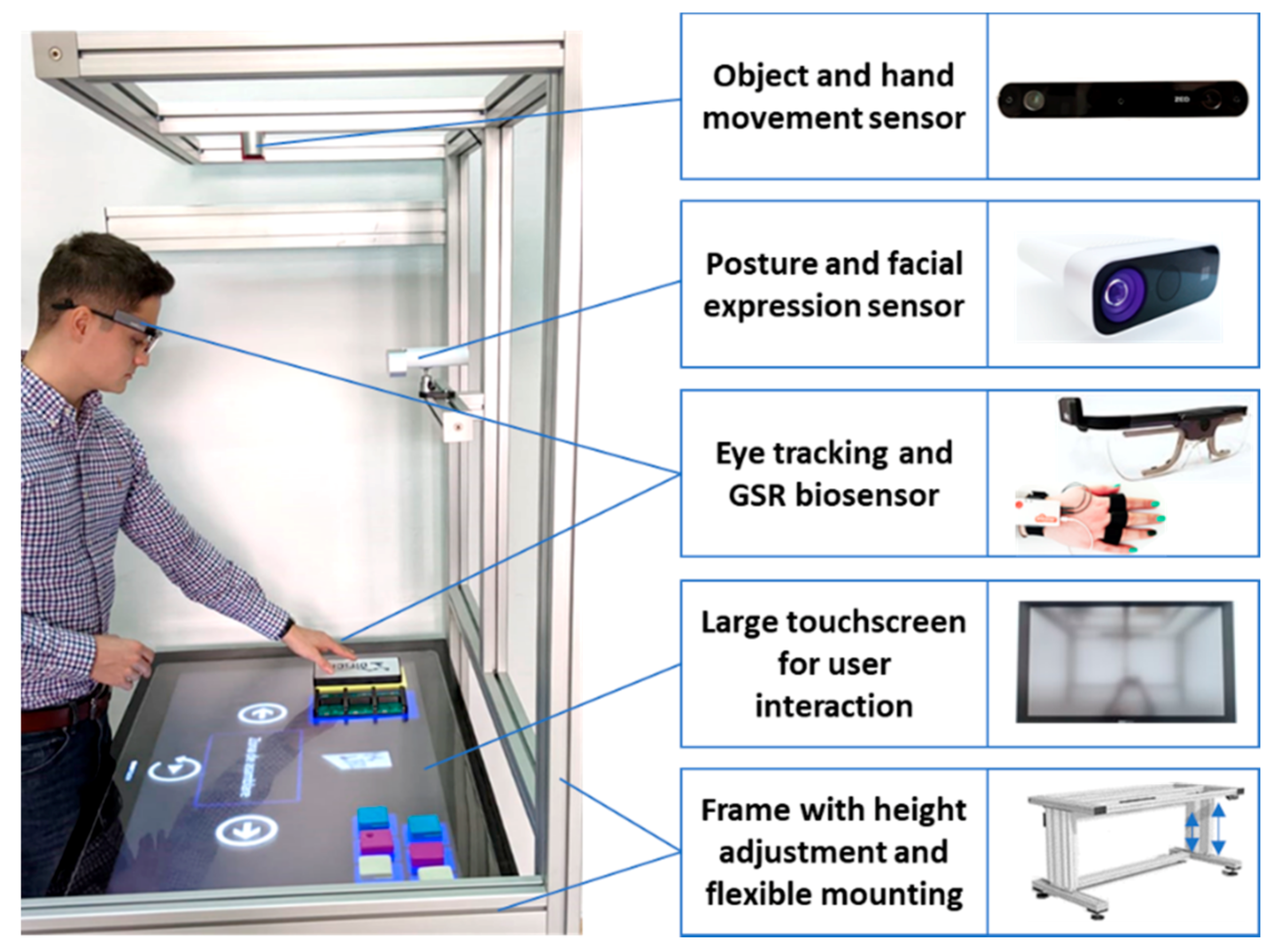

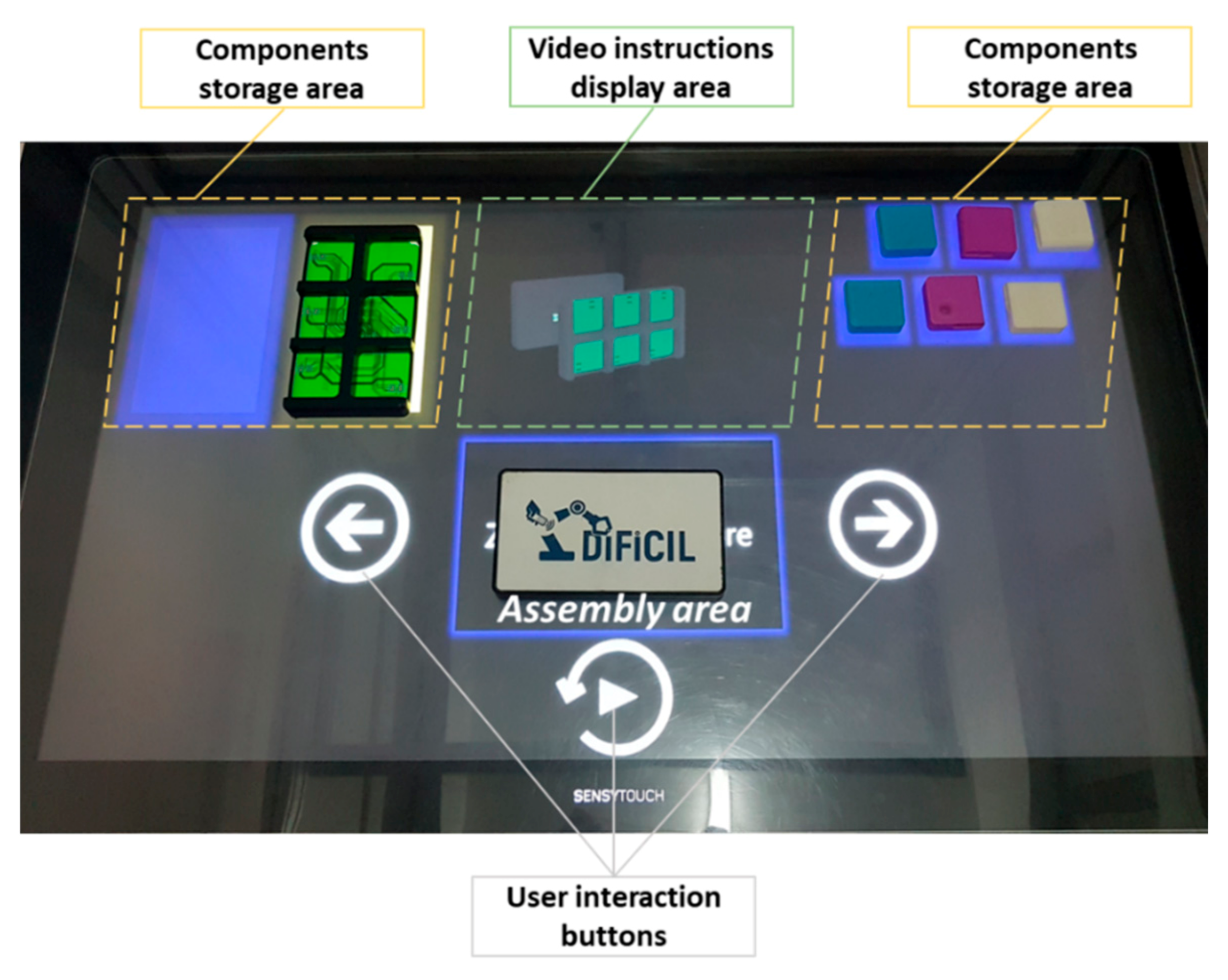

3.1. Assembly Assistance System

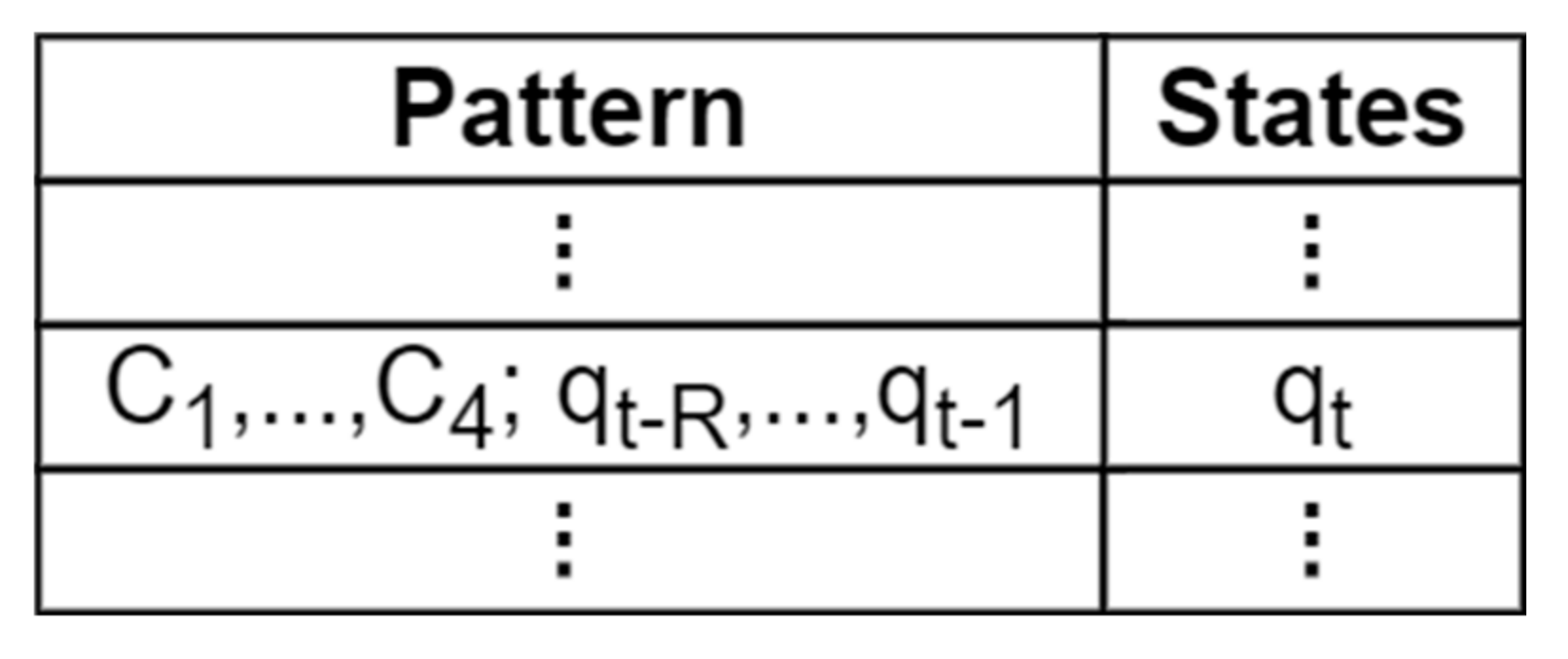

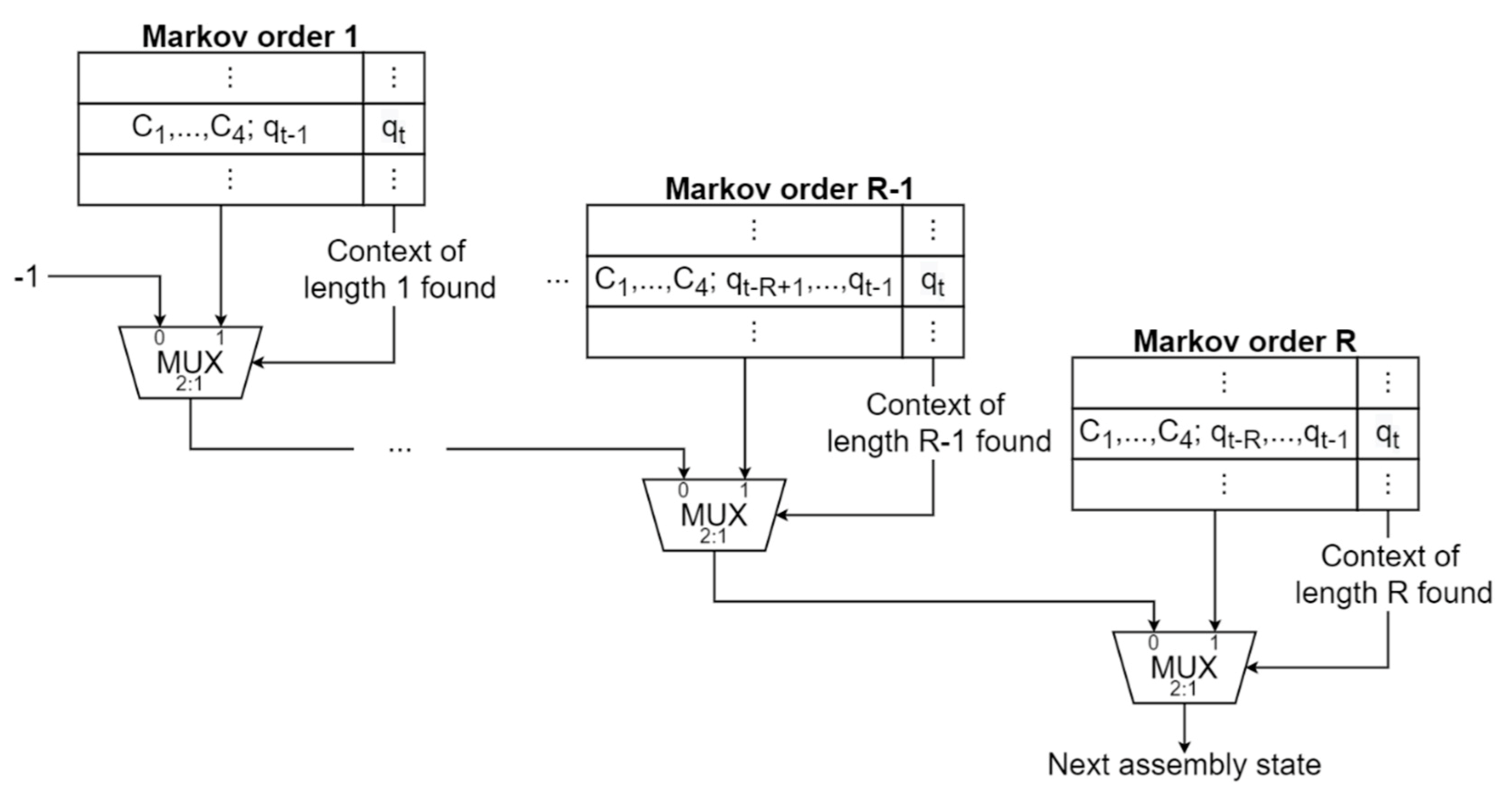

3.2. Providing Choices for the Next Assembly Step through Prediction by Partial Matching

4. Evaluation

4.1. Experimental Methodology

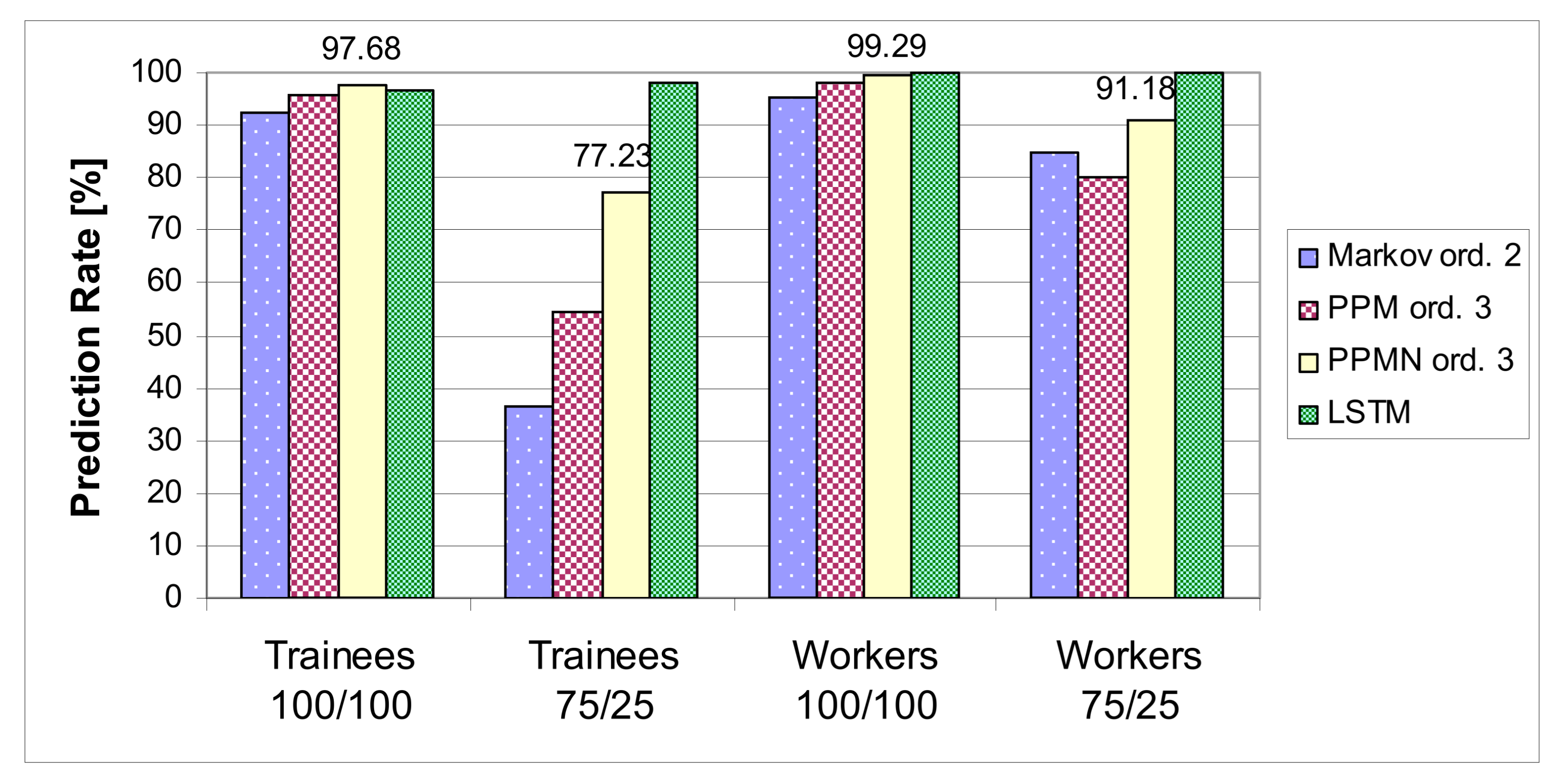

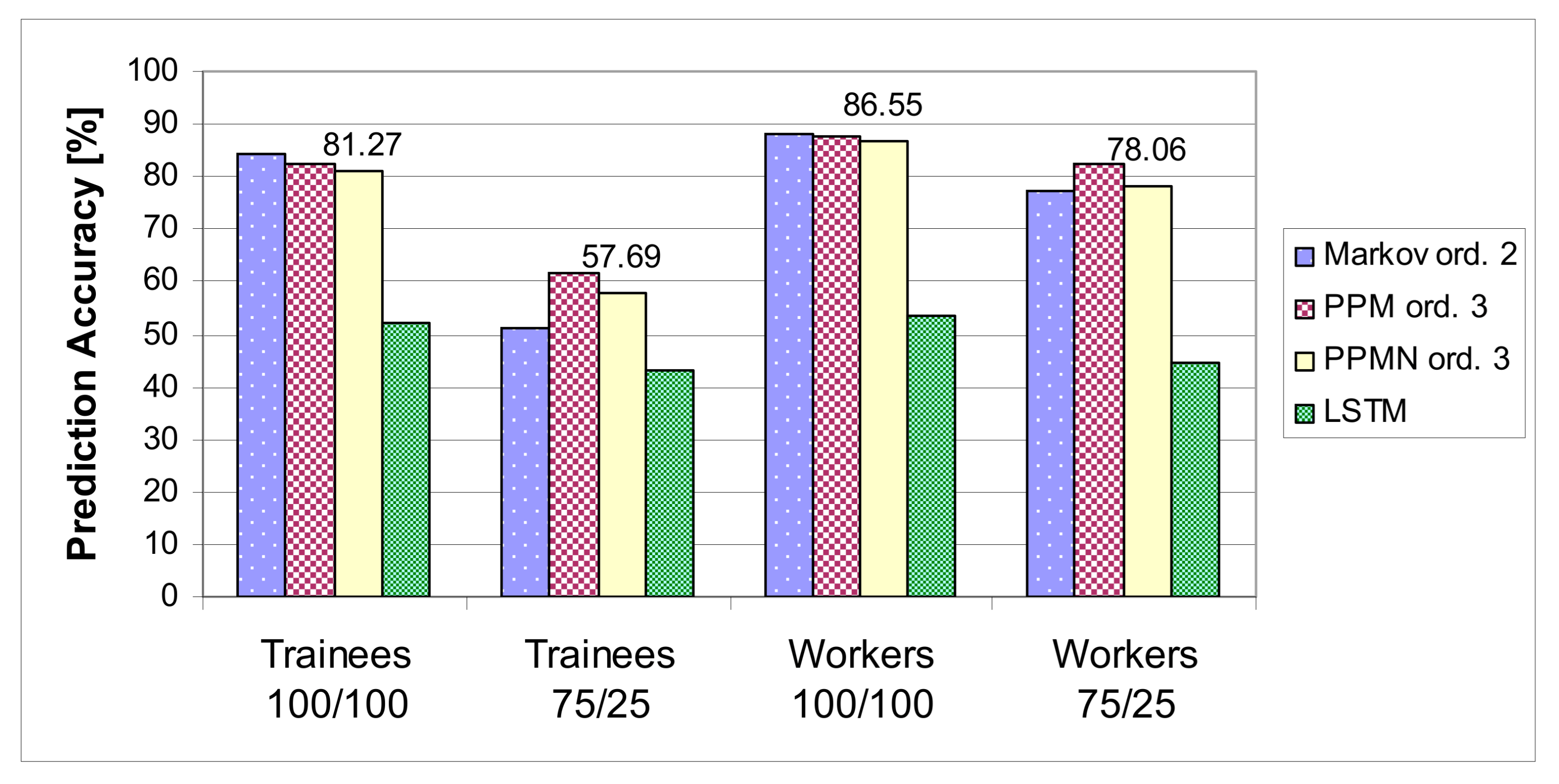

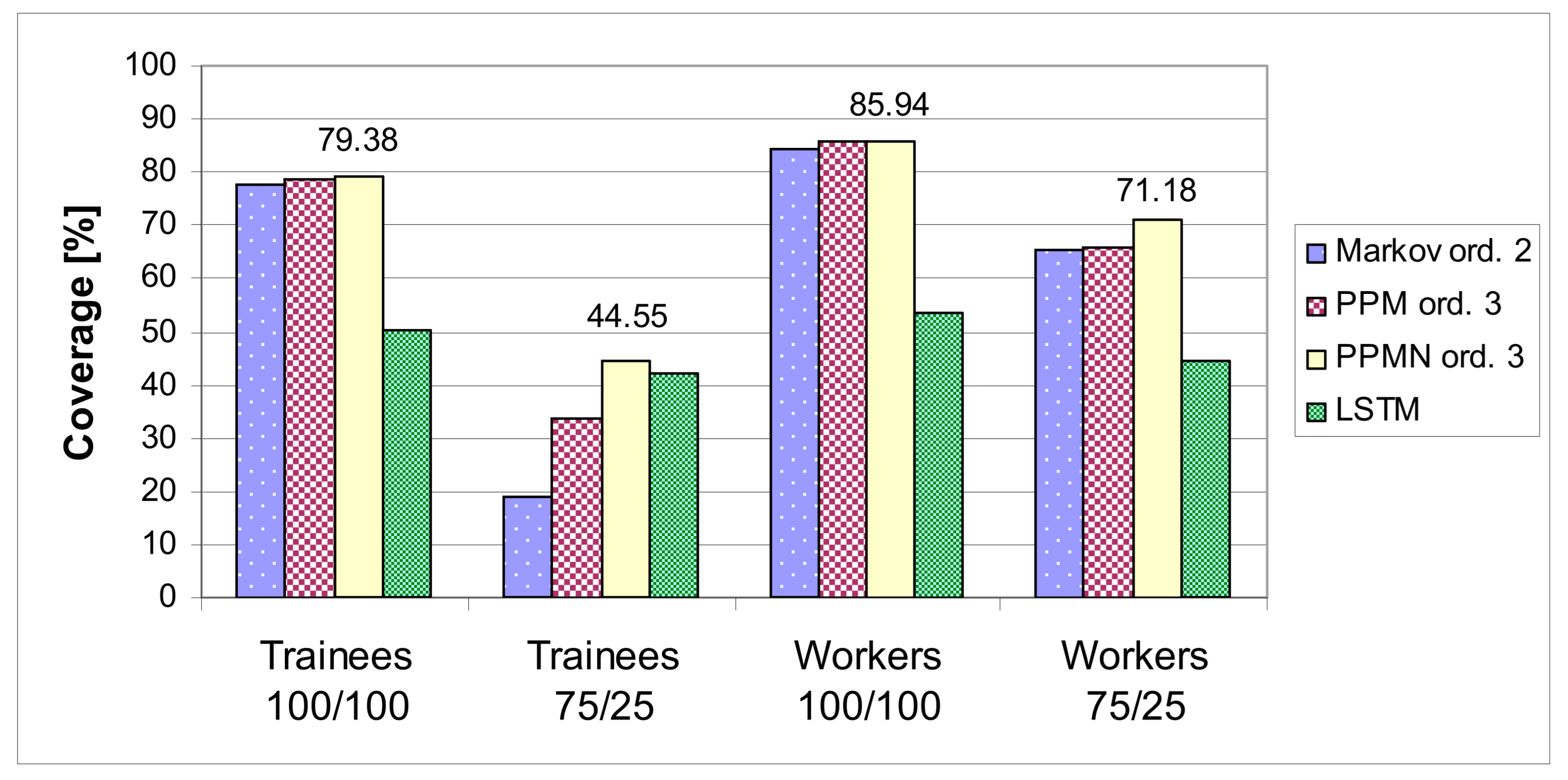

4.2. Experimental Results

5. Conclusions and Further Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rauch, E.; Linder, C.; Dallasega, P. Anthropocentric perspective of production before and within Industry 4.0. Comput. Ind. Eng. 2020, 139, 105644. [Google Scholar] [CrossRef]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Fast-Berglund, Å. The operator 4.0: Human cyber-physical systems and adaptive automation towards human-automation symbiosis work systems. In IFIP International Conference on Advances in Production Management Systems, Proceedings of the APMS 2016: Advances in Production Management Systems. Initiatives for a Sustainable World, Iguassu Falls, Brazil, 3–7 September 2016; Springer: Berlin/Heidelberg, Germany, 2016; Volume 488, pp. 677–686. [Google Scholar]

- Chiacchio, F.; Petropoulos, G.; Pichler, D. The Impact of Industrial Robots on EU Employment and Wages: A local Labour Market Approach; Working paper 25186; Bruegel: Saint-Josse-ten-Noode, Belgium, 2018. [Google Scholar]

- Funk, M.; Bächler, A.; Bächler, L.; Kosch, T.; Heidenreich, T.; Schmidt, A. Working with augmented reality? A long-term analysis of in-situ instructions at the assembly workplace. In Proceedings of the 10th ACM International Conference on Pervasive Technologies Related to Assistive Environments, Island of Rhodes, Greece, 21–23 June 2017; pp. 222–229. [Google Scholar]

- Gellert, A.; Zamfirescu, C.-B. Using Two-Level Context-Based Predictors for Assembly Assistance in Smart Factories. In Intelligent Methods in Computing, Communications and Control, Proceedings of the 8th International Conference on Computers Communications and Control, Băile Felix, Oradea, Romania, 11–15 May 2020; Springer: Oradea, Romania, 2020; pp. 167–176. [Google Scholar]

- Gellert, A.; Zamfirescu, C.-B. Assembly support systems with Markov predictors. In Proceedings of the 20th Open Conference of the IFIP WG 8.3 on Decision Support, Wrocław, Poland, 24–26 June 2020. Published in Journal of Decision Systems. [Google Scholar]

- Gellert, A.; Precup, S.-A.; Pirvu, B.-C.; Zamfirescu, C.-B. Prediction-based assembly assistance system. In Proceedings of the 25th International Conference on Emerging Technologies and Factory Automation, Vienna, Austria, 8–11 November 2020; pp. 1065–1068. [Google Scholar]

- Precup, S.-A.; Gellert, A.; Dorobantiu, A.; Zamfirescu, C.-B. Assembly process modeling through long short-term memory. In Proceedings of the 13th Asian Conference on Intelligent Information and Database Systems, Phuket, Thailand, 7–10 April 2021. [Google Scholar]

- Yamada, Y.; Konosu, H.; Morizono, T.; Umetani, Y. Proposal of skill-assist: A system of assisting human workers by reflecting their skills in positioning tasks. In Proceedings of the 1999 IEEE International Conference on Systems, Man, and Cybernetics, Tokyo, Japan, 12–15 October 1999; Volume 4, pp. 11–16. [Google Scholar]

- Tan, Q.; Tong, Y.; Wu, S.; Li, D. Anthropocentric approach for smart assembly: Integration and collaboration. J. Robot. 2019. [CrossRef]

- Rojas, R.; Rauch, E.; Dallasega, P.; Matt, D.T. Safe human-machine centered design of an assembly station in a learning factory environment. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bandung, Indonesia, 6–8 March 2018; pp. 403–411. [Google Scholar]

- Elkomy, M.; Abdelrahman, Y.; Funk, M.; Dingler, T.; Schmidt, A.; Abdennadher, S. ABBAS: An adaptive bio-sensors based assistive system. In Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, Osaka, Japan, 8–13 May 2017; pp. 2543–2550. [Google Scholar]

- Funk, M.; Dingler, T.; Cooper, J.; Schmidt, A. Stop helping me—I’m bored! why assembly assistance needs to be adaptive. In Proceedings of the 2015 ACM International Joint Conference on Pervasive and Ubiquitous Computing and 2015 ACM International Symposium on Wearable Computers, Osaka, Japan, 7–11 September 2015; pp. 1269–1273. [Google Scholar]

- Bertram, P.; Birtel, M.; Quint, F.; Ruskowski, M. Intelligent manual working station through assistive systems. In Proceedings of the 16th IFAC Symposium on Information Control Problems in Manufacturing, Bergamo, Italy, 11–13 June 2018; pp. 170–175. [Google Scholar]

- Mueller, R.; Vette-Steinkamp, M.; Hoerauf, L.; Speicher, C.; Bashir, A. Intelligent and flexible worker assistance systems. In Proceedings of the 13th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2018), Funchal, Madeira, Portugal, 27–29 January 2018; Volume 2: HUCAPP, pp. 77–85. [Google Scholar]

- Gorecky, D.; Khamis, M.; Mura, K. Introduction and establishment of virtual training in the factory of the future. Int. J. Comput. Integr. Manuf. 2017, 30, 182–190. [Google Scholar] [CrossRef]

- Tocu, N.-A.; Gellert, A.; Stefan, I.-R.; Nitescu, T.-M.; Luca, G.-A. The impact of virtual reality simulators in manufacturing industry. In Proceedings of the 12th Annual International Conference on Education and New Learning Technologies, Palma de Mallorca, Spain, 6–8 July 2020. [Google Scholar]

- Korn, O.; Schmidt, A.; Hörz, T. Assistive systems in production environments: Exploring motion recognition and gamification. In Proceeding of the 5th International Conference on Pervasive Technologies Related to Assistive Environments, Heraklion, Crete, Greece, 9–13 June 2012. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Lai, Z.-H.; Tao, W.; Leu, M.C.; Yin, Z. Smart augmented reality instructional system for mechanical assembly towards worker-centered intelligent manufacturing. J. Manuf. Syst. 2020, 55, 69–81. [Google Scholar] [CrossRef]

- Loskyll, M.; Heck, I.; Schlick, J.; Schwarz, M. Context-based orchestration for control of resource-efficient manufacturing processes. Future Internet 2012, 4, 737–761. [Google Scholar] [CrossRef]

- Gellert, A.; Florea, A. Web prefetching through efficient prediction by partial matching. World Wide Web J. 2016, 19, 921–932. [Google Scholar] [CrossRef]

- Gellert, A.; Florea, A.; Vintan, M.; Egan, C.; Vintan, L. Unbiased Branches: An Open Problem. In Proceeding of the 12th Asia-Pacific Computer Systems Architecture Conference (ACSAC 2007), Seoul, Korea, 23–25 August 2007; pp. 16–27. [Google Scholar]

| Component | Characteristics |

|---|---|

| Display | 43-inch 4K touchscreen |

| CPU | Intel i7-7700 |

| GPU | NVIDIA GeForce GTX 1060 |

| RAM | 16 GB |

| SSD | 250 GB |

| Operating System | Windows 10 |

| PPM Order | Prediction Rate (%) | Accuracy (%) | Coverage (%) | |||

|---|---|---|---|---|---|---|

| 100/100 | 75/25 | 100/100 | 75/25 | 100/100 | 75/25 | |

| 1 | 95.62 | 54.46 | 80.05 | 61.82 | 76.55 | 33.66 |

| 2 | 95.62 | 54.46 | 82.21 | 61.82 | 78.61 | 33.66 |

| 3 | 95.62 | 54.46 | 82.48 | 61.82 | 78.87 | 33.66 |

| 4 | 95.62 | 54.46 | 82.48 | 61.82 | 78.87 | 33.66 |

| 5 | 95.62 | 54.46 | 82.48 | 61.82 | 78.87 | 33.66 |

| 6 | 95.62 | 54.46 | 82.48 | 61.82 | 78.87 | 33.66 |

| 7 | 95.62 | 54.46 | 82.48 | 61.82 | 78.87 | 33.66 |

| PPMN Order | Prediction Rate (%) | Accuracy (%) | Coverage (%) | |||

|---|---|---|---|---|---|---|

| 100/100 | 75/25 | 100/100 | 75/25 | 100/100 | 75/25 | |

| 1 | 97.68 | 77.23 | 78.89 | 57.69 | 77.06 | 44.55 |

| 2 | 97.68 | 77.23 | 81 | 57.69 | 79.12 | 44.55 |

| 3 | 97.68 | 77.23 | 81.27 | 57.69 | 79.38 | 44.55 |

| 4 | 97.68 | 77.23 | 81.27 | 57.69 | 79.38 | 44.55 |

| 5 | 97.68 | 77.23 | 81.27 | 57.69 | 79.38 | 44.55 |

| 6 | 97.68 | 77.23 | 81.27 | 57.69 | 79.38 | 44.55 |

| 7 | 97.68 | 77.23 | 81.27 | 57.69 | 79.38 | 44.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gellert, A.; Precup, S.-A.; Pirvu, B.-C.; Fiore, U.; Zamfirescu, C.-B.; Palmieri, F. An Empirical Evaluation of Prediction by Partial Matching in Assembly Assistance Systems. Appl. Sci. 2021, 11, 3278. https://doi.org/10.3390/app11073278

Gellert A, Precup S-A, Pirvu B-C, Fiore U, Zamfirescu C-B, Palmieri F. An Empirical Evaluation of Prediction by Partial Matching in Assembly Assistance Systems. Applied Sciences. 2021; 11(7):3278. https://doi.org/10.3390/app11073278

Chicago/Turabian StyleGellert, Arpad, Stefan-Alexandru Precup, Bogdan-Constantin Pirvu, Ugo Fiore, Constantin-Bala Zamfirescu, and Francesco Palmieri. 2021. "An Empirical Evaluation of Prediction by Partial Matching in Assembly Assistance Systems" Applied Sciences 11, no. 7: 3278. https://doi.org/10.3390/app11073278

APA StyleGellert, A., Precup, S.-A., Pirvu, B.-C., Fiore, U., Zamfirescu, C.-B., & Palmieri, F. (2021). An Empirical Evaluation of Prediction by Partial Matching in Assembly Assistance Systems. Applied Sciences, 11(7), 3278. https://doi.org/10.3390/app11073278