Research on a Piezoelectric Pump with Flexible Valves

Abstract

1. Introduction

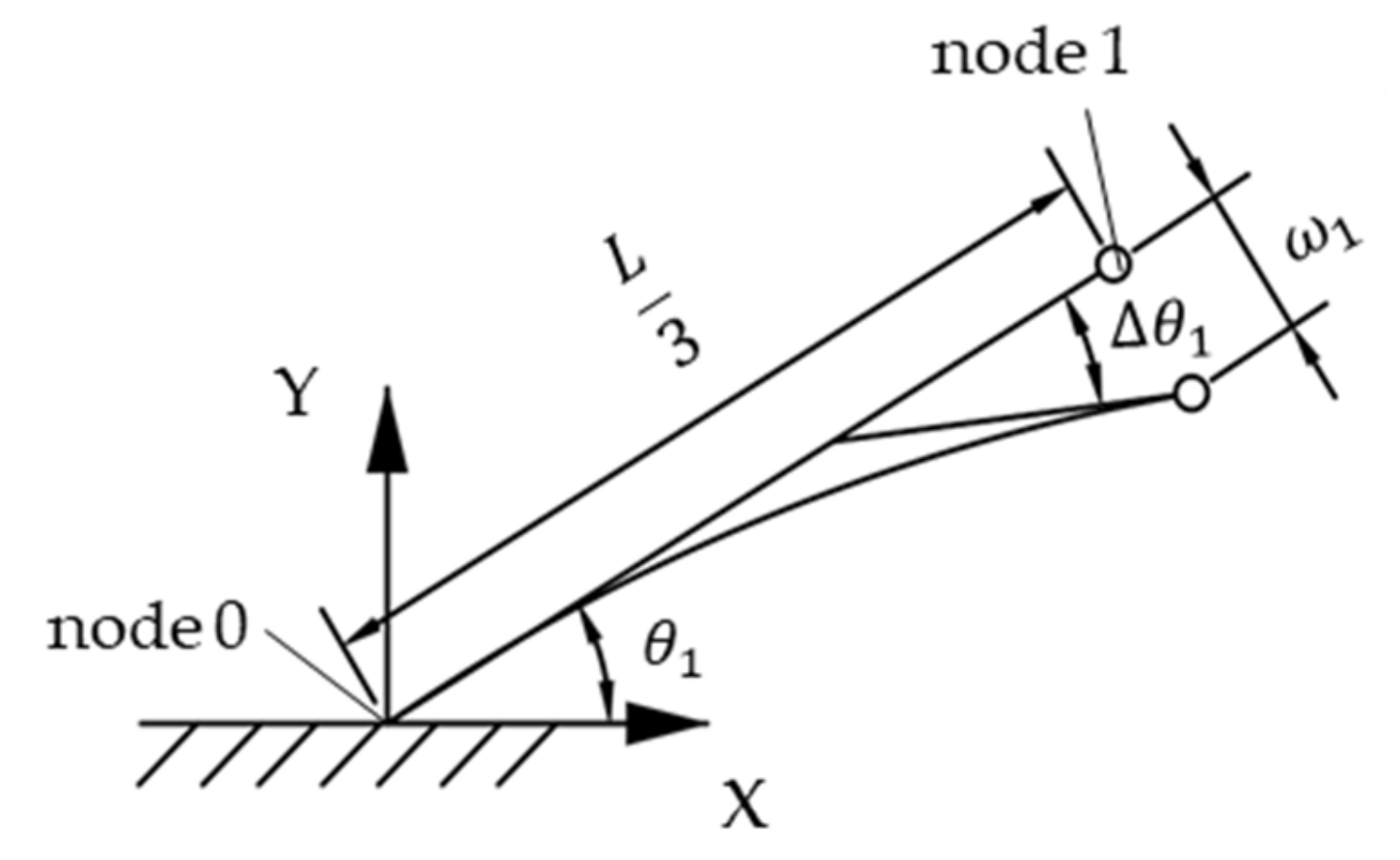

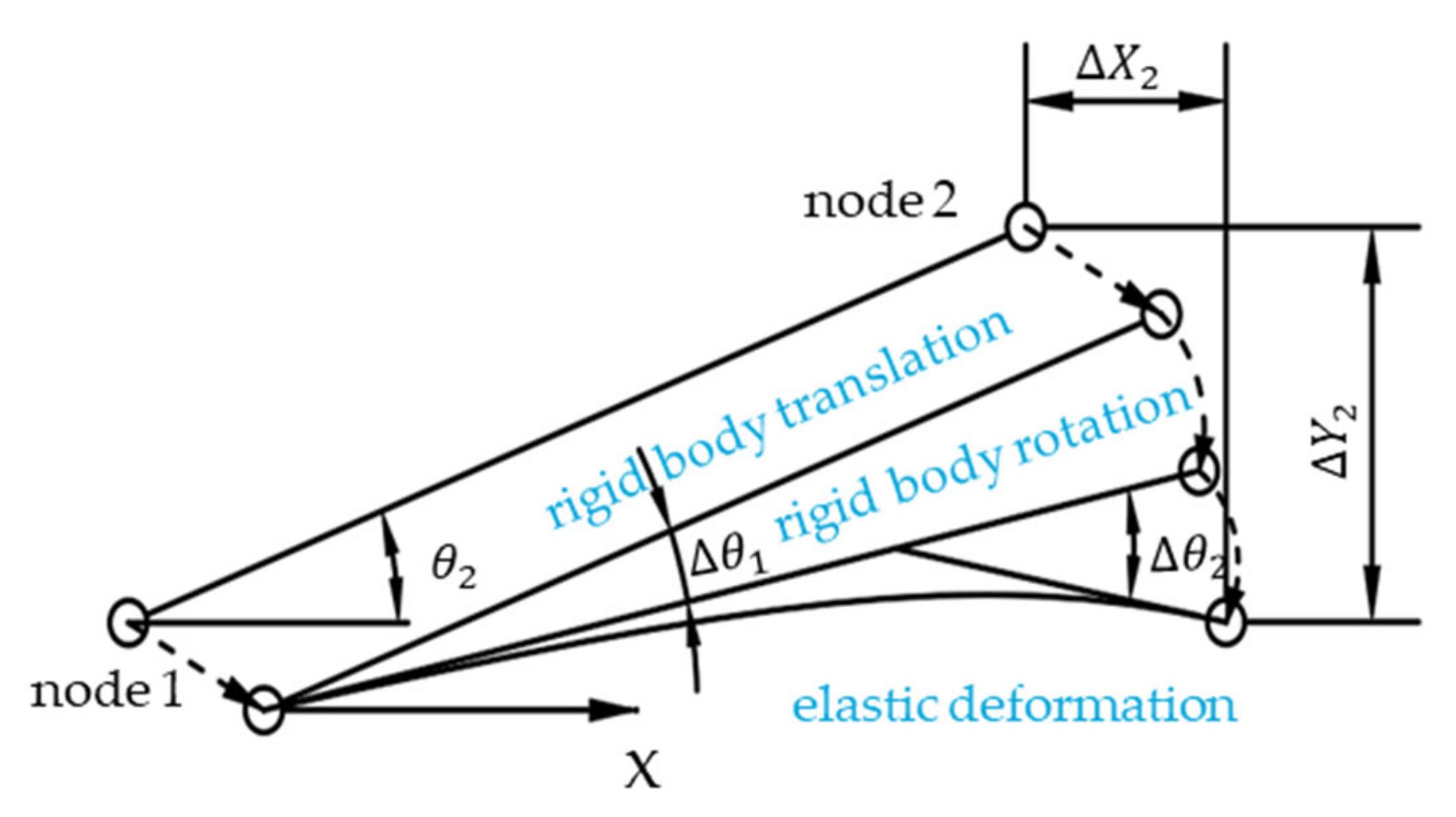

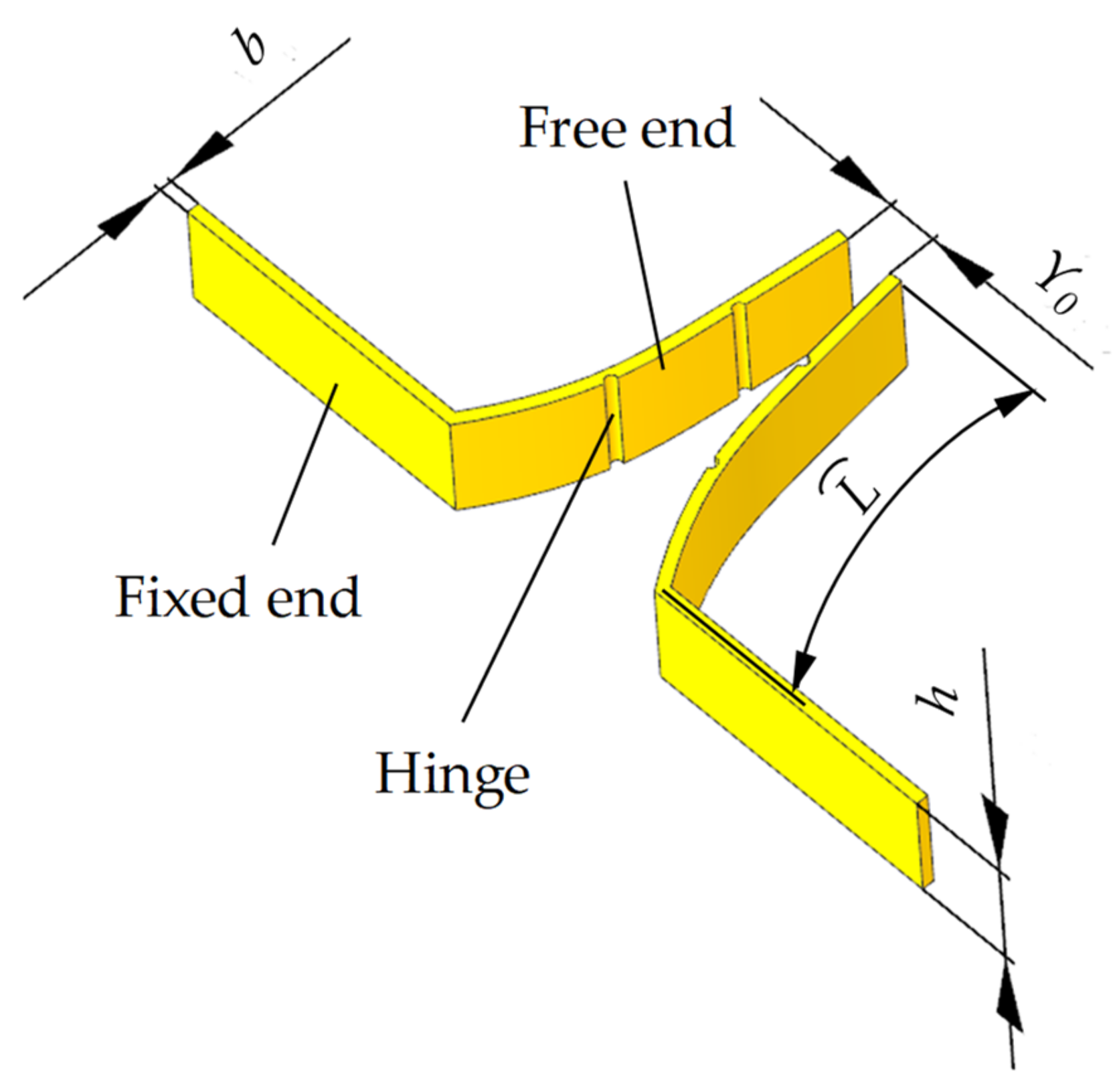

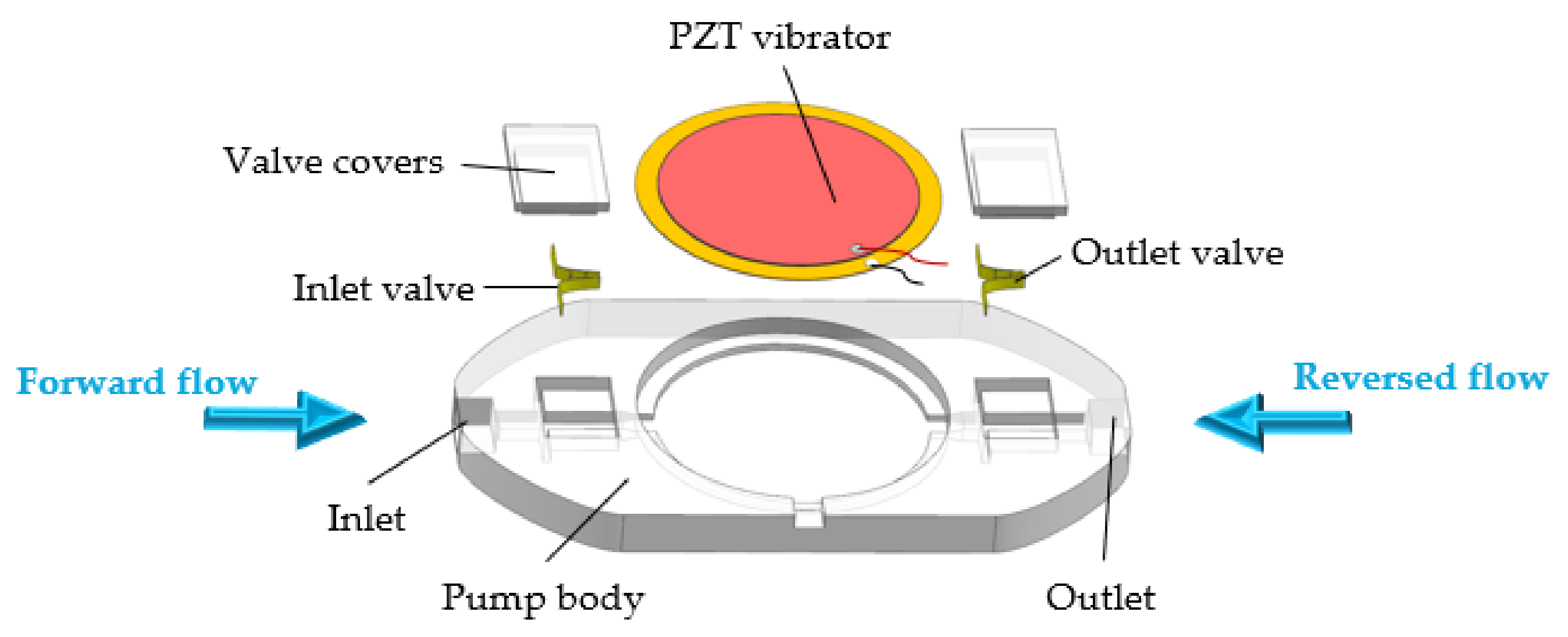

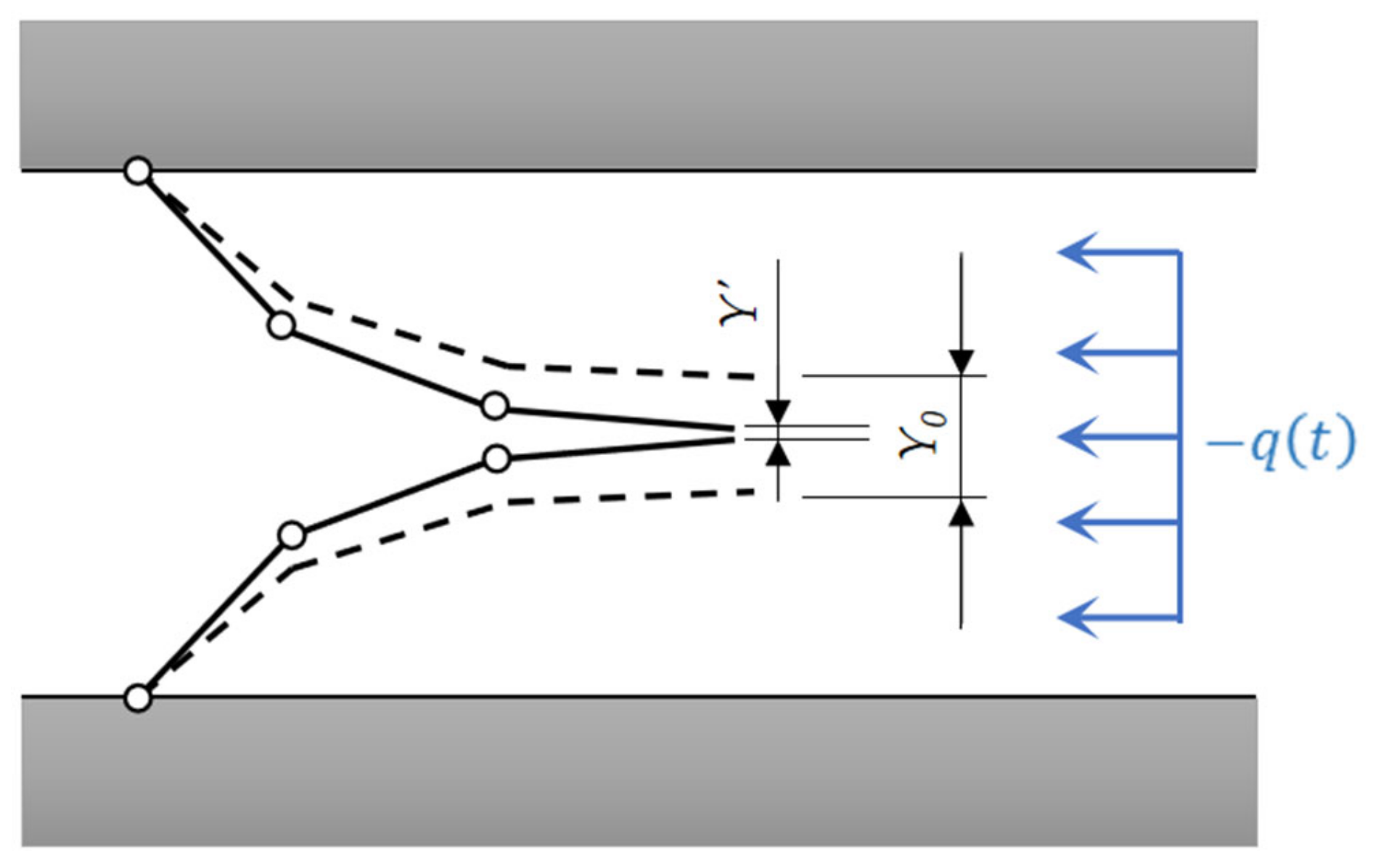

2. Structure and Working Principle

3. Theoretical Analysis

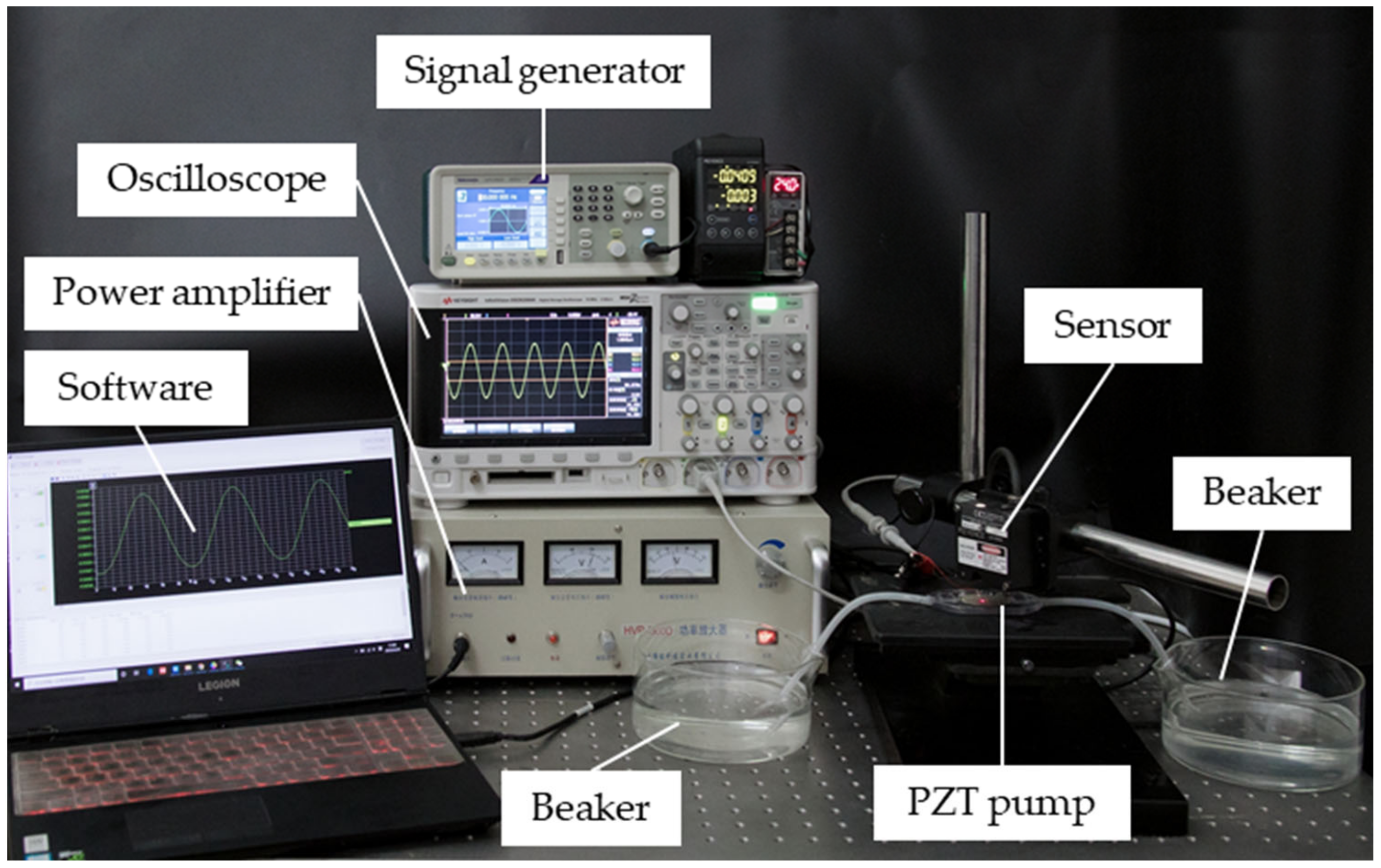

4. Experimental Results and Discussion

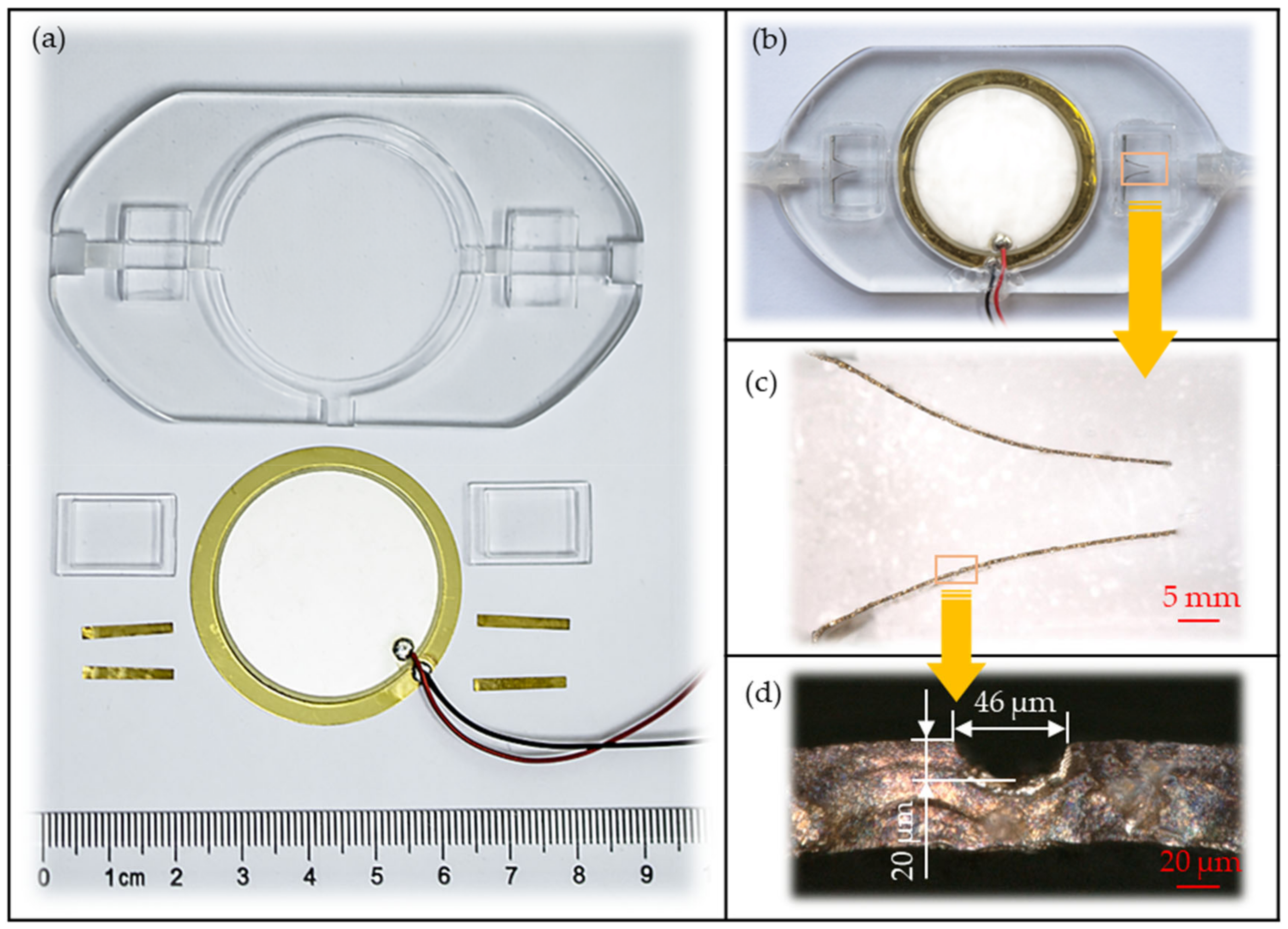

4.1. Fabrication

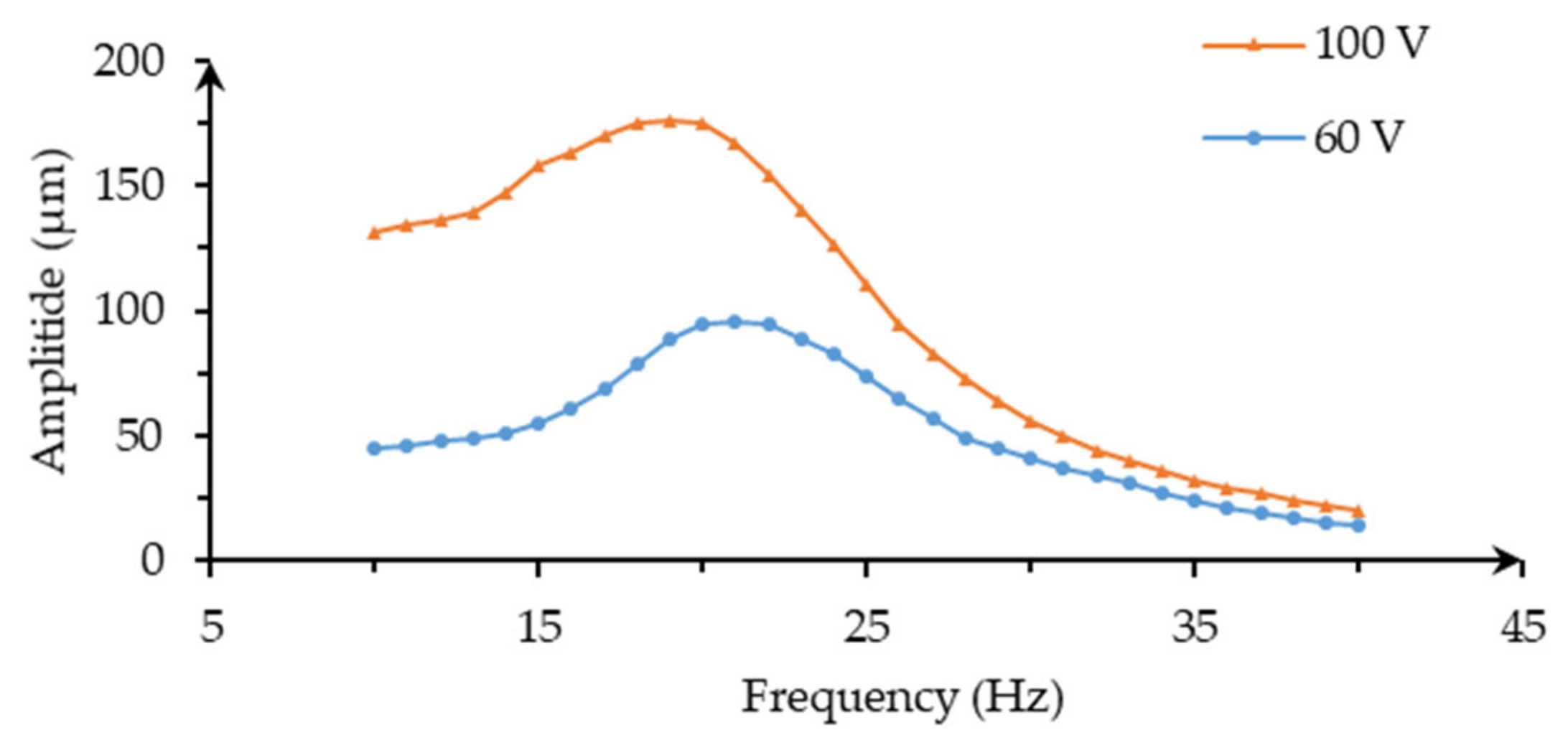

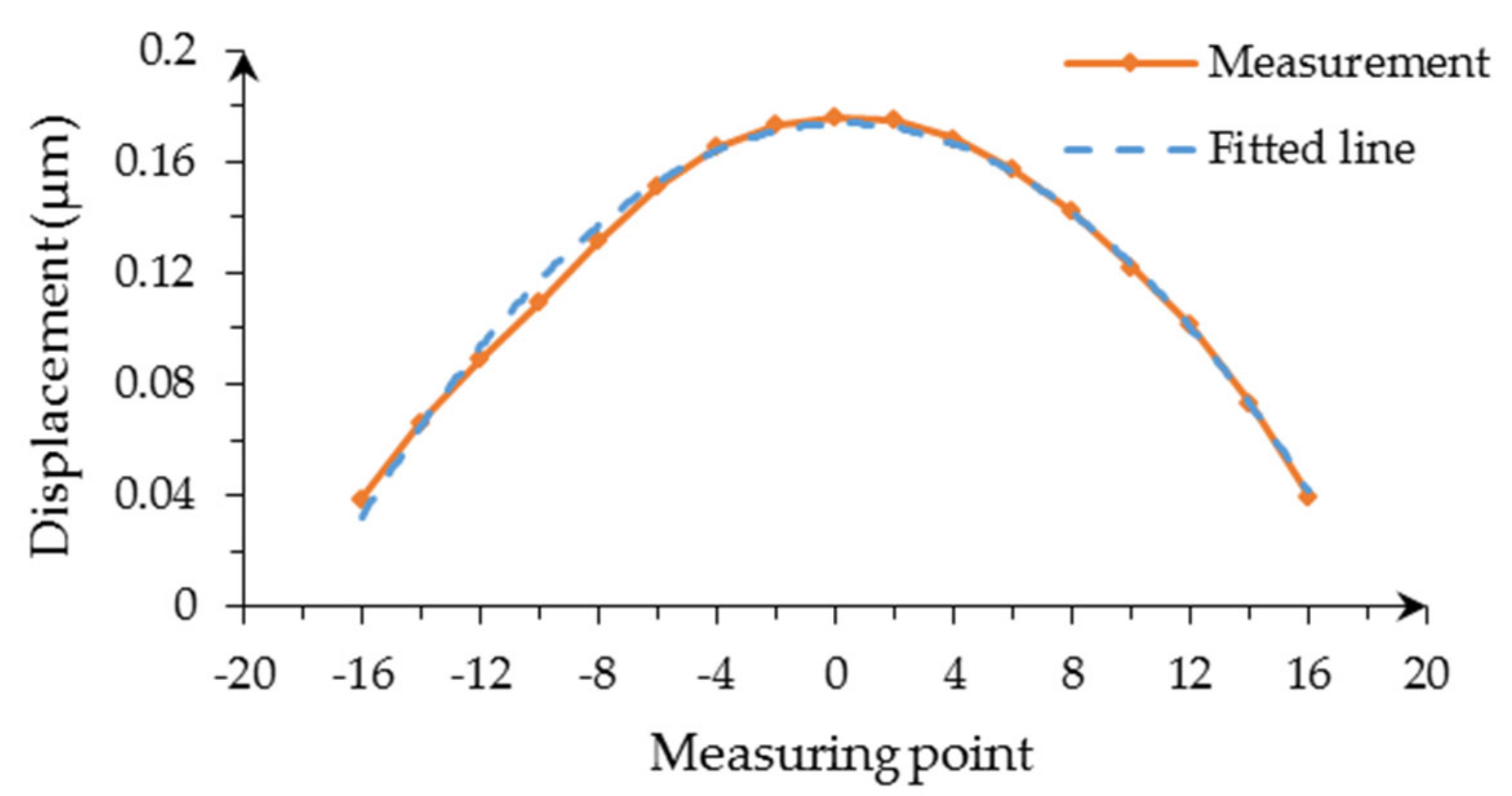

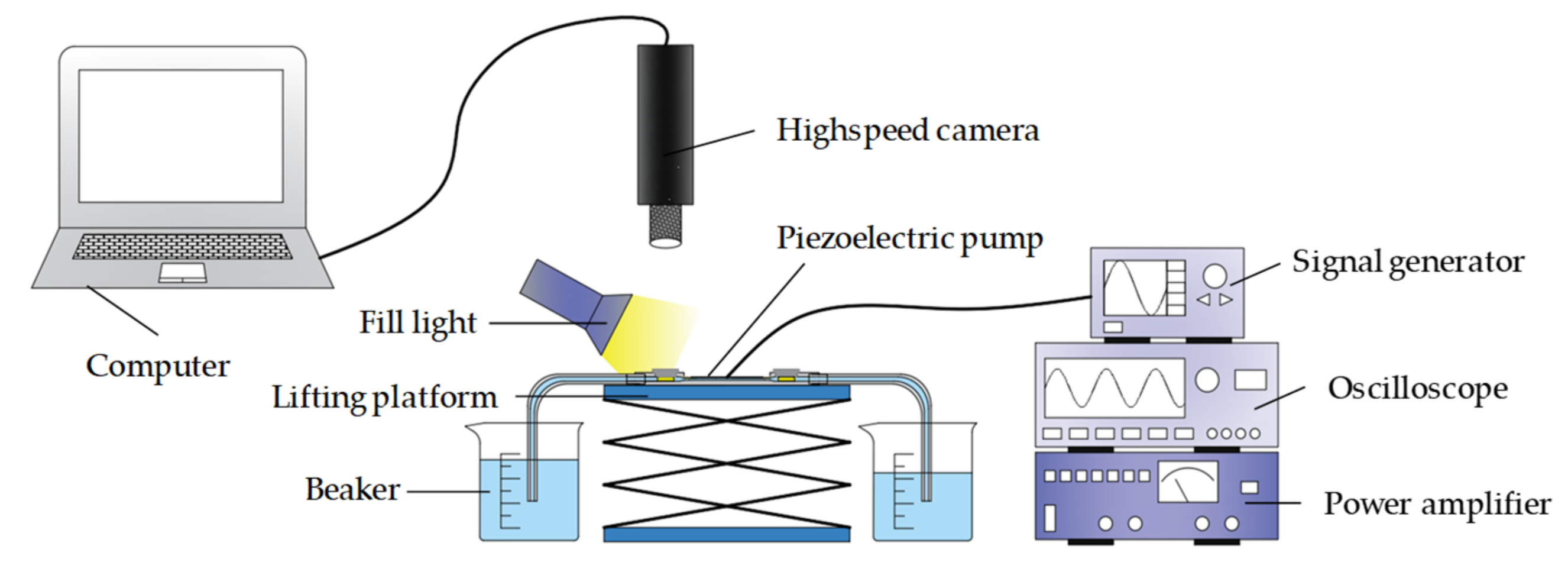

4.2. Amplitude Measurement

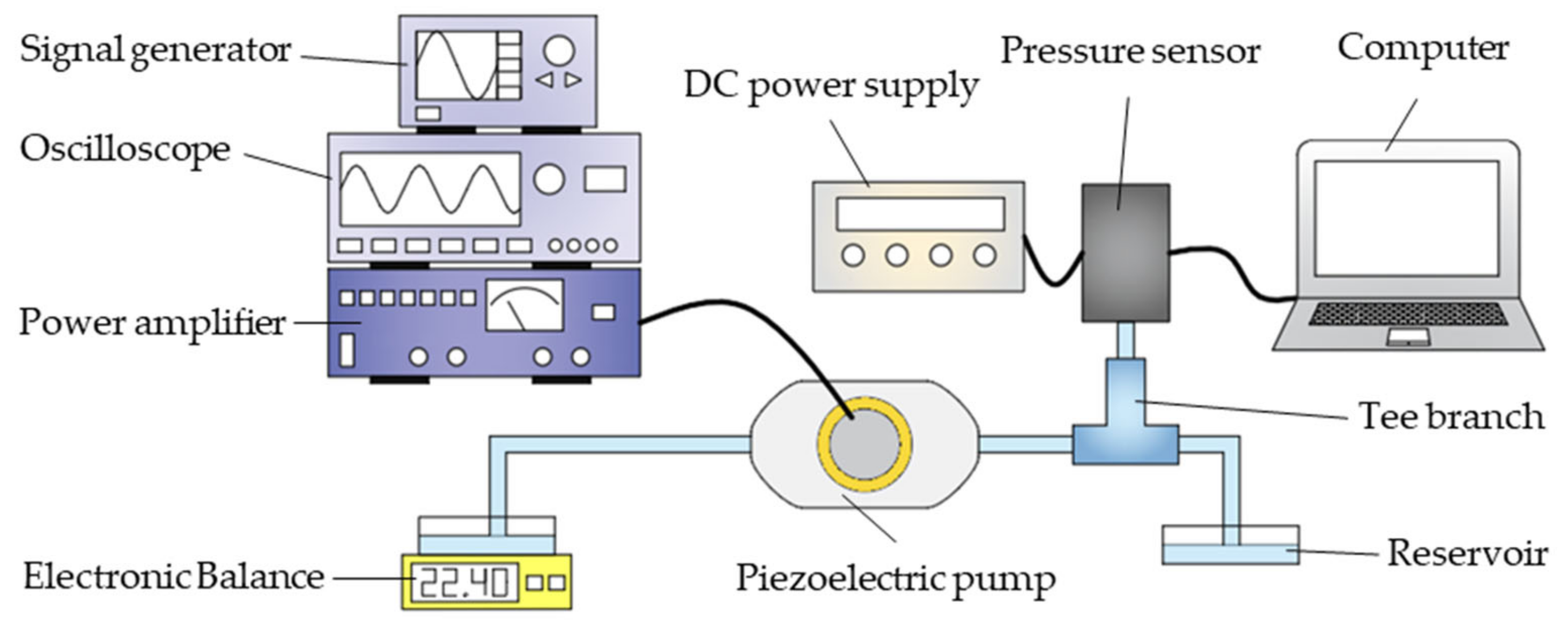

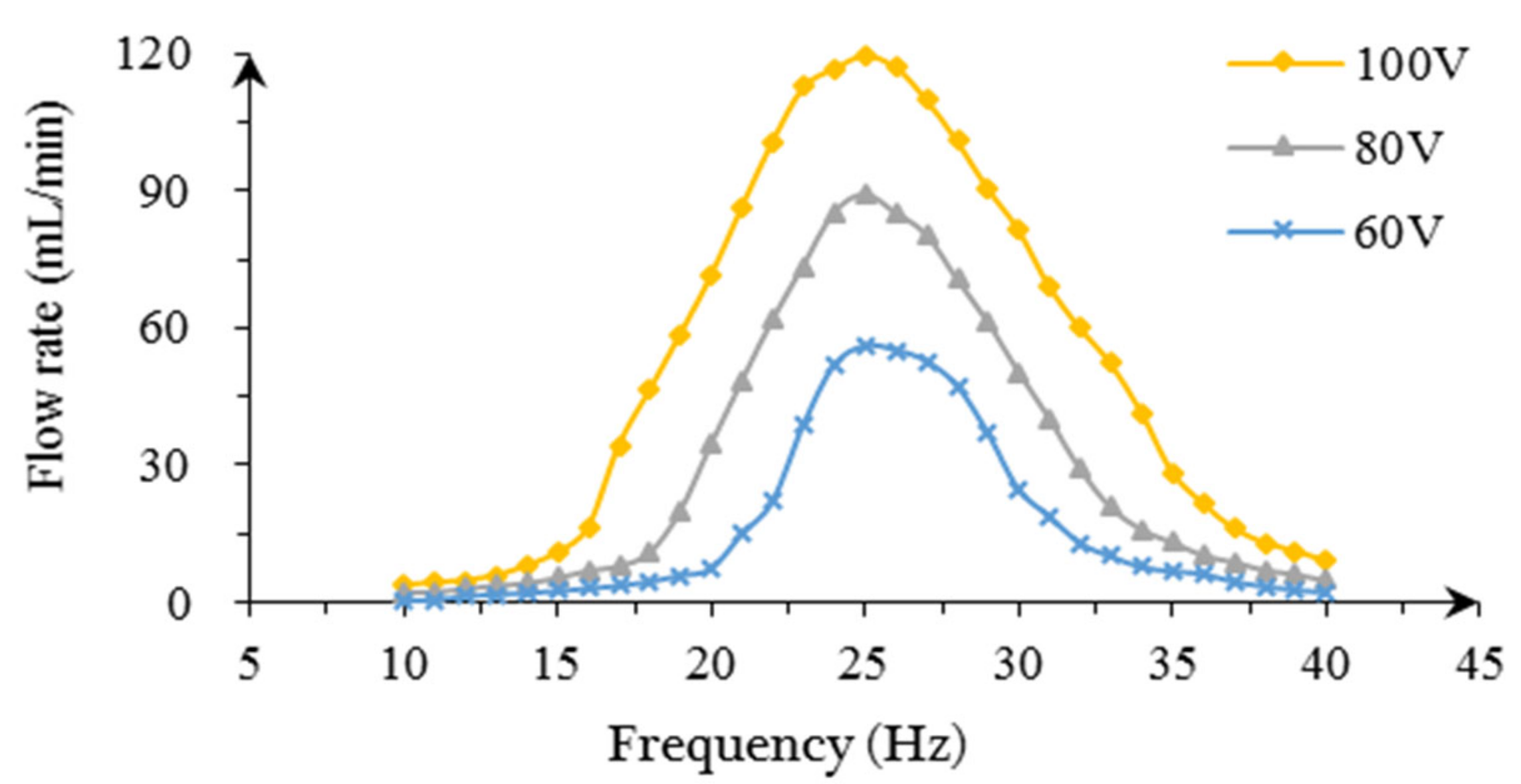

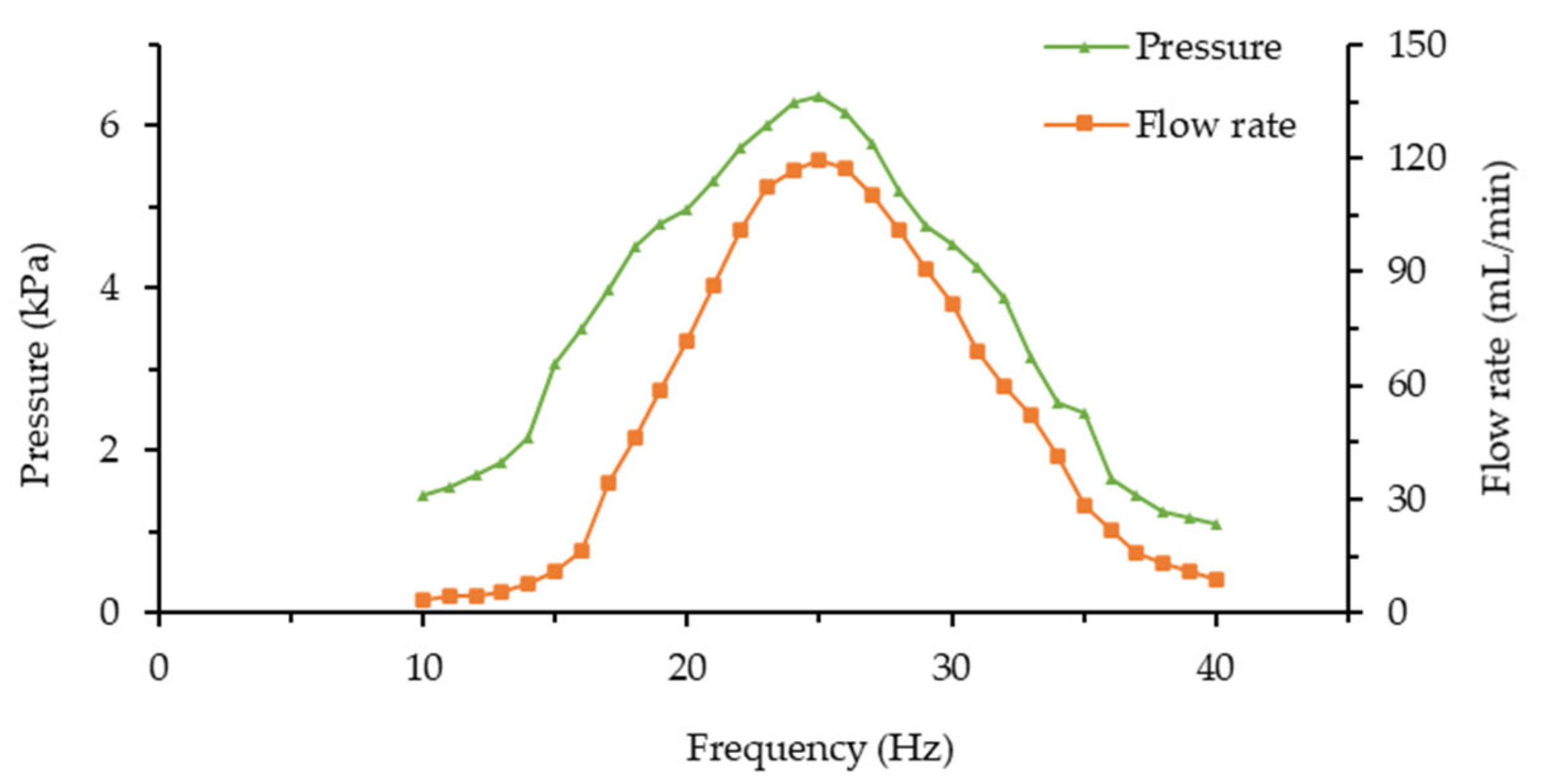

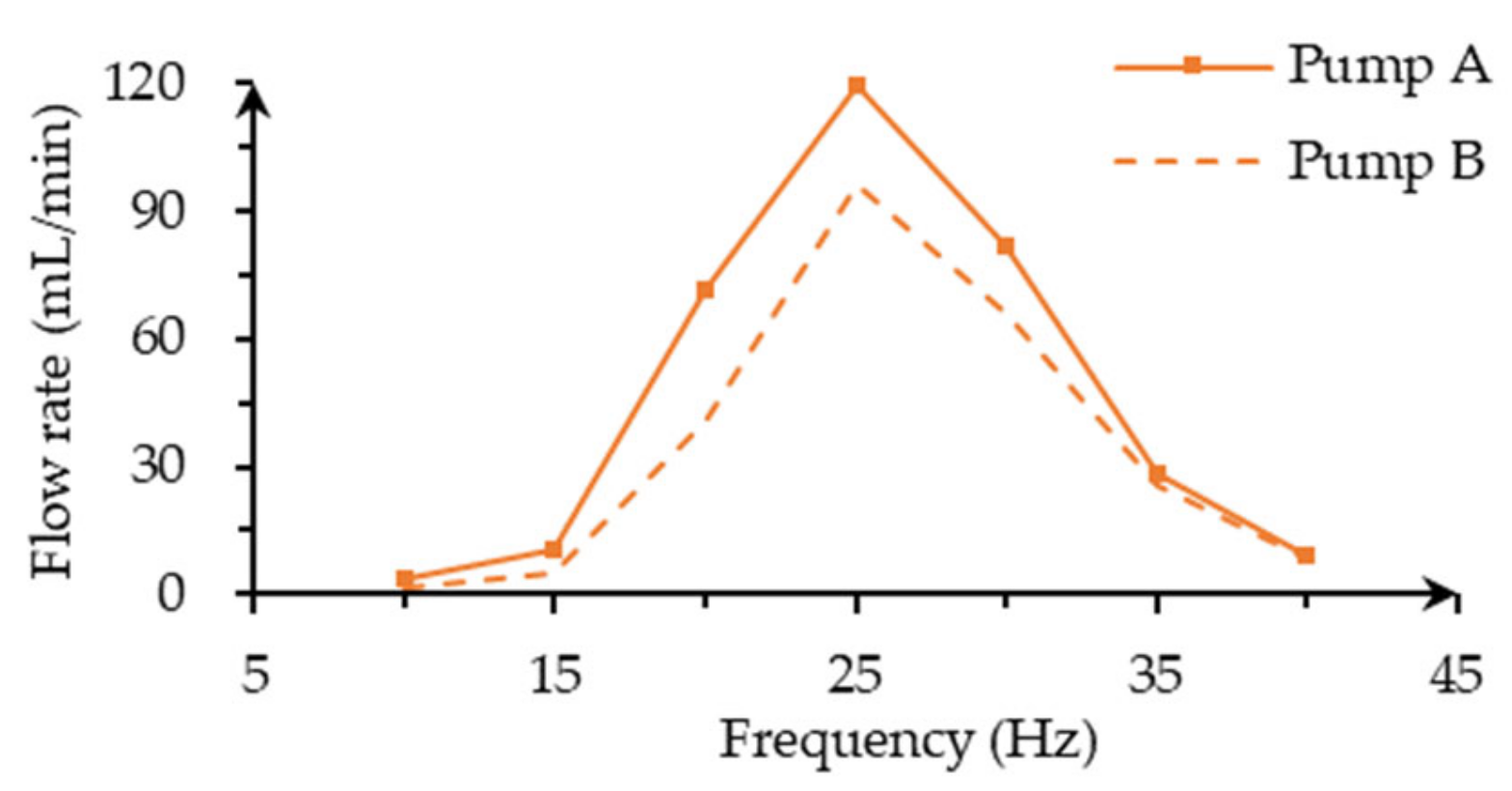

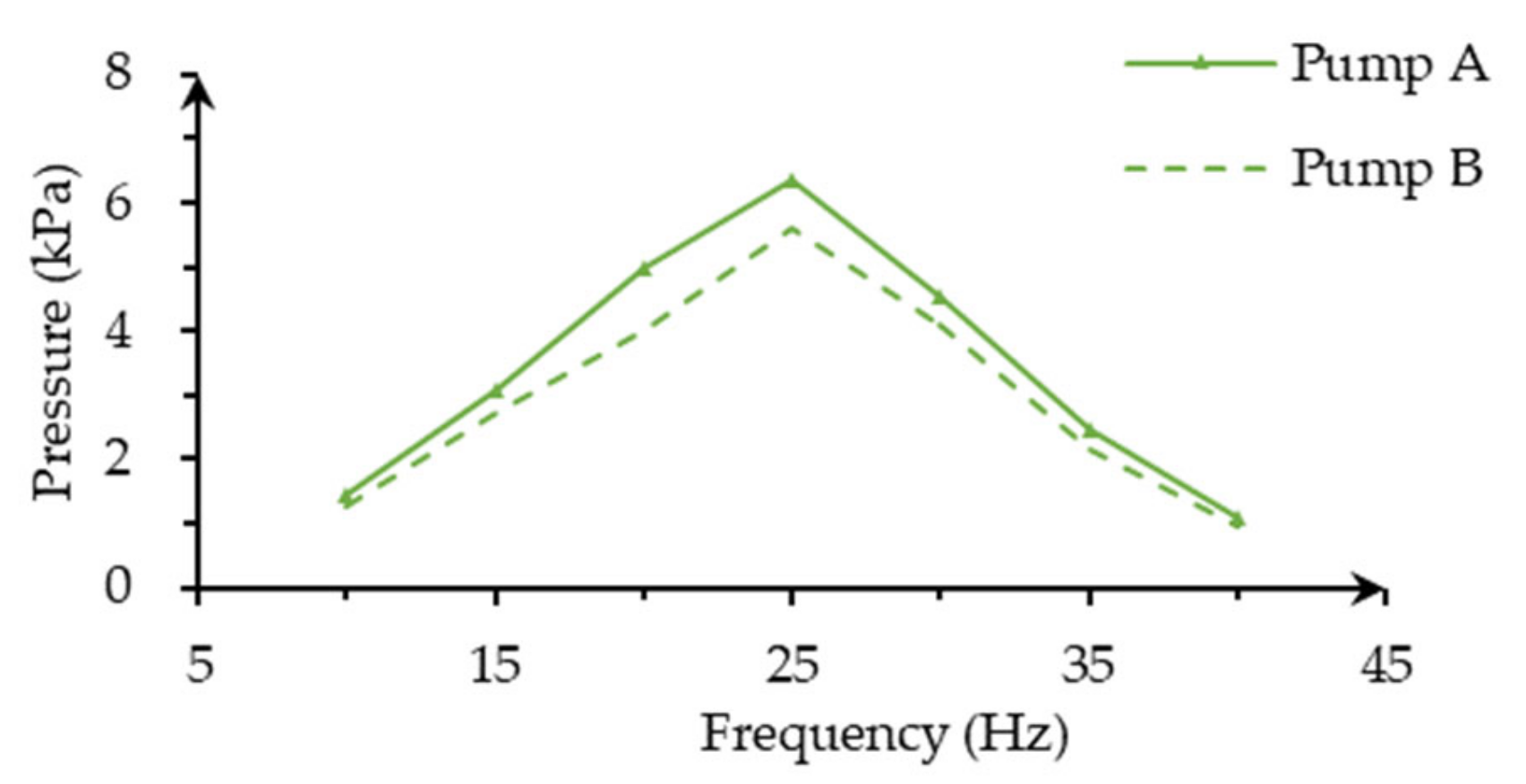

4.3. Flow Rate and Output Pressure Measurement

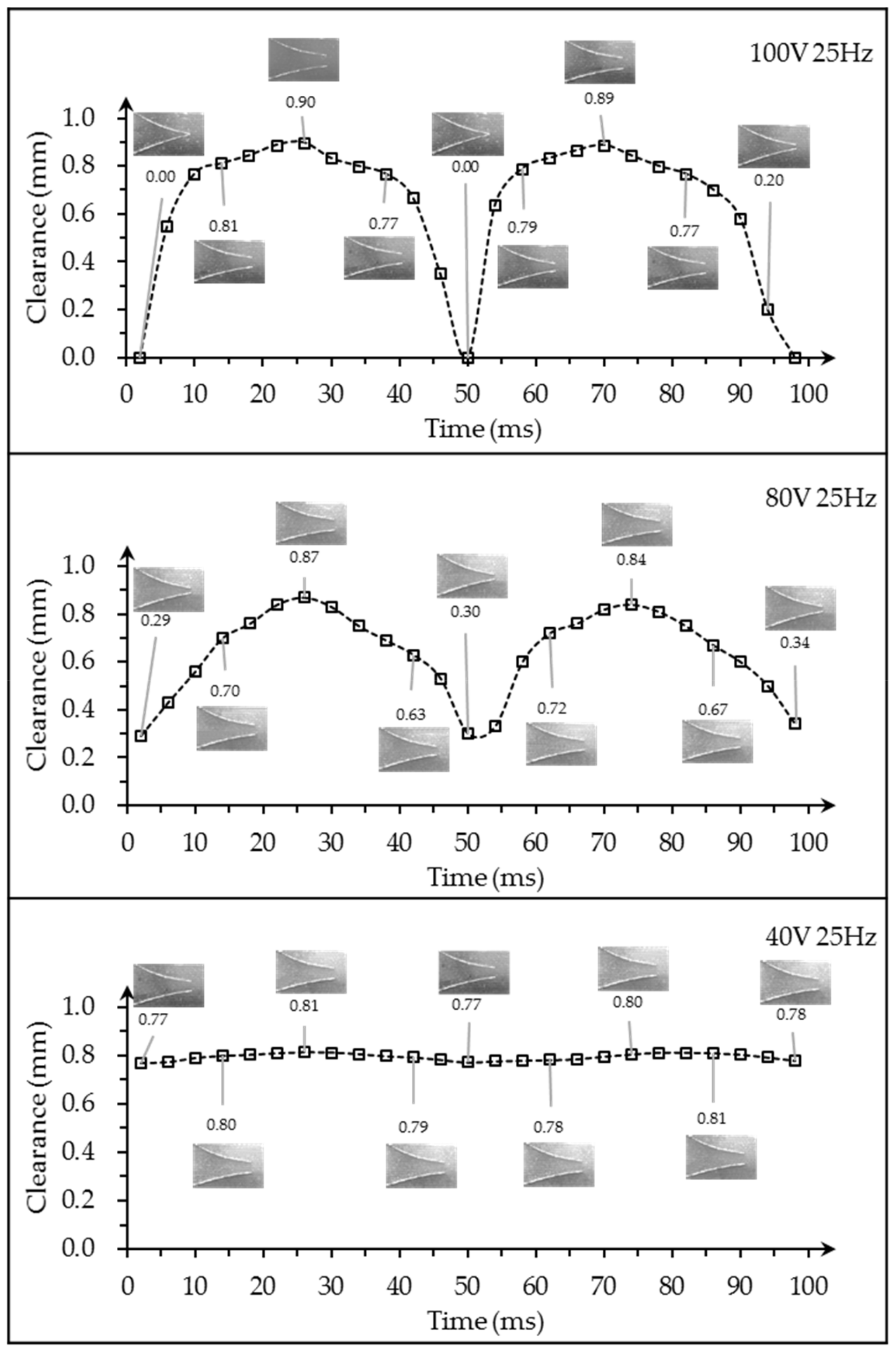

4.4. Working-State Analysis

5. Conclusions

- The working principle of the PPFV was introduced, a simplified model of the flexible valve was established, and its response to the loads was analyzed. It is known that the pressure change in the pump chamber caused by the vibration of the PZT vibrator is beneficial to the realization of the valve transport function. It was proved theoretically that this kind of pump can realize the conversion between a valved state and a valveless state by controlling the input signal of the PZT vibrator.

- The prototype of the PZT pump with flexible valves was manufactured, and its output performance was obtained through experimental research. The flow rate of the pump increased with the increase in voltage, but the flow rate–frequency relationships were not linear. The frequency corresponding to the maximum flow rate was not sensitive to the voltage change. The maximum flow rate measured under the voltage of 100 V was 119.61 mL/min (25 Hz), and the maximum output pressure was 6.16 kPa (25 Hz).

- We observed the working-state of one flexible valve in different input voltages, 100, 80, and 40 V at 25 Hz. It showed that the valved pump and the valveless pump existed in one, which proved that the valved state and the valveless state of the pump can be switched by adjusting the voltage. When the voltage was 100 V, it was a valveless PZT pump with a large flow rate and high output pressure. However, it was a valveless PZT pump with a small flow rate and low pressure difference when the voltage was lower than 80 V.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

References

- Gidde, R.R.; Pawar, P.M.; Dhamgaye, V.P. Fully coupled modeling and design of a piezoelectric actuation based valveless micropump for drug delivery application. Microsyst. Technol. Micro Nanosyst. Inf. Storage Process. Syst. 2020, 26, 633–645. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, Y.C. Simulation and experimental study of direct spray type piezoelectric air pumps based on synthetic jet. Microsyst. Technol. Micro Nanosyst. Inf. Storage Process. Syst. 2019, 25, 4445–4454. [Google Scholar] [CrossRef]

- Saren, A.; Smith, A.R.; Ullakko, K. Integratable magnetic shape memory micropump for high-pressure, precision microfluidic applications. Microfluid. Nanofluidics 2018, 22, 1–10. [Google Scholar] [CrossRef]

- Laser, D.J.; Santiago, J.G. A review of micropumps. J. Micromech. Microeng. 2004, 14, R35–R64. [Google Scholar] [CrossRef]

- Bian, K.; Huang, Z.; Bao, Q.B.; Zhang, J.H.; Lai, L.Y.; Chen, X.S.; Chen, Z.L. Design and Experiment of Streamlined Piezoelectric Pump with Low Vortex and Large Flow Rate. Trans. Nanjing Univ. Aeronaut. Astronaut. 2020, 37, 155–163. [Google Scholar]

- Dong, J.S.; Cao, Y.; Chen, Q.Q.; Wu, Y.; Liu, R.G.; Liu, W.S.; Yang, Y.; Yang, Z.G. Performance of single piezoelectric vibrator micropump with check valve. J. Intell. Mater. Syst. Struct. 2020, 31, 117–126. [Google Scholar] [CrossRef]

- Wang, J.T.; Zhao, X.L.; Chen, X.F.; Yang, H.R. A Piezoelectric Resonance Pump Based on a Flexible Support. Micromachines 2019, 10, 169. [Google Scholar] [CrossRef] [PubMed]

- Zeng, P.; Lin, J.G.; Cheng, G.M.; Yang, Z.G.; Wu, B.D.; Liu, G.J. A Study on Testing for Micro Piezo-pump with Integral Valve. Piezoelectric Acoustooptics 2006, 28, 594–596. [Google Scholar]

- Woo, J.; Sohn, D.K.; Ko, H.S. Performance and flow analysis of small piezo pump. Sens. Actuators A Phys. 2020, 301, 111766. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Liu, R. Theoretical and Experimental Research on the Piezoelectric Pump with Helical Linear Shaped Valve. J. Mech. Eng. 2016, 52, 144–150. [Google Scholar] [CrossRef]

- Zhang, J.H.; Huang, J.; Hu, X.Q.; Xi, Q.X. Novel piezoelectric pump with “E”-shaped valve found from sub-experiments. Front. Mech. Eng. China 2010, 5, 212–218. [Google Scholar] [CrossRef]

- He, X.H.; Cai, S.C.; Deng, Z.D.; Yang, S. Experimental and numerical study of flow characteristics of flat-walled diffuser/nozzles for valveless piezoelectric micropumps. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 2313–2326. [Google Scholar] [CrossRef]

- Stemme, E.; Stemme, G. A valveless diffuser/nozzle-based fluid pump. Sens. Actuators A Phys. 1993, 39, 159–167. [Google Scholar] [CrossRef]

- Forster, F.K.; Bardell, R.L.; Afromowitz, M.A.; Sharma, N.R.; Blanchard, A. Design, fabrication and testing of fixed-valve micro-pumps. Asme Publ. Fed 1995, 234, 39–44. [Google Scholar]

- Zhang, J.H.; Leng, X.F.; Zhao, C.S. A spiral-tube-type valveless piezoelectric pump with gyroscopic effect. Chin. Sci. Bull. 2014, 59, 1885–1889. [Google Scholar] [CrossRef]

- Huang, J.; Zou, L.; Tian, P.; Wang, Y.; Zhang, Q. Development of a valveless piezoelectric pump with vortex diodes. J. Micromech. Microeng. 2019, 29, 125006. [Google Scholar] [CrossRef]

- Tang, M.; Bao, Q.B.; Zhang, J.H.; Ning, Q.S.; Chen, C.B.; Huang, J.; Wu, C.Y. Design and Experimental Verification of a PZT Pump with Streamlined Flow Tubes. Appl. Sci. 2019, 9, 3881. [Google Scholar] [CrossRef]

- Li, F.; Zhang, J.H.; Tang, M.; Chen, C.B.; Bao, Q.B. Experimental study of valveless piezoelectric pump with raindrop-shaped tubes. In Proceedings of the 2018 International Conference on Service Robotics Technologies, Chengdu, China, 16–19 March 2018. [Google Scholar]

- Bao, Q.B.; Zhang, J.H.; Tang, M.; Huang, Z.; Lai, L.L.; Wu, C.Y. A novel PZT pump with built-in compliant structures. Sensors 2019, 19, 1301. [Google Scholar] [CrossRef]

- Li, L.L. Chain Algorithm for Solving Large Deflection and Its Application in Compliant Mechanisms’ Analysis. Ph.D. Thesis, Xidian University, Xi’an, China, 2012. [Google Scholar]

- Li, Y.L.; Zhang, J.H.; Xia, Q.X.; Lu, J.Z. Research on the Dynamic Characteristics of the Actuator for the Piezoelectric Pump. China Mech. Eng. 2007, 17, 2088–2093. [Google Scholar]

- Zeng, D.; Chen, Y. High-Order Modal Shape Measurement of Centrifugal Impeller Blade by Using Marco Fiber Composite. J. Propuls. Technol. 2020, 41, 1612–1620. [Google Scholar]

- Zhang, J.H.; Wang, Y.; Huang, J. Advances in valveless piezoelectric pump with cone-shaped tubes. Chin. J. Mech. Eng. 2017, 30, 766–781. [Google Scholar] [CrossRef]

- Zhang, J.H.; Fu, J.; Zhang, F.; Zhou, Y.; Huang, J.; Huang, W.Q.; Bian, K.; Liu, P.C. Redefining valves in volume pump. In Proceedings of the ACTUATOR 2018: 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018. [Google Scholar]

| Item | Size (mm) |

|---|---|

| Y0 | 0.8 |

| L | 5 |

| h | 1.9 |

| b | 0.05 |

| Flow channel width | 3.8 |

| Pump chamber diameter | 37 |

| Pump chamber height | 1 |

| Item | Size (mm) |

|---|---|

| Brass substrate diameter | 41 |

| Brass substrate thickness | 0.23 |

| PZT ceramic diameter | 35 |

| PZT ceramic thickness | 0.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Lai, L.; Chen, Z.; Chen, X.; Huang, Z.; Dai, J.; Zhang, F.; Zhang, J. Research on a Piezoelectric Pump with Flexible Valves. Appl. Sci. 2021, 11, 2909. https://doi.org/10.3390/app11072909

Huang W, Lai L, Chen Z, Chen X, Huang Z, Dai J, Zhang F, Zhang J. Research on a Piezoelectric Pump with Flexible Valves. Applied Sciences. 2021; 11(7):2909. https://doi.org/10.3390/app11072909

Chicago/Turabian StyleHuang, Weiqing, Liyi Lai, Zhenlin Chen, Xiaosheng Chen, Zhi Huang, Jietao Dai, Fan Zhang, and Jianhui Zhang. 2021. "Research on a Piezoelectric Pump with Flexible Valves" Applied Sciences 11, no. 7: 2909. https://doi.org/10.3390/app11072909

APA StyleHuang, W., Lai, L., Chen, Z., Chen, X., Huang, Z., Dai, J., Zhang, F., & Zhang, J. (2021). Research on a Piezoelectric Pump with Flexible Valves. Applied Sciences, 11(7), 2909. https://doi.org/10.3390/app11072909