Analytical Solutions of Model Problems for Large-Deformation Micromorphic Approach to Gradient Plasticity

Abstract

1. Introduction

2. A Conventional Micromorphic Approach for Gradient Plasticity

2.1. Kinematics

2.2. Micromorphic Variable

2.3. Balance Equations

3. Constitutive Equations

4. Model Problems

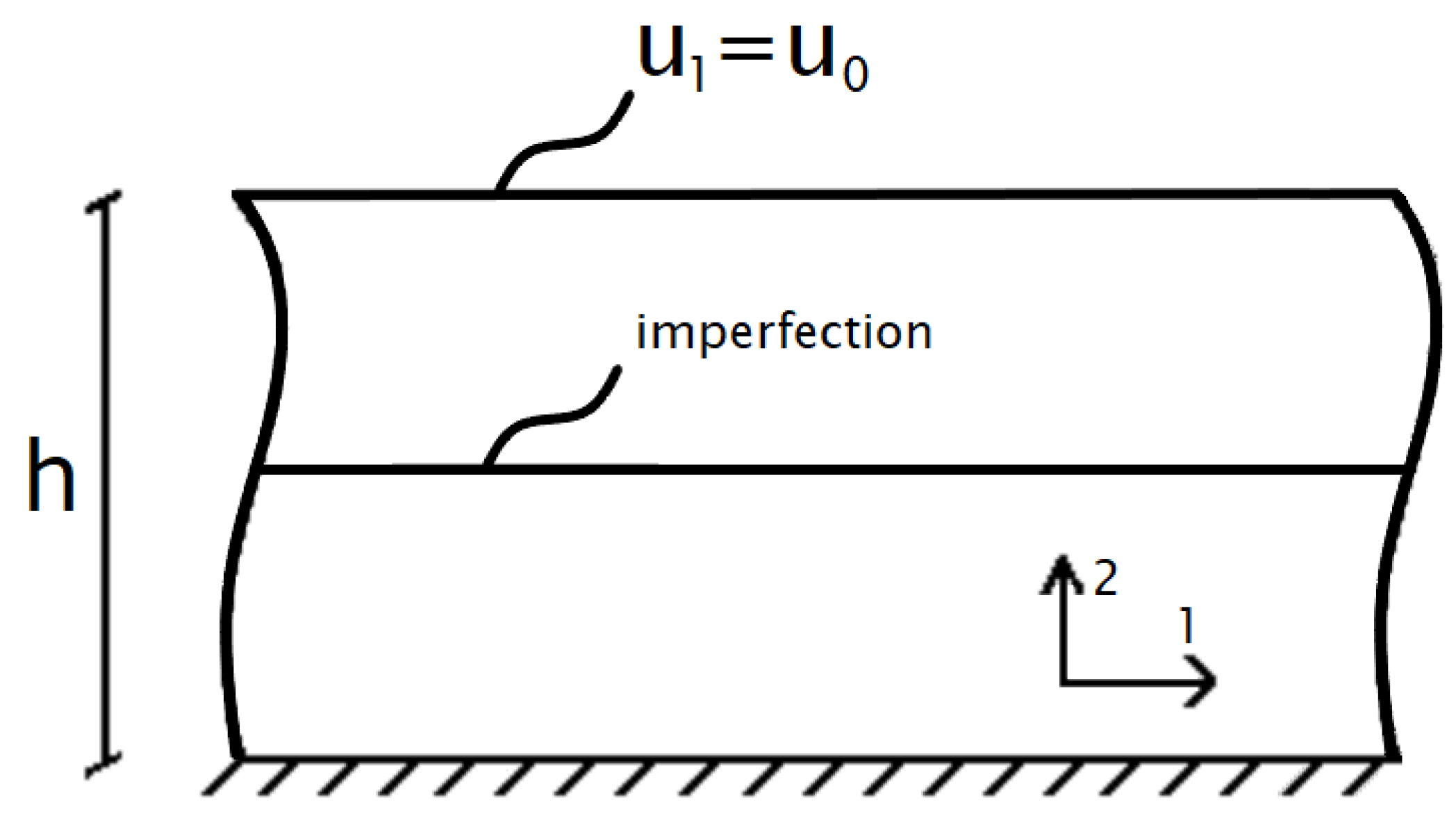

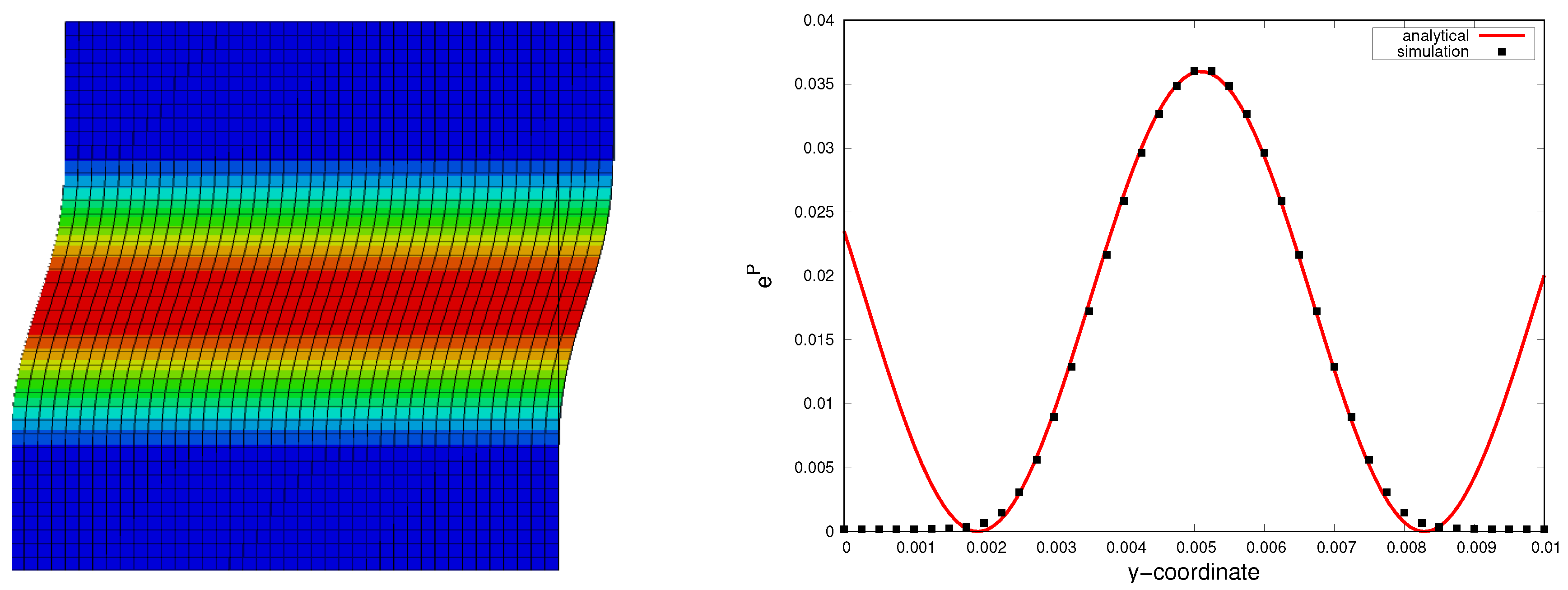

4.1. Simple Glide of a Softening Plate with a Central Imperfection

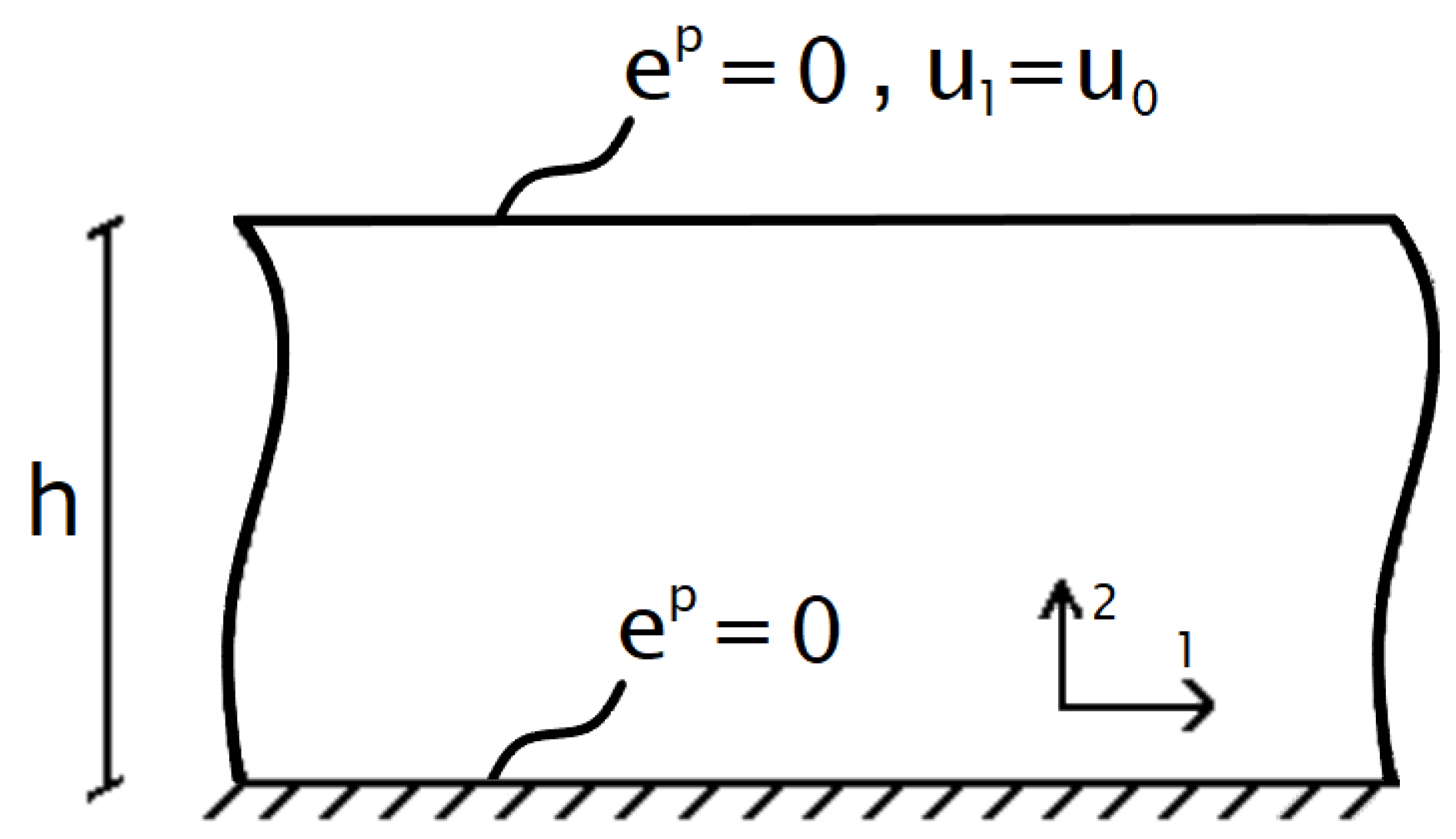

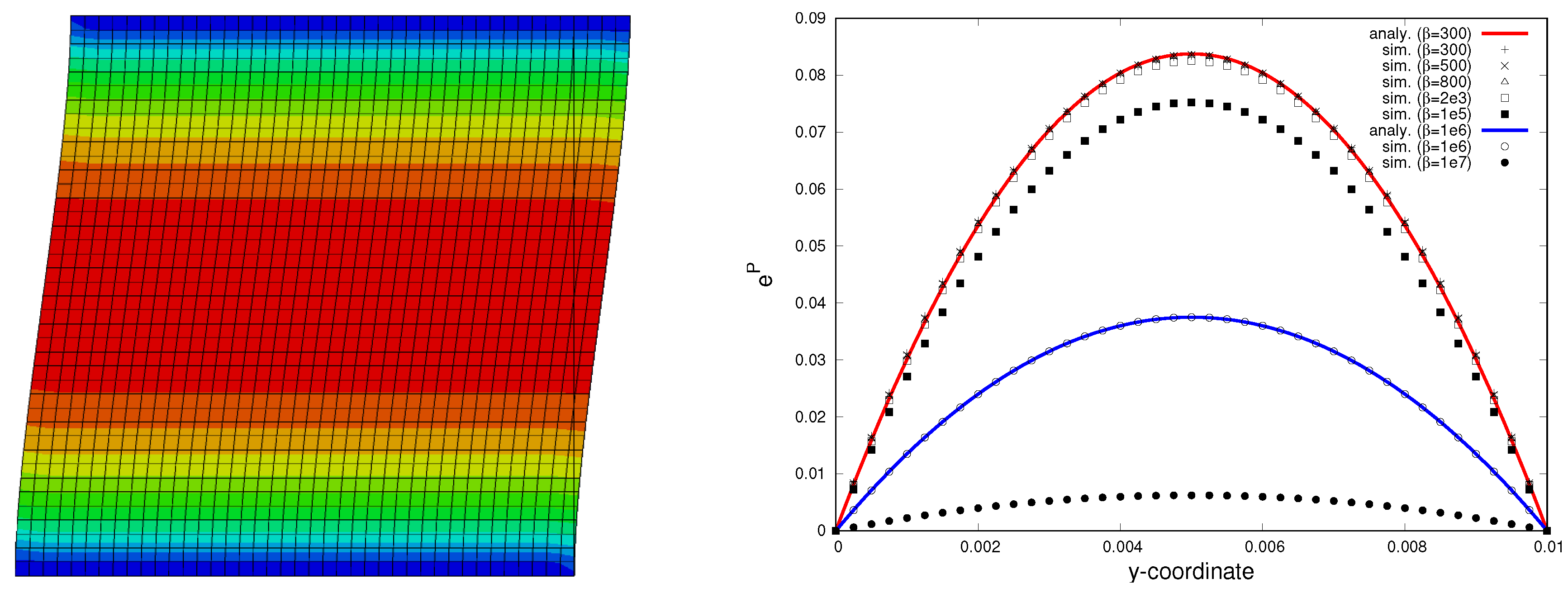

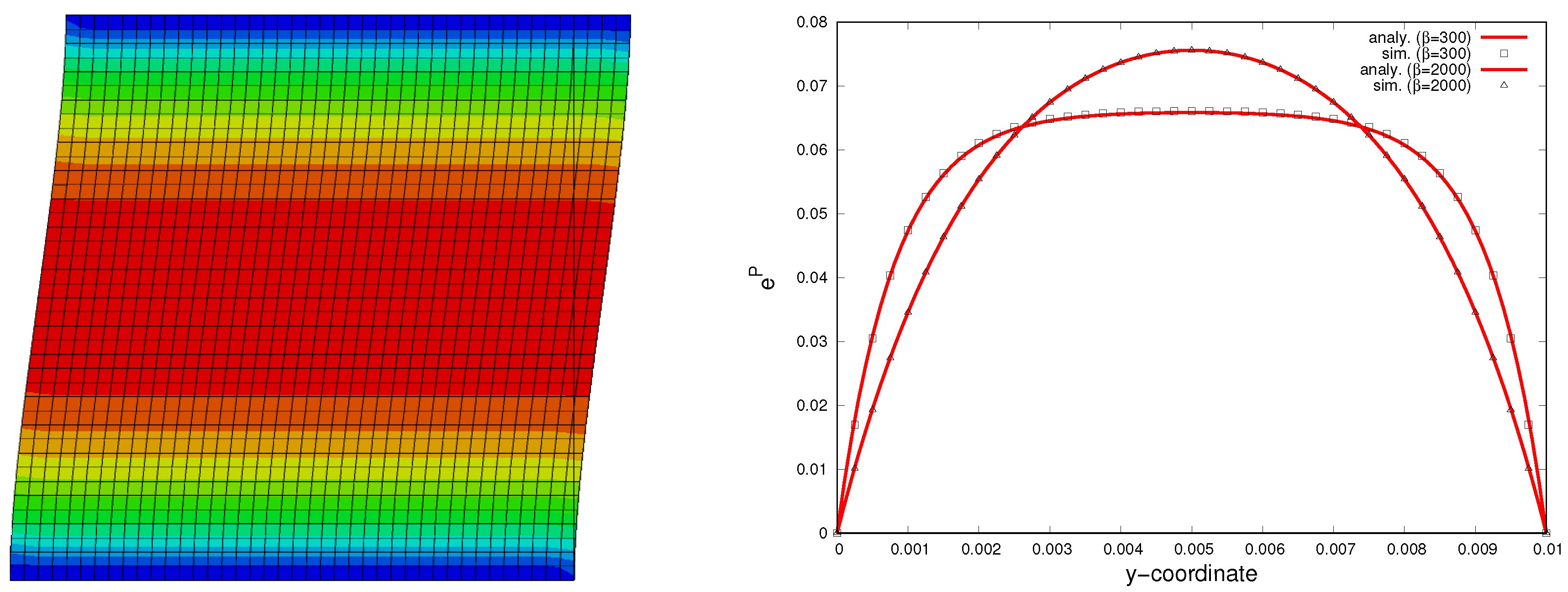

4.2. Simple Glide of a Perfectly Plastic Plate with Hard Boundary Conditions

4.3. Simple Glide of a Hardening Plate with Hard Boundary Conditions

5. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stelmashenko, N.A.; Walls, M.G.; Brown, L.M.; Milman, Y.V. Microindentations on W and Mo oriented single crystals: An STM study. Acta Metall. Mater. 1993, 41, 2855–2865. [Google Scholar] [CrossRef]

- Ma, Q.; Clarke, D.R. Size dependent hardness of silver single crystals. J. Mater. Res. 1995, 10, 853–863. [Google Scholar] [CrossRef]

- Fleck, N.A.; Muller, G.M.; Ashby, M.F.; Hutchinson, J.W. Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Stolken, J.S.; Evans, A.G. A microbend test method for measuring the plasticity length scale. Acta Mater. 1998, 46, 5109–5115. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Plasticity at the micron scale. Int. J. Solids Struct. 2000, 37, 225–238. [Google Scholar] [CrossRef]

- Aifantis, E.C. On the microstructural origin of certain inelastic models. J. Eng. Mat. Technol. 1984, 106, 106. [Google Scholar] [CrossRef]

- Aifantis, E.C. The physics of plastic deformation. Int. J. Plast 1987, 3, 211–247. [Google Scholar] [CrossRef]

- Anand, L.; Aslan, O.; Chester, S.A. A large-deformation gradient theory for elasticplastic materials: Strain softening and regularization of shear bands. Int. J. Plasticity 2012, 30–31, 116–143. [Google Scholar] [CrossRef]

- Forest, S. Micromorphic approach for gradient elasticity, viscoplasticity, and damage. J. Eng. Mech. 2009, 135, 117–131. [Google Scholar] [CrossRef]

- Mühlhaus, H.B.; Aifantis, E.C. A variational principle for gradient plasticity. Int. J. Solids Struct. 1991, 28, 845–857. [Google Scholar] [CrossRef]

- de Borst, R.; Mühlhaus, H.B. Gradient dependent plasticity: Formulation and algorithmic aspects. Int. J. Numer. Meth. Eng. 1992, 35, 521–539. [Google Scholar] [CrossRef]

- de Borst, R.; Sluys, L.J.; Mühlhaus, H.B.; Pamin, J. Fundamental issues in finite element analysis of localization of deformation. Eng. Comput. 1993, 10, 99–121. [Google Scholar] [CrossRef]

- de Borst, R.; Pamin, J. Some novel developments in finite element procedures for gradient-dependent plasticity. Int. J. Numer. Meth. Eng. 1996, 39, 2477–2505. [Google Scholar] [CrossRef]

- Engelen, R.A.B.; Geers, M.G.D.; Baaijens, F.P.T. Nonlocal implicit gradient enhanced elasto-plasticity for the modelling of softening behaviour. Int. J. Numer. Meth. Eng. 1996, 19, 403–433. [Google Scholar] [CrossRef]

- Geers, M.G.D. Finite strain logarithmic hyperelasto-plasticity with softening: A strongly non-local implicit gradient framework. Comput. Methods Appl. Mech. Eng. 1996, 193, 3377–3401. [Google Scholar] [CrossRef]

- Geers, M.G.D. On the role of moving elastic-plastic boundaries in strain gradient plasticity. Model. Simul. Mater. Sci. Eng. 2007, 15, 7723–7746. [Google Scholar]

- Gurtin, M.E.; Anand, L. A theory of strain-gradient plasticity for isotropic, plastically irrotational materials. Part I: Small deformations. J. Mech. Phys. Solids 2005, 53, 1624–1649. [Google Scholar] [CrossRef]

- Anand, L.; Gurtin, M.E.; Lele, S.P.; Gething, C. A one-dimensional theory of strain-gradient plasticity: Formulation, analysis, numerical results. J. Mech. Phys. Solids 2005, 53, 1789–1826. [Google Scholar] [CrossRef]

- Gurtin, M.E.; Anand, L. Thermodynamics applied to gradient theories involving the accumulated plastic strain: The theories of Aifantis and Fleck and Hutchinson and their generalization. J. Mech. Phys. Solids 2009, 57, 405–421. [Google Scholar] [CrossRef]

- Eringen, A.C. Microcontinuum Field Theories; Springer: New York, NY, USA, 1999. [Google Scholar]

- Aslan, O.; Forest, S. Crack growth modelling in single crystals based on higher order continua. Comp. Mater. Sci. 2009, 3, 756–761. [Google Scholar] [CrossRef]

- Aslan, O.; Cordero, N.M.; Gaubert, A.; Forest, S. Micromorphic approach to single crystal plasticity and damage. Int. J. Eng. Sci. 2011, 49, 1311–1325. [Google Scholar] [CrossRef]

- Aslan, O.; Quilici, S.; Forest, S. Numerical modeling of fatigue crack growth in single crystals based on microdamage theory. Int. J. Damage. Mech. 2011, 5, 681–705. [Google Scholar] [CrossRef]

- Forest, S.; Aifantis, E.C. Some links between recent gradient thermo-elasto-plasticity theories and the thermomechanics of generalized continua. Int. J. Solids Struct. 2010, 47, 3367–3376. [Google Scholar] [CrossRef]

- Aslan, O.; Bayraktar, E. A Large-Deformation Gradient Damage Model for Single Crystals Based on Microdamage Theory. Appl. Sci. 2020, 10, 9142. [Google Scholar] [CrossRef]

- Gurtin, M.E. A gradient theory of single-crystal viscoplasticity that accounts for geometrically necessary dislocations. J. Mech. Phys. Solids 2009, 50, 5–32. [Google Scholar] [CrossRef]

- Kröner, E. Allgemeine Kontinuumstheorie der Versetzungen und Eigenspannungen. Arch. Ration. Mech. Anal. 1959, 4, 273–334. [Google Scholar] [CrossRef]

- Hencky, H. The elastic behavior of vulcanized rubber. Rubber Chem. Technol. 1933, 2, 217–224. [Google Scholar] [CrossRef]

- Anand, L. Moderate deformations in extension-torsion of incompressible isotropic elastic materials. J. Mech. Phys. Solids 1986, 34, 293–304. [Google Scholar] [CrossRef]

- Anand, L.; On, H. Hencky’s approximate strain-energy function for moderate deformations. J. Appl. Mech. 2011, 46, 78–82. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aslan, O.; Bayraktar, E. Analytical Solutions of Model Problems for Large-Deformation Micromorphic Approach to Gradient Plasticity. Appl. Sci. 2021, 11, 2361. https://doi.org/10.3390/app11052361

Aslan O, Bayraktar E. Analytical Solutions of Model Problems for Large-Deformation Micromorphic Approach to Gradient Plasticity. Applied Sciences. 2021; 11(5):2361. https://doi.org/10.3390/app11052361

Chicago/Turabian StyleAslan, Ozgur, and Emin Bayraktar. 2021. "Analytical Solutions of Model Problems for Large-Deformation Micromorphic Approach to Gradient Plasticity" Applied Sciences 11, no. 5: 2361. https://doi.org/10.3390/app11052361

APA StyleAslan, O., & Bayraktar, E. (2021). Analytical Solutions of Model Problems for Large-Deformation Micromorphic Approach to Gradient Plasticity. Applied Sciences, 11(5), 2361. https://doi.org/10.3390/app11052361