Influence of Piping on On-Line Continuous Weighing of Materials inside Process Equipment: Theoretical Analysis and Experimental Verification

Abstract

:1. Introduction

2. Methodology

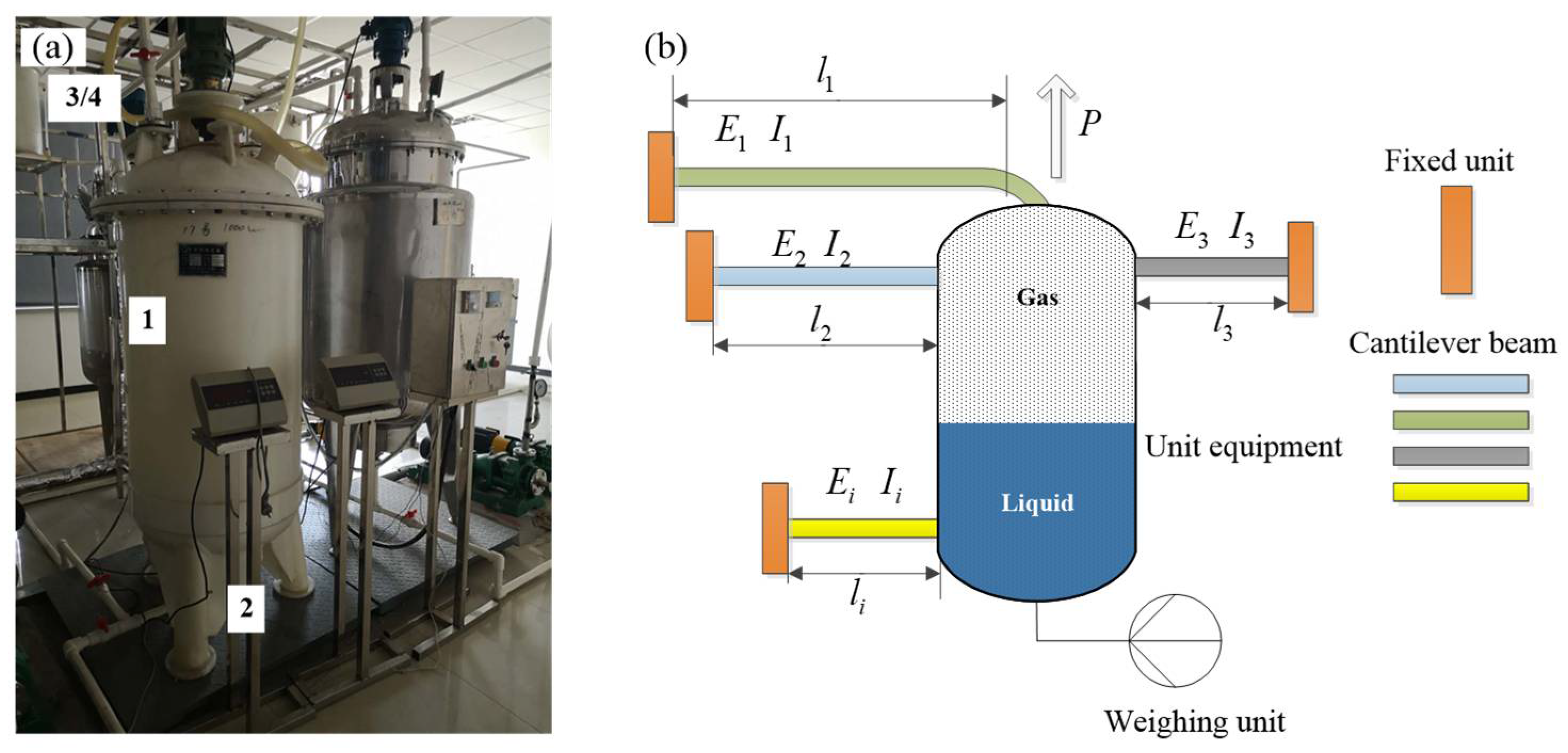

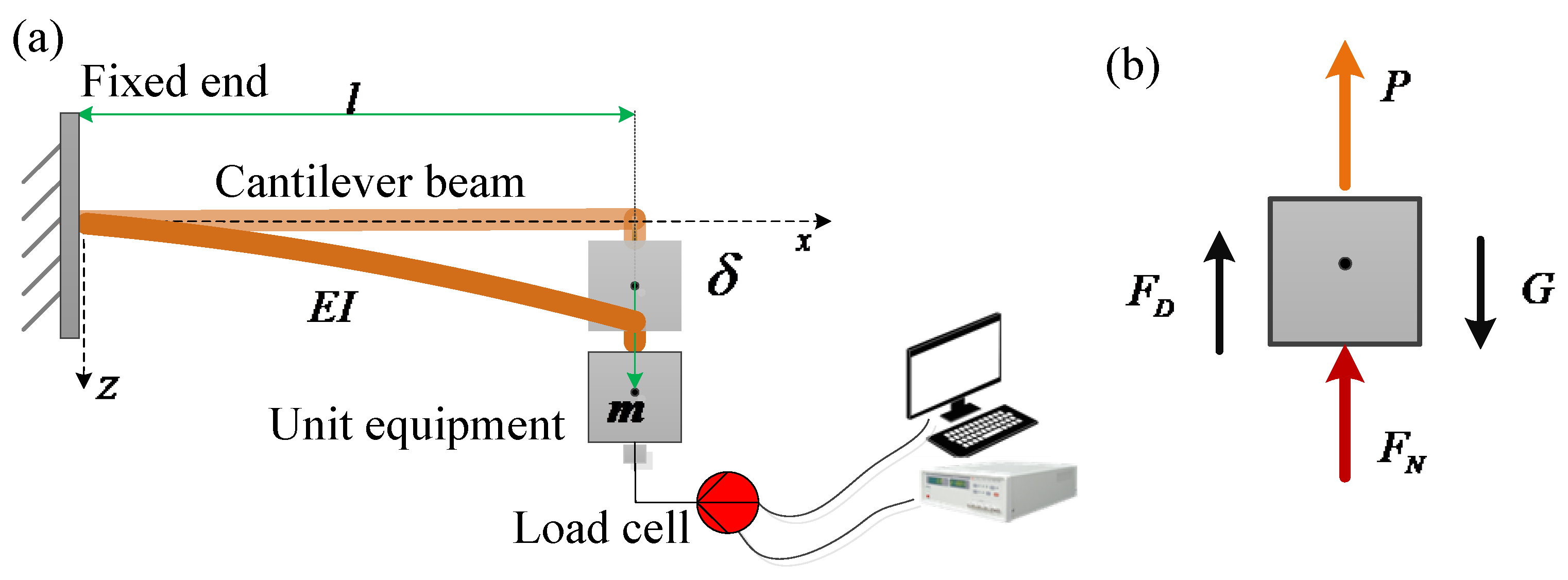

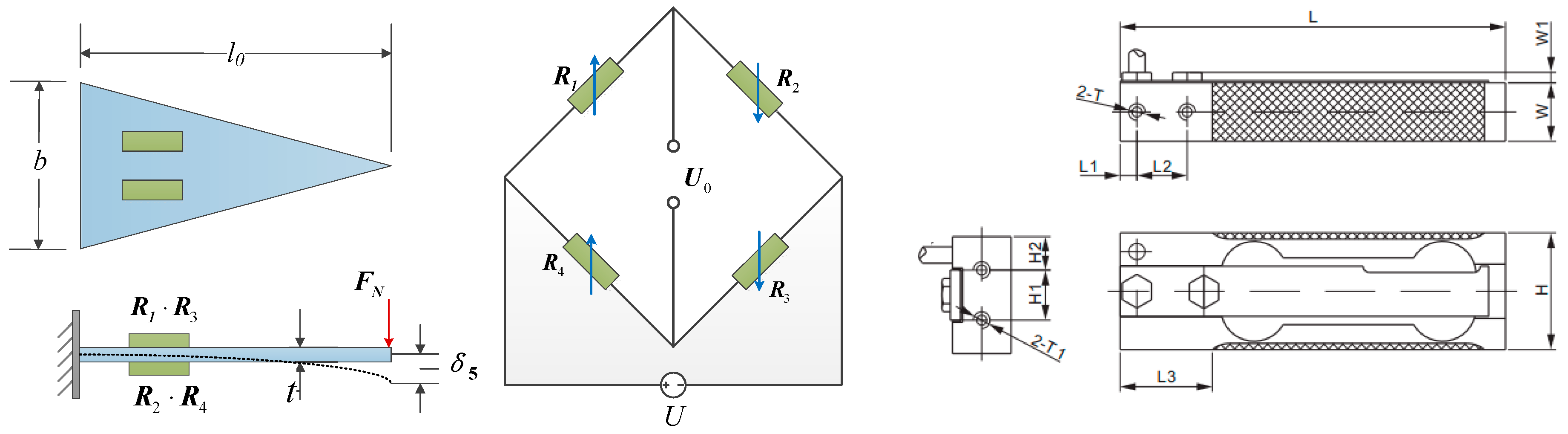

2.1. Analytical Model of the Material Weighing System inside Process Equipment

2.2. Linearization Analysis and Evaluation Criteria

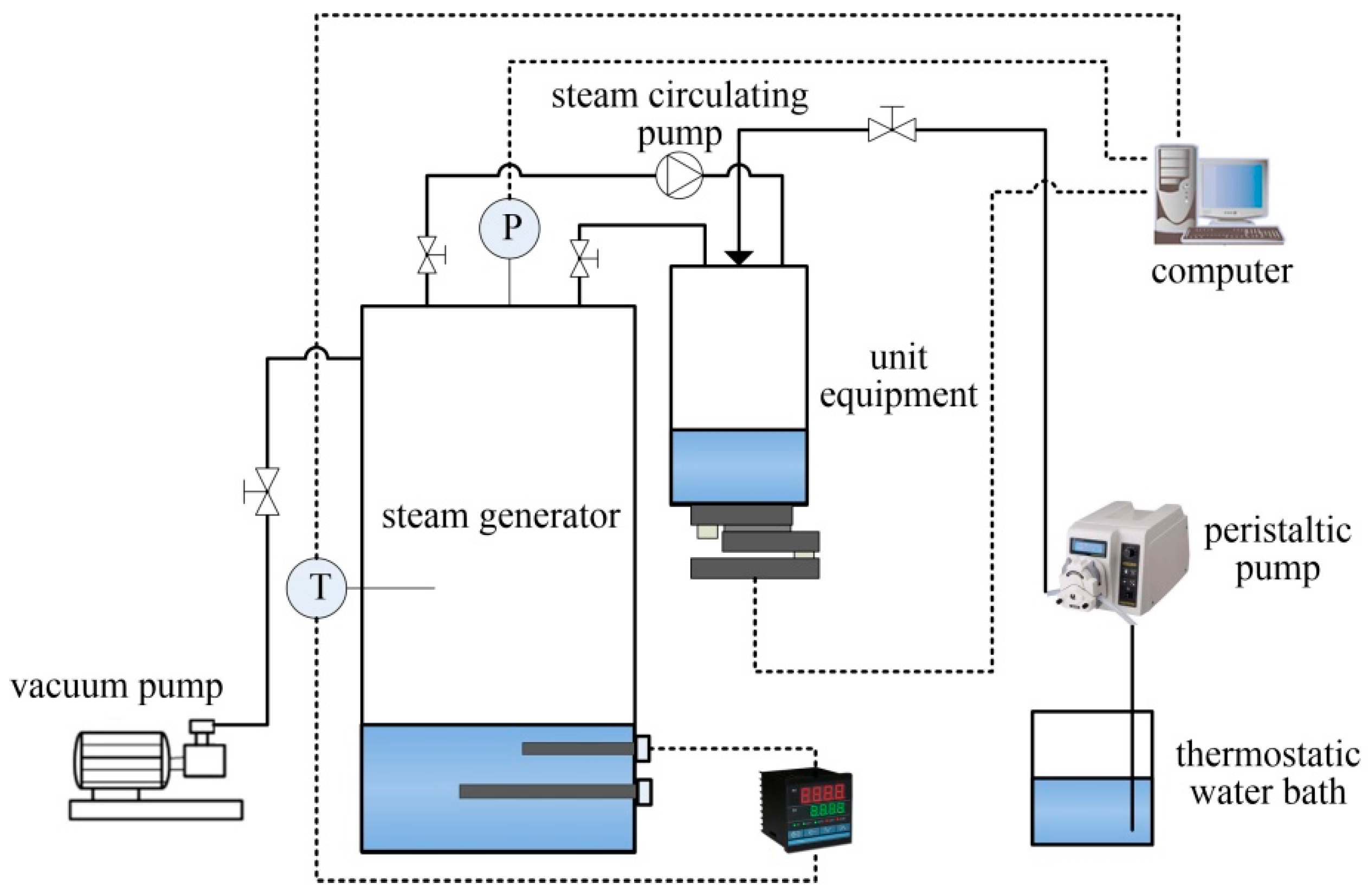

2.3. Experimental System and Conditions

3. Results and Discussion

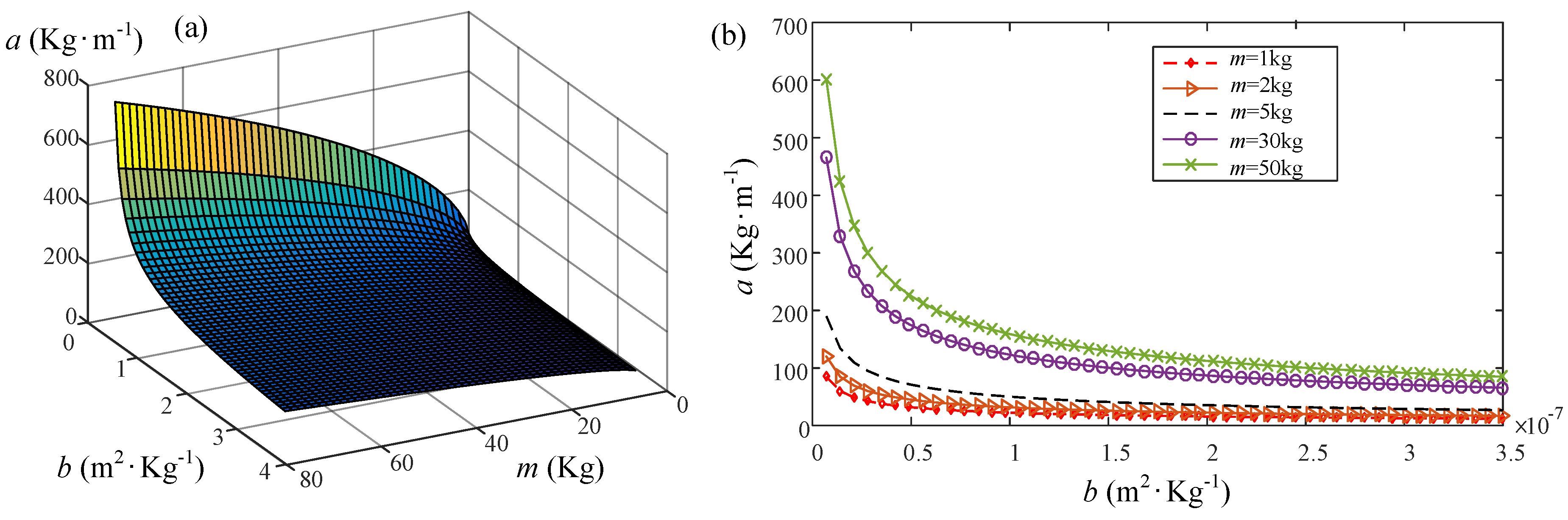

3.1. Influence Analysis of Connected Piping on Weighing Results

3.2. Experiment Verification

3.2.1. Linearization Verification of Static Weighing Results

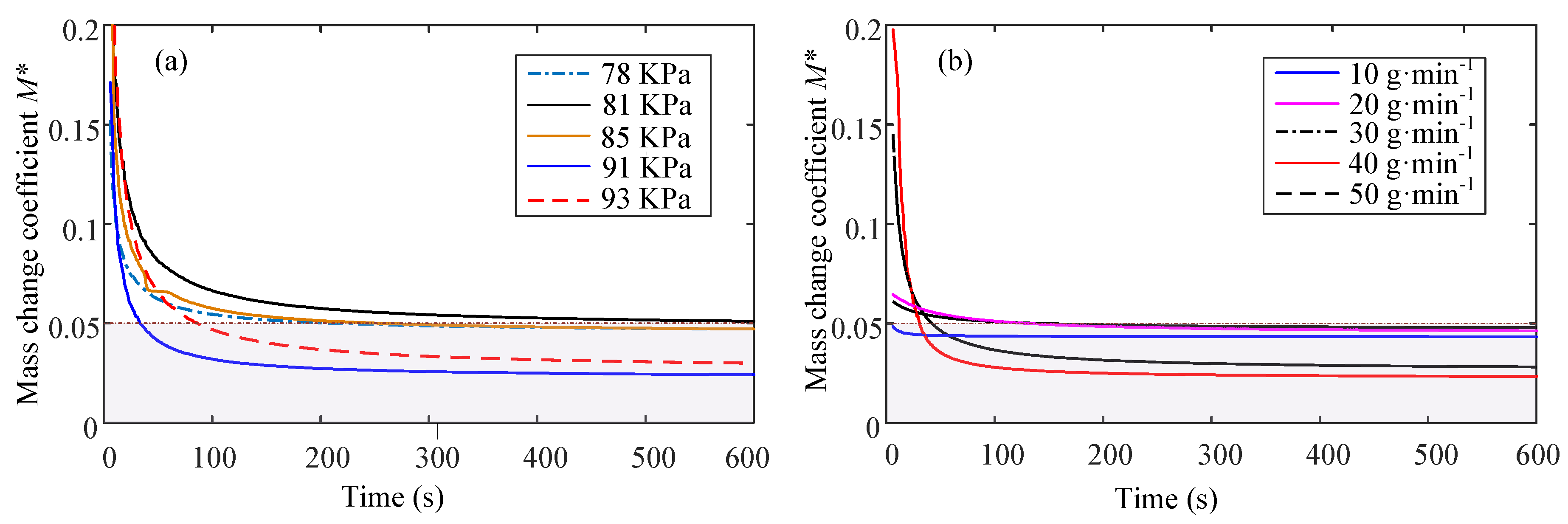

3.2.2. Influence of Operating Conditions on Dynamic Weighing

- If the unit equipment is a pressure vessel, the strain generated by pressure load will be superimposed to the total strain of the system to affect the weighing measurement result;

- The gas–liquid two-phase in the flowing state inside the unit equipment can generate dynamic load and act on the internal parts of the equipment, such as the additional load;

- Harmonic load or vibration load generated by power devices and attached to the system, such as stirring device and centrifugal pump.

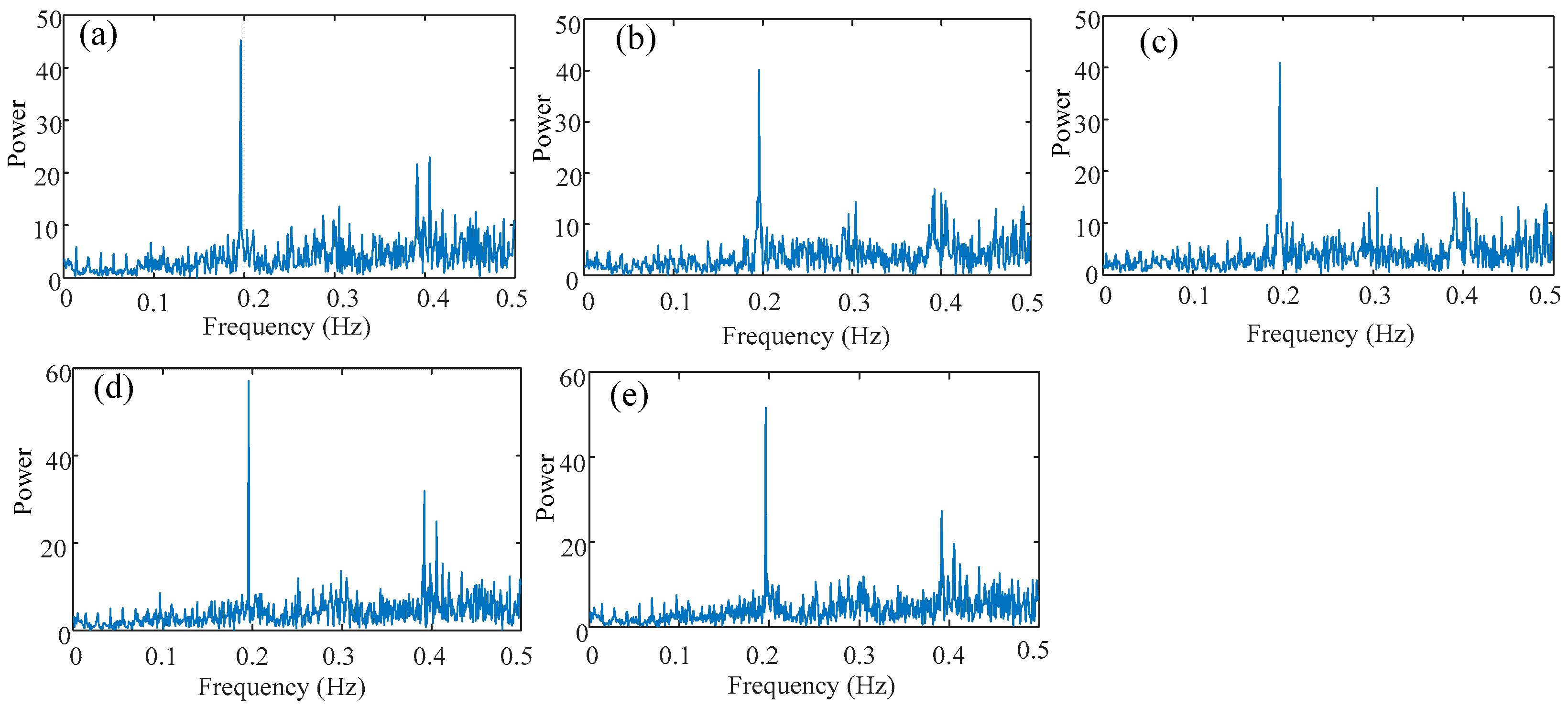

3.2.3. Linearization Verification of Dynamic Weighing Results

3.2.4. Uncertainty Evaluation by GUM Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Q.; Song, H.; Liu, G.; Feng, X. Processing Unit Mass Balance-Oriented Mathematical Optimization for Hydrogen Networks. Ind. Eng. Chem. Res. 2018, 57, 3685–3698. [Google Scholar] [CrossRef]

- Krolikowski, L.J. Distillation limit dependence on feed quality and column equipment. Chem. Eng. Res. Des. 2015, 99, 149–157. [Google Scholar] [CrossRef]

- Suziki, I.; Yagi, H.; Komatsu, H.; Hirata, M. Calculation of Multicomponent Distillation Accompanied by a Chemical Reaction. J. Chem. Eng. Jpn. 1971, 4, 26–33. [Google Scholar] [CrossRef] [Green Version]

- Boumans, G. Grain Handling and Storage; Elsevier: Amsterdam, The Netherlands, 1985; Volume 4, pp. 337–365. [Google Scholar]

- Sakai, N.; Saegusa, H.; Kobayashi, M.; Tachikawa, N.; Ishikawa, I.; Mooroka, S. Development of a neutron absorption tracer technique for evaluation of fluid dynamics in coal liquefaction reactors. Fuel Process. Technol. 2002, 76, 139–156. [Google Scholar] [CrossRef]

- Sakai, N.; Onozaki, M.; Saegusa, H.; Ishibashi, H.; Hayashi, T.; Kobayashi, M.; Tachikawa, N.; Ishikawa, I.; Mooroka, S. Fluid dynamics in coal liquefaction reactors using neutron absorption tracer technique. AlChE J. 2004, 8, 1688–1693. [Google Scholar] [CrossRef]

- Liu, M.-Y.; Yang, Y.; Xue, J.-P.; Hu, Z.-D. Measuring Techniques for Gas-Liquid-Solid Three-phase Fluidized Bed Reactors. Chin. J. Process Eng. 2005, 5, 217–222. [Google Scholar]

- Levec, J.; Sáez, A.E.; Carbonell, R.G. The Hydrodynamics of Trickling Flow in Packed Beds. Part II: Experimental Observations. AlChE J. 1986, 32, 369–380. [Google Scholar] [CrossRef]

- Sbarbaro, D.; Ortega, R. Averaging level control: An approach based on mass balance. J. Process. Control 2007, 17, 621–629. [Google Scholar] [CrossRef]

- Delgado, A.E.; Sun, D.-W. Heat and mass transfer models for predicting freezing processes—A review. J. Food Eng. 2001, 47, 157–174. [Google Scholar] [CrossRef]

- Wiberg, P.; Sehlstedt-P, S.; Morén, T.J. Heat and Mass Ttansfer During Sapwood Drying Above the Fibre Saturation Point. Dry Technol. 2000, 18, 1647–1664. [Google Scholar] [CrossRef]

- Mubarok, M.H.; Zarrouk, S.J.; Cater, J.E.; Mundakir, A.; Bramantyo, E.A.; Lim, Y.W. Real-time enthalpy measurement of two-phase geothermal fluid flow using load cell sensors: Field testing results. Geothermics 2021, 89, 101930. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, G.; Wen, J.; Huang, H. Thermal oxidation coking of aviation kerosene RP-3 at supercritical pressure in helical tubes. Appl. Therm. Eng. 2018, 128, 1186–1195. [Google Scholar] [CrossRef]

- Susanti, N.; Grosshans, H. Measurement of the deposit formation during pneumatic transport of PMMA powder. Adv. Powder Technol. 2020, 31, 3597–3609. [Google Scholar] [CrossRef]

- Holub, R.A.; Duduković, M.P.; Ramachandran, P.A. Pressure drop, liquid holdup, and flow regime transition in trickle flow. AIChE J. 1993, 39, 302–321. [Google Scholar] [CrossRef]

- García-Serna, J.; Gallina, G.; Biasi, P.; Salmi, T. Liquid Holdup by Gravimetric Recirculation Continuous Measurement Method. Application to Trickle Bed Reactors under Pressure at Laboratory Scale. Ind. Eng. Chem. Res. 2017, 56, 13294–13300. [Google Scholar] [CrossRef]

- Van Hessem, D.; Bosgra, O. Stochastic closed-loop model predictive control of continuous nonlinear chemical processes. J. Process. Control 2006, 16, 225–241. [Google Scholar] [CrossRef]

- Hanakuma, Y. Present Status and Future Tasks of Nonlinear Process Modeling for Control System Design in the Chemical Process Industry. Kagaku 1998, 24, 357–364. [Google Scholar] [CrossRef] [Green Version]

- Lakota, A. Hydrodynamics and Mass Transfer Characteristics of Trickle-Bed Reactors. Ph.D. Thesis, University of Ljubljana, Ljubljana, Slovenia, 1991. [Google Scholar]

- Pan, J. Failure Analysis for Cracking and Deflection Deformation of Pressure Pipe-line in Synthesis Ammonia Equipment. J. Press. Vessel Technol. 2009, 26, 23–28. [Google Scholar]

- Al-Dahhan, M.; Highfill, W. Liquid holdup measurement techniques in laboratory high pressure trickle Bed Reactors. Can. J. Chem. Eng. 1999, 77, 759–765. [Google Scholar] [CrossRef]

- Nemec, D.; Berčič, G.; Levec, J. Gravimetric Method for the Determination of Liquid Holdup in Pressurized Trickle-Bed Reactors. Ind. Eng. Chem. Res. 2001, 40, 3418–3422. [Google Scholar] [CrossRef]

- Crine, M.; Marchot, P. Measuring Dynamic Liquid Holdup in Trickle-Bed Reactors Under Actual Operating Conditions. Chem. Eng. Commun. 1981, 8, 365–371. [Google Scholar] [CrossRef]

- Doihara, R.; Shimada, T.; Cheong, K.-H.; Terao, Y. Liquid low-flow calibration rig using syringe pump and weighing tank system. Flow Meas. Instrum. 2016, 50, 90–101. [Google Scholar] [CrossRef]

- Pourmohamadian, N.; Philpott, M.; Shannon, M.A. Connection Methods for Non-Metallic, Flexible, Thin, Microchannel Heat Exchangers; Air Conditioning and Refrigeration Center, College of Engineering, University of Illinois at Urbana-Champaign: Urbana, IL, USA, 2004. [Google Scholar]

- Costin, I.; Vasilescu, S. Pipe Stress Analysis and Equipment Nozzle Loads Evaluations. Petroleum Gas University of Ploiesti Bulletin. Technol. Ser. 2012, 64, 65–68. [Google Scholar]

- Al-Dahhan, M.H.; Dudukovic, M.P. Pressure drop and liquid holdup in high pressure trickle-bed reactors. Chem. Eng. Sci 1994, 49, 5681–5698. [Google Scholar] [CrossRef]

- Yang, X.L.; Euzen, J.P.; Wild, G. Study of Liquid Retention in Fixed-bed Reactors with Upward Flow of Gas and Liquid. Int. Chem. Eng. 1993, 33, 72–84. [Google Scholar]

- Patnaik, S.N.; Hopkins, D.A. Strength of Materials; Butterworth-Heinemann: Waltham, MA, USA, 2004; pp. 129–215. [Google Scholar]

- Megson, T. Bending of Beams. In Structural and Residual Stress Analysis by Nondestructive Methods; Elsevier: Aachen, Germany, 2019; pp. 229–279. [Google Scholar]

- Neto, M.A.; Amaro, A.; Roseiro, L.; Cirne, J.; Leal, R. Engineering Computation of Structures: The Finite Element Method. In Engineering Computation of Structures: The Finite Element Method; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Barker, G.B. The Engineer’s Guide to Plant Layout and Piping Design for the Oil and Gas Industries; Gulf Professional Publishing: Oxford, UK, 2017; pp. 473–499. [Google Scholar]

- Lin, X.; Zhang, Y.X.; Pathak, P. Finite element analysis of reinforced concrete beams at elevated temperatures. In Nonlinear Finite Element Analysis of Composite and Reinforced Concrete Beams; Woodhead Publishing: Cambridge, UK, 2020; pp. 83–100. [Google Scholar]

- Fiorillo, A.; Critello, D.C.; Pullano, S. Theory, technology and applications of piezoresistive sensors: A review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Watkins, K. Force, Load and Weight Sensors. In Sensor Technology Handbook; Wilson, J.S., Ed.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 255–269. [Google Scholar]

- Hős, C.; Bazsó, C.; Champneys, A. Model reduction of a direct spring-loaded pressure relief valve with upstream pipe. IMA J. Appl. Math. 2014, 80, 1009–1024. [Google Scholar] [CrossRef] [Green Version]

- Amaral, A.M.; Filho, F.R.C.; Vellame, L.M.; Teixeira, M.B.; Soares, F.A.; dos Santos, L.N. Uncertainty of weight measuring systems applied to weighing lysimeters. Comput. Electron. Agric. 2018, 145, 208–216. [Google Scholar] [CrossRef]

- Réti, T.; Czinege, I. Shape characterization of particles via generalized Fourier analysis. J. Microsc. 1989, 156, 15–32. [Google Scholar] [CrossRef]

- Uncertainty of Measurement—Part 3: Guide to Expression of Uncertainty in Measurement (GUM 1995); International Organization for Standardization: Geneva, Switzerland, 2008; pp. 1–3.

| Parameters | Value |

|---|---|

| Pressure/Pa | 76/81/85/91/93 |

| Steam flow rate/L∙h−1 | 0/0.3 |

| Water flow rate/g∙min−1 | 10/20/30/40/50 |

| Measurement System | Equation | R2 |

|---|---|---|

| 1 | m1= 1.0161m − 1.6190 | 0.99999 |

| 2 | m1= 1.0186m − 1.7026 | 0.99995 |

| 3 | m1= 1.0184m − 1.5185 | 0.99997 |

| 4 | m1= 1.0190m − 1.5840 | 0.99997 |

| 5 | m1= 1.0188m − 1.6723 | 0.99997 |

| Measurement% | |

|---|---|

| Absolute maximum error | 0.0012 |

| Repeatability | 0.002 |

| Hysteresis | 0.001 |

| Linearity | 0.0014 |

| Measurement System | Equation | R2 |

|---|---|---|

| Vacuum/kPa | ||

| 76 | m1 = 1.0161m − 1.6190 | 0.99997 |

| 81 | m1 = 1.0186m − 1.6719 | 0.99997 |

| 85 | m1 = 1.0175m − 1.5234 | 0.99995 |

| 91 | m1 = 1.0187m − 1.6188 | 0.99996 |

| 93 | m1 = 1.0188m − 1.7030 | 0.99997 |

| Steam flow rate/L∙h−1 | ||

| 0 | m1 = 0.9680m − 0.8627 | 0.99997 |

| 0.3 | m1 = 0.9684m − 0.7229 | 0.99997 |

| Droplet velocity/g∙min−1 | ||

| 10 | m1 = 0.9948m − 0.3563 | 0.99997 |

| 20 | m1 = 0.9769m − 0.3164 | 0.99997 |

| 30 | m1 = 0.9772m − 0.5127 | 0.99996 |

| 40 | m1 = 1.0009m − 1.1095 | 0.99995 |

| 50 | m1 = 0.9751m − 0.6632 | 0.99997 |

| Repeatability% | Hysteresis% | Linearity% | |

|---|---|---|---|

| Vacuum/kPa | |||

| 76 | 0.191 | 0.169 | 0.141 |

| 81 | 0.292 | 0.203 | 0.199 |

| 85 | 0.357 | 0.208 | 0.231 |

| 91 | 0.357 | 0.159 | 0.153 |

| 93 | 0.201 | 0.126 | 0.115 |

| Steam flow rate/L∙h−1 | |||

| 0 | 0.353 | 0.270 | 0.286 |

| 0.3 | 0.410 | 0.269 | 0.284 |

| Droplet velocity/g∙min−1 | |||

| 10 | 0.327 | - | 0.301 |

| 20 | 0.441 | - | 0.272 |

| 30 | 0.471 | - | 0.289 |

| 40 | 0.398 | - | 0.334 |

| 50 | 0.498 | - | 0.311 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, Y.; Guo, F.; Wang, Y.; Huang, Q. Influence of Piping on On-Line Continuous Weighing of Materials inside Process Equipment: Theoretical Analysis and Experimental Verification. Appl. Sci. 2021, 11, 5246. https://doi.org/10.3390/app11115246

Jing Y, Guo F, Wang Y, Huang Q. Influence of Piping on On-Line Continuous Weighing of Materials inside Process Equipment: Theoretical Analysis and Experimental Verification. Applied Sciences. 2021; 11(11):5246. https://doi.org/10.3390/app11115246

Chicago/Turabian StyleJing, Yuanlin, Feng Guo, Yiping Wang, and Qunwu Huang. 2021. "Influence of Piping on On-Line Continuous Weighing of Materials inside Process Equipment: Theoretical Analysis and Experimental Verification" Applied Sciences 11, no. 11: 5246. https://doi.org/10.3390/app11115246

APA StyleJing, Y., Guo, F., Wang, Y., & Huang, Q. (2021). Influence of Piping on On-Line Continuous Weighing of Materials inside Process Equipment: Theoretical Analysis and Experimental Verification. Applied Sciences, 11(11), 5246. https://doi.org/10.3390/app11115246