1. Introduction

In recent years, with the increasing demand for underground space, underground tunnel excavation technology has transitioned from open excavation to underground excavation and has become a research hotspot [

1,

2,

3]. Among all excavation technologies, the earth pressure balance shield (EPBs) is the most commonly used [

4]. Under different stratum conditions, specific accidents may occur in the application of EPBs, which makes it difficult to apply this method. For example, different from tunneling in clayey soil, in a sandy gravel stratum accidents, such as groundwater spew and ground collapse, may occur when EPBs is used [

5,

6,

7]. Furthermore, since Beijing, Chengdu and other cities that are vigorously developing the metro are rich in sandy pebble stratum, a new soil conditioner for highly permeable sandy gravel to prevent water spewing has become a key technology problem to be solved in underground tunnel construction and in the application of EPBs in China [

8].

To ensure the successful excavation of a tunnel in the process of EPBs, an improvement technology to obtain the “ideal soil” (low permeability, moderate compressibility, small shear strength and certain fluidity) by adding soil conditioners was proposed [

9]. Large particle size, low clay content and low cohesion lead to poor plastic paste and the high permeability of sandy gravel soils. Soil conditioners can decrease the permeability and improve the plastic paste of sandy gravel soils, and many successful cases were obtained [

10].

Considerable studies on the improvement of sandy gravel soils have been conducted by researchers. A foam agent was added to enhance the plastic paste of the soil. Peila et al. (2009) [

11] studied the effect of different ratios of foam injection on the soil slump of various non-viscous coarse-grained soils. According to the foam loss, slump and water loss, the improvement results were divided into the non-suitable, the suitable, and the borderline. Mori et al. (2018) [

12] concluded that a foam agent can effectively fill the granular soil void, reduce the friction and shear strength between soil particles and improve the plasticity of soil. In the conditioned soil, qualitative evaluation standard considers the slump to be mainly related to the foam injection ratio and water content [

13].

However, enhancing the plastic and reducing the permeability are required to prevent water spewing in water-rich sandy gravel stratum [

14,

15]. When excavating in a coarse-grained stratum, it is insufficient to obtain a satisfactory conditioning by simply adding a foam agent. Some researchers proposed polymer or bentonite slurry for reducing soil permeability [

15]. Adding polymer material to the slurry not only increases the viscosity of the liquid, but also the polymer’s long-chain structure can enhance the adhesion between the fine particles of the slurry, so that the conditioned slurry has a better sealing effect on the large-grit sand-gravel soil [

16].

During the construction of the earth pressure balance shield tunnel in the high permeability stratum, some methods have been proposed to improve its permeability by adding water-insoluble fine particle solids (such as fine sand, calcium carbonate powder, etc.) or polymer materials. Fritz (2007) [

17] added fine sand (<1 mm), vermiculite (0.7–4 mm) and a small amount of high-polymer material to the soil of high permeability, which significantly reduced the permeability. In addition, filtration problems always occur in the formation of slurry. Bosshard (2011) [

18] used slurry and high polymer to improve the high-permeability (k > 3 × 10

−3 m/s) of gravel stratum in the process of Weinberg tunnel construction. Carrieri (2006) [

19] injected a turbid liquid of calcium carbonate powder as a filler into the excavation chamber, which improved high-permeability coarse sand formation in Turin Metro Line 1. Zhao (2018) [

20] improved the viscosity of sodium bentonite by sodium carbonate and carboxymethyl cellulose sodium (CMC) and obtained S1 bentonite slurry (the ratio of bentonite, water, Na

2CO

3 and CMC is 6:1:0.042:0.056), which was successfully applied to the waterless sand-pebble stratum of Urumqi Metro Line 1.

Previous studies concluded that the polymer can increase the cohesion by filling in the voids between the gravel particles, while the bentonite slurry or filler mainly filled in voids between the fine-grained particles and forms a slurry film, consequently reducing the permeability of the stratum.

To ensure a successful tunneling by EPBs in a water-rich sandy gravel stratum, this study proposed a new soil conditioner that is capable of effectively improving the plasticity and impermeability of sand and gravel. The main objects were: (1) to study the effect of ammonium chloride as a viscosity modifier on the apparent viscosity and rheology of sodium bentonite slurry; (2) to study the improvement effect of modified slurry on the plasticity of non-cohesive sand and gravel; and (3) to study the impermeability improvement of sandy gravel conditioned by sodium silicate solution, high molecular polymers and modified slurry.

2. Materials and Methods

2.1. The Modified Slurry Modifier Components

The traditional slurry is commonly the aqueous solution of sodium bentonite with 10–18 wt%. The preparation method added the weighted sodium bentonite powder to distilled water several times. It should be noted that the incorporation quality of sodium bentonite was less than 5 g to avoid an uneven blend and the solution was stirred at 1000 r/min.

In this study, ammonium chloride, sodium silicate and high molecular polymers were mixed into the traditional slurry to modify and improve it, in which ammonium chloride was the viscosity modifier to adjust the reaction time. In order to distinguish the traditional slurry, the mixed solution of modifier and slurry was called modified slurry. In addition, high molecular polymers were helpful for enhancing the impermeability of the mixed system.

In this study, the modified slurry preparation process mainly included two mixed solution systems, namely, the mixed solution of bentonite and sodium silicate as well as the mixed solution of ammonium chloride and high polymers. The sodium bentonite (Henan Zhongyuan Mining Company, Henan Province, China) chemical components and physical characteristics are shown in

Table 1 and

Table 2. Ammonium chloride (Beijing Chemical Reagent Factory, Beijing, China) formed the viscosity modifier for modified materials. The ammonium chloride was analytically pure (>99%), the sodium silicate solution (Shandong Dongyue Group, Shandong Province, China) had a Baume Degree of 40, and the content was 34 wt%. There were 6 kinds of polymers. They are carbomer (97%, Sumitomo Chemical Co., Ltd., Tokyo, Japan), guar gum (99%, Guangzhou Feirui Chemical Co., Ltd. Company, Guangzhou, China), xanthan gum (99%, Fufeng Group, Jinan, China), carboxymethyl cellulose sodium (99%, Yixing Tongda Chemical Co., Ltd., Yixing, China), hydroxyethyl cellulose (99%, Shanghai Huiguang Fine Chemical Co., Ltd., Shanghai, China) and polyacrylamide (99%, Shandong Baomo Biochemical Co., Ltd., Dongying, China). Details of the components are shown in

Table 3. Code B represents a solution of 13 wt% bentonite, other codes have similar meanings, and the solvent was water. In the process of polymer solution preparation, it should be noted that the weighed reagent was slowly added into the 50–60 °C distilled water and then the solution was stirred at 2000 r/min for more than 30 min until the solution was clear.

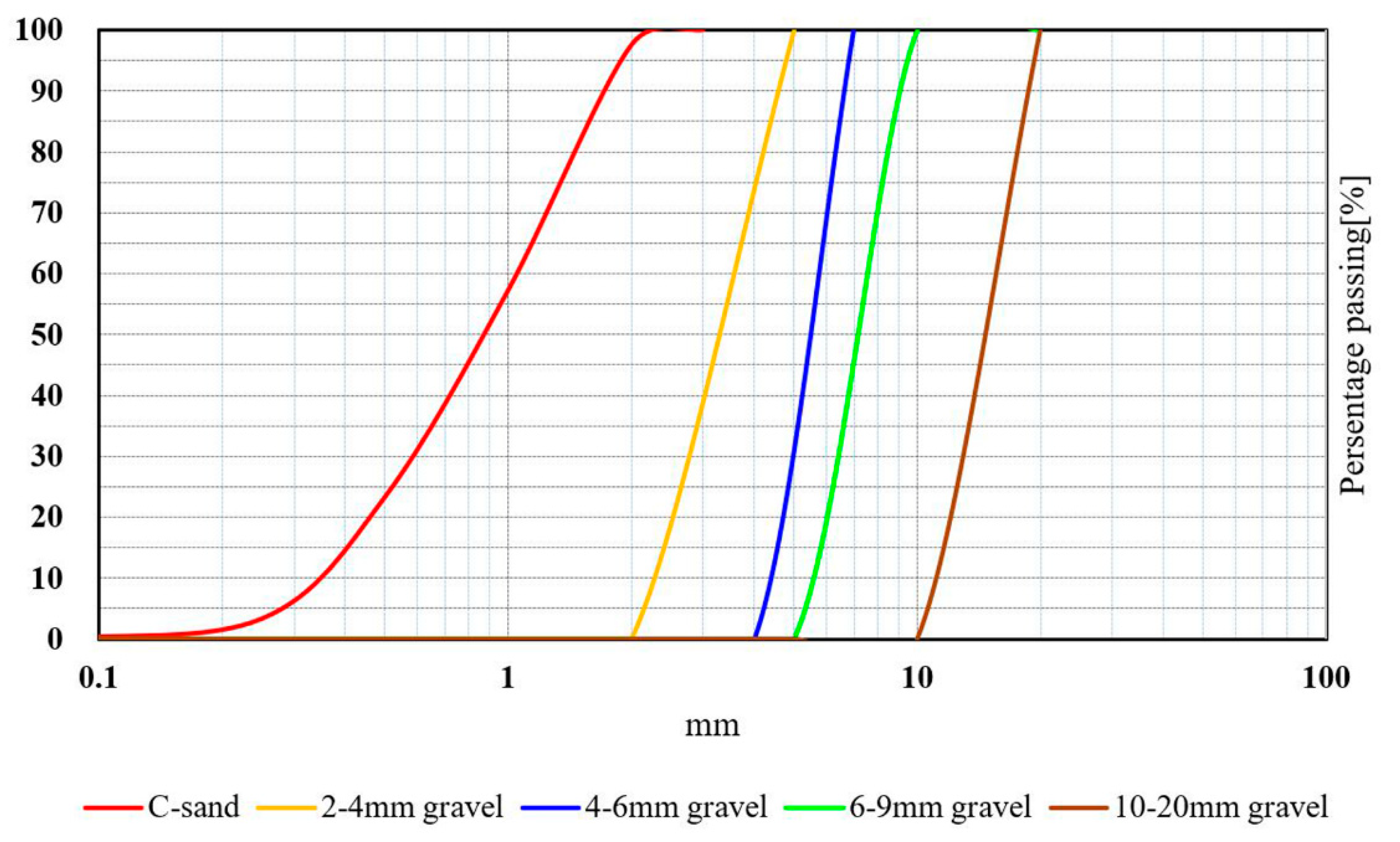

Four different grades of sandy gravel soil samples were prepared in the laboratory, in which the coarse sand was selected from standard sand, the main mineral component was quartz, and the gravel was a natural breccia-like cobblestone whose main mineral composition was quartz and carbonate minerals. The gradation curve and dry density information are shown in

Figure 1 and

Table 4.

2.2. Slurries Conditioner Preparation

Modified slurry is a mixed material prepared by adding ammonium chloride, sodium silicate and high molecular polymer into traditional slurry. In the preparation process of the modified slurry, the traditional slurry and each modifier solution were separately configured. Before the relevant tests, the solutions were mixed according to the experimental design ratio, and then stirred evenly with a glass rod.

In engineering applications, all fluid materials (such as slurry, foam, polymers solution, etc.) must be pumped into the excavation chamber, which consequently requires the materials to have good fluidity. On the one hand, the high apparent viscosity and non-flowing state of the modified slurry are the key to improving the plasticity and water blocking of sand and gravel soil. On the other hand, the fluidity of the slurry is a prerequisite for actual engineering use. Based on that, the traditional slurry and modifier solution involved in this article need fluid composition with good fluidity to ensure that the material can be easily pumped into the excavation cabin to mix and react to form a modified slurry.

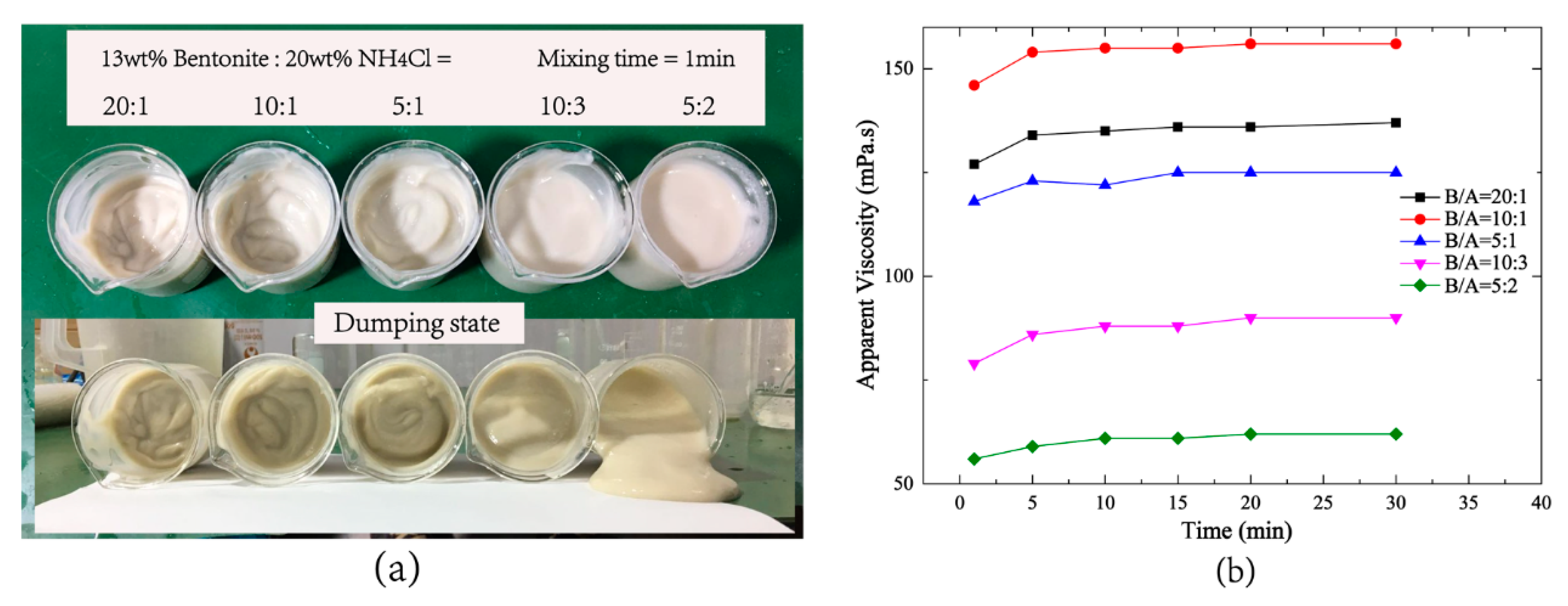

In this study, the main objective was to obtain the traditional slurry with moderate apparent viscosity, good time stability and fluidity. The apparent viscosity of traditional slurry samples with four bentonite concentrations (i.e., 10 wt%, 13 wt%, 15 wt% and 18 wt%) over time (0–50 h) are measured. The dumping method was used to compare with and analyze the slurry flow corresponding to different apparent viscosity values, and then the fluidity of each experimental group was evaluated. Afterwards, the optimal bentonite concentration was obtained. In order to study the apparent viscosity and fluidity of the mixed system after adding ammonium chloride solution to the traditional slurry, the experimental goals were to obtain the modified slurry with high apparent viscosity and low fluidity. In this study, five ratios of bentonite slurry and ammonium chloride solution were selected (B:A = 20:1, 10:1, 5: 1, 10: 3 and 5:2).

To study the effect of ammonium chloride on the water absorption time of bentonite slurry, six modifiers were prepared with different ammonium chloride concentrations, one modifier was used (i.e., Ammonium Chloride) but in six different ratios, one containing no ammonium chloride as a control. At this stage, no further additive was included in the mixture. The details are shown in

Table 5. The preparation process was as follows: a certain amount of water was added to the beaker, then bentonite with 13 wt% was added slowly to the beaker and the solution was stirred for another 30 min until there were no lumps on the surface and no sediment at the bottom of the solution (note that, through the process, the stir rate of the magnetic stirrer was 1500 r/m)). According to the solution dissolution efficiency and the experiment results, the optimum dissolved concentration of ammonium chloride was 20 wt%. In this study, the slurry solution was mainly composed of bentonite (B) and ammonium chloride (A), which is called B/A modified slurry. B/A refers to the mixture mainly formed by B and A.

In addition, to study the influence of sodium silicate concentration and polymers types on the impermeability improvement degree of soil, the conditioners containing different concentrations of sodium silicate and different types of polymers were prepared.

2.3. Analysis Method

2.3.1. Apparent Viscosity Test

The concentration and hydration time of bentonite play the key roles in affecting the fluidity of traditional slurry. Traditional slurry is the basic composition of modified slurry. The main targets for optimizing the composition of the traditional slurry are to be equipped with higher viscosity value, better viscosity stability and fluidity.

Apparent viscosity (i.e., effective viscosity) is an important parameter that characterizes fluid flow performance and can be used as an evaluation index for fluid pumping performance. The apparent viscosities of the conditioners prepared were tested by a ZNN-D6 six-speed rotational viscometer [

21]. In this study, the apparent viscosity values of the slurry samples were measured after the samples prepared 5–20 min. The test procedure was as follows: (1) the cup of the sample (350 mL) was placed on a tray that subsequently was elevated until the scale line outside the rotary sleeve was completely immersed in the sample; (2) stable readings at 600 r/m, 300 r/m, 200 r/m, 100 r/m, 6 r/m and 3 r/m were recorded. Steps (1) and (2) were repeated twice. The interval time of each experiment should not exceed 2 min. Half of the average value of three readings at a rate of 600 r/m is the apparent viscosity.

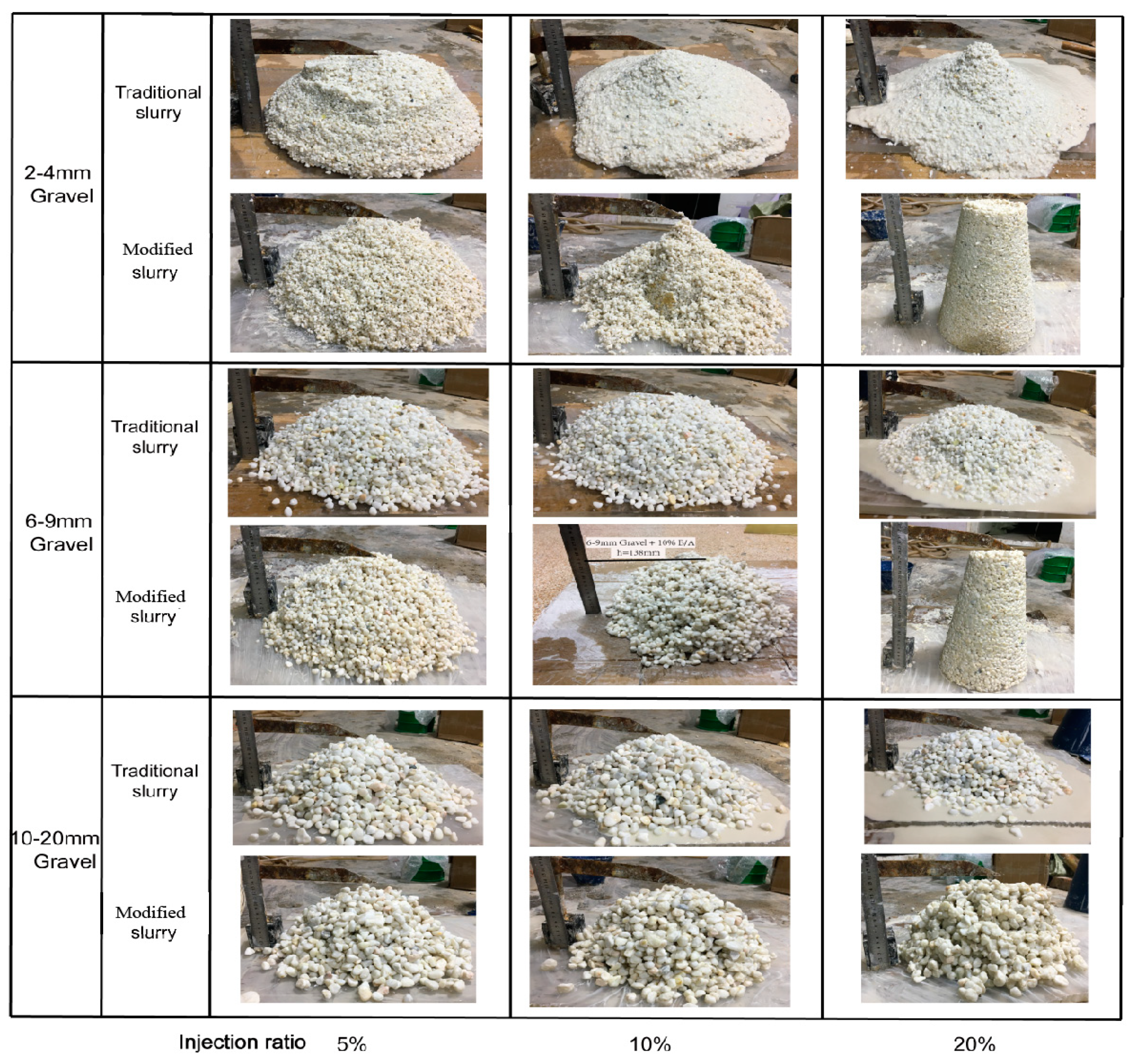

2.3.2. Slump Test

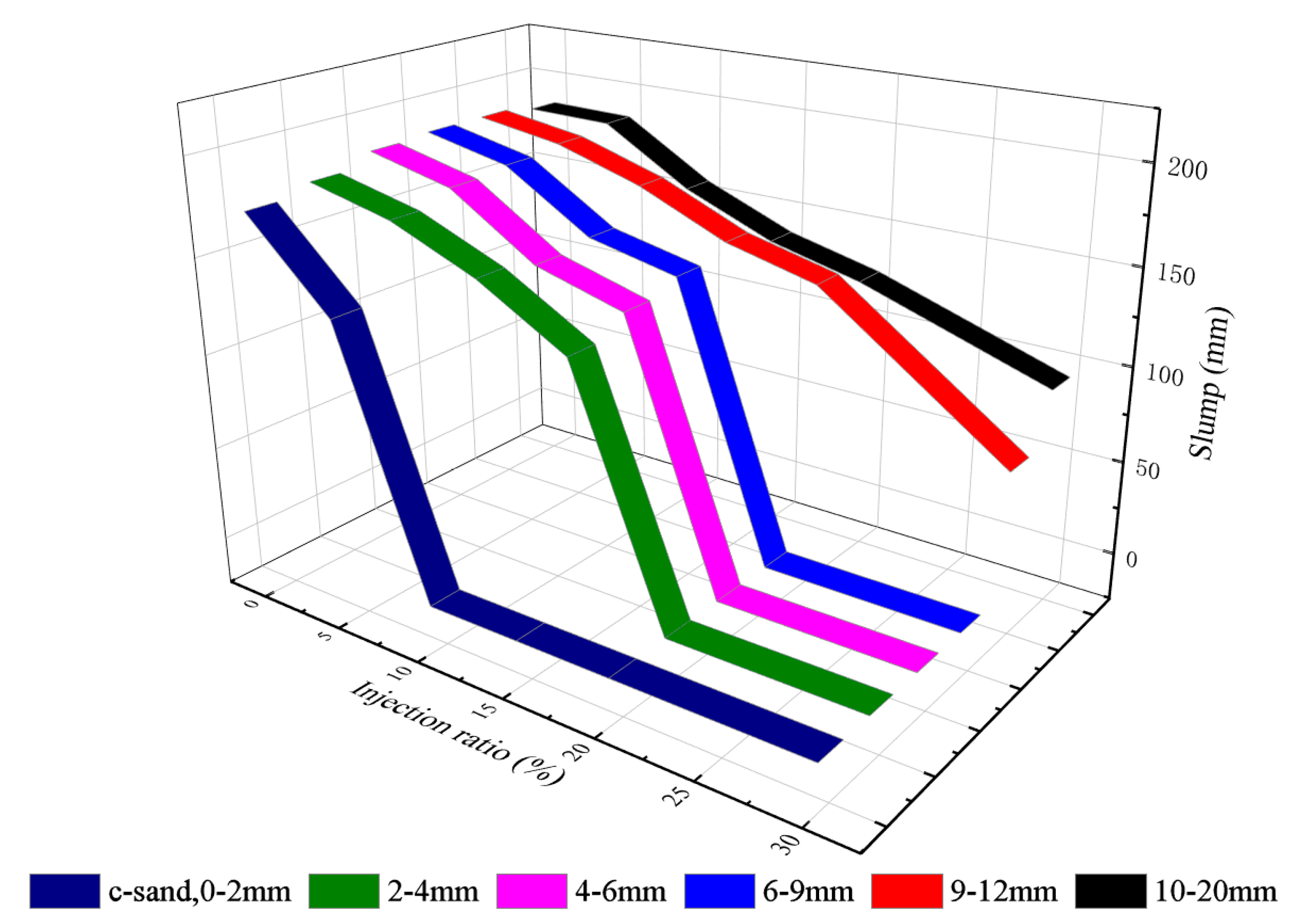

Slump test is a commonly used method to evaluate the effect of soil flow plasticity improvement during the construction of the earth pressure balance shield. Based on the results of the traditional slurry and the ammonium chloride optimization experiments, in order to compare with and analyze the plasticity improvement effects of traditional slurry and modified slurry on soil flow, the effects of the traditional slurry and ammonium chloride modified on the slump of six soil samples were studied. The flow plasticity of the improved soil is classified according to its slump value. Combining with the improvement of the goal of sand and gravel soil in actual engineering, the reasonable flow plasticity state of sand and gravel are discussed in this study.

In this study, the slump test was adopted to evaluate the flow plasticity of conditioned soil by modified slurry. Before the slump test, the soil samples (6 L) and the modified slurry were mixed with different experimental ratio (5%, 10%, 15%, 20%, 25% and 30%) and stirred with a mixer for 3 min. According to the slump test standard [

22], the test procedure was as follows: (1) the conditioned soil samples were loaded into the slumping cylinder three times until the cylinder was full, with 25 instances of tamping at each load, so that the thickness of each layer was approximately one third of the cylinder height; (2) the cylinder was elevated vertically and smoothly (within 5–20 s). The height difference s1 (before and after the test) was recorded, and the test was repeated two more times to obtain s2 and s3, respectively. The average value of the three slump tests is the result. In addition, the slump experiment was completed after the slurry samples had been prepared for no more than 20 min.

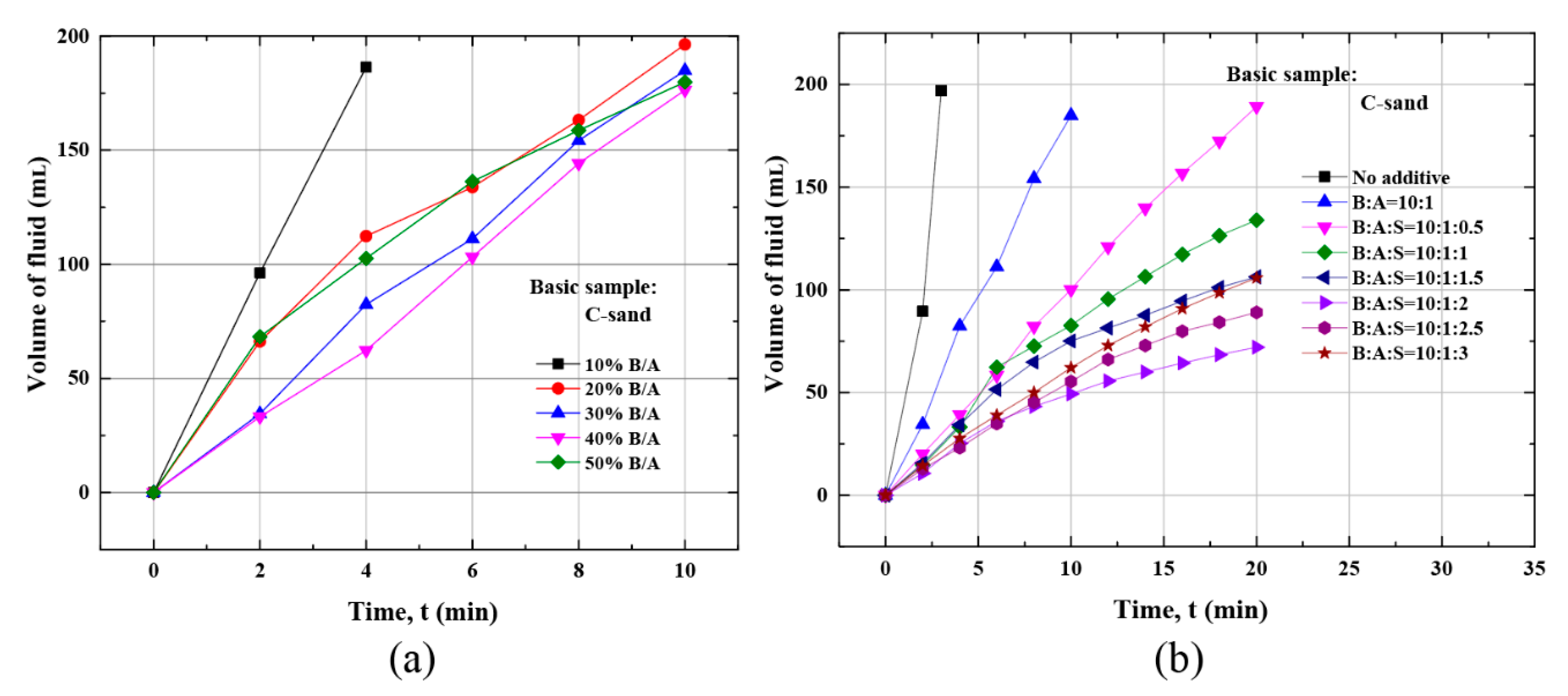

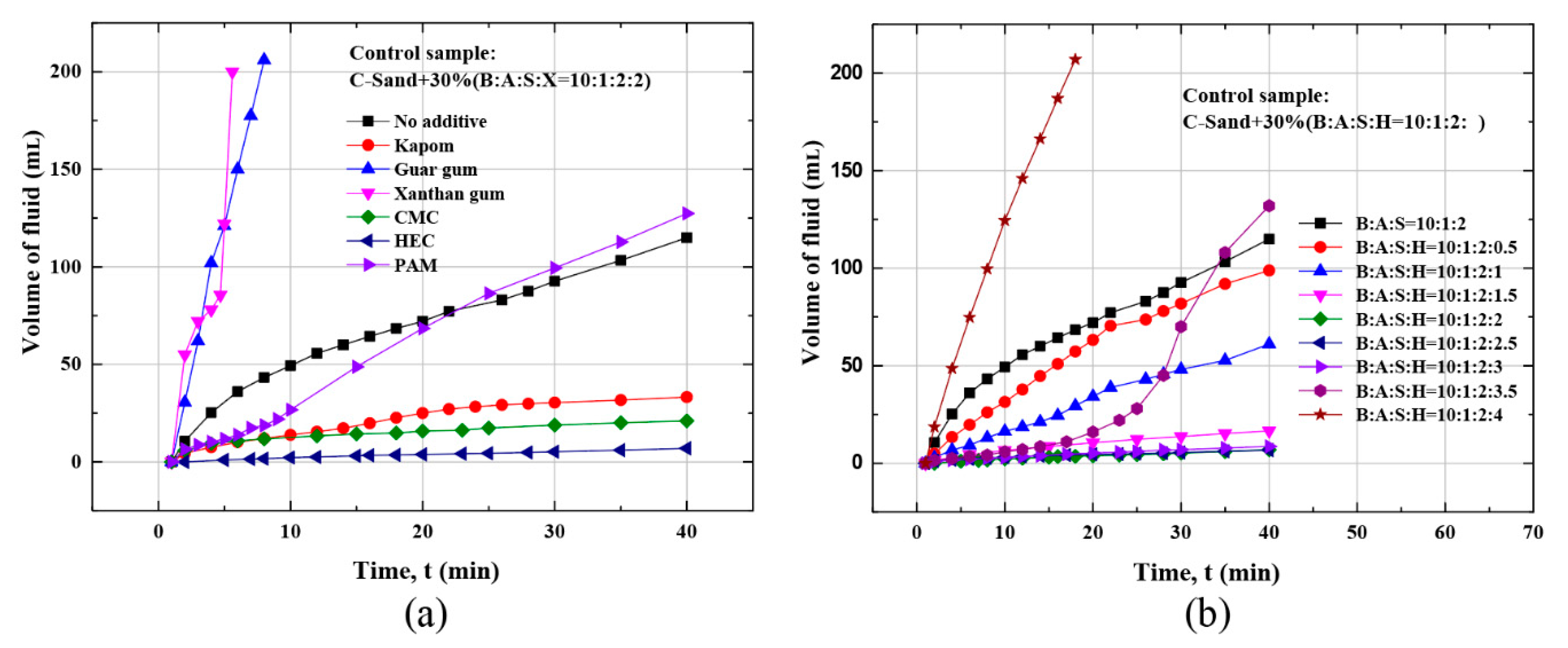

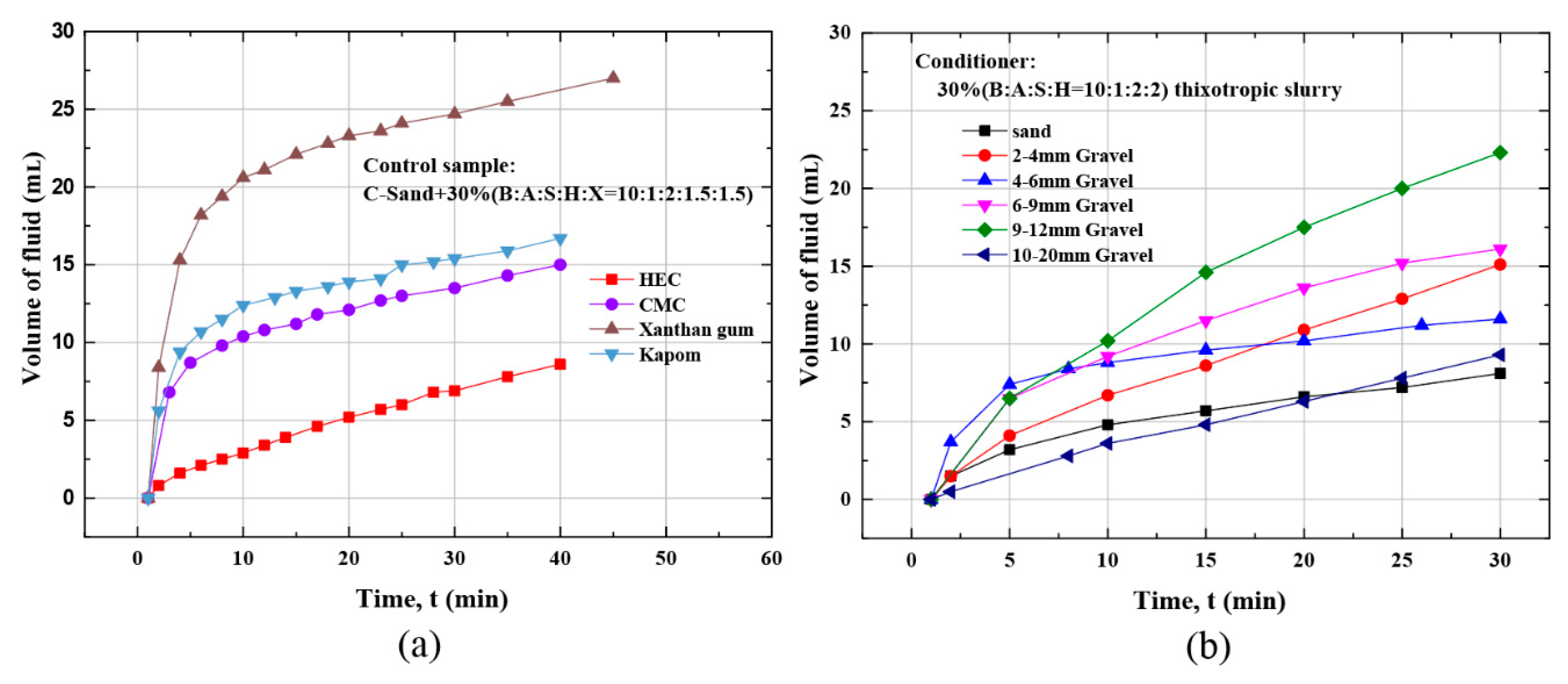

2.3.3. Permeability Test

Based on the apparent viscosity and slump test, decreasing the permeability of soil sample plays the key role in preventing the spewing problem of the screw machine in the excavation process of the earth pressure balance shield on the sand and gravel ground. In order to find a slurry additive material and a better ratio decrease to reduce the permeability of the slurry-soil mixture, a large number of experiments show that the permeability of mixing system is decreased with the sodium silicate solution or polymers solution is added into the traditional slurry-ammonium chloride mixing system. It is mainly caused by the fact that the silicate ions ionized by the sodium silicate solution can not only react with the calcium and magnesium ions in the slurry to form calcium silicate, magnesium silicate and other water-insoluble fine particles, but also react with chlorination the ammonium ion in the ammonium solution to produce water-insoluble silicic acid. The formation of insoluble matter, such as silicic acid, magnesium silicate and calcium silicate can increase the water-insoluble fine particulate matter in the slurry mixing system to reduce the permeability of the mixing system. Due to the special long-chain molecular structure of the polymer, the integrity of the bentonite particles was increased at the microscopic level, thereby improving the water blocking ability of the slurry.

Based on the experimental phenomena, the types and ratios of sodium silicate solution and polymer solution were optimized. This study investigated the change curve of the penetration rate and time of the slurry-soil mixed system when sodium silicate solution and polymer materials are used as slurry additives. Taking the minimum permeation amount of the mixing system per unit time as the preferred index, the ratio of sodium and sodium silicate solution and the type and ratio of polymer materials are optimized, respectively.

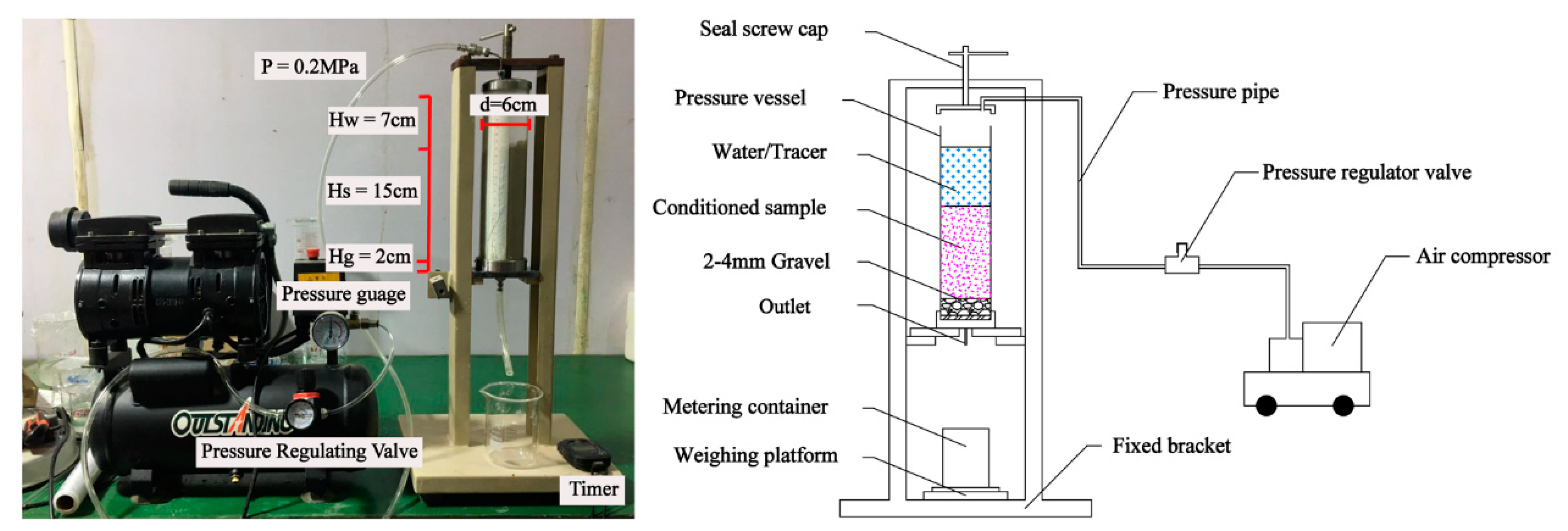

A permeability test device was developed, which mainly consists of a sealing cover, rubber pad, pressure-maintaining vessel, metal filter, high-pressure gas pipe, pressure regulator valve, air compressor, metering container, and electronic weighing platform (see

Figure 2). The pressure maintaining vessel is made of pressure-resistant acrylic material, and the cylinder is 260 mm high, 70 mm in diameter, 5 mm in wall thickness and 60 mm in inner diameter. The pressure vessel was designed to withstand a pressure of 5 bar.

The test procedure was as follows: (1) a gravel (2–4 mm) permeable layer was placed at the bottom of the pressure-maintaining vessel, and subsequently the conditioned soil sample was packed into the vessel until it was 15 cm in height. The sample was loaded every 2–3 cm of height with compaction; (2) 200 mL of water was poured into the vessel, which was subsequently sealed up; (3) The pressure was adjusted to 2 bar; (4) The pressure regulator valve was opened and timed at the same time; and (5) the water seepage volume was recorded every 1 min. When the water seepage volume was greater than 200 mL or the test time was greater than 30 min, the experiment was stopped and the pressure was relieved.

4. Conclusions

When EPB is used in the excavation of full-face water-rich sandy pebble stratum with high permeability, applying traditional conditioner may be insufficient, which will lead to accidents such as the spewing of the screw machine and ground collapse. In view of it, a new conditioner, modified slurry, was proposed in this paper. Modified slurry was prepared by using ammonium chloride as a viscosity modifier and sodium silicate solution and polymer as water shutoff agents. Two main aspects were studied: (1) viscosity modifier effect of modified slurry conditioner’s performance on the plasticity of sandy gravel soils with different particle sizes; (2) the effect of concentration and type of water shutoff agent on the improvement of conditioned soil impermeability.

Ammonium chloride can act as the viscosity modifier of traditional slurry and instantaneously increased the apparent viscosity of traditional slurry. The developed new modified slurry has an effect on improving the plasticity of sandy gravel soils. Sodium silicate and high-molecular polymer as the main water shutoff agents for modified slurry greatly enhanced the impermeability of conditioned samples. The optimum slurry is composed of B:A:S:H = 10:1:2:2 and its suggested injection ratio is 30%.

In addition, the suggested field application method is, separately, the injection of B, A, S and H (A and H should better be premixed) at the ratio of 10:1:2:2 into the excavation chamber through the slurry pipelines. After stirring through the cutterhead, these components react rapidly to form a modified slurry, which will consequently increase the plasticity and impermeability of the conditioned soils.