Two-Phase Flow Simulations Using 1D Centerline-Based C- and U-Shaped Pipe Meshes

Abstract

1. Introduction

2. Numerical Methods

2.1. Governing Equations

2.2. Turbulence Model

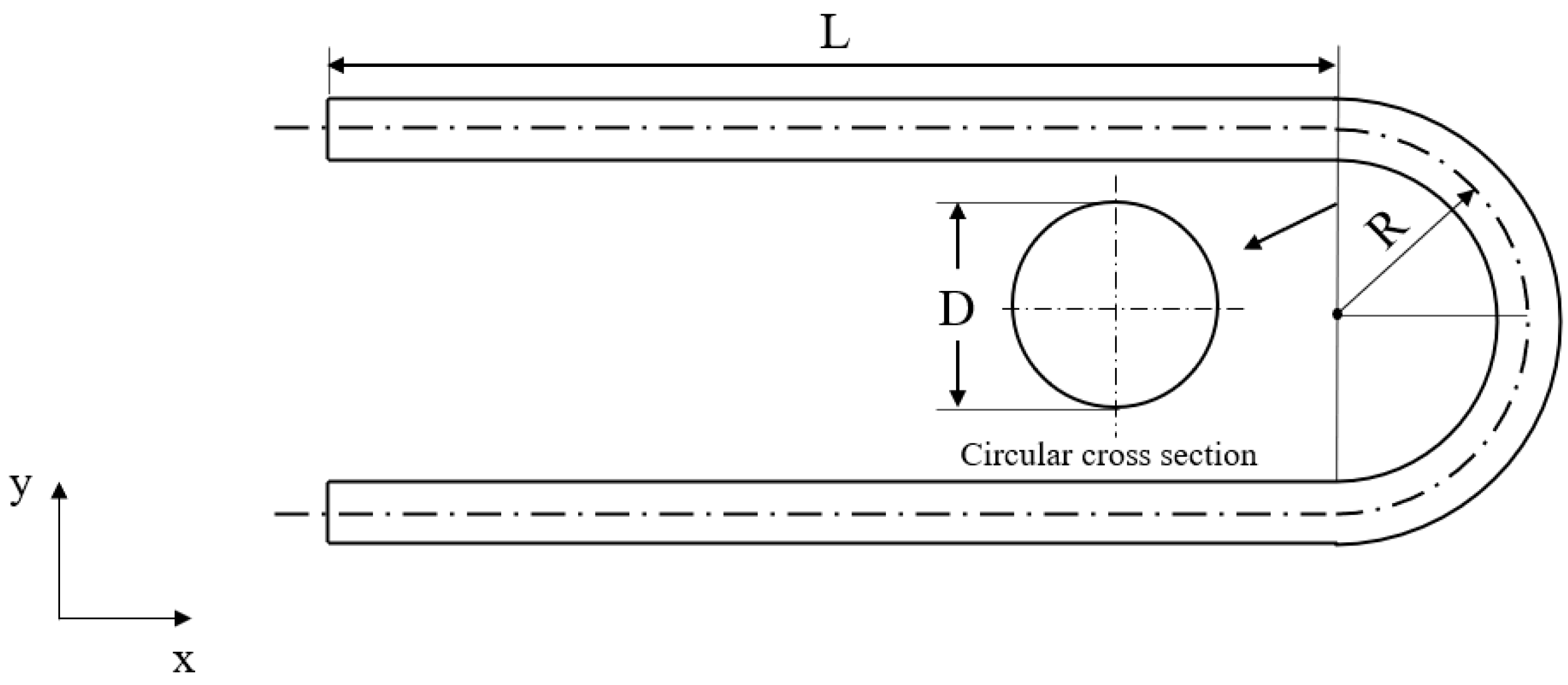

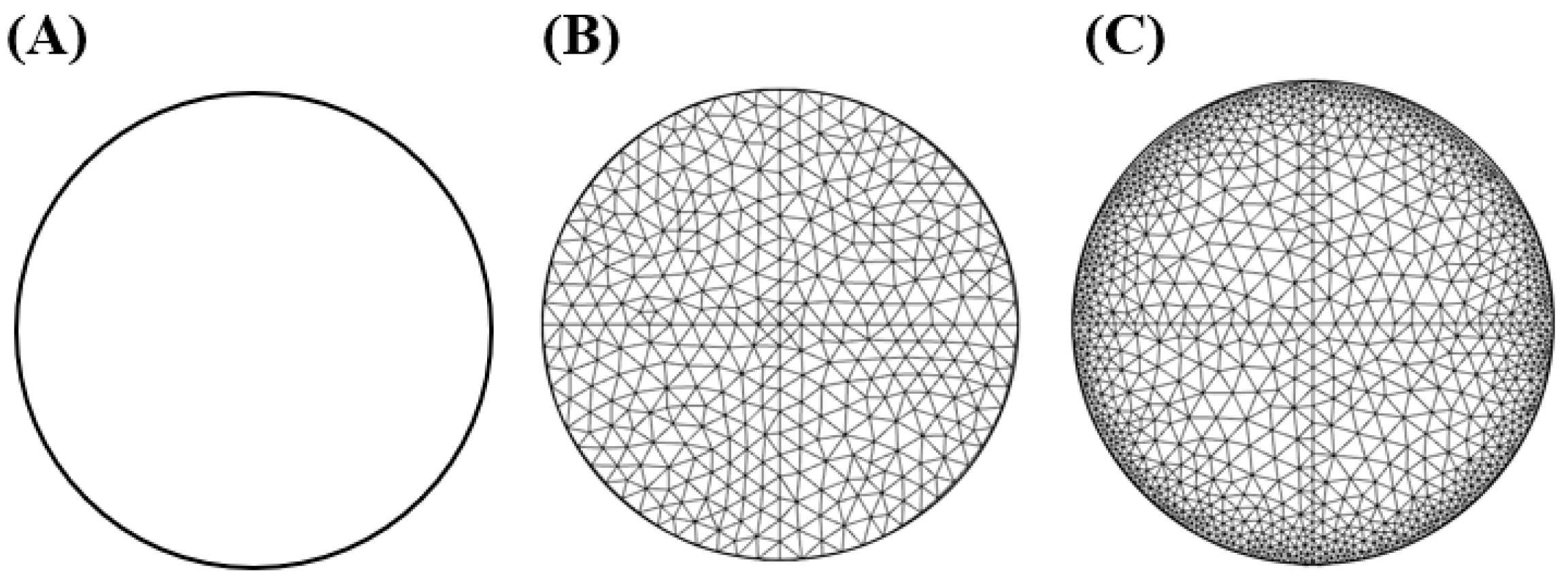

2.3. Mesh Generation

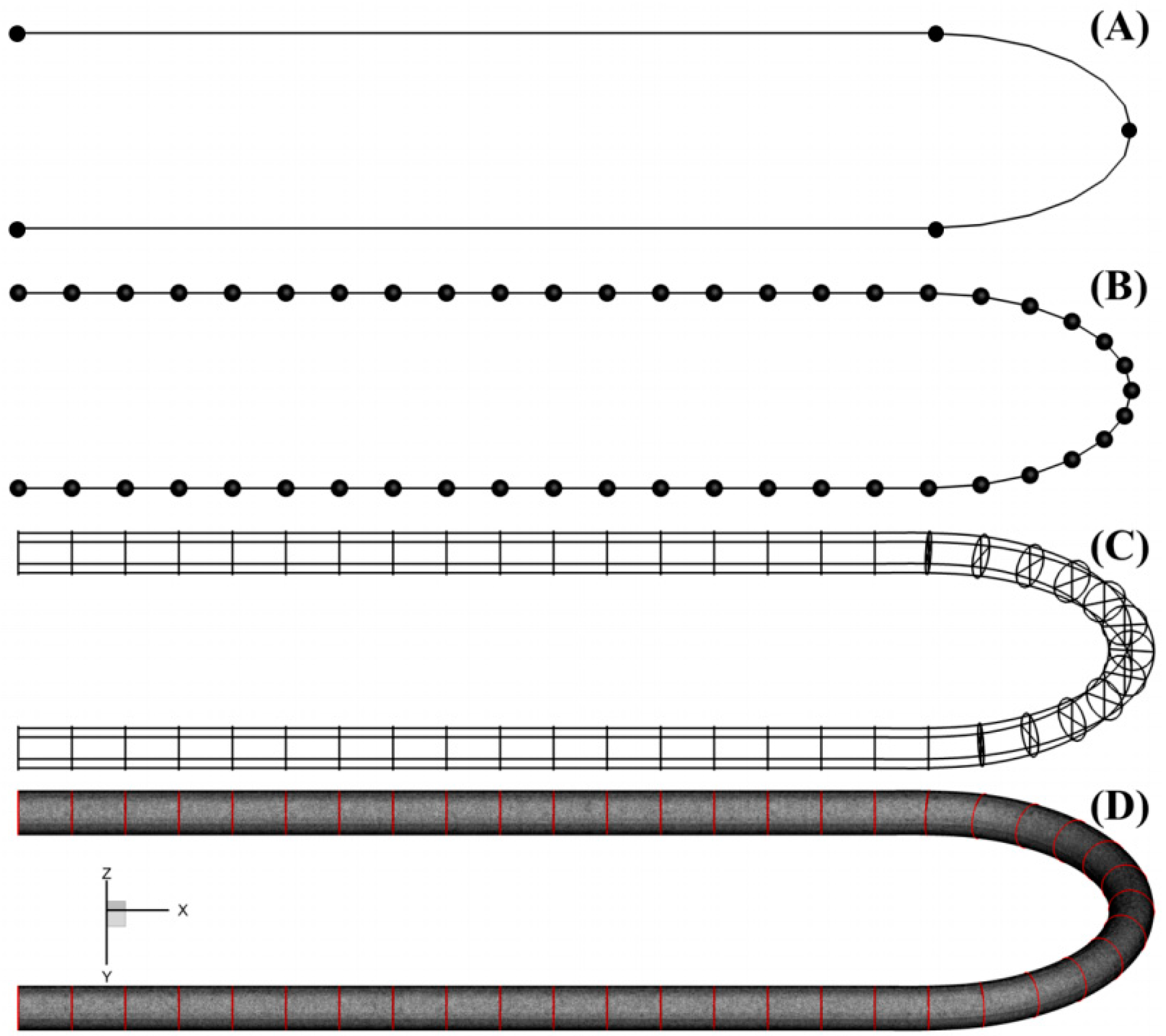

- Sweep the centerline (Figure 2A) to create the geometry. The linear and curve lines are written at the output file as the start and end points of each line, where the curve line additionally has the center point of the arc.

- Divide the 1D centerline into several linear lines (Figure 2B) using the Python programming language. Each line contains information of the cross-section radius and the divided line length; thus, we use the radius–length ratio to set the number of divided parts.

- Generate the last output before applying the meshing algorithm (Figure 2C).

2.4. Benchmark Case

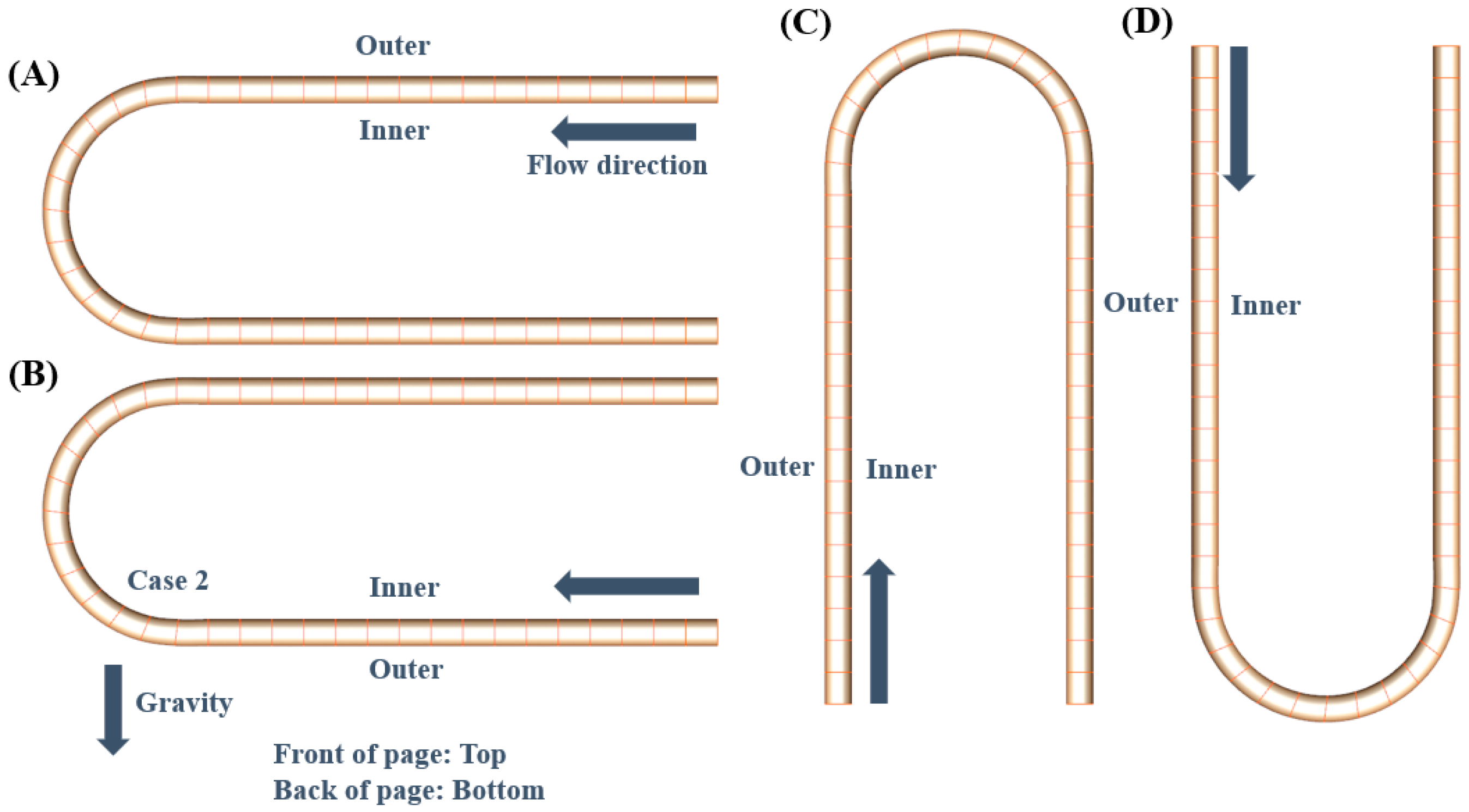

2.5. Four Different Gravity Cases

3. Results and Discussion

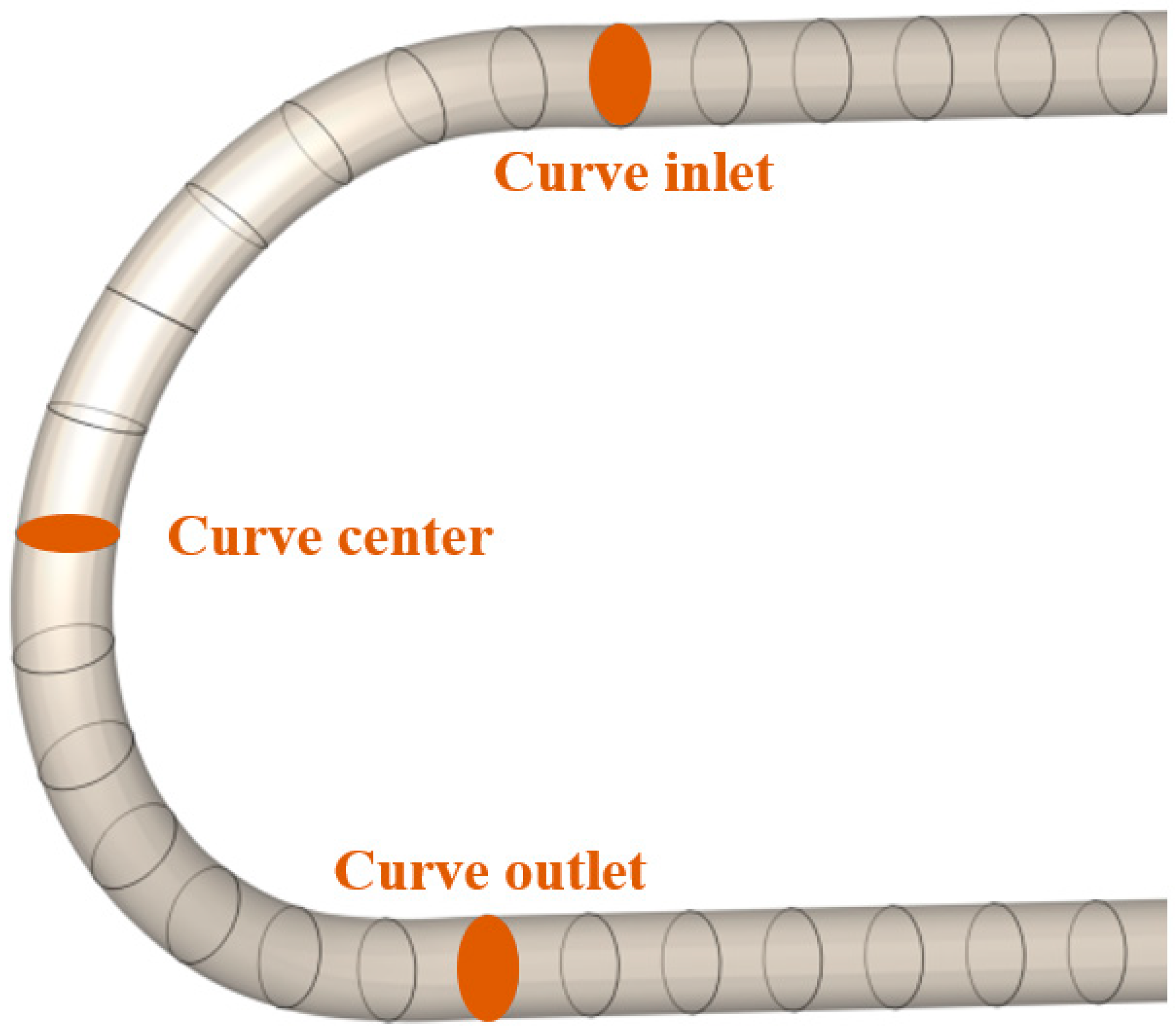

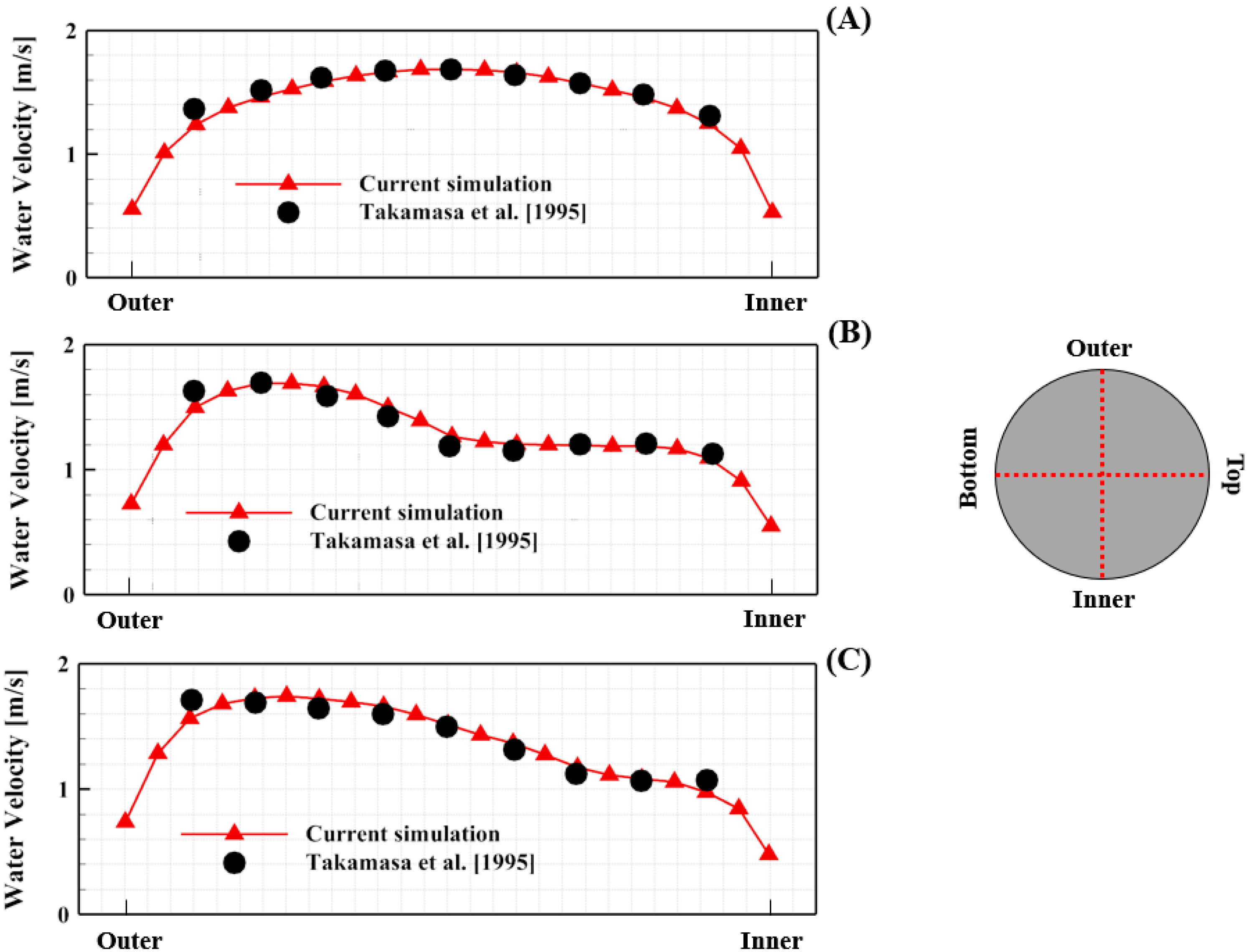

3.1. Benchmark Results

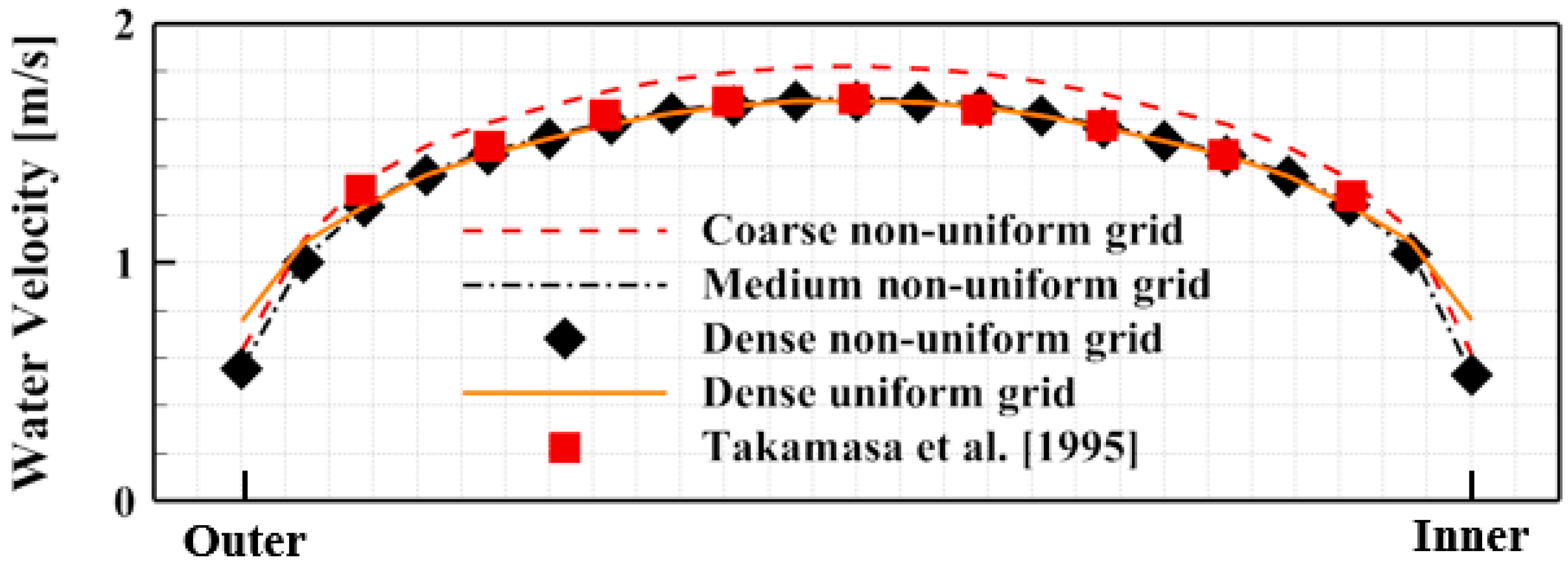

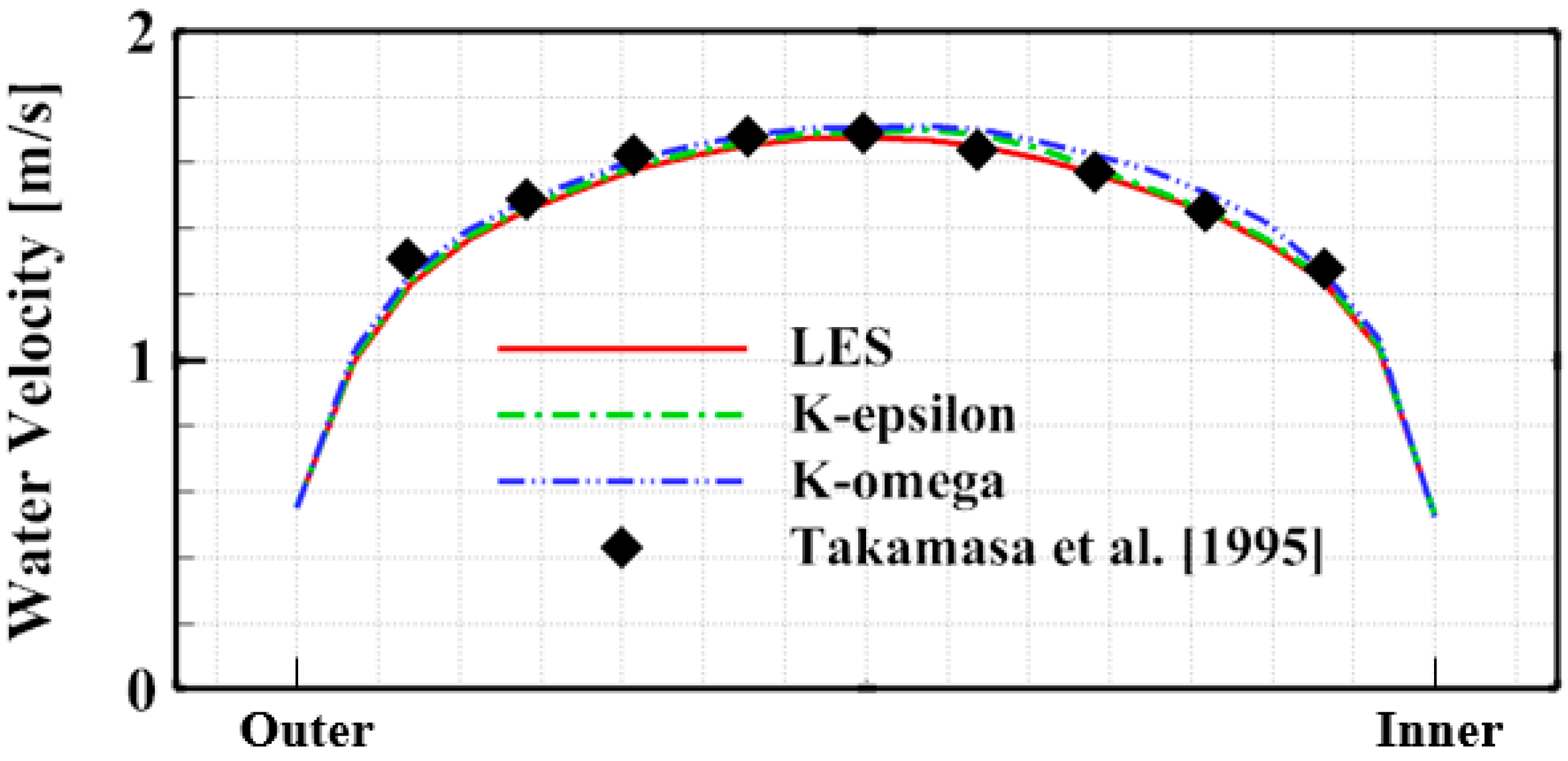

3.2. Grid Convergence Test and Sensitivity Analysis of Turbulence Model

3.3. Velocity and Pressure Distributions Depending on Four Gravitational Directions

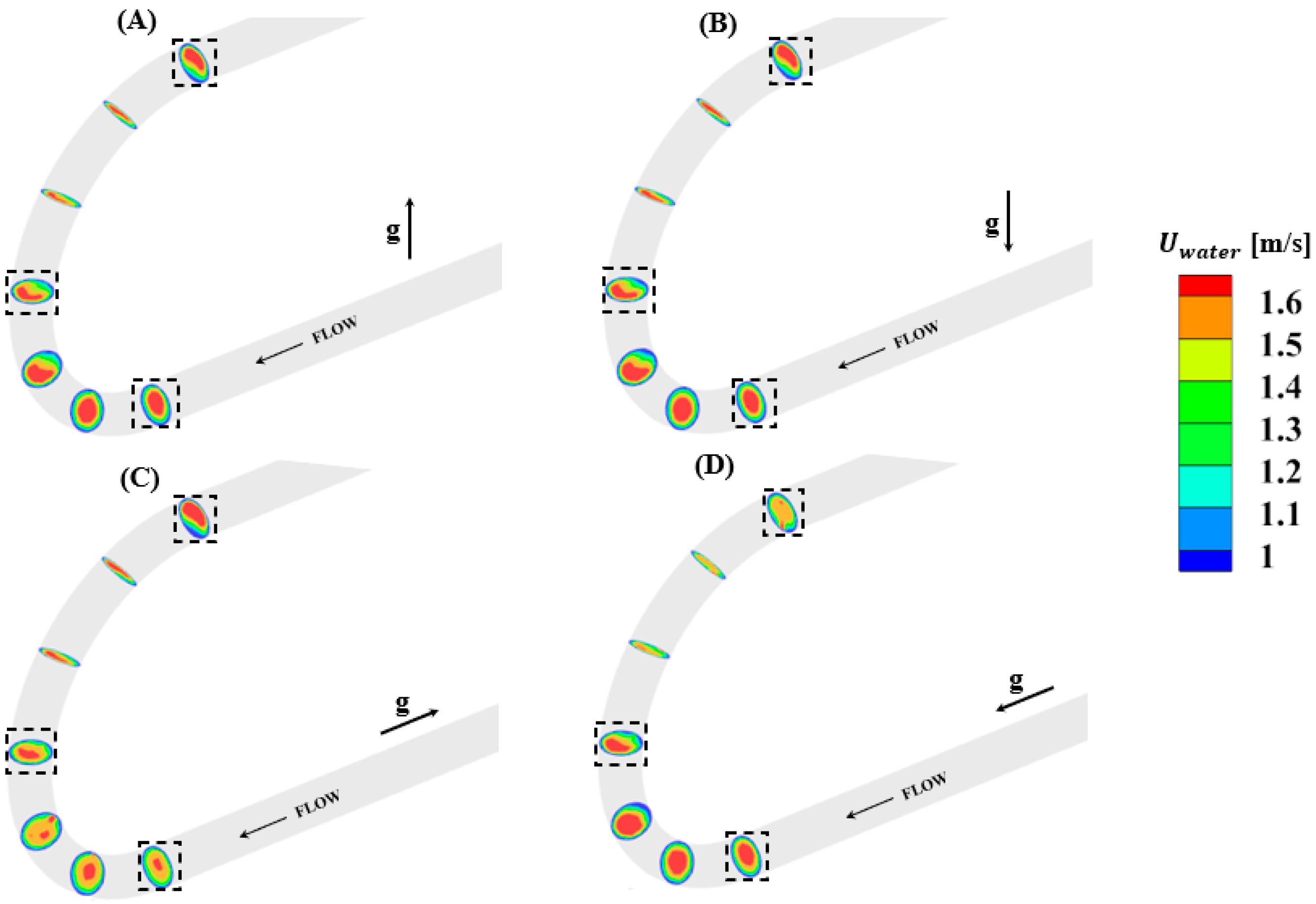

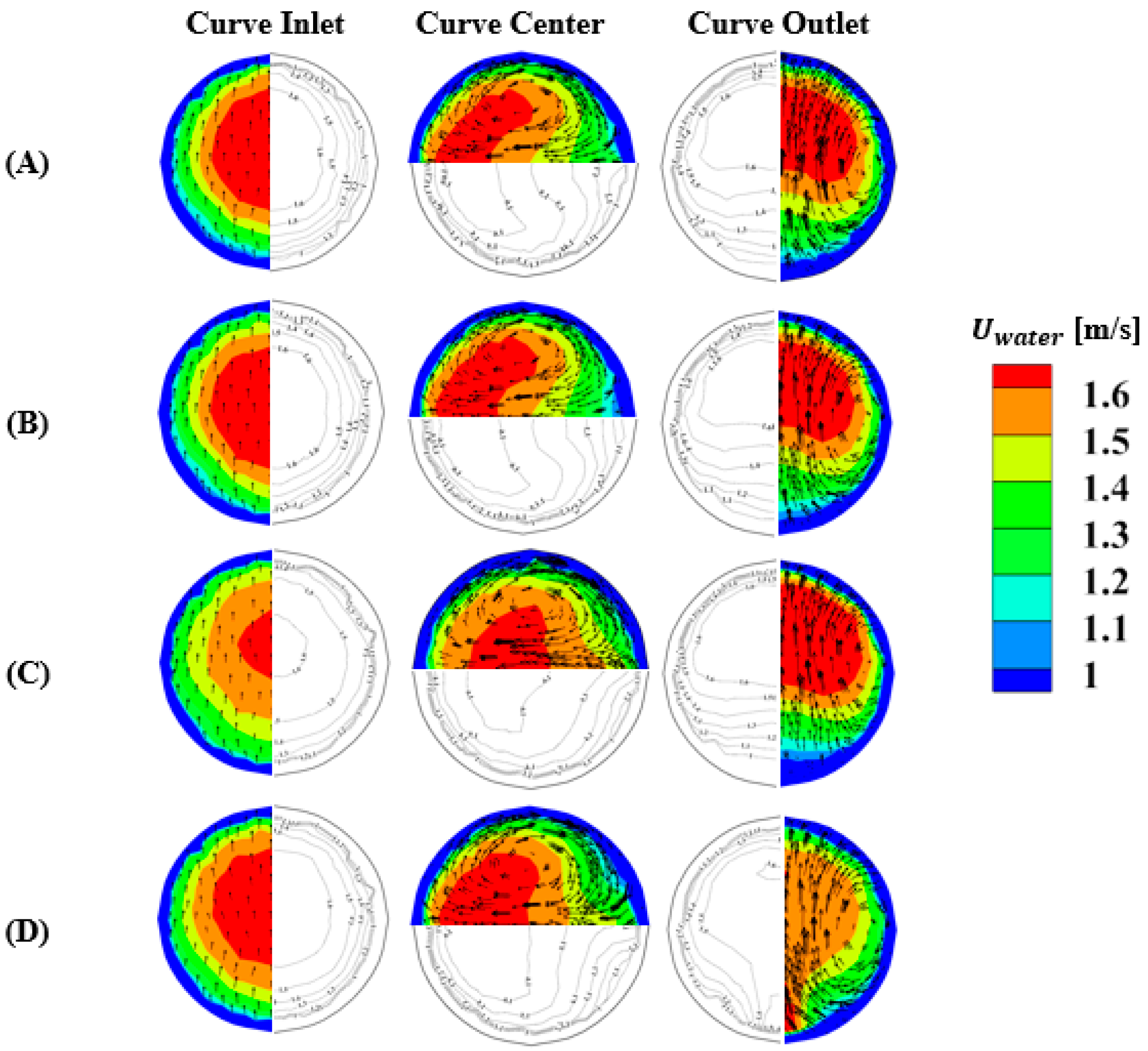

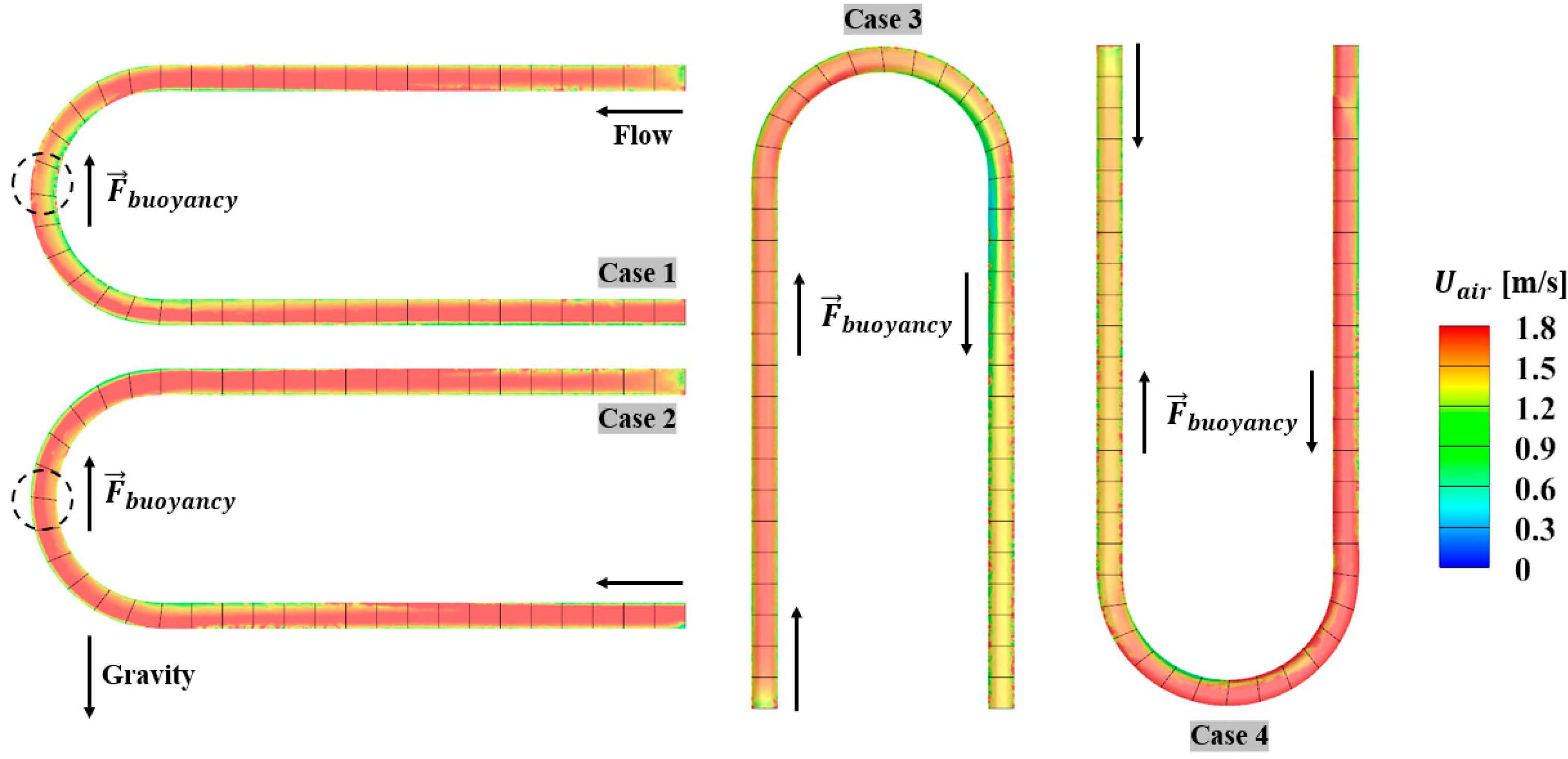

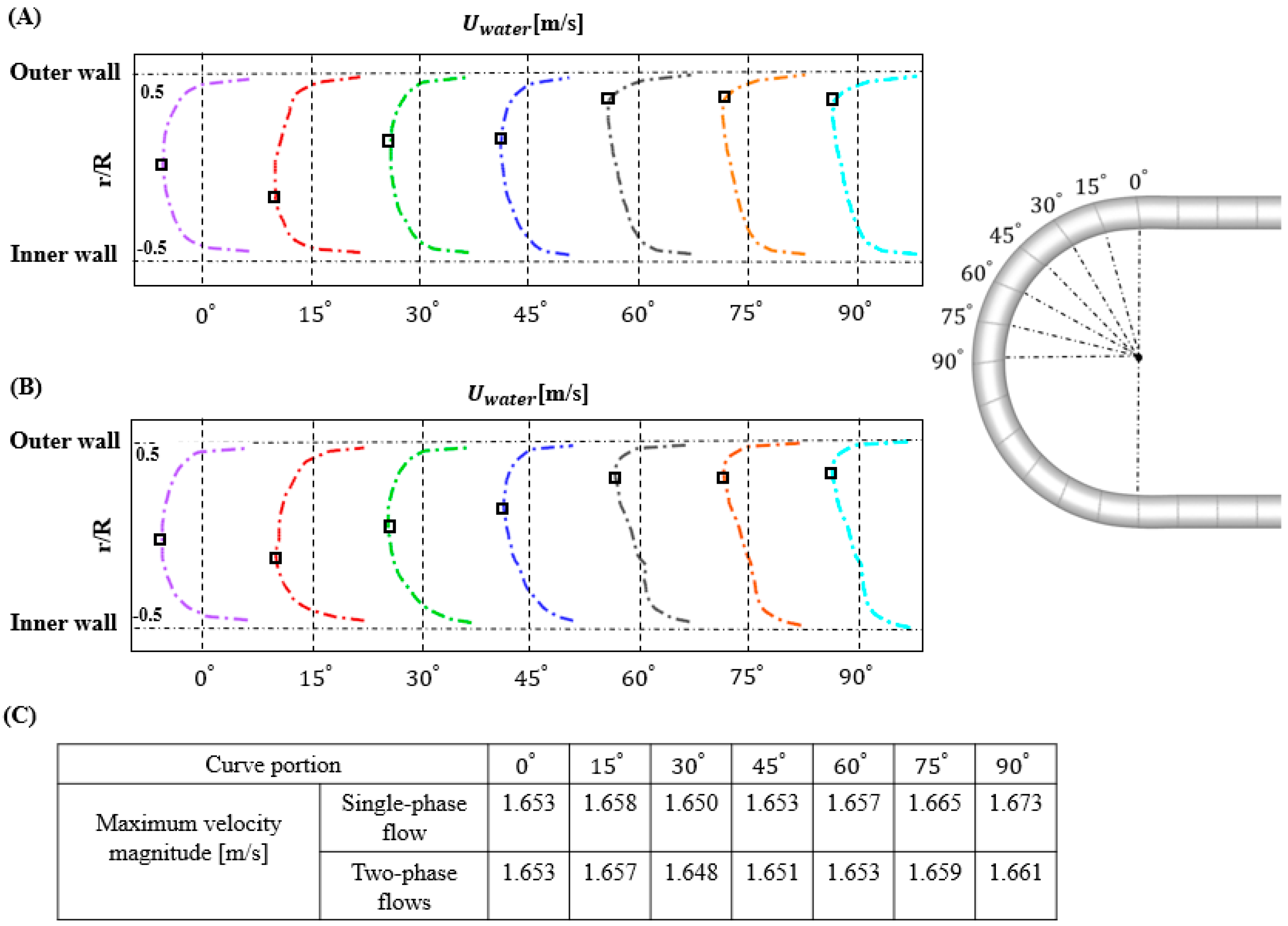

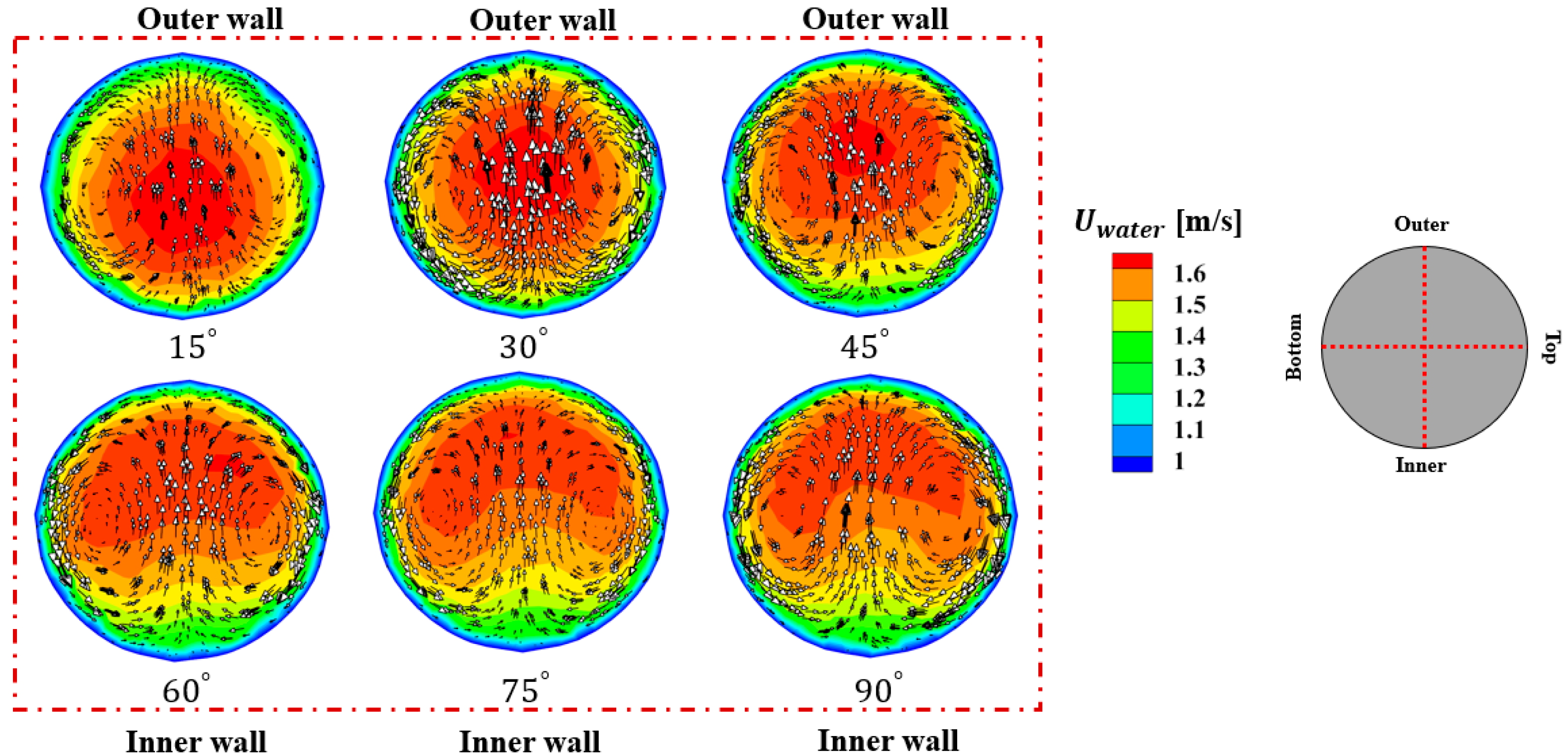

3.3.1. Water and Air Velocity Distributions of Two-Phase Flows

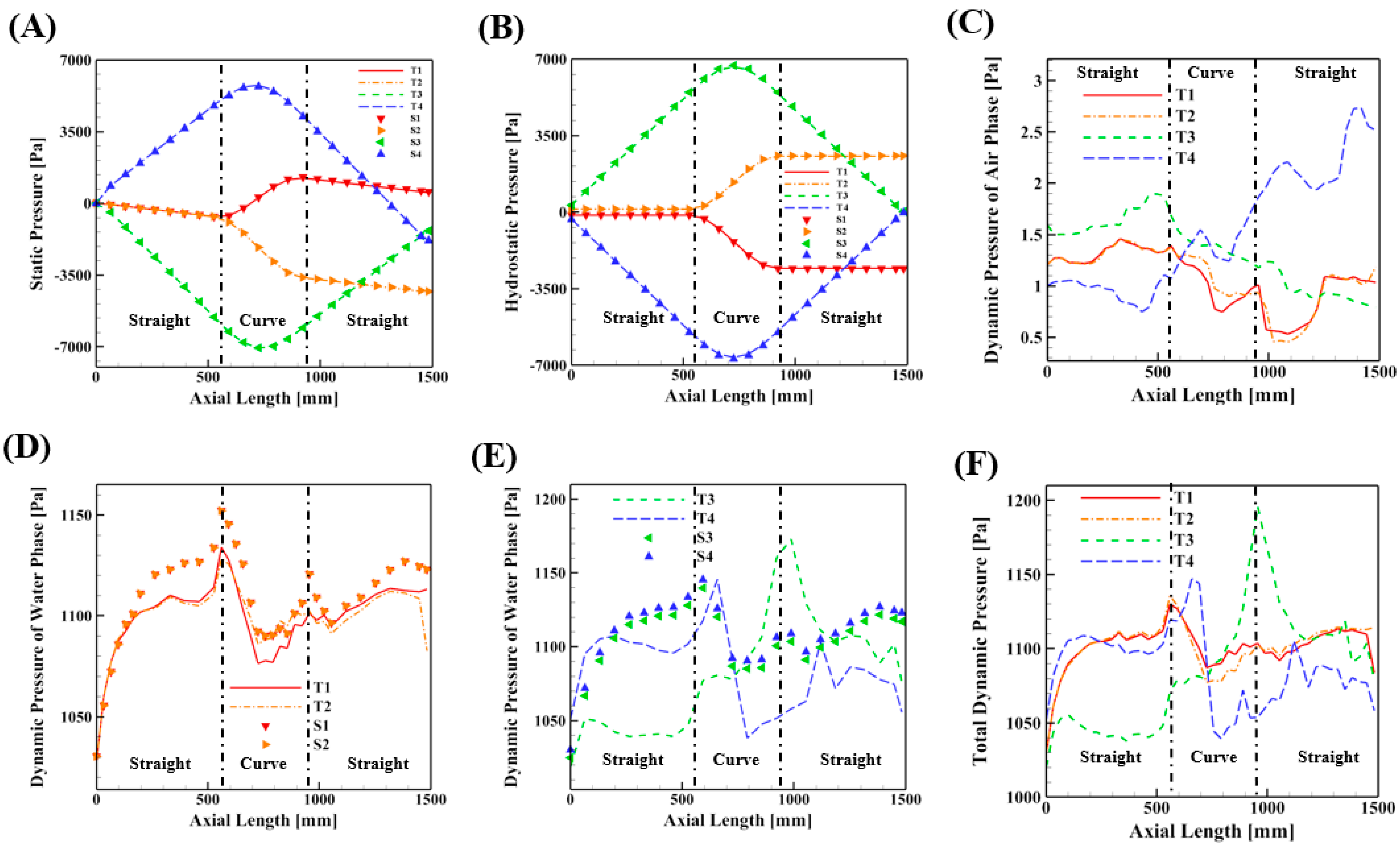

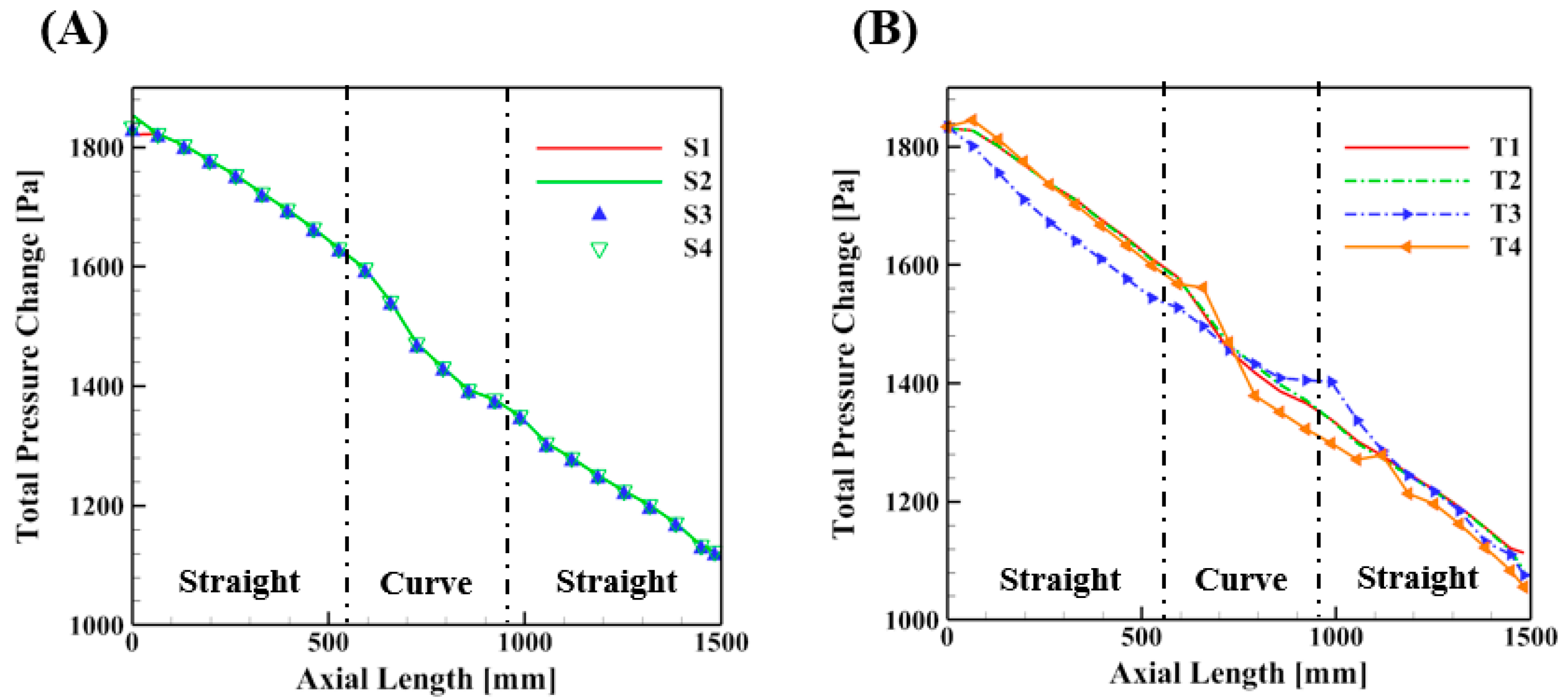

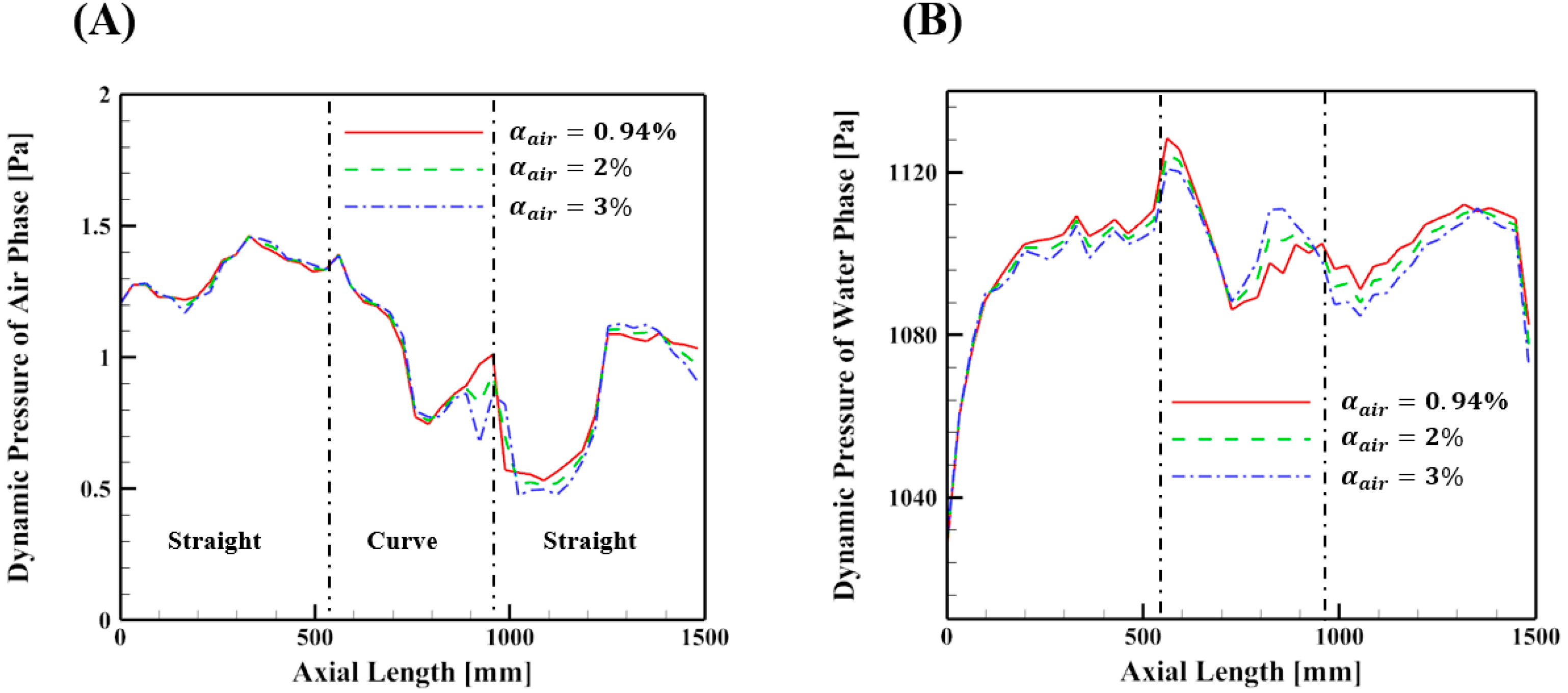

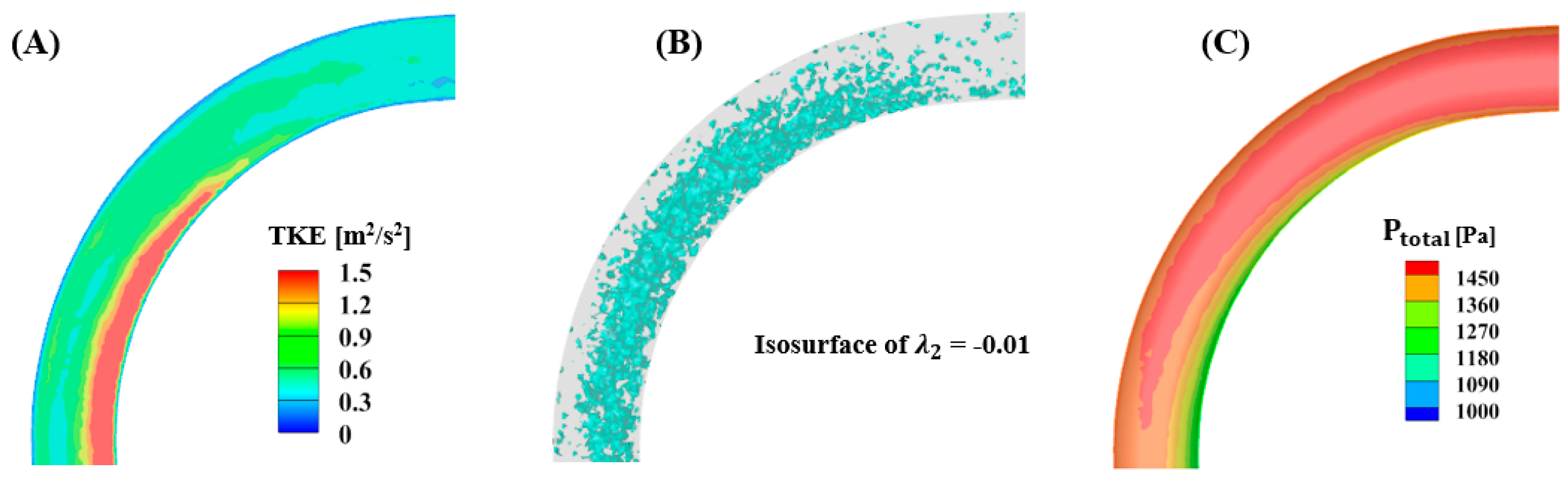

3.3.2. Static, Hydrostatic, and Dynamic Pressure Distributions in the Curve Pipes

3.4. Flow Physics in the C-Shaped Pipe (Case 1)

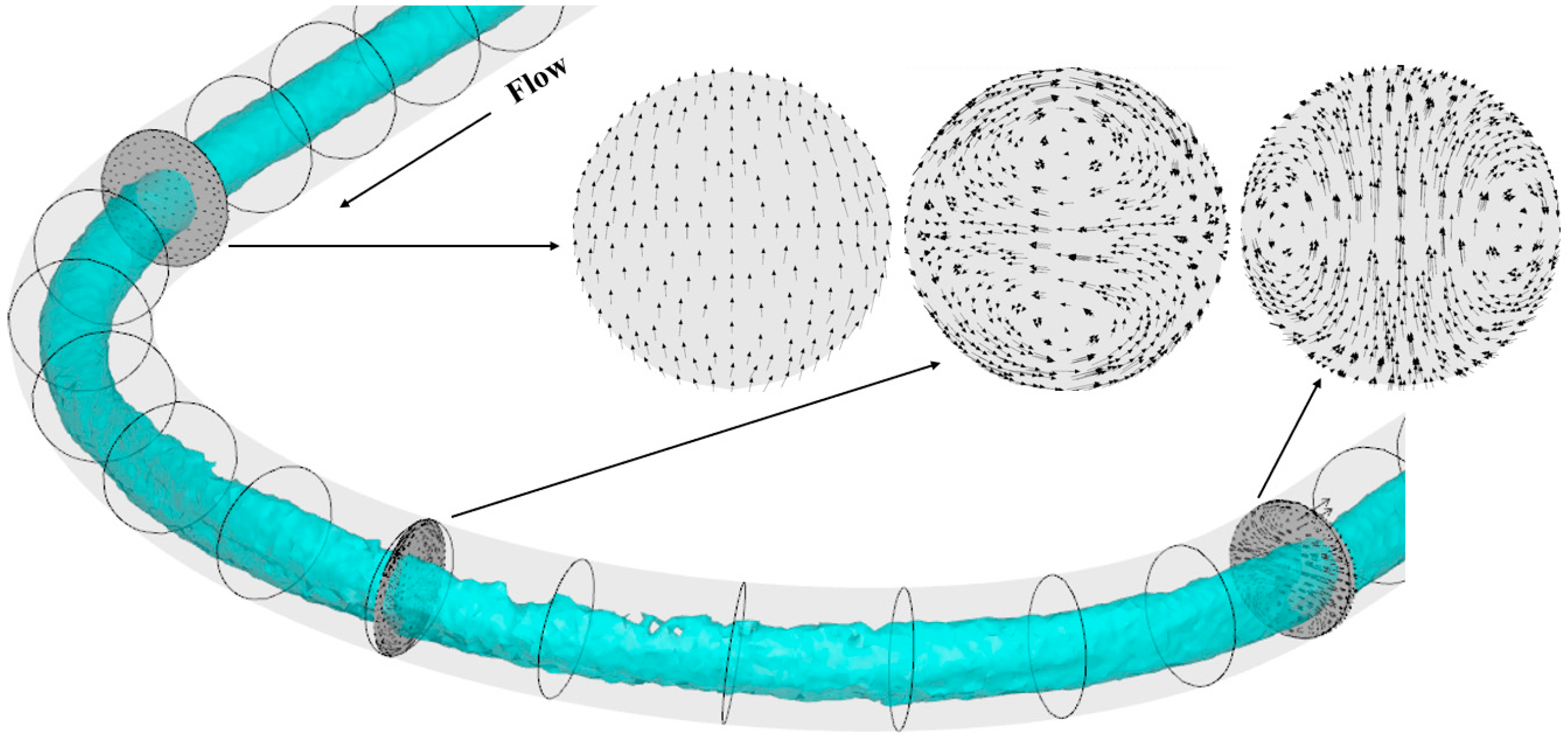

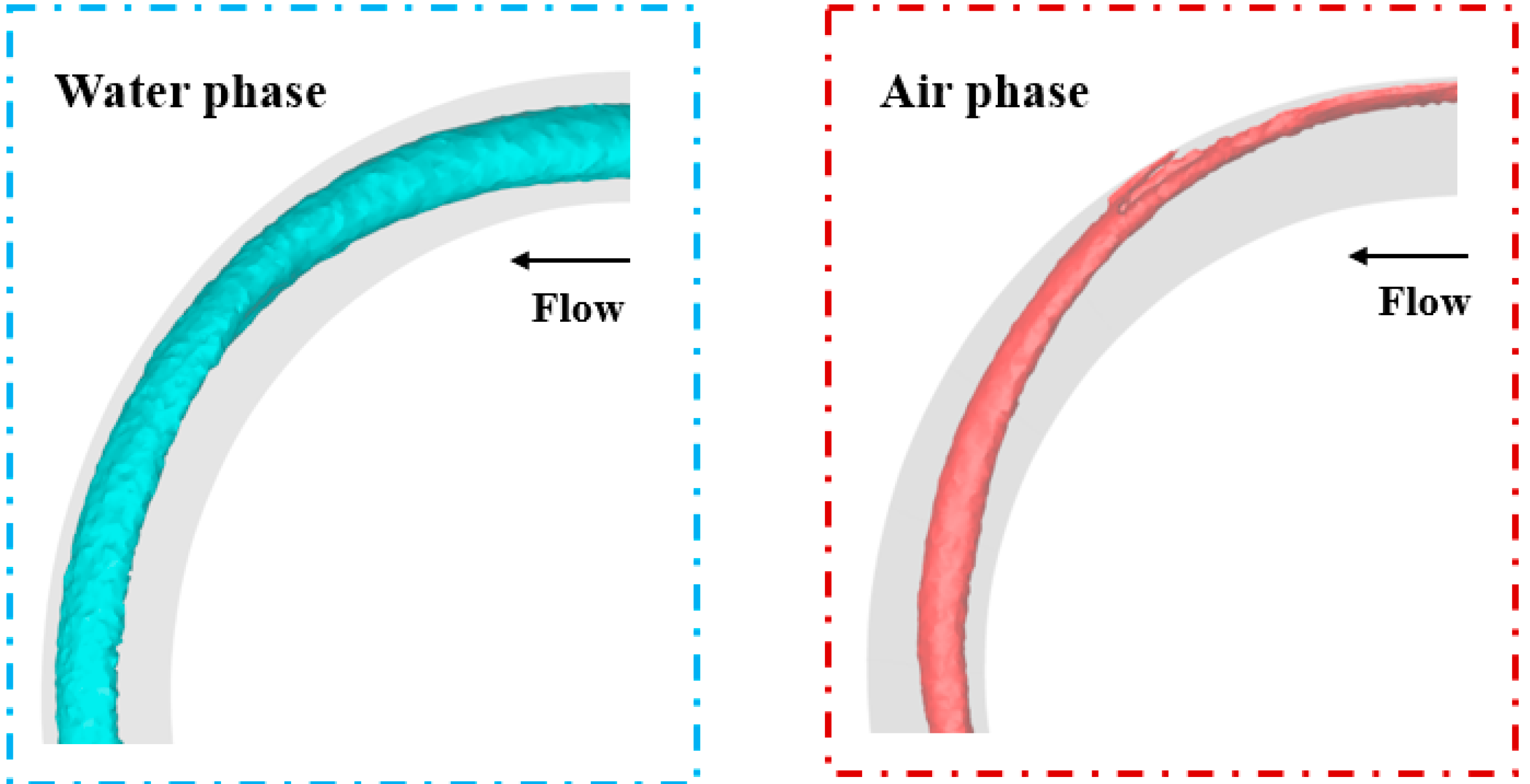

3.4.1. Flow and Bubble Redistribution in the C-Shaped Pipe

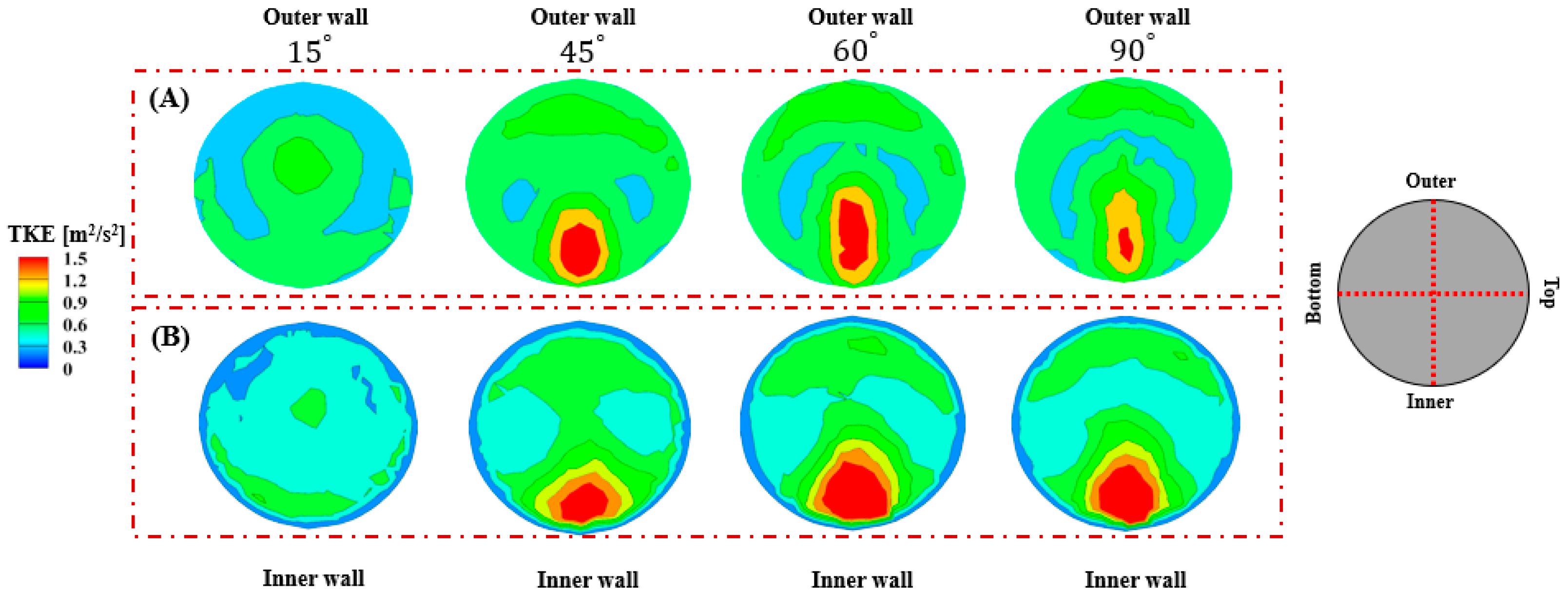

3.4.2. Turbulent Effect in the C-Shaped Pipe

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFD | Computational fluid dynamics |

| HVAC | Heating, ventilation, and air conditioning |

| g | Gravity (m2/s) |

| LES | Large eddy simulation |

| M | Momentum transfer |

| POD | Proper orthogonal decomposition |

| P | Pressure (Pa) |

| Re | Reynolds number |

| U | Average velocity magnitude (m/s) |

| u | Velocity vector (m/s) |

| Mean fluctuation velocity (m/s) | |

| TKE | Turbulent kinetic energy |

| Greek | |

| Volume fraction | |

| Fluid density | |

| Viscous stress tensor | |

| Subscripts | |

| Drag | Drag force |

| DP | Dynamic Pressure (Pa) |

| HP | Hydrostatic Pressure (Pa) |

| Lift | Lift force |

| ST | Static Pressure (Pa) |

| TOT | Total Pressure (Pa) |

| VM | Virtual mass force |

References

- Ohnuki, A.; Akimoto, H. Experimental study on transition of flow pattern and phase distribution in upward air–water two-phase flow along a large vertical pipe. Int. J. Multiph. Flow 2000, 26, 367–386. [Google Scholar] [CrossRef]

- Lucas, D.; Krepper, E.; Prasser, H.-M. Prediction of radial gas profiles in vertical pipe flow on the basis of bubble size distribution. Int. J. Therm. Sci. 2001, 40, 217–225. [Google Scholar] [CrossRef]

- Lucas, D.; Prasser, H.-M. Steam bubble condensation in sub-cooled water in case of co-current vertical pipe flow. Nucl. Eng. Des. 2007, 237, 497–508. [Google Scholar] [CrossRef]

- Shen, X.; Mishima, K.; Nakamura, H. Two-phase phase distribution in a vertical large diameter pipe. Int. J. Heat Mass Transf. 2005, 48, 211–225. [Google Scholar] [CrossRef]

- Yoneda, K.; Yasuo, A.; Okawa, T. Flow structure and bubble characteristics of steam–water two-phase flow in a large-diameter pipe. Nucl. Eng. Des. 2002, 217, 267–281. [Google Scholar] [CrossRef]

- Abdulkadir, M. Experimental and computational fluid dynamics (CFD) studies of gas-liquid flow in bends. PhD. Thesis, University of Nottingham, Nottingham, UK, 2011. [Google Scholar]

- Andrade, T.; Crivelaro, K.; Neto, S.; Lima, A. Isothermal and non-isothermal water and oil two-phase flow (core-flow) in curved pipes. Int. J. Multiphys 2016, 7. [Google Scholar] [CrossRef]

- Saffari, H.; Moosavi, R.; Gholami, E.; Nouri, N.M. The effect of bubble on pressure drop reduction in helical coil. Exp. Therm. Fluid Sci. 2013, 51, 251–256. [Google Scholar] [CrossRef]

- da Mota, F.R.; Pagano, D.J. Simulation and experimental study of phase segregation in helical pipes: A new method for flow conditioning. Flow Meas Instrum 2014, 35, 99–108. [Google Scholar] [CrossRef]

- Lee, G. A Numerical Study for Upward Two-Phase Flow inside the Curved Pipe. In Proceedings of the Transactions of the Society of Air-Conditioning and Refrigerator Engineers of Korea Summer Meeting, Gyeongju, Korea, June 16; pp. 1051–1054.

- Pruvost, J.; Legrand, J.; Legentilhomme, P. Numerical investigation of bend and torus flows, part I: Effect of swirl motion on flow structure in U-bend. Chem. Eng. Sci. 2004, 59, 3345–3357. [Google Scholar] [CrossRef]

- Rachman, F.F.; Sukarno, R.; Putra, N. Experimental and feasibility study of the utilization of u-shaped heat pipes for reducing air humidity in HVAC systems. Int. J. Adv. Sci 2020, 29, 3402–3410. [Google Scholar]

- Ong, K.-S.; Goh, G.; Tshai, K.; Chin, W. Performance of an R410a Filled C-Shape Heat Pipe. Front. Heat Pipes 2016, 7, 2–7. [Google Scholar] [CrossRef][Green Version]

- Takemura, T.; Roko, K.; Shiraha, M.; Midoriyama, S. Dryout characteristics and flow behavior of gas-water two-phase flow through U-shaped and inverted U-shaped bends. Nucl. Eng. Des 1986, 95, 365–373. [Google Scholar] [CrossRef]

- Pham, T.Q.D.; Jeon, J.; Choi, S. Quantitative comparison between volume-of-fluid and two-fluid models for two-phase flow simulation using OpenFOAM. J. Mech. Sci. Technol 2020, 34, 1–10. [Google Scholar] [CrossRef]

- Liang, L.; Michaelides, E.E. The magnitude of Basset forces in unsteady multiphase flow computations. J. Fluids Eng. 1992, 14, 417–419. [Google Scholar] [CrossRef]

- Miyawaki, S.; Hoffman, E.A.; Lin, C.-L. Numerical simulations of aerosol delivery to the human lung with an idealized laryngeal model, image-based airway model, and automatic meshing algorithm. Comput Fluids 2017, 148, 1–9. [Google Scholar] [CrossRef]

- Geuzaine, C.; Remacle, J.F.; Gmsh, A. 3D finite element mesh generator with built in pre and post processing facilities. Int. J. Numer. Methods Fluids 2009, 79, 1309–1331. [Google Scholar] [CrossRef]

- Takamasa, T.; Kondo, K. Measurement of interfacial configurations on bubbly flow in 180deg-bent tube using image-processing method. J. Nippon Kikai Gakkai Ronbunshu B Hen 1995, 61, 2372–2378. [Google Scholar]

- Dean, W.R. XVI. Note on the motion of fluid in a curved pipe. Mathematika 1927, 4, 208–223. [Google Scholar]

- Dennis, S.C.R.; Ng, M. Dual Solutions for Steady Laminar Flow Through A Curved Tube. Q. J. Mech. Appl. Math. 1982, 35, 305–324. [Google Scholar] [CrossRef]

- Band, S.S.; Al-Shourbaji, I.; Karami, H.; Karimi, S.; Esfandiari, J.; Mosavi, A. Combination of Group Method of Data Handling (GMDH) and Computational Fluid Dynamics (CFD) for Prediction of Velocity in Channel Intake. Appl. Sci. 2020, 10, 7521. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, X.; Xue, Q. A Deep Neural Network Based Glottal Flow Model for Predicting Fluid-Structure Interactions during Voice Production. Appl. Sci. 2020, 10, 705. [Google Scholar] [CrossRef]

- Pham, T.Q.D.; Choi, S. Numerical Analysis of Direct Contact Condensation-Induced Water Hammering Effect Using OpenFOAM in Realistic Steam Pipes. Int. J. Heat Mass Transfer. 2020. [Google Scholar] [CrossRef]

| Settings | ||

|---|---|---|

| Numerical solver in OpenFOAM | TwoPhaseEulerFoam | |

| Two-phase flow model | Two-fluid | |

| Time-step | 1 × 10−5 s | |

| Max Courant-Friedrichs-Lewy (CFL) | 0.5 | |

| Total time | 5 s | |

| Air volume fraction | 0.94% | |

| Initial conditions | Water was filled in the pipe initially | |

| Bubble diameter | mm | |

| Surface tension | 0.072 N/m | |

| Boundary conditions | Inlet | Uniform velocity |

| Outlet | Zero-gradient velocity | |

| Wall | No-slip velocity | |

| Coarse | Medium | Dense | ||

|---|---|---|---|---|

| Uniform | Node | - | - | 847,095 |

| Cell | - | - | 4,855,391 | |

| Non-uniform | Node | 139,436 | 664,278 | 905,524 |

| Cell | 709,221 | 3,686,309 | 5,021,251 | |

| Cases | Inlet-to-Curve Inlet [N/m3] | Curve Inlet-to-Curve Outlet [N/m3] | Curve Outlet-to-Outlet [N/m3] | Total [Pa] |

|---|---|---|---|---|

| S1 | 210 (375) | 233 (599) | 252 (450) | 696 (464) |

| S2 | 233 (417) | 233 (599) | 252 (450) | 720 (480) |

| S3 | 213 (381) | 233 (598) | 252 (451) | 700 (466) |

| S4 | 213 (381) | 233 (598) | 252 (450) | 699 (466) |

| T1 | 233 (416) | 243 (624) | 250 (447) | 727 (485) |

| T2 | 238 (426) | 258 (663) | 276 (493) | 773 (515) |

| T3 | 279 (499) | 289 (741) | 292 (521) | 860 (573) |

| T4 | 269 (481) | 287 (736) | 284 (507) | 840 (560) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, T.Q.D.; Jeon, J.; Jo, D.; Choi, S. Two-Phase Flow Simulations Using 1D Centerline-Based C- and U-Shaped Pipe Meshes. Appl. Sci. 2021, 11, 2020. https://doi.org/10.3390/app11052020

Pham TQD, Jeon J, Jo D, Choi S. Two-Phase Flow Simulations Using 1D Centerline-Based C- and U-Shaped Pipe Meshes. Applied Sciences. 2021; 11(5):2020. https://doi.org/10.3390/app11052020

Chicago/Turabian StylePham, Thinh Quy Duc, Jichan Jeon, Daeseong Jo, and Sanghun Choi. 2021. "Two-Phase Flow Simulations Using 1D Centerline-Based C- and U-Shaped Pipe Meshes" Applied Sciences 11, no. 5: 2020. https://doi.org/10.3390/app11052020

APA StylePham, T. Q. D., Jeon, J., Jo, D., & Choi, S. (2021). Two-Phase Flow Simulations Using 1D Centerline-Based C- and U-Shaped Pipe Meshes. Applied Sciences, 11(5), 2020. https://doi.org/10.3390/app11052020