Abstract

Native starch from potatoes and hybrid carrageenans from the red alga Mastocarpus stellatus have been used as gluten-free gelling matrices to obtain functional hydrogels. The enrichment of gelling matrices with antioxidant compounds from natural sources is an increasing market trend. In this context, this work is aimed at the formulation and thermo-rheological characterization of functional hydrogels using potato starch from agro-industrial waste and kappa–iota hybrid carrageenans extracted from the above seaweed, enriched with antioxidant compounds from different agro-industrial products, such as waste coming from the pruning of green tea and two varieties of hops used in the brewing industry. Environmentally friendly technologies such as microwave hydrodiffusion and gravity, microwave-assisted extraction, ultrasounds and autohydrolysis were used for the recovery of antioxidant compounds. The results point out that functional hydrogels based on potato starch and hybrid carrageenans with a wide range of viscoelastic features can be achieved, with the particularity of being suitable for people with celiac disease. The incorporation of selected antioxidant extracts from vegetable by-products involved the drop (about tenfold) of the viscous and elastic properties of the formulated gels. The sequential combination of the above treatments could even further expand the thermo-rheological properties of formulated hydrogels, with potential application in functional foodstuffs and novel gluten-free goods.

1. Introduction

Innovative functional hydrogels based on gluten-free matrices could be formulated from both the agricultural and marine environments. The main non-gluten agricultural sources for obtaining natural starches are cereals, roots, tubers and legumes. Starches, considered as one of the most suitable biopolymers, are usually employed in the food industry to make a wide array of pastry products, such as cookies, breads, puddings, cakes and pasta, among others [1]. Potato starch, considered a low-cost source that is easy to obtain and has multiple properties, is used as a gelling agent, stabilizer, emulsifier, thickener and adhesive nowadays, thus contributing to the improvement of the textural properties in food formulations [2]. Starch, in the presence of water and with the adequate supply of energy, undergoes a gelatinization process in which its crystalline structure is broken, passing from insoluble granules to obtaining a solution of its molecules, originating viscous pastes. During this process, the amylose molecules diffuse into the water and form a gel while the amylopectin loses its crystalline order [3]. It is this order–disorder transition that starch polymers undergo when subjected to heating which impacts the processing, quality and stability of starch-based products [1]. Other gelling agents and stabilizers that could be suitable for gluten intolerance come from algae polysaccharides such as alginates, carrageenates or agars. In this study, the red marine macroalga Mastocarpus stellatus, also known as false Irish moss or false carrageen moss, was employed as a rich source of hybrid carrageenans. These natural polymers are widely used in many industries from different fields due to their chemical and physical characteristics, giving them versatility in their applications [4,5].

Carrageenans can be used to give volume, texture and viscosity or as a powerful gelling agent [6] due to its singular properties of biodegradability and durability, which are widely used in the food industry to provide consistency to milk products or ice creams [7]. In particular, hybrid carrageenans extracted from the proposed alga are a group of long-chain polymers consisting of blocks of ĸ- and ı-carrageenan disaccharides placed along a chain, sharing with minor amounts of non-gelling disaccharide blocks [8] that are characterized by the formation of viscous gels when dispersed in water, due to the fact that they have a large number of hydroxyl groups. This increases their affinity for water molecules, providing a high flexibility similar to the natural tissue and the ability to modify the system’s rheology [9]. The combinations of both ĸ- and ı-carrageenans are fundamental for creating gels [7]. Kappa-type carrageenans provide hard, strong and brittle gels, whereas iota-type carrageenans are soft and weak; however, their characteristics and applicability depend on various physical-chemical factors, such as temperature, pressure, ionic strength (amount of ions of sodium and calcium) and pH changes [10].

Many recent studies can be found in the literature which were interested in the preparation of gluten-free hydrogels for food and even non-food applications [11]. In this study, novel raw materials such as tea pruning waste were considered a rich source of polyphenols [12,13] with antioxidant properties, as well as two varieties of hops considered for their microbial growth inhibitory power and relaxant and antioxidant properties. All this, encompassed with the use of green extraction techniques such as microwave-assisted extraction (MAE), microwave hydrodiffusion and gravity (MHG), ultrasound-assisted (US) extraction in a water bath or hot water under pressure or autohydrolysis (AH), promoted the recovery of high valuable compounds, using resources more efficiently and saving energy and time when compared with the traditional methods [14].

In this context, the main aim of this study is the preparation and thermomechanical characterization of alternative functional hydrogels based on potato starches and hybrid carrageenans supplemented with antioxidant compounds, which were obtained from tea pruning remains and hops pellets and were characterized by their nutraceuticals and healthy beneficial properties.

2. Materials and Methods

2.1. Raw Materials

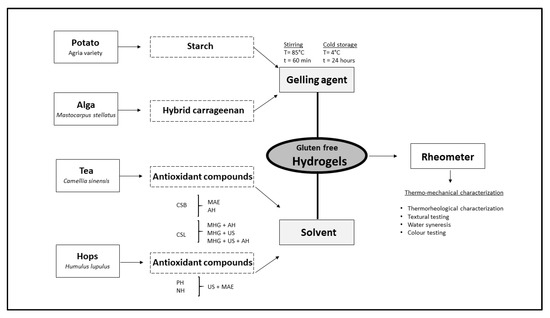

Figure 1 presents a brief outline of the experimental process. Irregularly shaped and small-sized potatoes from the Agria variety, which were harvested in Galicia (Spain), were kindly supplied by the Instituto Ourensán de Desenvolvemento Económico (INORDE). These discarded potatoes were used as raw material for starch extraction (moisture content 15.9% wet basis (w.b.)) following the procedure previously detailed in [15], where the fundamental physicochemical properties of the used starch were also reported. Dehydrated Mastocarpus stellatus red algae (moisture content 12.5% w.b.), used for hybrid carrageenan extraction according to the procedure previously described in [10], was provided by the Porto Muíños company (A Coruña, Spain). The main physicochemical and rheological characteristics of the kappa–iota hybrid carrageen used as a gelling agent was previously reported in a parallel work [16].

Figure 1.

General scheme of gluten-free hydrogel production. T = temperature; t = time; CSB = Camellia sinensis branches; CSL = Camellia sinensis leaves; PH and NH = industrial hops; MAE = microwave-assisted extraction; AH = autohydrolysis); MHG = microwave hydrodiffusion and gravity; US = ultrasounds.

For the antioxidant sources, soluble extracts from Camellia sinensis agricultural wastes (i.e., Camellia sinensis branches (CSB) and Camellia sinensis leaves (CSL)), gently provided by the Orballo company (A Coruña, Spain), and industrial hops (i.e., PH and NH), kindly supplied by Hijos de Rivera (A Coruña, Spain), were used. The extracts were recovered using operational conditions based on individual or sequential combinations of microwave hydrodiffusion and gravity (MHG), ultrasound-assisted (US) and pressurized hot water or autohydrolysis (AH) or microwave-assisted extraction (MAE), which were studied in parallel works [12,13]. Please see the selected treatments for the recovery of fractions with the maximum antioxidant content in Table 1. In an ongoing work, the extraction conditions for hops were determined using US and microwave (i.e., MAE) or autohydrolysis (AH) treatments [17].

Table 1.

The selected processing conditions for used antioxidant extracts from Camellia sinensis agricultural wastes (Camellia sinensis branches (CSB) and Camellia sinensis leaves (CSL)) and industrial hops (PH and NH).

2.2. Gluten-Free Gelled Matrix Formulation

Gluten-free gelled matrices were prepared with the selected anionic (potato starch) and ionic (hybrid carrageenan) biopolymers for comparative purposes. The soluble antioxidant extracts selected from Camellia sinensis (CSE) or hops (HE) were used as solvents. In both biopolymer-based systems, aqueous solutions were formulated at a fixed biopolymer content (i.e., 15% for potato starch and 2% for hybrid carrageenan) by dissolving the required biopolymer amount in the aqueous soluble extracts. Note that the matrices made with the ionic biopolymer were formulated in the presence of a salt medium (0.1 mol/L calcium chloride). It should be noted that the calcium chloride content already present in the extracted hybrid carrageenan was taken into account to compute the ionic strengths of the corresponding solutions [10]. All biopolymer solutions were kept under strong stirring at 85 °C for 60 min to ensure full biopolymer dissolution.

For thermorheological testing, hot solutions were immediately loaded into the measuring system, whereas for textural testing, all formulations were cold stored (4 °C) for 24 h in order to guarantee full gel maturation. The above processing conditions were set, taking into account the outcomes previously optimized for both gelled agents [10,15].

2.3. Thermorheological Testing of Gluten-Free Systems

Monitoring of the thermorheological behavior during the gel forming of the proposed gluten-free matrices was made throughout the storage (G’) and loss (G”) moduli. A controlled stress rheometer (MCR302, Anton Paar Physica, Austria) was used to conduct the small amplitude oscillatory shear (SAO) measurements. The selected measuring system was a sand-blasted parallel plate (25 mm in diameter). Hot biopolymer solutions were directly placed on the pre-heated (85 °C) plate–plate geometry (1 mm gap), and the edges of the samples were covered with light paraffin oil. The solutions were rested to favor temperature equilibration (5 min at 85 °C) before rheological testing. Then, stress sweep tests were run (1 Hz at 85 °C) to define the linear viscoelastic region below 30 Pa for all the tested systems. Afterward, the rheological testing consisted of a four-step procedure detailed in a previous work [10]: (1) cooling temperature sweeps from 85 to 25 °C (1 °C /min, 1 Hz, 10 Pa) to identify the gel setting temperatures (Tg) (tan δ = G"/ G’ = 1); (2) time sweeps (25 °C, 15 min, 1 Hz, 10 Pa) to monitor the gel maturation kinetics; (3) frequency sweeps from 0.1 to 10 Hz (25 °C, 10 Pa) without disturbing the gel structure; and (4) heating the ramp to 85 °C (1 °C/min, 1 Hz, 10 Pa) to monitor the gel melting behavior and the corresponding temperature Tm (tan δ = 1).). Rheological measurements were made at least in triplicate.

2.4. Textural Testing of Gelled Gluten-Free Matrices

Analyses of the macrostructural properties of the above gelled matrices (30 mm in diameter) were conducted on a texture analyzer (TA–XT2, Stable Microsystems, UK). Texture profile analysis (TPA) was carried out in compression mode (5 kg load cell) using a stainless steel probe (P50). The measurement conditions (2 mm compression, 1.0 mm/s crosshead speed) allowed for compacting the gelled matrices twice in a reciprocating motion. The firmness, cohesiveness, adhesiveness and springiness of the proposed gelled matrices were calculated from the TPA profiles. All measurements were made at least six times.

2.5. Water Syneresis of Gelled Gluten-Free Matrices

The water release was also assessed according to the experimental procedure previously detailed in [18]. Briefly, the gelled matrices were cold stored in centrifuge tubes (4 °C) for one month. Then, the samples were centrifuged (2000 g for 25 min), and the water syneresis was calculated as the percentage of water release with respect to the weight of the gelled matrices.

2.6. Color Testing of Gelled Gluten-Free Matrices

Color characteristics of the above formulated gelled matrices were performed using a colorimeter (Minolta CR–400, Japan) based on the CIELab system (L*, a* and b*). The assessed chromaticity parameters were L* (whiteness, 0 < L* < 100, brightness degree), a* (greenness (a* < 0) or redness (a* > 0) degree) and b* (blueness (b* < 0 degree) or yellowness (b* > 0)). The color differences (ΔE*) of the proposed matrices enriched with antioxidant compounds regarding the corresponding controls (hybrid carrageenan (C1) and potato starch (S1)) were determined. The colors of all the gelled matrices were measured at room temperature under the same light conditions at least six times.

2.7. Statistical Analysis

The data were statistically evaluated using one-factor analysis of variance through the PASW Statistics v.22 software (IBM SPSS Statistics, New York, NY, USA). Whenever differences in the means were found, a post-hoc Scheffé test was conducted to distinguish the average values with a 95% confidence interval (p < 0.05).

3. Results and Discussion

3.1. Thermorheological Behavior of Gluten-Free Matrices

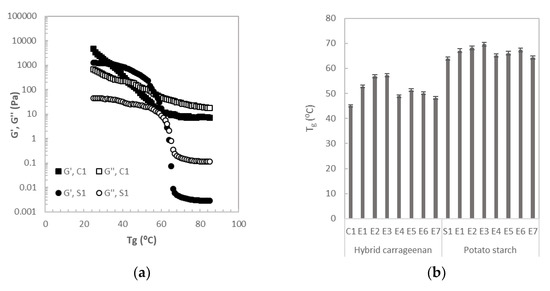

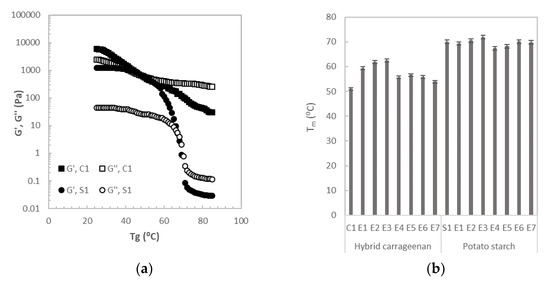

Monitoring of the thermorheological, textural and color features, as well as the water syneresis of the above systems, was performed in order to assess the quality of the proposed gluten-free matrices. Figure 2 shows the cooling profiles for the control aqueous samples prepared with hybrid carrageenan (C1) and potato starch (S1), representative of all the tested systems. Note that the matrices formulated with both gelling agents enriched with antioxidant extracts (E1–E7) exhibited the same trends as the corresponding control samples, but with lower magnitudes of both moduli (about eightfold). At a fixed temperature, it was observed that the incorporation of soluble extracts with the highest total phenolic content (Table 1) involved the softest viscoelastic properties, which could be related to increased competition for water between the gelling agents and the antioxidant compounds [19].

Figure 2.

Cooling profiles for (a) the control matrices prepared with the hybrid carrageenan (C1) or potato starch (S1), as well as (b) the corresponding gelling temperatures (Tg) for all formulated matrices. Note that in this and subsequent plots, error bars were not presented when they were smaller than the symbol size.

The viscous (G’’) and elastic (G’) moduli increased with decreasing temperatures. The rise of both moduli was more pronounced for the starch gelled matrices (around six decades for G’ and two decades for G’’) when compared with the hybrid carrageenan ones (around three decades for G’ and one decade for G’’). In all cases, the cooling profiles were consistent with those previously reported for other hybrid carrageenan [8] and starch solutions [15]. Regardless of the gelling agent used, G’’ was higher than G’ at the highest temperatures (liquid-like behavior). Subsequently, a crossover (tan δ = G’’/G’ = 1) related with the gelling temperature (Tg) was identified. The magnitude of Tg varied between 43 °C for the C1 system and 67 °C for the S1 system. The values of this parameter were shifted by the presence of antioxidant soluble extracts (Figure 1b). The determined Tg values were in the range of those reported for this kind of biopolymer [20]. Overall, it was observed that the systems with the lowest total phenolic contents required the highest gelling temperatures. For both gelling agents, the Tg varied significantly, following the order E2 ≈ E3 > E1 ≈ E5 > E4 ≈ E6 ≈ E7 > C1 and E1 ≈ E2 ≈ E3 > E4 ≈ E5 ≈ E6 ≈ E7. After the crossover, a steep increase of the elastic and viscous moduli (with G’ > G’’) was identified, as has been reported for other commonly used gelling agents [21].

It should be indicated that high stability was identified at 85 °C for all proposed matrices independent of the used extract, achieving straightaway G’ and G’’ moduli which were almost invariant over time (data from time sweeps not shown). These time sweeps highlighted that the dynamic equilibration of the gel network was immediately achieved. This is an interesting feature from the processing point of view, since the required time to reach stable G’ and G’’ moduli after the cooling step varied greatly, depending on the matrix employed [22].

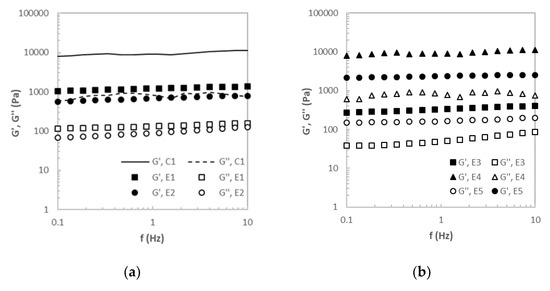

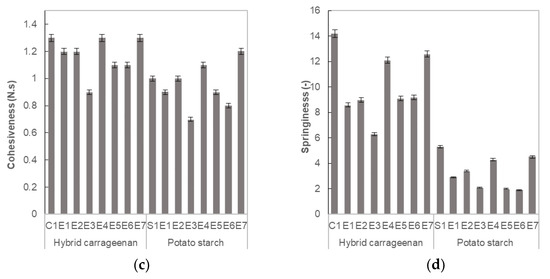

Figure 3 shows the viscoelastic properties of the above gelled matrices, taken after the cooling maturation stage. In all cases, a typical gel profile could be observed (G’ > G’’ and both moduli almost invariant over the tested frequency range) [23]. The softening of the gelled matrices in the presence of the tested extracts (E1–E7) was verified with the mechanical spectra. For the carrageenan gelled matrices, the strongest gels were found for E4 > E6 > E5 > E7 > E1 > E2 > E3. A similar tendency (E4 > E7 > E5 > E6 > E1 >E2 >E3) was identified for those formulated with starch as the gelling agent (Figure 2d), although notably lower values were obtained for the corresponding viscoelastic moduli (about tenfold). This supports the above hypothesis about the correlation between the mechanical properties and the phenolic contents of the samples. Note that the gels enriched with extracts from Camellia sinensis branches (E1) and industrial hops (E7) exhibited involved gels with close viscoelastic properties. In all cases, gluten-free gels with intermediate strengths were developed. The obtained viscoelastic values were in the range of those previously described for other gelled matrices for food purposes [22,24,25]. It should also be highlighted that after one month of cold storage, the thermorheological characteristics of the proposed gels were practically invariant, with drops in the values of both moduli being lower than 2%.

Figure 3.

Viscoelastic features of the proposed matrices, prepared with (a–c) hybrid carrageenan or (d) potato starch in the presence of extract from Camellia sinensis agricultural wastes and industrial hops (see Table 1 for coding). Note here that C1 and S1 are the controls prepared with hybrid carrageenan and potato starch, respectively.

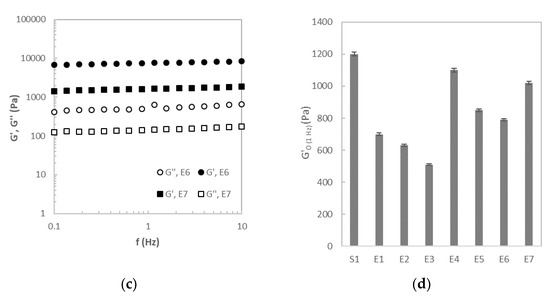

Figure 4 displays the representative viscoelastic behavior of the control gelled matrices formulated with hybrid carrageenan (C1) and potato starch (S1) during the heating stage. Similar profiles to those obtained during the cooling stage were identified here, though there were smaller differences between both moduli at the highest temperatures (about tenfold). At a fixed temperature, it should be also indicated that the presence of the tested extracts followed the same trends explained above for the mechanical spectra. Concerning the melting temperatures, the values were higher (about 10 °C) than those found for the gelling ones. The addition of extracts promoted greater differences in the hybrid carrageenan gels than in those formulated with potato starch (Figure 3b), although higher melting temperatures were needed when using this last gelling agent. These or even greater differences between the melting and gelling temperatures are commonly reported for a number of gelled agents in the presence or absence of nutritional enrichment components [2,20].

Figure 4.

Heating profiles for (a) control matrices prepared with the hybrid carrageenan (C1) or potato starch (S1), as well as (b) the corresponding melting temperatures Tm for all formulated matrices. Note than in this and subsequent plots, error bars were not presented whenever they were smaller than the symbol size.

3.2. Textural Behavior of Gluten-Free Matrices

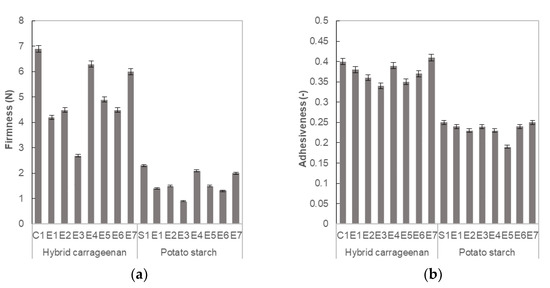

Figure 5 shows the (a) firmness, (b) adhesiveness, (c) cohesiveness and (d) springiness of the proposed gluten-free gelled matrices enriched with selected extracts (E1–E7). In general, all parameters exhibited higher values for those gelled matrices formulated with hybrid carrageenan, which is consistent with the results found during thermorheological testing. The firmness of the tested matrices was notably influenced by the presence of the soluble antioxidant extracts for both the hybrid carrageenan (E4 > E7 > E5 > E6 ≈ E2 > E1 > E3) and starch (E4 > E7 > E5 ≈ E6 ≈ E2 ≈ E1 > E3) matrices (Figure 5a). Anyway, the magnitudes of this parameter were over the range that was reported for other gluten-free matrices using different gelling agents for food purposes [22,26]. The adhesiveness values varied between 0.43 and 0.35 for the hybrid carrageenan matrices and between 0.22 and 0.18 for the potato starch ones (Figure 5b). The highest adhesiveness values were identified for E7, E5 and E1 with no significant differences when compared with the control sample (C1). For the starchy gels, similar values were observed for all extracts apart from E3, where the lowest adhesiveness was found. The magnitudes of the adhesiveness were consistent with previous results for other food matrices [27,28]. The cohesiveness exhibited similar trends to those observed for firmness, although lower differences between the matrices prepared with both gelled agents were observed in this case (Figure 5c). It should be noted that the matrices incorporated with E7 featured the highest cohesiveness values, even higher than the control for the starch gelled systems (S1). The springiness followed the tendencies aforementioned for the viscoelastic behavior monitored during the mechanical spectra of the developed gelled matrices. Again, the gels in the presence of E7 and E4 led to the highest values of this parameter for enriched systems, whereas those incorporated with E3 featured the lowest springiness values. The magnitudes were in accordance with those previously reported for other biopolymer-based gelled systems proposed for the food field [22], even though a wide range of gelled matrices with suitable characteristics from a food point of view were developed.

Figure 5.

Texture parameters in terms of (a) firmness, (b) adhesiveness, (c) cohesiveness and (d) springiness for the proposed matrices prepared with hybrid carrageenan or potato starch in the presence of selected extracts (E1–E7; see Table 1). The controls prepared with hybrid carrageenan (C1) and potato starch (S1) were also included.

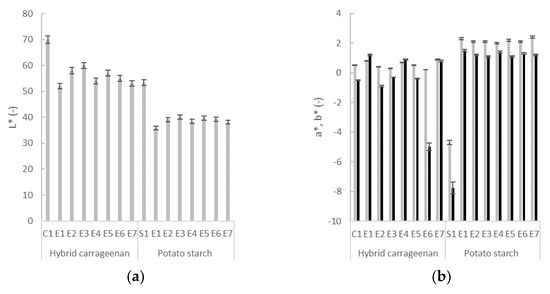

3.3. Color Properties of Proposed Gluten-Free Matrices

Figure 6 displays an overview of the color features in terms of (a) lightness and (b) a* and b* coordinates. A drop in the lightness values was noticed for the enriched hybrid carrageenan gels when compared with the control (C1), whereas no significant variations were identified for the starch gelled ones. In all cases, the hybrid carrageenan gels exhibited higher values of this parameter (about 30%) than those formulated with starch (Figure 2a). Concerning the a* and b* coordinates, both also exhibited higher values for the hybrid carrageenan matrices. It should be noted that the a* coordinate was slightly influenced by the presence of the extracts for both gelled matrices. In the case of b*, this coordinate significantly increased in the presence of the extracts when compared with the control system for starch-based matrices (S1). In general, the values of the color parameters were in the range of those reported for gelled systems prepared with these two gelling agents [29,30,31].

Figure 6.

Color parameters for proposed matrices prepared with (a) hybrid carrageenan or potato starch in the presence of the selected extracts (E1–E7; see Table 1) compared with the controls (C1 and S1). The gray and black bars in the plot (b) correspond to the a* and b* parameters, respectively.

Moreover, it should be remarked that the above proposed gluten-free gelled matrices incorporated with antioxidant extracts (E1–E7) did not present water release during one month of cold storage (4 °C), which is a relevant aspect from the processing point of view for the development of alternative gluten-free matrices [32,33,34,35].

4. Conclusions

The selected gelled matrices, incorporated with the proposed extracts from Camellia sinensis agricultural wastes (E1–E5) and industrial hops (E6–E7), could be attractive alternatives to cope with the growing gluten-free market demand for healthy foodstuffs. The addition of the above soluble extracts on the gelled systems favor the development of a number of matrices with a wide range of viscoelastic and textural properties suitable for the gluten-free field. The weakest and strongest enriched gels were featured by E3 and E7, respectively. The gelling temperature was also highly dependent on the selected extract, which was critically relevant for defining the processing conditions and the final food application. An additional relevant advantage is the high thermorheological stability after cooling, as well as the absence of water release after one month of cold storage. To conclude, the incorporation of selected extracts to the gelled matrices involves a significant improvement of potential end applications with healthy features, with consequent betterment from a social, wellbeing, industrial or environmental viewpoint.

Author Contributions

H.D. and M.D.T. conceived and planned the experiments. V.S. and M.D.T. participated in the sample preparation, data analysis and interpretation of the results and wrote the paper draft. M.D.T. and H.D. supervised the research work, contributed to the discussion of the data and revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science, Innovation and Universities of Spain (RTI2018–096376–B–I00) and the Consellería de Cultura, Educación e Universidade da Xunta de Galicia (ED431F 2020/01). M.D.T. acknowledges the Ministry of Science, Innovation and Universities of Spain for their postdoctoral grants (RYC2018–024454–I).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors thank the Orballo company (A Coruña, Spain) and Hijos de Rivera (A Coruña, Spain) for providing the raw materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Salgado-Ordosgoitia, R.D.; Paternina-Contreras, A.L.; Cohen-Manrique, C.S.; Rodríguez-Manrique, J.A. Analysis of the Gelatinization Curves of Native Starches of three Species of Yam: Criollo (Dioscorea alata), Hawthorn (Dioscorea rotundata) and Diamond 22. Inf. Tecnológica 2019, 30, 93–102. [Google Scholar] [CrossRef]

- Torres, M.D.; Chenlo, F.; Moreira, R. Rheological Effect of Gelatinisation Using Different Temperature-Time Conditions on Potato Starch Dispersions: Mechanical Characterisation of the Obtained Gels. Food Bioprocess Technol. 2018, 11, 132–140. [Google Scholar] [CrossRef]

- Singh, B.; Pal, J.; Kaur, A.; Singh, N. Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef] [PubMed]

- López-Hortas, L.; Conde, E.; Falqué, E.; Domínguez, H.; Torres, M.D. Recovery of aqueous phase of broccoli obtained by MHG technique for development of hydrogels with antioxidant properties. LWT Food Sci. Technol. 2019, 107, 98–106. [Google Scholar] [CrossRef]

- López-Hortas, L.; Conde, E.; Falqué, E.; Domínguez, H.; Torres, M.D. Preparation of Hydrogels Composed of Bioactive Compounds from Aqueous Phase of Artichoke Obtained by MHG Technique. Food Bioprocess Technol. 2019, 12, 1304–1315. [Google Scholar] [CrossRef]

- Gómez-Ordóñez, E.; Jiménez-Escrig, A.; Rupérez, P. Dietary fibre and physicochemical properties of several edible seaweeds from the northwestern Spanish coast. Int. Food Res. J. 2010, 43, 2289–2294. [Google Scholar] [CrossRef]

- Pereira, L.; Van De Velde, F. Portuguese carrageenophytes: Carrageenan composition and geographic distribution of eight species (Gigartinales, Rhodophyta). Carbohydr. Polym. 2011, 84, 614–623. [Google Scholar] [CrossRef]

- Torres, M.D.; Chenlo, F.; Moreira, R. Rheology of ĸ/ı -hybrid carrageenan from Mastocarpus stellatus: Critical parameters for the gel formation. Int. J. Biol. Macromol. 2016, 86, 418–424. [Google Scholar] [CrossRef]

- Milani, J.; Maleki, G. Hydrocolloids in Food Industry. In Food Industrial Processes-Methods and Equipments; Valdez, B., Ed.; Intech Open: Rijeka, Croatia, 2012; pp. 17–38. [Google Scholar] [CrossRef]

- Azevedo, G.; Torres, M.D.; Sousa-Pinto, I.; Hilliou, L. Effect of pre-extraction alkali treatment on the chemical structure and gelling properties of extracted hybrid carrageenan from Chondrus crispus and Ahnfeltiopsis devoniensis. Food Hydrocoll. 2015, 50, 150–158. [Google Scholar] [CrossRef]

- Rodríguez-Seoane, P.; Domínguez, H.; Torres, M.D. Mechanical Characterization of Biopolymer-Based Hydrogels Enriched with Paulownia Extracts Recovered Using a Green Technique. Appl. Sci. 2020, 10, 8439. [Google Scholar] [CrossRef]

- Sanz, V.; Flórez-Fernández, N.; Domínguez, H.; Torres, M.D. Valorisation of Camellia sinensis branches as a raw product with green technology extraction methods. Curr. Res. Nutr. 2020, 2, 20–24. [Google Scholar] [CrossRef]

- Sanz, V.; Flórez-Fernández, N.; Domínguez, H.; Torres, D. Clean technologies applied to the recovery of bioactive extracts from Camellia sinensis leaves agricultural wastes. Food Bioprod. Process. 2020, 122, 214–221. [Google Scholar] [CrossRef]

- Ameer, K.; Shahbaz, H.M.; Kwon, J. Green Extraction Methods for Polyphenols from Plant Matrices and Their Byproducts: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 295–315. [Google Scholar] [CrossRef]

- Torres, M.D.; Fradinho, P.; Rodríguez, P.; Falqué, E.; Santos, V.; Domínguez, H. Biorefinery concept for discarded potatoes: Recovery of starch and bioactive compounds. J. Food Eng. 2020, 275, 109886. [Google Scholar] [CrossRef]

- Ponthier, E.; Domínguez, H.; Torres, M.D. The microwave assisted extraction sway on the features of antioxidant compounds and gelling biopolymers from Mastocarpus stellatus. Algal Res. 2020, 51, 102081. [Google Scholar] [CrossRef]

- Sanz, V.; Torres, M.D.; López Vilariño, J.M.; Domínguez, H. Green extraction of biocompounds from Perle Hallertau and Nuggets hops pellets. Under review. 2021. [Google Scholar]

- Bashir, K.; Swer, T.L.; Prakash, K.S.; Aggarwal, M. Physico-chemical and functional properties of gamma irradiated whole wheat flour and starch. LWT Food Sci. Technol. 2017, 76, 131–139. [Google Scholar] [CrossRef]

- Lefatle, M.C.; John, M.J. Mechanical, rheological and viscoelastic properties of polysaccharide and protein based aerogels. RSC Green Chem. R. Soc. Chem. 2018, 177–200. [Google Scholar] [CrossRef]

- Xing, J.-J.; Li, D.; Wang, L.-J.; Adhikari, B. Temperature thresholds and time-temperature dependence of gelatinization for heat-moisture treated corn starch. J. Food Eng. 2018, 217, 43–49. [Google Scholar] [CrossRef]

- Hang, N.D.; Van Thinh, L.; Duong, D.Q. Development and evaluation of neem gel formulation using gum karaya as gelling agent. RJPT 2020, 13, 1859–1864. [Google Scholar]

- Nunes, M.C.; Raymundo, A.; Sousa, I. Rheological behavior and microstructure of pea protein/κ- carrageenan/starch gels with different setting conditions. Food Hydrocoll. 2006, 20, 106–113. [Google Scholar] [CrossRef]

- Imeson, A. Food Stabilisers, Thickeners and Gelling Agents; Wiley Online Library: Oxford, UK, 2010. [Google Scholar]

- Mao, L.; Lu, Y.; Cui, M.; Miao, S.; Gao, Y. Design of gel structures in water and oil phases for improved delivery of bioactive food ingredients. Crit. Rev. Food Sci. Nutr. 2020, 60, 1651–1666. [Google Scholar] [CrossRef] [PubMed]

- Moreira, R.; Chenlo, F.; Torres, M.D. Effect of shortenings on the rheology of gluten-free doughs: Study of chestnut flour with chia flour, olive and sunflower oils. J. Texture Stud. 2012, 43, 375–383. [Google Scholar] [CrossRef]

- Fradinho, P.; Sousa, I.; Raymundo, A. Functional and thermorheological properties of rice flour gels for gluten-free pasta applications. Int. J. Food Sci. Technol. 2019, 54, 1109–1120. [Google Scholar] [CrossRef]

- Fradinho, P.; Soares, R.; Niccolai, A.; Sousa, I.; Raymundo, A. Pyllium husk gel to reinforce structure of gluten-free pasta? LWT 2020, 131, 109787. [Google Scholar] [CrossRef]

- Hargreaves, S.M.; Zandonadi, R.P. Flaxseed and Chia Seed Gel on Characteristics of Gluten-Free Cake. J. Culin. Sci. Technol. 2018, 16, 378–388. [Google Scholar] [CrossRef]

- Purwandari, U.; Farida, U.; Dianing, V.P.P.; Sari, L.Y.; Kurniawati, A.G.; Warnianti, A.; Fauziyah, E. Texture, sensory, antioxidant, and blood glucose profile of gluten-free taro and banana noodles using gathotan flour as texturing agent. Int. Food Res. J. 2018, 25, 2459–2466. [Google Scholar]

- Aparicio-García, N.; Martínez-Villaluenga, C.; Frias, J.; Peñas, E. Sprouted oat as a potential gluten-free ingredient with enhanced nutritional and bioactive properties. Food Chem. 2021, 338, 127972. [Google Scholar] [CrossRef]

- Chen, N.; Chen, L.; Gao, H.-X.; Zeng, W.-C. Mechanism of bridging and interfering effects of tea polyphenols on starch molecules. J. Food Process. Preserv. 2020, 44, 14576. [Google Scholar] [CrossRef]

- Torres, M.D.; Arufe, S.; Chenlo, F.; Moreira, R. Coeliacs cannot live by gluten-free bread alone—Every once in awhile they need antioxidants. Int. J. Food Sci. Technol. 2017, 52, 81–90. [Google Scholar] [CrossRef]

- Szabłowska, E.; Tańska, M. Acorn flour properties depending on the production method and laboratory baking test results: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 980–1008. [Google Scholar] [CrossRef] [PubMed]

- Betoret, E.; Rosell, C.M. Enrichment of bread with fruits and vegetables: Trends and strategies to increase functionality. Cereal Chem. 2020, 97, 9–19. [Google Scholar] [CrossRef]

- Xu, J.; Wang, W.; Li, Y. Dough properties, bread quality, and associated interactions with added phenolic compounds: A review. J. Funct. Foods 2019, 52, 629–639. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).