1.1. Outline of the Research

The goal of reducing global fuel consumption and fuel-related emissions has placed tremendous pressure on the aviation industry. In 2018, the aviation industry was responsible for 895 million tons of CO

2 emissions globally emitted into the atmosphere [

1]. Reducing fuel consumption will benefit both the world environment and the air transport industry. According to the Aviation Transport Action Group (ATAG), a reduction in fuel burning will have a significant impact on the aviation industry because the largest operating cost of this industry is fuel [

1]. Drastic measures are still required even though some steps have already been taken to reduce these emissions. Various solutions have been implemented by the aviation industry, including smart material technology, laminar flow technology, air traffic management technologies, advanced propulsion techniques and sustainable fuels [

2,

3,

4]. Morphing wing technology is one of the technologies showing high potential in decreasing aircraft fuel consumption [

5,

6,

7,

8]. Even though there is no settled definition for “morphing”, this term is borrowed in Aviation Technology from avian flight to describe the ability to modify maneuvers at certain flight characteristics in order to obtain the best possible performance. This type of application requires morphing structures capable of adapting to changing flight conditions. Morphing systems include several wing shape modifications, span or sweep changes, changes in twist or dihedral angle [

9] and variations of the airfoil camber [

7] or of the thickness distribution [

4]. In the design phase, both military and civilian aircraft traditionally fly at a single or few optimum flight conditions; morphing, however, is envisioned to increase the number of optimum operational points for a given aircraft [

5].

The morphing strategy scope is broad in the sense that an optimal solution can be generated in various ways with respect to a wide spectrum of mission profiles and types, and flight regimes. Novel technologies need to be part of recent efforts to produce environmentally sustainable and efficient aircraft. To meet environmental guidelines, including those of the International Civil Aviation Organization’s (ICAO’s) Committee on Aviation Environmental Protection (CAEP), innovative technologies such as “morphing” are fascinating as they provide advantages over conventional wing configurations [

10]. Additionally, “morphing” is more practically applied in Unmanned Aerial Vehicles (UAVs) because of their reduced scale and lower complexity in terms of wing design structure and energy consumption expressed in terms of actuation power [

6,

11,

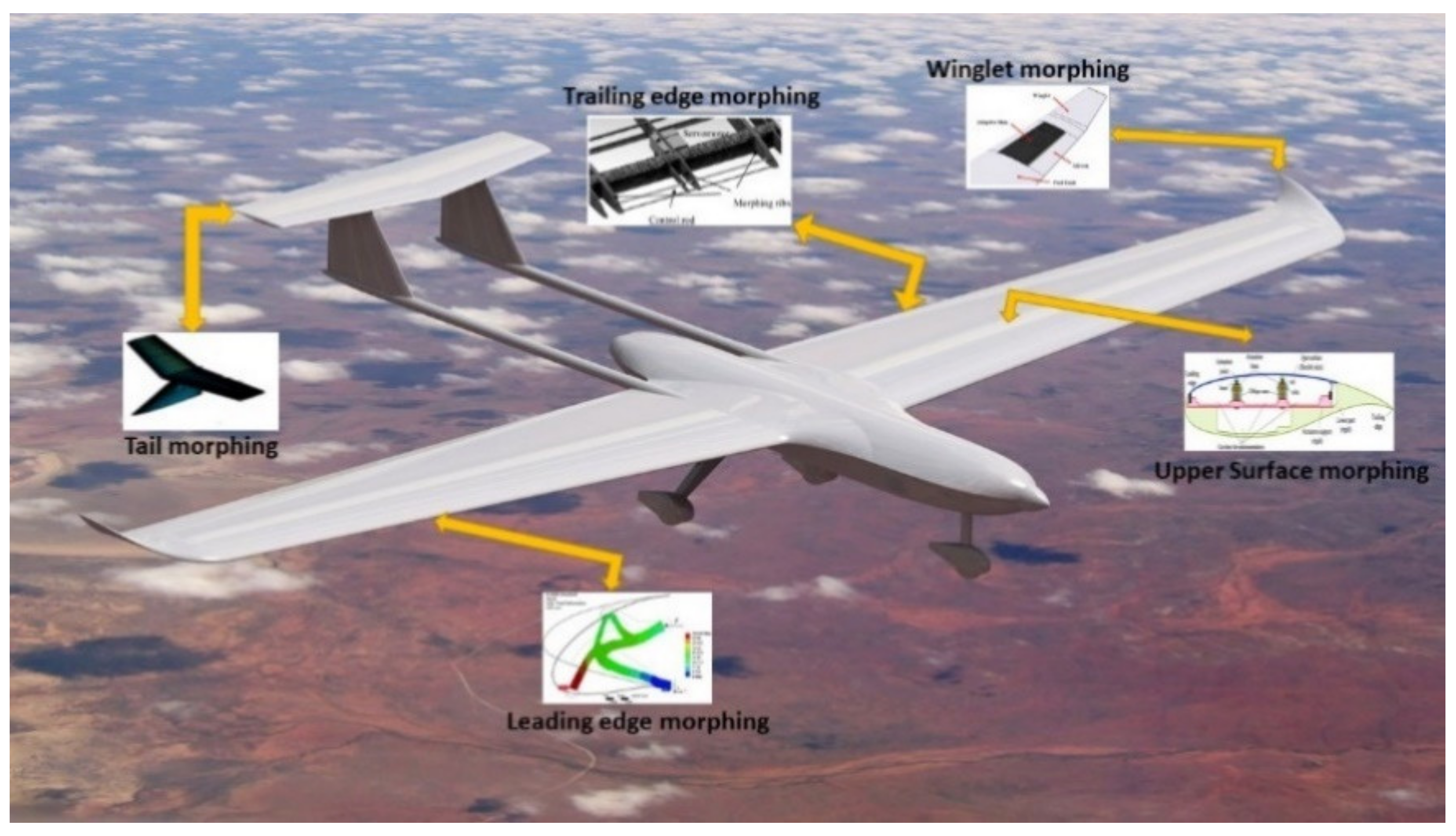

12], in addition to the advantages that morphing designs are lighter and less noisy than their conventional designs. Some morphing opportunities with potential benefits for increasing aerodynamic performance of the UAS-S45 are shown in

Figure 1.

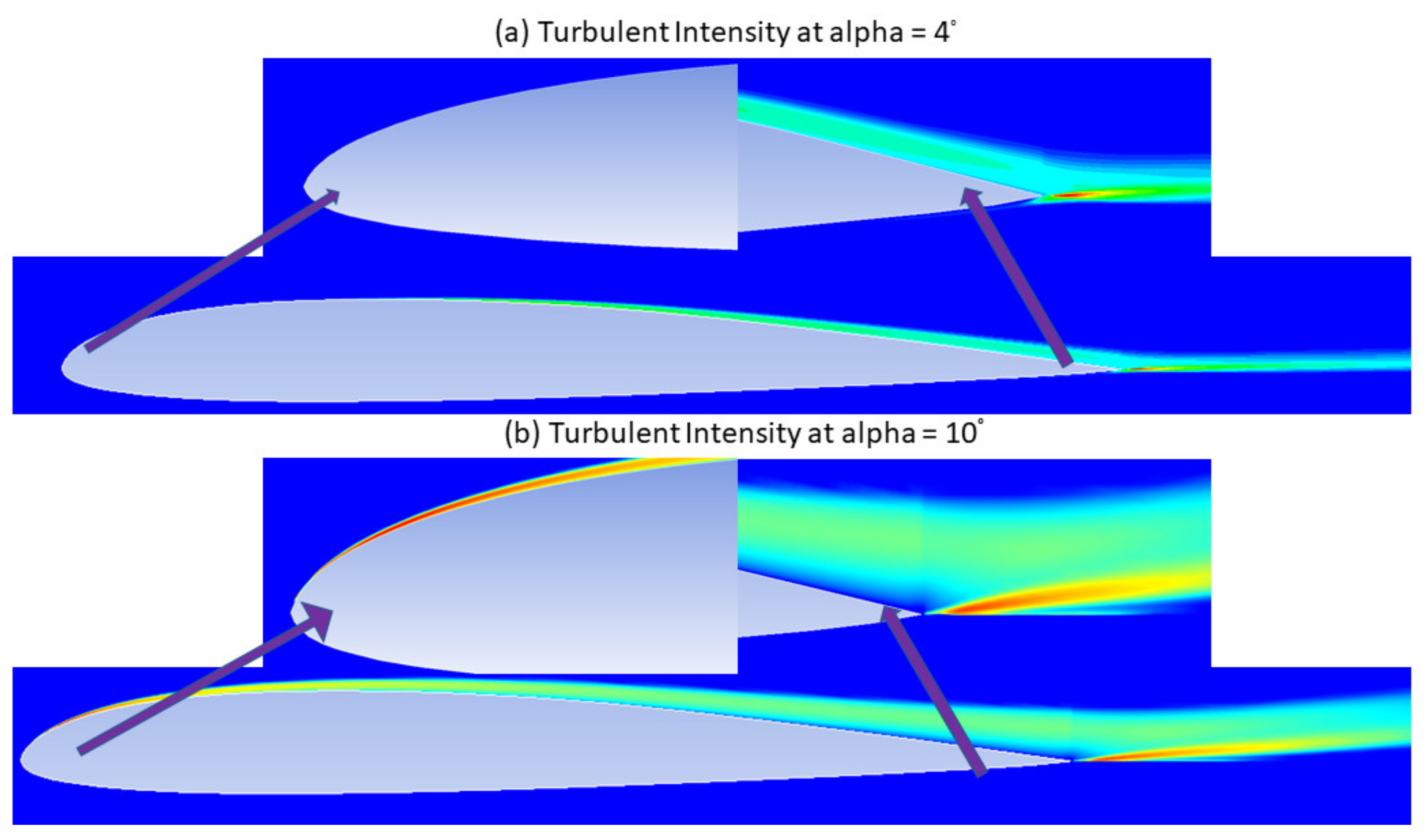

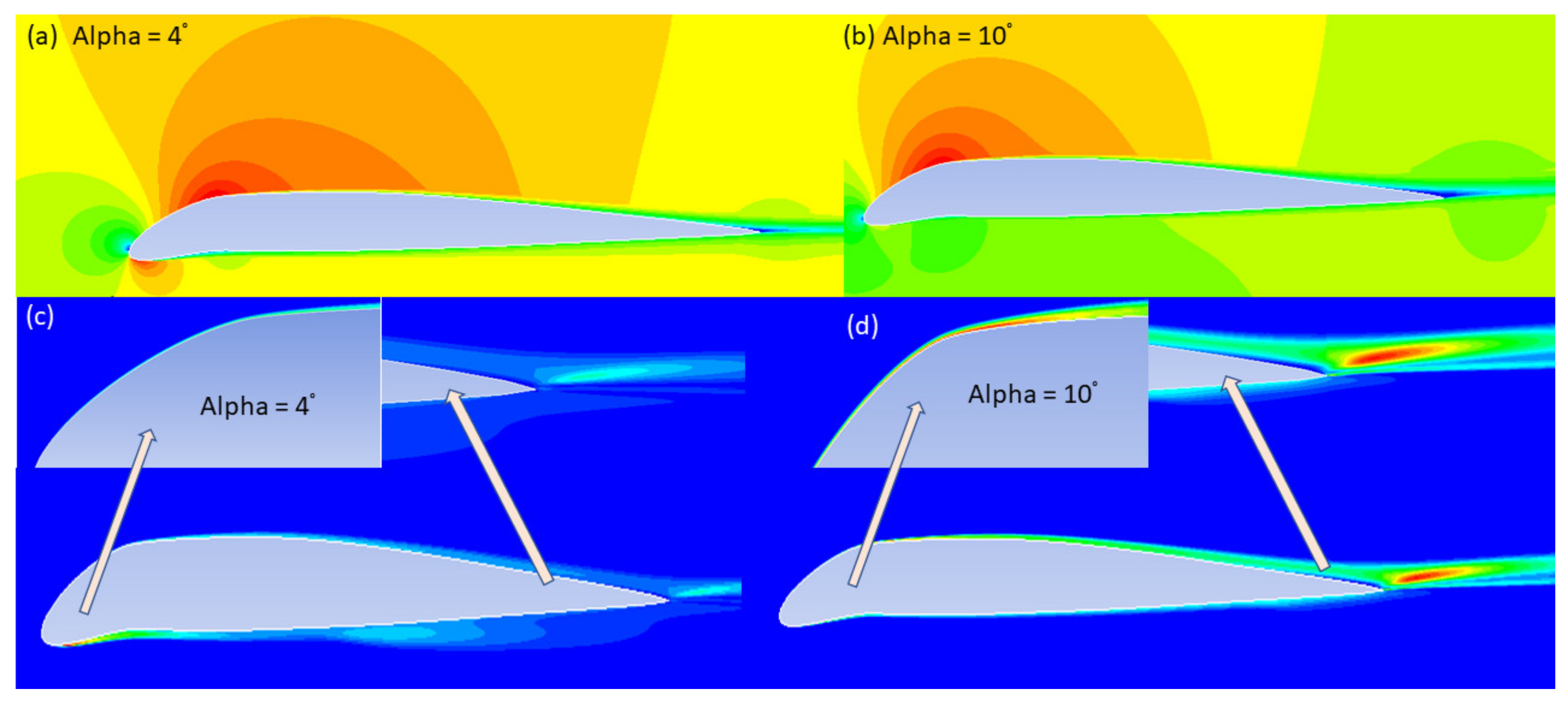

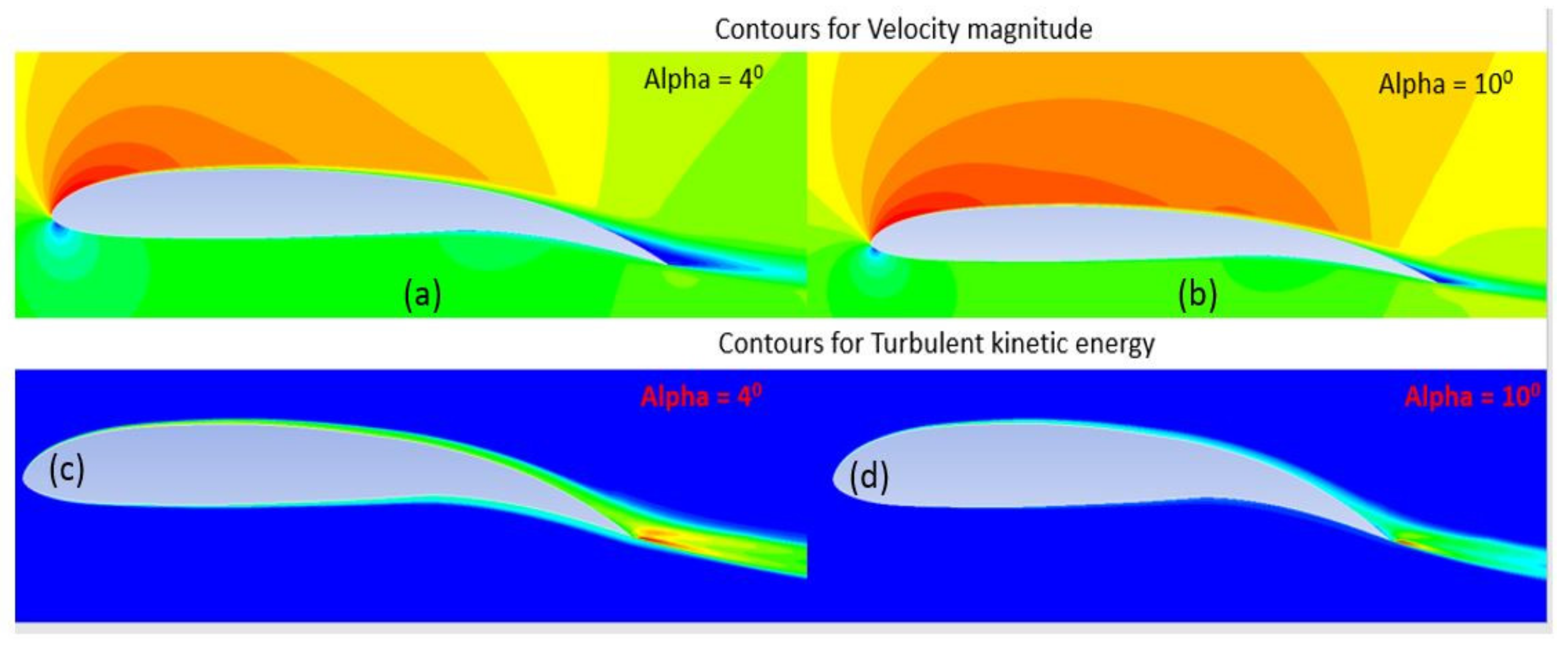

Aircraft are designed to achieve optimal aerodynamic performance (maximum lift-to-drag ratio) for a mission specification and for an extended range of flight conditions. Nevertheless, these mission specifications change continuously throughout the different flight phases, and an aircraft often flies at non-optimal flight conditions. Although the conventional hinged high lifting devices and trailing edge surfaces (discrete control surfaces) in aircraft are effective in controlling the airflow for different flight conditions, they create surface discontinuities, which increase the drag [

13,

14]. The disadvantages of these hinged surfaces are found in both their deployed and retracted configurations [

15]. When deployed, the gaps between the high lifting surface and the wing can cause noise and turbulence, and therefore can produce a turbulent boundary layer and thus increase drag. Even when retracted, the trailing edge hinges still produce a turbulent boundary layer. Numerous researchers believe that the laminar flow technology has the maximum potential to reduce drag and to avoid flow separation [

16,

17]. For this goal, the wings require the design of thin airfoils, seamless high-quality surfaces and variable droop leading edges. The use of these high continuous smooth lifting devices in UAVs will further broaden their flight envelope and extend their endurance. These challenges can be addressed by using morphing technology in the current aviation industry.

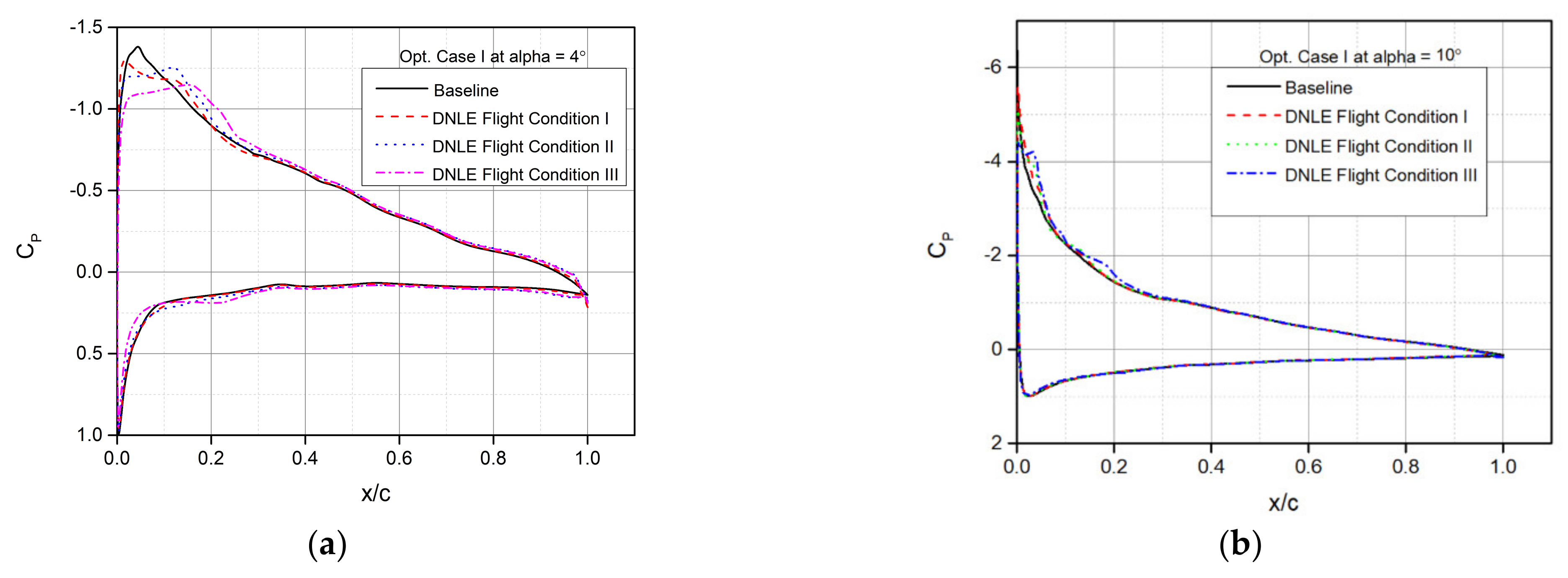

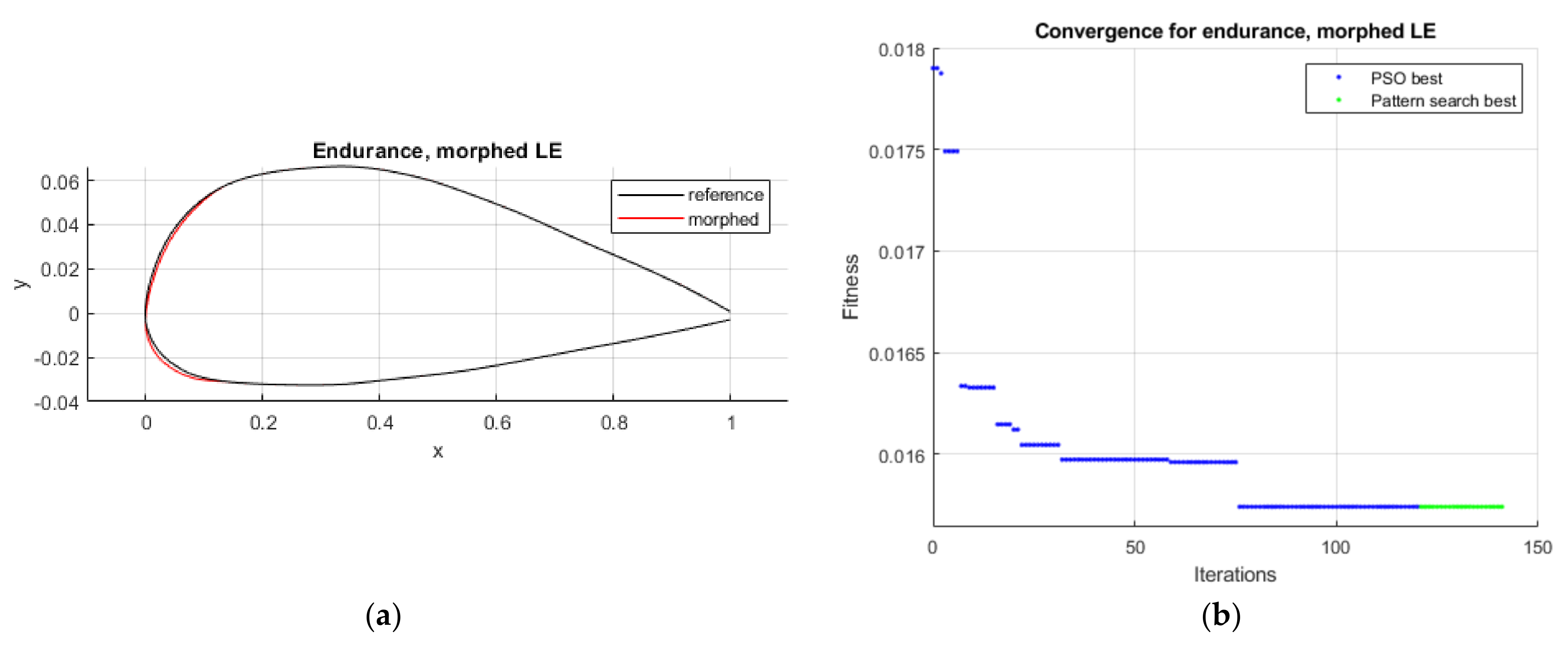

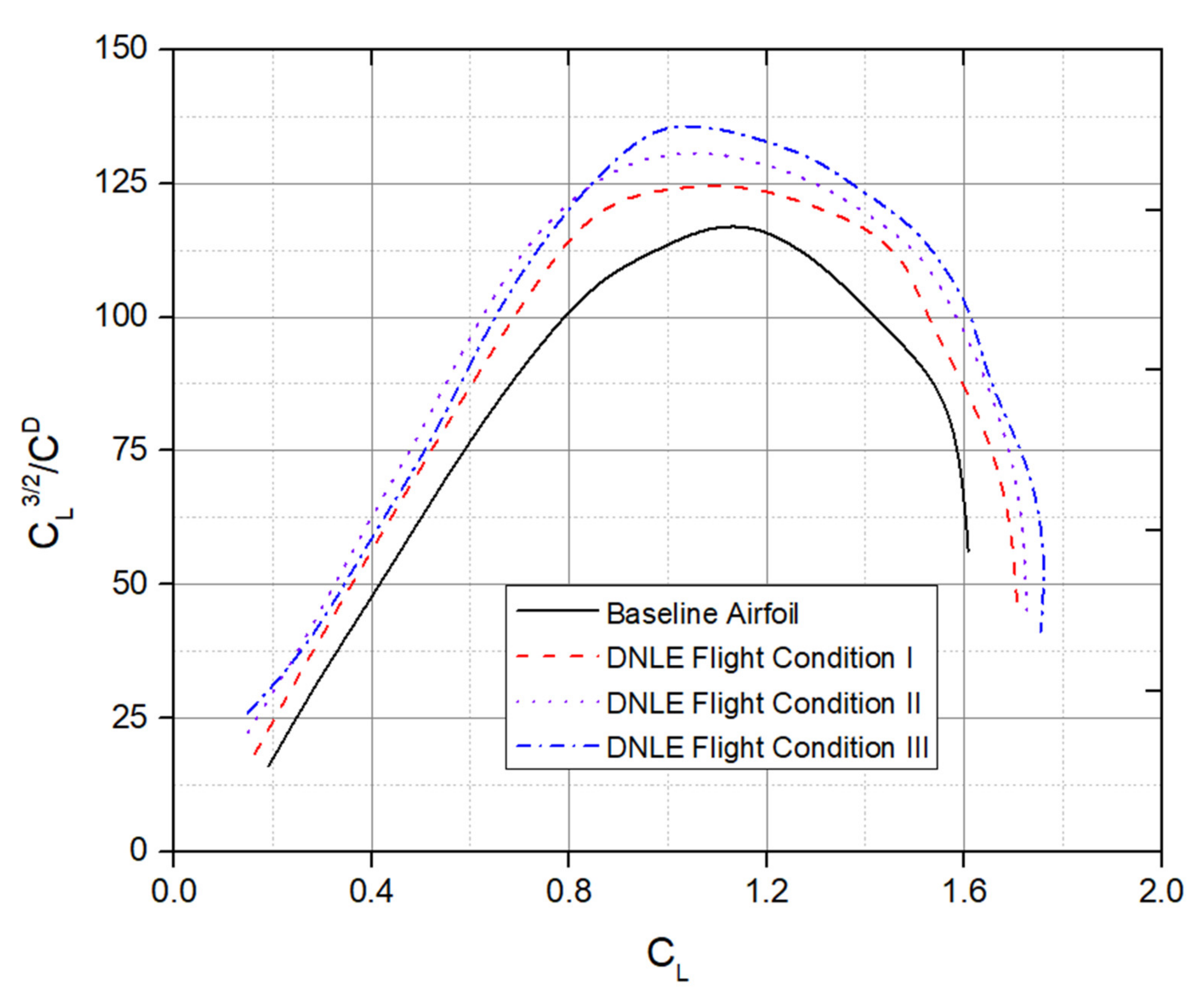

The aim of this study is thus to investigate the aerodynamic optimization by employing constrained shape parameterization for UAS-S45 root airfoil using Droop Nose Leading Edge (DNLE) and Morphing Trailing Edge (MTE) technologies. The aerodynamic design of continuous morphing wing surfaces employed to replace traditional discrete control surfaces, such as flaps, ailerons or sometimes slats, to adjust the camber of the wing, are discussed in this paper along with the parameterization strategy and the optimization algorithm.

1.2. Literature Survey

The potential in the field of aircraft morphing is evident as hundreds of research groups worldwide have been dedicated to studying the different aspects of morphing. Two of the earliest groups were launched by NASA, and they worked within the “Active Flexible Wing program” and the “Mission Adaptive Wing program” [

18,

19]. In these programs, flutter suppression, load alleviation and load control during rapid roll maneuvers were investigated.

One of the potential consequences of flexible morphing structures is that both dynamic properties and aerodynamic loads of the wing are affected. Hence, the aeroelastic effects arising from interactions between the configuration-varying aerodynamics and the morphing structure are significant. Li et al. have presented important morphing studies in terms of aeroelastic, control and optimization aspects [

20].

The nonlinear aeroelastic behaviour of a composite wing with morphing trailing-edge has been studied [

21]. Moreover, the nonlinear aeroelastic behaviour of a composite wing with morphing trailing-edge has been studied.

Aero-elastically stable configurations of a morphing wing trailing edge driven by electromechanical actuators have been investigated [

22]. The effects induced by trailing-edge actuators stiffnesses on the aeroelastic behaviour of the wing were simulated using different approaches. The results revealed that flutter could be avoided if sufficient stiffness was provided by these actuators.

An analytical sensitivity calculation platform for flexible wings has been studied [

23,

24]. This platform has been used to perform wing aeroelastic optimization and stability analysis.

In another study, a low-fidelity model of an active camber aero-elastic morphing wing was developed to investigate the critical speed values by varying its chord-wise dimension [

25]. A wide range of configurations was explored to predict the dynamic behaviour of these active camber morphing wings.

The combined flutter behaviour and gust response of a series of flexible airfoils has been investigated [

26]. Rayleigh’s beam equation was used to model this series of flexible airfoils. The effect of chordwise flexibility of a compliant airfoil was investigated numerically to demonstrate its dynamical stability [

27,

28]. An actuated two-dimensional membrane airfoil was investigated experimentally and numerically, and it was found that membrane flexibility decreased the drag and delayed the stall.

These aeroelastic studies are significant in understanding the flexible morphing wing and its potentially relevant effects. However, our study does not consider the structural effects of morphing, and therefore the optimization is aimed to improve the aerodynamic drag performance and endurance in the given range of angles of attack.

Other research projects in the US and Canada include the “Smart Materials and Structures Demonstration” program initiated to develop new affordable smart materials to establish the performance gains by investigating smart rotors, the smart aircraft and the marine propulsion system; the “Aircraft Morphing” program [

29]; the “Advanced Fighter Technology Integration” (AFTI) program, aimed to develop and demonstrate in flight a smooth variable camber wing and flight control system capable of adjusting the wing’s shape in response to flight conditions to maximize aerodynamic efficiency; the “Active Aeroelastic Wing” program, demonstrated to improve aircraft roll control through aerodynamically induced wing twist on a full-scale high-performance aircraft at transonic and supersonic speeds; the “Morphing Aircraft Structures” program [

30]; the “Mission Optimized Smart Structures” (MOSS), in which aerodynamic optimization was performed with the stretching of the leading edge using a novel skin material developed with a nanocomposite at the National Research Council of Canada [

31]; and the “Controller Design and Validation for Laminar Flow Improvement on a Morphing Research Wing–Validation of Numerical Studies with Wind Tunnel Tests—CRIAQ MDO 7.1” [

32,

33]. The CRIAQ 7.1 project took place at our Laboratory of Applied Research in Active Controls, Avionics and AeroServoElasticity LARCASE.

The European Union has conducted several projects, including the “Active Aeroelastic Aircraft Structures” (3AS) project, to develop novel active aeroelastic control strategies to improve aircraft performance (structural weight, better control effectiveness) by controlling structural deformations to modulate the desired aerodynamic deformations [

34]; the “Aircraft Wing Advanced Technology Operations” (AWIATOR) project, in which novel fixed wing configurations were introduced aimed at reducing the vortex hazard by implementing larger winglets and further improving aircraft efficiency and reducing farfield impact [

35]; the “New Aircraft Concepts Research” (NACRE) project, in which Powered Tails and Advanced Wings were studied to obtain high environmental performance (noise and CO2 emissions)—both high aspect ratio low-sweep wings and forward-swept wings (with natural laminar flow) contributed to achieving good fuel efficiency [

36]; the “Smart Leading Edge Device” (SmartLED) project [

13]; the “Smart High Lift Devices for Next Generation Wings” (SADE) project [

37]. Both SmartLED and SADE were aimed to develop and investigate the morphing high lift devices, “smart leading edge” to enable seamless high lift devices and therefore enable laminar wings and “smart single-slotted flap”, for the next generation aircraft of high surface quality for drag reduction. Projects by the European Union also included the “Smart Fixed Wing Aircraft” (SFWA) project [

38] and the “Smart Intelligent Aircraft Structures” (SARISTU) project to address the physical integration of smart intelligent structural concepts. The SARISTU included a series of research collaborations to addresses aircraft weight and operational cost reductions as well as an improvement in the flight profile specific aerodynamic performance [

39]. Other projects by the European Union were the “Novel Air Vehicle Configurations” (NOVEMOR) project, in which morphing wing solutions (span and camber strategies and wing-tip devices) were proposed to enhance lift capabilities and maneuvering [

40]; the “Clean-Sky 1 and 2” projects [

41,

42]; the “Combined Morphing Assessment Software Using Flight Envelope Data” (CHANGE) project, which developed a modular software architecture capable of determining and achieving optimum wing shape [

43]; and the “Sustainable and Energy Efficient Aviation” (SE2A) project aimed to investigate the Morphing structures for the 1g-wing to exploit the nonlinear structural behavior of wing design components to achieve passive load alleviation [

44].

The “Morphing Architectures and Related Technologies for Wing Efficiency Improvement-CRIAQ MDO 505” was also realized at the LARCASE in the continuation of the CRIAQ 7.1 project mentioned above. The achievements of the international Canadian-Italian CRIAQ MODO 505 project are mentioned in various publications [

45,

46].

The aircraft optimization process has evolved dramatically over the past decades. The design of new intelligent algorithms and computational solvers has substantially impacted the overall design process, including the “morphing aircraft optimization”. The verification and validation of aircraft design using optimization techniques has reduced its huge experimental costs and has been achieved by the use of efficient algorithms and computational solvers [

47,

48]. An optimization process is initiated by minimizing or maximizing an objective function for the target design concept with respect to design variables subjected to given constraints, which were applied to limit the search space and therefore to yield physically feasible optimization results. Both gradient-based and gradient-free intelligent algorithms have been used in these optimization processes, and their results are dependent on the type of optimization problem to be solved [

47]. These algorithms are discussed in the following sections. Many optimization techniques based on bioinspired processes and Surrogate-Assisted natural methods have been formulated, and mathematical and statistical analysis of these algorithms has been performed [

49,

50,

51,

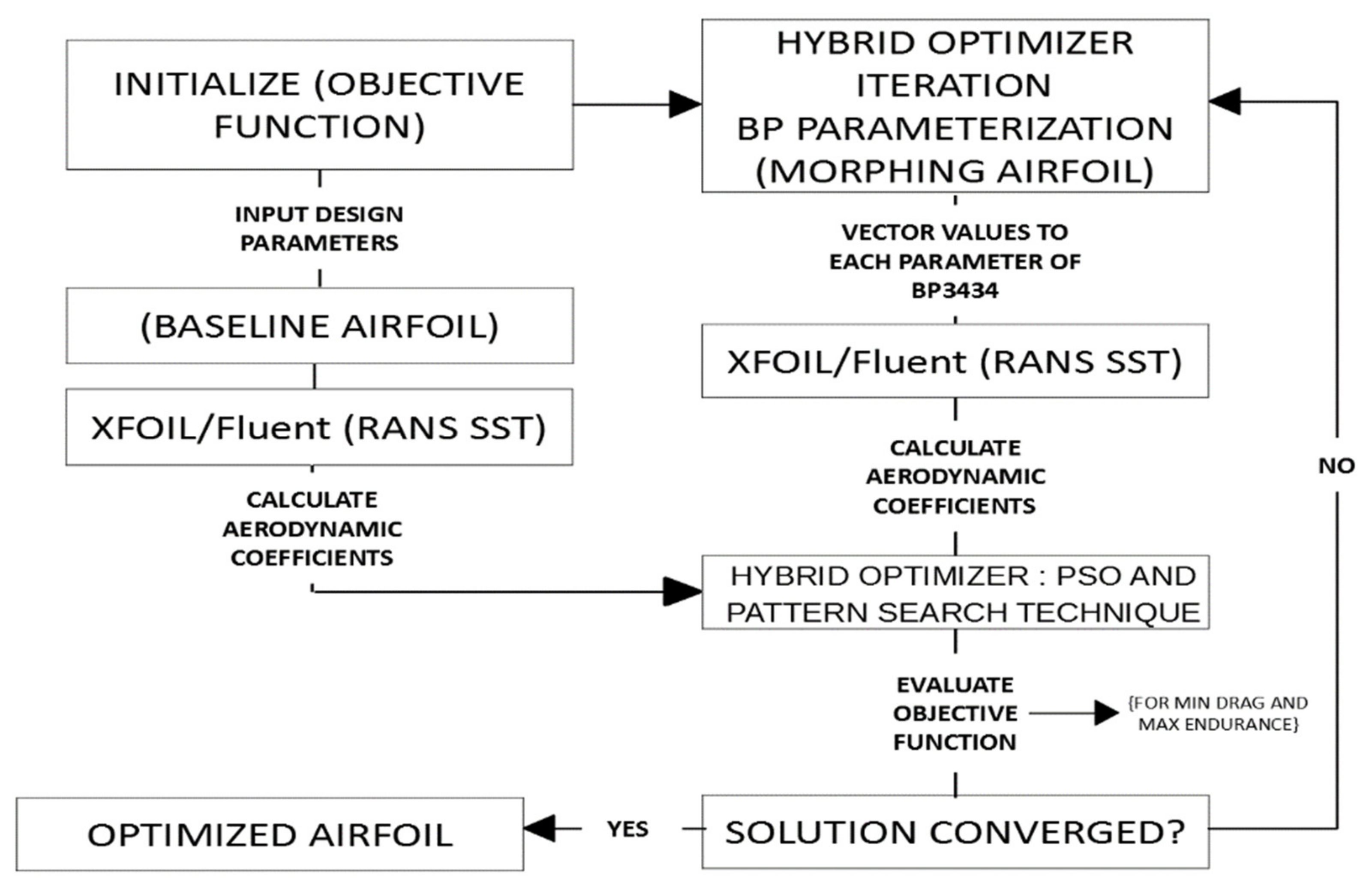

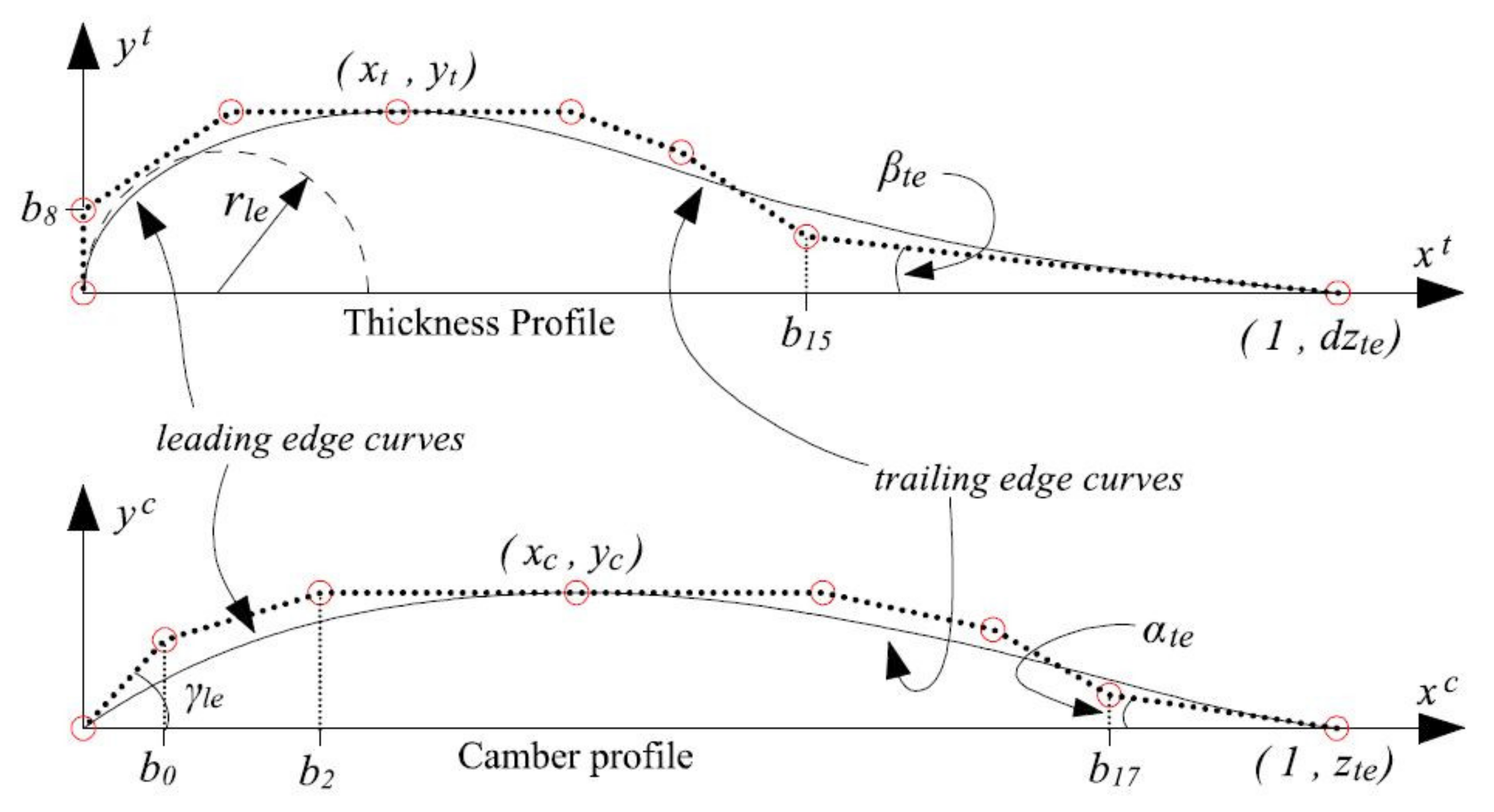

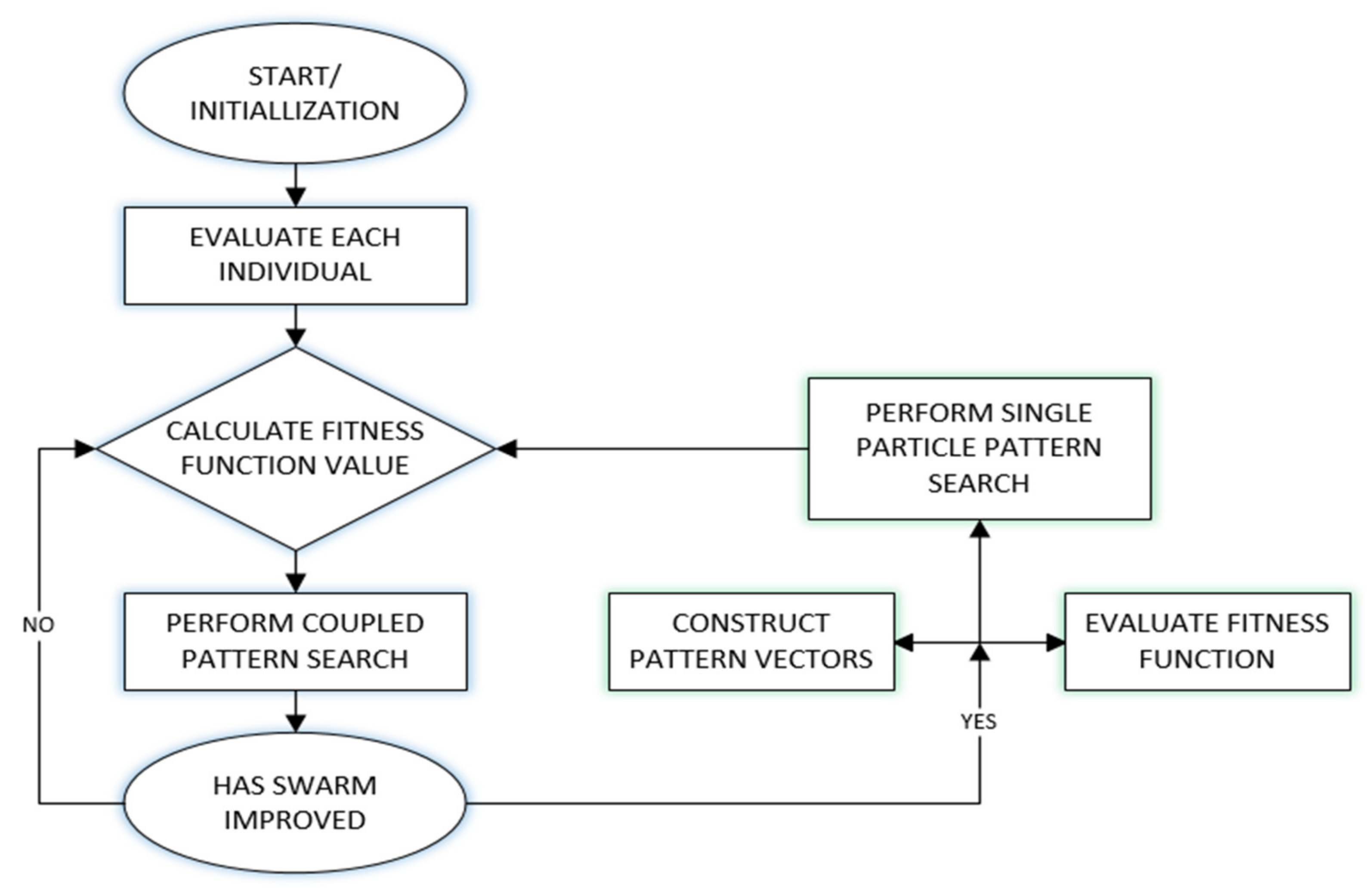

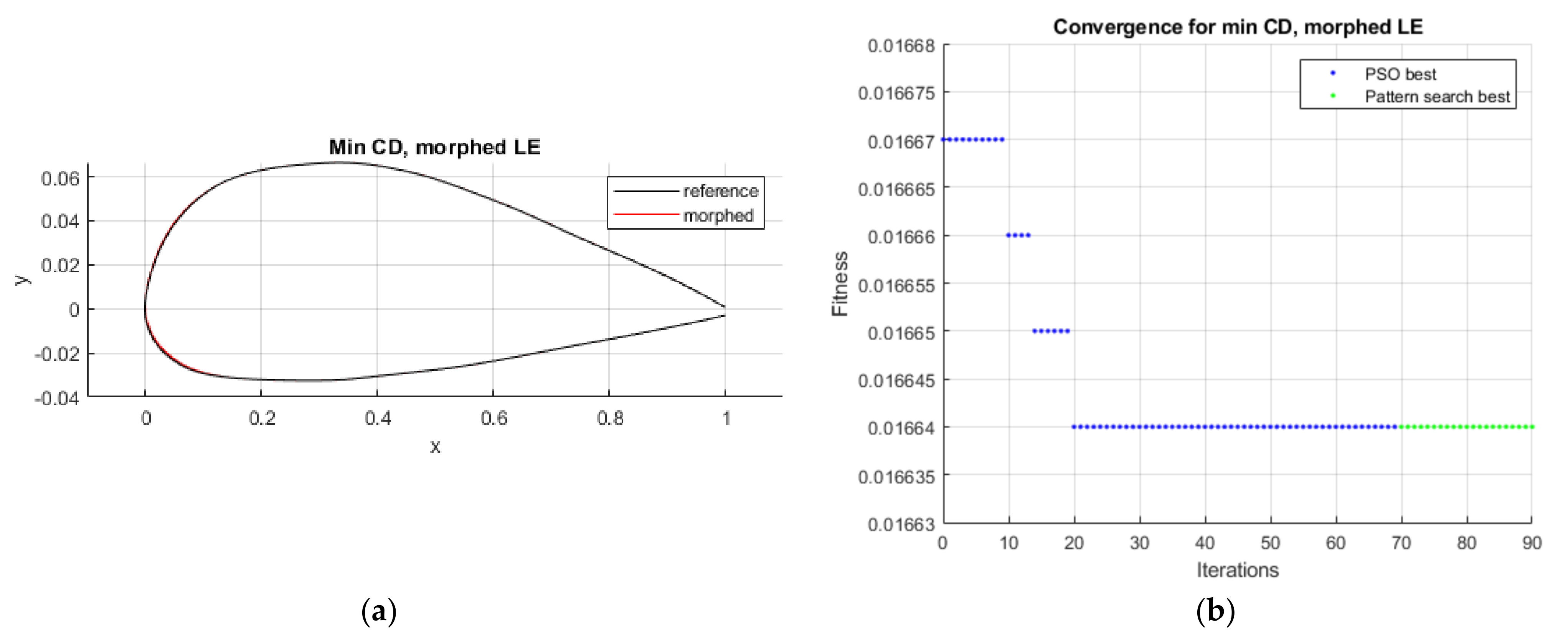

52]. The comparative performance study based on convergence trends was performed with different geometry parameterization techniques. Both advantages and disadvantages can be found in these optimization algorithms for complex shape functions. However, the goal of this study is to perform aerodynamic design optimization of morphing airfoil using Particle Swarm Optimization (PSO) algorithm combined with Pattern Search technique.

Similarly, various computational solvers are employed based on their desired solution accuracy and computational cost [

53]. Researchers have conducted various aerodynamic and structural optimization studies, including design studies of different surfaces (components) of the wing, such as its upper surface, trailing edge or leading edge. Adjoint-based airfoil optimization has been studied using Euler equations [

54], while other researchers have implemented extensive gradient-based aerodynamic shape optimization methodologies for transonic wing design using high-fidelity RANS solvers [

55]. Many other optimization studies have been performed using different optimization techniques. Some of the most notable works are summarized in

Table 1.

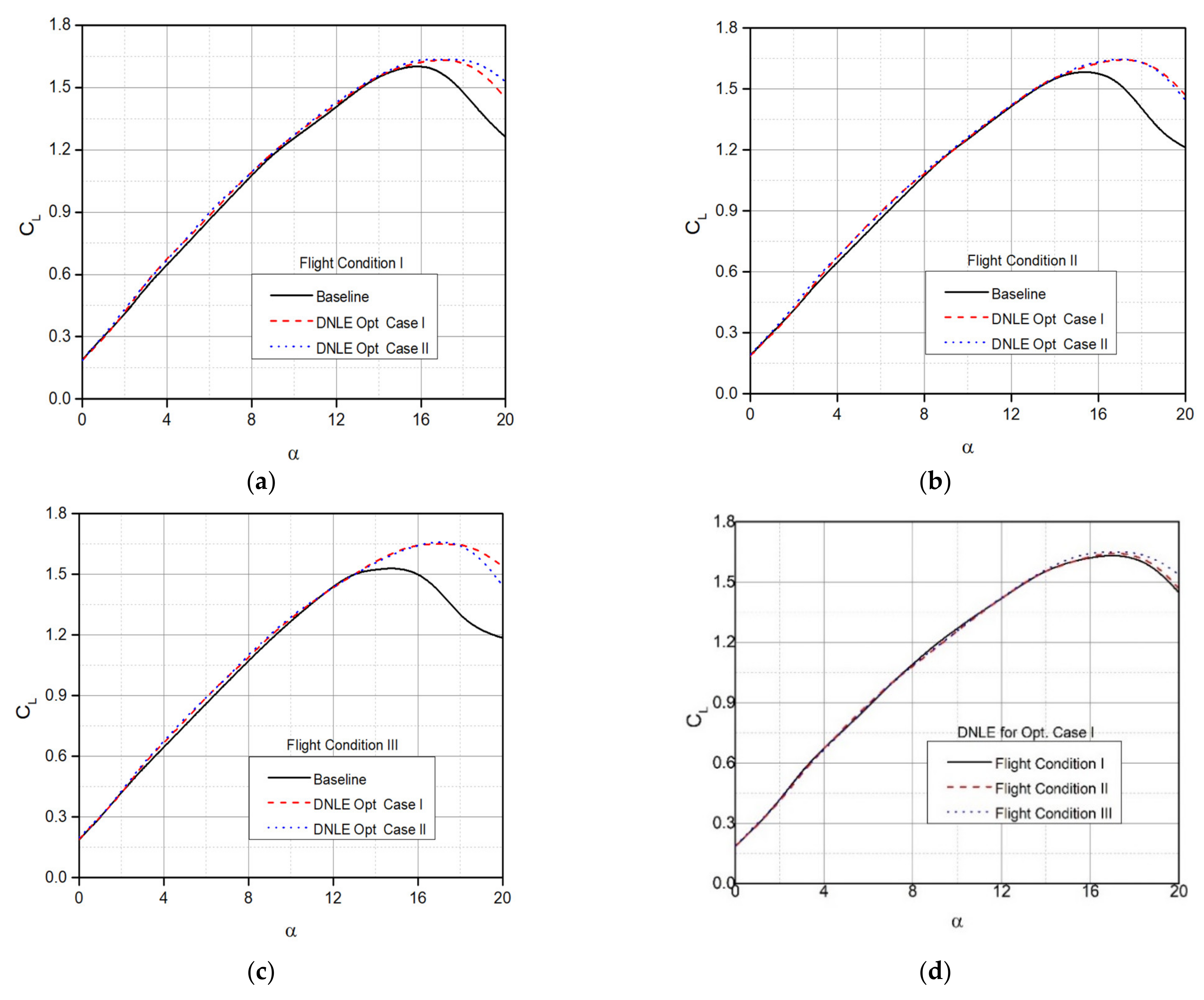

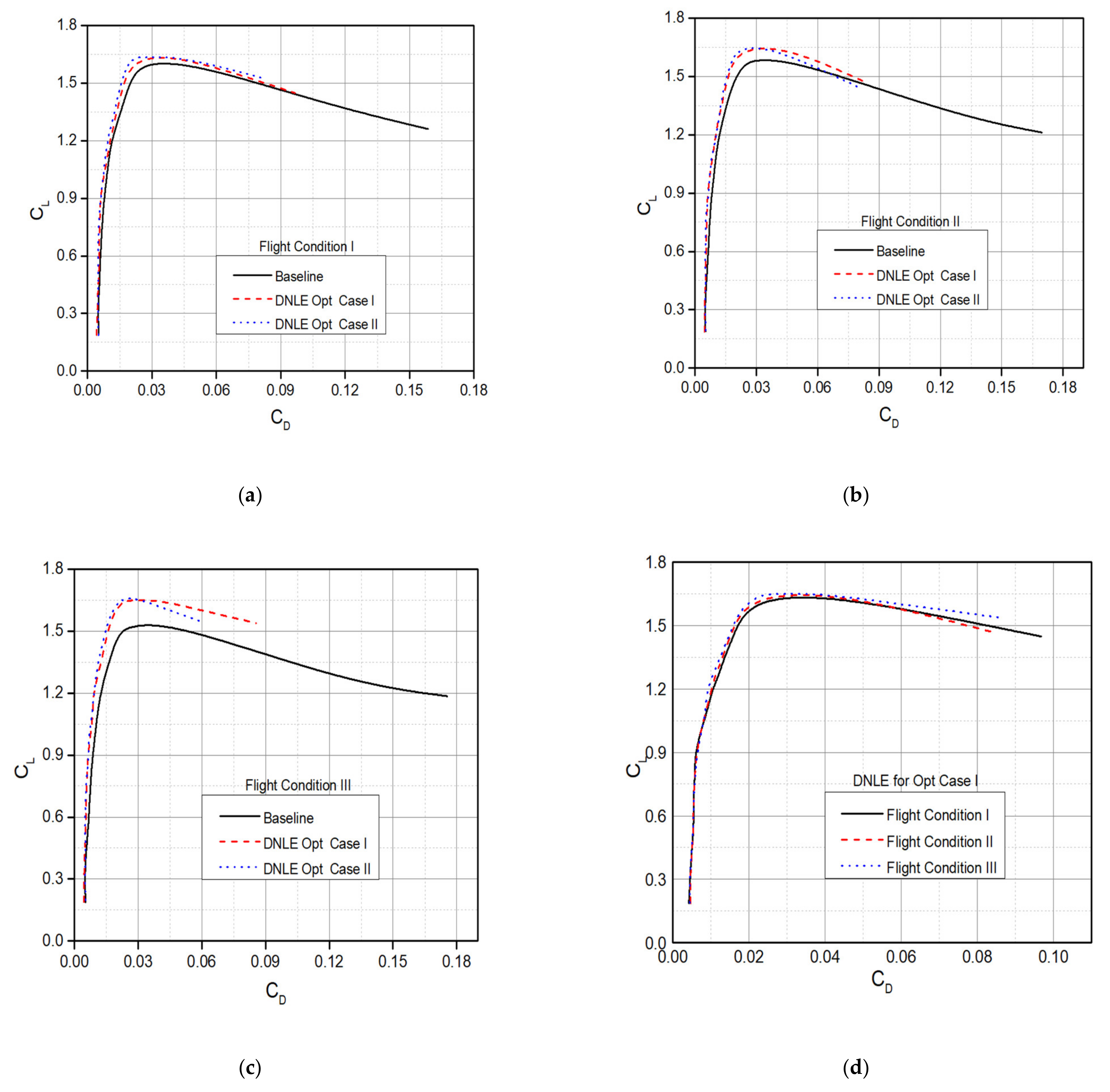

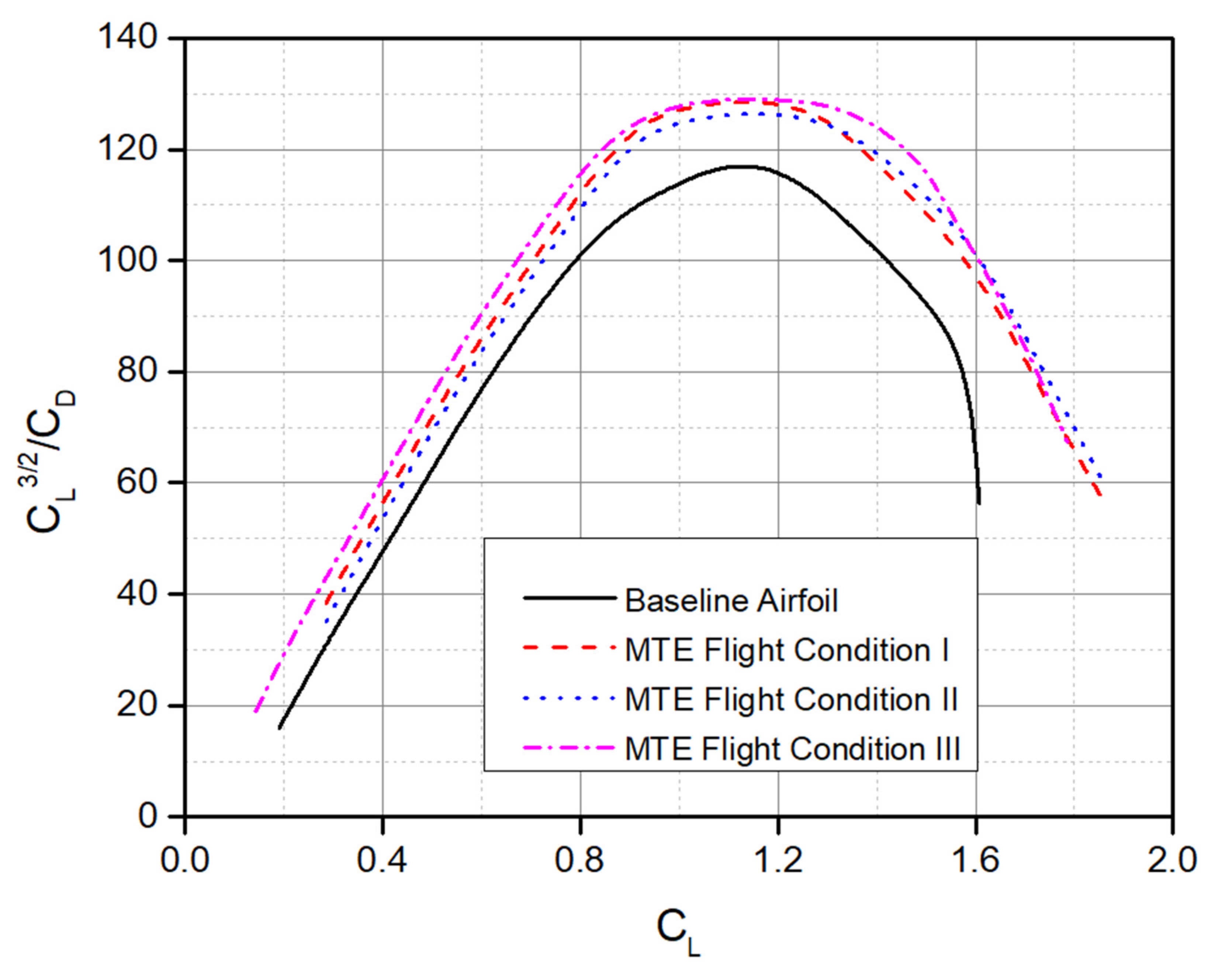

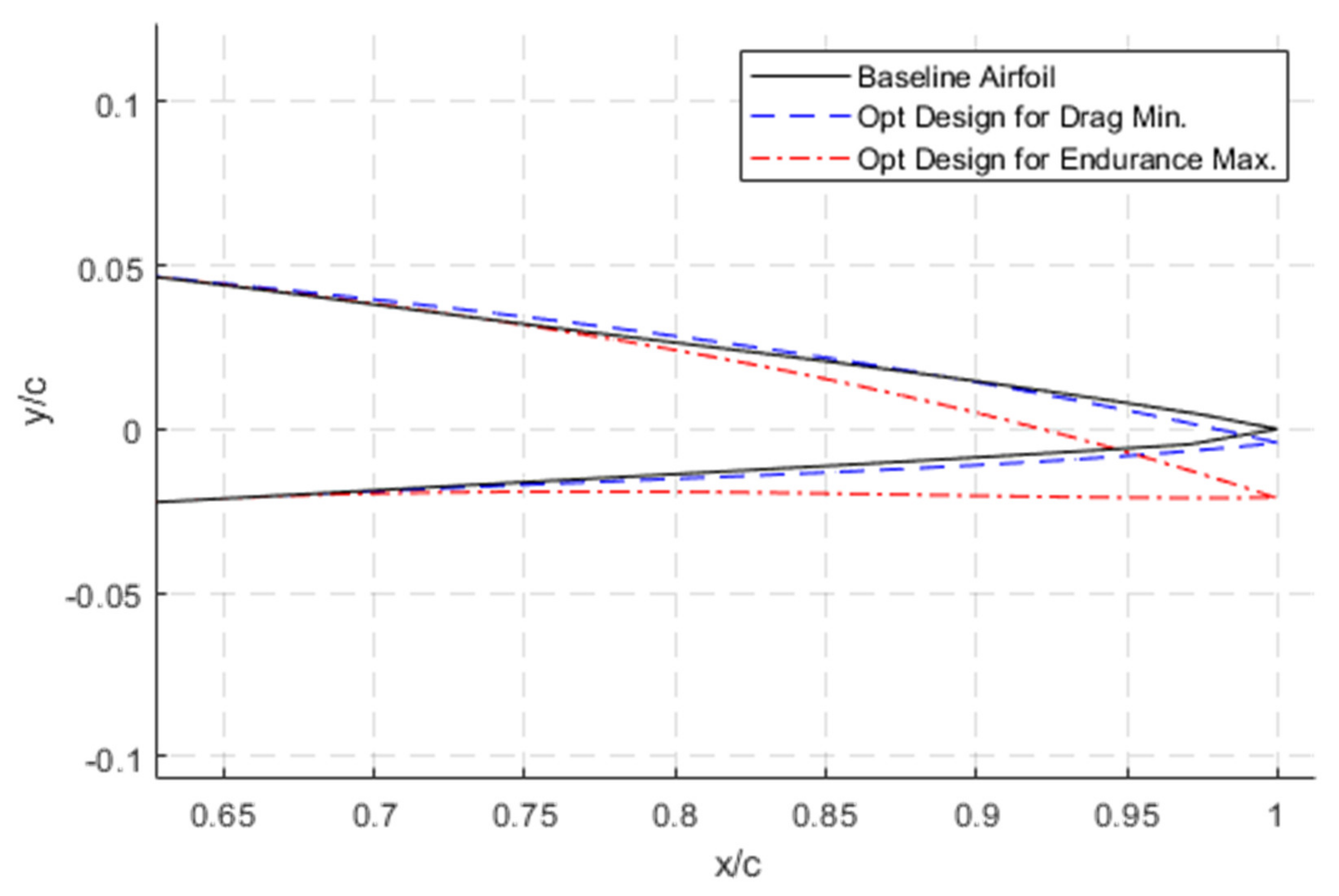

The study presented in this paper analyses the aerodynamic optimization of the Hydra Technologies S45 Balaam UAS airfoil. This unmanned aerial surveillance (UAS) system is needed to provide security and surveillance capabilities for the Mexican Air Forces, as well as civilian protection in dangerous situations. This study of Morphing Wing Technology has the aim to enhance the aerodynamic efficiency and the effective range of the UAS S45, as well as to extend the flight time. The next section of this paper presents the optimization framework of the overall methodology, which includes two objective functions’ formulations (“drag minimization” and “endurance maximization”). The parameterization technique is also presented in

Section 2 and has the aim to obtain the “optimal aerodynamic shapes”; the computational solvers for calculating aerodynamic coefficients and the optimization algorithms employed are also presented. The results obtained by these solvers and algorithms for the UAS-S45 optimized designs are compared with the baseline UAS-S45 model results.