1. Introduction

Iterative learning control (ILC) is a control method that is suitable for the repetitive control processes, such as reciprocating robot manipulator and multi-batch chemical production processes. In each of these tasks, the system is required to perform the same task over and over again. The learning process uses information from previous repetitions to improve the control data for the current repetition. It can efficiently track a desired trajectory for an uncertainty nonlinear dynamic system without requiring the mathematics model of the system. So, ILC is a model-free data-driven control method. Additionally, it has important practical value for high-precision industrial control systems without an accurate mathematic model [

1,

2]. After more than 40 years of development, ILC have made many important achievements in theoretical research [

3,

4,

5] and practical applications [

6,

7,

8].

The premise of ILC is that the parameters, desired trajectory and initial state of the system must remain unchanged for all repetitive periods [

9]. However, if the premise cannot be strictly met, methods should be discovered to expand the scope of application of the ILC, or continue to use the control data obtained from the previous iterative learning, and avoid relearning from the beginning; this is the focus of many scholars in this field.

For the situations in which the desired trajectory is not strictly consistent or there is an initial state deviation, Hou proposed to use an extended state observer to estimate the non-strict repetitive disturbance and cancel its influence in advance. It made ILC applicable to the system with limited disturbance [

10]. Sun proposed an iterative learning algorithm with initial correction effect and final state attraction, which effectively solved the problem of trajectory deviation in the case of fixed deviation between the iterative initial state and the desired initial state [

11]. Liu proposed a flexible ILC for systems with similar desired trajectories by means of Cartesian product [

12]. Foudeh proposed gradient-based norm optimal ILC for unmanned aerial vehicles to cope with exogenous disturbances caused by wind gusts [

13]. Chen developed a distributed controller to solve the leader-follower consensus of multiple flexible manipulators with uncertain parameters, unknown disturbances, and actuator dead zones, in which iterative learning is used to handle the repeatable disturbances [

14]. All the above studies mainly focus on tracking the trajectory with certain deviation or disturbance. There is no pre-adjustment of the ILC experience data according to the deviation or disturbance.

In iterative learning control, the initial iteration control data are usually set to zero or a constant. Once the controlled system or the desired trajectory changes, ILC needs to relearn from the beginning. As a result, in many high-precision machining processes, the original ILC experience is no longer applicable in the situations like a component is replaced, or the working environment changes, or the desired trajectory is adjusted. So ILC needs to go through many turns of learning again. In this process, a large amount of waste will be generated, leading to serious loss of time, materials and energy. Therefore, the research of inheriting the learning experience of former ILC in the new working conditions becomes a very necessary problem.

Some researches tried to inherit the experience of former ILC as the initial data of new ILC process when the desired trajectory changes. Xu designed a direct learning control method according to the proportional relationship between the new desired trajectory and the former desired trajectory in the amplitude axis and time axis, respectively [

15,

16]. After transforming the former ILC control data on the amplitude axis and time axis, it is used as the initial iterative control data of the new desired trajectory. Pu divided the gradient surface of the machined parts into a group of homogeneous trajectory groups [

17], with final ILC control data of the first trajectory acting as reference. Then, those ILC control data are transformed via proportional scale and offset, which are used as the initial data of the next adjacent trajectory iterative learning. Hoelzle expressed the new desired trajectory as combinations of serial former trajectories, and combined the control data obtained from the former ILC as the initial iteration data of the new desired trajectory [

18]. Xu proposed an ILC algorithm for optimal matching of trajectories [

19]. The new desired trajectory is segmented, translated and rotated to obtain the primitive combined trajectory. Through the series combination of trajectory, control data and time-scale transformation, the initial iteration control data are obtained. Pang used the control data of symmetric trajectories for iterative learning control via mirror transformation [

20]. Alajmi constructed an initial iterative control data set containing multi-frequency components of the system [

21]. He also introduced an upper limit to the initial data for the input signal of ILC to avoid the aggressive response due to the uncertainty that lies in high frequencies. Besides, the robust iterative learning model predictive control algorithm with variable reference trajectory proposed by Ma also aimed at solving the control experience inheritance problem of ILC when the desired trajectory changes [

22]. These studies used the pre-adjusted experience data from former ILC for a new desired trajectory. As the convergence of the error depends highly on the initial choice of input applied to the ILC, a set of good initial data would make learning faster and, as a consequence, the error tends to the required accuracy faster as well.

All the above studies only consider the ILC experience inheritance in the situations where the desired trajectory changes in the new control task. However, there are some other neglected situations which need ILC experience inheritance. For example, a new motor with higher power substitutes the old one in the robot manipulator driving unit, or some other parameters like the load, the damp ratio changes in the system. Until now, no research involving the ILC experience inheritance in such situations has been reported.

In modern industry, the changes of working process occur frequently. As the structure and essence of the system remain unchanged, so it is possible to transfer the former control experience or knowledge into the new system. For such systems, according to the specific relation within the parameters change, the inner relevance of two systems, the experience obtained from the former ILC might be inherited and transformed as the initial iterative control data of the new iterative learning process, which could save the time and resource in the new system.

The paper is organized as follows. In the second section, the traditional ILC algorithm is introduced. Its limitations are described. In the third section, an ILC of recombining transform strategy is presented. In the fourth section, an ILC of translational adjusting strategy is introduced. In the fifth section, an ILC of amplitude adjusting strategy is introduced. The simulation results are given to illustrate its merits over the traditional ILC in each section. Next, the convergence property of the ILC with experience transfer is analyzed. The conclusion is drawn in the final section.

2. Problem Description

2.1. Iterative Learning Control

ILC aims at a specific controlled system with a repetitive working process. ILC uses its historical operation data to modify the control action continuously, so as to improve the control accuracy. The typical P-ILC algorithm is described as follows:

where

i is the index of iterations;

k is the time of discretization;

ui+1 is the control input of the (

i + 1)-th iteration;

ui is the control input of the

i-th iteration;

L is the learning gain and

ei is the error between the desired

yd and the output

yi in the

i-th iteration process.

It can be seen from the above that the control input

u is adjusted iteratively on the iteration axis according to the input and output error of former iterations, which can be written as follows:

where

u0(k) is the initial control input of iterative learning. If the initial control input of the first iteration could be close to the control input of the final iteration, the turns of iterations required to achieve the desired control accuracy will be significantly reduced.

2.2. Description of Controlled System

The transfer function and state equation of the controlled system are generally described as following a transfer function or state equation:

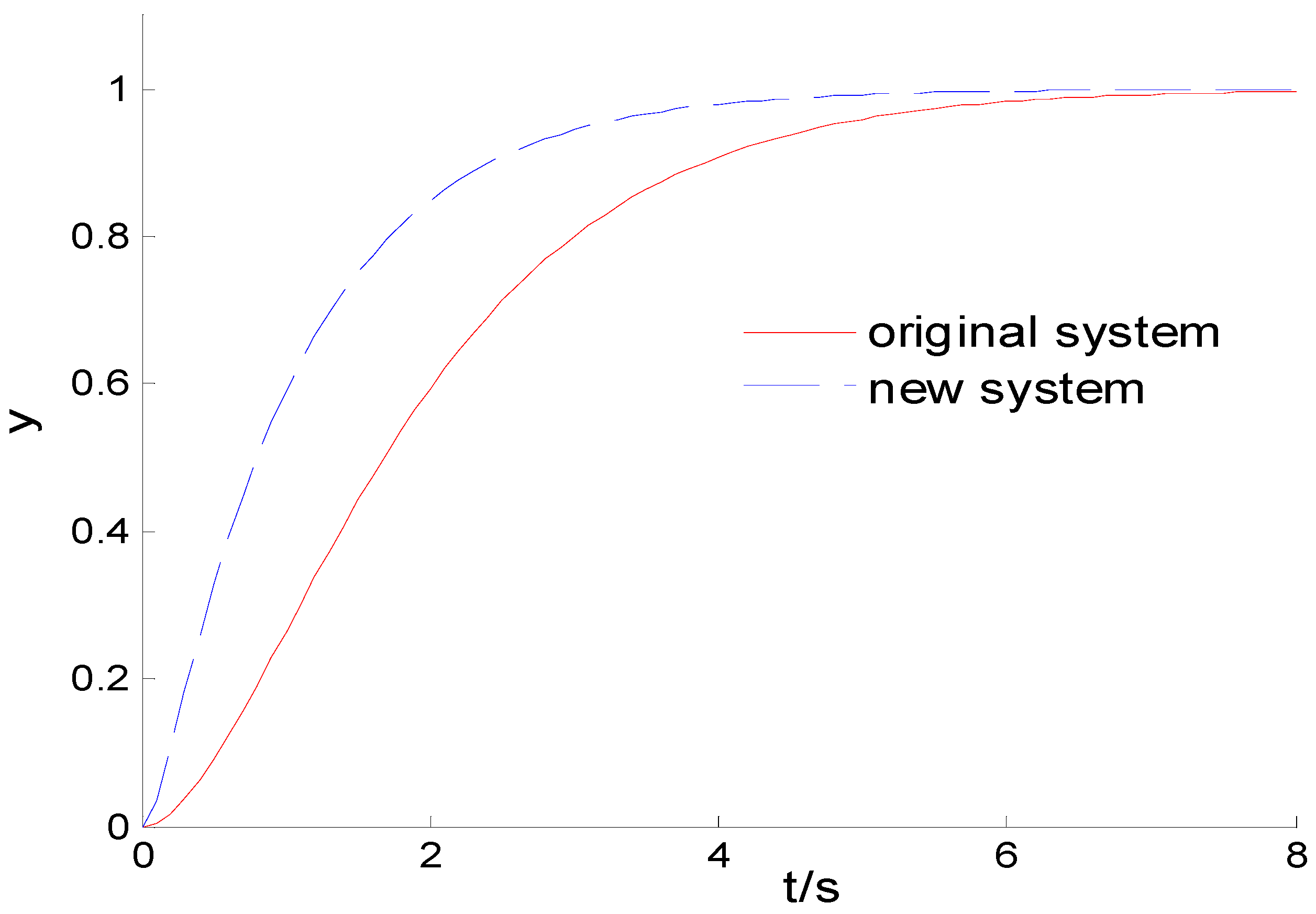

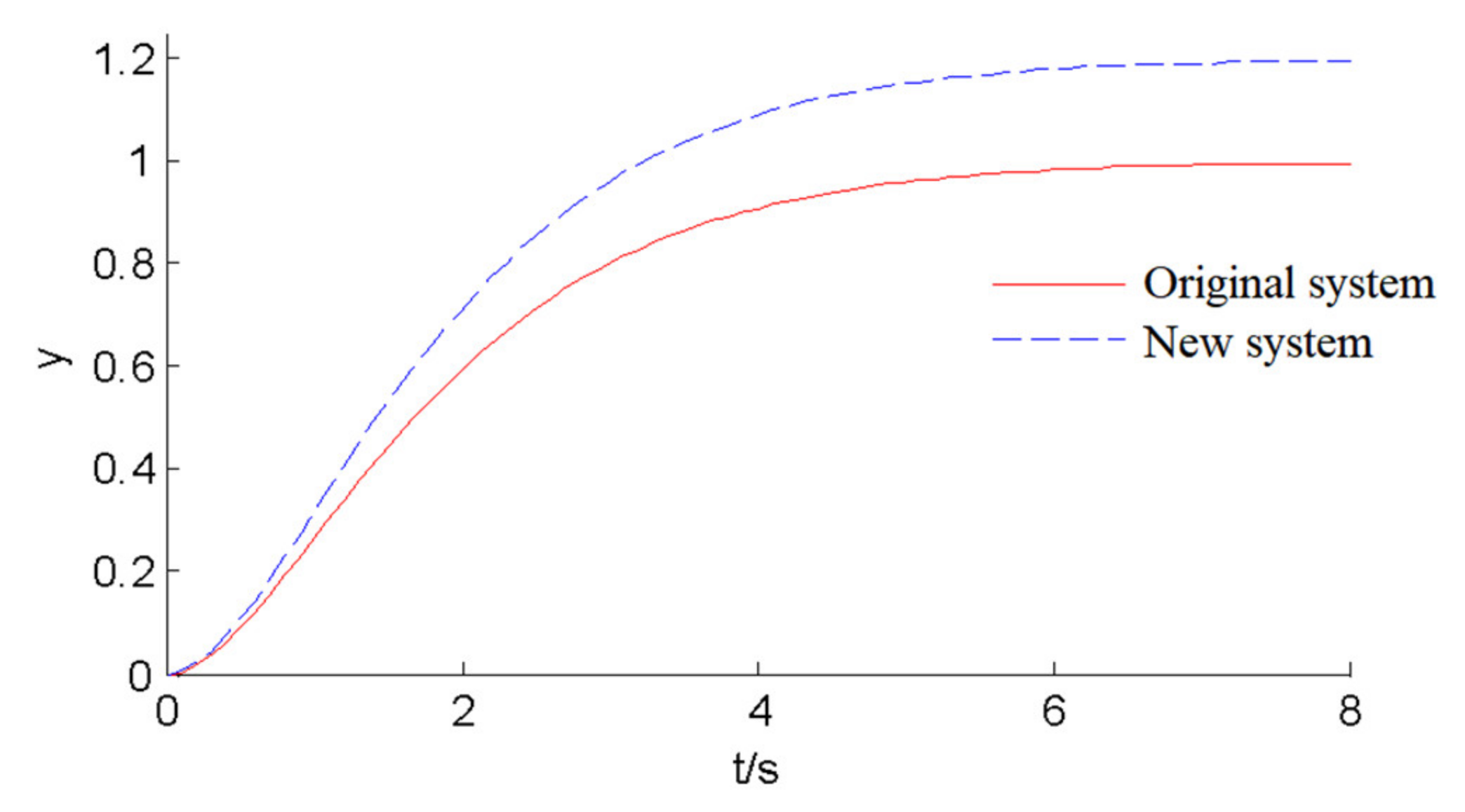

In the transfer function shown in Equation (3), K is the system gain, which is generally affected by the driving power and load. It is related to the B in the state Equation (4). The T in transfer function is the inertia time constant of controlled system, which is related to the parameters of A in the state equation. τ is the delay of control system, which is related to the action process of actuator. The matrix C in the state equation is the parameters related with system output.

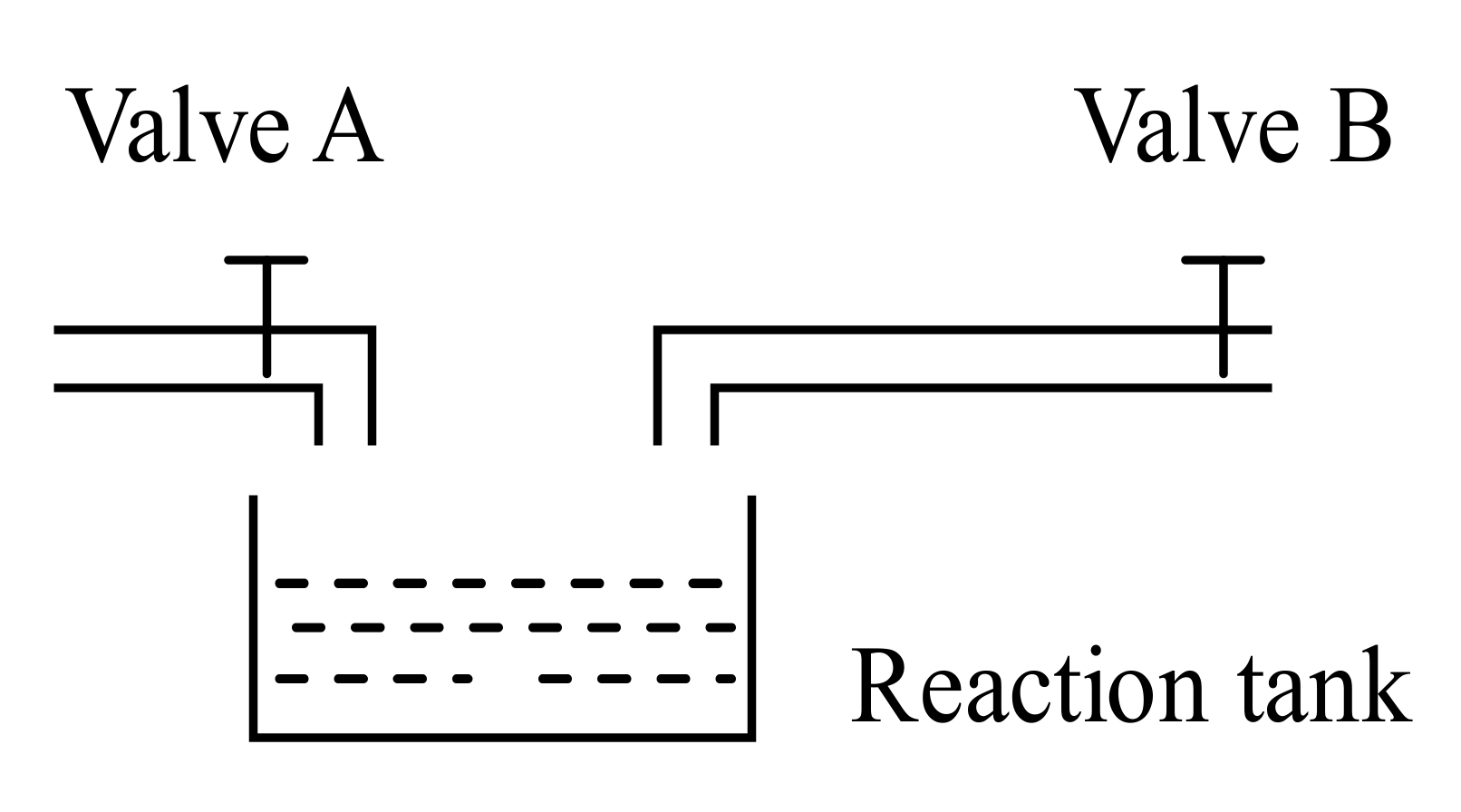

In the application of ILC, the parameters in Equation (3) or (4) must be the same in all iterations. However, sometimes, one of the parameters in the system might change due to the replacement of a unit in the system, such as a motor, a sensor, a harder material, a lighter load, etc. Although one parameter changes in the system, the structure and the order of the transfer function or state equation remain unchanged. This paper focuses on the above situations and manages to transfer the experience obtained in the ILC of the former system into the new system. In this paper, only the following changes are considered: the change of transfer function on time constant T of dominant pole due to the change of controlled system’s damping, the change of state equation’s parameters in matrix A due to parts’ replacement, the change of parameters in the matrix B due to the change of power intensity in the driving unit, the change of the parameters in the matrix C due to change of the sensor’s proportional coefficient in the sampling unit, and the change of the lag time in the system input and feedback units due to the replacement of actuators or sensors.

2.3. Problems Raised

In the industrial production or process control, when parts of the equipment or the materials of the processed parts are changed, the experience gained from original iterative learning control is no longer applicable. In general, learning should be resumed from zero initial data. In this re-learning process, there would be a negative impact on production efficiency and cost. For the mass production, this negative impact can be ignored, considering that tens of thousands of products are produced. However, for the small batch production, it is intolerable to ignore the negative impact caused by the continual changing of production process and equipment, which poses new challenges to the application of traditional ILC. How to effectively use the original control experience data of ILC in the new tasks becomes an important issue.

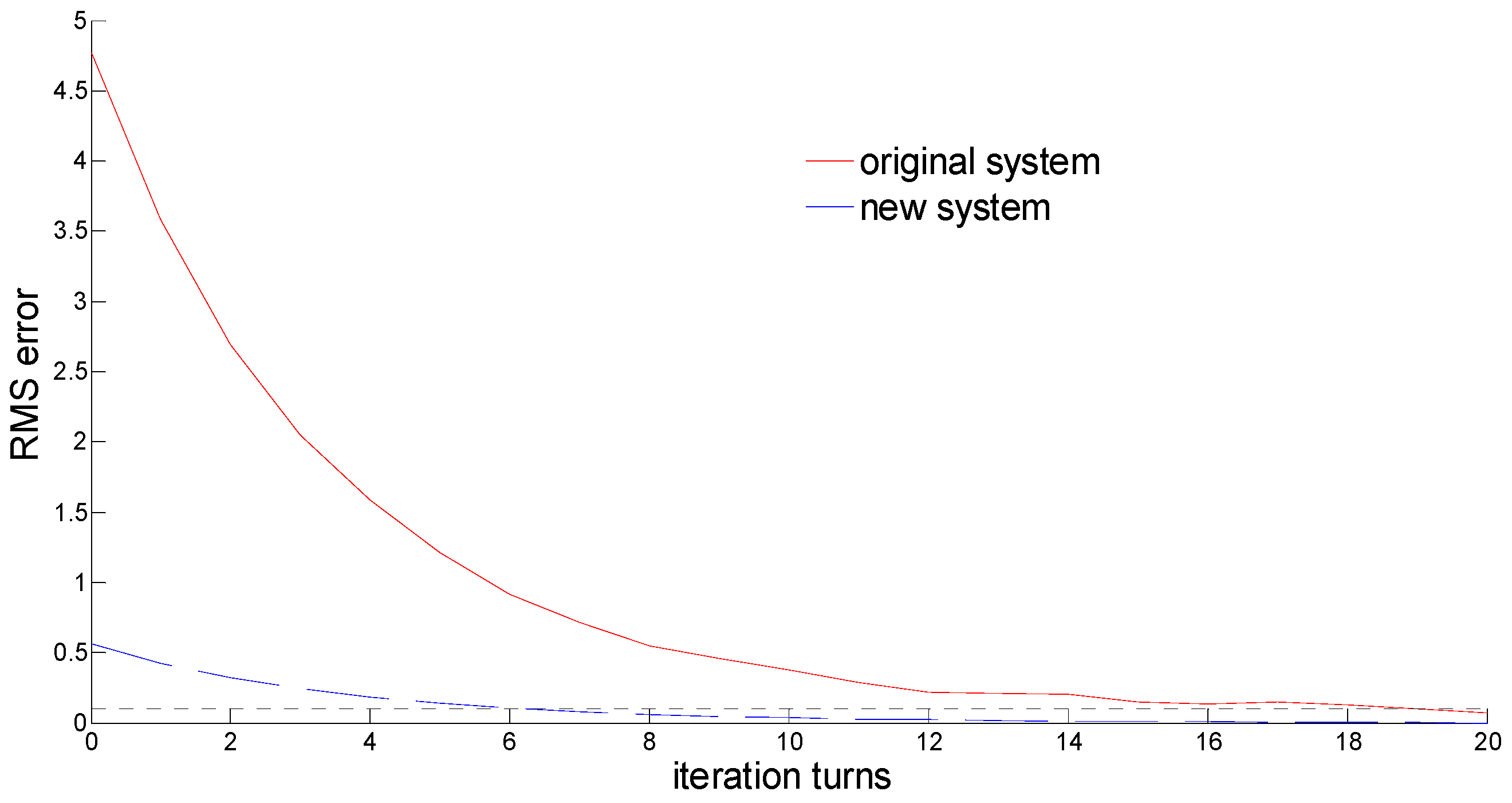

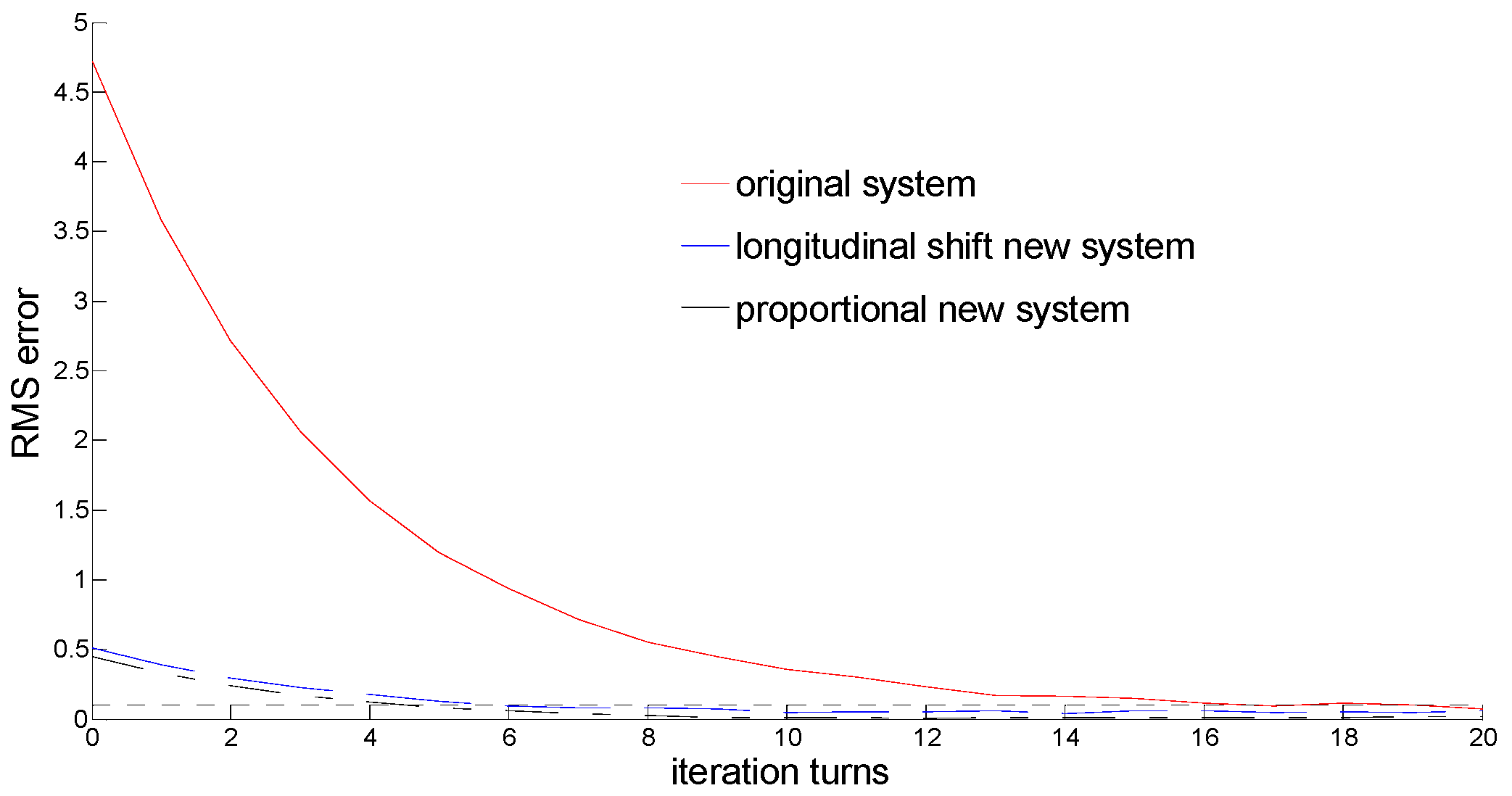

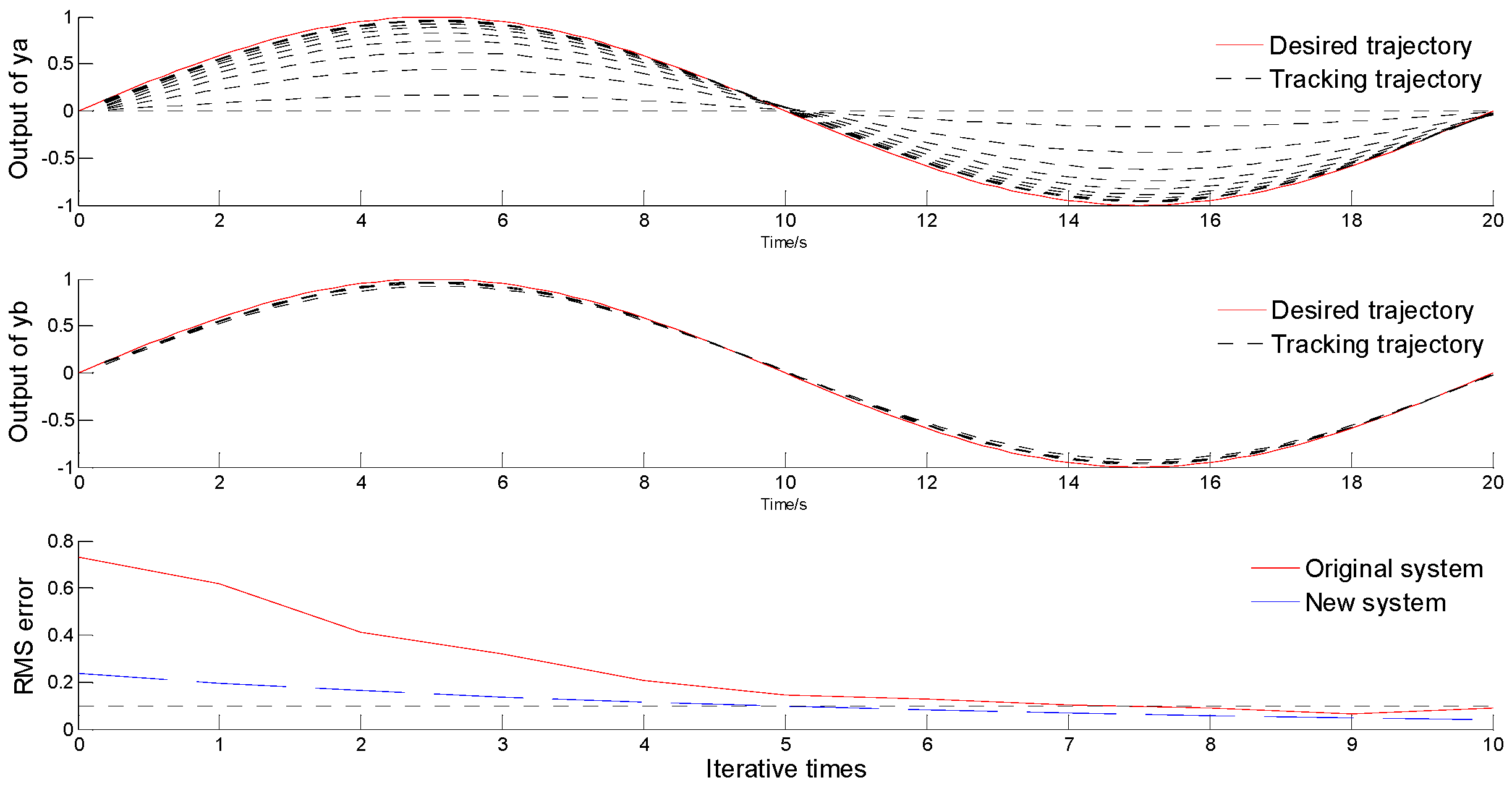

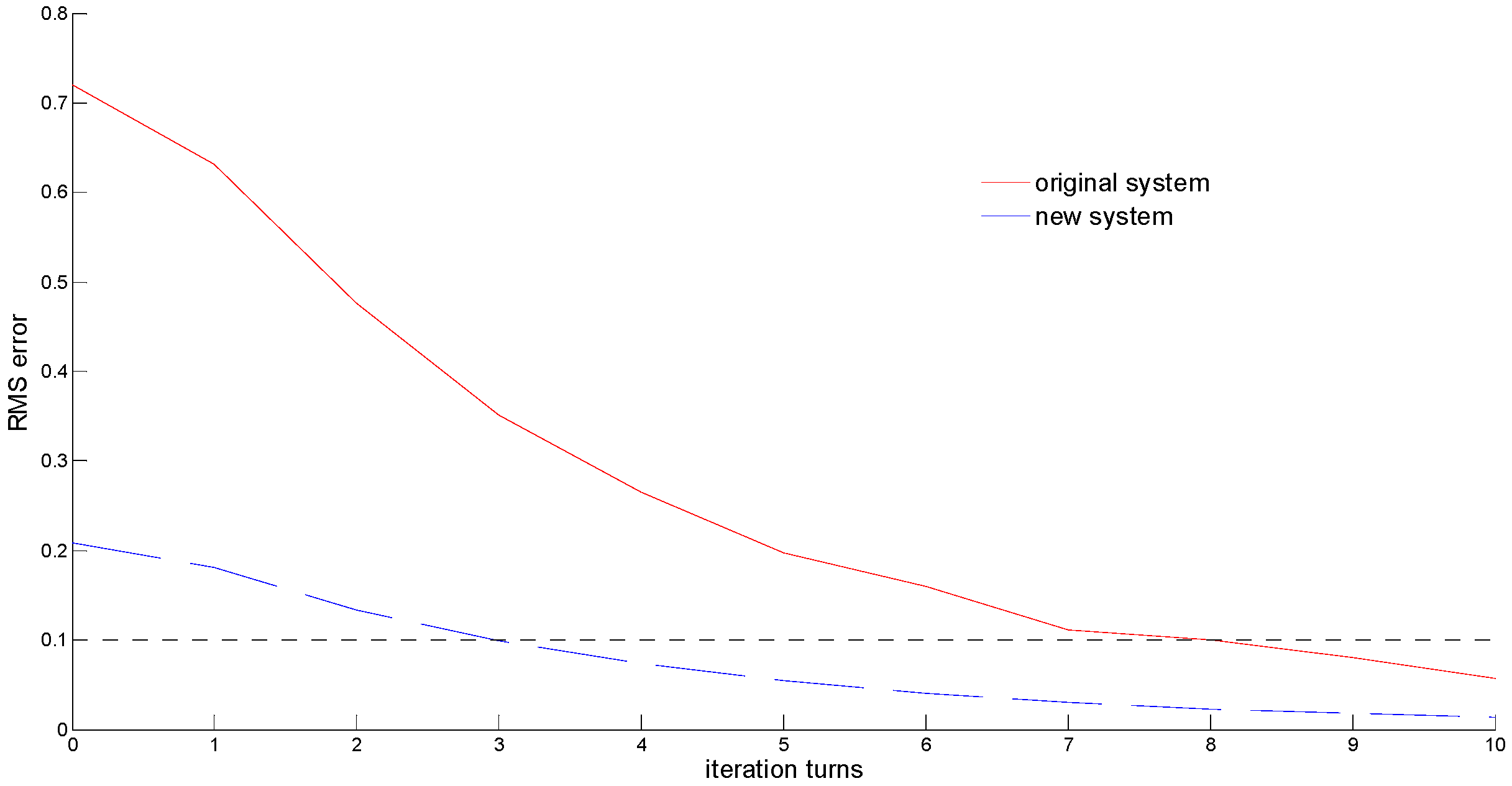

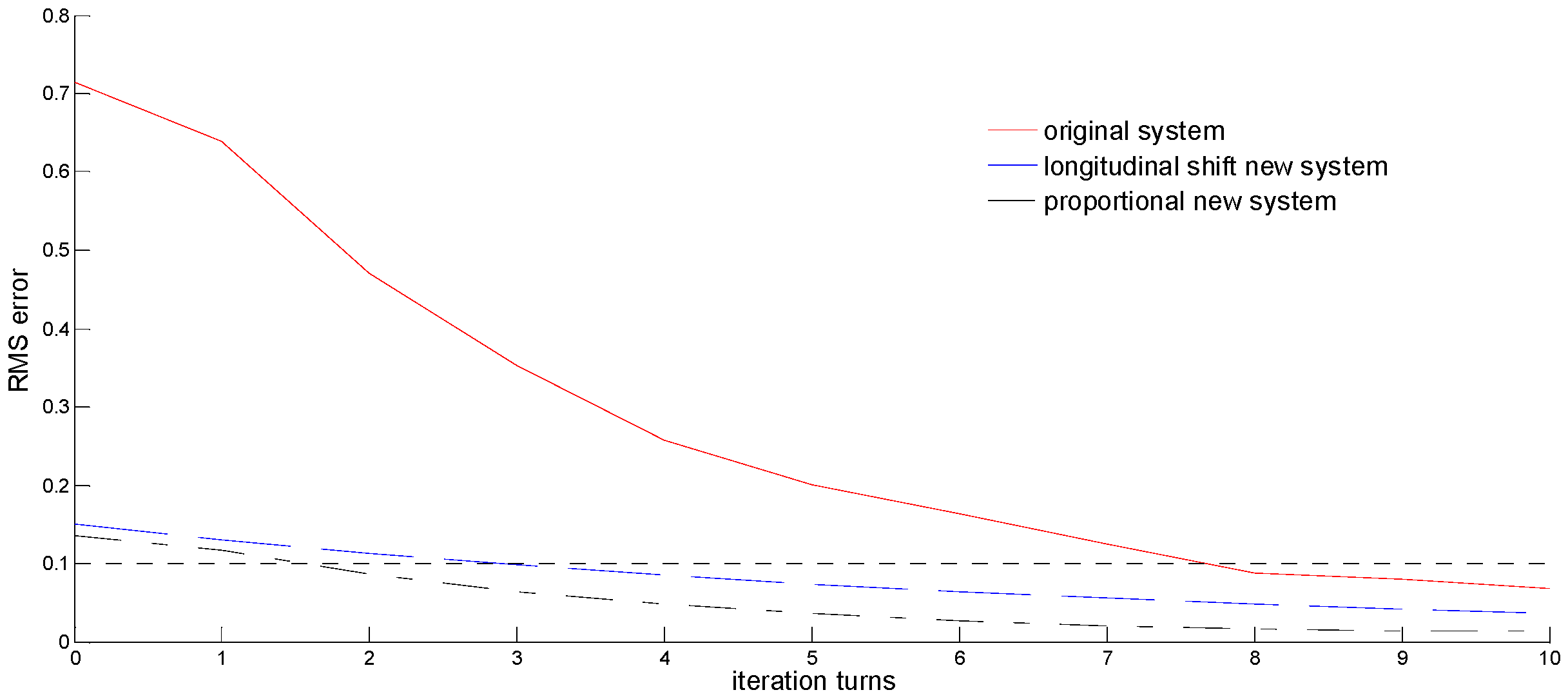

If the existing iterative learning control experience of the original system is directly taken as the initial iterative learning control value of the new system, the effect is generally better than that of learning from zero initial data. However, it is just a simple direct inheritance of experience. It lacks the necessary pre-adjustment according to the specific differences between the old and new systems. So, there is still room for further optimization in the setting of the initial iterative control data according to the experience obtained from the former ILC.

In general, when the parameter in the system is changed, e.g., the power of driving motor, the damping of the pipeline, system lag, and so on, the difference between the old and the new system can be checked via the equipment manual or be measured through tests. This is similar to the situation of an experienced technician who is asked to deal with a new material. The technician can compare the performance difference of new material with the former ones via testing or reading the users’ manual of the new material. Then the difference could be used in the adjustment of the working experience. As a result, the technician could soon be able to make qualified products with the new material. In this paper, this process is called iterative learning control with experience transfer.

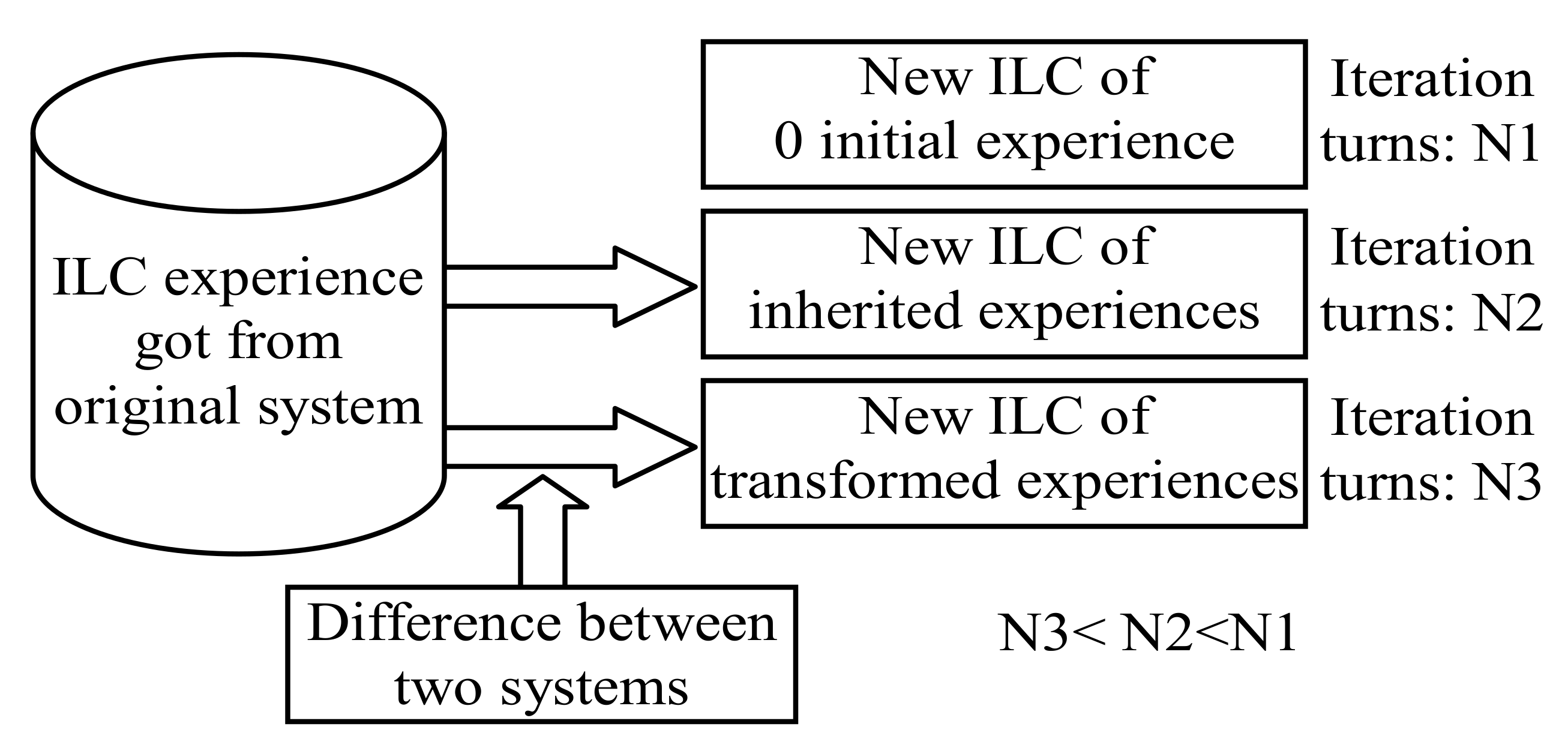

In this paper, the initial data of ILC are studied. The experience gained from the ILC in the original system is inherited and transformed to decrease the iteration turns in the ILC of new system, as shown in

Figure 1. As the method proposed in this paper only changes the initial data of ILC, there is no change to the algorithm itself. So, the convergence property of the ILC with experience inheritance and transform is not changed too.

6. Convergence Analyze

The general convergence condition of ILC is shown below

where

I is identity matrix;

L is the learning gain of ILC;

C and

B are matrix in the system state equation. In this paper, if the parameters in

C and

B change, the

L should be regulated too. As mentioned in

Section 5.1, to replace the electric heating elements or motors with another one of different rated power, the change of the conveying pipe’s cross-sectional area, or the improvement of the output efficiency, would cause the change of

B. The change of sensors or amplifiers in sampling circuit would cause the change of

C. To guarantee the convergence and the speed, the learning gain

L should be regulated accordingly.

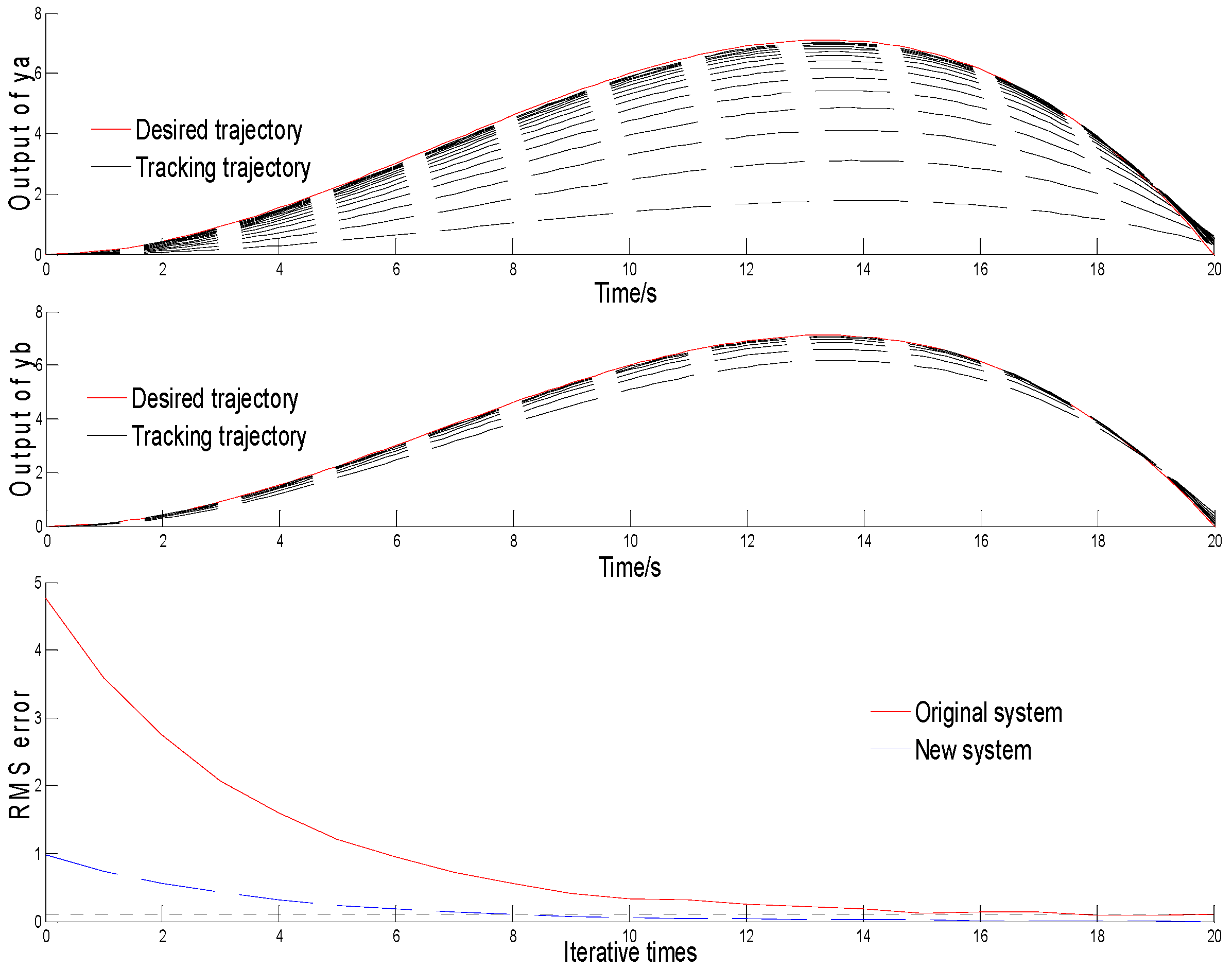

The ILC with experience transfer from former ILC only changes the initial data in new ILC process. It does not change the nature of the algorithm itself; neither the learning gain, nor the algorithm mechanism. So, the convergence property of the ILC with experience inheritance and transform can be guaranteed.

As the initial data in new ILC process are transferred from former ILC process with the reference information according to the difference between the new system and the former ones, the system could be accelerated to reach the required convergent accuracy with fewer error reduction iteration turns, which has been supported by the simulation tests in

Section 3,

Section 4 and

Section 5. As a result, the efficiency of ILC for the new system could be improved.