Use of Reservoir Sediments to Improve Engineering Properties of Dune Sand in Oman

Abstract

:1. Introduction

2. Materials and Methods

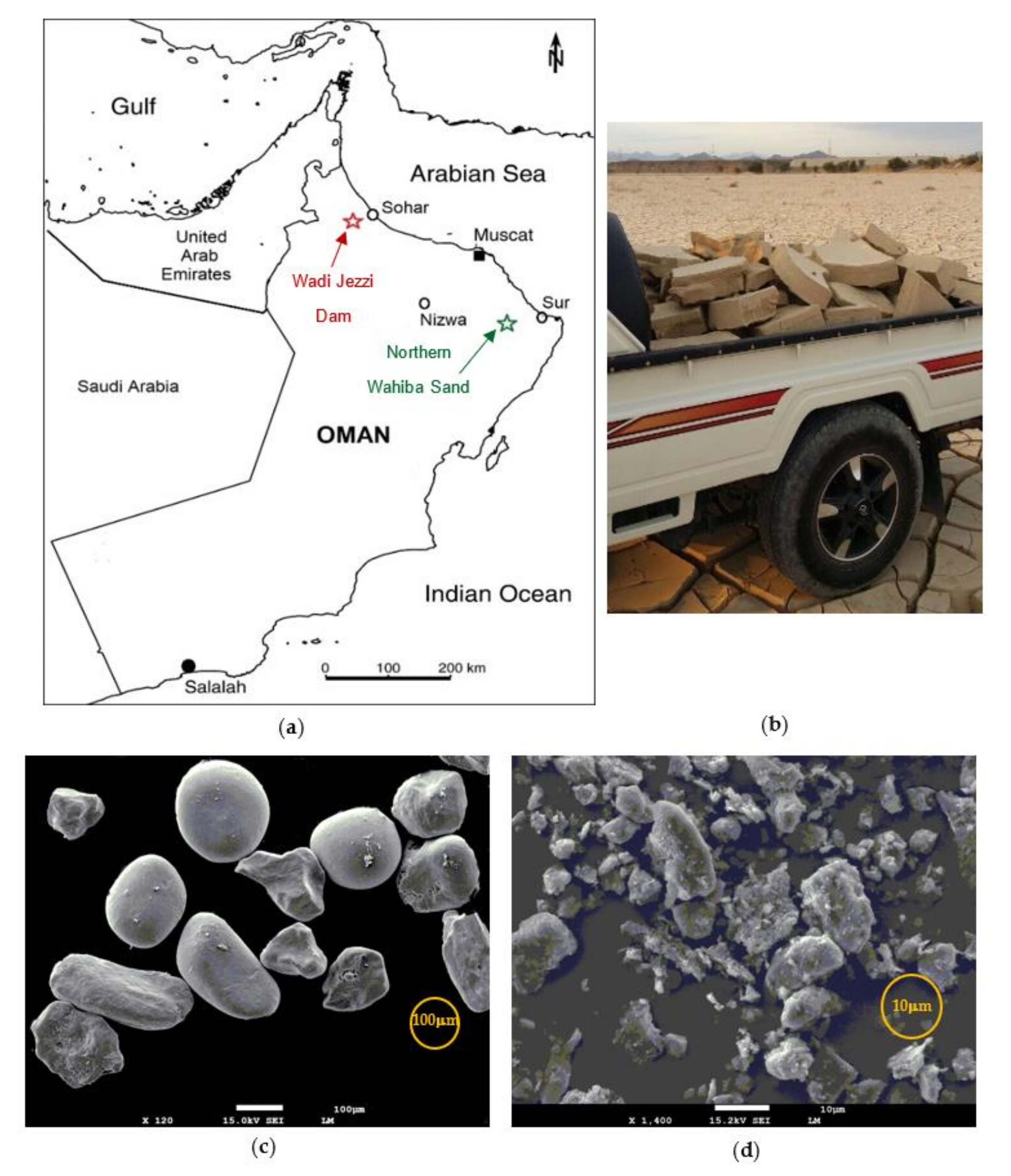

2.1. Dune Sand

2.2. Reservoir Sediment

2.3. Experimental Program

3. Results and Discussions

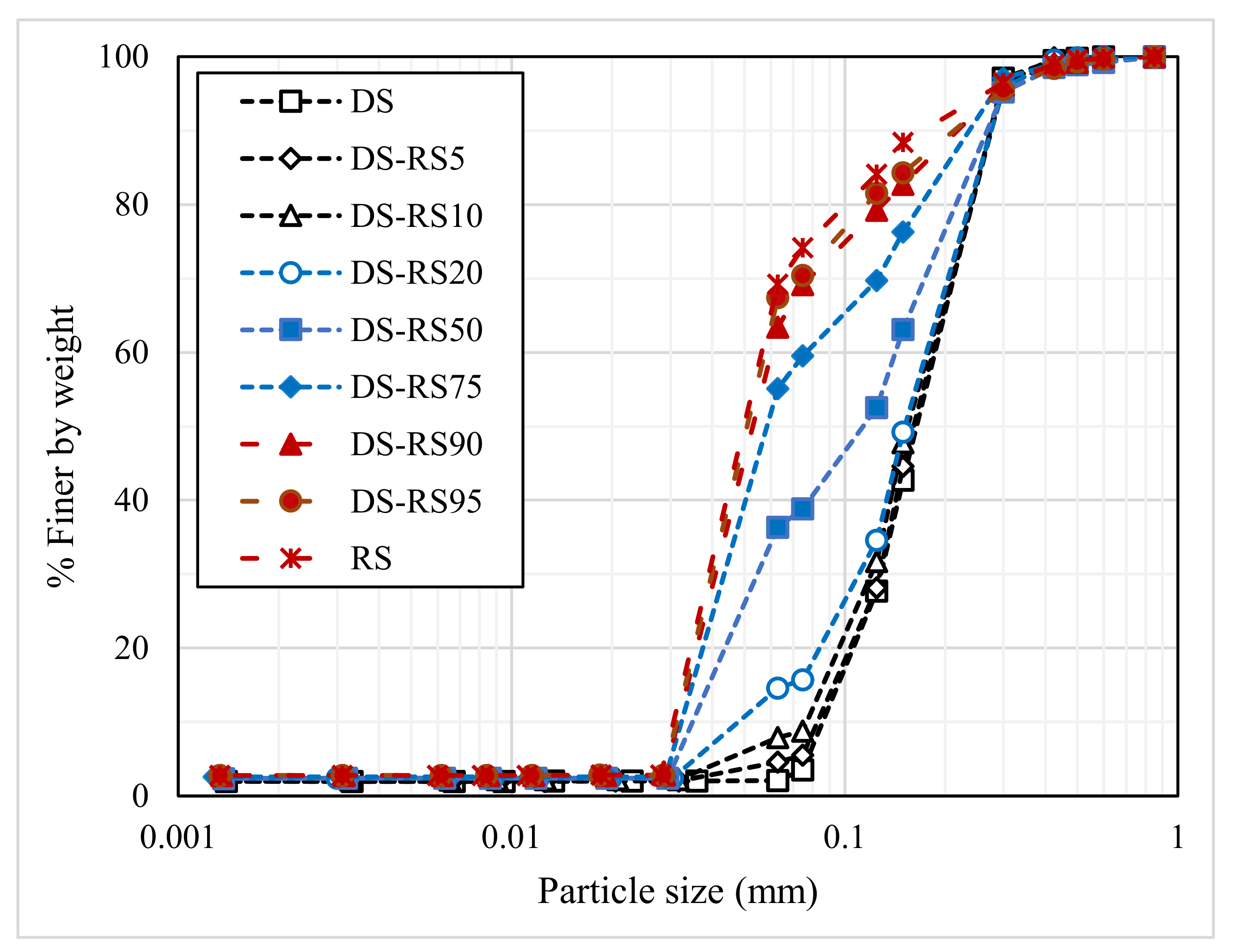

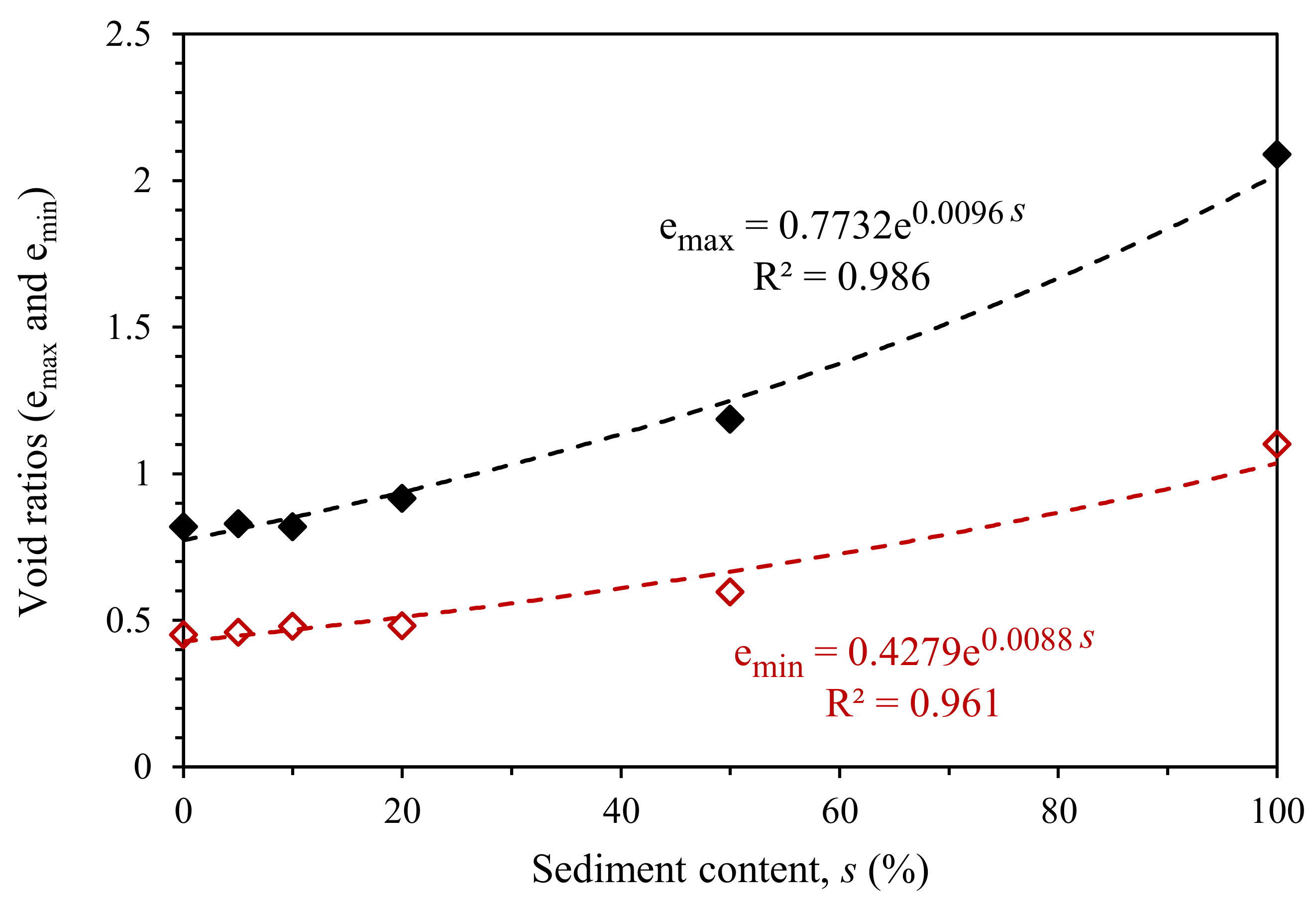

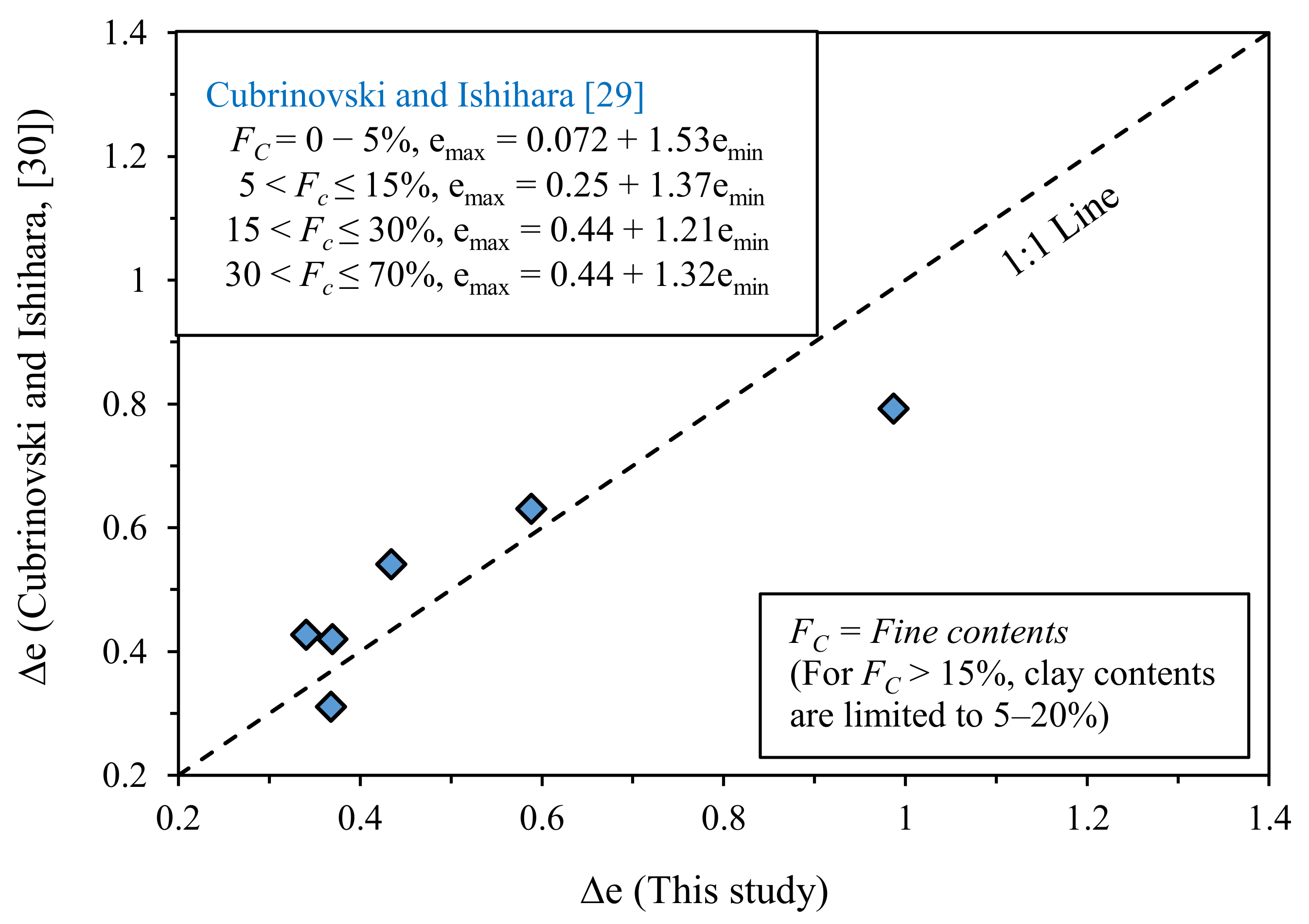

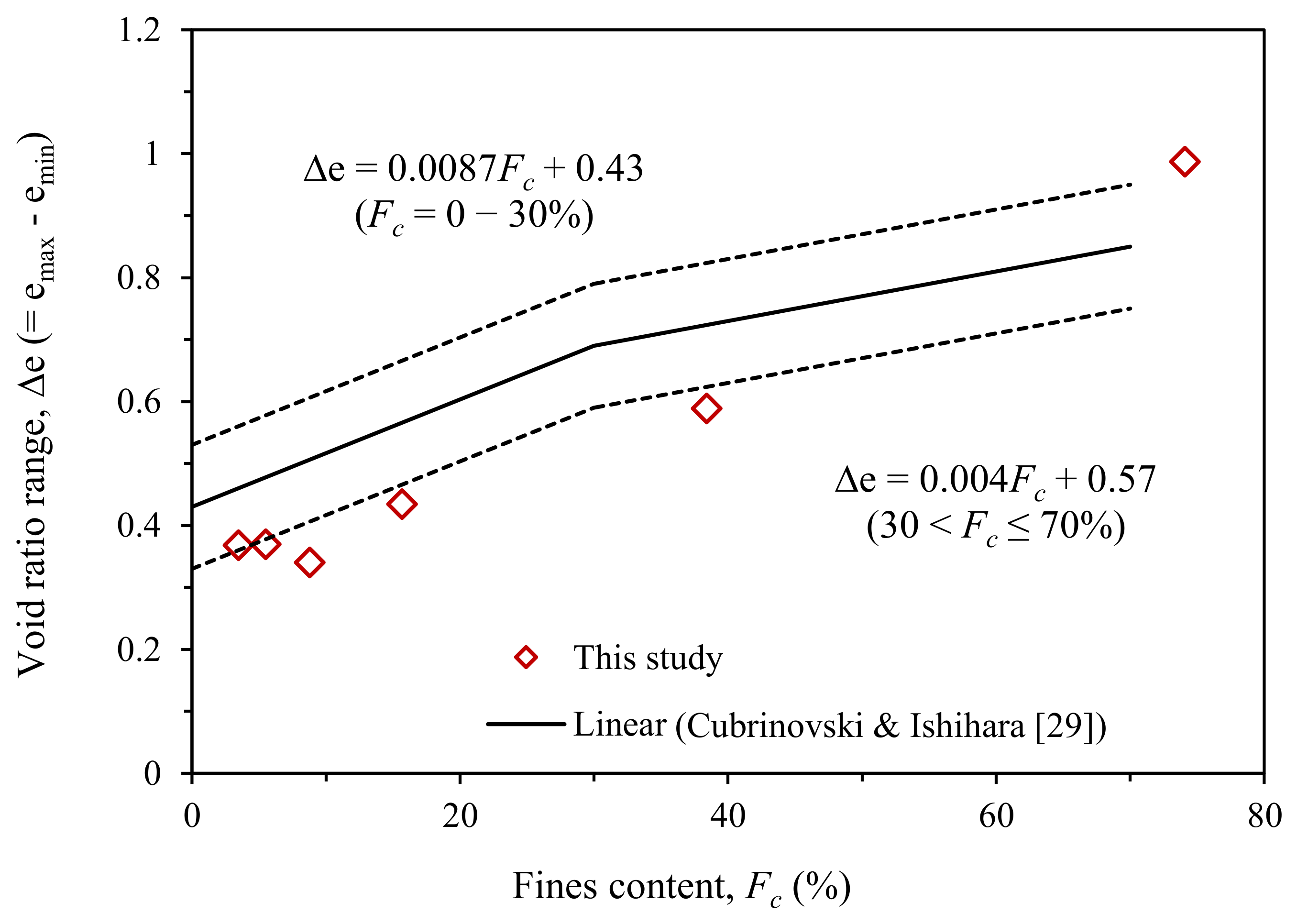

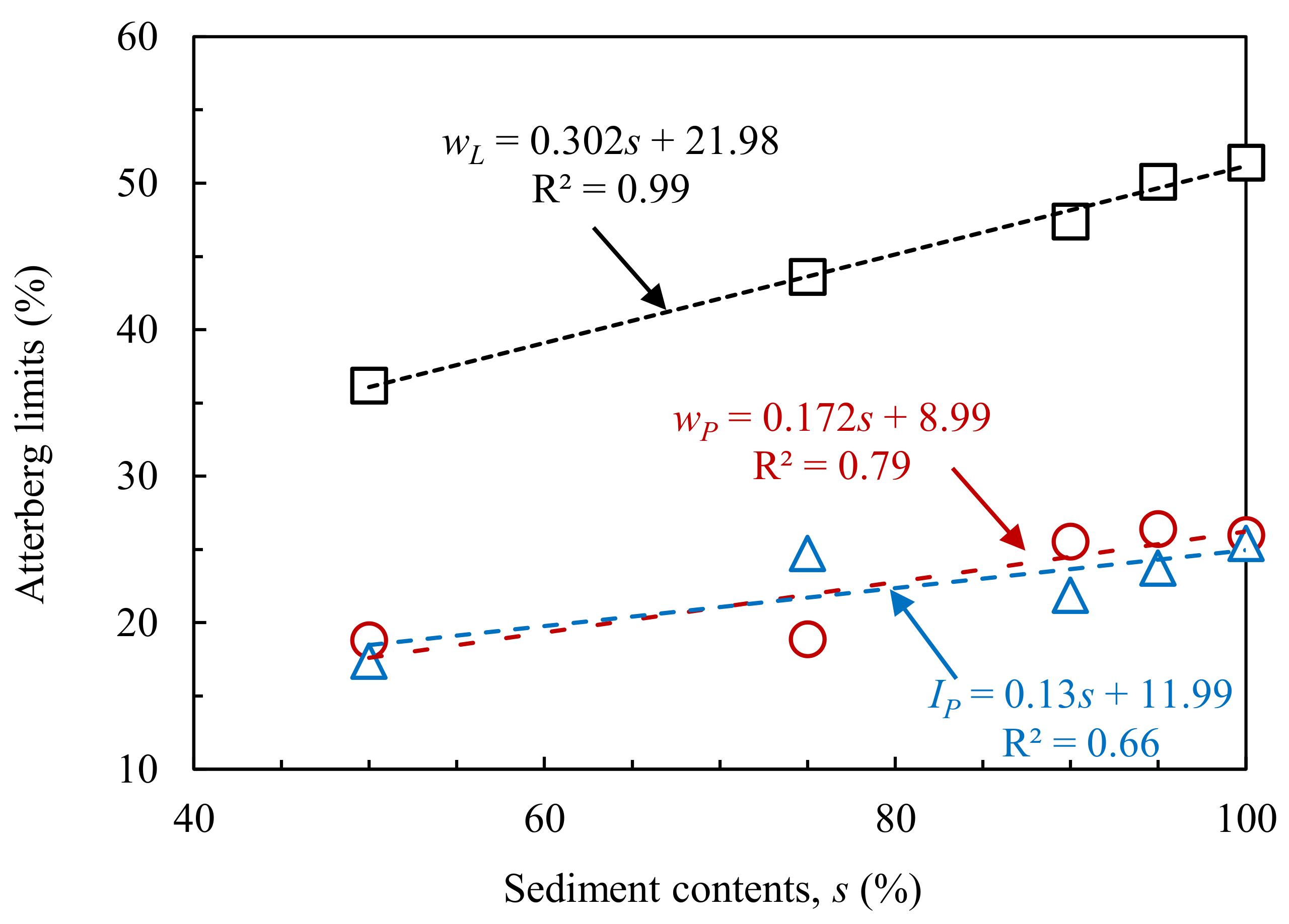

3.1. Index Properties

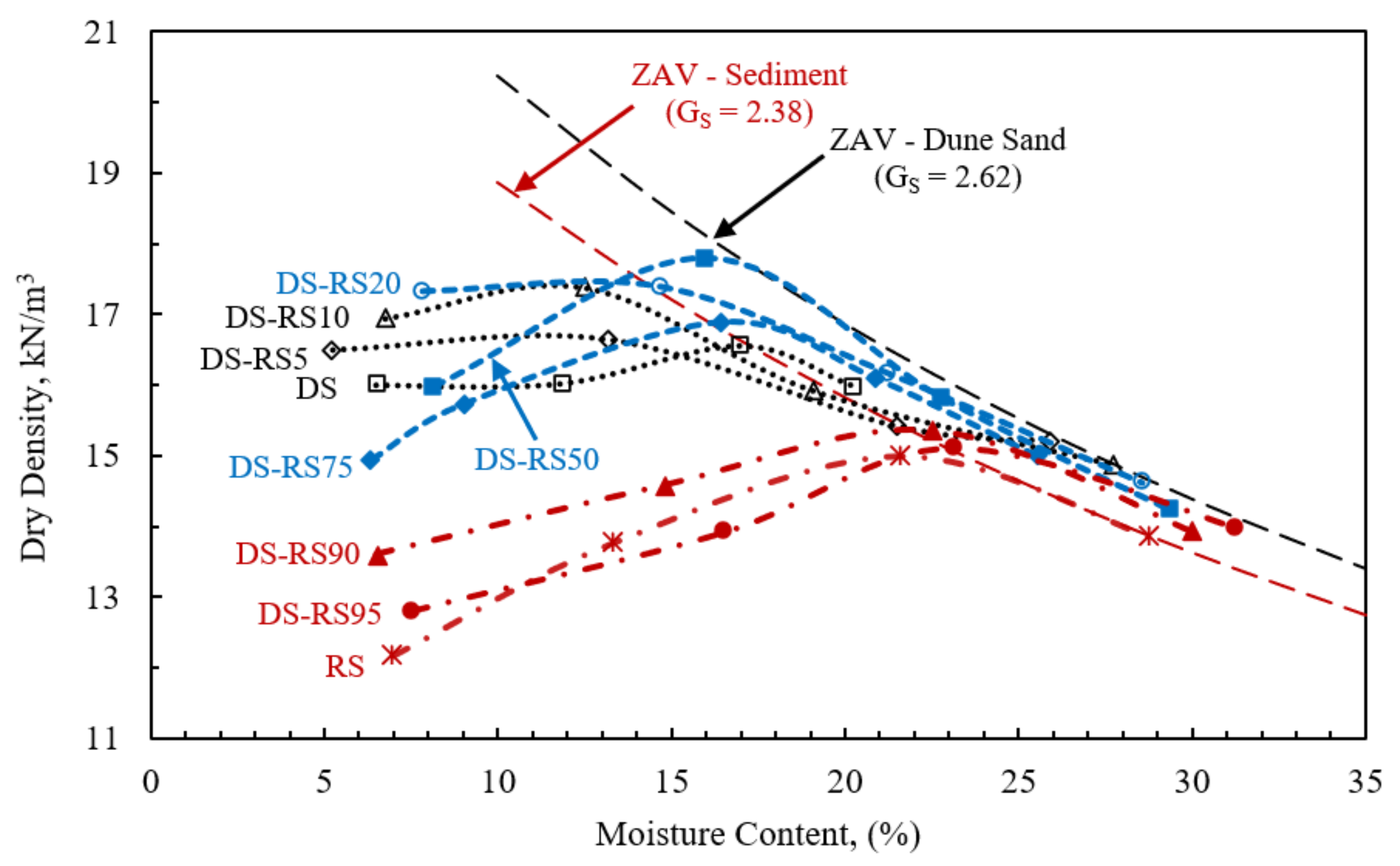

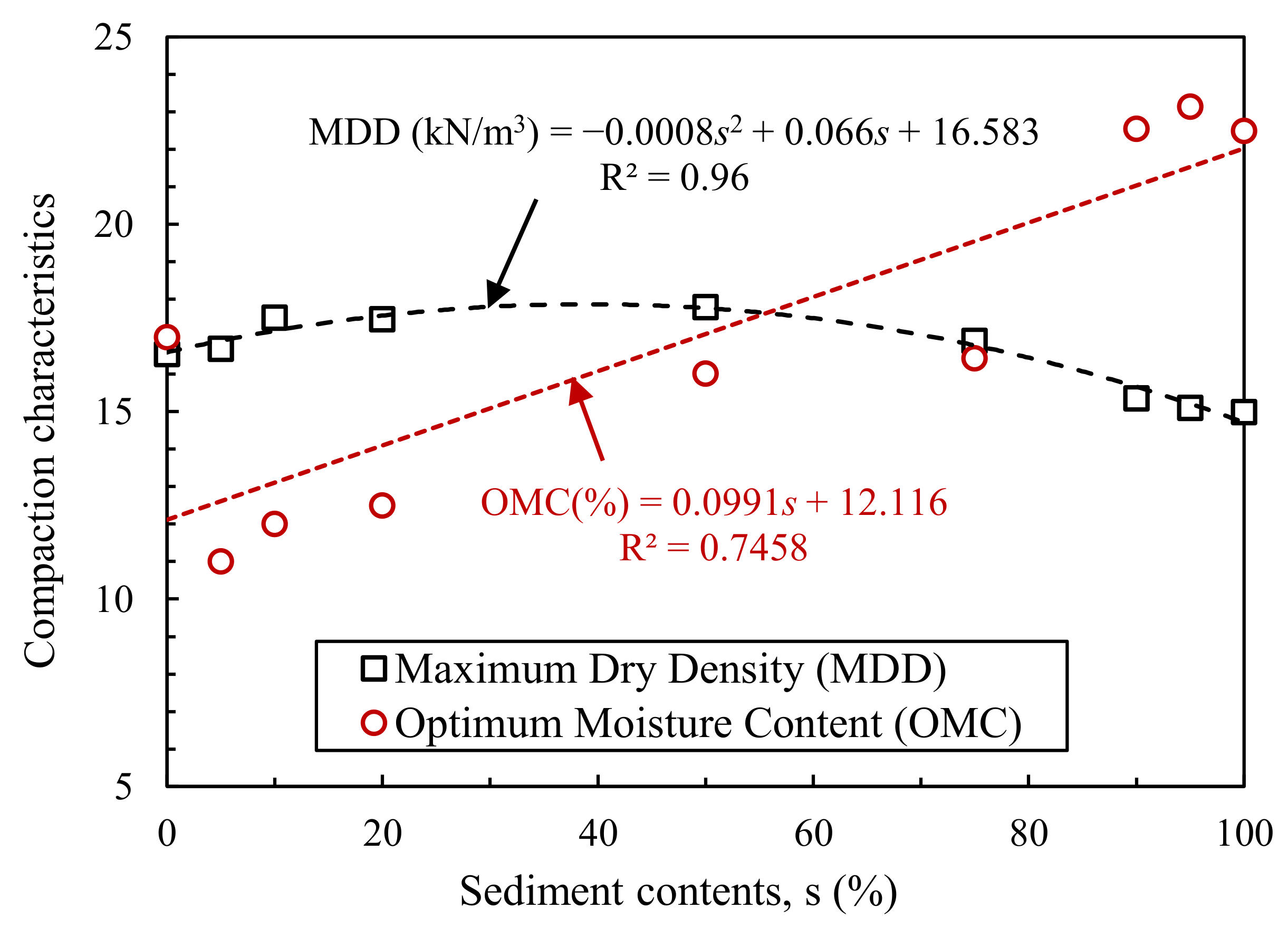

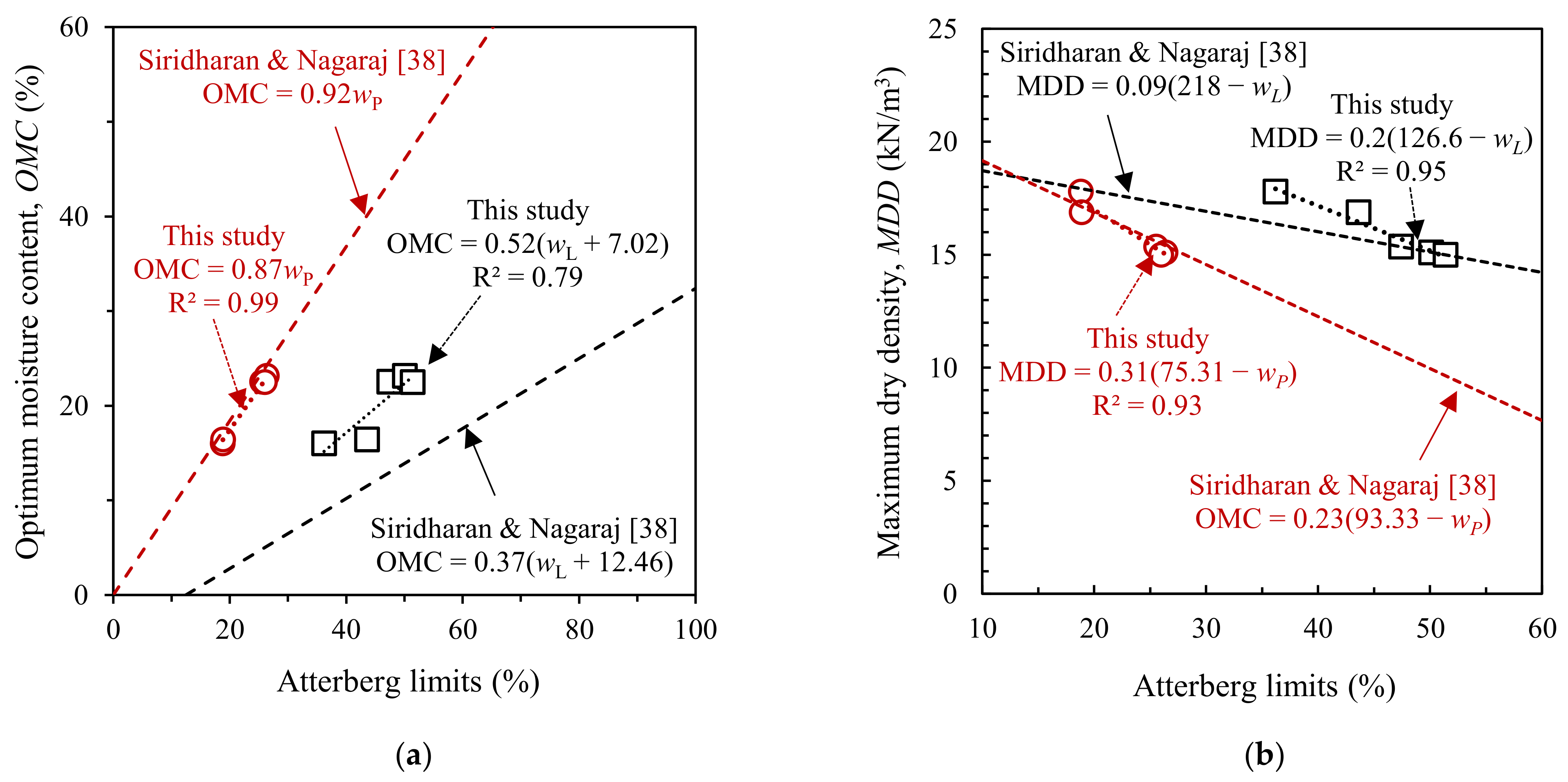

3.2. Compaction Tests

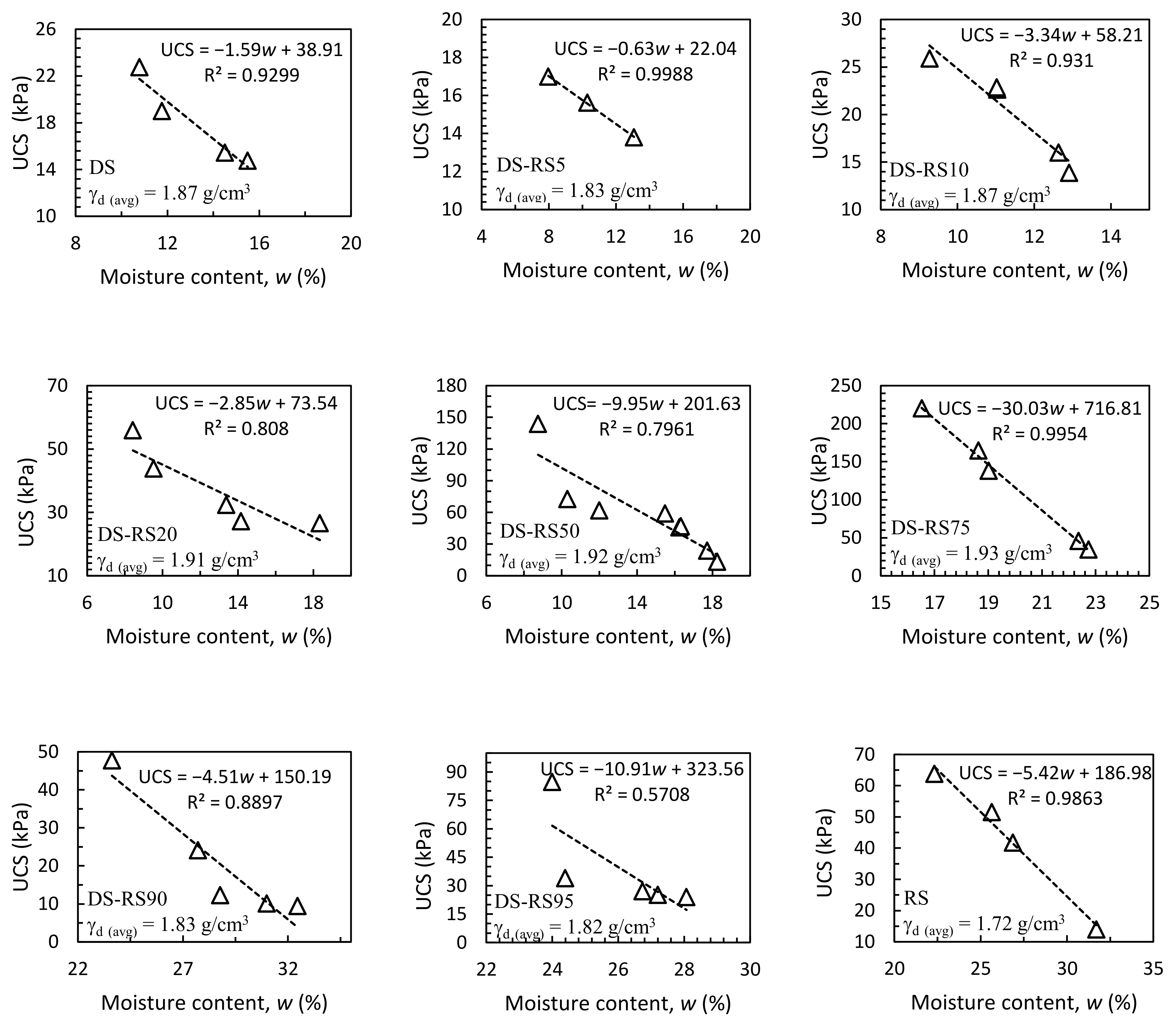

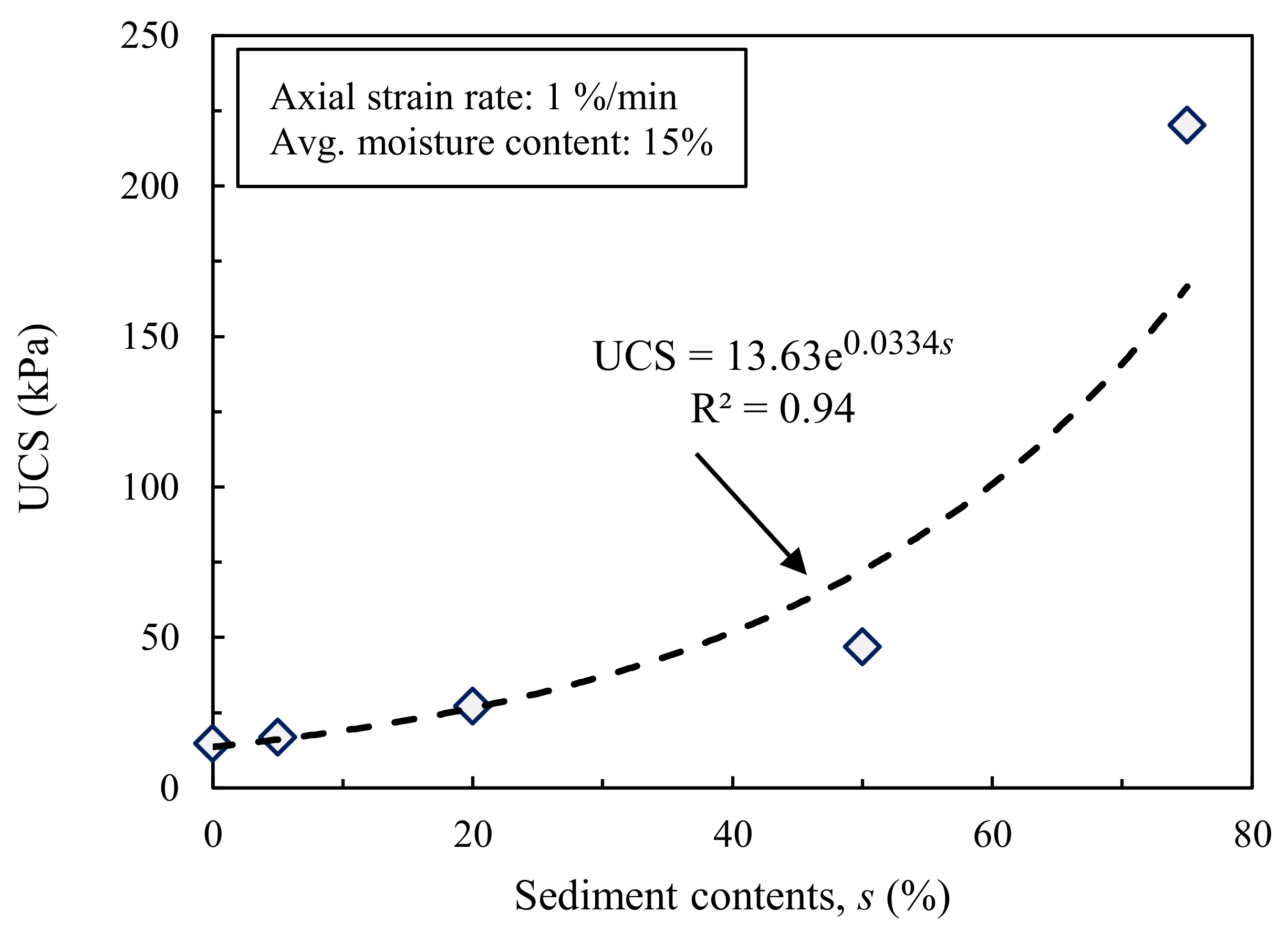

3.3. Unconfined Compression Strength

4. Discussion

5. Conclusions

- The sediment substantially increases the unconfined compressive strength of the treated sand. The unconfined compressive strength increases with sediment content up to 75% and decreases afterwards. The binary mixture of sand sediment is sensitive to moisture, however the order of strength stability against moisture is DSS75 > DSS50 > DSS20.

- The addition of sediment in sand has improved the maximum dry density up to a treatment ratio of 50%, however, OMC increases from 17% for pure sand to 22.5% for pure sediment. The OMC shows good correlation with the plastic limit of the binary mixtures of sand and sediment.

- The addition of sediment to sand has improved the uniformity coefficient of the sand to some extent with an increase in the maximum and minimum void ratios as well.

- The elemental analysis of the sediment confirmed the material as non-contaminated and suitable for engineering application without causing any environmental issues.

- The regression models generated from the experimental data presented in this study are in good agreement with the published literature and these empirical correlations can be considered as reliable for dune sands treated with the reservoir sediments to save time and effort involved in laboratory and field testing for engineering characterization of these materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qureshi, M.U.; Chang, I.; Al-Sadarani, K. Strength and durability characteristics of biopolymer-treated desert sand. Geomech. Eng. 2017. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef] [Green Version]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.M.; Im, J.; Cho, G.C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Adongo, T.A.; Kyei-Baffour, N.; Abagale, F.K.; Agyare, W.A. Assessment of reservoir sedimentation of irrigation dams in northern Ghana. Lake Reserv. Manag. 2020, 36, 87–105. [Google Scholar] [CrossRef]

- Abdalla, O.A.E.; Al-Rawahi, A.S. Groundwater recharge dams in arid areas as tools for aquifer replenishment and mitigating seawater intrusion: Example of AlKhod, Oman. Environ. Earth Sci. 2013, 69, 1951–1962. [Google Scholar] [CrossRef]

- Studds, P.; Miller, Z.M. Sustainable material reuse solutions for dredged sediments. Int. J. Sustain. Eng. 2010, 3, 33–39. [Google Scholar] [CrossRef]

- Shillaber, C.M.; Mitchell, J.K.; Dove, J.E. Energy and Carbon Assessment of Ground Improvement Works. II: Working Model and Example. J. Geotech. Geoenviron. Eng. 2016, 142, 04015084. [Google Scholar] [CrossRef]

- Singh, S.P.; Ma, L.Q.; Tack, F.M.G.; Verloo, M.G. Trace Metal Leachability of Land-Disposed Dredged Sediments. J. Environ. Qual. 2000, 29, 1124–1132. [Google Scholar] [CrossRef] [Green Version]

- Mulligan, C.N.; Yong, R.N.; Gibbs, B.F. An evaluation of technologies for the heavy metal remediation of dredged sediments. J. Hazard. Mater. 2001, 85. [Google Scholar] [CrossRef]

- Peng, J.; Song, Y.; Yuan, P.; Cui, X.; Qiu, G. The remediation of heavy metals contaminated sediment. J. Hazard. Mater. 2009, 161. [Google Scholar] [CrossRef]

- Wang, D.; Abriak, N.E.; Zentar, R. Dredged marine sediments used as novel supply of filling materials for road construction. Mar. Georesources Geotechnol. 2017, 35, 472–480. [Google Scholar] [CrossRef]

- Maherzi, W.; Abdelghani, F. Ben Dredged Marine Raw Sediments Geotechnical Characterization for their Reuse in Road Construction. Eng. J. 2014, 18, 27–37. [Google Scholar] [CrossRef] [Green Version]

- Quek, A.; Wu, D.; Xu, W.; Guo, L. Feasibility of Singapore IBA waste for land reclamation. Environ. Geotech. 2017, 4, 56–64. [Google Scholar] [CrossRef]

- Aoual-Benslafa, F.K.; Kerdal, D.; Ameur, M.; Mekerta, B.; Semcha, A. Durability of Mortars Made with Dredged Sediments; Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 118, pp. 240–250. [Google Scholar]

- Karnati, N.V.; Mandavkar, S.; Payne, R. An Innovative Approach to Reuse and Retain Dredged Sediment for Erosion Control Using Geotextile Containers in Ecosystem Restoration. In GeoCongress 2012; American Society of Civil Engineers: Reston, VA, USA, 2012. [Google Scholar]

- Tang, C.-W.; Chen, H.-J.; Wang, S.-Y.; Spaulding, J. Production of synthetic lightweight aggregate using reservoir sediments for concrete and masonry. Cem. Concr. Compos. 2011, 33. [Google Scholar] [CrossRef]

- Di Emidio, D.; Verastegui Flores, R.D.; Bezuijen, A. Reuse of dredged sediments for hydraulic barriers: Adsorption and Hydraulic conductivity improvement through polymers. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering: Challenges and Innovations in Geotechnics, ICSMGE 2013, Paris, France, 2–6 September 2013; Volume 4, pp. 3191–3194. [Google Scholar]

- Grubb, D.G.; Malasavage, N.E.; Smith, C.J.; Chrysochoou, M. Stabilized Dredged Material. II: Geomechanical Behavior. J. Geotech. Geoenviron. Eng. 2010, 136, 1025–1036. [Google Scholar] [CrossRef]

- Bortone, G.; Arevalo, E.; Deibel, I.; Detzner, H.D.; de Propris, L.; Elskens, F.; Giordano, A.; Hakstege, P.; Hamer, K.; Harmsen, J.; et al. Synthesis of the SedNet work package 4 outcomes. J. Soils Sediments 2004, 4, 225–232. [Google Scholar] [CrossRef]

- Smith, B.T.; Howard, I.L.; Vahedifard, F. Lightly cemented dredged sediments for sustainable reuse. Environ. Geotech. 2018, 5, 324–335. [Google Scholar] [CrossRef]

- Deb, K.; Sawant, V.A.; Kiran, A.S. Effects of fines on compaction characteristics of poorly graded sands. Int. J. Geotech. Eng. 2010, 4, 299–304. [Google Scholar] [CrossRef]

- O’Sadnick, D.L.; Simpson, B.E.; Kasel, G.K. Evaluation and performance of a sand/bentonite liner. In Proceedings of the Geoenvironment 2000@ sCharacterization, Containment, Remediation, and Performance in Environmental Geotechnics; New Orleans, LA, USA; ASCE: New York, NY, USA, 1995; pp. 688–701. [Google Scholar]

- Mohamedzein, Y.E.A.; Al-Aghbari, M.Y. The Use of Municipal Solid Waste Incinerator Ash to Stabilize Dune Sands. Geotech. Geol. Eng. 2012, 30, 1335–1344. [Google Scholar] [CrossRef]

- Qureshi, M.U.; Al-Sawafi, B.; Al-Washahi, M.; Al-Saidi, M.; Al-Badi, S. The Sustainable Use of Fine Marble Waste Powder for the Stabilization of Desert Sand in Oman. In Geoenvironmental Engineering. GeoMEast 2017. Sustainable Civil Infrastructures; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Qureshi, M.U.; Al-Hilly, A.; Al-Zeidi, O.; Al-Barrami, A.; Al-Jabri, A. Vane shear strength of bio-improved sand reinforced with natural fibre. In Proceedings of the 7th International Symposium on Deformation Characteristics of Geomaterials (IS-Glasgow 2019), Glasgow, UK; 2019; Volume 92, p. 12004. [Google Scholar]

- Consoli, N.C.; Vendruscolo, M.A.; Fonini, A.; Rosa, F.D. Fiber reinforcement effects on sand considering a wide cementation range. Geotext. Geomembr. 2009, 27, 196–203. [Google Scholar] [CrossRef]

- Park, T.W.; Kim, H.J.; Tanvir, M.T.; Lee, J.B.; Moon, S.G. Influence of coarse particles on the physical properties and quick undrained shear strength of fine-grained soils. Geomech. Eng. 2018, 14, 99–105. [Google Scholar] [CrossRef]

- Choo, H.; Lee, W.; Lee, C. Compressibility and small strain stiffness of kaolin clay mixed with varying amounts of sand. KSCE J. Civ. Eng. 2017, 21, 2152–2161. [Google Scholar] [CrossRef]

- Cubrinovski, M.; Ishihara, K. Maximum and minimum void ratio characteristics of sands. Soils Found. 2002, 42, 65–78. [Google Scholar] [CrossRef] [Green Version]

- ASTM D2487-17e1 Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2017.

- Khalaf, F.I.; Gharib, I.M. Roundness parameters of quartz grains of Recent aeolian sand deposits in Kuwait. Sediment. Geol. 1985, 45. [Google Scholar] [CrossRef]

- Poulos, H.G. A review of geological and geotechnical features of some Middle Eastern countries. Innov. Infrastruct. Solut. 2018, 3, 51. [Google Scholar] [CrossRef] [Green Version]

- Lade, P.V.; Liggio, C.D.; Yamamuro, J.A. Effects of Non-Plastic Fines on Minimum and Maximum Void Ratios of Sand. Geotech. Test. J. 1998, 21, 336–347. [Google Scholar] [CrossRef]

- ASTM D4318-17e1 Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D698-12e2 Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)); ASTM International: West Conshohocken, PA, USA, 2012.

- Al-Aghbari, M.Y.; Mohamedzein, Y.E.-A.; Taha, R. Stabilisation of desert sands using cement and cement dust. Proc. Inst. Civ. Eng. Gr. Improv. 2009, 162, 145–151. [Google Scholar] [CrossRef]

- ASTM D2166/D2166M Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2016; Volume 4, pp. 1–6.

- Sridharan, A.; Nagaraj, H.B. Plastic limit and compaction characteristics of finegrained soils. Proc. Inst. Civ. Eng. Gr. Improv. 2005, 9. [Google Scholar] [CrossRef]

| Element (%) | Oxygen (O) | Carbon (C) | Silicon (Si) | Magnesium (Mg) | Calcium (Ca) | Aluminium (Al) | Iron (Fe) | Potassium (K) |

|---|---|---|---|---|---|---|---|---|

| Dune sand (DS) | 53.3 | 16.2 | 2,7 | 1.2 | 24.3 | 1.2 | 1.1 | - |

| Reservoir sediment (RS) | 48.6 | 21.9 | 12.5 | 8.9 | 3.7 | 2.4 | 1.6 | 0.5 |

| Material | Specimen Designation | Sand Contents (%) | Sediment Content, s (%) | Fc (%) | Gs | USCS |

|---|---|---|---|---|---|---|

| Dune sand (DS) | DS | 100 | 0 | 3.5 | 2.62 | SP: poorly graded sand |

| Mixes (DS-RS) | DS-RS5 | 95 | 5 | 5.5 | 2.6 | SP: poorly graded sand |

| DS-RS10 | 90 | 10 | 8.8 | 2.58 | SP-SM: poorly graded sand to silty sand | |

| DS-RS20 | 80 | 20 | 15.7 | 2.56 | SC: clayey silt | |

| DS-RS50 | 50 | 50 | 38.4 | 2.49 | SC: clayey silt | |

| DS-RS75 | 25 | 75 | 59.4 | 2.43 | CL: low plasticity clay | |

| DS-RS90 | 10 | 90 | 69.1 | 2.41 | CL: low plasticity clay | |

| DS-RS95 | 5 | 95 | 70.4 | 2.39 | CH: high plasticity clay | |

| Reservoir sediment (RS) | RS | 0 | 100 | 74.1 | 2.38 | CH: high plasticity clay |

| Specimen Designation | DS | DS-RS5 | DS-RS10 | DS-RS20 | DS-RS50 | DS-RS75 | DS-RS90 | DS-RS95 | RS |

|---|---|---|---|---|---|---|---|---|---|

| MDD (kN/m3) | 16.54 | 16.64 | 17.78 | 17.38 | 17.78 | 16.88 | 15.35 | 15.1 | 14.99 |

| OMC (%) | 16.99 | 11 | 12 | 12.5 | 16.02 | 16.43 | 22.55 | 23.15 | 22.5 |

| Properties | Regression Models | R2 Value |

|---|---|---|

| Sediment content (s) and maximum (emax)/minimum (emin) void ratios | emax = 0.7732e0.0096s emin = 0.4279e0.0088s | 0.99 0.96 |

| Sediment content (s) and Atterberg limits (Liquid limit, wL and plastic limit, wP) Sediment content (s) and Plasticity index (IP) | wL = 0.302s + 21.98 wP = 0.172s + 8.99 IP = 0.13s + 11.99 | 0.99 0.79 0.66 |

| Sediment content (s) and compaction characteristics (Maximum dry density, MDD and Optimum moisture content, OMC) | MDD (kN/m3) = −0.0008s2 + 0.066s + 16.58 OMC(%) = 0.0991s + 12.116 | 0.96 0.75 |

| Atterberg limits (wL and wP) and compaction characteristics (OMC and MDD) | OMC (%) = 0.52(wL + 7.02) OMC (%) = 0.87wP MDD (kN/m3) = 0.2(126.6 − wL) MDD (kN/m3) = 0.31(75.31 − wP) | 0.79 0.99 0.95 0.93 |

| Sediment content (s) and unconfined compressive strength (UCS) | UCS = 13.63e0.0334s | 0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qureshi, M.U.; Alsaidi, M.; Aziz, M.; Chang, I.; Rasool, A.M.; Kazmi, Z.A. Use of Reservoir Sediments to Improve Engineering Properties of Dune Sand in Oman. Appl. Sci. 2021, 11, 1620. https://doi.org/10.3390/app11041620

Qureshi MU, Alsaidi M, Aziz M, Chang I, Rasool AM, Kazmi ZA. Use of Reservoir Sediments to Improve Engineering Properties of Dune Sand in Oman. Applied Sciences. 2021; 11(4):1620. https://doi.org/10.3390/app11041620

Chicago/Turabian StyleQureshi, Mohsin Usman, Maryam Alsaidi, Mubashir Aziz, Ilhan Chang, Ali Murtaza Rasool, and Zaheer Abbas Kazmi. 2021. "Use of Reservoir Sediments to Improve Engineering Properties of Dune Sand in Oman" Applied Sciences 11, no. 4: 1620. https://doi.org/10.3390/app11041620

APA StyleQureshi, M. U., Alsaidi, M., Aziz, M., Chang, I., Rasool, A. M., & Kazmi, Z. A. (2021). Use of Reservoir Sediments to Improve Engineering Properties of Dune Sand in Oman. Applied Sciences, 11(4), 1620. https://doi.org/10.3390/app11041620